Improvement of Temperature Performance of Singlemode-Multimode-Singlemode Fiber Structure

Abstract

1. Introduction

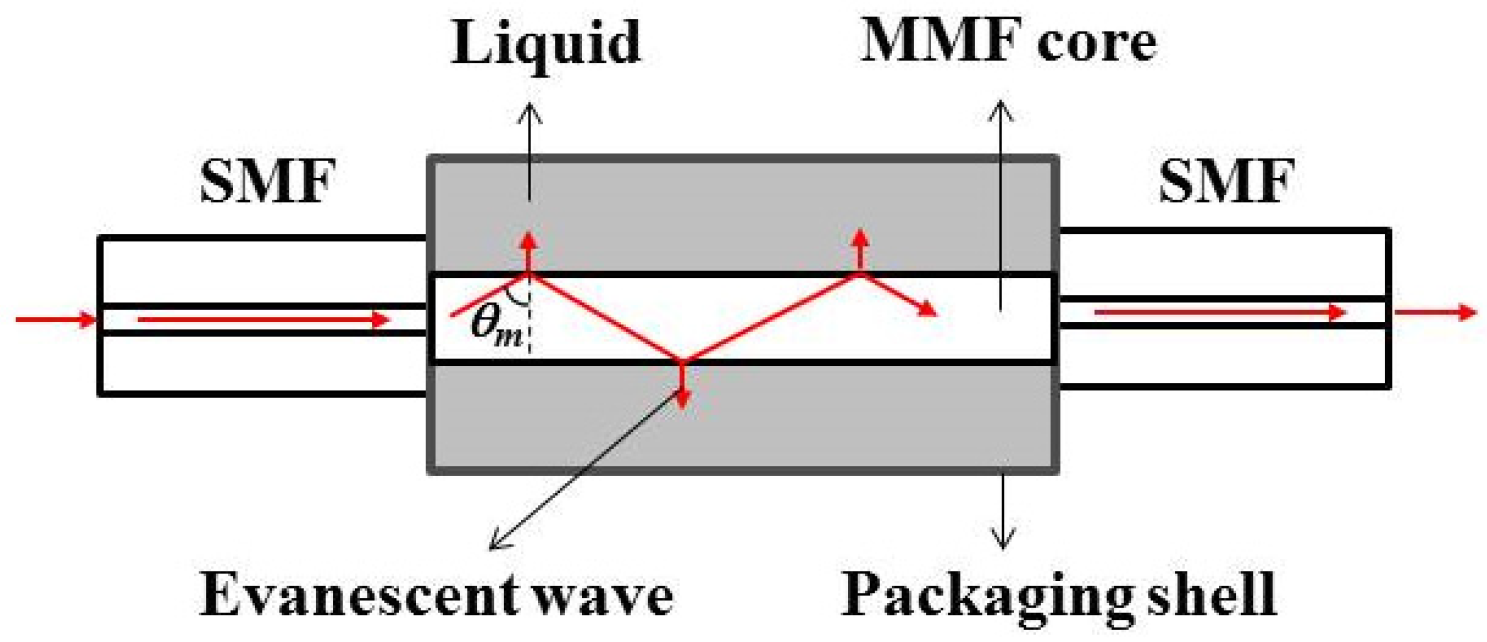

2. Theoretical Model

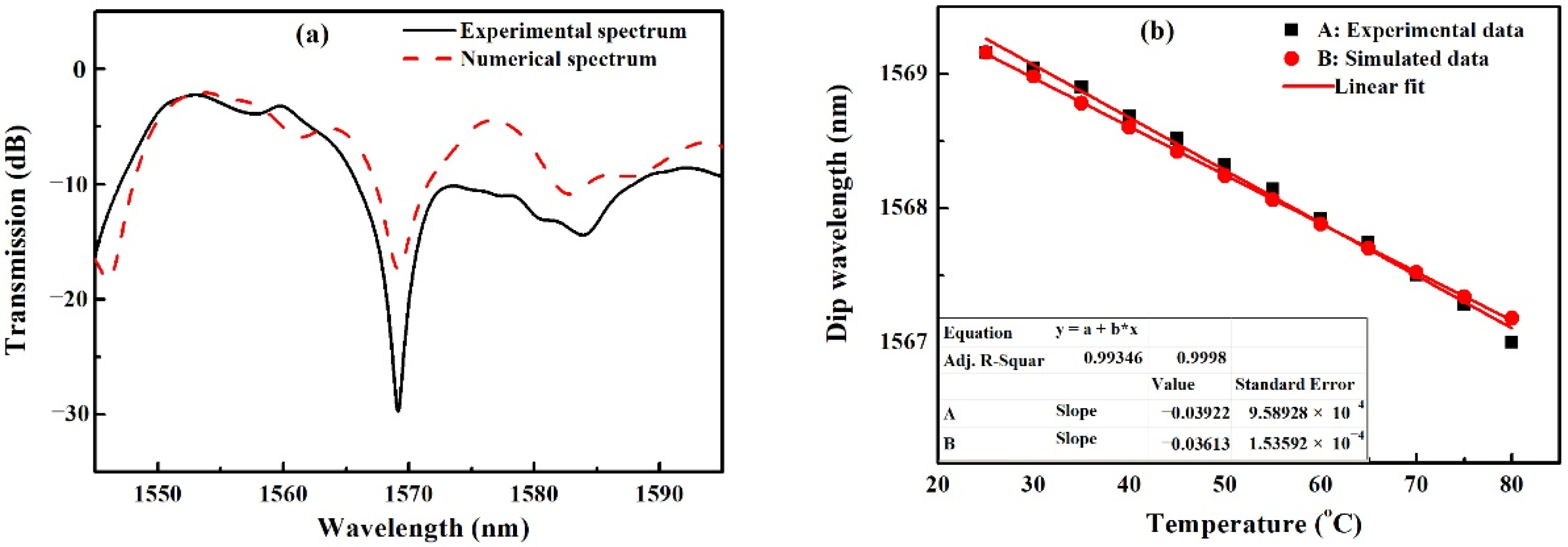

3. Experimental and Simulated Results

4. Impact of MMF on the Temperature Performance of SMS Fiber Structure

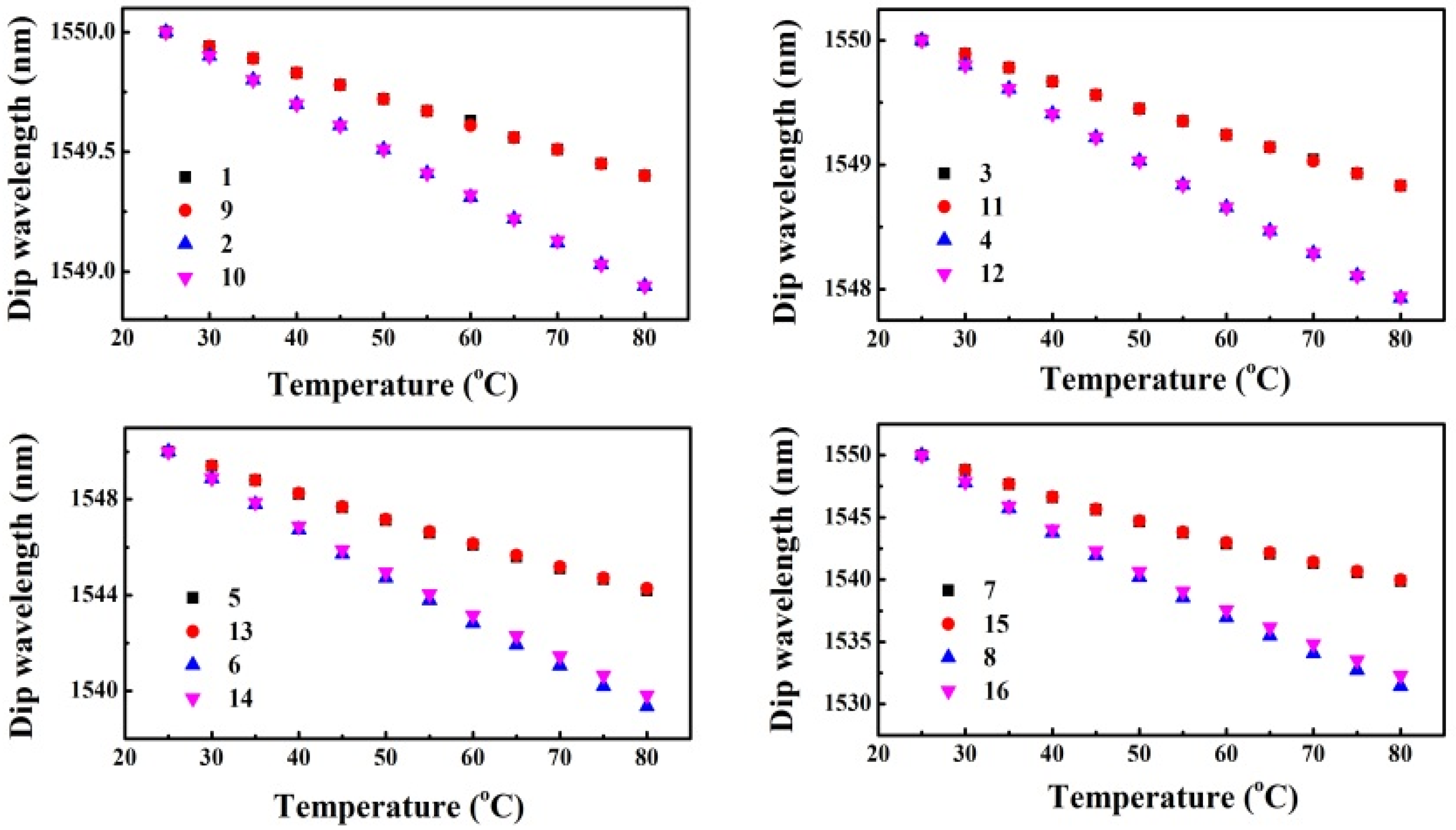

4.1. Effect of TOE of MMF Cladding (TOEcl)

4.2. Effect of TOE of MMF Core (TOEco)

4.3. Effect of TEE

4.4. Effect of Thermal Effect of Absorption Characteristic of the MMF

5. Improvement of Temperature Performance

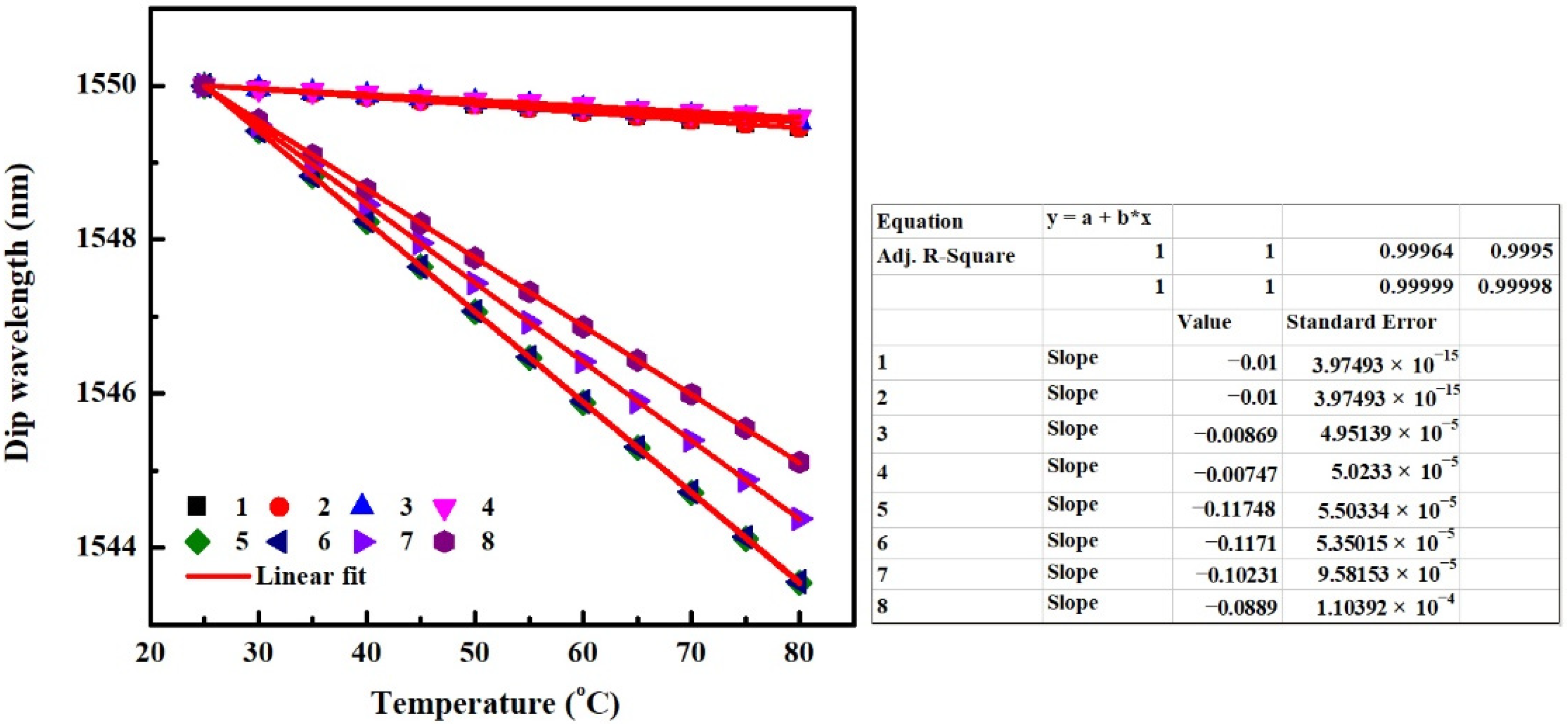

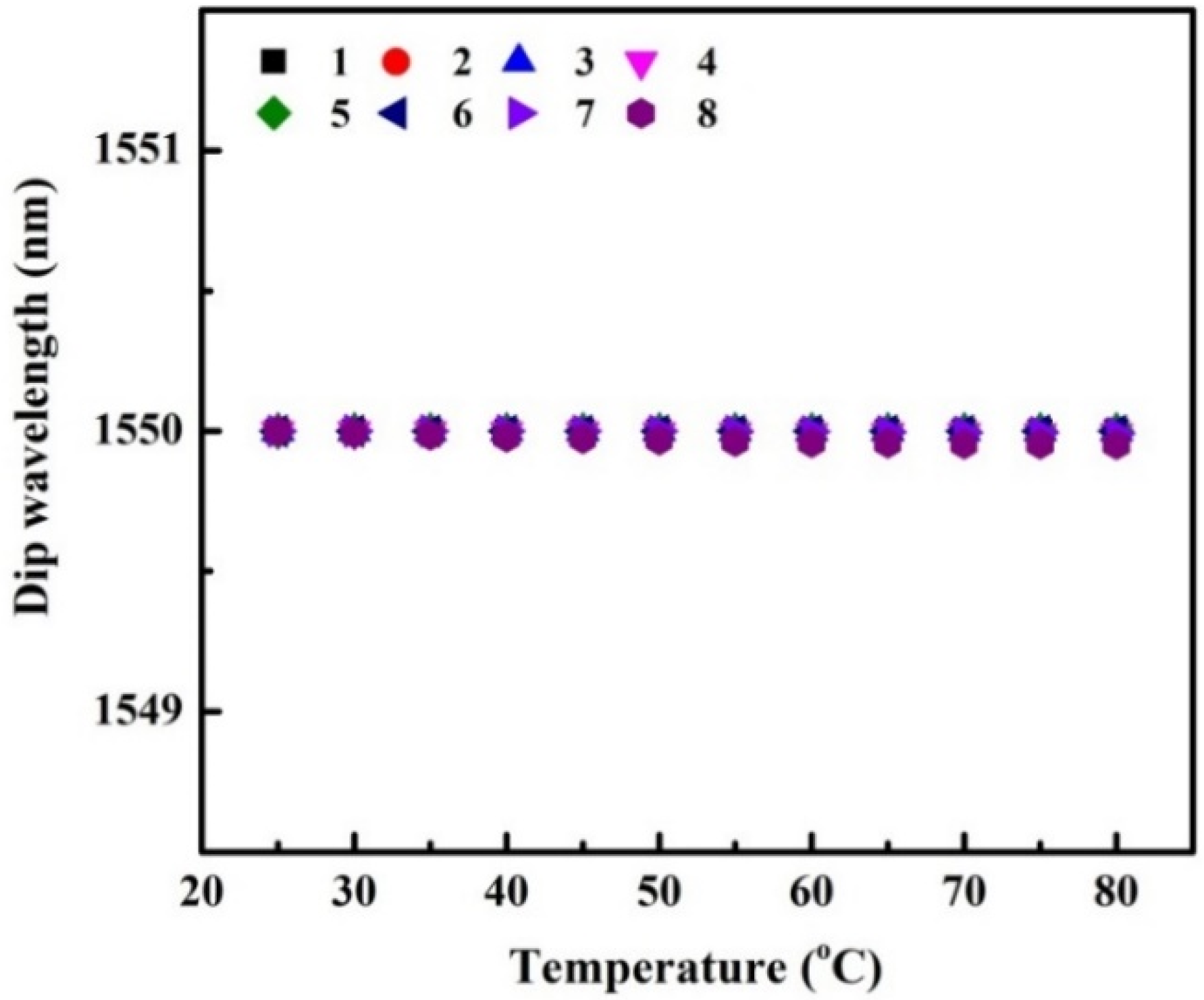

5.1. Improvement of Temperature Stability

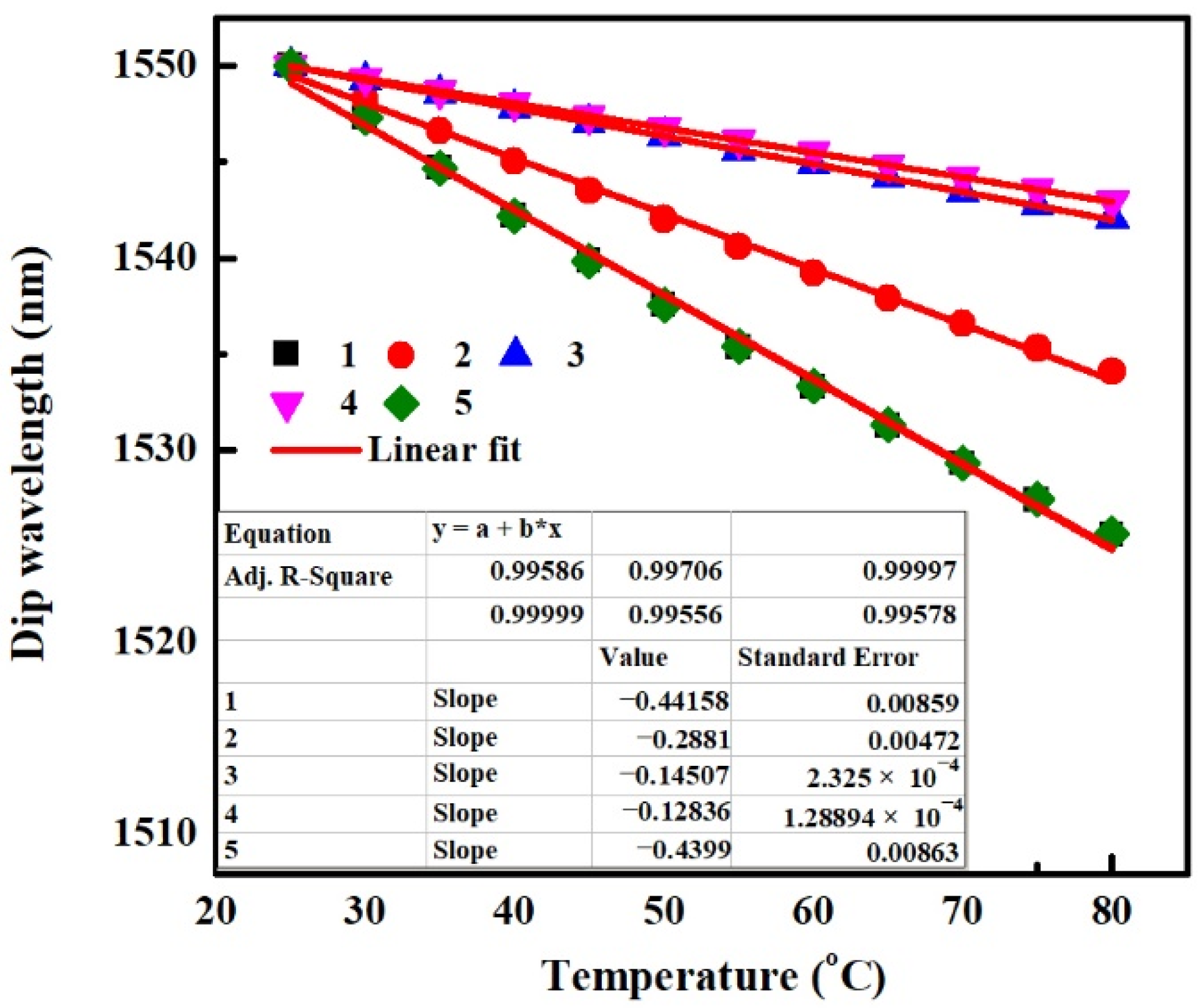

5.2. Improvement of Temperature Sensitivity

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, Q.; Semenova, Y.; Wang, P.; Farrell, G. High sensitivity SMS fiber structure based refractometer–analysis and experiment. Opt. Express 2011, 19, 7937–7944. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Han, Q.; Liu, T.; Xiao, H. Wavelength dependence of the sensitivity of all-fiber refractometers based on the singlemode-multimode-singlemode structure. IEEE Photon. J. 2014, 6, 6801807. [Google Scholar]

- Tang, J.; Zhou, J.; Guan, J.; Long, S.; Yu, J.; Guan, H.; Lu, H.; Luo, Y.; Zhang, J.; Chen, Z. Fabrication of side-polished single mode-multimode-single mode fiber and its characteristics of refractive index sensing, IEEE J. Sel. Top. Quantum. Electron. 2017, 23, 238–245. [Google Scholar] [CrossRef]

- Li, E. Sensitivity-enhanced fiber-optic strain sensor based on interference of higher order modes in circular fibers. IEEE Photon. Technol. Lett. 2007, 19, 1266–1268. [Google Scholar]

- Bai, Y.; Zeng, J.; Huang, J.; Yan, Z.; Wu, Y.; Li, K.; Wu, Q.; Liang, D. Air pressure measurement of circular thin plate using optical fiber multimode interferometer. Measurement 2021, 182, 109784. [Google Scholar]

- Pang, Y.; Liu, B.; Liu, J.; Wan, S.; Wu, T.; Yuan, J.; Xin, X.; He, X.; Wu, Q. Singlemode-multimode-singlemode optical fiber sensor for accurate blood pressure monitoring. J. Lightwave Technol. 2022, 40, 4443–4450. [Google Scholar]

- Irawati, N.; Hatta, A.M.; Yhuwana, Y.G.Y.; Sekartedjo. Heart rate monitoring sensor based on singlemode-multimode-singlemode fiber. Photonic Sens. 2020, 10, 186–193. [Google Scholar] [CrossRef]

- Li, E.; Wang, X.; Zhang, C. Fiber-optic temperature sensor based on interference of selective higher-order modes. Appl. Phys. Lett. 2006, 89, 091119. [Google Scholar]

- Silva, S.; Pachon, E.G.P.; Franco, M.A.R.; Hayashi, J.G.; Malcata, F.X.; Frazão, O.; Jorge, P.; Cordeiro, C.M.B. Ultrahigh-sensitivity temperature fiber sensor based on multimode interference. Appl. Opt. 2012, 51, 3236–3242. [Google Scholar]

- Sun, H.; Hu, M.; Rong, Q.; Du, Y.; Yang, H.; Qiao, X. High sensitivity optical fiber temperature sensor based on the temperature cross-sensitivity feature of RI-sensitive device. Opt. Commun. 2014, 323, 28–31. [Google Scholar]

- Chen, Y.; Han, Q.; Liu, T.; Lü, X. Self-temperature-compensative refractometer based on singlemode–multimode–singlemode fiber structure. Sens. Actuators B Chem. 2015, 212, 107–111. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G.; Yan, W. Investigation on single-mode–multimode–single-mode fiber structure. J. Lightwave Technol. 2008, 26, 512–519. [Google Scholar] [CrossRef]

- Wang, H.; Pu, S.; Wang, N.; Dong, S.; Huang, J. Magnetic field sensing based on singlemode–multimode–singlemode fiber structures using magnetic fluids as cladding. Opt. Lett. 2013, 38, 3765–3768. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Han, Q.; Liu, T.; Lan, X.; Xiao, H. Optical fiber magnetic field sensor based on single-mode–multimode–single-mode structure and magnetic fluid. Opt. Lett. 2013, 38, 3999–4001. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, T.; Han, Q.; Chen, Y.; Li, L.; Yao, X.S. Temperature cross-sensitivity characteristics of singlemode–multimode–singlemode fiber structure. Rev. Sci. Instrum. 2015, 86, 013108. [Google Scholar] [CrossRef]

- Keiser, G. Optical Fiber Communications; McGraw-Hill Education: New York, NY, USA, 2010. [Google Scholar]

- Gupta, B.D.; Dodeja, H.; Tomar, A.K. Fibre-optic evanescent field absorption sensor based on a U-shaped probe. Opt. Quantum. Electron. 1996, 28, 1629–1639. [Google Scholar] [CrossRef]

- Tripathi, S.M.; Kumar, A.; Varshney, R.K.; Kumar, Y.B.P.; Marin, E.; Meunier, J.-P. Strain and temperature sensing characteristics of single-mode–multimode–single-mode structures. J. Lightwave Technol. 2009, 27, 2348–2356. [Google Scholar] [CrossRef]

- Abbate, G.; Attanasio, A.; Bernini, U.; Ragozzino, E.; Somma, F. The direct determination of the temperature dependence of the refractive index of liquids and solids. J. Phys. D Appl. Phys. 1976, 9, 1945–1951. [Google Scholar] [CrossRef]

- Pu, S.; Chen, X.; Chen, Y.; Liao, W.; Chen, L.; Xia, Y. Measurement of the refractive index of a magnetic fluid by the retroreflection on the fiber-optic end face. Appl. Phys. Lett. 2005, 86, 171904. [Google Scholar] [CrossRef]

- Abbate, G.; Bernini, U.; Ragozzino, E.; Somma, F. The temperature dependence of the refractive index of water. J. Phys. D Appl. Phys. 1978, 11, 1167–1172. [Google Scholar] [CrossRef]

- Kedenburg, S.; Vieweg, M.; Gissibl, T.; Giessen, H. Linear refractive index and absorption measurements of nonlinear optical liquids in the visible and near-infrared spectral region. Opt. Mater. Express 2012, 2, 1588–1611. [Google Scholar] [CrossRef]

- Collins, J.R. Change in the infra-red absorption spectrum of water with temperature. Phys. Rev. 1925, 26, 771–779. [Google Scholar] [CrossRef]

| Number of SMS Structure | α (/m) | RIcl | TOCcl (/°C) | d (μm) |

|---|---|---|---|---|

| 1 | 103 | 1.32 | −1 × 10−4 | 105 |

| 2 | 103 | 1.32 | −1 × 10−4 | 60 |

| 3 | 103 | 1.32 | −2 × 10−4 | 105 |

| 4 | 103 | 1.32 | −2 × 10−4 | 60 |

| 5 | 103 | 1.42 | −1 × 10−4 | 105 |

| 6 | 103 | 1.42 | −1 × 10−4 | 60 |

| 7 | 103 | 1.42 | −2 × 10−4 | 105 |

| 8 | 103 | 1.42 | −2 × 10−4 | 60 |

| Number of SMS Structure | α (/m) | RIcl | d (μm) |

|---|---|---|---|

| 1 | 103 | 1.32 | 105 |

| 2 | 103 | 1.32 | 60 |

| 3 | 103 | 1.42 | 105 |

| 4 | 103 | 1.42 | 60 |

| Number of SMS Structure | α (/m) | TECp (/°C) | RIcl | d (μm) |

|---|---|---|---|---|

| 1 | 103 | 5 × 10−6 | 1.32 | 105 |

| 2 | 103 | 5 × 10−6 | 1.32 | 60 |

| 3 | 103 | 5 × 10−6 | 1.42 | 105 |

| 4 | 103 | 5 × 10−6 | 1.42 | 60 |

| 5 | 103 | 5 × 10−5 | 1.32 | 105 |

| 6 | 103 | 5 × 10−5 | 1.32 | 60 |

| 7 | 103 | 5 × 10−5 | 1.42 | 105 |

| 8 | 103 | 5 × 10−5 | 1.42 | 60 |

| Number of SMS Structure | α (/m) | δα (/m/°C) | RIcl | d (μm) |

|---|---|---|---|---|

| 1 | 103 | −5 | 1.32 | 105 |

| 2 | 103 | −5 | 1.32 | 60 |

| 3 | 103 | −5 | 1.42 | 105 |

| 4 | 103 | −5 | 1.42 | 60 |

| 5 | 103 | −50 | 1.32 | 105 |

| 6 | 103 | −50 | 1.32 | 60 |

| 7 | 103 | −50 | 1.42 | 105 |

| 8 | 103 | −50 | 1.42 | 60 |

| Number of SMS Structure | α (/m) | δα (/m/°C) | TOCcl (/°C) | TECp (/°C) | RIcl | d (μm) |

|---|---|---|---|---|---|---|

| 1 | 103 | −5 | −1 × 10−4 | 5 × 10−6 | 1.32 | 105 |

| 2 | 103 | −5 | −1 × 10−4 | 5 × 10−6 | 1.32 | 60 |

| 3 | 103 | −5 | −1 × 10−4 | 5 × 10−6 | 1.42 | 105 |

| 4 | 103 | −5 | −1 × 10−4 | 5 × 10−6 | 1.42 | 60 |

| 5 | 103 | −5 | −1 × 10−4 | 5 × 10−7 | 1.32 | 105 |

| 6 | 0 | 0 | −1 × 10−4 | 5 × 10−7 | 1.32 | 105 |

| Number of SMS Structure | α (/m) | δα (/m/°C) | TOCcl (/°C) | TECp (/°C) | RIcl | d (μm) |

|---|---|---|---|---|---|---|

| 1 | 103 | −50 | −2 × 10−4 | 5 × 10−5 | 1.42 | 60 |

| 2 | 103 | −50 | −2 × 10−4 | 5 × 10−5 | 1.42 | 105 |

| 3 | 103 | −50 | −2 × 10−4 | 5 × 10−5 | 1.32 | 60 |

| 4 | 103 | −50 | −2 × 10−4 | 5 × 10−5 | 1.32 | 105 |

| 5 | 0 | 0 | −2 × 10−4 | 5 × 10−5 | 1.42 | 60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Wang, W.; Zhang, J.; Han, Y.; Liu, T. Improvement of Temperature Performance of Singlemode-Multimode-Singlemode Fiber Structure. Sensors 2022, 22, 8262. https://doi.org/10.3390/s22218262

Zhang R, Wang W, Zhang J, Han Y, Liu T. Improvement of Temperature Performance of Singlemode-Multimode-Singlemode Fiber Structure. Sensors. 2022; 22(21):8262. https://doi.org/10.3390/s22218262

Chicago/Turabian StyleZhang, Rongxiang, Weiyu Wang, Jianfei Zhang, Yuhong Han, and Tao Liu. 2022. "Improvement of Temperature Performance of Singlemode-Multimode-Singlemode Fiber Structure" Sensors 22, no. 21: 8262. https://doi.org/10.3390/s22218262

APA StyleZhang, R., Wang, W., Zhang, J., Han, Y., & Liu, T. (2022). Improvement of Temperature Performance of Singlemode-Multimode-Singlemode Fiber Structure. Sensors, 22(21), 8262. https://doi.org/10.3390/s22218262