Accounting for Viscoelasticity When Interpreting Nano-Composite High-Deflection Strain Gauges

Abstract

:1. Introduction

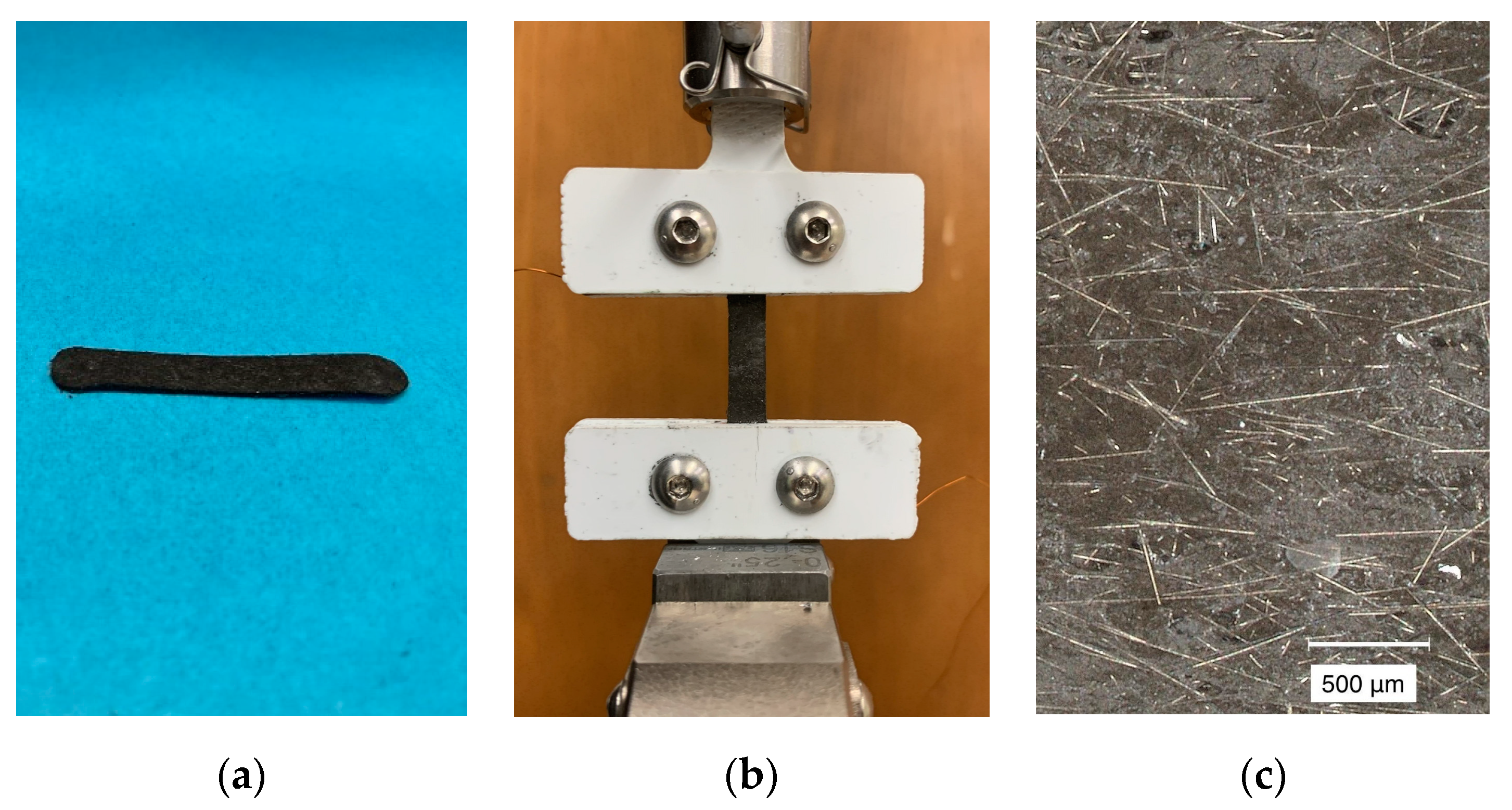

2. Materials and Methods

2.1. Model Development

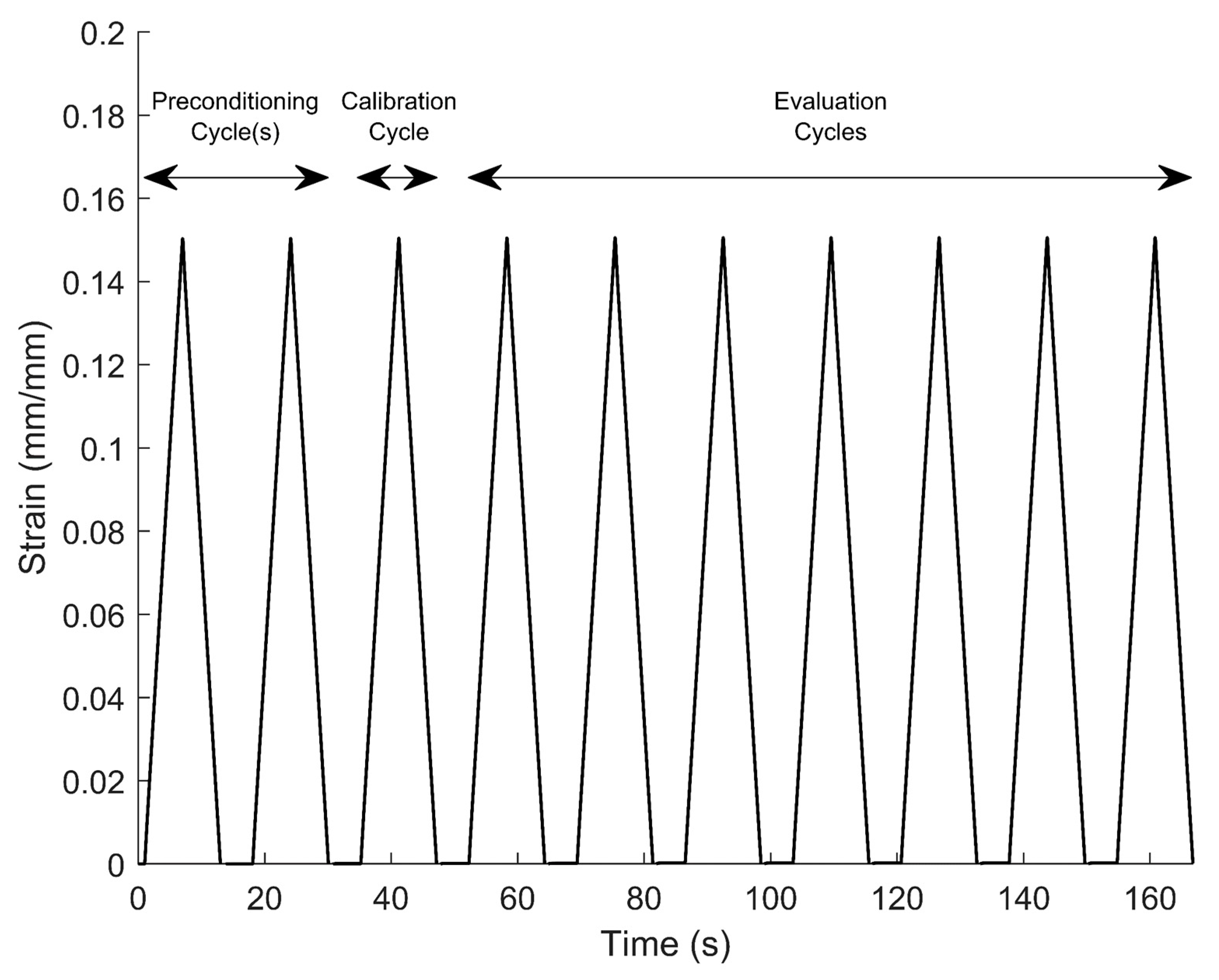

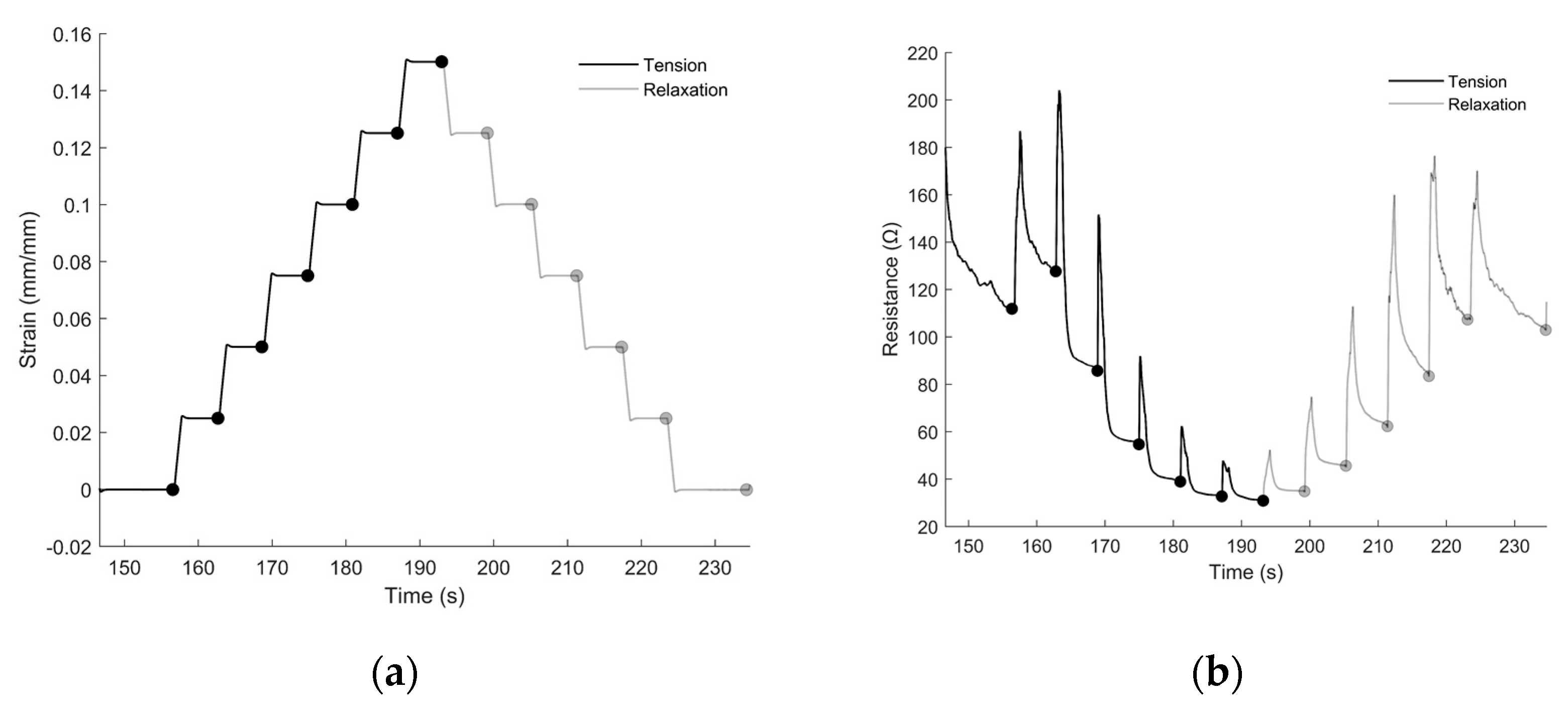

2.1.1. Experimentation

2.1.2. Quasi-Static Model

- Determine a functional relationship between sensor strain and sensor resistance that approximates the steady-state behavior, based upon tabulating and interpolating experimental data.

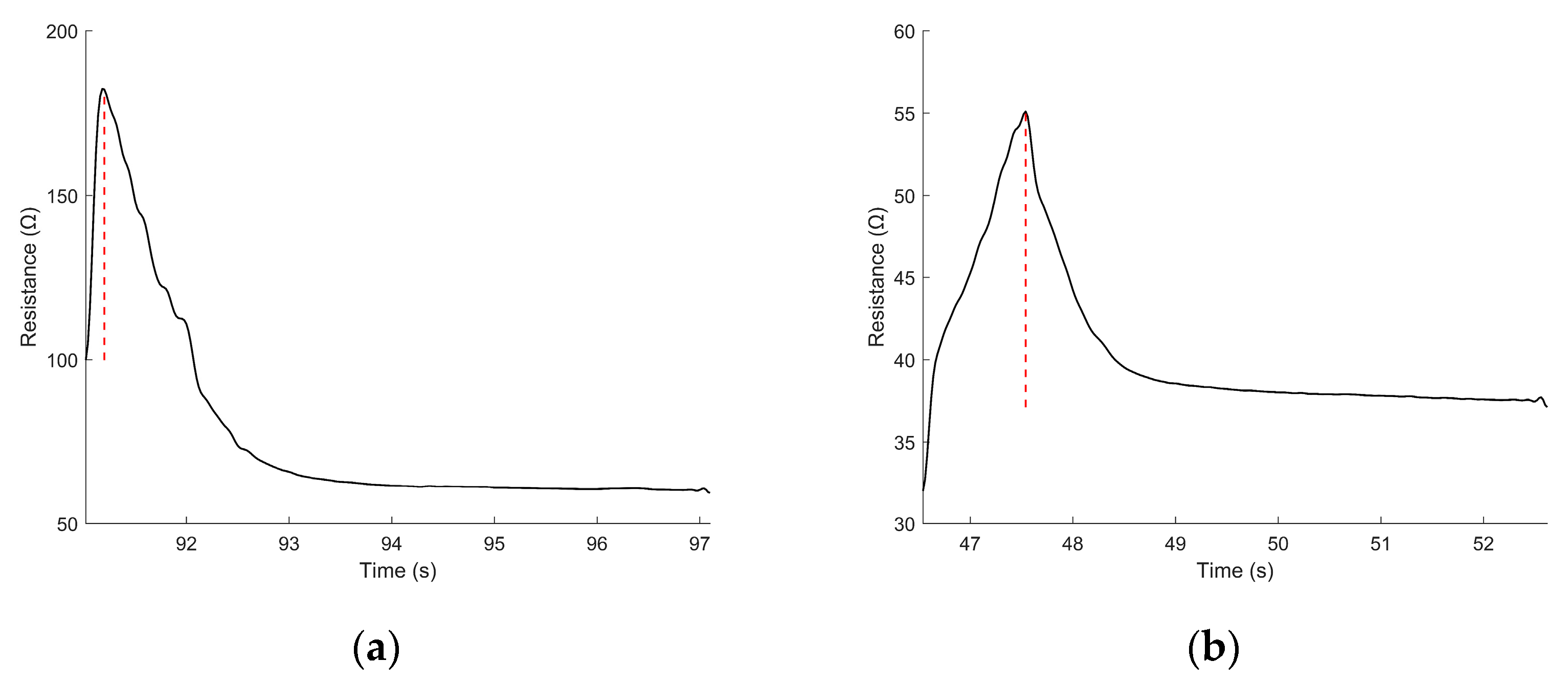

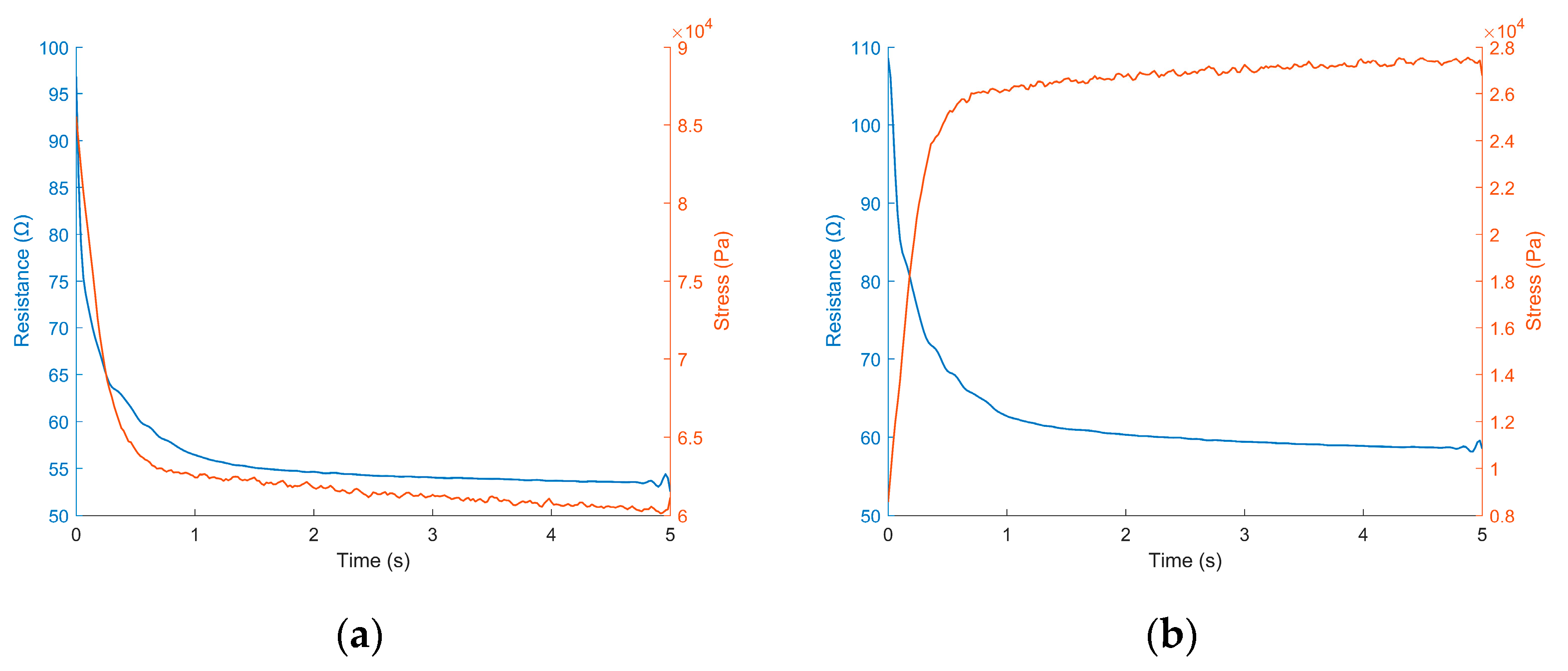

- Incorporate the short-term resistance peaks (“spikes”) and subsequent decay into the model based on observations of how strain magnitude and strain rate affect resistance spike magnitude and decay rate.

2.1.3. Dynamic Model

2.1.4. Combined Model

2.2. Model Validation

- Quasi-static interpretation: The static-strain resistance model (Equation (1)) was used to interpret the sensor resistance under static conditions to predict the sensor strain.

- Sensor output predictions: The dynamic-strain resistance model (Equation (3)) was used to predict sensor resistance as a function of a known strain and strain rate.

- Biomechanical application: The dynamic-strain resistance model (Equation (3)) was used to interpret sensor strain and strain rate during a tensile test that imitates cyclical biomechanical function.

2.2.1. Quasi-Static Interpretation

2.2.2. Sensor-Output Predictions

2.2.3. Model Evaluation during Simulated Biomechanical Application

3. Results

3.1. Model

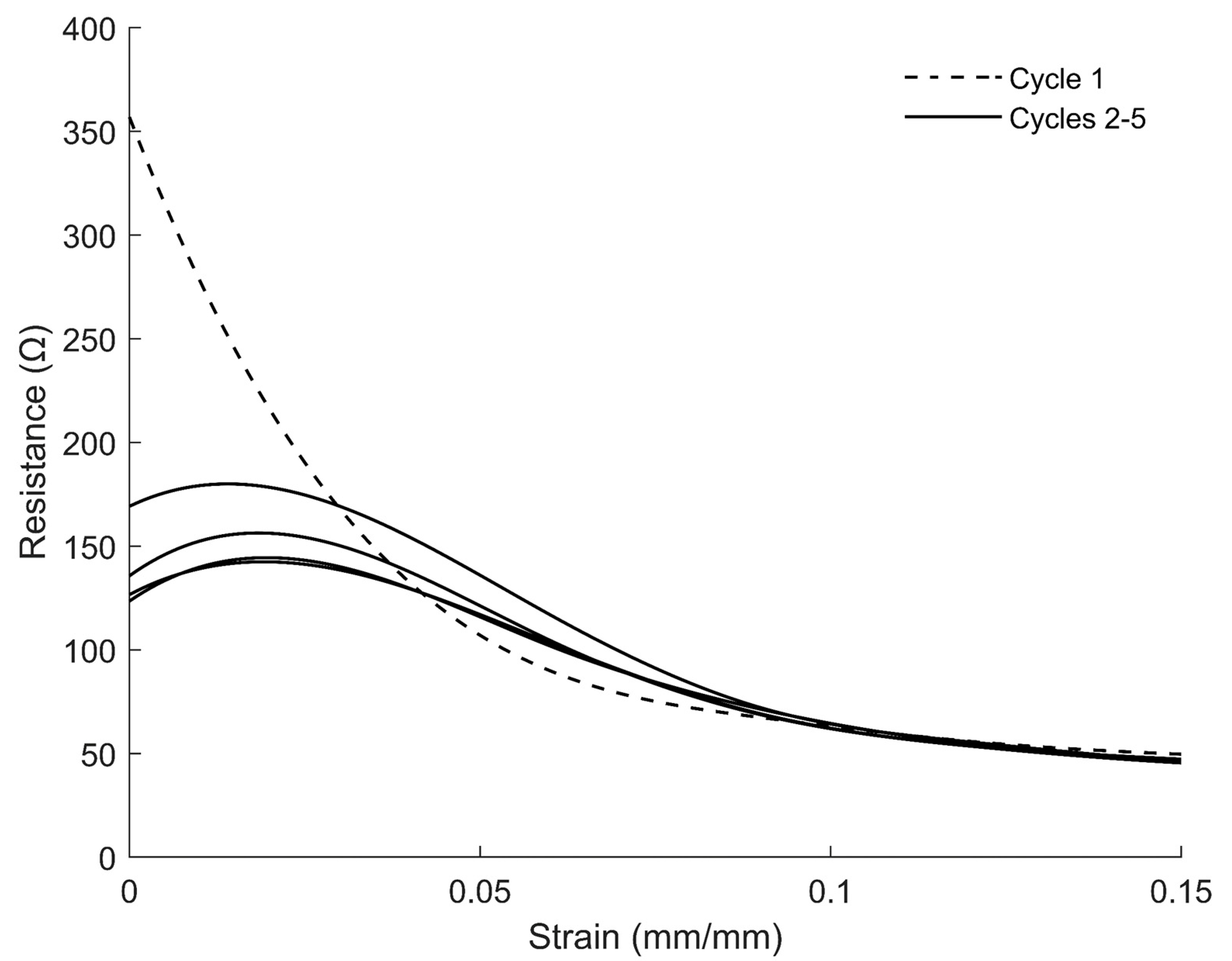

3.1.1. Quasi-Static Model

3.1.2. Dynamic Model

3.1.3. Combined Model

3.2. Model Validation

3.2.1. Quasi-Static Model Performance

3.2.2. Dynamic Model’s Performance

3.2.3. Model Evaluation during Simulated Biomechanical Application

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Clayton, M.F.; Bilodeau, R.A.; Bowden, A.E.; Fullwood, D.T. Nanoparticle orientation distribution analysis and design for polymeric piezoresistive sensors. Sens. Actuators A Phys. 2020, 303, 111851. [Google Scholar] [CrossRef]

- Johnson, O.K.; Kaschner, G.C.; Mason, T.A.; Fullwood, D.T.; Hansen, G. Optimization of nickel nanocomposite for large strain sensing applications. Sens. Actuators A Phys. 2011, 166, 40–47. [Google Scholar] [CrossRef]

- Wood, D.S.; Fullwood, D.T.; Bowden, A.E. Multi-Objective Bayesian Optimization for the Design of a Piezoresistive Composite; Society for the Advancement of Material and Process Engineering: Diamond Bar, CA, USA, 2021. [Google Scholar]

- Shamsi, R.; Asghari, G.H.; Sadeghi, G.M.M.; Nazarpoorfard, H. The effect of multiwalled carbon nanotube and crosslinking degree on creep-recovery behavior of PET waste originated-polyurethanes and their nanocomposites. Polym. Compos. 2018, 39, E1013–E1024. [Google Scholar] [CrossRef]

- Yao, Z.; Wu, D.; Chen, C.; Zhang, M. Creep behavior of polyurethane nanocomposites with carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2013, 50, 65–72. [Google Scholar] [CrossRef]

- Guedes, R.M.; Singh, A.; Pinto, V. Viscoelastic modelling of creep and stress relaxation behaviour in PLA-PCL fibres. Fibers Polym. 2017, 18, 2443–2453. [Google Scholar] [CrossRef]

- Koes, B.W.; van Tulder, M.; Thomas, S. Diagnosis and treatment of low back pain. Br. Med. J. 2006, 332, 1430–1434. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- National Institute of Neurological Disorders and Stroke. Low Back Pain Fact Sheet. 2021. Available online: https://www.ninds.nih.gov/sites/default/files/low_back_pain_20-ns-5161_march_2020_508c.pdf (accessed on 28 October 2021).

- Andersson, G.B. Epidemiological features of chronic low-back pain. Lancet 1999, 354, 581–585. [Google Scholar] [CrossRef]

- Marras, W.S.; Ferguson, S.A.; Gupta, P.; Bose, S.; Parnianpour, M.; Kim, J.Y.; Crowell, R.R. The quantification of low back disorder using motion measures: Methodology and validation. Spine 1999, 24, 2091. [Google Scholar] [CrossRef] [PubMed]

- Martineau, A.D. Estimation of Knee Kinematics Using Non-Monotonic Nanocomposite High-Deflection Strain Gauges. Master’s Thesis, Brigham Young University, Ann Arbor, MI, USA, 2018; p. 28103751. Available online: http://erl.lib.byu.edu/login/?url=https://www.proquest.com/dissertations-theses/estimation-knee-kinematics-using-non-monotonic/docview/2432850839/se-2?accountid=4488 (accessed on 21 May 2021).

- Remington, T.D. Biomechanical Applications and Modeling of Quantum Nano-Composite Strain Gauges. Master’s Thesis, Brigham Young University, Ann Arbor, MI, USA, 2014; p. 28105896. Available online: http://erl.lib.byu.edu/login/?url=https://www.proquest.com/dissertations-theses/biomechanical-applications-modeling-quantum-nano/docview/2490992132/se-2?accountid=4488 (accessed on 28 October 2021).

- Hyatt, T.; Fullwood, D.; Bradshaw, R.; Bowden, A.; Johnson, O. Nano-composite sensors for wide range measurement of ligament strain. In Experimental and Applied Mechanics; Springer: Berlin, Germany, 2011; Volume 6, pp. 359–364. [Google Scholar]

- Baradoy, D.A. Composition Based Modaling of Silicone Nano-Composite Strain Gauges. Master’s Thesis, Brigham Young University, Ann Arbor, MI, USA, 2015; p. 28105748. Available online: http://erl.lib.byu.edu/login/?url=https://www.proquest.com/dissertations-theses/composition-based-modaling-silicone-nano/docview/2445589613/se-2?accountid=4488 (accessed on 19 October 2021).

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes–Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef] [PubMed]

- Diani, J.; Fayolle, B.; Gilormini, P. A review on the Mullins effect. Eur. Polym. J. 2009, 45, 601–612. [Google Scholar] [CrossRef] [Green Version]

- Jeong, Y.R.; Park, H.; Jin, S.W.; Hong, S.Y.; Lee, S.-S.; Ha, J.S. Highly Stretchable and Sensitive Strain Sensors Using Fragmentized Graphene Foam. Adv. Funct. Mater. 2015, 25, 4228–4236. [Google Scholar] [CrossRef]

| Strain Rate (mm/s) | Linear Strain (Percent) |

|---|---|

| 5.00 | 11.26 |

| 0.50 | 12.35 |

| 0.05 | 12.41 |

| 0 | 1.468 × 106 | −1.793 × 105 | 4.520 × 103 | 1.383 × 102 |

| 0.025 | 1.468 × 106 | −6.906 × 104 | −1.697 × 103 | 1.622 × 102 |

| 0.05 | 3.629 × 105 | 4.120 × 104 | −2.394 × 103 | 9.940 × 101 |

| 0.075 | −6.710 × 104 | 1.399 × 104 | −1.014 × 103 | 5.963 × 101 |

| 0.10 | −8.356 × 104 | 8.941 × 103 | −4.400 × 102 | 4.194 × 101 |

| 0.125 | −8.356 × 104 | 2.674 × 103 | −1.496 × 102 | 3.522 × 101 |

| Strain Rate (mm/s) | ||||

|---|---|---|---|---|

| 0.05 | 8.51 | 8.50 | 5.69 | 4.64 |

| 0.5 | 17.92 | 15.18 | 7.38 | 5.05 |

| 5.0 | 16.79 | 11.16 | 6.40 | 6.51 |

| Rate (mm/s) | Strain (Percent) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 2.5 | 5 | 7.5 | 10 | 12.5 | 15 | |

| 0.05 | 0.182 | 0.187 | 0.263 | 0.319 | 0.230 | 0.264 | 0.214 |

| 0.5 | 0.429 | 0.534 | 0.673 | 0.785 | 0.700 | 0.566 | 0.449 |

| 5.0 | 0.915 | 0.981 | 1.192 | 1.358 | 1.173 | 0.899 | 0.751 |

| Rate (mm/s) | Strain (Percent) | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 2.5 | 5 | 7.5 | 10 | 12.5 | 15 | |

| 0.05 | 0.433 | 0.718 | 0.778 | 0.804 | 0.818 | 0.815 | 0.736 |

| 0.5 | 0.875 | 1.914 | 1.979 | 2.011 | 2.089 | 2.220 | 1.641 |

| 5.0 | 1.121 | 4.390 | 3.178 | 4.051 | 4.176 | 4.231 | 3.391 |

| Strain Rate (mm/s) | R2 | |

|---|---|---|

| 0.05 | 0.96 | 5.00 |

| 0.50 | 0.96 | 4.03 |

| 5.00 | 0.80 | 8.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baker, S.A.; McFadden, M.D.; Bowden, E.E.; Bowden, A.E.; Mitchell, U.H.; Fullwood, D.T. Accounting for Viscoelasticity When Interpreting Nano-Composite High-Deflection Strain Gauges. Sensors 2022, 22, 5239. https://doi.org/10.3390/s22145239

Baker SA, McFadden MD, Bowden EE, Bowden AE, Mitchell UH, Fullwood DT. Accounting for Viscoelasticity When Interpreting Nano-Composite High-Deflection Strain Gauges. Sensors. 2022; 22(14):5239. https://doi.org/10.3390/s22145239

Chicago/Turabian StyleBaker, Spencer A., McKay D. McFadden, Emma E. Bowden, Anton E. Bowden, Ulrike H. Mitchell, and David T. Fullwood. 2022. "Accounting for Viscoelasticity When Interpreting Nano-Composite High-Deflection Strain Gauges" Sensors 22, no. 14: 5239. https://doi.org/10.3390/s22145239

APA StyleBaker, S. A., McFadden, M. D., Bowden, E. E., Bowden, A. E., Mitchell, U. H., & Fullwood, D. T. (2022). Accounting for Viscoelasticity When Interpreting Nano-Composite High-Deflection Strain Gauges. Sensors, 22(14), 5239. https://doi.org/10.3390/s22145239