Domain Adaptation for In-Line Allergen Classification of Agri-Food Powders Using Near-Infrared Spectroscopy

Abstract

1. Introduction

2. Materials and Methods

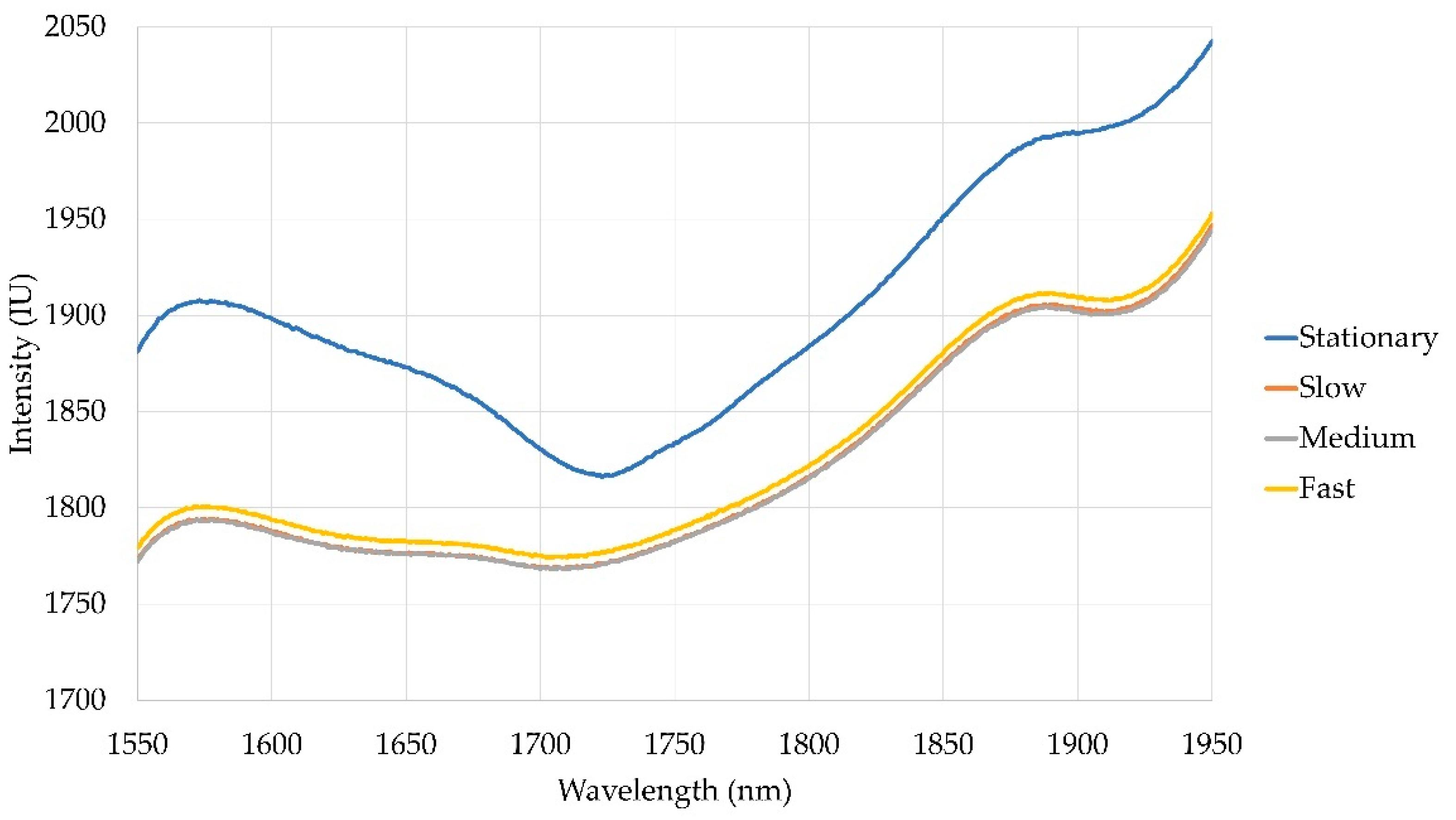

2.1. Near-Infrared Spectroscopy Measurement

2.2. Domain Adaptation

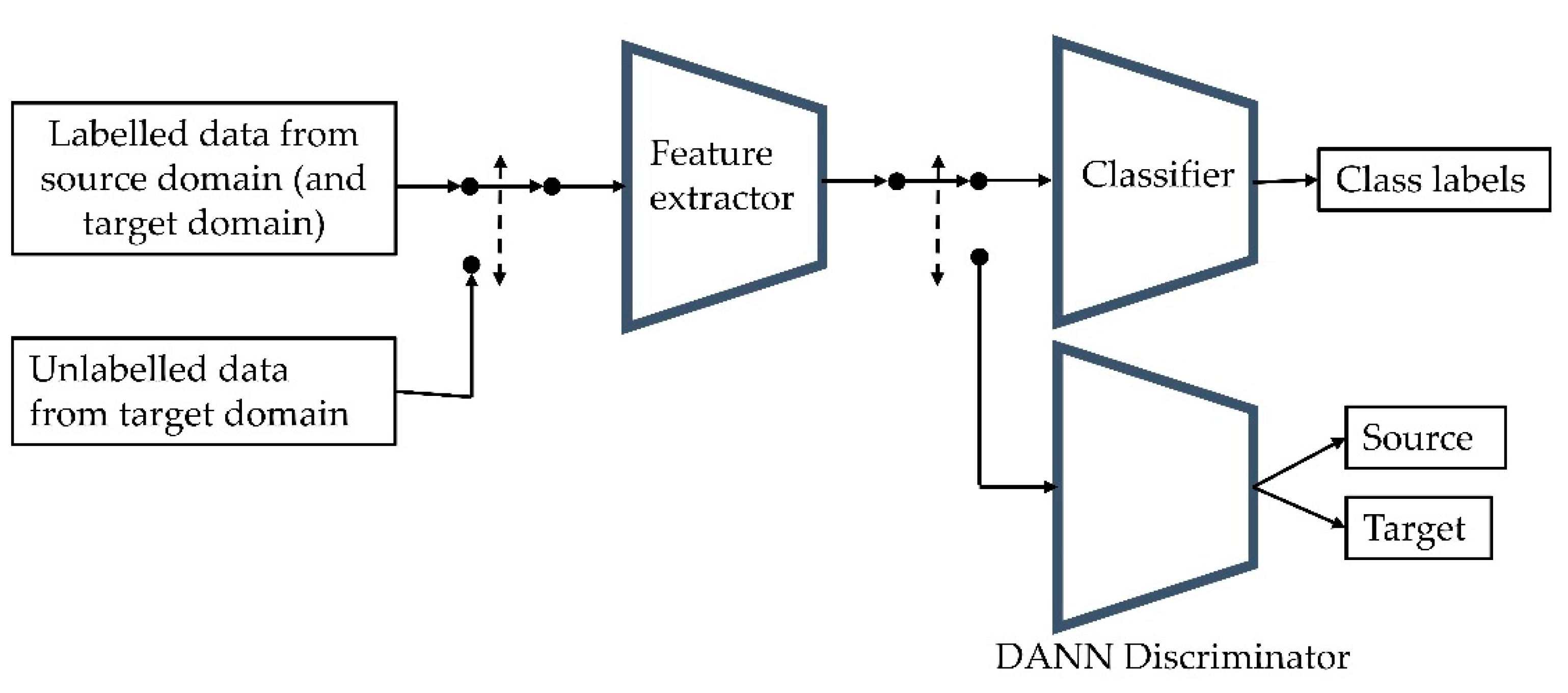

2.2.1. Domain-Adversarial Neural Networks

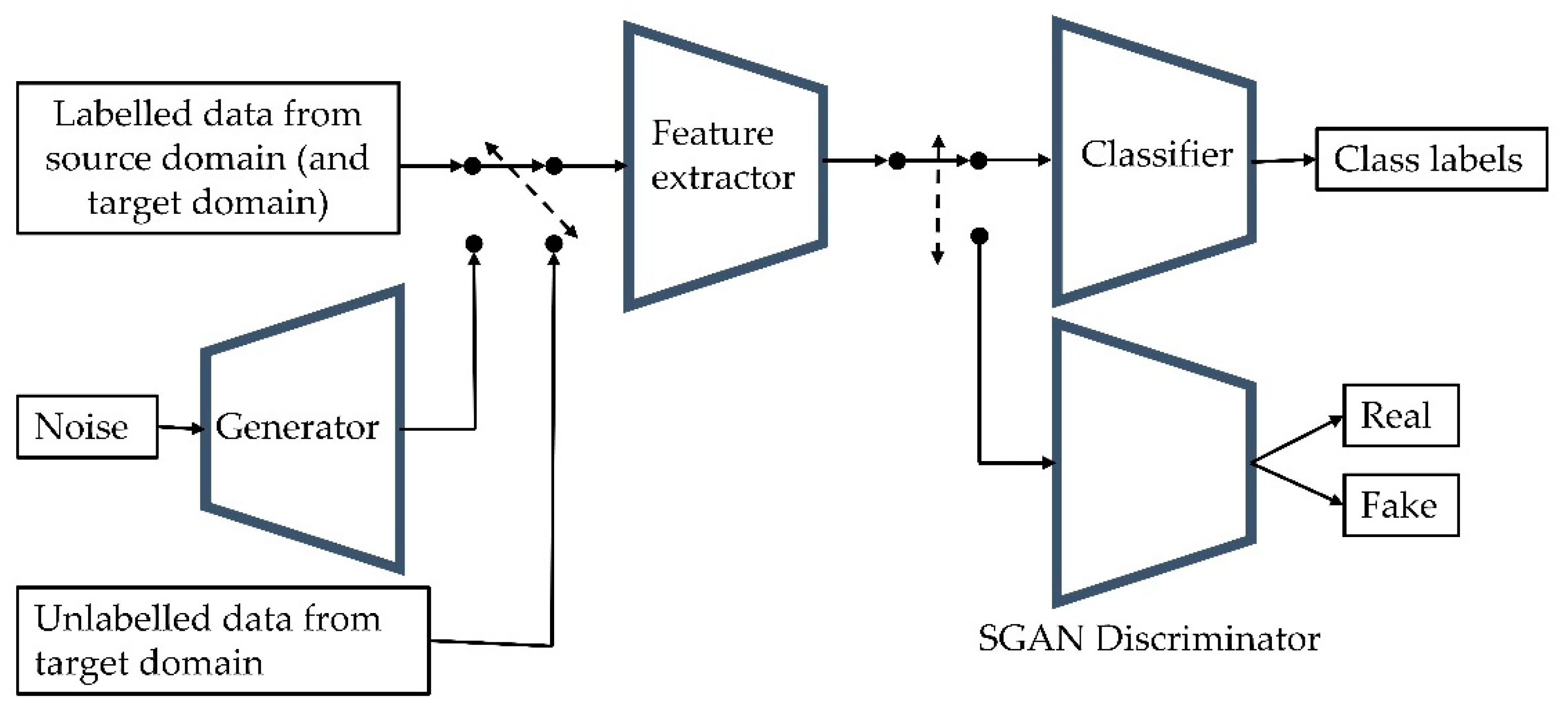

2.2.2. Semisupervised Generative Adversarial Neural Networks

2.2.3. Model Training

2.2.4. Trust in Machine Learning

3. Results

3.1. Uncertainty

3.2. Interpretability

3.3. Comparison to Previous Work

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, W.; Chen, F.; Wang, X.; Meng, Q. Recent advances in processing food powders by using superfine grinding techniques: A review. Compr. Rev. Food Sci. Food 2020, 19, 2222–2255. [Google Scholar] [CrossRef] [PubMed]

- Okere, E.E.; Arendse, E.; Nieuwoudt, H.; Fawole, O.A.; Perold, W.J.; Opara, U.L. Non-invasive methods for predicting the quality of processed horticultural food products, with emphasis on dried powders, juices and oils: A review. Foods 2021, 10, 3061. [Google Scholar] [CrossRef] [PubMed]

- Juarez-Enriquez, E.; Olivas, G.I.; Zamudio-Flores, P.B.; Perez-Vega, S.; Salmeron, I.; Ortega-Rivas, E.; Sepulveda, D.R. A review on the influence of water on food powder flowability. J. Food Process. Eng. 2022, 45, e14031. [Google Scholar] [CrossRef]

- Food Standard Agency. Business Committee Meeting—September 2020. Available online: https://www.food.gov.uk/sites/default/files/media/document/fsa-20-09-12-incidents-resilience-annual-report.pdf (accessed on 7 April 2022).

- Loh, W.; Tang, M.L.K. The epidemiology of food allergy in the global context. Int. J. Environ. Res. Public Health 2018, 15, 2043. [Google Scholar] [CrossRef]

- Qu, J.-H.; Liu, D.; Cheng, J.-H.; Sun, D.-W.; Ma, J.; Pu, H.; Zeng, X.-A. Applications of Near-infrared Spectroscopy in Food Safety Evaluation and Control: A Review of Recent Research Advances. Crit. Rev. Food Sci. Nutr. 2015, 55, 1939–1954. [Google Scholar] [CrossRef]

- Wang, L.; Sun, D.-W.; Pu, H.; Cheng, J.-H. Quality analysis, classification, and authentication of liquid foods by near-infrared spectroscopy: A review of recent research developments. Crit. Rev. Food Sci. Nutr. 2017, 57, 1524–1538. [Google Scholar] [CrossRef]

- Porep, J.U.; Kammerer, D.R.; Carle, R. On-line application of near infrared (NIR) spectroscopy in food production. Trends Food Sci. Technol. 2015, 46, 211–230. [Google Scholar] [CrossRef]

- Ma, H.-L.; Wang, J.-W.; Chen, Y.-J.; Cheng, J.-L.; Lai, Z.-T. Rapid authentication of starch adulterations in ultrafine granular powder of Shanyao by near-infrared spectroscopy coupled with chemometric methods. Food Chem. 2017, 215, 108–115. [Google Scholar] [CrossRef]

- Ingle, P.D.; Christian, R.; Purohit, P.; Zarraga, V.; Handley, E.; Freel, K.; Abdo, S. Determination of protein content by NIR spectroscopy in protein powder mix products. J. AOAC Int. 2016, 99, 360–363. [Google Scholar] [CrossRef]

- Morellos, A.; Pantazi, X.; Moshou, D.; Alexandridis, T.; Whetton, R.; Tziotzios, G.; Wiebensohn, J.; Ralf, B.; Mouazen, A.M. Machine learning based prediction of soil total nitrogen, organic carbon and moisture content by using VIS-NIR spectroscopy. Biosyst. Eng. 2016, 152, 104–116. [Google Scholar] [CrossRef]

- Ng, W.; Minasny, B.; Montazerolghaem, M.; Padarian, J.; Ferguson, R.; Bailey, S.; McBratney, A.B. Convolutional neural network for simultaneous prediction of several soil properties using visible/near-infrared, mid-infrared, and their combined spectra. Geoderma 2019, 352, 251–267. [Google Scholar] [CrossRef]

- Chen, H.; Chen, A.; Xu, L.; Xie, H.; Qiao, H.; Lin, Q.; Cai, K. A deep learning CNN architecture applied in smart near-infrared analysis of water pollution for agricultural irrigation resources. Agric. Water Manag. 2020, 240, 106303. [Google Scholar] [CrossRef]

- Hildrum, K.I.; Nilsen, B.N.; Westad, F.; Wahlgren, N.M. In-line analysis of ground beef using a diode array near infrared instrument on a conveyor belt. J. Near Infrared Spectrosc. 2004, 12, 367–376. [Google Scholar] [CrossRef]

- Dixit, Y.; Casado-Gavalda, M.P.; Cama-Moncunill, R.; Cama-Moncunill, X.; Cullen, P.J.; Sullivan, C. Prediction of beef fat content simultaneously under static and motion conditions using near infrared spectroscopy. J. Near Infrared Spectrosc. 2016, 24, 353–361. [Google Scholar] [CrossRef]

- Salguero-Chaparro, L.; Baeten, V.; Fernández-Pierna, J.A.; Peña-Rodríguez, F. Near infrared spectroscopy (NIRS) for on-line determination of quality parameters in intact olives. Food Chem. 2013, 139, 1121–1126. [Google Scholar] [CrossRef] [PubMed]

- Cama-Moncunill, R.; Markiewicz-Keszycka, M.; Dixit, Y.; Cama-Moncunill, X.; Casado-Gavalda, M.P.; Cullen, P.J.; Sullivan, C. Multipoint NIR spectroscopy for gross composition analysis of powdered infant formula under various motion conditions. Talanta 2016, 154, 423–430. [Google Scholar] [CrossRef]

- Berntsson, O.; Danielsson, L.-G.; Folestad, S. Characterization of diffuse reflectance fiber probe sampling on moving solids using a Fourier transform near-infrared spectrometer. Anal. Chim. Acta 2001, 431, 125–131. [Google Scholar] [CrossRef]

- Martínez, L.; Peinado, A.; Liesum, L.; Betz, G. Use of near-infrared spectroscopy to quantify drug content on a continuous blending process: Influence of mass flow and rotation speed variations. Eur. J. Pharm. Biopharm. 2013, 84, 606–615. [Google Scholar] [CrossRef]

- Bowler, A.L.; Pound, M.P.; Watson, N.J. A review of ultrasonic sensing and machine learning methods to monitor industrial processes. Ultrasonics 2022, 124, 106776. [Google Scholar] [CrossRef]

- Andries, E.; Kalivas, J.H.; Gurung, A. Sample and feature augmentation strategies for calibration updating. J. Chemom. 2019, 33, e3080. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, L.; Li, J.; Zhou, W. A feature domain space transfer method for improving identification of maize haploid seed based on near-infrared spectroscopy. In Proceedings of the 2019 International Conference on High Performance Big Data and Intelligent Systems (HPBD&IS), Shenzhen, China, 9–11 May 2019. [Google Scholar] [CrossRef]

- Huang, G.; Chen, X.; Li, L.; Chen, X.; Yuan, L.; Shi, W. Domain adaptive partial least squares regression. Chemom. Intell. Lab. Syst. 2020, 201, 103986. [Google Scholar] [CrossRef]

- Mishra, P.; Nikzad-Langerodi, R. A brief note on application of domain-invariant PLS for adapting near-infrared spectroscopy calibrations between different physical forms of samples. Talanta 2021, 232, 122461. [Google Scholar] [CrossRef] [PubMed]

- Shi, G.; Cao, J.; Li, C.; Liang, Y. Compression strength prediction of Xylosma racemosum using a transfer learning system based on near-infrared spectral data. J. For. Res. 2020, 31, 1061–1069. [Google Scholar] [CrossRef]

- Diaz, V.F.; Mishra, P.; Roger, J.-M.; Saeys, W. Domain invariant covariate selection (Di-CovSel) for selecting generalized features across domains. Chemom. Intell. Lab. Syst. 2022, 222, 104499. [Google Scholar] [CrossRef]

- Spiers, R.C.; Kalivas, J.H. Reliable Model Selection without Reference Values by Utilizing Model Diversity with Prediction Similarity. J. Chem Inf Model. 2021, 61, 2220–2230. [Google Scholar] [CrossRef]

- Zhuang, F.; Qi, Z.; Duan, K.; Xi, D.; Zhu, Y.; Zhu, H.; Xiong, H.; He, Q. A Comprehensive Survey on Transfer Learning. Proc. IEEE 2021, 109, 43–76. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, C.; Wang, B.; Chen, C.; He, J.; Zhou, Y.; Li, J. An infrared pedestrian detection method based on segmentation and domain adaptation learning. Comput. Electr. Eng. 2022, 99, 107781. [Google Scholar] [CrossRef]

- Nikisins, O.; George, A.; Marcel, S. Domain Adaptation in Multi-Channel Autoencoder based Features for Robust Face Anti-Spoofing. In Proceedings of the 2019 International Conference on Biometrics (ICB), Crete, Greece, 4–7 June 2019. [Google Scholar] [CrossRef]

- Song, S.; Yu, H.; Miao, Z.; Fang, J.; Zheng, K.; Ma, C.; Wang, S. Multi-spectral salient object detection by adversarial domain adaptation. Proc. AAAI Conf. Artif. Intell. 2020, 34, 12023–12030. [Google Scholar] [CrossRef]

- Song, S.; Miao, Z.; Yu, H.; Fang, J.; Zheng, K.; Ma, C.; Wang, S. Deep Domain Adaptation Based Multi-Spectral Salient Object Detection. IEEE Trans. Multimed. 2022, 24, 128–140. [Google Scholar] [CrossRef]

- Ganin, Y.; Ustinova, E.; Ajakan, H.; Germain, P.; Larochelle, H.; Laviolette, F.; Marchand, M.; Lempitsky, V. Domain-adversarial training of neural networks. J. Mach. Learn. Res. 2016, 17, 1–35. [Google Scholar]

- Salimans, T.; Goodfellow, I.; Zaremba, W.; Cheung, V.; Radford, A.; Chen, X. Improved techniques for training GANs. In Proceedings of the Advances in Neural Information Processing Systems 29: Annual Conference on Neural Information Processing Systems 2016, Barcelona, Spain, 5–10 December 2016; pp. 2234–2242. [Google Scholar]

- Abdar, M.; Pourpanah, F.; Hussain, S.; Rezazadegan, D.; Liu, L.; Ghavamzadeh, M.; Fieguth, P.; Cao, X.; Khosravi, A.; Acharya, U.R.; et al. A review of uncertainty quantification in deep learning: Techniques, applications and challenges. Inf. Fusion 2021, 76, 243–297. [Google Scholar] [CrossRef]

- Molnar, C. Interpretable Machine Learning: A Guide for Making Black Box Models Explainable (2nd ed.). 2022. Available online: Christophm.github.io/interpretable-ml-book/ (accessed on 18 August 2022).

- Vitelli, M.; Mehrtash, H.; Assatory, A.; Tabtabaei, S.; Legge, R.L.; Rajabzadeh, A.R. Rapid and non-destructive determination of protein and starch content in agricultural powders using near-infrared and fluorescence spectroscopy, and data fusion. Powder Technol. 2021, 381, 620–631. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Zhang, Y.; Wang, D.; Wang, X.; Yu, L.; Zhang, W.; Li, P. Review of NIR spectroscopy methods for nondestructive quality analysis of oilseeds and edible oils. Trends Food Sci. Technol. 2020, 101, 172–181. [Google Scholar] [CrossRef]

- Rady, A.; Fischer, J.; Reeves, S.; Logan, B.; Watson, N.J. The effect of light intensity, sensor height, and spectral pre-processing methods when using nir spectroscopy to identify different allergen- containing powdered foods. Sensors 2020, 20, 230. [Google Scholar] [CrossRef] [PubMed]

- Pu, Y.; Pérez-Marín, D.; O’Shea, N.; Garrido-Varo, A. Recent advances in portable and handheld NIR spectrometers and applications in milk, cheese and dairy powders. Foods 2021, 10, 2377. [Google Scholar] [CrossRef]

- Mishra, P.; Passos, D. A synergistic use of chemometrics and deep learning improved the predictive performance of near-infrared spectroscopy models for dry matter prediction in mango fruit. Chemom. Intell. Lab. Syst. 2021, 212, 104287. [Google Scholar] [CrossRef]

- Mishra, P.; Nikzad-Langerodi, R. Partial least square regression versus domain invariant partial least square regression with application to near-infrared spectroscopy of fresh fruit. Infrared Phys. Technol. 2020, 111, 103547. [Google Scholar] [CrossRef]

- Mishra, P.; Roger, J.M.; Rutledge, D.N.; Woltering, E. Two standard-free approaches to correct for external influences on near-infrared spectra to make models widely applicable. Postharvest Biol. Technol. 2020, 170, 111326. [Google Scholar] [CrossRef]

| Allergen | Materials |

|---|---|

| Gluten | Spelt, rye, buckwheat, oat, barley, brown, wheat (three brands), and wheat gluten flours |

| Gluten-free | Gluten-free white (three brands), coconut, tapioca, corn, and rice flours |

| Peanut | Peanut and peanut butter powders |

| Tree nut | Almond flour (three brands) |

| Egg | Whole egg, egg yolk, and egg white powders |

| Accuracy (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Method | SGAN + DANN | SGAN | DANN | TL | |||||

| Labelled Data Instances | None | Single | None | Single | None | Single | None | Single | |

| Sensor | Speed | ||||||||

| Both | Slow | 95.04 | 99.36 | 89.76 | 98.56 | 94.08 | 99.04 | 89.92 | 96.80 |

| Medium | 95.20 | 99.20 | 92.48 | 95.70 | 92.16 | 99.68 | 87.36 | 94.72 | |

| Fast | 95.04 | 98.24 | 93.76 | 97.44 | 96.00 | 97.12 | 92.96 | 94.08 | |

| S2.0 | Slow | 93.20 | 95.60 | 94.12 | 92.88 | 92.76 | 95.00 | 88.56 | 93.34 |

| Medium | 91.60 | 92.12 | 90.80 | 94.32 | 89.72 | 96.72 | 88.32 | 92.96 | |

| Fast | 86.36 | 91.64 | 87.40 | 90.12 | 87.80 | 88.28 | 86.56 | 89.12 | |

| S2.5 | Slow | 60.96 | 89.12 | 65.28 | 84.32 | 79.36 | 80.80 | 70.40 | 90.88 |

| Medium | 65.12 | 84.16 | 65.60 | 84.32 | 72.00 | 82.88 | 61.12 | 82.88 | |

| Fast | 65.12 | 86.56 | 74.72 | 77.92 | 74.08 | 87.84 | 71.20 | 86.88 | |

| Confidence Score | |||||||

|---|---|---|---|---|---|---|---|

| 0.6 | 0.8 | 1.0 | Total Count | ||||

| Count | Percentage | Count | Percentage | Count | Percentage | ||

| Correct | 15 | 68.2 | 38 | 90.5 | 553 | 98.6 | 606 |

| Incorrect | 7 | 31.8 | 4 | 9.5 | 8 | 1.4 | 19 |

| Total | 22 | 42 | 561 | 625 | |||

| Misclassified Materials | Real Allergen Category | Predicted Allergen Category | Frequency (Confidence Scores) |

|---|---|---|---|

| Coconut flour | Gluten-free | Gluten | 5 (0.8, 0.6, 0.6, 0.6, 0.6) |

| Egg yolk powder | Egg | Gluten | 1 (0.6) |

| Gluten free white flour | Gluten-free | Gluten | 1 (0.6) |

| Oat flour | Gluten | Peanut | 4 (1.0, 1.0, 0.8, 0.6) |

| Peanut flour | Peanut | Gluten | 4 (1.0, 1.0, 1.0, 0.8) |

| Peanut butter powder | Peanut | Gluten | 3 (1.0, 1.0, 1.0) |

| Rice flour | Gluten-free | Gluten | 1 (0.8) |

| Wavelength Range (nm) (in Order of Importance, Top to Bottom) | Spectral Features |

|---|---|

| 1785–1870 | Range between long-chain fatty acid and water-absorption bands |

| 1686–1744 | Long-chain fatty acids producing a CH2 first overtone at 1725–1750 nm [37,38] |

| 1931–1951 | Water-absorption bands due to the vibration of O-H bonds [39] |

| 2111–2132 | Protein-absorption band [37,40,41] |

| 1569–1604 | O-H stretching of the first overtone in carbohydrates [17] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bowler, A.L.; Ozturk, S.; Rady, A.; Watson, N. Domain Adaptation for In-Line Allergen Classification of Agri-Food Powders Using Near-Infrared Spectroscopy. Sensors 2022, 22, 7239. https://doi.org/10.3390/s22197239

Bowler AL, Ozturk S, Rady A, Watson N. Domain Adaptation for In-Line Allergen Classification of Agri-Food Powders Using Near-Infrared Spectroscopy. Sensors. 2022; 22(19):7239. https://doi.org/10.3390/s22197239

Chicago/Turabian StyleBowler, Alexander Lewis, Samet Ozturk, Ahmed Rady, and Nicholas Watson. 2022. "Domain Adaptation for In-Line Allergen Classification of Agri-Food Powders Using Near-Infrared Spectroscopy" Sensors 22, no. 19: 7239. https://doi.org/10.3390/s22197239

APA StyleBowler, A. L., Ozturk, S., Rady, A., & Watson, N. (2022). Domain Adaptation for In-Line Allergen Classification of Agri-Food Powders Using Near-Infrared Spectroscopy. Sensors, 22(19), 7239. https://doi.org/10.3390/s22197239