Use of a Piezoelectric Bender Element for the Determination of Initial and Final Setting Times of Metakaolin Geopolymer Pastes, with Applications to Laterite Soils

Abstract

:1. Introduction

2. Materials and Methods

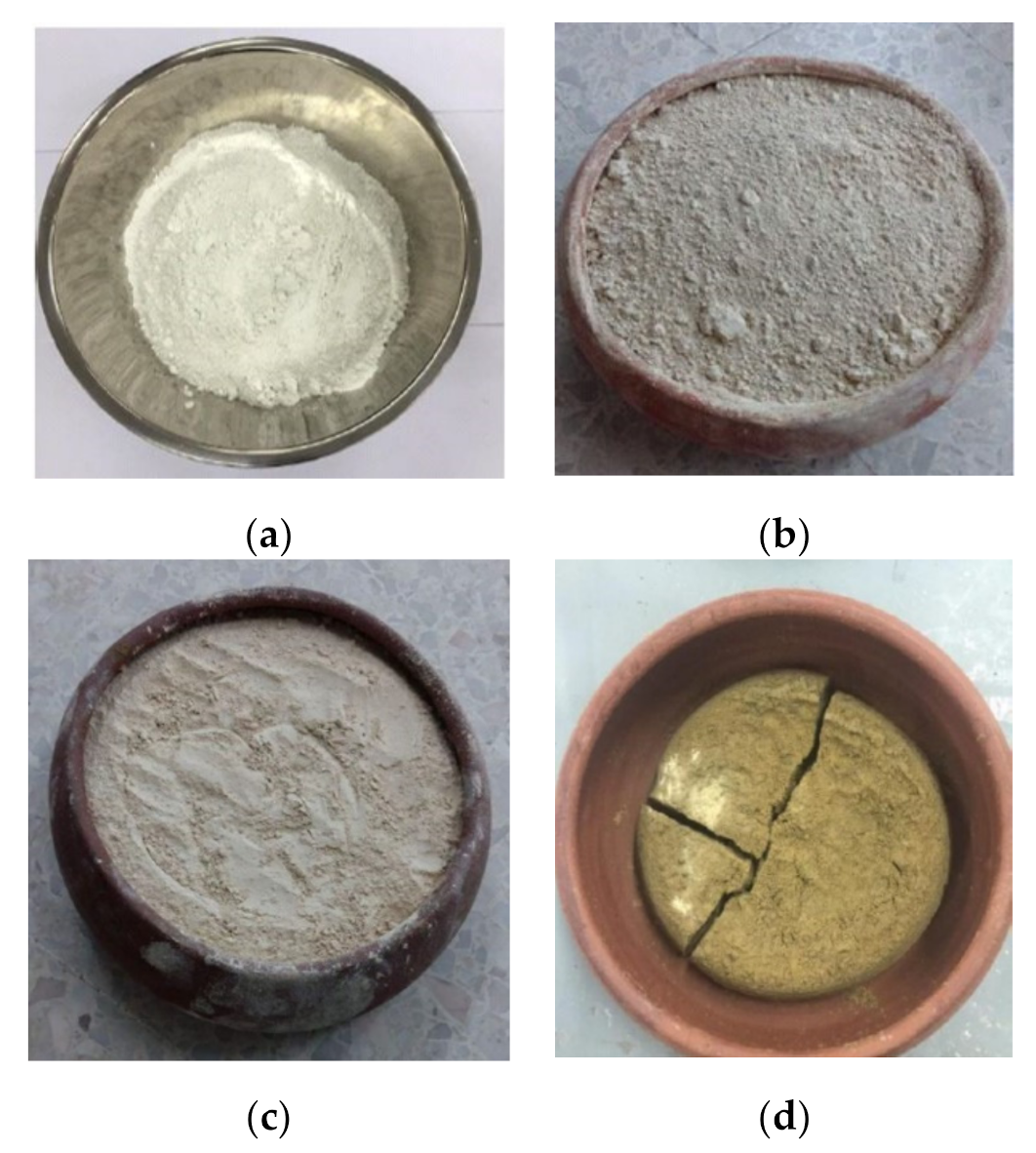

2.1. Metakaolin Geopolymer

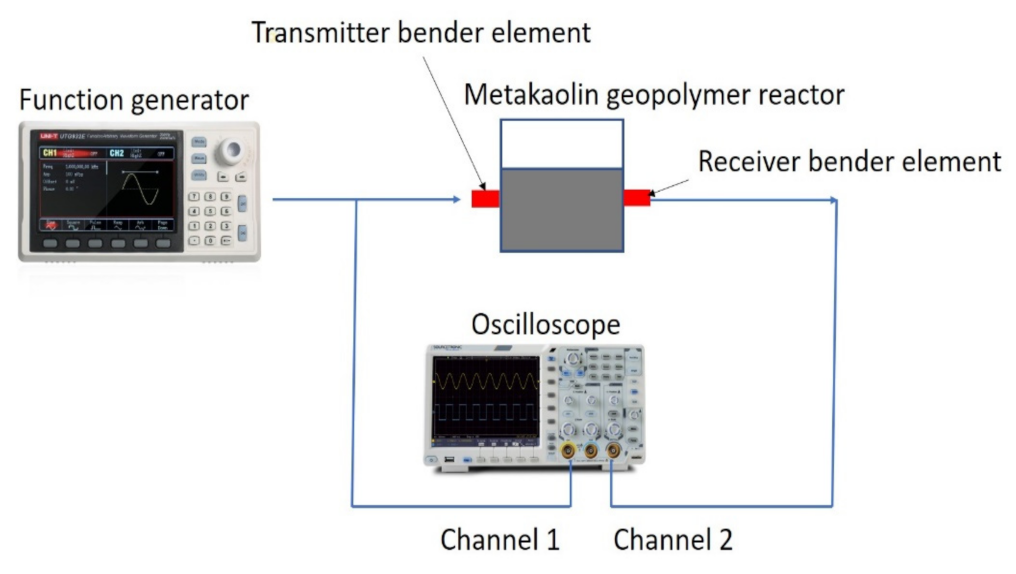

2.2. Piezoelectric Transducers

2.3. Shear Wave Velocity Measurement

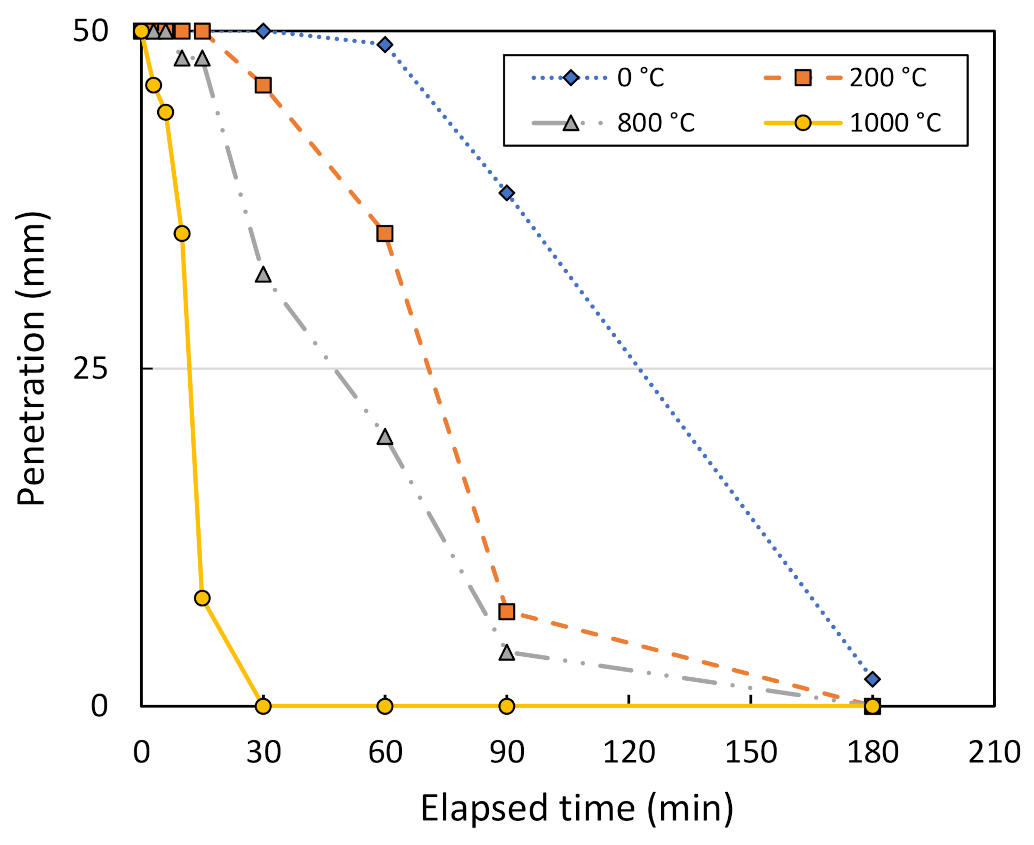

2.4. Vicat Needle

2.5. Laterite Soil

3. Results and Discussions

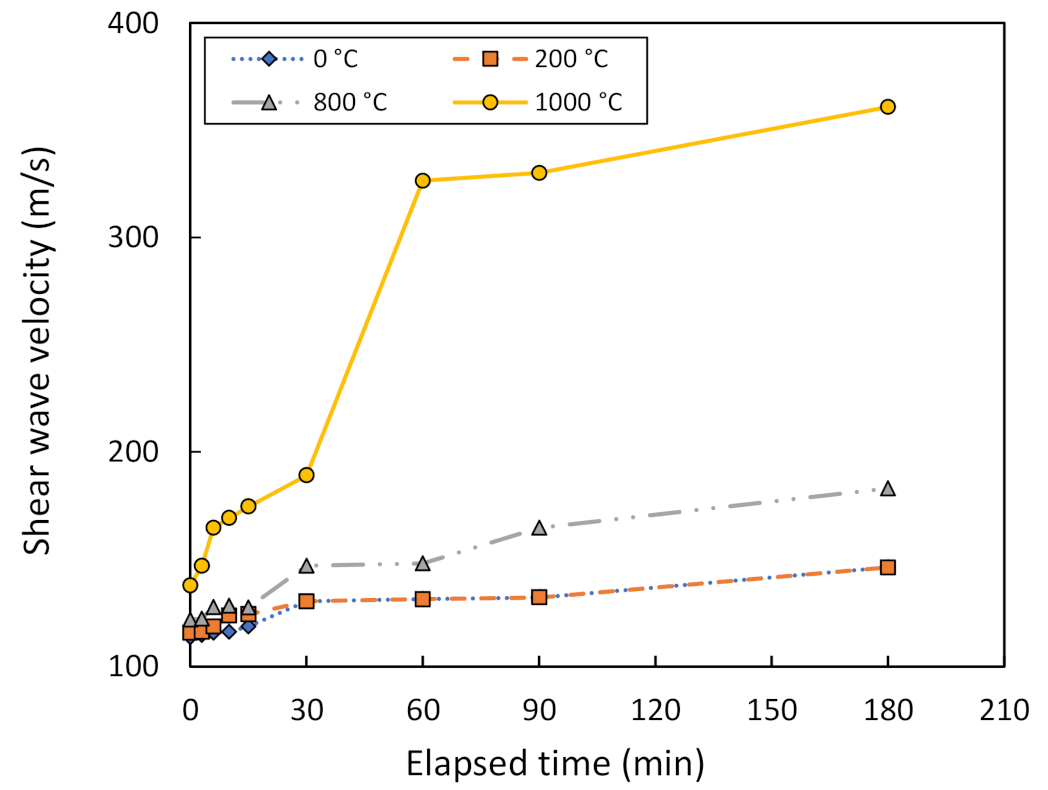

3.1. Effect of Thermal Treatment on Metakaolin

3.2. Effect of the Ratio of NaOH: Na2SiO3 for Preparing the Geopolymer Solution

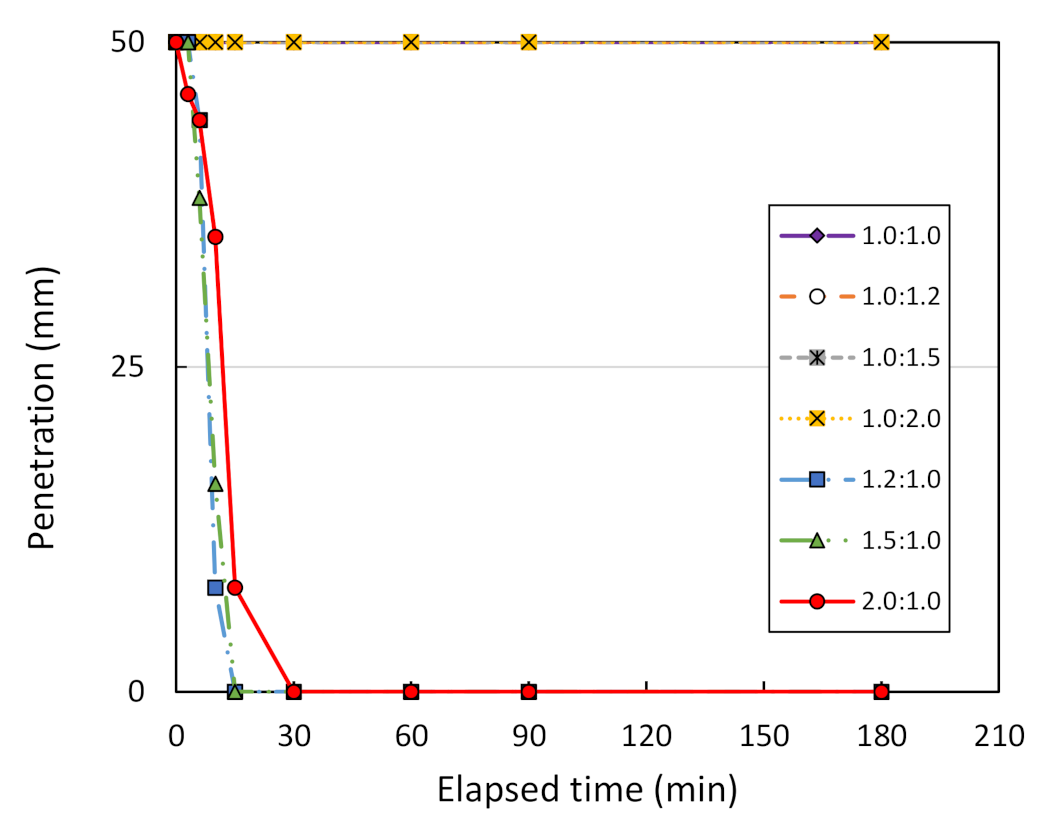

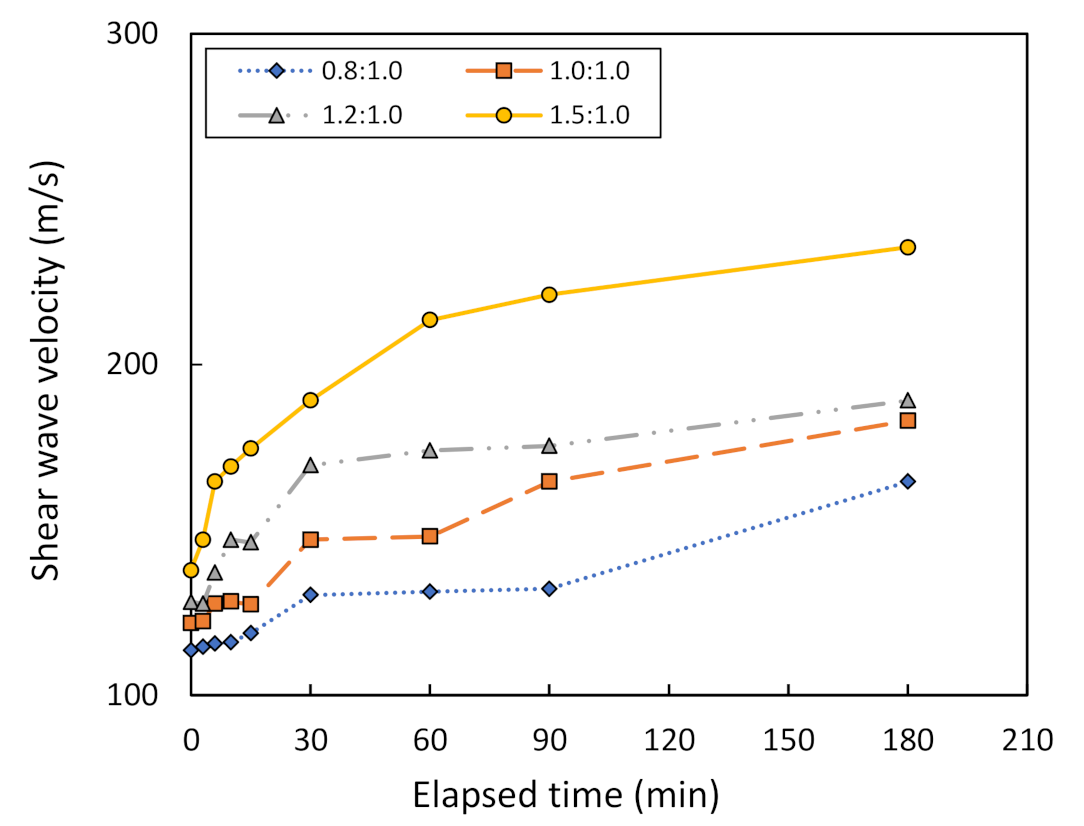

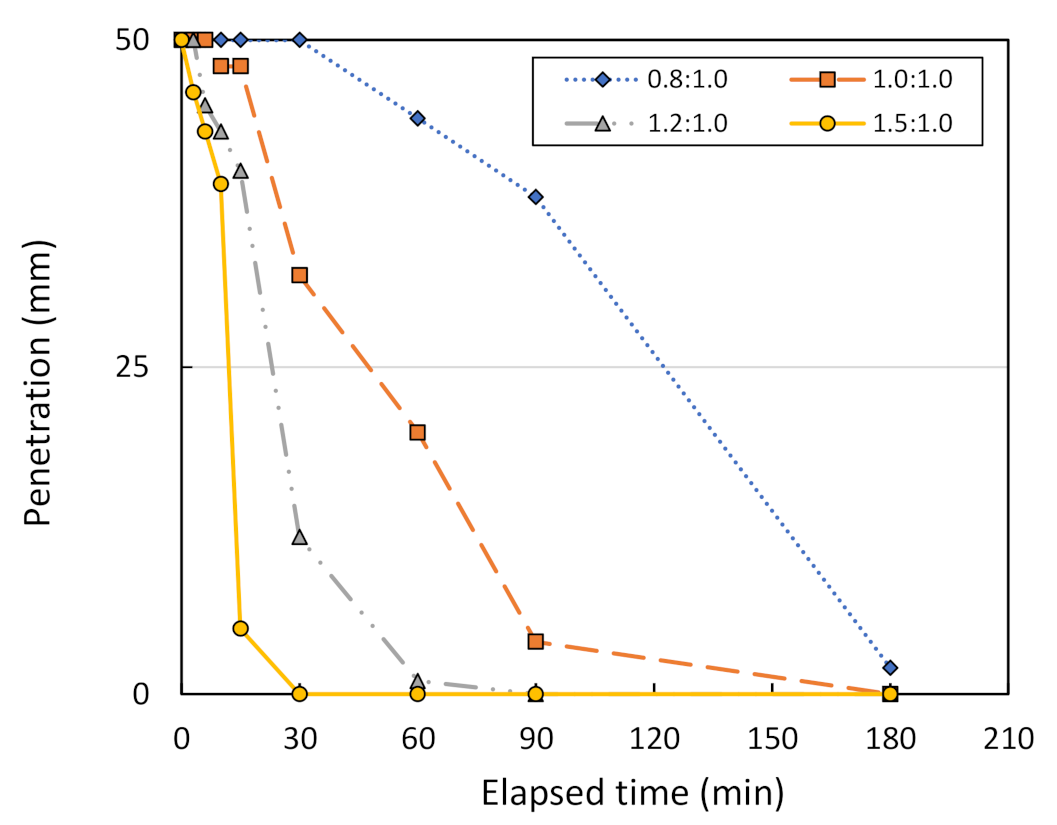

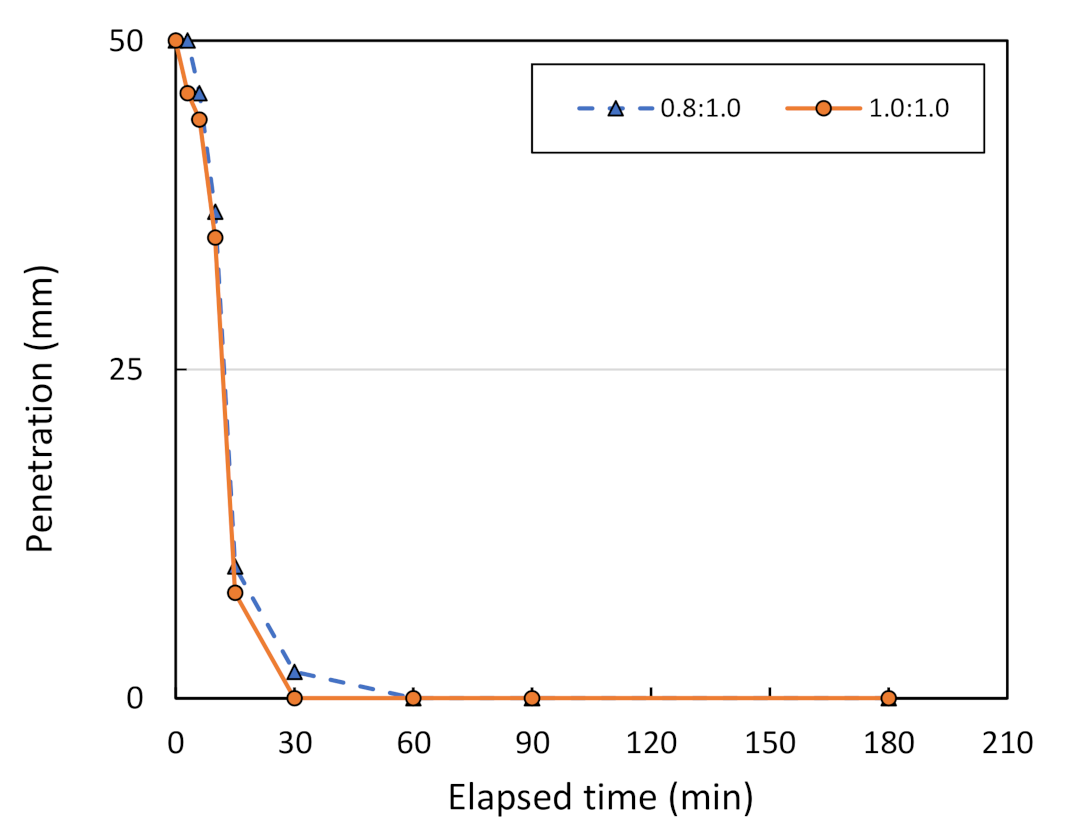

3.3. Effect of Mixed Proportions between the Metakaolin and the Geopolymer Solution

3.4. Relationship between Shear Wave Velocity and Setting Times

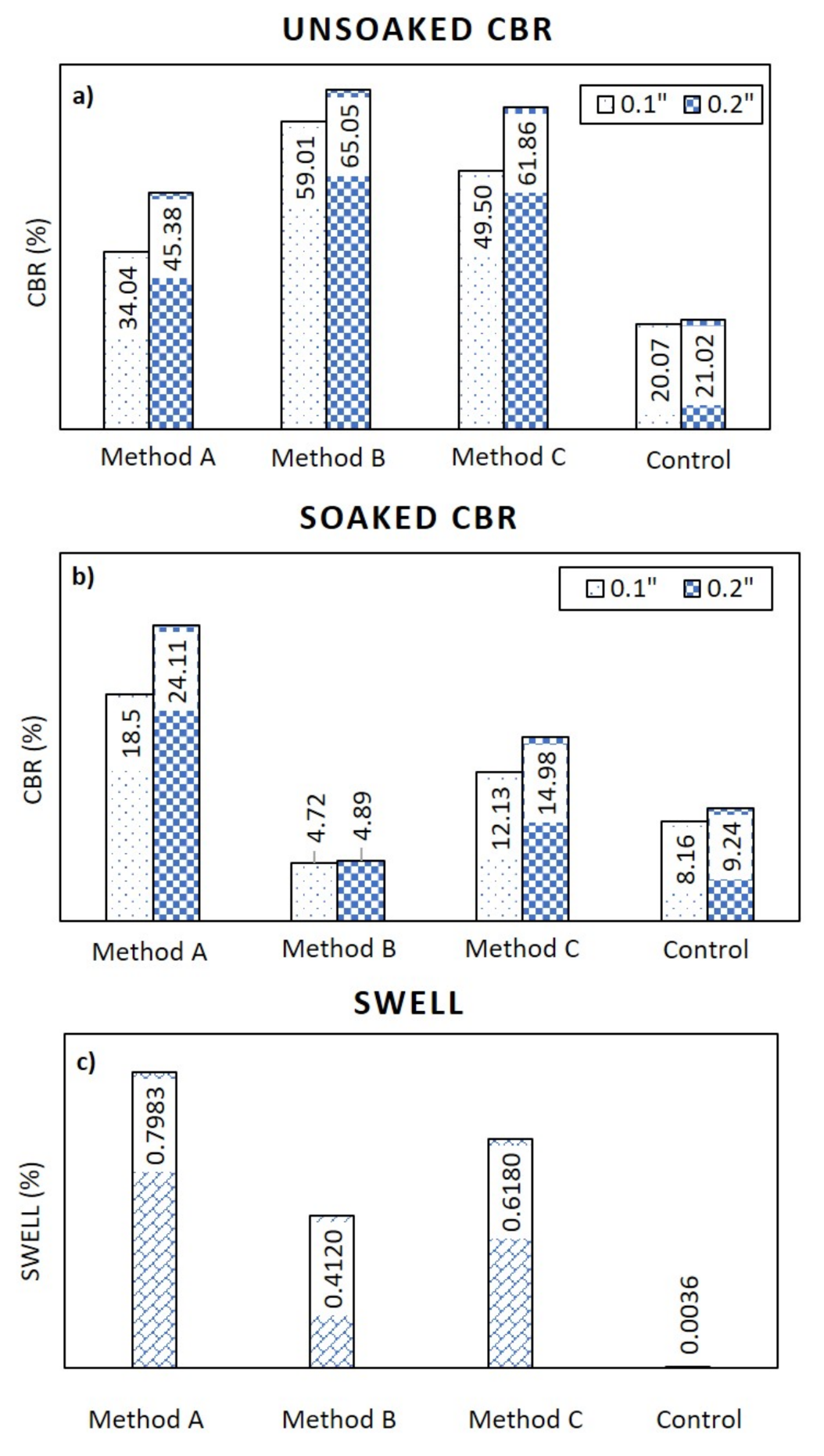

3.5. Effect of CBR on Mixing Methods for Laterite

4. Conclusions

- By varying the treatment temperature, the solution ratio between sodium hydroxide (NaOH) and sodium silicate (Na2SiO3), as well as the mixing ratio between the metakaolin powder and the geopolymer solution, their optimum value can be investigated. In other words, the optimum treatment temperature in producing metakaolin is herein found to be 1000 °C; the optimum solution ratio and the optimum mixing ratio were found to be 2.0:1.0 and 1.0:1.0, respectively.

- Assuming solution ratios between NaOH and Na2SiO3 to be 1.2:1.0, 1.5:1.0, and 2.0:1.0, the relationships between shear wave velocity and Vicat penetration appear to be linear, for a mixing ratio between the metakaolin treated at 1000 °C and the geopolymer solution of 1.0:1.0. According to these three solution ratios, the initial setting time was found to be 136, 142, and 168 m/s, respectively, but the final setting time was found to be 138, 148, and 187 m/s, respectively. Moreover, the optimum solution ratio was found to be 2.0:1.0, according to the maximum shear wave velocity.

- Assuming the solution ratio between NaOH and Na2SiO3 to be 2.0:1.0, as well as assuming the mixing ratio between metakaolin treated at 1000 °C and the geopolymer solution to be 1.0:1.0, CBR tests can be conducted on laterite soils mixed with metakaolin geopolymer and on control laterite soil samples. From the tests, mixing method B is found to be the best for the unsoaked CBR test; its CBR values were about 3 times higher than the control sample. For the soaked CBR test, mixing method A was found to be the best because its CBR values were about 3 times higher than the control sample. However, mixing method B was found to be the best for the swelling CBR tests as it demonstrated the best CBR test results.

- For further study, there are two recommendations. First, a study that extensively focuses on the strength development of metakaolin geopolymer pastes should be conducted, although the current study focuses on the shear wave velocity, which might imply their strength. Second, the use of scanning electron microscopy (SEM) testing was also recommended, in order to further observe the microstructure of metakaolin geopolymer pastes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Iamchaturapatr, J.; Piriyakul, K.; Ketklin, T.; Di Emidio, G.; Petcherdchoo, A. Sandy soil improvement using MICP-based urease enzymatic acceleration method monitored by real-time system. In Advances in Materials Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar] [CrossRef]

- Shirley, D.J.; Hampton, L.D. Shear-wave measurement in laboratory sediments. J. Acoust. Soc. Am. 1978, 63, 607–613. [Google Scholar] [CrossRef]

- Brignoli, E.G.M.; Gotti, M.; Stokoe, K.H. Measurement of shear waves in laboratory specimens by means of piezoelectric transduces. Geotech. Test. J. 1996, 19, 384–397. [Google Scholar]

- Piriyakul, K. A development of a bender element apparatus. J. KMUTNB. 2010, 20, 363–369. [Google Scholar]

- Kim, D.; Yu, J.; Byun, Y. Piezoelectric ring bender for characterization of shear waves in compacted sandy soils. Sensors 2021, 21, 1226. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Park, G.; Byun, Y.; Lee, C. Modified fixed wall oedometer when considering stress dependence of elastic wave velocities. Sensors 2020, 20, 6291. [Google Scholar] [CrossRef]

- Kim, J.; Lee, J.; Arnold, C.; Kim, S.Y. Evaluation of thawing and stress restoration method for artificial frozen sandy soils using sensors. Sensors 2021, 21, 1916. [Google Scholar] [CrossRef]

- Park, J.; Lee, J.; Won, J.; Kim, J. Evaluation of small strain soil stiffness during freeze-thaw cycle: Transition from capillarity to cementation examined using magnetic and piezo crystal sensors. Sensors 2021, 21, 2992. [Google Scholar] [CrossRef]

- Ahn, C.; Kim, D.; Byun, Y. Expansion-induced crack propagation in rocks monitored by using piezoelectric transducer. Sensors 2020, 20, 6054. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, J.; Park, J. Response of transitional mixtures retaining memory of in-situ overburden pressure monitored using electromagnetic and piezo crystal sensors. Sensors 2021, 21, 2570. [Google Scholar] [CrossRef]

- Gabryś, K.; Sas, W.; Soból, E.; Gluchowski, A. Application of bender elements technique in testing of anthropogenic soil-recycled concrete aggregate and its mixture with rubber chips. J. Appl. Sci. 2017, 7, 741. [Google Scholar] [CrossRef] [Green Version]

- Ju, T.; Achenbach, J.D.; Jacobs, L.J.; Guimaraes, M.; Qu, J. Ultrasonic nondestructive evaluation of alkali-silica reaction damage in concrete prism samples. Mater. Struct. 2016, 50, 60. [Google Scholar] [CrossRef]

- Zhu, J.; Cao, J.N.; Bate, B.; Khayat, K.H. Determination of mortar setting times using shear wave velocity evaluation curves measured by the bender element technique. Cem. Concr. Res. 2018, 106, 1–11. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, J.; Seraj, S.; Cano, R.; Juenger, M. Monitoring setting and hardening process of mortar and concrete using ultrasonic shear waves. Constr. Build. Mater. 2014, 72, 248–255. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Grosse, C.U. Continuous monitoring of setting and hardening of mortar and concrete. J. Constr. Build. Mater. 2004, 18, 145–154. [Google Scholar] [CrossRef]

- Petcherdchoo, A. Sensitivity of service life extension and CO2 emission due to repairs by silane treatment applied on concrete structures under time-dependent chloride attack. Adv. Mater. Sci. Eng. 2018, 2018, 2793481. [Google Scholar] [CrossRef] [Green Version]

- Petcherdchoo, A. Probability-based sensitivity of service life of chloride-attacked concrete structures with multiple cover concrete repairs. Adv. Civ. Eng. 2018, 2018, 4525646. [Google Scholar] [CrossRef]

- Piotr Rożek, O.B.; Florek, P.; Mozgawa, W.; Król, M. Alkaline activation of kaolin group minerals. Crystals 2020, 10, 268. [Google Scholar]

- Petcherdchoo, A. Service life and environmental impact due to repairs by metakaolin concrete after chloride attack. RILEM Bookser. 2015, 10, 35–41. [Google Scholar]

- Sullivan, M.S.; Chorzepa, M.G.; Hamid, H.; Durham, S.A.; Kim, S.S. Sustainable materials for transportation infrastructures: Comparison of three commercially-available metakaolin products in binary cementitious systems. J. Infrastruct. 2018, 3, 17. [Google Scholar] [CrossRef] [Green Version]

- Selmani, S.; Sdiri, A.; Bouaziz, S.; Joussein, E.; Rossignol, S. Effects of metakaolin addition on geopolymer prepared from natural kaolinitic clay. Appl. Clay Sci. 2017, 146, 457–467. [Google Scholar] [CrossRef]

- Vali, K.S.; Murugan, S.B. Effect of different binders on cold-bonded artificial lightweight aggregate properties. J. Adv. Concr. Constr. 2020, 9, 183–193. [Google Scholar]

- Wang, X.; Lee, H. Microstructure modeling of carbonation of metakaolin blended concrete. Adv. Concr. Constr. 2019, 7, 167–174. [Google Scholar]

- Attanasio, A.; Pascali, L.; Tarantino, V.; Arena, W.; Largo, A. Alkali-activated mortars for sustainable building solutions: Effect of binder composition on technical performance. J. Environ. 2018, 5, 35. [Google Scholar] [CrossRef] [Green Version]

- Nas, M.; Kurbetci, Ş. Durability properties of concrete containing metakaolin. J. Adv. Concr. Constr. 2018, 6, 159–175. [Google Scholar]

- Petcherdchoo, A.; Hongubon, T.; Thanasisathit, N.; Punthutaecha, K.; Jang, S.-H. Effect of curing time on bond strength between reinforcement and fly-ash geopolymer concrete. Appl. Sci. Eng. Prog. 2020, 13, 127–135. [Google Scholar] [CrossRef]

- Elimbi, A.; Tchakoute, H.K.; Njopwouo, D. Effects of calcination temperature of kaolinite clays on the properties of geopolymer cements. Constr. Build. Mater. 2011, 25, 2805–2812. [Google Scholar] [CrossRef]

- Alaskar, A.; Shah, S.N.R.; Keerio, M.A.; Phulpoto, J.A.; Baharom, S.; Assilzadeh, H.; Alyousef, R.; Alabduljabbar, H.; Mohamed, M. Development of pozzolanic material from clay. J. Adv. Concr. Constr. 2020, 10, 301–310. [Google Scholar]

- Abadel, A.; Albidah, S.A.; Attheeb, A.; Alrshoudi, F.A.; Abbas, H.; Al-Salloum, Y.A. Effect of mortar ratios on strength, microstructure & embodied energy of metakaolin geopolymer. J. Adv. Concr. Constr. 2021, 11, 127–140. [Google Scholar]

- Palumbo, G.; Iadicicco, A.; Messina, F.; Ferone, C.; Campopiano, S.; Cioffi, R.; Colangelo, F. Characterization of early age curing and shrinkage of metakaolin-based inorganic binders with different rheological behavior by fiber Bragg grating sensors. Materials 2018, 11, 10. [Google Scholar] [CrossRef] [Green Version]

- Murri, A.N.; Medri, V.; Papa, E.; Laghi, L.; Mingazzini, C.; Landi, E. Porous geopolymer insulating core from a metakaolin/biomass ash composite. Environments 2017, 4, 86. [Google Scholar] [CrossRef] [Green Version]

- Ricciotti, L.; Molino, A.J.; Roviello, V.; Chianese, E.; Cennamo, P.; Roviello, G. Geopolymer composite for potential applications in cultural heritage. Environments 2017, 4, 91. [Google Scholar] [CrossRef] [Green Version]

- Vegere, K.; Vitola, L.; Argalis, P.P.; Bajare, D.; Krauklis, A.E. Alkali-activated metakaolin as a zeolite-like binder for the production of adsorbents. Inorganics 2019, 7, 141. [Google Scholar] [CrossRef] [Green Version]

- Pereira, P.M.; Ferreira, B.F.; Oliveira, N.P.; Nassar, E.J.; Ciuffi, K.J.; Vicente, M.A.; Trujillano, R.; Rives, V.; Gil, A.; Korili, S.; et al. Synthesis of zeolite a from metakaolin and its application in the adsorption of cationic dyes. Appl. Sci. 2018, 8, 608. [Google Scholar] [CrossRef] [Green Version]

- Piriyakul, K.; Iamchaturapatr, J. Horizontally mounted bender elements for measuring shear modulus in soaked sand specimen. Adv. Mater. Res. 2014, 931–932, 496–500. [Google Scholar] [CrossRef]

- Ylmén, R.; Jäglid, U.; Steenari, B.M.; Panas, I. Early hydration and setting of Portland cement monitored by IR, SEM and Vicat techniques. Cem. Concr. Res. 2008, 38, 1336–1342. [Google Scholar] [CrossRef]

| Chemical Composition | Content (%) |

|---|---|

| SiO2 | 65–70 |

| Al2O3 | 17–20 |

| K2O | 4.20 |

| Na2O | 3.30 |

| MgO | 1.66 |

| Fe2O3 | ˂1.60 |

| TiO2 | 0.10 |

| CaO | 0.07 |

| Properties | Unit |

|---|---|

| Moisture | 1.0% max. |

| Particle sizes that pass through mesh No. 400 (38 μm) | 100% |

| Finer than 2 microns | 30–40% |

| pH | 6.5 ± 1 |

| Oil absorption | 37 ± 2 gm/100 gm |

| Brightness Liquid limit Plastic limit Plastic index Total unit weight | 80 ± 2% 46.84% 34.19% 12.65% 2.36 T/m3 |

| Properties | Unit |

|---|---|

| Liquid Limit, LL | 20% |

| Plastic Limit, PL | 13.53% |

| Plastic Index, PI | 6.47% |

| Specific gravity, Gs | 2.76 |

| Maximum dry unit weight | 2.069 T/m3 |

| Optimum moisture content | 10.17% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iamchaturapatr, J.; Piriyakul, K.; Petcherdchoo, A. Use of a Piezoelectric Bender Element for the Determination of Initial and Final Setting Times of Metakaolin Geopolymer Pastes, with Applications to Laterite Soils. Sensors 2022, 22, 1267. https://doi.org/10.3390/s22031267

Iamchaturapatr J, Piriyakul K, Petcherdchoo A. Use of a Piezoelectric Bender Element for the Determination of Initial and Final Setting Times of Metakaolin Geopolymer Pastes, with Applications to Laterite Soils. Sensors. 2022; 22(3):1267. https://doi.org/10.3390/s22031267

Chicago/Turabian StyleIamchaturapatr, Janjit, Keeratikan Piriyakul, and Aruz Petcherdchoo. 2022. "Use of a Piezoelectric Bender Element for the Determination of Initial and Final Setting Times of Metakaolin Geopolymer Pastes, with Applications to Laterite Soils" Sensors 22, no. 3: 1267. https://doi.org/10.3390/s22031267

APA StyleIamchaturapatr, J., Piriyakul, K., & Petcherdchoo, A. (2022). Use of a Piezoelectric Bender Element for the Determination of Initial and Final Setting Times of Metakaolin Geopolymer Pastes, with Applications to Laterite Soils. Sensors, 22(3), 1267. https://doi.org/10.3390/s22031267