A Measurement-Aided Control System for Stabilization of the Real-Life Stewart Platform

Abstract

:1. Introduction

- An original measurement-aided approach to the stabilization of the physical Stewart platform system is introduced.

- A proposed algorithm is strictly dedicated to the complex nonlinear plant subjected to a set of different disturbances.

- A smart methodology employing the innovative embedded-originated sensor and control layers is accented.

- A number of analytical investigations involving the signal processing-based operations mainly respecting the Lagrangian and Kalman paradigms are considered.

- The real-life confirmation certainly favors an application of the Stewart platform stabilization system in the modern film industry.

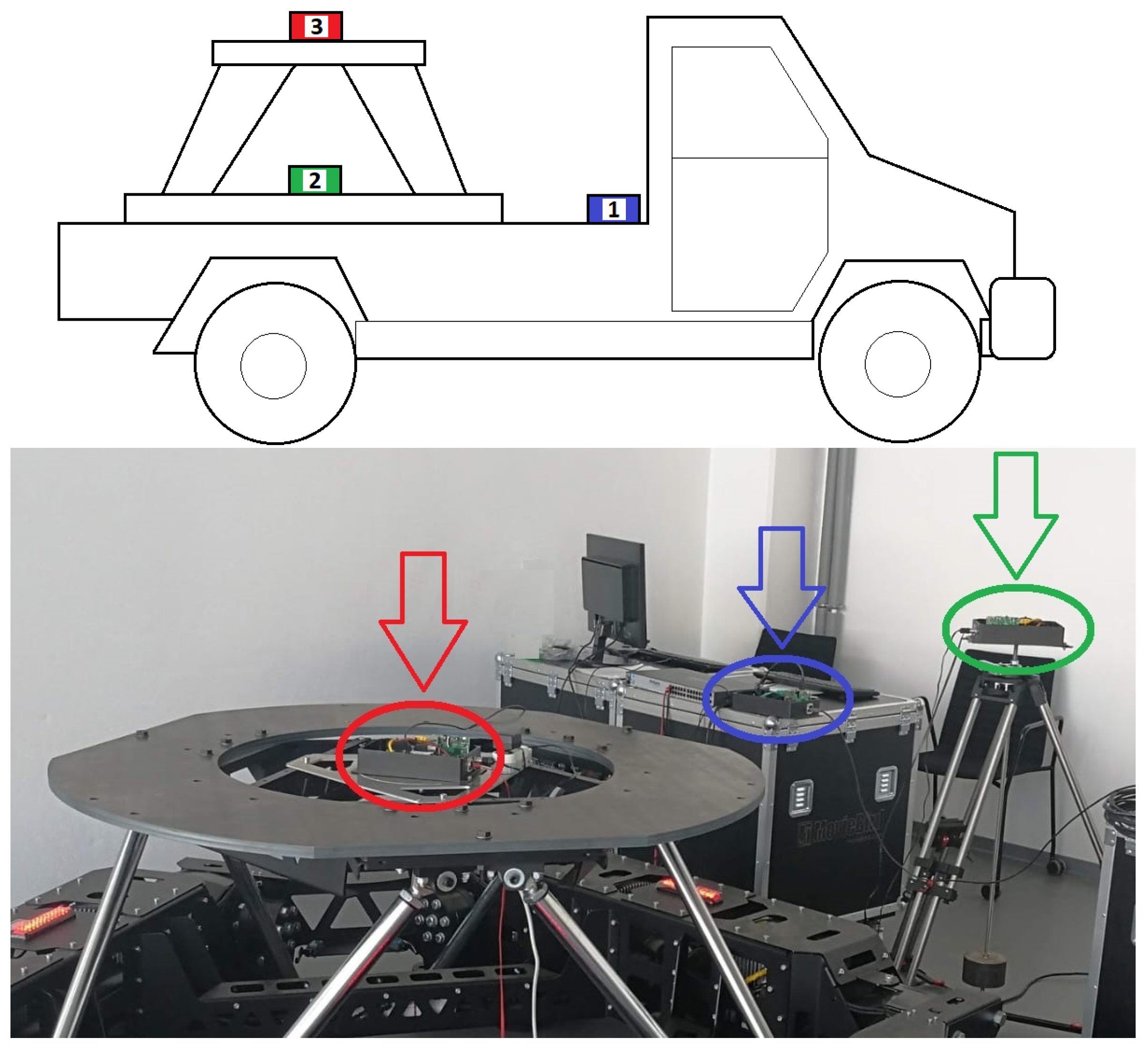

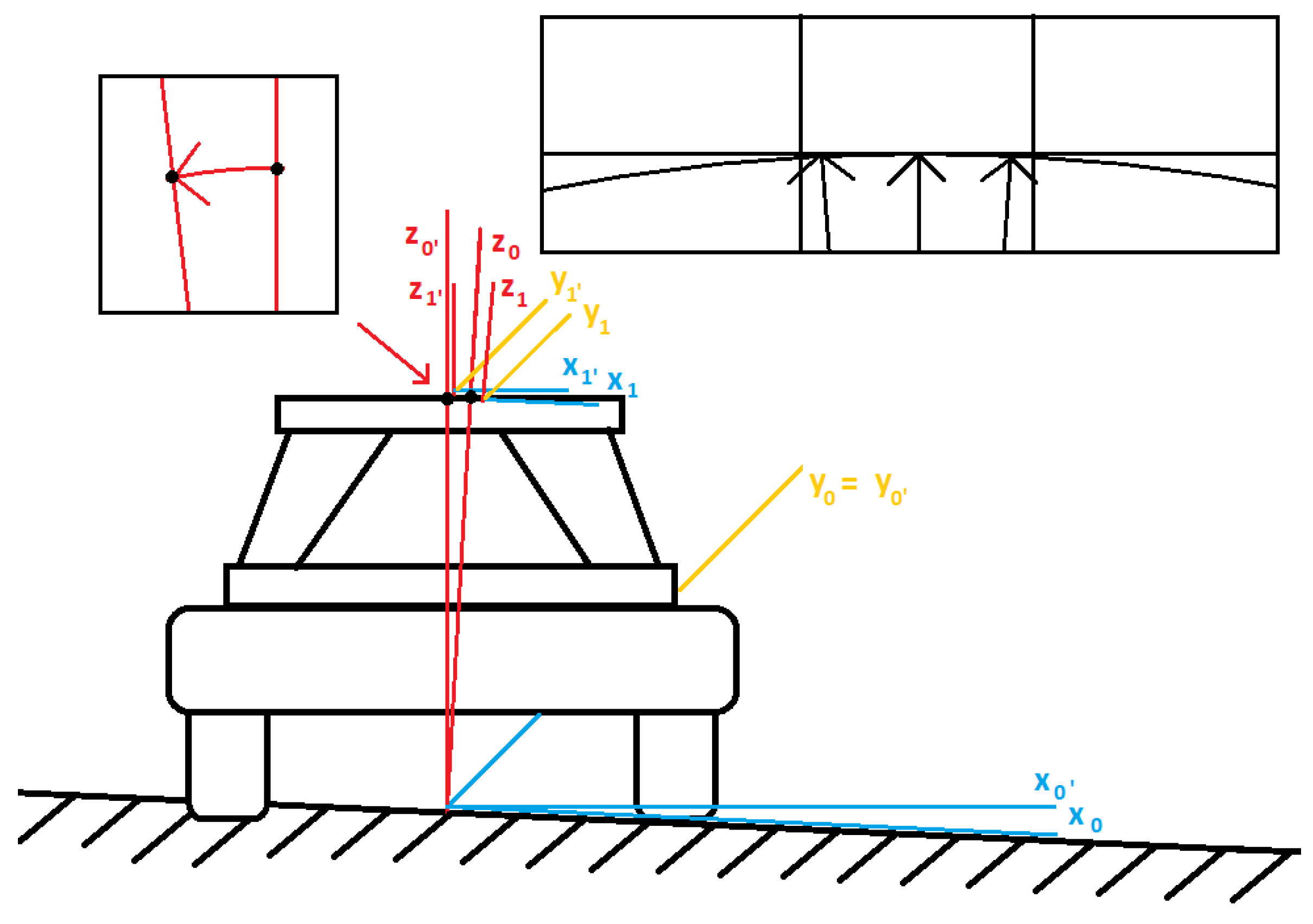

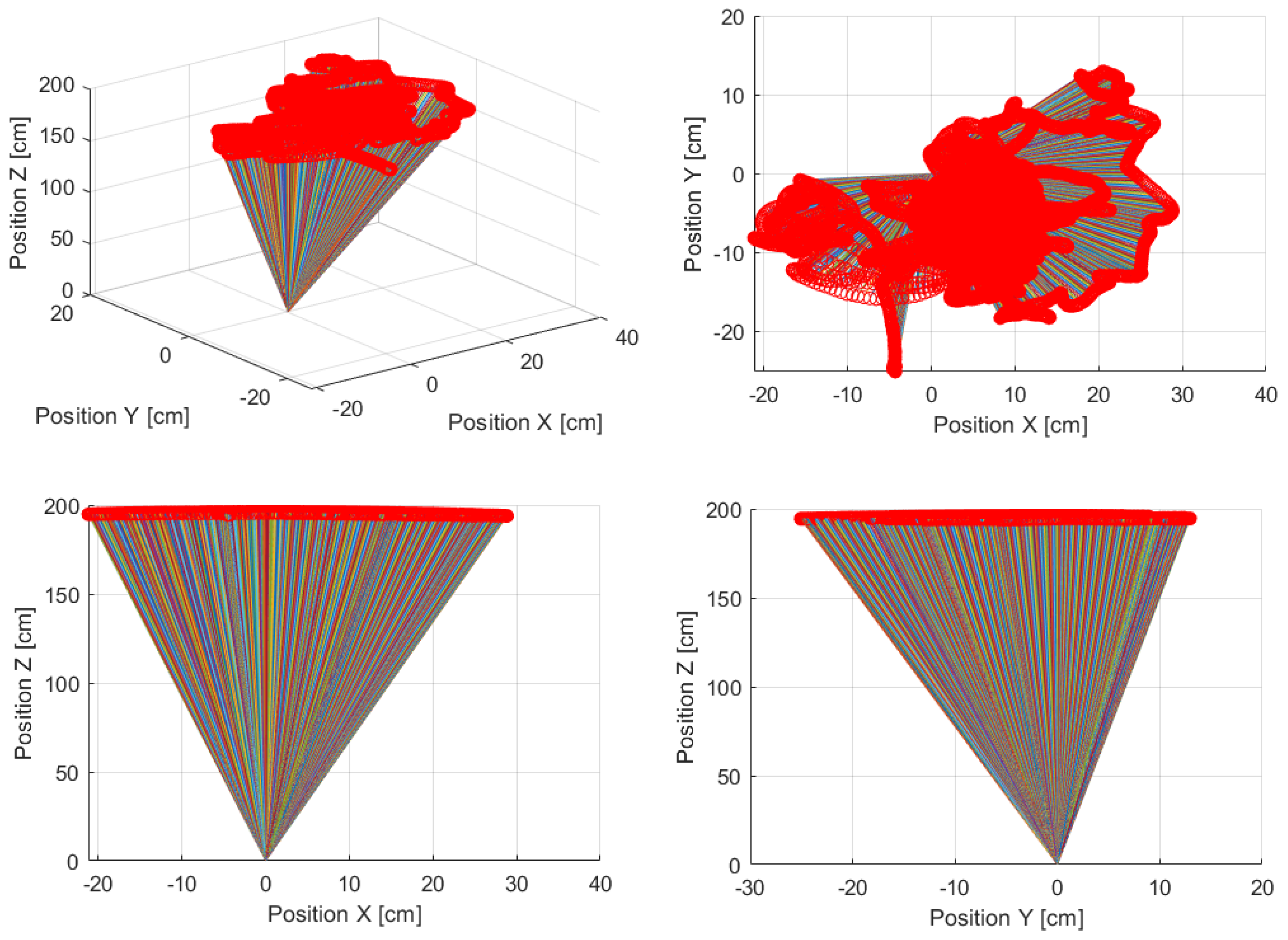

2. System Representation

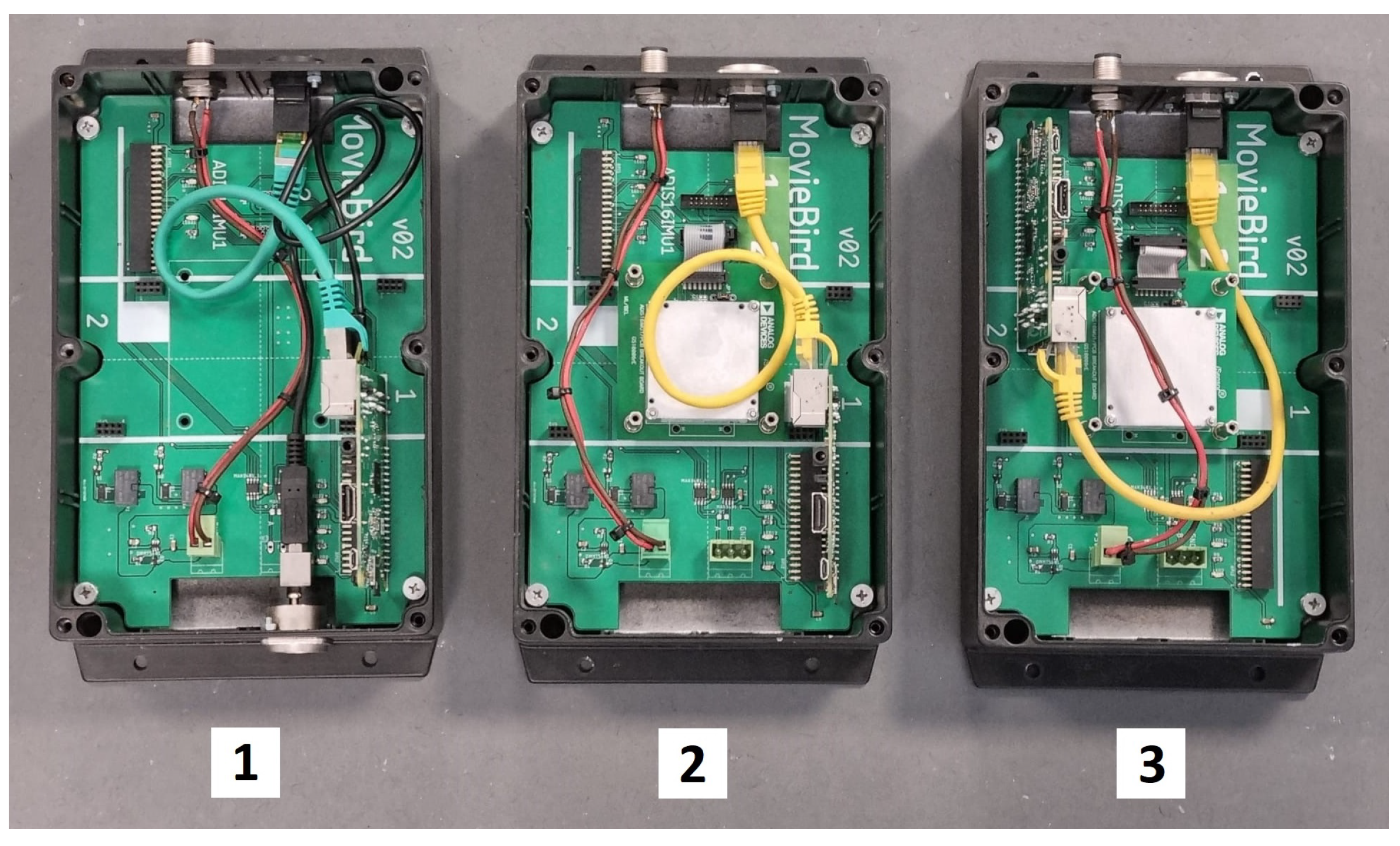

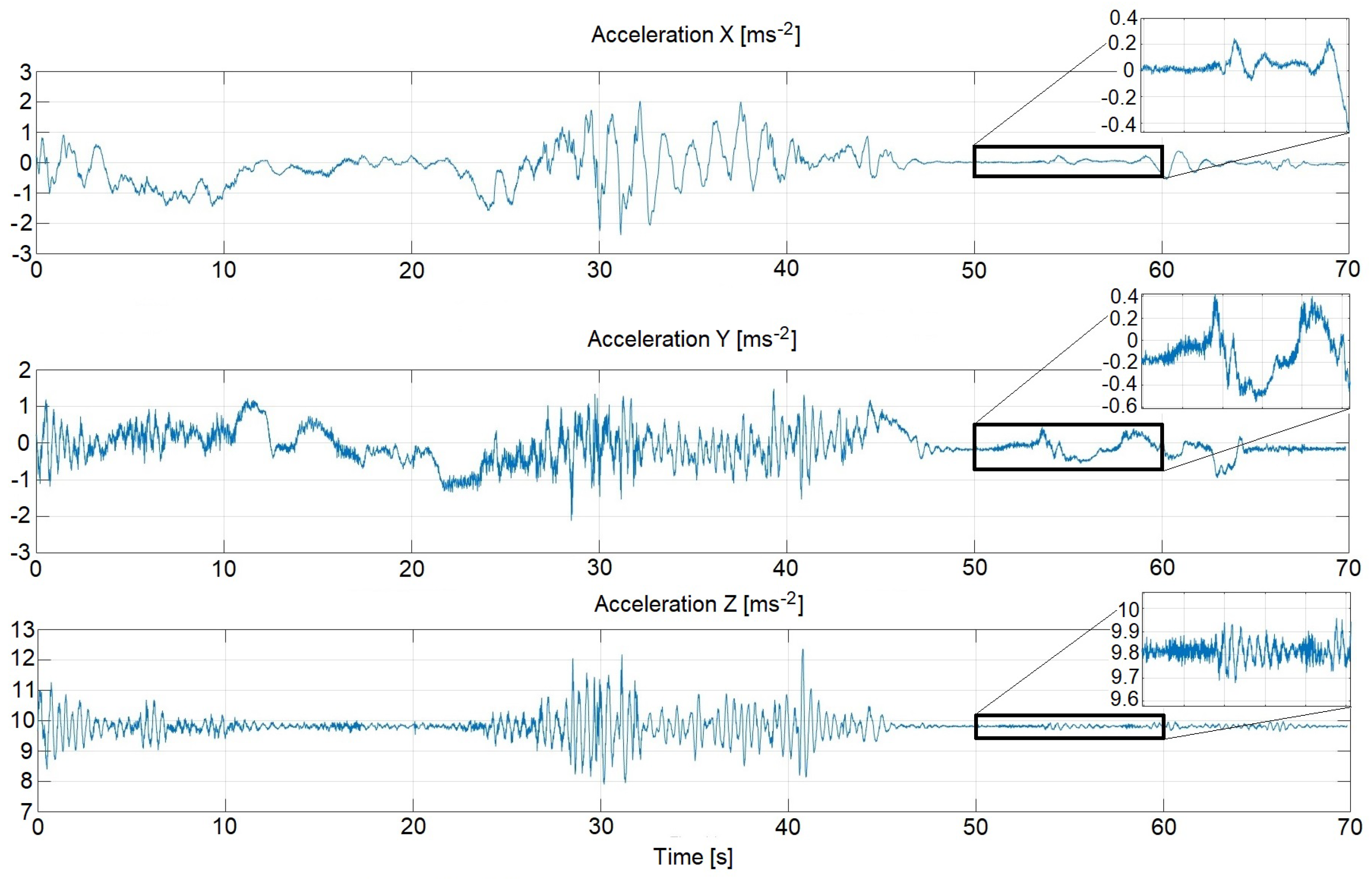

3. Measurement System

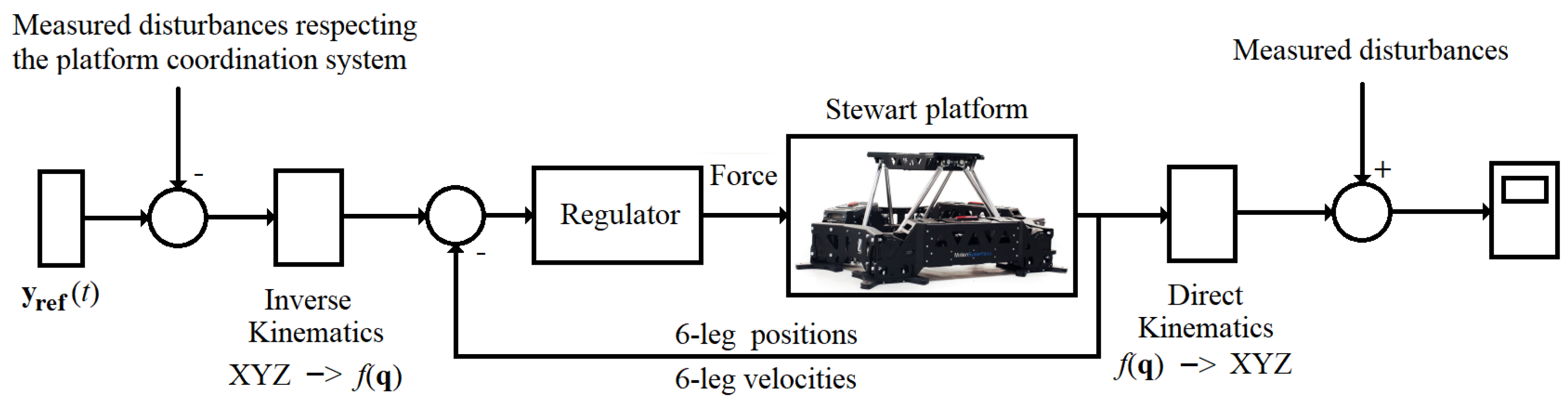

4. Control System

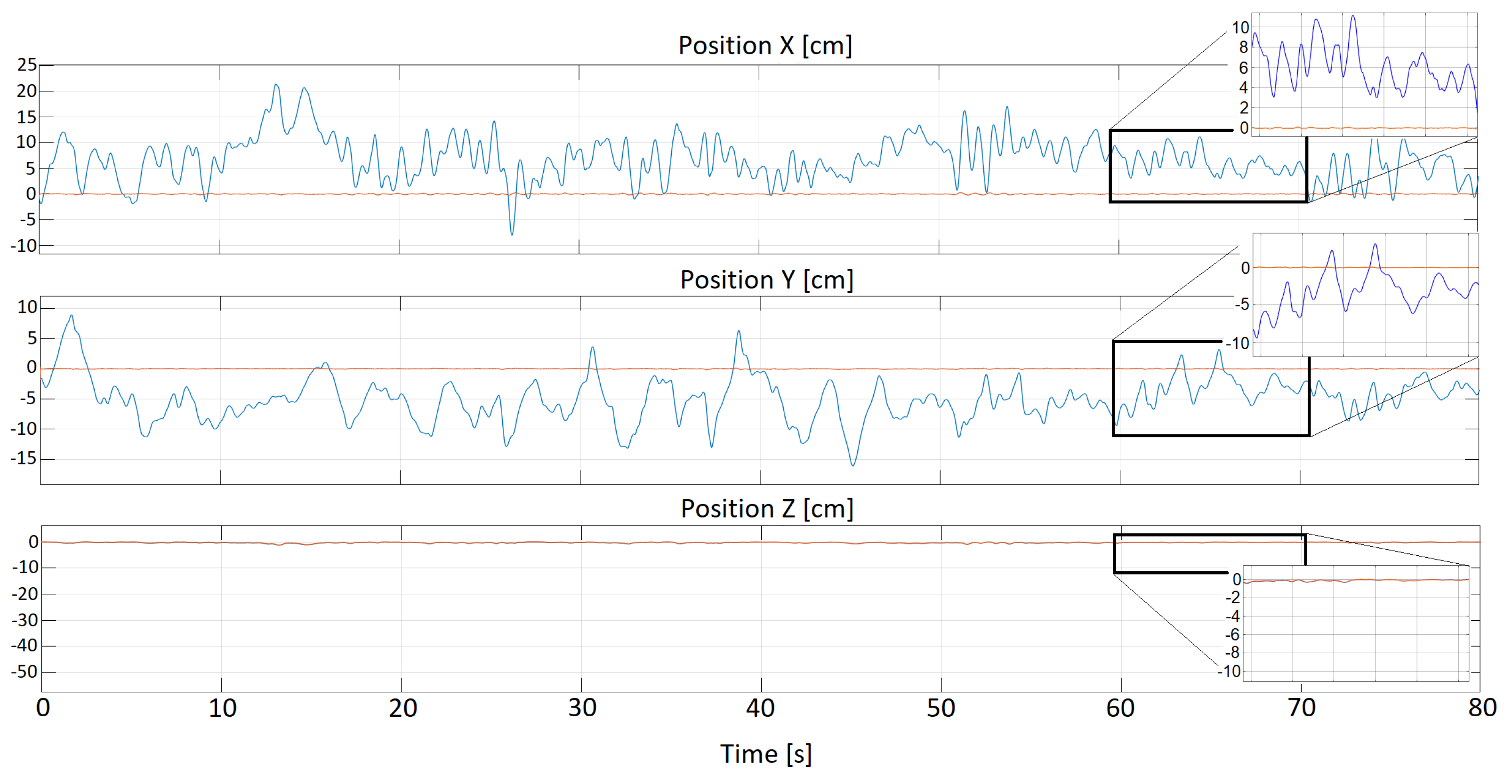

Gyroscopic Measurements

5. Conclusions and Open Problems

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Helma, V.; Goubej, M. Active anti-sway crane control using partial state feedback from inertial sensor. In Proceedings of the 2021 23rd International Conference on Process Control (PC), Štrbské Pleso, Slovakia, 1–4 June 2021; pp. 137–142. [Google Scholar] [CrossRef]

- Omar, M.N.; Ismail, M.M.; Ayob, M.N.; Arith, F. Upgrading for overhead crane anti-sway method using variable frequency drive. Bull. Electr. Eng. Inform. 2022, 11, 1837–1844. [Google Scholar] [CrossRef]

- Qian, Y.; Hu, D.; Chen, Y.; Fang, Y.; Hu, Y. Adaptive Neural Network-Based Tracking Control of Underactuated Offshore Ship-to-Ship Crane Systems Subject to Unknown Wave Motions Disturbances. IEEE Trans. Syst. Man Cybern. Syst. 2022, 52, 3626–3637. [Google Scholar] [CrossRef]

- Ali, G.M.; Mansoor, A.; Liu, S.; Olearczyk, J.; Bouferguene, A.; Al-Hussein, M. Decision support for hydraulic crane stabilization using combined loading and crane mat strength analysis. Autom. Constr. 2021, 131, 103884. [Google Scholar] [CrossRef]

- Qi, X.; Ye, H.; Li, C. Stabilization of the Overhead Crane System via Saturation Technique. In Proceedings of the 2021 40th Chinese Control Conference (CCC), Shanghai, China, 26–28 July 2021; pp. 297–301. [Google Scholar]

- Sabetghadam, B.; Alcántara, A.; Capitán, J.; Cunha, R.; Ollero, A.; Pascoal, A. Optimal Trajectory Planning for Autonomous Drone Cinematography. In Proceedings of the 2019 European Conference on Mobile Robots (ECMR), Prague, Czech Republic, 4–6 September 2019; pp. 1–7. [Google Scholar] [CrossRef]

- Pătru, G.C.; Vasilescu, I.; Rosner, D.; Tudose, D. Aerial Drone Platform for Asset Tracking Using an Active Gimbal. In Proceedings of the 2021 23rd International Conference on Control Systems and Computer Science (CSCS), Bucharest, Romania, 26–28 May 2021; pp. 138–142. [Google Scholar] [CrossRef]

- Nocerino, E.; Menna, F.; Verhoeven, G. Good vibrations? How image stabilisation influences photogrammetry. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2022, 46, 395–400. [Google Scholar] [CrossRef]

- Ordaz, P.; Poznyak, A. ‘KL’-gain adaptation for attractive ellipsoid method. IMA J. Math. Control. Inf. 2015, 32, 447–469. [Google Scholar] [CrossRef]

- Knudsen, M.; Hendseth, S.; Tufte, G.; Sandvig, A. Model-free Control of Partially Observable Underactuated Systems by pairing Reinforcement Learning with Delay Embeddings. Model. Identif. Control. 2022, 43, 1–8. [Google Scholar] [CrossRef]

- Wu, T.S.; Karkoub, M.; Yu, W.S.; Chen, C.T.; Her, M.G.; Wu, K.W. Anti-sway tracking control of tower cranes with delayed uncertainty using a robust adaptive fuzzy control. Fuzzy Sets Syst. 2016, 290, 118–137. [Google Scholar] [CrossRef]

- Astrov, I.; Udal, A.; Molder, H. A Trajectory Control Method for a Strongly Underactuated Spherical Underwater Surveillance Robot. In Proceedings of the 2021 IEEE 25th International Conference on Intelligent Engineering Systems (INES), Budapest, Hungary, 7–9 July 2021; pp. 43–48. [Google Scholar] [CrossRef]

- García-Martínez, J.R.; Cruz-Miguel, E.E.; Carrillo-Serrano, R.V.; Mendoza-Mondragón, F.; Toledano-Ayala, M.; Rodríguez-Reséndiz, J. A PID-Type Fuzzy Logic Controller-Based Approach for Motion Control Applications. Sensors 2020, 20, 5323. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, B.; Mao, D. MIMO Fuzzy Sliding Mode Control for Three-Axis Inertially Stabilized Platform. Sensors 2019, 19, 1658. [Google Scholar] [CrossRef]

- Chaubey, S.; Puig, V. Autonomous Vehicle State Estimation and Mapping Using Takagi-Sugeno Modeling Approach. Sensors 2022, 22, 3399. [Google Scholar] [CrossRef] [PubMed]

- Fujita, H.; Sugiyama, H. Development of flexible telescopic boom model using absolute nodal coordinate formulation sliding joint constraints with LuGre friction. Theor. Appl. Mech. Lett. 2012, 2, 063005. [Google Scholar] [CrossRef]

- Koumboulis, F.N.; Kouvakas, N.D.; Giannaris, G.L.; Vouyioukas, D. Independent motion control of a tower crane through wireless sensor and actuator networks. ISA Trans. 2016, 60, 312–320. [Google Scholar] [CrossRef]

- Pertsch, A.; Sawodny, O. Modelling and control of coupled bending and torsional vibrations of an articulated aerial ladder. Mechatronics 2016, 33, 34–48. [Google Scholar] [CrossRef]

- Kalmari, J.; Backman, J.; Visala, A. Nonlinear model predictive control of hydraulic forestry crane with automatic sway damping. Comput. Electron. Agric. 2014, 109, 36–45. [Google Scholar] [CrossRef]

- Ismail, R.R.; That, N.D.; Ha, Q. Modelling and robust trajectory following for offshore container crane systems. Autom. Constr. 2015, 59, 179–187. [Google Scholar] [CrossRef]

- MotionSystems. Motion Platform PS-6TM-2500; Technical Report; MotionSystems: Nadolice Wielkie, Poland, 2022. [Google Scholar]

- Jajarmi, A.; Baleanu, D.; Zarghami Vahid, K.; Mohammadi Pirouz, H.; Asad, J. A new and general fractional Lagrangian approach: A capacitor microphone case study. Results Phys. 2021, 31, 104950. [Google Scholar] [CrossRef]

- Shinde, V.J.; Gaitonde, D.V. Lagrangian approach for modal analysis of fluid flows. J. Fluid Mech. 2021, 928, A35. [Google Scholar] [CrossRef]

- Nacivet, S.; Pierre, C.; Thouverez, F.; Jezequel, L. A dynamic Lagrangian frequency–time method for the vibration of dry-friction-damped systems. J. Sound Vib. 2003, 265, 201–219. [Google Scholar] [CrossRef]

- Zucca, S.; Firrone, C.; Gola, M. Numerical assessment of friction damping at turbine blade root joints by simultaneous calculation of the static and dynamic contact loads. Nonlinear Dyn. 2012, 67, 1943–1955. [Google Scholar] [CrossRef]

- El-Nabulsi, R.A.; Anukool, W. A new approach to nonlinear quartic oscillators. Arch. Appl. Mech. 2022, 92, 351–362. [Google Scholar] [CrossRef]

- El-Nabulsi, R.A. Some Geometrical Aspects of Fractional Nonconservative Autonomous Lagrangian Mechanics. Int. J. Appl. Math. Stat. 2006, 5, 50–64. [Google Scholar]

- El-Nabulsi, R.A. Fractional variational approach for dissipative mechanical systems. Anal. Theory Appl. 2014, 30, 249–259. [Google Scholar] [CrossRef]

- He, Z.; Feng, X.; Zhu, Y.; Yu, Z.; Li, Z.; Zhang, Y.; Wang, Y.; Wang, P.; Zhao, L. Progress of Stewart Vibration Platform in Aerospace Micro–Vibration Control. Aerospace 2022, 9, 324. [Google Scholar] [CrossRef]

- Markou, A.A.; Elmas, S.; Filz, G.H. Revisiting Stewart–Gough platform applications: A kinematic pavilion. Eng. Struct. 2021, 249, 113304. [Google Scholar] [CrossRef]

- Shao, K.; Tang, R.; Xu, F.; Wang, X.; Zheng, J. Adaptive sliding mode control for uncertain Euler–Lagrange systems with input saturation. J. Frankl. Inst. 2021, 358, 8356–8376. [Google Scholar] [CrossRef]

- Muñoz-Vázquez, A.J.; Parra-Vega, V.; Sánchez-Orta, A.; Sánchez-Torres, J.D. High-gain PI-like control of Euler–Lagrange mechanical systems: Simulations and experiments in 2DoF robotic manipulators. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2022, 236, 857–869. [Google Scholar] [CrossRef]

- Farnam, A.; Mehdizadeh Gavgani, B.; Crevecoeur, G. A Robust Synchronizing Distributed Controller for Multi-Robotic Manipulators with Euler-Lagrange Equations. In Proceedings of the Flanders Make Conference on Machines, Vehicles and Production Technology, Ghent, Belgium, 14–15 September 2022. [Google Scholar]

- XSENS Technologies. MTi-28A53G25 Miniature Attitude and Heading Reference System; Technical Report; XSENS Technologies: Enschede, The Netherlands, 2009. [Google Scholar]

- Mathworks. Description of Matlab Ahrsfilter—Orientation from Accelerometer, Gyroscope, and Magnetometer Readings; Mathworks: Natick, MA, USA, 2022. [Google Scholar]

- Bottle, K. Stewart Platform Mechanical System; Technical Report; Mathworks: Natick, MA, USA, 2016. [Google Scholar]

- Fortuna, L.; Muscato, G. A roll stabilization system for a monohull ship: Modeling, identification, and adaptive control. IEEE Trans. Control. Syst. Technol. 1996, 4, 18–28. [Google Scholar] [CrossRef]

| Sensor Performance | Rotate of Turn | Acceleration | Magnetic Field |

|---|---|---|---|

| Dimensions | 3 axes | 3 axes | 3 axes |

| Full scale | ±300 deg/s | ±50 m/ | ±750 mGauss |

| Noise | 0.05 deg/s/ | 0.002 m// | 0.5 mGauss |

| Alignment error | 0.1 deg | 0.1 deg | 0.1 deg |

| Attitude and Heading | Value | ||

| Static accuracy (roll/pitch) | <0.5 deg | ||

| Static accuracy (heading) | <1 deg | ||

| Dynamic accuracy | 2 deg RMS | ||

| Angular resolution | 0.05 deg | ||

| Gyroscope Noise Variance | Accelerometer Noise Variance | Magnetometer Noise Variance |

|---|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hunek, W.P.; Majewski, P.; Zygarlicki, J.; Nagi, Ł.; Zmarzły, D.; Wiench, R.; Młotek, P.; Warmuzek, P. A Measurement-Aided Control System for Stabilization of the Real-Life Stewart Platform. Sensors 2022, 22, 7271. https://doi.org/10.3390/s22197271

Hunek WP, Majewski P, Zygarlicki J, Nagi Ł, Zmarzły D, Wiench R, Młotek P, Warmuzek P. A Measurement-Aided Control System for Stabilization of the Real-Life Stewart Platform. Sensors. 2022; 22(19):7271. https://doi.org/10.3390/s22197271

Chicago/Turabian StyleHunek, Wojciech P., Paweł Majewski, Jarosław Zygarlicki, Łukasz Nagi, Dariusz Zmarzły, Roman Wiench, Paweł Młotek, and Piotr Warmuzek. 2022. "A Measurement-Aided Control System for Stabilization of the Real-Life Stewart Platform" Sensors 22, no. 19: 7271. https://doi.org/10.3390/s22197271

APA StyleHunek, W. P., Majewski, P., Zygarlicki, J., Nagi, Ł., Zmarzły, D., Wiench, R., Młotek, P., & Warmuzek, P. (2022). A Measurement-Aided Control System for Stabilization of the Real-Life Stewart Platform. Sensors, 22(19), 7271. https://doi.org/10.3390/s22197271