Smart E-Textiles: Overview of Components and Outlook

Abstract

:1. Introduction

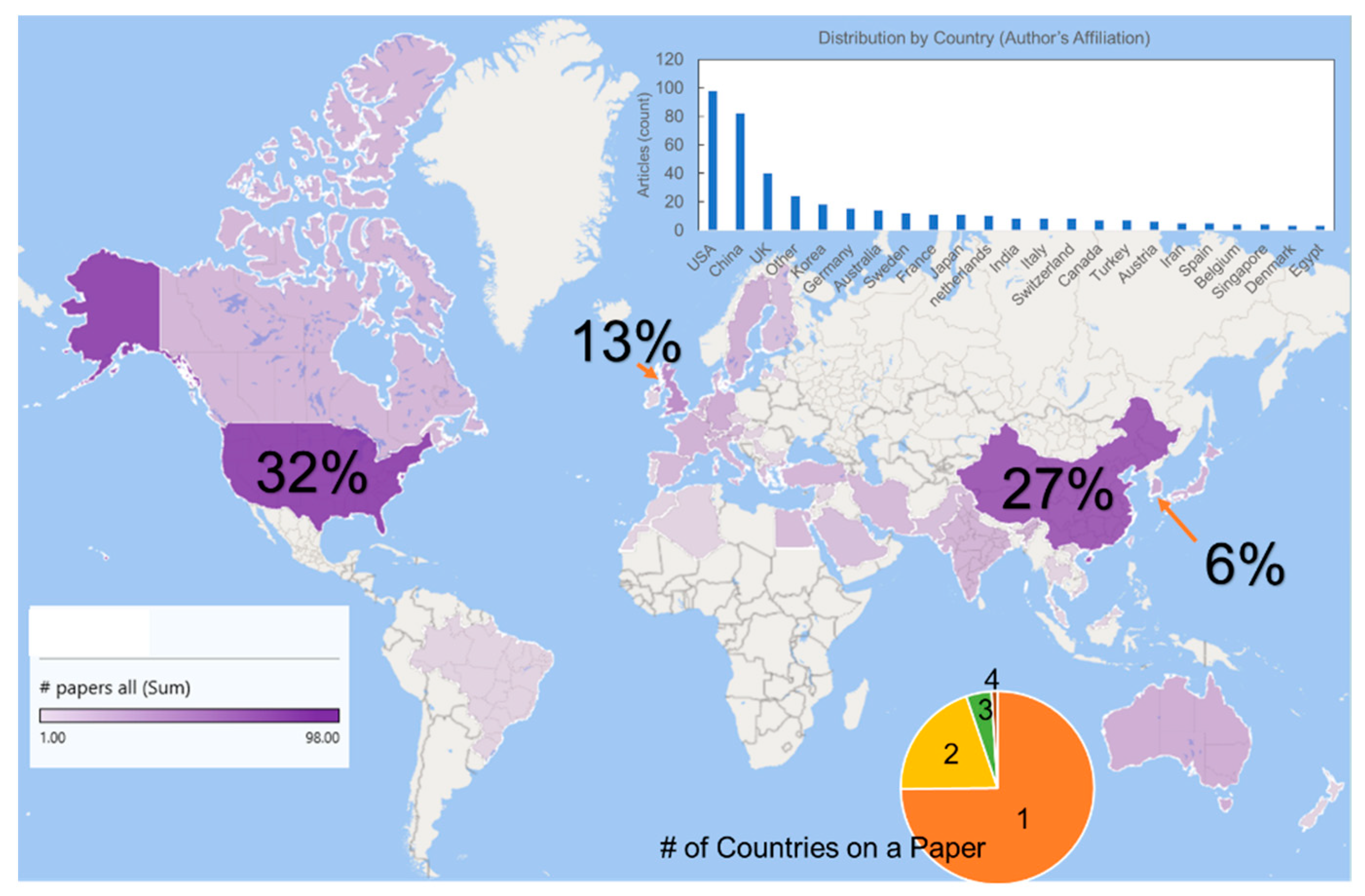

2. Components of Electronic Textiles

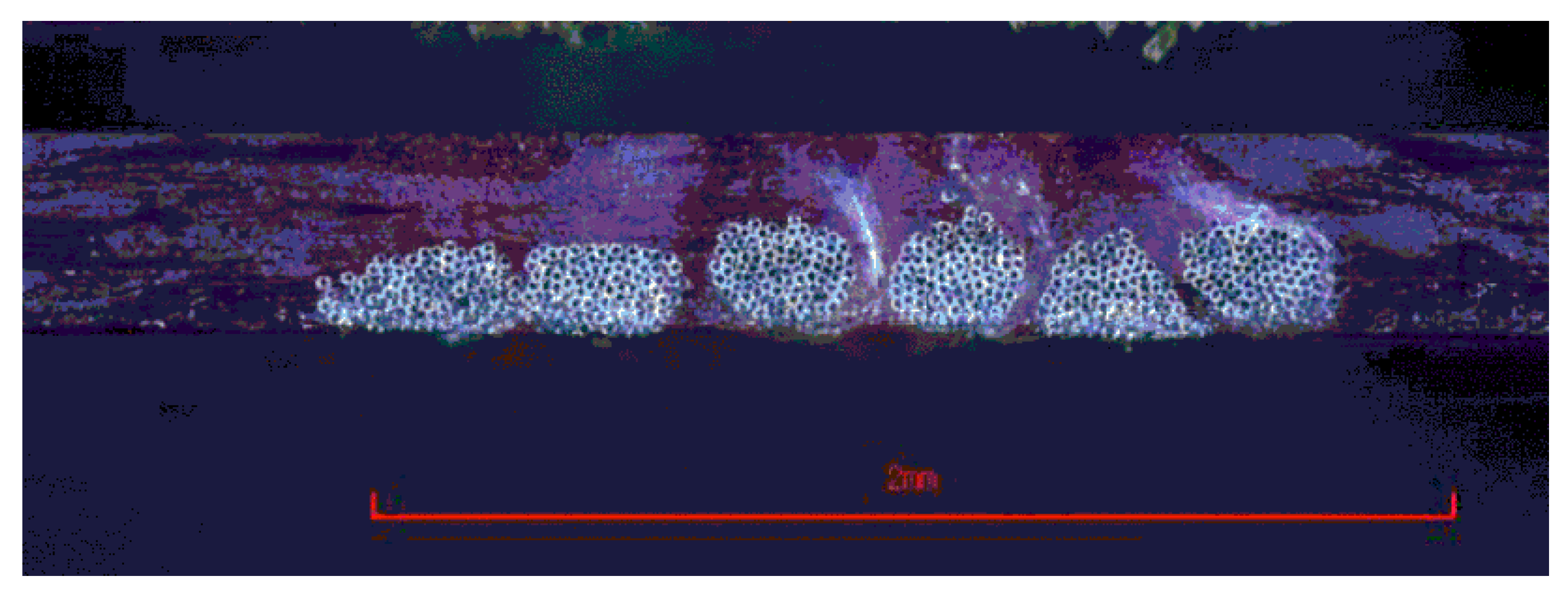

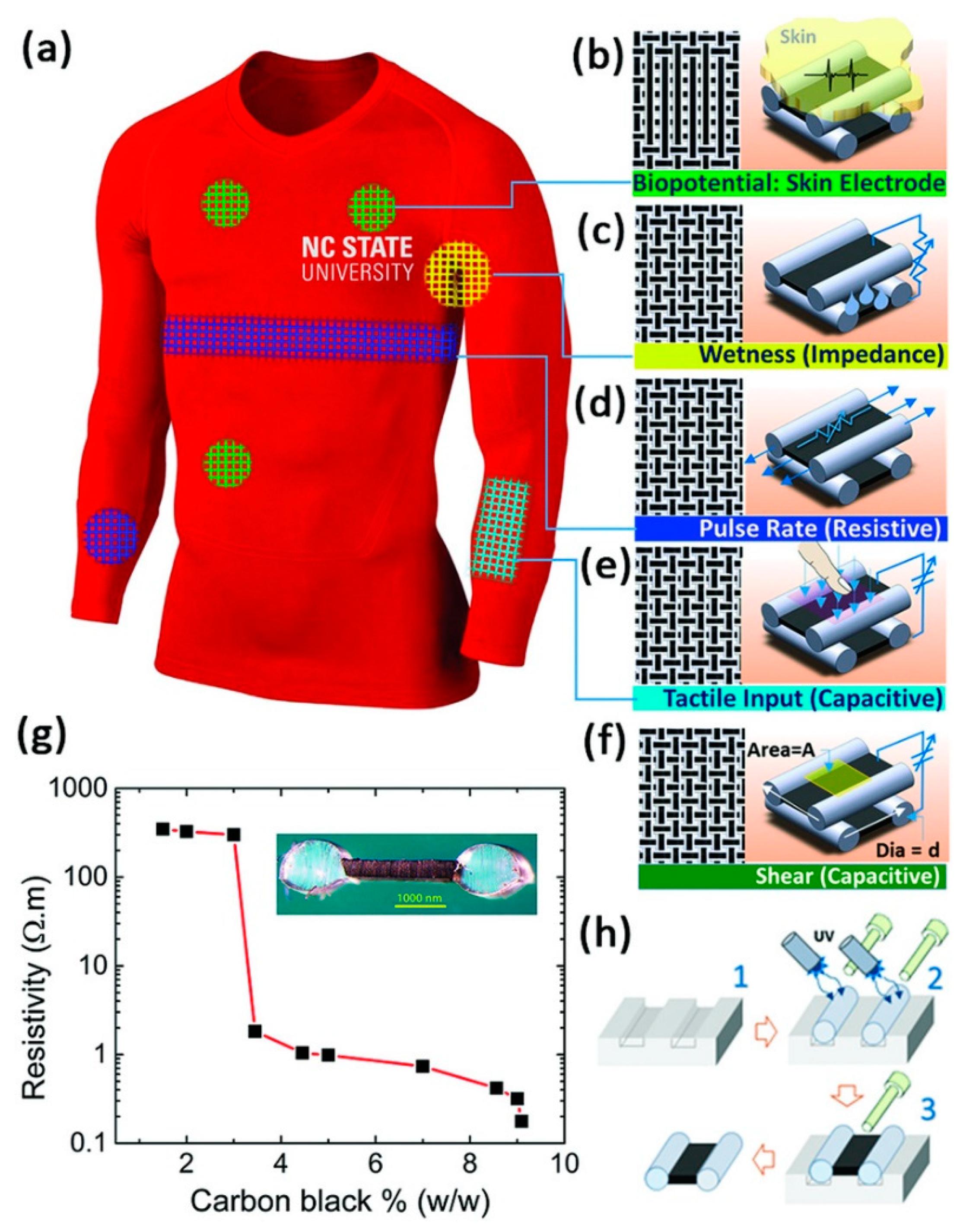

2.1. Conductive Materials

2.2. Interconnects and Communication

2.3. Electronic Sensors and Actuators

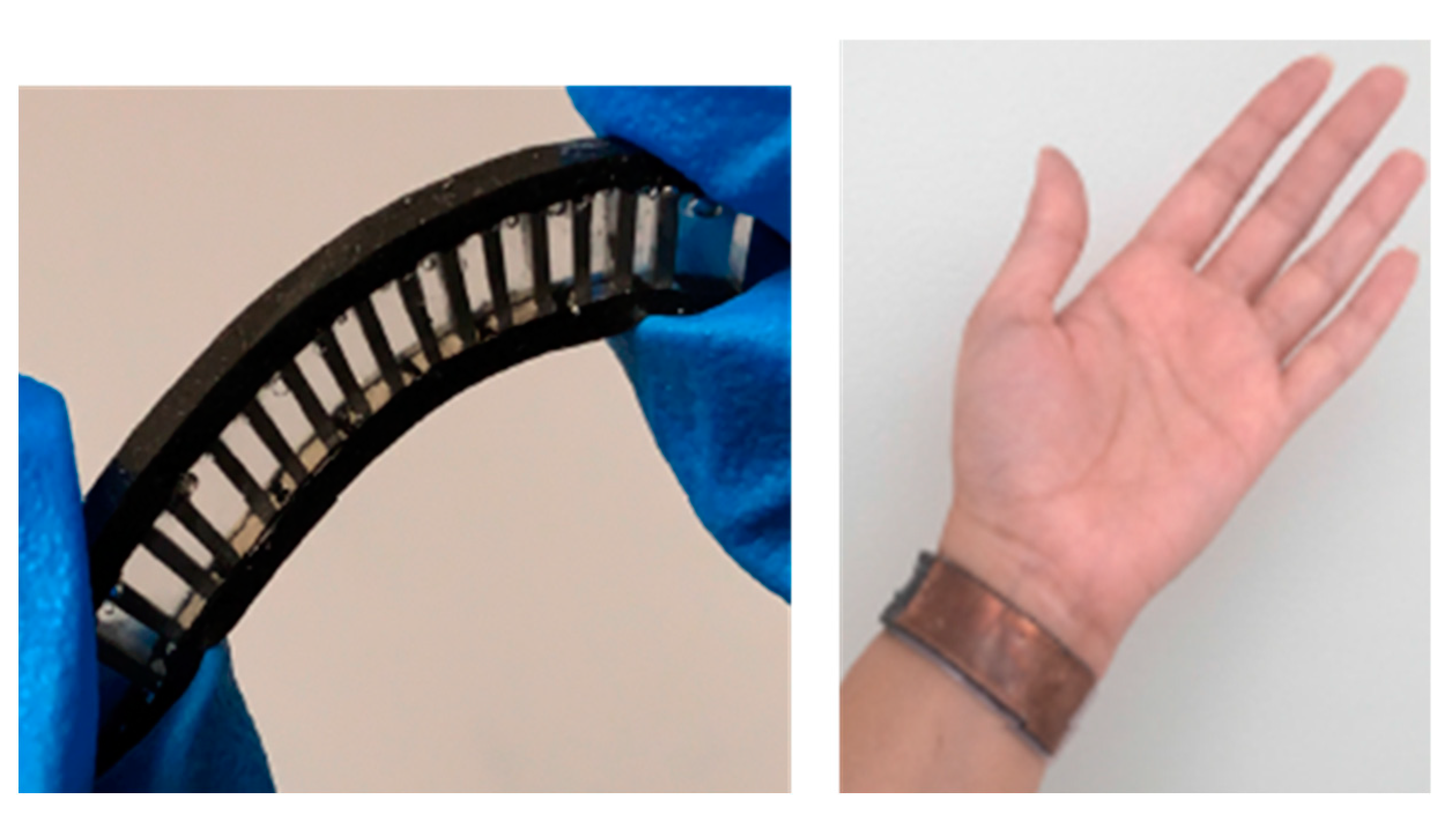

2.4. Power–Energy Generation and Storage

2.5. Computer or Central Processing Unit

2.6. General Applications of Electronic Textiles

3. Current Limitations

3.1. Wearer Needs

3.2. Interdisciplinary Collaborations: United Intention with Divided Focus

3.3. Quality and Testing Standards

3.4. Prototyping

3.5. Standardized Electronic Textile

3.6. Commercial Products

4. Outlook

4.1. New Textile Production Methods

4.2. A Smart Textiles Journal

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Posch, I.; Stark, L.; Fitzpatrick, G. eTextiles: Reviewing a Practice through its Tool/Kits. In Proceedings of the 2019 International Symposium on Wearable Computers (ISWC ‘19), London, UK, 9–13 September 2019; Association for Computing Machinery: New York, NY, USA, 2019. [Google Scholar]

- Cutcher-Gershenfeld, J.; Gershenfeld, A.; Gershenfeld, N. Digital Fabrication and the Future of Work. Perspect. Work 2008, 22, 8–13. [Google Scholar]

- Hassib, M.; Khamis, M.; Schneegass, S.; Shirazi, A.S.; Alt, F. Investigating User Needs for Bio-sensing and Affective Wearables. In Proceedings of the CHI 2016 Late-Breaking Work: Designing Interactive Systems, San Jose, CA, USA, 7 May 2016. [Google Scholar]

- Mossé, A. Gossamer timescapes: A design-led investigation into electro-active and light responsive textiles for the home. Smart Mater. Struct. 2018, 27, 074009. [Google Scholar] [CrossRef]

- Herbert, K.M.; Schrettl, S.; Rowan, S.J.; Weder, C. 50th Anniversary Perspective: Solid-State Multistimuli, Multiresponsive Polymeric Materials. Macromolecules 2017, 50, 8845–8870. [Google Scholar] [CrossRef]

- Hu, J.; Meng, H.; Li, G.; Ibekwe, S.I. A review of stimuli-responsive polymers for smart textile applications. Smart Mater. Struct. 2012, 21, 053001. [Google Scholar] [CrossRef]

- Heinzel, T.; Hinestroza, J.P. Revolutionary Textiles: A Philosophical Inquiry on Electronic and Reactive Textiles. Des. Issues 2020, 36, 45–58. [Google Scholar] [CrossRef]

- Karana, E.; Nimkulrat, N.; Giaccardi, E.; Niedderer, K.; Fan, J.-N. Alive. Active. Adaptive: Experiential Knowledge and Emerging Materials. Int. J. Des. 2019, 13, 1–5. [Google Scholar]

- Ghahremani, M.; Latifi, M.; Babaei, M. Simulation of conductivity made by inkjet-printed silver tracks in E-textiles with different weave Patterns. J. Ind. Text. 2017, 47, 173–196. [Google Scholar] [CrossRef]

- Ferri, A.; Plutino, M.R.; Rosace, G. Recent trends in smart textiles: Wearable sensors and drug release systems. AIP Conf. Proc. 2019, 2145, 020014. [Google Scholar]

- Fernández-Caramés, T.M.; Fraga-Lamas, P. Towards The Internet of Smart Clothing: A Review on IoT Wearables and Garments for Creating Intelligent Connected E-Textiles. Electronics 2018, 7, 405. [Google Scholar] [CrossRef]

- Ray, S.; Park, J.; Bhunia, S. Wearables, Implants, and Internet of Things: The Technology Needs in the Evolving Landscape. IEEE Trans. Multi-Scale Comput. Syst. 2016, 2, 123–128. [Google Scholar] [CrossRef]

- Jansen, K.M.B. How to Shape the Future of Smart Clothing. In Proceedings of the UbiComp/ISWC 2019—Adjunct Proceedings of the 2019 ACM International Joint Conference on Pervasive and Ubiquitous Computing and Proceedings of the 2019 ACM International Symposium on Wearable Computers, London, UK, 9 September 2019. [Google Scholar]

- Yang, K.; Isaia, B.; Brown, L.J.; Beeby, S. E-Textiles for Healthy Ageing. Sensors 2019, 19, 4463. [Google Scholar] [CrossRef]

- Stewart, R. Cords and Chords: Exploring the Role of E-Textiles in Computational Audio. Front. ICT 2019, 6, 12. [Google Scholar] [CrossRef]

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- Sanchez, V.; Walsh, C.J.; Wood, R.J. Textile Technology for Soft Robotic and Autonomous Garments. Adv. Funct. Mater. 2021, 31, 2008278. [Google Scholar] [CrossRef]

- Tabor, J.; Chatterjee, K.; Ghosh, T.K. Smart Textile-Based Personal Thermal Comfort Systems: Current Status and Potential Solutions. Adv. Mater. Technol. 2020, 5, 1901155. [Google Scholar] [CrossRef]

- Loke, G.; Yan, W.; Khudiyev, T.; Noel, G.; Fink, Y. Recent Progress and Perspectives of Thermally Drawn Multimaterial Fiber Electronics. Adv. Mater. 2020, 32, 1904911. [Google Scholar] [CrossRef]

- Ruckdashel, R.R.; Venkataraman, D.; Park, J.H. Smart textiles: A toolkit to fashion the future. J. Appl. Phys. 2021, 129, 130903. [Google Scholar] [CrossRef]

- Nanjappan, V.; Shi, R.; Liang, H.-N.; Lau, K.K.-T.; Yue, Y.; Atkinson, K. Towards a Taxonomy for In-Vehicle Interactions Using Wearable Smart Textiles: Insights from a User-Elicitation Study. Multimodal Technol. Interact. 2019, 3, 33. [Google Scholar] [CrossRef]

- Gonçalves, C.; da Silva, A.F.; Gomes, J.; Simoes, R. Wearable E-Textile Technologies: A Review on Sensors, Actuators and Control Elements. Inventions 2018, 3, 14. [Google Scholar] [CrossRef]

- Komolafe, A.; Torah, R.; Tudor, M.; Beeby, S. Modelling Reliable Electrical Conductors for E-Textile Circuits on Polyimide Filaments. Multidiscip. Digit. Publ. Inst. Proc. 2019, 32, 11. [Google Scholar]

- Tasnim, F.; Sadraei, A.; Datta, B.; Khan, M.; Choi, K.Y.; Sahasrabudhe, A.; Gálvez, T.A.V.; Wicaksono, I.; Rosello, O.; Nunez-Lopez, C.; et al. Towards personalized medicine: The evolution of imperceptible health-care technologies. Foresight 2018, 20, 589–601. [Google Scholar] [CrossRef]

- Corchia, L.; Monti, G.; de Benedetto, E.; Tarricone, L. A Chipless Humidity Sensor for Wearable Applications. In Proceedings of the IEEE International Conference on RFID Technology and Applications (RFID-TA), Pisa, Italy, 25–27 September 2019. [Google Scholar]

- Borazan, I.; Kaplan, M.; Uzumcu, M.B. Utilization of Metallic Fibers in Textiles. In Proceedings of the 2nd International Congress of Innovative Textiles, Lisbon, Portugal, 19–21 June 2019. [Google Scholar]

- Dong, K.; Peng, X.; Wang, Z.L. Fiber/Fabric-Based Piezoelectric and Triboelectric Nanogenerators for Flexible/Stretchable and Wearable Electronics and Artificial Intelligence. Adv. Mater. 2019, 32, e1902549. [Google Scholar] [CrossRef]

- Gao, Y.; Cho, J.H.; Ryu, J.; Choi, S. A scalable yarn-based biobattery for biochemical energy harvesting in smart textiles. Nano Energy 2020, 74, 104897. [Google Scholar] [CrossRef]

- Alharbi, S.; Chaudhari, S.; Inshaar, A.; Shah, H.; Zou, C.; Harne, R.L.; Kiourti, A. E-Textile Origami Dipole Antennas With Graded Embroidery for Adaptive RF Performance. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 2218–2222. [Google Scholar] [CrossRef]

- Conductive Materials, Metals and Stainless Steels Properties Table: Tibtech. Available online: https://www.tibtech.com/conductivite.php?lang=en_US (accessed on 27 July 2022).

- Wang, J.; Chang, A.S.; Sherfield, S.N.; Golobic, A.M.; Hunter, S.L.; Duoss, E.B.; Matthews, M.J. Electrical Properties of Copper Loaded Polymer Composites. In Proceedings of the SPIE Smart Structures + Nondestructive Evaluation, Denver, CO, USA, 4–7 March 2019. [Google Scholar]

- Liu, F.; Shang, S.; Duan, Y.; Li, L. Electrical and optical properties of polymer-Au nanocomposite films synthesized by magnetron cosputtering. J. Appl. Polym. Sci. 2012, 123, 2800. [Google Scholar] [CrossRef]

- Deepa, K.; Gopika, M.; James, J. Influence of matrix conductivity and Coulomb blockade effect on the percolation threshold of insulator–conductor composites. Compos. Sci. Technol. 2013, 78, 18. [Google Scholar] [CrossRef]

- Pantea, D.; Darmstadt, H.; Kaliaguine, S.; Sümmchen, L.; Roy, C. Electrical conductivity of thermal carbon blacks: Influence of surface chemistry. Carbon 2001, 39, 1147. [Google Scholar] [CrossRef]

- Choi, H.-J.; Kim, M.S.; Ahn, D.; Yeo, S.Y.; Lee, S. Electrical percolation threshold of carbon black in a polymer matrix and its application to antistatic fibre. Sci. Rep. 2019, 9, 6338. [Google Scholar] [CrossRef]

- Du, X.; Skachko, I.; Barker, A.; Andrei, E.Y. Approaching ballistic transport in suspended graphene. Nat. Nanotechnol. 2008, 3, 491. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Zheng, W.-G.; Yan, Q.; Yang, Y.; Wang, J.-W.; Lu, Z.-H.; Ji, G.-Y.; Yu, Z.-Z. Electrically conductive polyethylene terephthalate/graphene nanocomposites prepared by melt compounding. Polymer 2010, 51, 1191. [Google Scholar] [CrossRef]

- Choi, J.; Zhang, Y. Single-Double Multi-Walled Carbon Nanotubes; Millipore Sigma Aldrich: St. Louis, MO, USA.

- Wang, S.H.; Wan, Y.; Sun, B.; Liu, L.Z.; Xu, W. Mechanical and electrical properties of electrospun PVDF/MWCNT ultrafine fibers using rotating collector. Nanoscale Res. Lett. 2014, 9, 522. [Google Scholar] [CrossRef] [PubMed]

- Galiński, M.; Lewandowski, A.; Stępniak, I. Ionic liquids as electrolytes. Electrochim. Acta 2006, 51, 5567. [Google Scholar] [CrossRef]

- Aranburu, N.; Otaegi, I.; Guerrica-Echevarria, G. Using an Ionic Liquid to Reduce the Electrical Percolation Threshold in Biobased Thermoplastic Polyurethane/Graphene Nanocomposites. Polymers 2019, 11, 435. [Google Scholar] [CrossRef] [PubMed]

- Puértolas, J.; García-García, J.; Pascual, F.; González-Domínguez, J.; Martínez, M.; Ansón-Casaos, A. Dielectric behavior and electrical conductivity of PVDF filled with functionalized single-walled carbon nanotubes. Compos. Sci. Technol. 2017, 152, 263. [Google Scholar] [CrossRef]

- Micus, S.; Kirsten, I.; Haupt, M.; Gresser, G.T. Analysis of Hot Bar Soldering, Insulation Displacement Connections (IDC), and Anisotropic Conductive Adhesives (ACA), for the Automated Production of Smart Textiles. Sensors 2020, 20, 5. [Google Scholar] [CrossRef]

- Ayodele, E.; Zaidi, S.; Zhang, Z.; Scott, J.; Kong, Q.; McLernon, D. Weft Knit Smart Data Glove. In Proceedings of the IEEE 16th International Conference on Wearable and Implantable Body Sensor Networks (BSN), Chicago, IL, USA, 19–22 May 2019. [Google Scholar]

- Stark, L. Data Vows: Reimagining Ritual through eTextile Practice. In Proceedings of the ISWC ‘17: Proceedings of the 2017 ACM International Symposium on Wearable Computers, Maui, HI, USA, 11–15 September 2017. [Google Scholar]

- Baum, T.C.; Ziolkowski, R.W.; Ghorbani, K.; Nicholson, K.J. Embroidered Active Microwave Composite Preimpregnated Electronics—Pregtronics. IEEE Trans. Microw. Theory Tech. 2016, 64, 3175–3186. [Google Scholar] [CrossRef]

- Orth, M. Defining Flexibility and sewability in conductive yarns. Proc. Mater. Res. Soc. Symp. 2002, 736, 37–48. [Google Scholar] [CrossRef]

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 5. [Google Scholar] [CrossRef]

- Sargolzaeiaval, Y.; Ramesh, V.P.; Neumann, T.V.; Misra, V.; Vashaee, D.; Dickey, M.D.; Öztürk, M.C. Flexible thermoelectric generators for body heat harvesting—Enhanced device performance using high thermal conductivity elastomer encapsulation on liquid metal interconnects. Appl. Energy 2020, 262, 114370. [Google Scholar] [CrossRef]

- Coyle, S.; Lau, K.-T.; Moyna, N.; O’Gorman, D.; Diamond, D.; di Francesco, F.; Costanzo, D.; Salvo, P.; Trivella, M.G.; de Rossi, D.E.; et al. BIOTEX—Biosensing Textiles for Personalised Healthcare Management. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 364–370. [Google Scholar] [CrossRef]

- Lemey, S.; Agneessens, S.; Rogier, H. Wearable Smart Objects. IEEE Microw. Mag. 2018, 19, 83–100. [Google Scholar] [CrossRef]

- Agrawal, R.; Koteswarapavan, C.; Kaushik, N.; Matre, P. Smart actuators for innovative biomedical applications. In Applied Microbiology and Bioengineering: An Interdisciplinary Approach; Shukla, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 110–111. [Google Scholar]

- Nesenbergs, K.; Selavo, L. Smart textiles for wearable sensor networks: Review and early lessons. In Proceedings of the 2015 IEEE International Symposium on Medical Measurements and Applications (MeMeA) Proceedings, Torino, Italy, 7–9 May 2015. [Google Scholar]

- Chen, Y.; Xu, B.; Gong, J.; Wen, J.; Hua, T.; Kan, C.-W.; Deng, J. Design of High-Performance Wearable Energy and Sensor Electronics from Fiber Materials. Appl. Mater. Interfaces 2019, 11, 2120–2129. [Google Scholar] [CrossRef]

- Bahadır, S.K.; Atalay, Ö.; Kalaoglu, F.; Mitilineos, S.A.; Vassiliadis, S. High Frequency Attenuation Characterization of Knitted E-Textile Structures. IOP Conf. Ser. Mater. Sci. Eng. 2018, 460, 012054. [Google Scholar] [CrossRef]

- Rezaei, A.; Cuthbert, T.J.; Gholami, M.; Menon, C. Application-Based Production and Testing of a Core–Sheath Fiber Strain Sensor for Wearable Electronics: Feasibility Study of Using the Sensors in Measuring Tri-Axial Trunk Motion Angles. Sensors 2019, 19, 4288. [Google Scholar] [CrossRef]

- Shui, X.; Chung, D.D.L. A piezoresistive carbon filament polymer-matrix composite strain sensor. Smart Mater. Struct. 1996, 5, 243–246. [Google Scholar] [CrossRef]

- McLaren, R.; Joseph, F.; Baguley, C.; Taylor, D. A review of e-textiles in neurological rehabilitation: How close are we? J. NeuroEngineering Rehabil. 2016, 13, 59. [Google Scholar] [CrossRef]

- Strohmeier, P.R.; Vertegaal, R.; Girouard, A. With a flick of the wrist: Stretch sensors as lightweight input for mobile devices. In Proceedings of the 6th International Conference on Tangible and Embedded Interaction 2012, Kingston, ON, Canada, 19–22 February 2012. [Google Scholar]

- Fobelets, K.; Thielemans, K.; Mathivanan, A.; Papavassiliou, C. Characterization of Knitted Coils for e-Textiles. IEEE Sens. J. 2019, 19, 7835–7840. [Google Scholar] [CrossRef]

- He, W.; Wang, C.; Wang, H.; Jian, M.; Lu, W.; Liang, X.; Zhang, X.; Yang, F.; Zhang, Y. Integrated textile sensor patch for real-time and multiplex sweat analysis. Sci. Adv. 2019, 5, 11. [Google Scholar] [CrossRef]

- Soroudi, A.; Hernández, N.; Wipenmyr, J.; Nierstrasz, V. Surface modification of textile electrodes to improve electrocardiography signals in wearable smart garment. J. Mater. Sci. Mater. Electron. 2019, 30, 16666–16675. [Google Scholar] [CrossRef]

- Shu, L.; Xu, T.; Xu, X. Multilayer Sweat-Absorbable Textile Electrode for EEG Measurement in Forehead Site. IEEE Sens. J. 2019, 19, 5995–6005. [Google Scholar] [CrossRef]

- Saied, I.M.; Chandran, S.; Arslan, T. Integrated Flexible Hybrid Silicone-Textile Dual-Resonant Sensors and Switching Circuit for Wearable Neurodegeneration Monitoring Systems. IEEE Trans. Biomed. Circuits Syst. 2019, 13, 1304–1312. [Google Scholar] [CrossRef]

- Komolafe, A.; Torah, R.; Nunes-Matos, H.; Tudor, M.; Beeby, S. Integration of temperature sensors in fabrics. In Proceedings of the 2019 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Glasgow, UK, 7–10 July 2019. [Google Scholar]

- Han, J.-W.; Kim, B.; Li, J.; Meyyappan, M. A carbon nanotube based ammonia sensor on cotton textile. Appl. Phys. Lett. 2013, 102, 193104. [Google Scholar] [CrossRef]

- Ye, C.; Ren, J.; Wang, Y.; Zhang, W.; Qian, C.; Han, J.; Zhang, C.; Jin, K.; Buehler, M.J.; Kaplan, D.L.; et al. Design and Fabrication of Silk Templated Electronic Yarns and Applications in Multifunctional Textiles. Matter 2019, 1, 1411–1425. [Google Scholar] [CrossRef]

- González, E.; Shepherd, L.M.; Saunders, L.; Frey, M.W. Surface Functional Poly(lactic Acid) Electrospun Nanofibers for Biosensor Applications. Materials 2016, 9, 47. [Google Scholar] [CrossRef]

- Haque, M. Nano Fabrics in the 21st century: A review. Asian J. Nanosci. Mater. 2019, 2, 131–148. [Google Scholar]

- Soroudi, A.; Hernandez, N.; Berglin, L.; Nierstrasz, V. Electrode placement in electrocardiography smart garments: A review. J. Electrocardiol. 2019, 57, 27–30. [Google Scholar] [CrossRef]

- Drew, B. Standardization of electrode placement for continuous patient monitoring: Introduction of an assessment tool to compare proposed electrocardiogram lead configurations. J. Electrocardiol. 2011, 44, 115–118. [Google Scholar] [CrossRef]

- Kono, T.; Watanabe, K. Filum: A Sewing Technique to Alter Textile Shapes. In Proceedings of the UIST’17 Adjunct Publication of the 30th Annual ACM Symposium, Québec City, QC, Canada, 20 October 2017. [Google Scholar]

- Buckner, T.L.; Bilodeau, R.A.; Ki, S.Y.; Kramer-Bottiglio, R. Roboticizing fabric by integrating functional fibers. Proc. Natl. Acad. Sci. USA 2020, 117, 25360–25369. [Google Scholar] [CrossRef]

- Guo, J.; Xiang, C.; Helps, T.; Taghavi, M.; Rossiter, J. Electroactive textile actuators for wearable and soft robots. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018. [Google Scholar]

- Zhang, Z.; Cui, L.; Shi, X.; Tian, X.; Wang, D.; Gu, C.; Chen, E.; Cheng, X.; Xu, Y.; Hu, Y.; et al. Textile Display for Electronic and Brain-Interfaced Communications. Adv. Mater. 2018, 30, e1800323. [Google Scholar] [CrossRef]

- Sahoo, D.R.; Hornbæk, K.; Subramanian, S. Deepak Ranjan Sahoo1, TableHop: An Actuated Fabric Display Using Transparent Electrodes. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems (CHI ‘16), New York, NY, USA, 7–12 May 2016. [Google Scholar]

- Mohammadia, A.; Abdelkhalekb, M.; Sadrafsharia, S. Resonance frequency selective electromagnetic actuation for high-resolution vibrotactile displays. Sens. Actuators A Phys. 2020, 302, 111818. [Google Scholar] [CrossRef]

- Kiourti, A. Textile-Based Flexible Electronics for Wearable Applications: From Antennas to Batteries. In Proceedings of the 2018 2nd URSI Atlantic Radio Science Meeting (AT-RASC), Gran Canaria, Spain, 11–12 June 2018. [Google Scholar]

- García Núñez, C.; Manjakkal., L.; Dahiya, R. Energy autonomous electronic skin. NPJ Flex. Electron. 2019, 3, 1–24. [Google Scholar] [CrossRef]

- Lemey, S.; Agneessens, S.; Rogier, H. Textile SIW Antennas as Hybrid Energy Harvesting and Power Management Platforms. In Proceedings of the 45th European Microwave Conference, Paris, France, 11 September 2015. [Google Scholar]

- Komolafe, A.; Wagih, M.; Valavan, A.; Ahmed, Z.; Stuikys, A.; Zaghari, B. A Smart Cycling Platform for Textile-Based Sensing and Wireless Power Transfer in Smart Cities. Multidiscip. Digit. Publ. Inst. Proc. 2019, 32, 7. [Google Scholar]

- Chen, G.; Li, Y.; Bick, M.; Chen, J. Smart Textiles for Electricity Generation. Chem. Rev. 2020, 120, 3668–3720. [Google Scholar] [CrossRef] [PubMed]

- Nozariasbmarz, A.; Collins, H.; Dsouza, K.; Polash, M.H.; Hosseini, M.; Hyland, M.; Liu, J.; Malhotra, A.; Ortiza, F.M.; Mohaddes, F.; et al. Review of wearable thermoelectric energy harvesting: From body temperature to electronic systems. Appl. Energy 2020, 258, 114069. [Google Scholar] [CrossRef]

- Toivola, M.; Ferenets, M.; Lund, P.; Harlin, A. Photovoltaic fiber. Thin Solid Film. 2009, 517, 2799–2802. [Google Scholar] [CrossRef]

- Park, N.-G. Perovskite solar cells: An emerging photovoltaic technology. Materialstoday 2015, 18, 65–72. [Google Scholar] [CrossRef]

- Rein, M.; Favrod, V.D.; Hou, C.; Khudiyev, T.; Stolyarov, A.; Cox, J.; Chung, C.-C.; Chhav, C.; Ellis, M.; Joannopoulos, J.; et al. Diode fibres for fabric-based optical communications. Nature 2018, 560, 214–218. [Google Scholar] [CrossRef]

- Yan, W.; Page, A.; Nguyen-Dang, T.; Qu, Y.; Sordo, F.; Wei, L.; Sorin, F. Advanced Multimaterial Electronic and Optoelectronic Fibers and Textiles. Adv. Mater. 2019, 31, e1802348. [Google Scholar] [CrossRef]

- Lee, M.R.; Eckert, R.; Forberich, K.; Dennler, G.; Brabec, C.J.; Gaudiana, R.A. Solar Power Wires Based on Organic Photovoltaic Materials. Science 2009, 324, 232–235. [Google Scholar] [CrossRef]

- Lund, A.; Rundqvist, K.; Nilsson, E.; Yu, L.; Hagström, B.; Müller, C. Energy harvesting textiles for a rainy day: Woven piezoelectrics based on melt-spun PVDF microfibres with a conducting core. NPJ Flex. Electron. 2018, 2, 9. [Google Scholar] [CrossRef]

- Posch, I.; Kurbak, E. Crafted Logic: Towards Hand-Crafting a Computer. In Proceedings of the CHI’16 Extended Abstracts, San Jose, CA, USA, 7–12 May 2016. [Google Scholar]

- Shi, Q.; Zhang, Z.; Chen, T.; Lee, C. Minimalist and multi-functional human machine interface (HMI) using a flexible wearable triboelectric patch. Nano Energy 2019, 62, 355–366. [Google Scholar] [CrossRef]

- Xu, P.A.; Mishra, A.K.; Bai, H.; Aubin, C.A.; Zullo, L.; Shepherd, R.F. Optical lace for synthetic afferent neural networks. Sci. Robot. 2019, 4, eaaw6304. [Google Scholar] [CrossRef]

- Peng, H.; Mankoff, J.; Hudson, S.E.; McCann, J. A Layered Fabric 3D Printer for Soft Interactive Objects. In Proceedings of the CHI 2015, Crossings, Design and 3D Object Fabrication, Seoul, Korea, 18–23 April 2015. [Google Scholar]

- Loughborough University London. Textile Intersections. In Intersections Exhibition. 2019. Available online: https://cfpr.uwe.ac.uk/textile-intersections-exhibition/ (accessed on 1 August 2022).

- Dong, W.; Xiao, L.; Hu, W.; Zhu, C.; Huang, Y.; Yin, Z. Wearable human–machine interface based on PVDF piezoelectric sensor. Trans. Inst. Meas. Control 2017, 39, 398–403. [Google Scholar] [CrossRef]

- Seth, R. Wearable Wireless Hmi Device. United States of. America Patent US 9,417,693 B2, 16 August 2016. [Google Scholar]

- Poupyrev, I.; Gong, N.-W.; Fukuhara, S.; Karagozler, M.E.; Schwesig, C.; Robinson, K.E. Project Jacquard: Interactive Digital Textiles at Scale; CHI: San Jose, CA, USA, 2016. [Google Scholar]

- Khoshkava, V.; Cruz-Hernandez, J.M. Bifunctional Fiber for Combined Sensing and Haptic Feedback. USA Patent 2018/0258561 A1, 13 September 2018. [Google Scholar]

- Gorgutsa, S.; Gu, J.F.; Skorobogatiy, M. A woven 2D touchpad sensor and a 1D slide sensor using soft capacitor fibers. Smart Mater. Struct. 2012, 21, 015010. [Google Scholar] [CrossRef]

- Kapoor, A.; McKnight, M.; Chatterjee, K.; Agcayazi, T.; Kausche, H.; Bozkurt, A.; Ghosh, T.K. Toward Fully Manufacturable, Fiber Assembly–Based Concurrent Multimodal and Multifunctional Sensors for e-Textiles. Adv. Mater. Technol. 2019, 4, 1800281. [Google Scholar] [CrossRef]

- Mikkonen, J.; Townsend, R. Frequency-Based Design of Smart Textiles. In Proceedings of the CHI Conference on Human Factors in Computing Systems Proceedings (CHI 2019), Glasgow, UK, 4–9 May 2019; ACM: New York, NY, USA, 2019. [Google Scholar]

- Zolyomi, A.; Gotfrid, T.; Shinohara, K. Socializing via a Scarf: Individuals with Intellectual and Developmental Disabilities Explore Smart Textiles; CHI 2019: Glasgow, UK, 2019. [Google Scholar]

- Paret, D.; Crégo, P. Wearables, Smart Textiles & Smart Apparel; ISTE Press: London, UK; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Rantakari, J.; Inget, V.; Colley, A.; Häkkila, J. Charting Design Preferences on Wellness Wearables. In Proceedings of the 7th Augmented Human International Conference 2016 (AH ’16). Association for Computing Machinery, New York, NY, USA, 25–27 February 2016. [Google Scholar]

- Moradi, B.; Fernandez-Garcia, R.; Gil, I. Effect of smart textile metamaterials on electromagnetic performance for wireless body area network systems. Text. Res. J. 2019, 89, 2892–2899. [Google Scholar] [CrossRef]

- Bryan-Kinns, N.; Wu, Y.; Liu, S.; Baker, C. WEAR Sustain Network: Ethical and Sustainable Technology Innovation in Wearables and Etextiles. In Proceedings of the IEEE Games, Entertainment, Media Conference (GEM), Galway, Ireland, 15–17 August 2018. [Google Scholar]

- Lam, C.-S.; Ramanathan, S.; Carbery, M.; Gray, K.; Vanka, K.S.; Maurin, C.; Bush, R.; Palanisami, T. A Comprehensive Analysis of Plastics and Microplastic Legislation Worldwide. Water Air Soil Pollut. 2018, 229, 345. [Google Scholar] [CrossRef]

- Mahmoud, K.H.M.; Salam, S.H.A.; El-Hadi, H. Designing Smart Textiles Prints with Interactive Capability. J. Des. Sci. Appl. Arts 2020, 1, 96–107. [Google Scholar] [CrossRef]

- Lee, J.J.; Hammer, J. Gamification in Education: What, How, Why Bother? Acad. Exch. Q. 2011, 15, 146. [Google Scholar]

- Pal, D.; Vanijja, V.; Arpnikanondt, C.; Zhang, X.; Papasratorn, B. A Quantitative Approach for Evaluating the Quality of Experience of Smart-Wearables From the Quality of Data and Quality of Information: An End User Perspective. IEEE Access 2019, 7, 64266–64278. [Google Scholar] [CrossRef]

- Latour, B.; Woolgar, S. Laboratory Life: The Construction of Scientific Facts, 2nd ed.; Princeton University Press: Princeton, NJ, USA, 1986. [Google Scholar]

- Alvesson, M.; Sandberg, J. Generating Research Questions Through Problematization. Acad. Manag. Rev. 2011, 36, 247–271. [Google Scholar]

- Simon, C.; Potter, E.; McCabe, M.; Baggerman, C. Smart Fabrics Technology Development; NASA: Houston, TX, USA, 2010. [Google Scholar]

- Jansen, K. Smart textiles: How electronics merge into our clothing. In Proceedings of the 20th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Hannover, Germany, 24–27 March 2019. [Google Scholar]

- International Electrotechnical Commission. Available online: https://www.iec.ch/dyn/www/f?p=103:30:5818194881611::::FSP_ORG_ID,FSP_LANG_ID:20537,25 (accessed on 1 August 2022).

- Sparkfun. Lilypad Protosnap Plus Kit. Sparkfun. Available online: https://www.sparkfun.com/products/12922 (accessed on 1 August 2022).

- Adafruit. Wearables. Adafruit. Available online: https://www.adafruit.com/category/65 (accessed on 1 August 2022).

- du Pont. Stretchable Inks for Wearable Electronics. du Pont. Available online: https://www.dupont.com/products/stetchable-inks-for-wearable-electronics.html (accessed on 7 January 2020).

- Smart Fabric Inks. Product. Smart Fabric Inks. Available online: http://www.fabinks.com/product/ (accessed on 1 August 2022).

- Primo1D. The Technology. Primo1D. Available online: https://www.primo1d.com/e-thread/the-technology (accessed on 1 August 2022).

- Bekaert. Conductive Fibers and Yarns for Smart Textiles. Bekaert. Available online: https://www.bekaert.com/en/products/basic-materials/textile/conductive-fibers-and-yarns-for-smart-textiles (accessed on 1 August 2022).

- Vieroth, R.; Löher, T.; Seckel, M.; Dils, C.; Kallmayer, C.; Ostmann, A.; Reichl, H. Stretchable circuit board technology and application. In Proceedings of the 2009 International Symposium on Wearable Computers (ISWC ‘09), Linz, Austria, 4–7 September 2009. [Google Scholar]

- Levy, S. Google Glass 2.0 Is a Startling Second Act. Wired. 18 July 2017. Available online: https://www.wired.com/story/google-glass-2-is-here/ (accessed on 1 August 2022).

- Kirsh, D. Mojo Vision Developing “Smart” Contact Lens. Mass Device. 17 January 2020. Available online: https://www.massdevice.com/mojo-vision-developing-smart-contact-lens/ (accessed on 1 August 2022).

- Moore, G.A. Crossing the Chasm: Marketing and Selling High-Tech Products to Mainstream Customers, Revised ed.; Harper Business: New York, NY, USA, 2006. [Google Scholar]

- Newmarker, C. 4 Medical Device Industry Trends Affecting Innovation. Medical Design & Outsourcing. 6 January 2020. Available online: https://www.medicaldesignandoutsourcing.com/4-medical-device-industry-trends-affecting-innovation/ (accessed on 1 August 2022).

- Dianese. Space Suits. Dianese. Available online: https://www.dainese.com/us/en/technology-innovation/space-suits.html (accessed on 1 August 2022).

- Arion. Wearable. Arion. Available online: https://www.arion.run/wearable/ (accessed on 1 August 2022).

- Crotti, N. Heraeus Medical Components and Myant Partner on Electrical Sensing for Textiles. Medical Design & Outsourcing. 22 January 2020. Available online: https://www.medicaldesignandoutsourcing.com/heraeus-medical-components-and-myant-partner-on-electrical-sensing-for-textiles/ (accessed on 1 August 2022).

- Texisense. Texisense Corporate Website. Texisense. Available online: https://www.texisense.com/ (accessed on 1 August 2022).

- Blaze Wear. About US: Blaze Wear. Blaze Wear. Available online: https://www.blazewear.com/about-us (accessed on 1 August 2022).

- Noe, R. How Team USA’s Self-Heating Olympic Jackets Work, and a List of the Design Firms That Helped to Create Them. Core77. 12 February 2018. Available online: https://www.core77.com/posts/73270/How-Team-USAs-Self-Heating-Olympic-Jackets-Work-and-a-List-of-the-Design-Firms-That-Helped-to-Create-Them (accessed on 1 August 2022).

- TIBTECH Innovations. Home: TIBTECH Innovations. TIBTECH Innovations. Available online: https://www.tibtech.com/ (accessed on 1 August 2022).

- Torah, R.; Wei, Y.; Grabham, N.; Li, Y.; de Vos, M.; Todorov, T.; Popov, B.; Marinov, V.; Stoyanov, S.; Todorov, V.; et al. Enabling platform technology for smart fabric design and printing. J. Eng. Fibers Fabr. 2019, 14, 1–14. [Google Scholar] [CrossRef]

- Calisch, S.; Gershenfeld, N.A. Kirigami Fabrication of Shaped, Flat-Foldable Cellular Materials Based on the Tachi-Miura Polyhedron; MIT: Boston, MA, USA, 2018. [Google Scholar]

| Material | Conductivity | Percolation Threshold * |

|---|---|---|

| Copper | 5.87 × 107 S/m [30] | 37% volume [31] |

| Gold | 4.42 × 107 S/m [30] | 39% volume for co-sputtered gold/poly(tetrafluoroethylene) (PTFE) film [32] |

| Silver | 6.21 × 107 S/m [30] | 7–16 vol% in polyvinylidene difluoride (PVDF) [33] |

| Carbon Black | 101–104 S/m [34] | 0.58 wt% in polyethylene terephthalate (PET) [35] |

| Graphene | 6.0 × 105 S/m (isolated) [36] | 0.47 vol% in PET [37] |

| Carbon Nanotube (CNT) | 106–107 S/m [38] | 1.2 wt% (CNT in PVDF) [39] |

| Ionic Liquid | 1.3 × 10−2 –1.4 × 100 S/m [40] | Decreased percolation threshold of graphene in urethane from 3.21 wt% to 1.99 wt% due to better graphene dispersion [41] |

| PVDF | 10−2 S/m [42] | N/A—typically used as a matrix |

| Type | Material | Format | Mechanism | Ref. |

|---|---|---|---|---|

| Motion | Rigid electronic | Inertial motion capture | magnetometers, accelerometers, and gyroscopes | [56] |

| Bending sensor | Optical fiber (Bragg grating) | Optics | [22] | |

| Carbon black dip-coated co-polyester elastomer or spandex filament | Sensors attached to t-shirt | Strain-induced disruption and connection of conductive pathways affects electrical resistance (piezoresistive). | [56] | |

| Machine knit elastomeric and conductive (80% polyester, 20% stainless steel) multifilament yarns | Rehabilitation glove | Strain affects contact resistance (Holm’s contact theory) | [44] | |

| Flexible, non-crocking reduced graphene oxide fabric through dip coating and nickel electroless plating | Strain sensor | Strain affects resistance | [54] | |

| Conductive polymer filaments | Strain sensor | resistance change in paired (stretched/relaxed) sensors | [59] | |

| Hand-knit together cotton yarn and wire | Inductor coils | Increasing radius increases inductance | [60] | |

| Physiology | Electrode | Carbon or conductive yarns (stainless steel) | Change in resistance due to stimuli | [50] |

| highly conductive, nitrogen-doped working electrodes | carbonized or graphitized woven silk fabric | Circuit converts signal into data for mobile display Current: glucose, lactate Potential: sodium, potassium | [61] | |

| “wet” electrode (sweat is electrolyte) | conductive knit fabric (Shieldex Fabric by Statex) knife-coated with a conductive paste | Measure Biopotential | [62] | |

| (EEG) sensor | layers of conductive and sweat absorbent fabrics | Measure Biopotential (~100 μV) | [63] | |

| Blood oxygenation | Rigid electronics | oxygenated and deoxygenated hemoglobin absorb different amounts of light | [52] | |

| Antennas | Conductive fabric attached to silicone rubber substrate | Resonance frequency interference between antennas corresponds to brain atrophy and lateral ventricle enlargement | [64] | |

| Environment | Temperature sensors | printing conductive inks | change resistance in response to temperature [22] | [65] |

| Temperature sensors | weaving electronic strips into textile | change resistance in response to temperature [22] | [65] | |

| Temperature sensors | encapsulating temperature sensor in yarn core | change resistance in response to temperature [22] | [65] | |

| Humidity sensor | poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) on a substrate of polyacrylonitrile nanofibers | materials change conductivity in response to moisture | [22] | |

| flexible ammonia sensor | cotton yarn coated with carbon nanotube ink | exposure to chemical changes resistance, “chemiresistor” | [66] | |

| multimodal | “Carbon Nanotube Paint” coated degummed silk fiber | electrical resistance changes with stimuli | [67] |

| Type | Material | Mechanism | Ref. |

|---|---|---|---|

| Speakers | sandwiching layers of piezoelectric polyvinylidene difluoride (PVDF) film/zinc oxide pillars on fabrics printed with conductive inks | Electronics | [14] |

| Mechanical actuator | Motorized seams sewn onto fabric | pulling seam changes the textile shape | [72] |

| Sensor/actuator | sewing, couching, shape memory alloy fiber onto fabric and painting conductive ink | strain sensor which responds to cutting, heating, or pressure | [73] |

| Mechanical actuator | conductive textiles cut, coated, and laminated | Electro-adhesive actuators and dielectric elastomer actuators | [74] |

| Display | knit or woven electroluminescent fibers | electrically controlled fabric visual display | [75] |

| Display | tactile enhanced fabric display | electrostatically actuated with electrodes | [76] |

| Vibrotactile displays | film | tactile elements operate independently based on mechanical resonance frequency | [77] |

| Component | Company | Description | Ref. |

|---|---|---|---|

| Sensor + Actuator + Interconnects | Dupont | Stretchable inks for wearables: carbon, silver, or silver/silver chloride conductor encapsulant material | [118] |

| Sensor + Actuator + Interconnects | FabInks | Smart fabric inks (ultraviolet (UV) or thermal cured) interface, encapsulation, conductor, dielectric, piezoelectric, thermochromic, electrode, sacrificial | [119] |

| Sensor | Primo1D e-Thread | RFID yarn: yarn twisted around chip to hide it [103] | [120] |

| Sensor + Actuator + Interconnects | Bekaert Fibre Technologies | Conductive yarn 1–80 μm diameter, 8–14 μm fibers | [26,121] |

| Actuator Fabric | Thermolactyl | Triboelectric heating fiber | [103] |

| Journal Focus | Purpose | Disciplines |

|---|---|---|

| Prototypes of Wearables | Focused on e-textile system (power, sensing/actuating, connections). | Electrical and computer engineering, information systems |

| User experience/ adoption of tech | Voice of the customer, market analysis | Business, marketing, design, computer–human interface (CHI), psychology, philosophy |

| Materials processing | Material properties and interactions, integration into a textile or a wearable medium | Materials science, chemical engineering, mechanical engineering, plastics engineering, textile sciences |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruckdashel, R.R.; Khadse, N.; Park, J.H. Smart E-Textiles: Overview of Components and Outlook. Sensors 2022, 22, 6055. https://doi.org/10.3390/s22166055

Ruckdashel RR, Khadse N, Park JH. Smart E-Textiles: Overview of Components and Outlook. Sensors. 2022; 22(16):6055. https://doi.org/10.3390/s22166055

Chicago/Turabian StyleRuckdashel, Rebecca R., Ninad Khadse, and Jay Hoon Park. 2022. "Smart E-Textiles: Overview of Components and Outlook" Sensors 22, no. 16: 6055. https://doi.org/10.3390/s22166055

APA StyleRuckdashel, R. R., Khadse, N., & Park, J. H. (2022). Smart E-Textiles: Overview of Components and Outlook. Sensors, 22(16), 6055. https://doi.org/10.3390/s22166055