Advanced Control Systems in Industry 5.0 Enabling Process Mining

Abstract

:1. Introduction

- We provide a new theoretical model of PM integrating a DSS based on AI-supervised and unsupervised algorithms;

- We discuss an application field applying PM in food roasting process (application of AI unsupervised algorithm);

- We discuss an application field applying PM in energy production (application of AI supervised algorithm);

- We analyze different aspects concerning electronic/mechatronic implementations and procedures;

- We discuss PM and AI aspects as regards impacts in the supply chains and in organizational processes, thus providing an overview of different possible implementations of the proposed PM model.

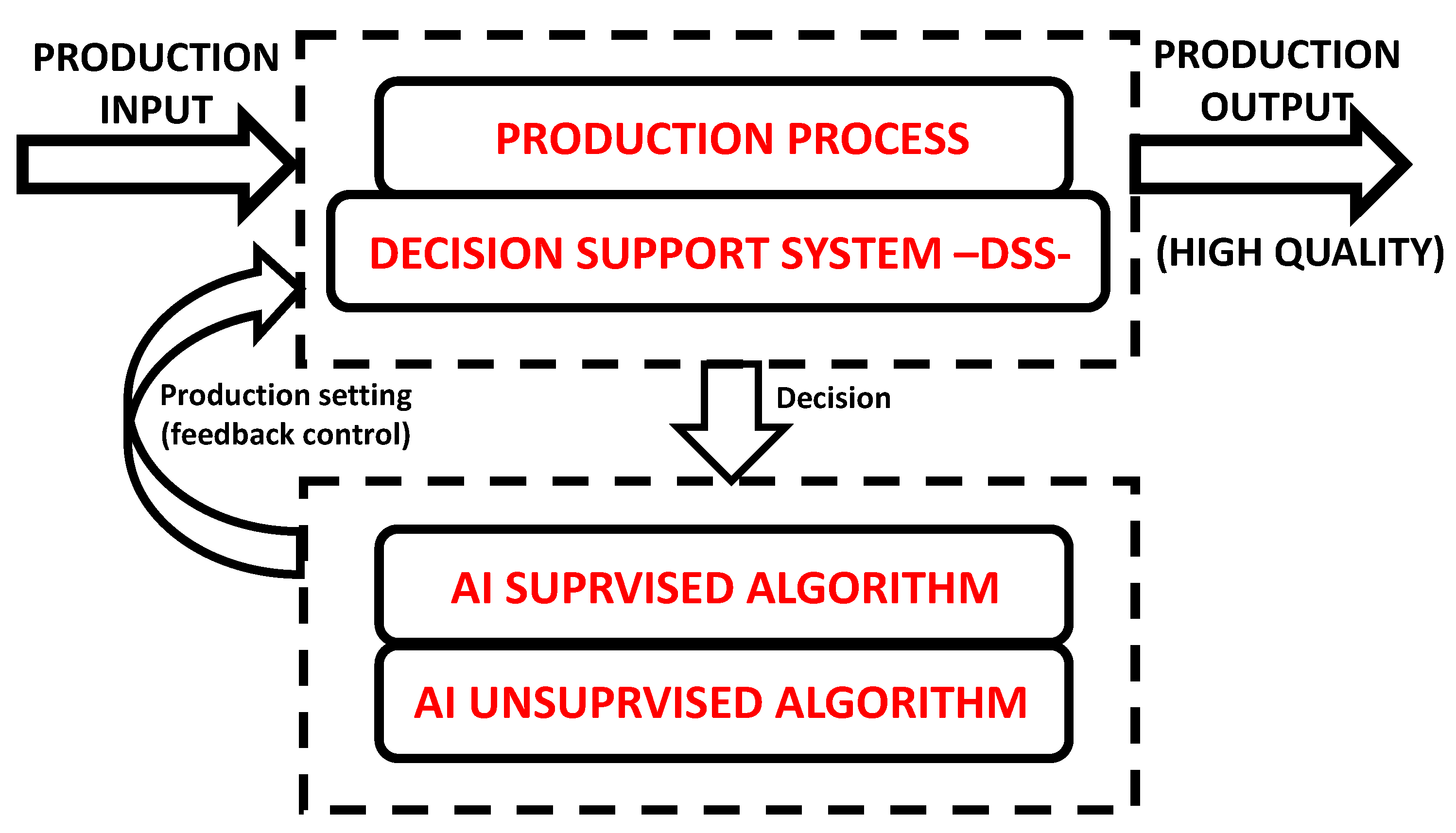

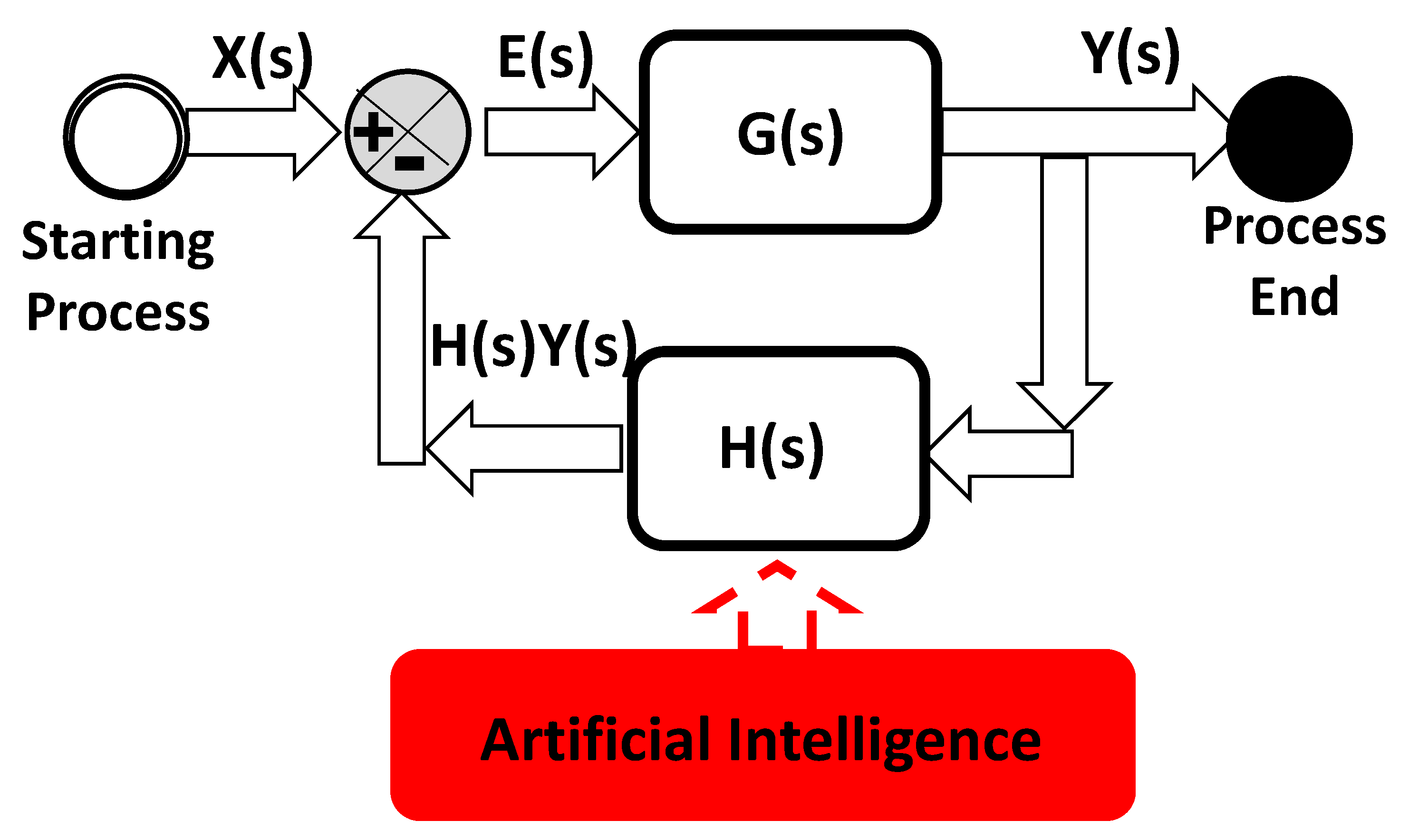

2. Materials and Methods: Process Mining (PM) Model and AI Integration

- DSS Main Process. This pool represents the main process of the PM model, and integrates the DSS enabling supervised and unsupervised AI algorithms. The choice of the algorithm is based on the available dataset typology. The decision to select AI data processing is established by means of the “Exclusive Event based” gateway: in the case of a positive check of the monitored variables the production process continues; besides this, in the case of negative check, the AI algorithm will be able to optimize the machine parameter setting or to decide the intervention to perform. According to the alerting level detected by the AI algorithms, a standard parameter setting (moderate alerting level requiring a soft variation of the machine parameters) or a non-standard parameter setting (high alerting level requiring a strong variation of machine parameters or further corrective interventions) will be activated. Corrective actions include predictive maintenance, possible slowdowns in production, major control by enforcing human resource operation, etc.;

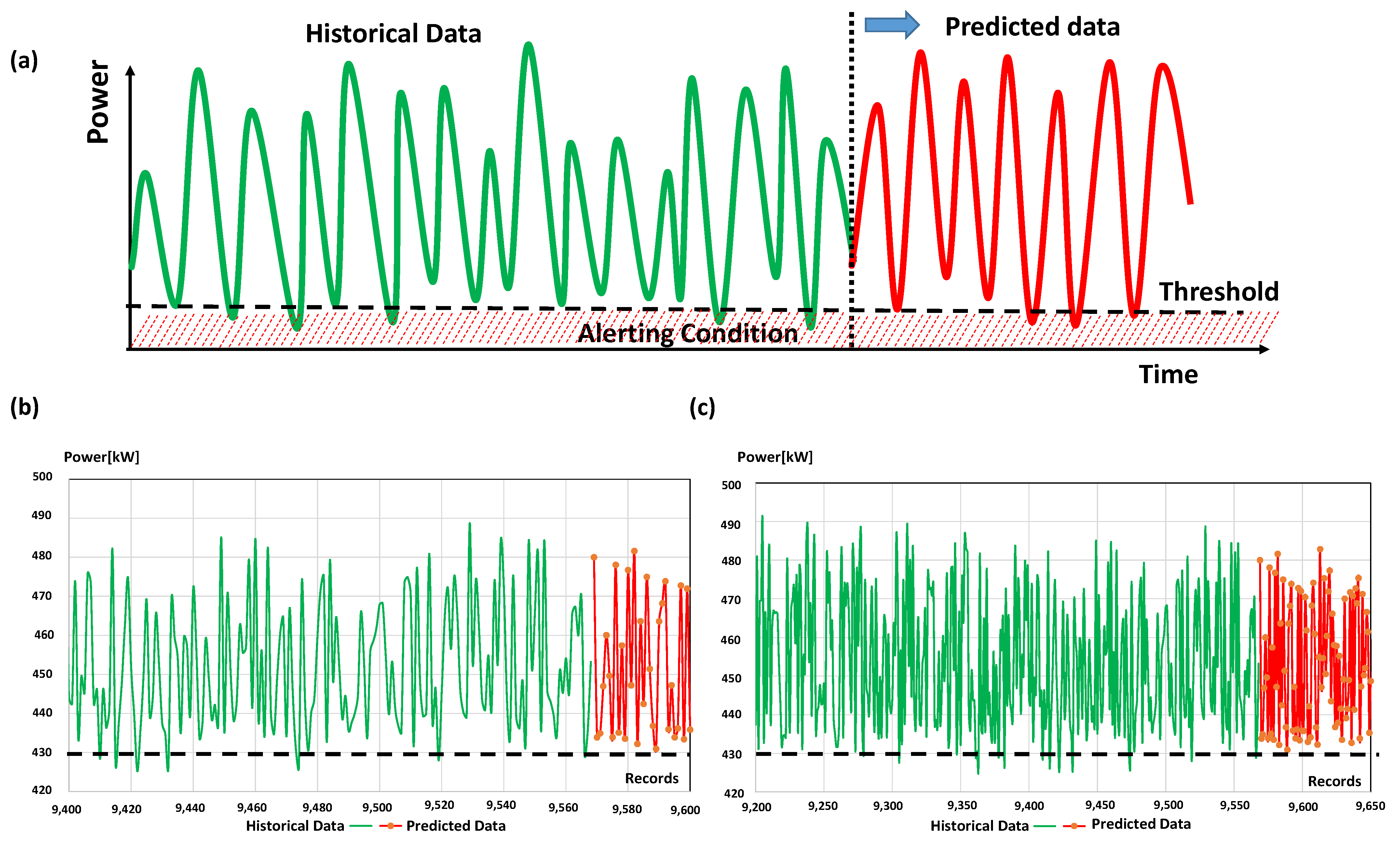

- AI Engine (Supervised Model). This pool concerns the application of the supervised AI algorithm in processing data by means of the training and testing phases. The outputs are predicted or classified data defining alerting risk maps (two alerting levels are considered in the simplified model of Figure 2) driving parameter setting and interventions. The supervised models are preferred when a significant production variable to control is identified (labeled variable);

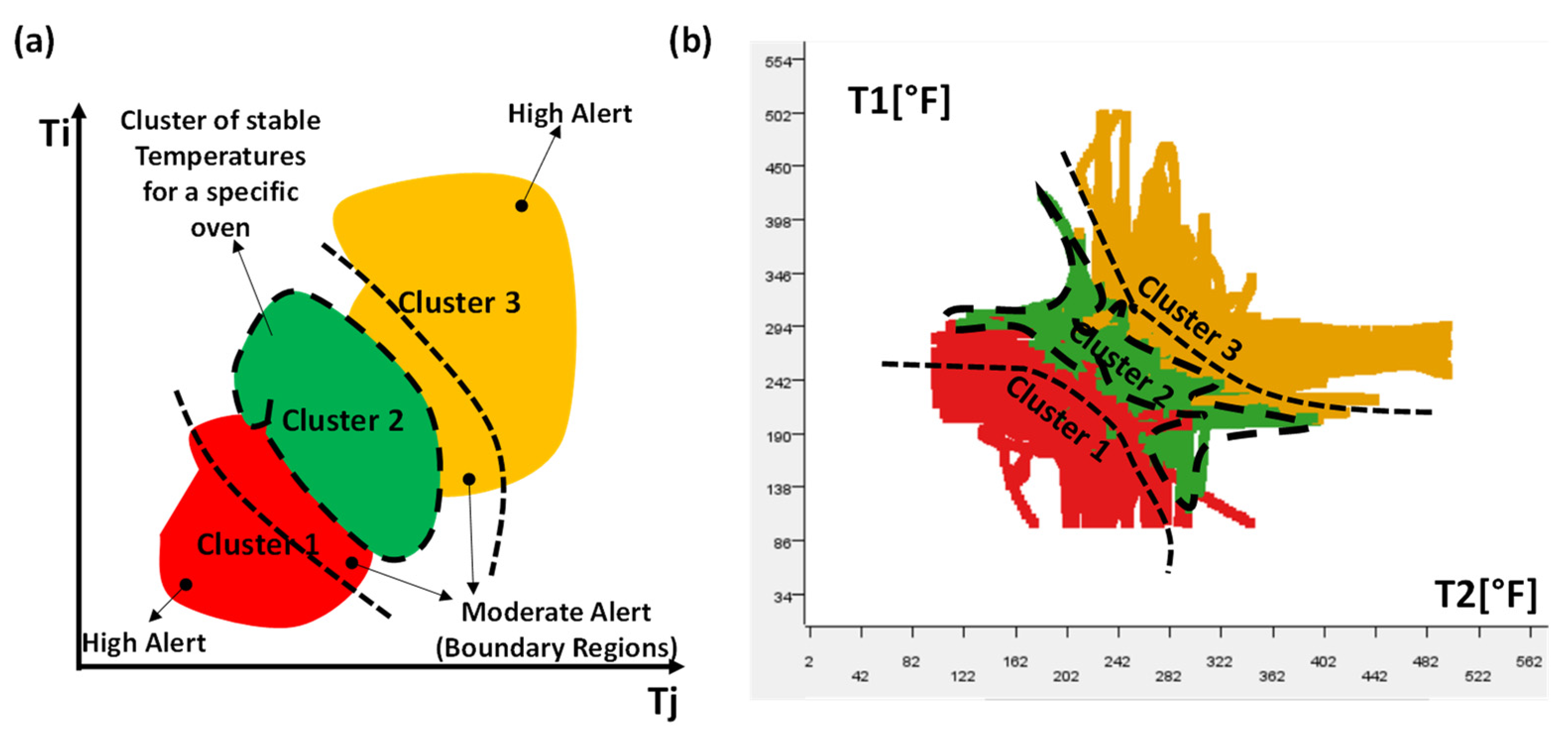

- AI Engine (Unsupervised Model). This pool represents the data clustering process defining the risk maps based on the alerting levels [22]. The output are the data clusters indicating the risk maps (two alerting levels are considered in the simplified model of Figure 2). The unsupervised models are preferred when there are more variables to control without knowing the “weight” of each variable for the specific production process.

| Algorithm 1: PM pseudocode |

|

- The roasting process of a food product passing into five ovens;

- The energy generation process of a Combined Cycle Power Plant (CCPP).

3. Results: Applications of the PM Model

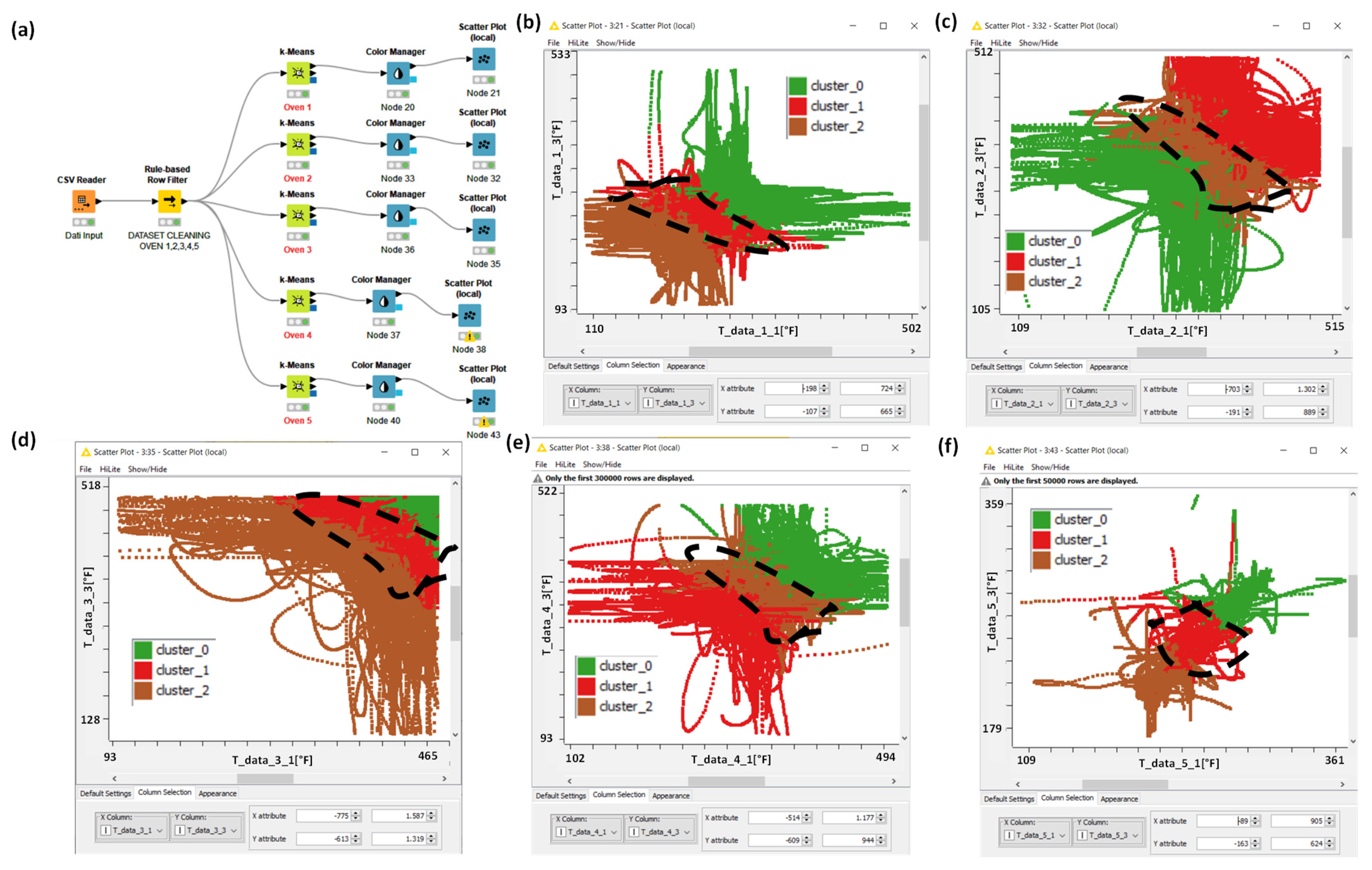

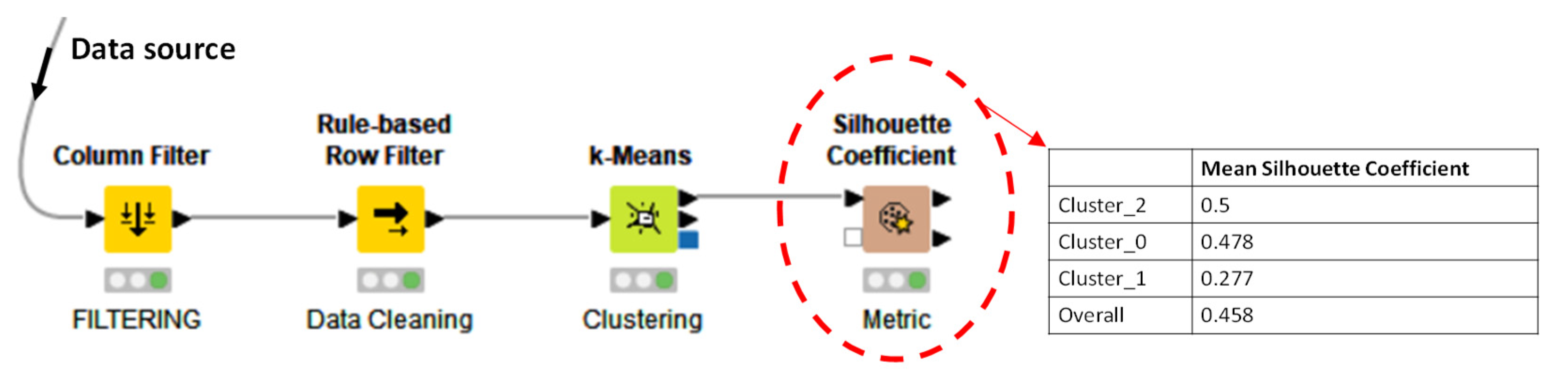

3.1. AI Engine (Unsupervised Model): The Roasting Process

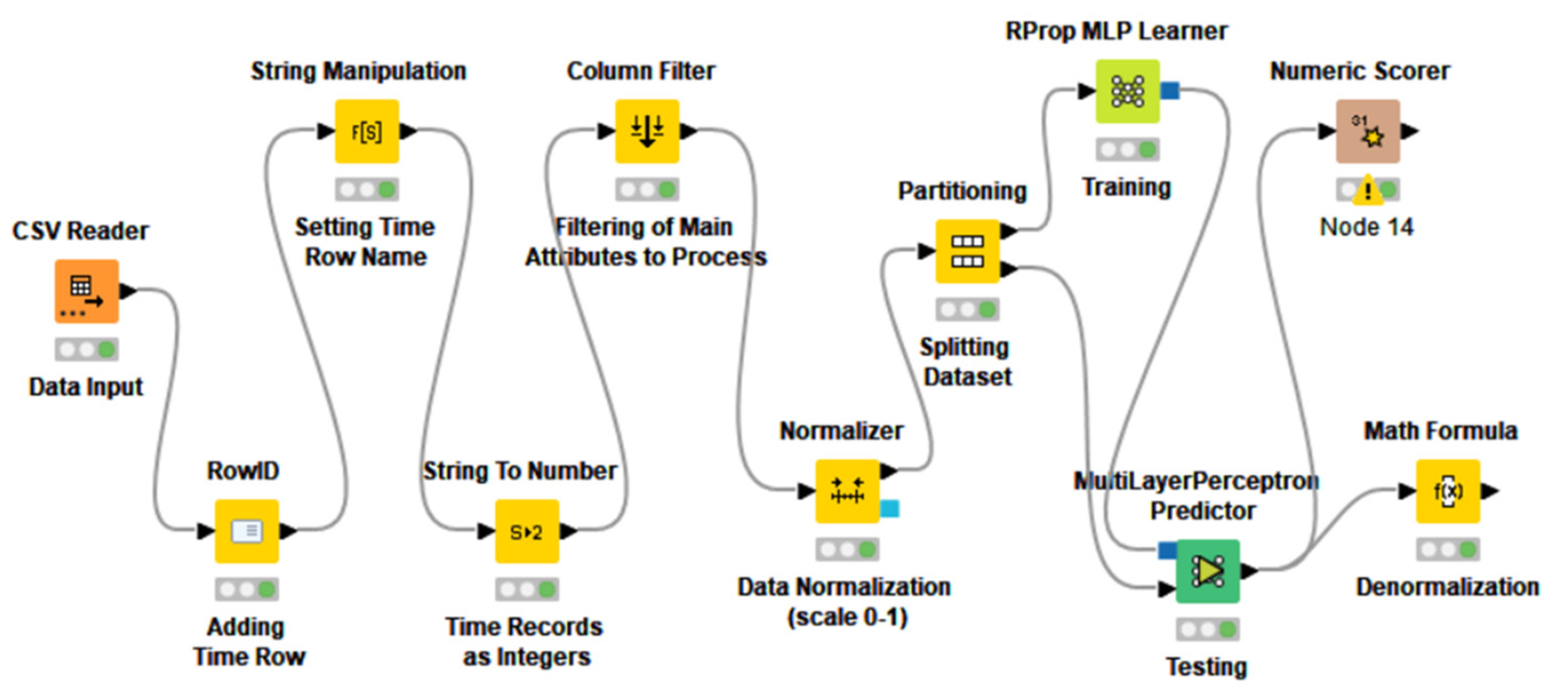

3.2. AI Engine (Supervised Model): Energy Production

4. Discussion

- tool speed regulation integrating AI intelligent control (DC motor controlled by a voltage signal as output of the AI engine);

- tool speed regulation integrating AI controlling an electrical current traveling in series resistors;

- tool speed regulation integrating AI controlling values of series of resistors;

- tool speed regulation integrating AI controlling the value of a single resistance;

- collaborative exoskeletons with auto-adaptive solutions controlling motion trajectory and torque;

- AI controller for current-source inverter circuits (control of the switching conditions) as for three-phase Current-Source Inverters (CSIs);

- intelligent converter control;

- wave rectifier control;

- control of voltage-source inverters;

- control of current-source inverters;

- robotic PID controller based on AI learning;

- AI controller adjusting tool trajectory;

- AI-based image processing selecting inline objects (unsupervised algorithms);

- soft robotics for intelligent collaborative robotics reading disturbance measurements;

- additive manufacturing control (pulsed signal techniques);

- AI image vision circuits implementing AND logic ports.

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Roasting Production Process and DSS Implementing an AI Unsupervised Model

Appendix B. AI Supervised Algorithm Predicting Energy Power

| Parameter | Value |

|---|---|

| R2 | 0.935 |

| Mean Absolute Error (MAE) | 0.045 |

| Mean Squared Error (MSE) | 0.003 |

| Root Mean Squared Error (RMSE) | 0.058 |

| Mean Signed Difference (MSD) | 0.002 |

References

- Massaro, A. Electronic in Advanced Research Industry: From Industry 4.0 to Industry 5.0 Advances; Wiley: Hoboken, NJ, USA; IEEE: New York, NY, USA, 2021; ISBN 9781119716877. [Google Scholar]

- Drakoulogkonas, P.; Apostolou, D. On the Selection of Process Mining Tools. Electronics 2021, 10, 451. [Google Scholar] [CrossRef]

- Lecture Notes in Business Information Processing. Available online: https://www.springer.com/series/7911 (accessed on 23 September 2022).

- Brzychczy, E.; Gackowiec, P.; Liebetrau, M. Data Analytic Approaches for Mining Process Improvement—Machinery Utilization Use Case. Resources 2020, 9, 17. [Google Scholar] [CrossRef] [Green Version]

- Vladareanu, L. Advanced Intelligent Control through Versatile Intelligent Portable Platforms. Sensors 2020, 20, 3644. [Google Scholar] [CrossRef]

- Karthik, T.S.; Kamala, B. Cloud Based AI Approach for Predictive Maintenance and Failure Prevention. J. Phys. Conf. Ser. 2021, 2054, 012014. [Google Scholar] [CrossRef]

- Massaro, A.; Manfredonia, I.; Galiano, A.; Pellicani, L.; Birardi, V. Sensing and Quality Monitoring Facilities Designed for Pasta Industry Including Traceability, Image Vision and Predictive Maintenance. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 68–72. [Google Scholar]

- Mehdiyev, N.; Fettke, P. Explainable Artificial Intelligence for Process Mining: A General Overview and Application of a Novel Local Explanation Approach for Predictive Process Monitoring. In Studies in Computational Intelligence; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–28. [Google Scholar]

- Kim, K.; Kim, B. Decision-Making Model for Reinforcing Digital Transformation Strategies Based on Artificial Intelligence Technology. Information 2022, 13, 253. [Google Scholar] [CrossRef]

- Pilipczuk, O. Transformation of the Business Process Manager Profession in Poland: The Impact of Digital Technologies. Sustainability 2021, 13, 13690. [Google Scholar] [CrossRef]

- Bellantuono, N.; Nuzzi, A.; Pontrandolfo, P.; Scozzi, B. Digital Transformation Models for the I4.0 Transition: Lessons from the Change Management Literature. Sustainability 2021, 13, 12941. [Google Scholar] [CrossRef]

- Fetais, A.; Abdella, G.M.; Al-Khalifa, K.N.; Hamouda, A.M. Business Process Re-Engineering: A Literature Review-Based Analysis of Implementation Measures. Information 2022, 13, 185. [Google Scholar] [CrossRef]

- Massaro, A.; Galiano, A. Re-Engineering Process in a Food Factory: An Overview of Technologies and Approaches for the Design of Pasta Production Processes. Prod. Manuf. Res. 2020, 8, 80–100. [Google Scholar] [CrossRef] [Green Version]

- Massaro, A.; Contuzzi, N.; Galiano, A.; Manfredonia, I.; Xhahysa, B. A Preliminar Research Industry Project: A Case of Study Defining Requirements for Knowledge Base Gain and Technological Upgrade in Industry Working in Train Parts Processing and Testing. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 172–176. [Google Scholar]

- Liagkou, V.; Stylios, C.; Pappa, L.; Petunin, A. Challenges and Opportunities in Industry 4.0 for Mechatronics, Artificial Intelligence and Cybernetics. Electronics 2021, 10, 2001. [Google Scholar] [CrossRef]

- Fernandes, J.; Reis, J.; Melão, N.; Teixeira, L.; Amorim, M. The Role of Industry 4.0 and BPMN in the Arise of Condition-Based and Predictive Maintenance: A Case Study in the Automotive Industry. Appl. Sci. 2021, 11, 3438. [Google Scholar] [CrossRef]

- Zareen, S.; Akram, A.; Ahmad Khan, S. Security Requirements Engineering Framework with BPMN 2.0.2 Extension Model for Development of Information Systems. Appl. Sci. 2020, 10, 4981. [Google Scholar] [CrossRef]

- Massaro, A. Information Technology Infrastructures Supporting Industry 5.0 Facilities. In Electronics in Advanced Research Industries; Wiley: New York, NY, USA, 2021; pp. 51–101. [Google Scholar] [CrossRef]

- Releases Notes for 20.3.0. Available online: https://github.com/jgraph/drawio-desktop/releases (accessed on 25 September 2022).

- Berthold, M.R.; Cebron, N.; Dill, F.; Gabriel, T.R.; Kötter, T.; Meinl, T.; Ohl, P.; Sieb, C.; Thiel, K.; Wiswedel, B. KNIME: The Konstanz Information Miner. In Data Analysis, Machine Learning and Applications; Springer: Berlin/Heidelberg, Germany, 2008; pp. 319–326. [Google Scholar]

- KNIME. Available online: https://www.knime.com/ (accessed on 25 September 2022).

- Massaro, A.; Cosoli, G.; Leogrande, A.; Magaletti, N. Predictive Maintenance and Engineered Processes in Mechatronic Industry: An Italian Case Study. Int. J. Artific. Appl. 2022, 13, 37–54. [Google Scholar] [CrossRef]

- Production Quality. Available online: https://www.kaggle.com/datasets/podsyp/production-quality (accessed on 27 September 2022).

- Ahmed, M.; Seraj, R.; Islam, S.M.S. The k-means Algorithm: A Comprehensive Survey and Performance Evaluation. Electronics 2020, 9, 1295. [Google Scholar] [CrossRef]

- Combined Cycle Power Plant. Available online: https://www.kaggle.com/datasets/shivendraverma/combined-cycle-power-plant (accessed on 27 September 2022).

- Taleb, I.; Guerard, G.; Fauberteau, F.; Nguyen, N. A Flexible Deep Learning Method for Energy Forecasting. Energies 2022, 15, 3926. [Google Scholar] [CrossRef]

- Saloko, S.; Sulastri, Y.; Murad; Rinjani, M.A. The Effects of Temperature and Roasting Time on the Quality of Ground Robusta Coffee (Coffea Rabusta) Using Gene Café Roaster. In Proceedings of the 2nd International Conference on Bioscience, Biotechnology, and Biometrics 2019, Lombok, Indonesia, 13–14 August 2019; AIP Publishing: Melville, NY, USA, 2019. [Google Scholar]

- Catelani, T.A.; Páscoa, R.N.M.J.; Santos, J.R.; Pezza, L.; Pezza, H.R.; Lima, J.L.F.C.; Lopes, J.A. A Non-Invasive Real-Time Methodology for the Quantification of Antioxidant Properties in Coffee during the Roasting Process Based on near-Infrared Spectroscopy. Food Bioprocess Technol. 2017, 10, 630–638. [Google Scholar] [CrossRef] [Green Version]

- Schiuma, G.; Lerro, A.; Sanitate, D. The Intellectual Capital Dimensions of Ducati’s Turnaround: Exploring Knowledge Assets Grounding a Change Management Program. Int. J. Innov. Manag. 2008, 12, 161–193. [Google Scholar] [CrossRef]

- Massaro, A. “Energetic” KPI in Logistics: Complex System Theory and Multi-Level Modeling. Zenodo. 2022. Available online: https://zenodo.org/record/6137729#.Y1lLGXZBxPY (accessed on 31 October 2022).

- Vujanovic, D.; Mijailovic, R.; Momcilovic, V.; Papic, V. Energy Efficiency as a Criterion in the Vehicle Fleet Management Process. Therm. Sci. 2010, 14, 865–878. [Google Scholar] [CrossRef]

- Massaro, A.; Starace, G. Advanced and Complex Energy Systems Monitoring and Control: A Review on Available Technologies and Their Application Criteria. Sensors 2022, 22, 4929. [Google Scholar] [CrossRef]

- Massaro, A.; Panarese, A.; Gargaro, M.; Colonna, A.; Galiano, A. A Case Study of Innovation in the Implementation of a DSS System for Intelligent Insurance Hub Services. Comput. Sci. Inf. Technol. 2021, 9, 14–23. [Google Scholar] [CrossRef]

- Massaro, A. Rapid Prototyping. In Electronics in Advanced Research Industries; Wiley: New York, NY, USA, 2021; pp. 381–444. [Google Scholar] [CrossRef]

- Alnamrouti, A.; Rjoub, H.; Ozgit, H. Do Strategic Human Resources and Artificial Intelligence Help to Make Organisations More Sustainable? Evidence from Non-Governmental Organisations. Sustainability 2022, 14, 7327. [Google Scholar] [CrossRef]

- Achchab, S.; Temsamani, Y.K. Artificial Intelligence Use in Human Resources Management: Strategy and Operation’s Impact. In Proceedings of the 2021 IEEE 2nd International Conference on Pattern Recognition and Machine Learning (PRML), Chengdu, China, 16–18 July 2021; pp. 311–315. [Google Scholar]

- Tewari, I.; Pant, M. Artificial Intelligence Reshaping Human Resource Management: A Review. In Proceedings of the 2020 IEEE International Conference on Advent Trends in Multidisciplinary Research and Innovation (ICATMRI), Buldhana, India, 30 December 2020; pp. 1–4. [Google Scholar]

- Massaro, A. Electronic and Reverse Engineering. In Electronics in Advanced Research Industries; Wiley: New York, NY, USA, 2021; pp. 341–380. [Google Scholar] [CrossRef]

- Chouchene, A.; Carvalho, A.; Lima, T.M.; Charrua-Santos, F.; Osorio, G.J.; Barhoumi, W. Artificial Intelligence for Product Quality Inspection toward Smart Industries: Quality Control of Vehicle Non-Conformities. In Proceedings of the 2020 9th International Conference on Industrial Technology and Management (ICITM), Oxford, UK, 11–13 February 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 127–131. [Google Scholar]

- Papageorgiou, E.I.; Theodosiou, T.; Margetis, G.; Dimitriou, N.; Charalampous, P.; Tzovaras, D.; Samakovlis, I. Short Survey of Artificial Intelligent Technologies for Defect Detection in Manufacturing. In Proceedings of the 2021 12th International Conference on Information, Intelligence, Systems & Applications (IISA), Chania, Greece, 12–14 July 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–7. [Google Scholar]

- Damacharla, P.; Rao, A.; Ringenberg, J.; Javaid, A.Y. TLU-Net: A Deep Learning Approach for Automatic Steel Surface Defect Detection. In Proceedings of the 2021 International Conference on Applied Artificial Intelligence (ICAPAI), Halden, Norway, 19–21 May 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar]

- Massaro, A.; Manfredonia, I.; Galiano, A.; Xhahysa, B. Advanced Process Defect Monitoring Model and Prediction Improvement by Artificial Neural Network in Kitchen Manufacturing Industry: A Case of Study. In Proceedings of the 2019 II Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), Naples, Italy, 4–6 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 64–67. [Google Scholar]

- Smith, C.J.; Wong, A.T.C. Advancements in Artificial Intelligence-Based Decision Support Systems for Improving Construction Project Sustainability: A Systematic Literature Review. Informatics 2022, 9, 43. [Google Scholar] [CrossRef]

- Aranganayagi, S.; Thangavel, K. Clustering Categorical Data Using Silhouette Coefficient as a Relocating Measure. In Proceedings of the International Conference on Computational Intelligence and Multimedia Applications (ICCIMA 2007), Sivakasi, India, 13–15 December 2007; IEEE: Piscataway, NJ, USA, 2007; Volume 2, pp. 13–17. [Google Scholar]

| Topic | Industry 4.0 Scenario | Industry 5.0 Scenario [1] |

|---|---|---|

| PM | Industrial process are typically mapped by BPMN approach: standard workflow defines a static representation of the scenario where digital sensors transmit data and actuation systems are not managed by the same PM model. | Processes are mapped by considering decisional logics integrated in the PM model: the process is dynamic and the choice of the sub-process is a function of the real-time automatic decisions performed by a calculus unit (implementation of decision-making logics depending on AI output). |

| DSS | The user working on a production machine can control and manage the machine parameter through cloud applications reading sensors and enabling remote actuation. The main function of the DSS is to provide alerting signals that can be monitored online. | The DSS is a standalone system that auto-adapts the machine parameter’s setting depending on the self-learning approach: the historical sensor data are used to implement DSS detecting alerts, but also to automatically set optimal machines and tools for self-adaptive production. |

| Electronic components | Electronic components are mainly used for the realization of sensors and Human–Machine Interfaces (HMIs) applied on production machines. | Innovative advanced electronic systems can be manufactured by developing electronic chips and boards integrated in the production machine, and having AI logics (implementation of McCulloch–Pitts neurons by transistors and other electronic components reproducing the AI logics by logic ports). The Machine to Machine (M2M) interfaces are managed by AI networks based on feedback systems. |

| Management Class in Industries | Supply Chain Aspects Generated by PM Models | Organizational Impact Description | AI References |

|---|---|---|---|

| Production of products | Mechatronic and electronic components interfaced via the AI algorithm providing the self-adaption of the machine parameter setting. | An accurate human resource training approach focusing on advanced electronic and mechatronic technologies is necessary for the best production efficiency. The accurate reading of AI-predicted results optimizes a possible predictive maintenance procedure or the corrective action plans avoiding defects. | [1] |

| Logistics | Intralogistics and logistics improvements suggested by AI-DSS (load prediction, priorities of transport activities, fuel consumption optimization, etc.). | We require a formulation of Key Performance Indicators (KPIs) oriented towards the optimization of logistics using the available resources and layouts (human resources, vehicles, etc.). CM models, together with AI results (for example, regarding load prediction), could support all the logistics activities. | [30,31] |

| Energy | The whole supply chain must be “energetically efficient” to reduce the high costs due to the energy consumption rate. The energy monitoring and the AI energy forecasting are important tools to reduce costs. | Energy consumption monitoring, especially for energy-intensive industries, suggests new production layouts and a possible re-organization of the whole production process deciding priorities according to the product request in the market (very high impact). | [32] |

| Services and micro-services | Companies working in services require AI tools to optimize marketing actions and customer care (as for recommender systems). The parameters to assess are KPI associated with the implementation of services. | We require new knowledge based on information about customer profiles and customer behavior, together with a strategic provisional analysis of marketing. | [33] |

| Rapid Prototyping (RP) | PM-AI models are applied for a specific phase of the production of prototypes. | PM is important to defining the best way to perform rapid prototyping (RP) in short times, thus helping the manager to decide “in time” and to continue onto the next development phase of the pre-series production. RP requires a structured team with different skills. | [34] |

| Human Resource (HR) | Selection processes of HR improved by executing PM-AI models. | Human capital in industries is very important for the organization and for production efficiency. CM models are matched with PM ones, thus structuring in the best way all the supply chain activities and the most suitable teams to execute specific processes. | [35,36,37] |

| Reverse Engineering (RE) | RE can be modeled by a PM model. This new concept of RE could optimize company strategies regarding quality process optimization. | The RE processes require advanced technologies (3D scanners, feelers, etc.) and well-defined procedures to detect object shapes with a specific tolerance depending on the accuracy of the adopted tool. Workers should be continuously trained on the updating of technologies and procedures. This requires an investment plan for the company in the training of its personnel. | [38] |

| Quality check | All quality processes concerning product quality checks by AI. | The quality processes drastically influence production and marketing strategies. A new concept of quality checking by means of the execution of PM models reliably optimizes the checkpoint definition (according to ISO 9001:2015 standard). The implementation of new quality processes involving AI technologies requires a revision of the organizational model related to quality control. In this area can be applied CM models closely related to quality. | [39,40,41,42] |

| Project Management (PM) | PM can be applied also for the management of projects regarding different sectors of the supply chain or global projects (new production line, new product, etc.). | AI plays an important role in decision-making and risk management in project management activities. The PM and the CM models are able to enact the whole range of activities (task) that should be developed by ensuring the good execution of the project. | [43] |

| BPMN Approach | Advantages | Disadvantages |

|---|---|---|

| Integrating Unsupervised Algorithm |

|

|

| Integrating Supervised Algorithm |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massaro, A. Advanced Control Systems in Industry 5.0 Enabling Process Mining. Sensors 2022, 22, 8677. https://doi.org/10.3390/s22228677

Massaro A. Advanced Control Systems in Industry 5.0 Enabling Process Mining. Sensors. 2022; 22(22):8677. https://doi.org/10.3390/s22228677

Chicago/Turabian StyleMassaro, Alessandro. 2022. "Advanced Control Systems in Industry 5.0 Enabling Process Mining" Sensors 22, no. 22: 8677. https://doi.org/10.3390/s22228677

APA StyleMassaro, A. (2022). Advanced Control Systems in Industry 5.0 Enabling Process Mining. Sensors, 22(22), 8677. https://doi.org/10.3390/s22228677