Physics-Based Simulation of Soft-Body Deformation Using RGB-D Data

Abstract

1. Introduction

2. Related Works

2.1. Non-Rigid-Object Tracking

2.2. Physics-Based Simulation of Non-Rigid Objects

2.3. Tracking and Simulation of Non-Rigid Objects

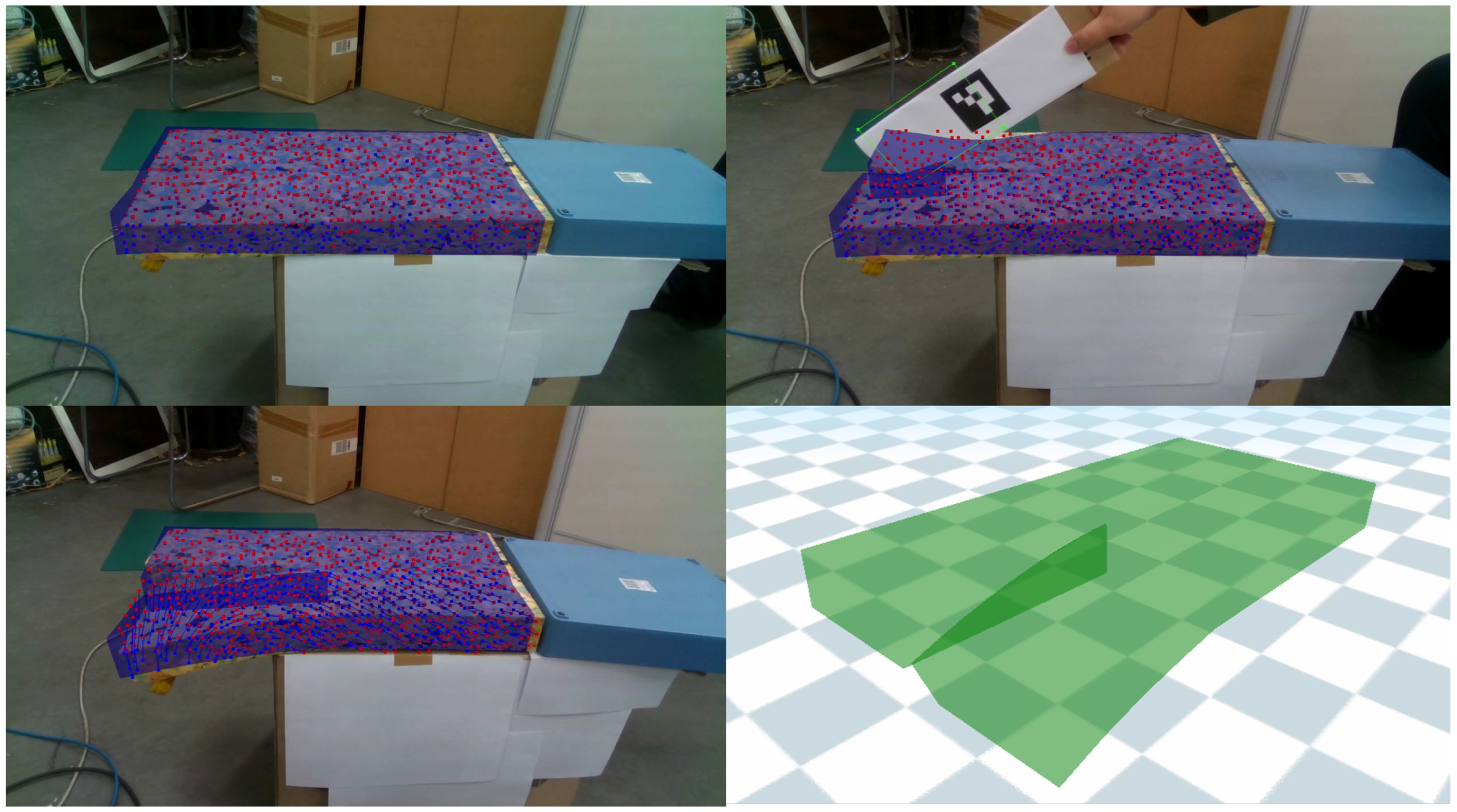

3. Overview

- Initialization: A set of polygonal 3D models are prepared for the deformation of an observed object. These include a low-resolution model with a volumetric model for soft-body simulation and a high-resolution model for the visual output. A sequence of RGB-D images is continuously provided by a sensor.

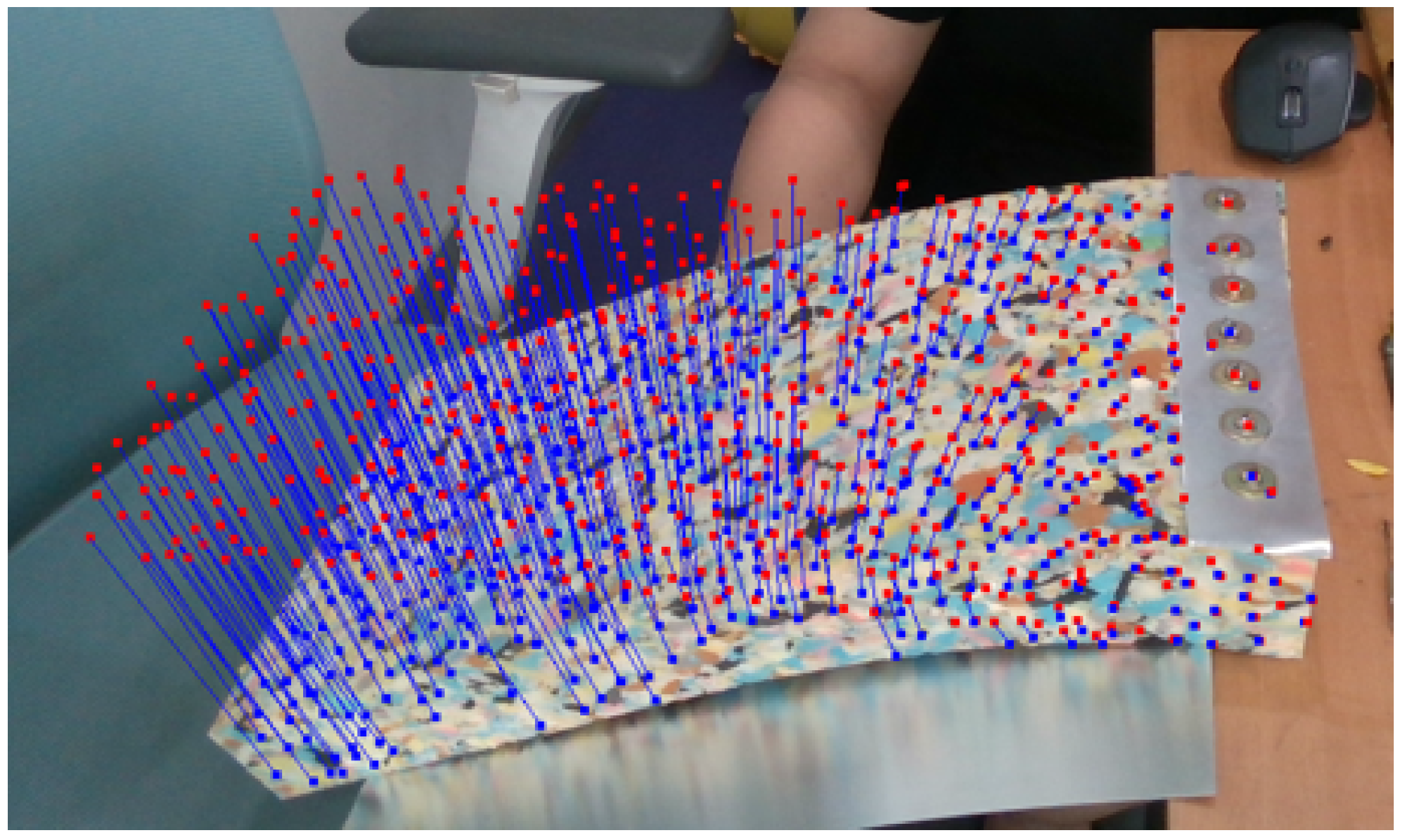

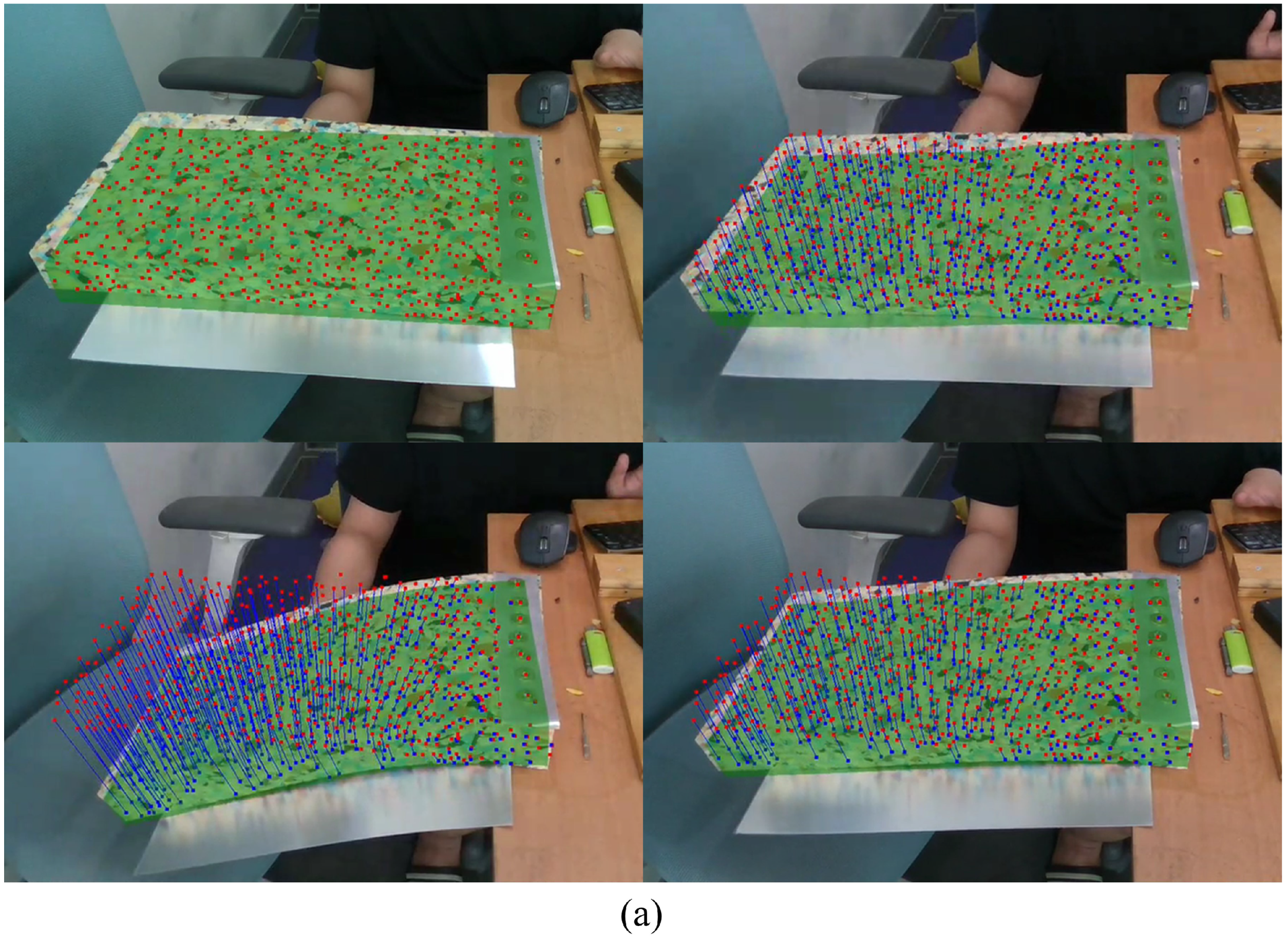

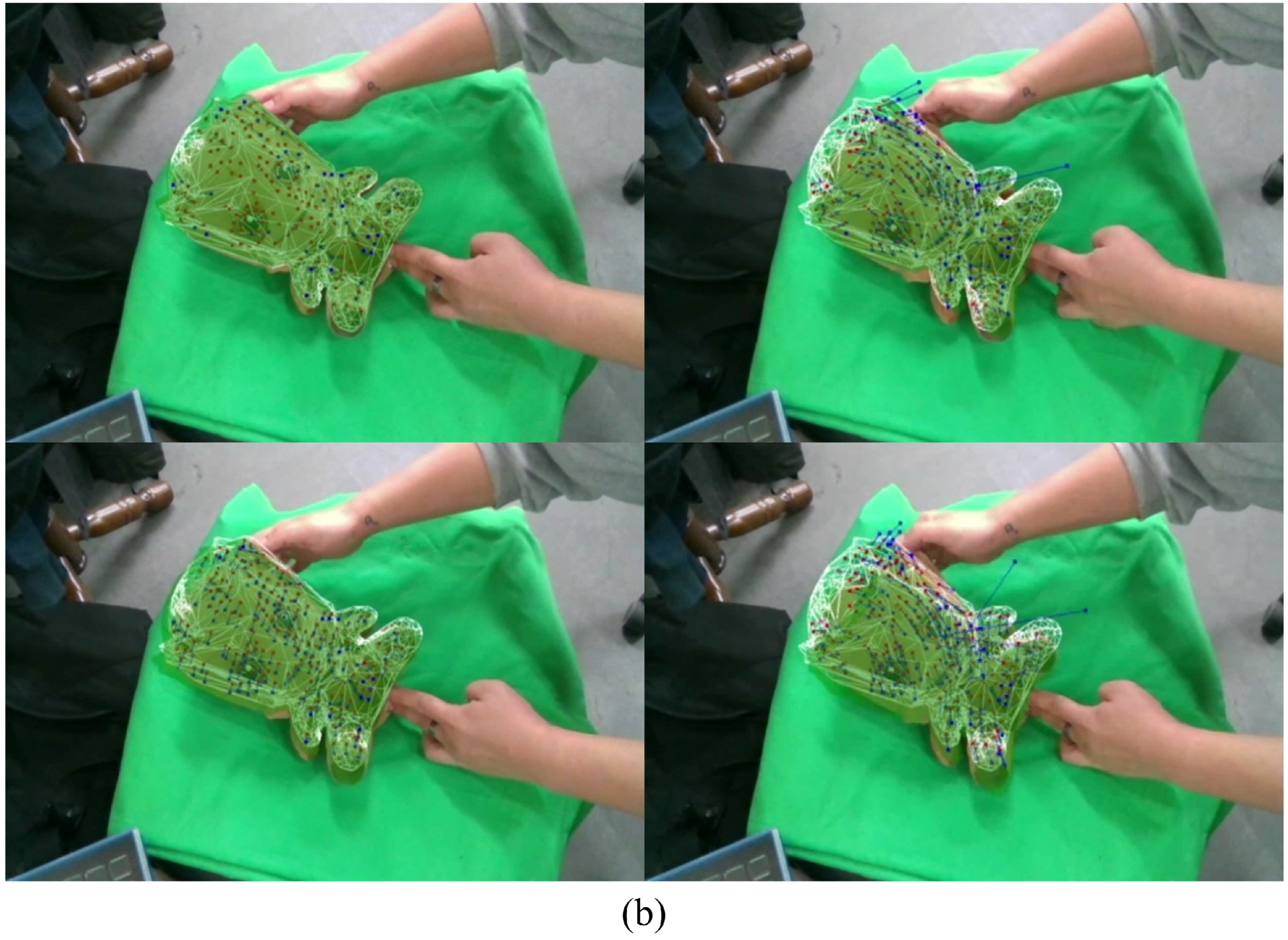

- Feature-point tracking: In the initial frame, a set of feature points are detected from RGB images using a local feature detector. For every frame, these points are tracked as feature vectors between two adjacent frames.

- Model registration: To set the correspondences between the feature points and surface vertices in the model, a low-resolution model is coordinately aligned using an iterative closest point method. For a smooth deformation, each feature point controls the surface vertices using weight values that are assigned to each vertex.

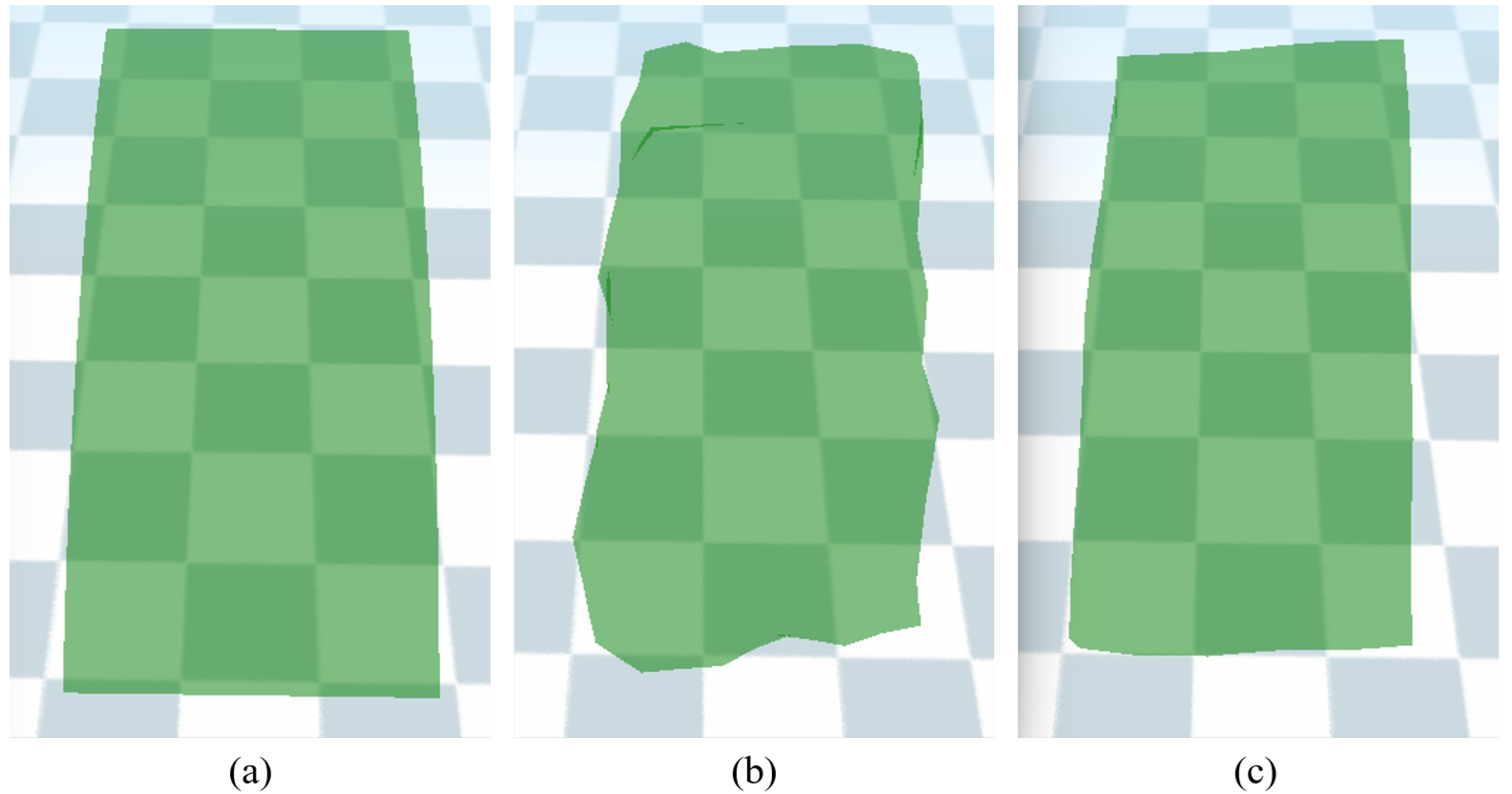

- Soft-body simulation: To determine the deformation of a soft-body model, the internal force is estimated by applying a physical force to the volumetric model. A projective dynamics method is adopted to accelerate the force calculation for each vertex.

- Resolution enhancement: To visualize the observed object in high detail, the deformed model in low resolution is mapped into a high-resolution model. During the mapping process, a weight-based interpolation method is used to control the surface vertices in the high-resolution model.

- Topological editing: To handle topological deformations, such as cutting or tearing, a cutting tool’s trajectory is tracked by a sensor. The intersected part is reshaped to a triangulated model using Delaunay triangulation, representing a new surface of the model.

4. Object Tracking

4.1. Initialization

4.2. Feature-Point Tracking

4.3. Model Registration

4.3.1. Coordinate Alignment

4.3.2. Correspondence Mapping

5. Soft-Body Simulation

5.1. Internal Force Estimation

5.2. Projective Dynamics for Physical Force

5.3. Resolution Enhancement

5.4. Topological Editing

6. Experimental Results

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| VR | Virtual reality |

| AR | Augmented reality |

| IK | Inverse kinematics |

| FEM | Finite-element method |

| FAST | Features from accelerated segment test |

| BRIEF | Binary robust independent elementary features |

| ORB | Oriented FAST and rotated BRIEF |

| ICP | Iterative closest point |

| SVD | Single-value decomposition |

| KNN-IDW | K-nearest neighbor approach with an inverse distance weighting |

| PD | Projective dynamics |

| MVC | Mean-value coordinate |

References

- Jung, T.; Dieck, M.C.T. Augmented Reality and Virtual Reality; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Lungu, A.J.; Swinkels, W.; Claesen, L.; Tu, P.; Egger, J.; Chen, X. A review on the applications of virtual reality, augmented reality and mixed reality in surgical simulation: An extension to different kinds of surgery. Expert Rev. Med. Devices 2021, 18, 47–62. [Google Scholar] [CrossRef] [PubMed]

- Baek, S.; Gil, Y.H.; Kim, Y. VR-Based Job Training System Using Tangible Interactions. Sensors 2021, 21, 6794. [Google Scholar] [CrossRef]

- Collins, T.; Bartoli, A. Realtime Shape-from-Template: System and Applications. In Proceedings of the ISMAR, Yucatan, Mexico, 19–23 September 2015; pp. 116–119. [Google Scholar]

- Tien Ngo, D.; Park, S.; Jorstad, A.; Crivellaro, A.; Yoo, C.D.; Fua, P. Dense image registration and deformable surface reconstruction in presence of occlusions and minimal texture. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 7–13 December 2015; pp. 2273–2281. [Google Scholar]

- Yu, R.; Russell, C.; Campbell, N.D.; Agapito, L. Direct, dense, and deformable: Template-based non-rigid 3d reconstruction from rgb video. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 7–13 December 2015; pp. 918–926. [Google Scholar]

- Salzmann, M.; Fua, P. Linear local models for monocular reconstruction of deformable surfaces. IEEE Trans. Pattern Anal. Mach. Intell. 2010, 33, 931–944. [Google Scholar] [CrossRef] [PubMed]

- Bartoli, A.; Gérard, Y.; Chadebecq, F.; Collins, T.; Pizarro, D. Shape-from-template. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 37, 2099–2118. [Google Scholar] [CrossRef]

- Ngo, D.T.; Óstlund, J.; Fua, P. Template-based monocular 3D shape recovery using laplacian meshes. IEEE Trans. Pattern Anal. Mach. Intell. 2015, 38, 172–187. [Google Scholar] [CrossRef] [PubMed]

- Chhatkuli, A.; Pizarro, D.; Bartoli, A.; Collins, T. A stable analytical framework for isometric shape-from-template by surface integration. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 39, 833–850. [Google Scholar] [CrossRef]

- Torresani, L.; Kolmogorov, V.; Rother, C. Feature correspondence via graph matching: Models and global optimization. In Proceedings of the European Conference on Computer Vision, Marseille, France, 12–18 October 2008; pp. 596–609. [Google Scholar]

- Zhou, F.; De la Torre, F. Deformable graph matching. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Portland, OR, USA, 23–28 June 2013; pp. 2922–2929. [Google Scholar]

- Collins, T.; Mesejo, P.; Bartoli, A. An analysis of errors in graph-based keypoint matching and proposed solutions. In Proceedings of the European Conference on Computer Vision, Zurich, Switzerland, 6–12 September 2014; pp. 138–153. [Google Scholar]

- Wang, T.; Ling, H.; Lang, C.; Feng, S.; Hou, X. Deformable surface tracking by graph matching. In Proceedings of the IEEE International Conference on Computer Vision, Seoul, Korea, 27 October–2 November 2019; pp. 901–910. [Google Scholar]

- Zhang, Z. Microsoft kinect sensor and its effect. IEEE Multimed. 2012, 19, 4–10. [Google Scholar] [CrossRef]

- Keselman, L.; Iselin Woodfill, J.; Grunnet-Jepsen, A.; Bhowmik, A. Intel realsense stereoscopic depth cameras. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition Workshops, Honolulu, HI, USA, 21–26 July 2017; pp. 1–10. [Google Scholar]

- Ren, Z.; Yuan, J.; Meng, J.; Zhang, Z. Robust part-based hand gesture recognition using kinect sensor. IEEE Trans. Multimed. 2013, 15, 1110–1120. [Google Scholar] [CrossRef]

- Patil, J.V.; Bailke, P. Real time facial expression recognition using RealSense camera and ANN. In Proceedings of the 2016 International Conference on Inventive Computation Technologies (ICICT), Coimbatore, India, 26–27 August 2016; Volume 2, pp. 1–6. [Google Scholar]

- Lee, Y.; Kwon, T. Performance-Based Biped Control using a Consumer Depth Camera. In Computer Graphics Forum; Wiley Online Library: Hoboken, NJ, USA, 2017; Volume 36, pp. 387–395. [Google Scholar]

- Siena, F.L.; Byrom, B.; Watts, P.; Breedon, P. Utilising the intel realsense camera for measuring health outcomes in clinical research. J. Med Syst. 2018, 42, 53. [Google Scholar] [CrossRef] [PubMed]

- Terzopoulos, D.; Platt, J.; Barr, A.; Fleischer, K. Elastically deformable models. In Proceedings of the 14th Annual Conference on Computer Graphics and Interactive Techniques, Anaheim, CA, USA, 27–31 July 1987; pp. 205–214. [Google Scholar]

- Bathe, K.J. Finite Element Procedures; Klaus-Jurgen Bathe: Cambridge, MA, USA, 2006. [Google Scholar]

- Kaufmann, P.; Martin, S.; Botsch, M.; Gross, M. Flexible simulation of deformable models using discontinuous Galerkin FEM. Graph. Model. 2009, 71, 153–167. [Google Scholar] [CrossRef]

- Irving, G.; Teran, J.; Fedkiw, R. Invertible finite elements for robust simulation of large deformation. In Proceedings of the 2004 ACM SIGGRAPH/Eurographics Symposium on Computer Animation, Grenoble, France, 27–29 August 2004; pp. 131–140. [Google Scholar]

- Irving, G.; Schroeder, C.; Fedkiw, R. Volume conserving finite element simulations of deformable models. ACM Trans. Graph. TOG 2007, 26, 13-es. [Google Scholar] [CrossRef]

- Bargteil, A.W.; Wojtan, C.; Hodgins, J.K.; Turk, G. A finite element method for animating large viscoplastic flow. ACM Trans. Graph. TOG 2007, 26, 16-es. [Google Scholar] [CrossRef]

- Kim, J.; Pollard, N.S. Fast simulation of skeleton-driven deformable body characters. ACM Trans. Graph. (TOG) 2011, 30, 1–19. [Google Scholar] [CrossRef]

- Müller, M.; Dorsey, J.; McMillan, L.; Jagnow, R.; Cutler, B. Stable real-time deformations. In Proceedings of the 2002 ACM SIGGRAPH/Eurographics Symposium on Computer Animation, San Antonio, TX, USA, 21–22 July 2002; pp. 49–54. [Google Scholar]

- Nesme, M.; Payan, Y.; Faure, F. Efficient, physically plausible finite elements. In Proceedings of the EG Short Presentations. The Eurographics Association, Dublin, Ireland, 29 August 2–September 2005. [Google Scholar] [CrossRef]

- James, D.L.; Pai, D.K. Multiresolution green’s function methods for interactive simulation of large-scale elastostatic objects. ACM Trans. Graph. TOG 2003, 22, 47–82. [Google Scholar] [CrossRef]

- Barbič, J.; James, D.L. Real-time subspace integration for St. Venant-Kirchhoff deformable models. ACM Trans. Graph. (TOG) 2005, 24, 982–990. [Google Scholar] [CrossRef]

- Kim, T.; James, D.L. Skipping steps in deformable simulation with online model reduction. In Proceedings of the ACM SIGGRAPH Asia 2009 Papers, Yokohama, Japan, 16–19 December 2009; pp. 1–9. [Google Scholar]

- Haouchine, N.; Dequidt, J.; Kerrien, E.; Berger, M.O.; Cotin, S. Physics-based augmented reality for 3d deformable object. In Proceedings of the Eurographics Workshop on Virtual Reality Interaction and Physical Simulation, Darmstadt, Germany, 6–7 December 2012; pp. 31–38. [Google Scholar]

- Leizea, I.; Alvarez, H.; Aguinaga, I.; Borro, D. Real-time deformation, registration and tracking of solids based on physical simulation. In Proceedings of the 2014 IEEE International Symposium on Mixed and Augmented Reality (ISMAR), Munich, Germany, 10–12 September 2014; pp. 165–170. [Google Scholar]

- Petit, A.; Lippiello, V.; Siciliano, B. Real-time tracking of 3D elastic objects with an RGB-D sensor. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 3914–3921. [Google Scholar]

- Sengupta, A.; Krupa, A.; Marchand, E. Tracking of non-rigid objects using rgb-d camera. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019; pp. 3310–3317. [Google Scholar]

- Rublee, E.; Rabaud, V.; Konolige, K.; Bradski, G. ORB: An efficient alternative to SIFT or SURF. In Proceedings of the 2011 International Conference on Computer Vision, Barcelona, Spain, 6–13 November 2011; pp. 2564–2571. [Google Scholar]

- Besl, P.J.; McKay, N.D. A Method for Registration of 3-D Shapes. Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Kim, Y.; Baek, S.; Bae, B.C. Motion Capture of the Human Body Using Multiple Depth Sensors. ETRI J. 2017, 39, 181–190. [Google Scholar] [CrossRef]

- Martin, S.; Thomaszewski, B.; Grinspun, E.; Gross, M. Example-based elastic materials. In Proceedings of the ACM SIGGRAPH 2011 Papers, Vancouver, BC, Canada, 7–11 August 2011; pp. 1–8. [Google Scholar]

- Bouaziz, S.; Martin, S.; Liu, T.; Kavan, L.; Pauly, M. Projective dynamics: Fusing constraint projections for fast simulation. ACM Trans. Graph. TOG 2014, 33, 1–11. [Google Scholar] [CrossRef]

- Lee, S.; Yu, R.; Park, J.; Aanjaneya, M.; Sifakis, E.; Lee, J. Dexterous manipulation and control with volumetric muscles. ACM Trans. Graph. TOG 2018, 37, 1–13. [Google Scholar] [CrossRef]

- Ju, T.; Schaefer, S.; Warren, J. Mean value coordinates for closed triangular meshes. In Proceedings of the ACM Siggraph, Los Angeles, CA, USA, 31 July–4 August 2005; pp. 561–566. [Google Scholar]

- Muñoz-Salinas, R.; Garrido-Jurado, S. ArUco Library. 2013. Available online: https://docs.opencv.org (accessed on 1 March 2022).

- Móller, T.; Trumbore, B. Fast, minimum storage ray-triangle intersection. J. Graph. Tools 1997, 2, 21–28. [Google Scholar] [CrossRef]

- Nienhuys, H.W.; van der Stappen, A.F. A Delaunay approach to interactive cutting in triangulated surfaces. In Algorithmic Foundations of Robotics V; Springer: Berlin/Heidelberg, Germany, 2004; pp. 113–129. [Google Scholar]

| Model | Sponge | Doll | ||

|---|---|---|---|---|

| Number | Vertices | Polygons | Vertices | Polygons |

| High-resolution | 522 | 1040 | 18,650 | 7190 |

| Low-resolution | 132 | 260 | 128 | 252 |

| Volumetric | 132 | 300 | 154 | 494 |

| Model | Sponge | Doll | ||

|---|---|---|---|---|

| Time (ms) | Init. | Sim. | Init. | Sim. |

| Feature-Point Tracking | 15.51 | 0.56 | 22.53 | 0.67 |

| Soft-body Simulation | 21.22 | 10.62 | 23.61 | 29.02 |

| Resolution Enhancement | 18.41 | 0.38 | 542.31 | 2.81 |

| Total | 55.14 | 11.56 | 588.45 | 32.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, D.; Moon, J.; Yang, S.; Kwon, T.; Kim, Y. Physics-Based Simulation of Soft-Body Deformation Using RGB-D Data. Sensors 2022, 22, 7225. https://doi.org/10.3390/s22197225

Kang D, Moon J, Yang S, Kwon T, Kim Y. Physics-Based Simulation of Soft-Body Deformation Using RGB-D Data. Sensors. 2022; 22(19):7225. https://doi.org/10.3390/s22197225

Chicago/Turabian StyleKang, Daeun, Jaeseok Moon, Saeyoung Yang, Taesoo Kwon, and Yejin Kim. 2022. "Physics-Based Simulation of Soft-Body Deformation Using RGB-D Data" Sensors 22, no. 19: 7225. https://doi.org/10.3390/s22197225

APA StyleKang, D., Moon, J., Yang, S., Kwon, T., & Kim, Y. (2022). Physics-Based Simulation of Soft-Body Deformation Using RGB-D Data. Sensors, 22(19), 7225. https://doi.org/10.3390/s22197225