Recent Advances in Flexible Sensors and Their Applications

Abstract

:1. Introduction

2. Selection of Materials

2.1. Metal Materials

2.2. Carbon-Based Materials

2.3. Polymer Materials

3. General Design and Categories of Flexible Sensors

3.1. Piezo-Resistive Sensor

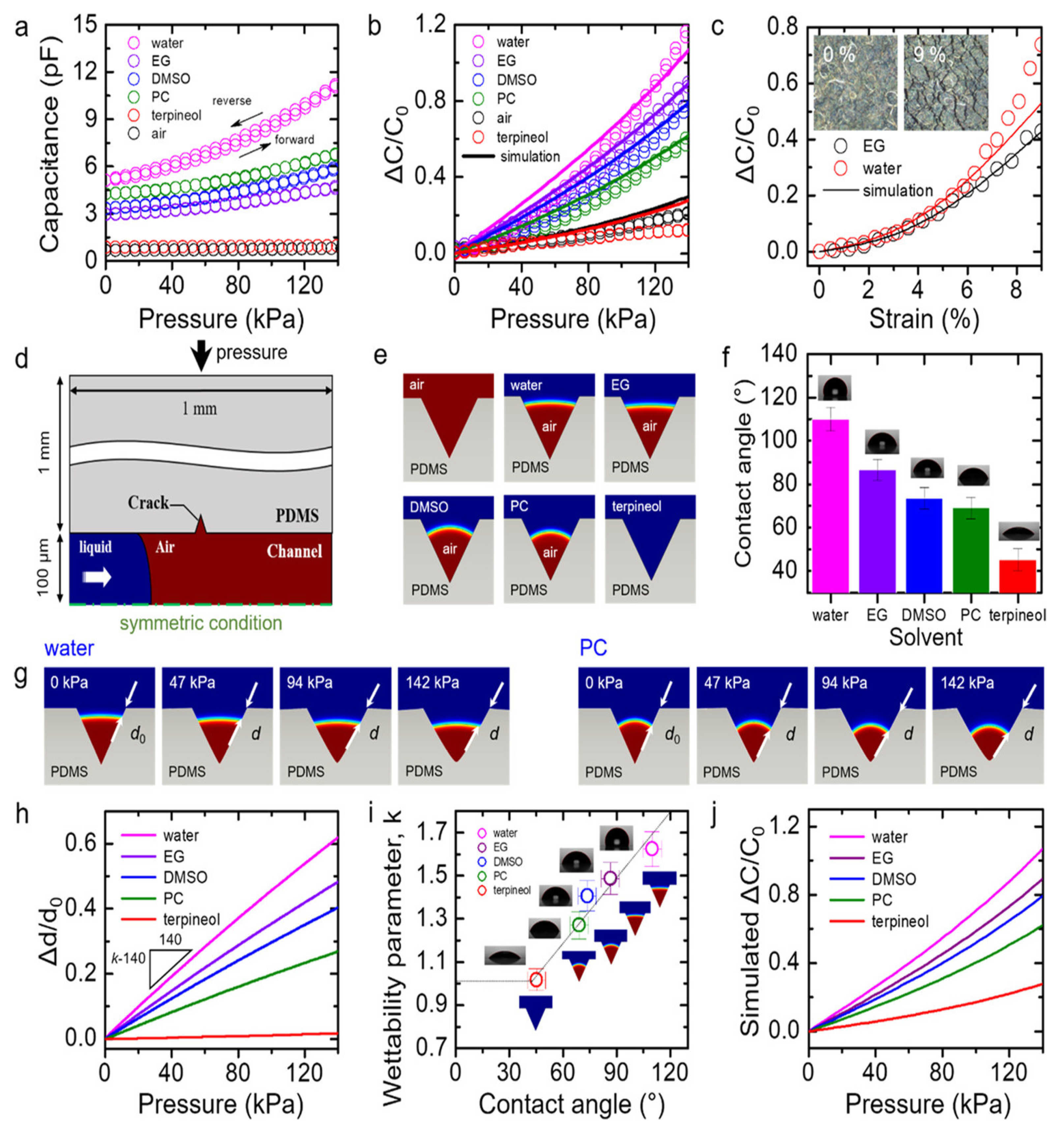

3.2. Capacitive Sensor

3.3. Piezoelectric Sensor

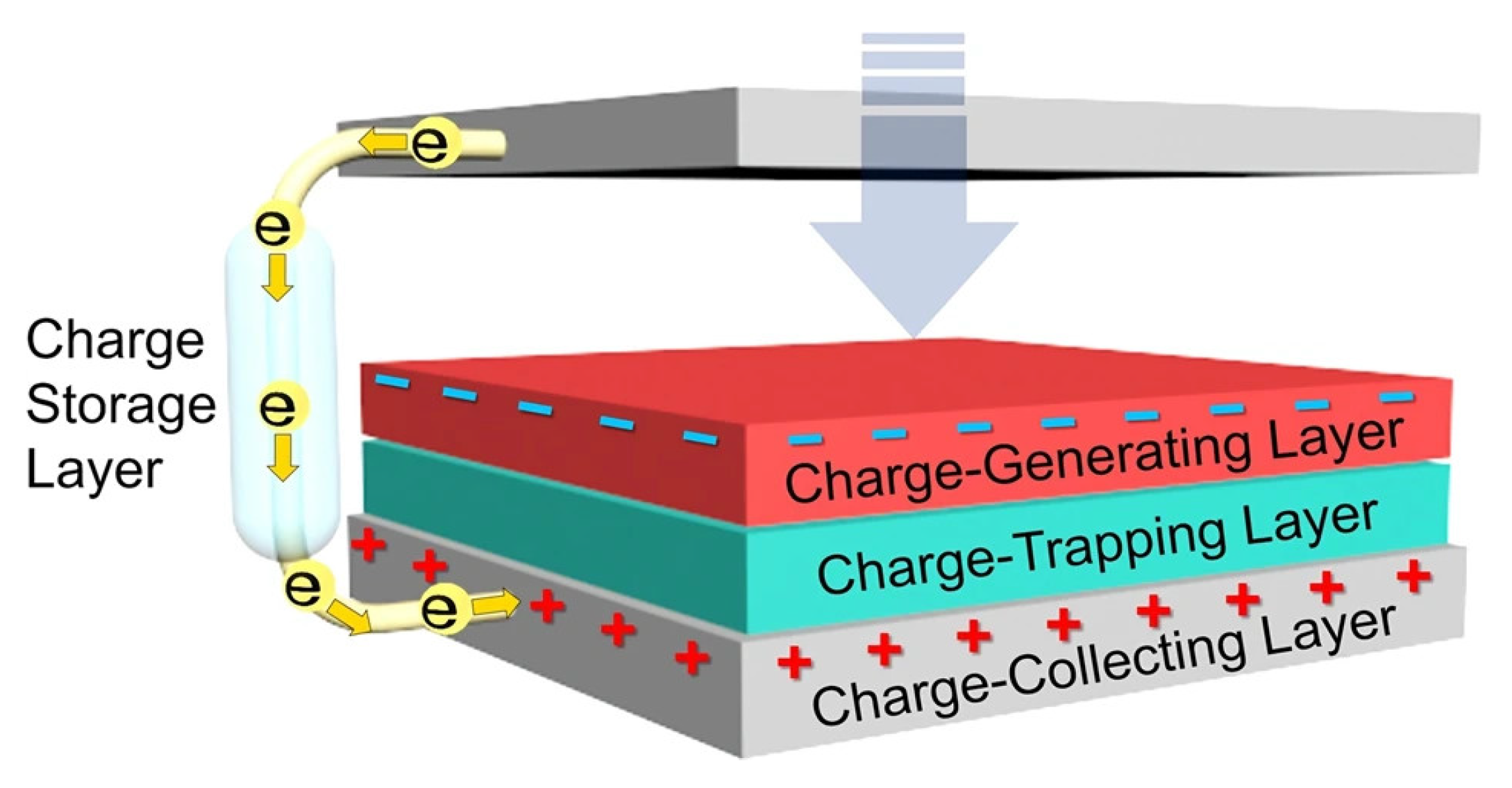

3.4. Triboelectric Sensor

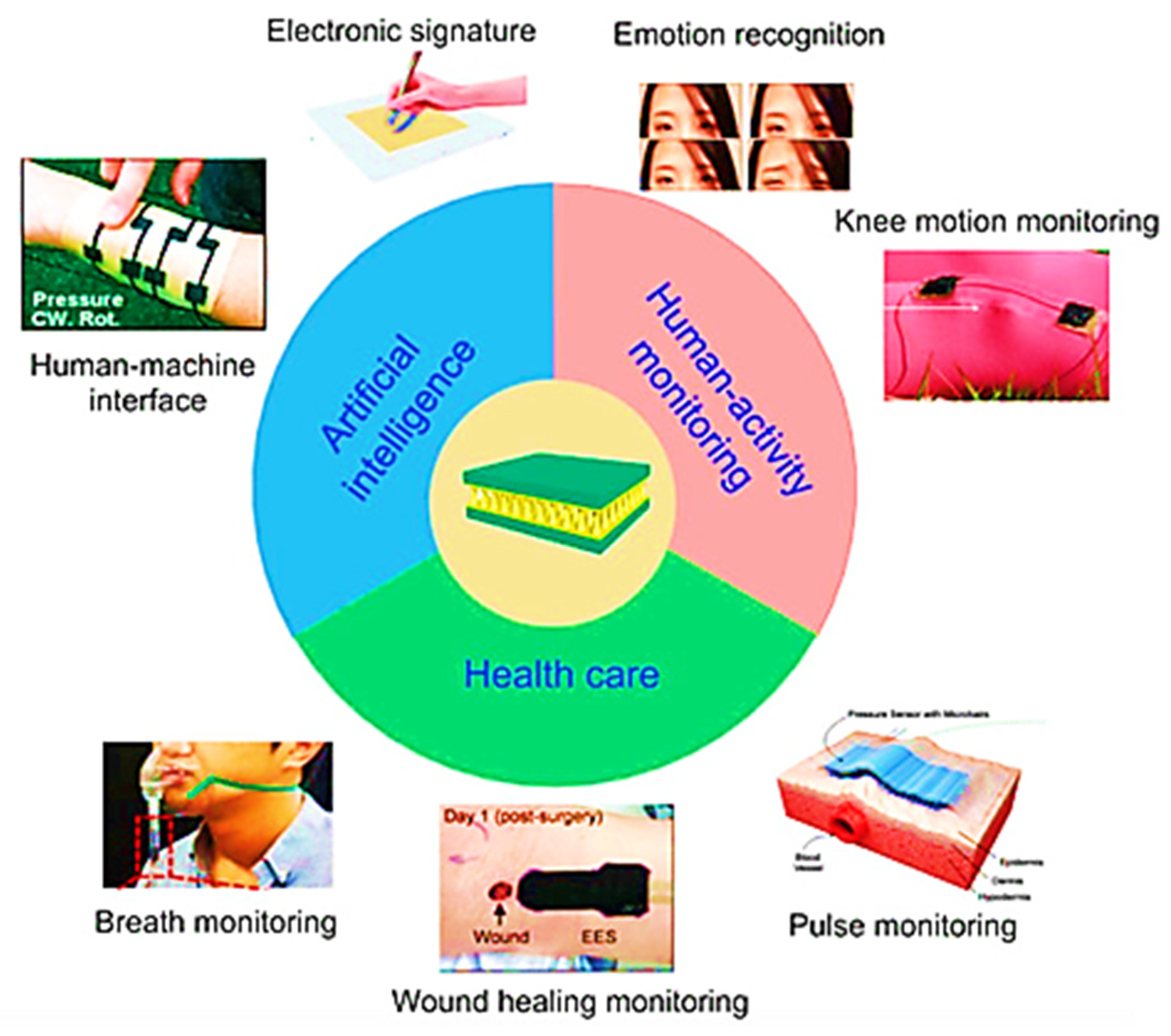

4. Applications of Flexible Sensors

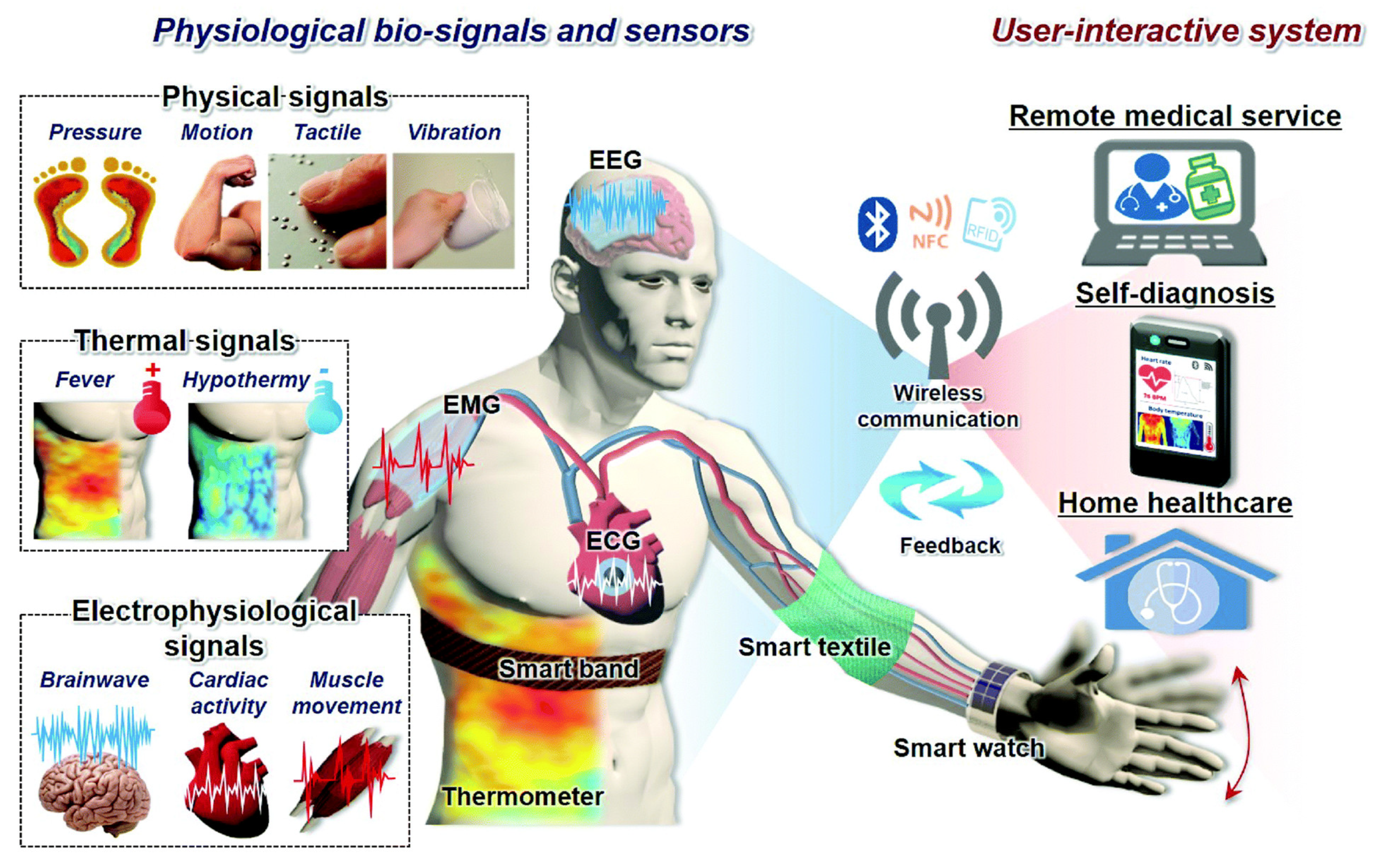

4.1. Flexible Sensors as Biomedical Devices

4.2. Flexible Sensors as Wearable Device

4.3. Flexible Sensors for Soft Robotics Applications

5. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, T.; Lee, W.; Kim, S.W.; Kim, J.J.; Kim, B.S. Flexible Textile Strain Wireless Sensor Functionalized with Hybrid Carbon Nanomaterials Supported ZnO Nanowires with Controlled Aspect Ratio. Adv. Funct. Mater. 2016, 26, 6206–6214. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, L.; Yeo, J.C.; Lim, C.T. Flexible hybrid sensors for health monitoring: Materials and mechanisms to render wearability. Adv. Mater. 2020, 32, 1902133. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Qi, J.; Fan, S.; Qiao, Z.; Yeo, J.C.; Lim, C.T. Flexible Wearable Sensors for Cardiovascular Health Monitoring. Adv. Healthc. Mater. 2021, 10, 2100116. [Google Scholar] [CrossRef] [PubMed]

- Saleh, M.A.; Kempers, R.; Melenka, G.W. A comparative study on the electromechanical properties of 3D-Printed rigid and flexible continuous wire polymer composites for structural health monitoring. Sens. Actuators A Phys. 2021, 328, 112764. [Google Scholar] [CrossRef]

- Lee, G.; Wei, Q.; Zhu, Y. Emerging Wearable Sensors for Plant Health Monitoring. Adv. Funct. Mater. 2021, 31, 2106475. [Google Scholar] [CrossRef]

- Sankar, V.; Nambi, A.; Bhat, V.N.; Sethy, D.; Balasubramaniam, K.; Das, S.; Guha, M.; Sundara, R. Waterproof Flexible Polymer-Functionalized Graphene-Based Piezoresistive Strain Sensor for Structural Health Monitoring and Wearable Devices. ACS Omega 2020, 5, 12682–12691. [Google Scholar] [CrossRef]

- Yin, R.; Wang, D.; Zhao, S.; Lou, Z.; Shen, G. Wearable sensors-enabled human–machine interaction systems: From design to application. Adv. Funct. Mater. 2021, 31, 2008936. [Google Scholar] [CrossRef]

- He, F.; You, X.; Wang, W.; Bai, T.; Xue, G.; Ye, M. Recent Progress in Flexible Microstructural Pressure Sensors toward Human–Machine Interaction and Healthcare Applications. Small Methods 2021, 5, 2001041. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, Z.; Zhong, M.; Wan, P.; Zhang, W.; Zhang, L. A Flexible Wearable Pressure Sensor with Bioinspired Microcrack and Interlocking for Full-Range Human-Machine Interfacing. Small 2018, 14, e1803018. [Google Scholar] [CrossRef]

- Chen, R.; Luo, T.; Geng, D.; Shen, Z.; Zhou, W. Facile fabrication of a fast-response flexible temperature sensor via laser reduced graphene oxide for contactless human-machine interface. Carbon 2022, 187, 35–46. [Google Scholar] [CrossRef]

- Guo, Y.; Zhong, M.; Fang, Z.; Wan, P.; Yu, G. A Wearable Transient Pressure Sensor Made with MXene Nanosheets for Sensitive Broad-Range Human–Machine Interfacing. Nano Lett. 2019, 19, 1143–1150. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Karakurt, I.; Beker, L.; Kubota, Y.; Xu, R.; Ho, K.Y.; Zhao, S.; Zhong, J.; Zhang, M.; Wang, X.; et al. Piezoresistive stretchable strain sensors with human machine interface demonstrations. Sens. Actuators A Phys. 2018, 279, 46–52. [Google Scholar] [CrossRef]

- Wang, M.; Wang, T.; Luo, Y.; He, K.; Pan, L.; Li, Z.; Cui, Z.; Liu, Z.; Tu, J.; Chen, X. Fusing Stretchable Sensing Technology with Machine Learning for Human–Machine Interfaces. Adv. Funct. Mater. 2021, 31, 2008807. [Google Scholar] [CrossRef]

- Heng, W.; Solomon, S.; Gao, W. Flexible Electronics and Devices as Human–Machine Interfaces for Medical Robotics. Adv. Mater. 2021, 34, 2107902. [Google Scholar] [CrossRef]

- Yiu, C.; Wong, T.; Liu, Y.; Yao, K.; Zhao, L.; Li, D.; Hai, Z.; Zheng, H.; Wang, Z.; Yu, X. Skin-Like Strain Sensors Enabled by Elastomer Composites for Human–Machine Interfaces. Coatings 2020, 10, 711. [Google Scholar] [CrossRef]

- Wan, Y.; Wang, Y.; Guo, C.F. Recent progresses on flexible tactile sensors. Mater. Today Phys. 2017, 1, 61–73. [Google Scholar] [CrossRef]

- Liao, X.; Liao, Q.; Yan, X.; Liang, Q.; Si, H.; Li, M.; Wu, H.; Cao, S.; Zhang, Y. Flexible and Highly Sensitive Strain Sensors Fabricated by Pencil Drawn for Wearable Monitor. Adv. Funct. Mater. 2015, 25, 2395–2401. [Google Scholar] [CrossRef]

- Li, J.; Bao, R.; Tao, J.; Peng, Y.; Pan, C. Recent progress in flexible pressure sensor arrays: From design to applications. J. Mater. Chem. C 2018, 6, 11878–11892. [Google Scholar] [CrossRef]

- Jiang, P.; Ji, Z.; Zhang, X.; Liu, Z.; Wang, X. Recent advances in direct ink writing of electronic components and functional devices. Prog. Addit. Manuf. 2018, 3, 65–86. [Google Scholar] [CrossRef]

- Costa, J.C.; Spina, F.; Lugoda, P.; Garcia-Garcia, L.; Roggen, D.; Munzenrieder, N. Flexible Sensors—From Materials to Applications. Technologies 2019, 7, 35. [Google Scholar] [CrossRef] [Green Version]

- Hogas, I.; Fosalau, C.; Zet, C. A new strain sensor based on electrospinning and thin film technologies. In Proceedings of the 2016 International Conference and Exposition on Electrical and Power Engineering (EPE), Iasi, Romania, 20–22 October 2016. [Google Scholar]

- Zhao, Q.; Zhao, M.; Qiu, J.; Lai, W.-Y.; Pang, H.; Huang, W. One Dimensional Silver-based Nanomaterials: Preparations and Electrochemical Applications. Small 2017, 13, 1701091. [Google Scholar] [CrossRef]

- Ahn, K.; Kim, K.; Kim, J. Thermal conductivity and electric properties of epoxy composites filled with TiO2 -coated copper nanowire. Polymer 2015, 76, 313–320. [Google Scholar] [CrossRef]

- Gong, S.; Zhao, Y.; Yap, L.W.; Shi, Q.; Wang, Y.; Bay, J.A.P.B.; Lai, D.T.H.; Uddin, H.; Cheng, W. Fabrication of Highly Transparent and Flexible NanoMesh Electrode via Self-assembly of Ultrathin Gold Nanowires. Adv. Electron. Mater. 2016, 2, 1600121. [Google Scholar] [CrossRef]

- Chung, W.-H.; Kim, S.-H.; Kim, H.-S. Welding of silver nanowire networks via flash white light and UV-C irradiation for highly conductive and reliable transparent electrodes. Sci. Rep. 2016, 6, 32086. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, X.; Wei, Y.; Chen, S.; Lin, Y.; Liu, L.; Li, J. A linear and large-range pressure sensor based on a graphene/silver nanowires nanobiocomposites network and a hierarchical structural sponge. Compos. Sci. Technol. 2018, 155, 108–116. [Google Scholar] [CrossRef]

- Kwon, S.; Kim, S.; Kim, I.; Hong, Y.K.; Na, S. Direct 3D Printing of Graphene Nanoplatelet/Silver Nanoparticle-Based Nanocomposites for Multiaxial Piezoresistive Sensor Applications. Adv. Mater. Technol. 2019, 4, 1800500. [Google Scholar] [CrossRef]

- Wang, X.; Van Humbeeck, J.; Verlinden, B.; Kustov, S. Thermal cycling induced room temperature aging effect in Ni-rich NiTi shape memory alloy. Scr. Mater. 2016, 113, 206–208. [Google Scholar] [CrossRef]

- Dickey, M.; Chiechi, R.; Larsen, R.J.; Weiss, E.A.; Weitz, D.A.; Whitesides, G.M. Eutectic Gallium-Indium (EGaIn): A Liquid Metal Alloy for the Formation of Stable Structures in Microchannels at Room Temperature. Adv. Funct. Mater. 2008, 18, 1097–1104. [Google Scholar] [CrossRef]

- Ali, S.; Maddipatla, D.; Narakathu, B.B.; Chlaihawi, A.A.; Emamian, S.; Janabi, F.; Bazuin, B.J.; Atashbar, M.Z. Flexible Capacitive Pressure Sensor Based on PDMS Substrate and Ga–In Liquid Metal. IEEE Sens. J. 2019, 19, 97–104. [Google Scholar] [CrossRef]

- Jiang, J.; Li, Y.; Liu, J.; Huang, X.; Yuan, C.; Lou, X.W. Recent Advances in Metal Oxide-based Electrode Architecture Design for Electrochemical Energy Storage. Adv. Mater. 2012, 24, 5166–5180. [Google Scholar] [CrossRef]

- Manjakkal, L.; Szwagierczak, D.; Dahiya, R. Metal oxides based electrochemical pH sensors: Current progress and future perspectives. Prog. Mater. Sci. 2020, 109, 100635. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Tanvir, A.; Sadasivuni, K.K.; Krupa, I. Piezoresistive Sensors Based on Electrospun Mats Modified by 2D Ti3C2Tx MXene. Sensors 2019, 19, 4589. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, J.C. Carbon black filled conducting polymers and polymer blends. Adv. Polym. Technol. J. Polym. Process. Inst. 2002, 21, 299–313. [Google Scholar] [CrossRef]

- Shintake, J.; Piskarev, Y.; Jeong, S.H.; Floreano, D. Ultrastretchable Strain Sensors Using Carbon Black-Filled Elastomer Composites and Comparison of Capacitive Versus Resistive Sensors. Adv. Mater. Technol. 2018, 3, 1700284. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Guan, X.; Huang, H.; Wang, H.; Lin, W.; Peng, Z. Full 3D printing of stretchable piezoresistive sensor with hierarchical porosity and multimodulus architecture. Adv. Funct. Mater. 2019, 29, 1807569. [Google Scholar] [CrossRef]

- Chen, K.; Gao, W.; Emaminejad, S.; Kiriya, D.; Ota, H.; Nyein, H.Y.Y.; Takei, K.; Javey, A. Printed Carbon Nanotube Electronics and Sensor Systems. Adv. Mater. 2016, 28, 4397–4414. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Iijima, S.; Ichihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Shi, J.; Li, X.; Cheng, H.; Liu, Z.; Zhao, L.; Yang, T.; Dai, Z.; Cheng, Z.; Shi, E.; Yang, L.; et al. Graphene Reinforced Carbon Nanotube Networks for Wearable Strain Sensors. Adv. Funct. Mater. 2016, 26, 2078–2084. [Google Scholar] [CrossRef]

- Abshirini, M.; Charara, M.; Liu, Y.; Saha, M.; Altan, M.C. 3D Printing of Highly Stretchable Strain Sensors Based on Carbon Nanotube Nanocomposites. Adv. Eng. Mater. 2018, 20, 1800425. [Google Scholar] [CrossRef]

- Gilshteyn, E.P.; Romanov, S.A.; Kopylova, D.S.; Savostyanov, G.V.; Anisimov, A.S.; Glukhova, O.E.; Nasibulin, A.G. Mechanically Tunable Single-Walled Carbon Nanotube Films as a Universal Material for Transparent and Stretchable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 27327–27334. [Google Scholar] [CrossRef] [PubMed]

- Secor, E.B.; Prabhumirashi, P.L.; Puntambekar, K.; Geier, M.L.; Hersam, M.C. Inkjet Printing of High Conductivity, Flexible Graphene Patterns. J. Phys. Chem. Lett. 2013, 4, 1347–1351. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hao, J.; Huang, Z.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 2018, 126, 360–371. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Lan, Y.S.; Zeng, Z.Y.; Chen, X.R.; Chen, Q.F. Magnetic structures and optical properties of rare-earth orthoferrites RFeO3 (R = Ho, Er, Tm and Lu). Solid State Commun. 2019, 288, 10–17. [Google Scholar] [CrossRef]

- Lu, Y.; Biswas, M.C.; Guo, Z.; Jeon, J.-W.; Wujcik, E.K. Recent developments in bio-monitoring via advanced polymer nanocomposite-based wearable strain sensors. Biosens. Bioelectron. 2019, 123, 167–177. [Google Scholar] [CrossRef]

- Rycewicz, M.; Ficek, M.; Gajewski, K.; Kunuku, S.; Karczewski, J.; Gotszalk, T.; Wlasny, I.; Wysmołek, A.; Bogdanowicz, R. Low-strain sensor based on the flexible boron-doped diamond-polymer structures. Carbon 2021, 173, 832–841. [Google Scholar] [CrossRef]

- Pataniya, P.M.; Sumesh, C.K.; Tannarana, M.; Zankat, C.K.; Solanki, G.K.; Patel, K.D.; Pathak, V.M. Flexible paper based piezo-resistive sensor functionalised by 2D-WSe2 nanosheets. Nanotechnology 2020, 31, 435503. [Google Scholar] [CrossRef]

- Jeong, J.W.; Jang, Y.W.; Lee, I.; Shin, S.; Kim, S. Wearable Respiratory Rate Monitoring using Piezo-resistive Fabric Sensor. In Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Munich, Germany, 7–12 September 2009; Springer: Berlin, Germany, 2009; pp. 282–284. [Google Scholar]

- Ben Atitallah, B.; Rajendran, D.; Hu, Z.; Ramalingame, R.; Jose, R.B.Q.; Torres, R.D.V.; Bouchaala, D.; Derbel, N.; Kanoun, O. Piezo-Resistive Pressure and Strain Sensors for Biomedical and Tele-Manipulation Applications. Adv. Sens. Biomed. Appl. 2021, 47–65. [Google Scholar] [CrossRef]

- Zhong, W.; Ding, X.; Li, W.; Shen, C.; Yadav, A.; Chen, Y.; Bao, M.; Jiang, H.; Wang, D. Facile Fabrication of Conductive Graphene/Polyurethane Foam Composite and Its Application on Flexible Piezo-Resistive Sensors. Polymers 2019, 11, 1289. [Google Scholar] [CrossRef] [Green Version]

- Kannichankandy, D.; Pataniya, P.M.; Narayan, S.; Patel, V.; Sumesh, C.; Patel, K.D.; Solanki, G.K.; Pathak, V.M. Flexible piezo-resistive pressure sensor based on conducting PANI on paper substrate. Synth. Met. 2021, 273, 116697. [Google Scholar] [CrossRef]

- You, I.; Kim, B.; Park, J.; Koh, K.; Shin, S.; Jung, S.; Jeong, U. Stretchable E-Skin Apexcardiogram Sensor. Adv. Mater. 2016, 28, 6359–6364. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Bao, R.; Tao, J.; Li, J.; Dong, M.; Pan, C. Recent progress in tactile sensors and their applications in intelligent systems. Sci. Bull. 2020, 65, 70–88. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Bu, T.; Zhang, X.; Pang, Y.; Li, W.; Zhang, Z.; Liu, G.; Wang, Z.L.; Zhang, C. Intrinsically Stretchable Organic-Tribotronic-Transistor for Tactile Sensing. Research 2020, 2020, 1398903. [Google Scholar] [CrossRef] [PubMed]

- Jheng, W.-W.; Su, Y.-S.; Hsieh, Y.-L.; Lin, Y.-J.; Tzeng, S.-D.; Chang, C.-W.; Song, J.-M.; Kuo, W. Gold Nanoparticle Thin Film-Based Strain Sensors for Monitoring Human Pulse. ACS Appl. Nano Mater. 2021, 4, 1712–1718. [Google Scholar] [CrossRef]

- Chiolerio, A.; Adamatzky, A. Tactile sensing and computing on a random network of conducting fluid channels. Flex. Print. Electron. 2020, 5, 025006. [Google Scholar] [CrossRef]

- Gong, S.; Lai, D.T.; Wang, Y.; Yap, L.W.; Si, K.J.; Shi, Q.; Jason, N.N.; Sridhar, T.; Uddin, H.; Cheng, W. Tattoolike Polyaniline Microparticle-Doped Gold Nanowire Patches as Highly Durable Wearable Sensors. ACS Appl. Mater. Interfaces 2015, 7, 19700–19708. [Google Scholar] [CrossRef]

- Wu, J.; Wang, H.; Su, Z.; Zhang, M.; Hu, X.; Wang, Y.; Wang, Z.; Zhong, B.; Zhou, W.; Liu, J.; et al. Highly Flexible and Sensitive Wearable E-Skin Based on Graphite Nanoplatelet and Polyurethane Nanocomposite Films in Mass Industry Production Available. ACS Appl. Mater. Interfaces 2017, 9, 38745–38754. [Google Scholar] [CrossRef]

- Park, J.-B.; Belharouak, I.; Lee, Y.J.; Sun, Y.-K. A carbon-free ruthenium oxide/mesoporous titanium dioxide electrode for lithium-oxygen batteries. J. Power Sources 2015, 295, 299–304. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.; Pu, J.; Guo, X.; Qiu, J.; Ma, Y.; Zhang, Y.; Yang, X. Resistive pressure sensor for high-sensitivity e-skin based on porous sponge dip-coated CB/MWCNTs/SR conductive composites. Mater. Res. Express 2018, 5, 065701. [Google Scholar] [CrossRef]

- Cao, M.; Su, J.; Fan, S.; Qiu, H.; Su, D.; Li, L. Wearable piezoresistive pressure sensors based on 3D graphene. Chem. Eng. J. 2021, 406, 126777. [Google Scholar] [CrossRef]

- Niu, F.; Qin, Z.; Min, L.; Zhao, B.; Lv, Y.; Fang, X.; Pan, K. Ultralight and Hyperelastic Nanofiber-Reinforced MXene–Graphene Aerogel for High-Performance Piezoresistive Sensor. Adv. Mater. Technol. 2021, 6, 2100394. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y.; Chen, D.; Miao, J.; Lin, S.; Cui, D. Highly Sensitive and Flexible Piezoresistive Pressure Sensors Based on 3D Reduced Graphene Oxide Aerogel. IEEE Electron Device Lett. 2021, 42, 589–592. [Google Scholar] [CrossRef]

- Guan, H.; Dai, X.; Ni, L.; Hu, J.; Wang, X. Highly Elastic and Fatigue-Resistant Graphene-Wrapped Lamellar Wood Sponges for High-Performance Piezoresistive Sensors. ACS Sustain. Chem. Eng. 2021, 9, 15267–15277. [Google Scholar] [CrossRef]

- Gong, S.; Lai, D.T.H.; Su, B.; Si, K.J.; Ma, Z.; Yap, L.W.; Guo, P.; Cheng, W. Highly Stretchy Black Gold E-Skin Nanopatches as Highly Sensitive Wearable Biomedical Sensors. Adv. Electron. Mater. 2015, 1, 1400063. [Google Scholar] [CrossRef]

- Kovacs, G.T. Micromachined Transducers Sourcebook; McGraw-Hill: New York, NY, USA, 1998. [Google Scholar]

- French, P.; Evans, A. Piezoresistance in polysilicon and its applications to strain gauges. Solid-State Electron. 1989, 32, 1–10. [Google Scholar] [CrossRef]

- Strass, J.; Eickhoff, M.; Kroetz, G. The influence of crystal quality on the piezoresistive effect of /spl beta/-SiC between RT and 450/spl deg/C measured by using microstructures. In Proceedings of the International Solid State Sensors and Actuators Conference (Transducers ‘97), Chicago, IL, USA, 16–19 August 1997. [Google Scholar]

- Li, H.; Zhang, J.; Chen, J.; Luo, Z.; Zhang, J.; Alhandarish, Y.; Liu, Q.; Tang, W.; Wang, L. A Supersensitive, Multidimensional Flexible Strain Gauge Sensor Based on Ag/PDMS for Human Activities Monitoring. Sci. Rep. 2020, 10, 5450. [Google Scholar] [CrossRef]

- Sahli, S.; Aslam, D. Ultra-high sensitivity intra-grain poly-diamond piezoresistors. Sens. Actuators A Phys. 1998, 71, 193–197. [Google Scholar] [CrossRef]

- Hempel, M.; Nezich, D.; Kong, J.; Hofmann, M. A Novel Class of Strain Gauges Based on Layered Percolative Films of 2D Materials. Nano Lett. 2012, 12, 5714–5718. [Google Scholar] [CrossRef]

- Van der Goes, F.M.; Meijer, G.C. A novel low-cost capacitive-sensor interface. IEEE Trans. Instrum. Meas. 1996, 45, 536–540. [Google Scholar] [CrossRef] [Green Version]

- Yu, P.; Li, X.; Li, H.; Fan, Y.; Cao, J.; Wang, H.; Guo, Z.; Zhao, X.; Wang, Z.; Zhu, G. All-Fabric Ultrathin Capacitive Sensor with High Pressure Sensitivity and Broad Detection Range for Electronic Skin. ACS Appl. Mater. Interfaces 2021, 13, 24062–24069. [Google Scholar] [CrossRef]

- Ge, C.; Yang, B.; Wu, L.; Duan, Z.; Li, Y.; Ren, X.; Jiang, L.; Zhang, J. Capacitive Sensor Combining Proximity and Pressure Sensing for Accurate Grasping of a Prosthetic Hand. ACS Appl. Electron. Mater. 2022, 4, 869–877. [Google Scholar] [CrossRef]

- Luo, G.; Zhang, Q.; Li, M.; Chen, K.; Zhou, W.; Luo, Y.; Li, Z.; Wang, L.; Zhao, L.; Teh, K.S.; et al. A flexible electrostatic nanogenerator and self-powered capacitive sensor based on electrospun polystyrene mats and graphene oxide films. Nanotechnology 2021, 32, 405402. [Google Scholar] [CrossRef] [PubMed]

- Guerrero, J.M.; Castilla, A.E.; Fernandez, J.A.S.; Platero, C.A. Transformer Oil Diagnosis Based on a Capacitive Sensor Frequency Response Analysis. IEEE Access 2021, 9, 7576–7585. [Google Scholar] [CrossRef]

- Hoffmann, R.; Brodowski, H.; Steinhage, A.; Grzegorzek, M. Detecting Walking Challenges in Gait Patterns Using a Capacitive Sensor Floor and Recurrent Neural Networks. Sensors 2021, 21, 1086. [Google Scholar] [CrossRef] [PubMed]

- Beverte, I.; Cabulis, U.; Gaidukovs, S. Polytetrafluoroethylene Films in Rigid Polyurethane Foams’ Dielectric Permittivity Measurements with a One-Side Access Capacitive Sensor. Polymers 2021, 13, 1173. [Google Scholar] [CrossRef]

- Kozyr, P.; Saveliev, A.; Kuznetsov, L. Determining Distance to an Object and Type of its Material Based on Data of Capacitive Sensor Signal and Machine Learning Techniques. In Proceedings of the 2021 International Siberian Conference on Control and Communications (SIBCON), Kazan, Russia, 13–15 May 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Cai, L.; Song, L.; Luan, P.; Zhang, Q.; Zhang, N.; Gao, Q.; Xie, S. Super-stretchable, transparent carbon nanotube-based capacitive strain sensors for human motion detection. Sci. Rep. 2013, 3, 3408. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E.; et al. Conductive Fiber-Based Ultrasensitive Textile Pressure Sensor for Wearable Electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef]

- Ho, D.H.; Song, R.; Sun, Q.; Park, W.-H.; Kim, S.Y.; Pang, C.; Kim, D.H.; Kim, S.-Y.; Lee, J.; Cho, J.H. Crack-Enhanced Microfluidic Stretchable E-Skin Sensor. ACS Appl. Mater. Interfaces 2017, 9, 44678–44686. [Google Scholar] [CrossRef]

- Wang, G.; Yang, X.; Li, J.; Wang, Y.; Qing, X. A flexible microfluidic sensor based on main-channel and branch-channels for aerodynamic pressure measurement. Sens. Actuators A Phys. 2021, 319, 112546. [Google Scholar] [CrossRef]

- Tien, N.T.; Jeon, S.; Kim, D.-I.; Trung, T.Q.; Jang, M.; Hwang, B.-U.; Byun, K.-E.; Bae, J.; Lee, E.; Tok, J.B.-H.; et al. A Flexible Bimodal Sensor Array for Simultaneous Sensing of Pressure and Temperature. Adv. Mater. 2014, 26, 796–804. [Google Scholar] [CrossRef]

- An, J.; Le, T.-S.D.; Huang, Y.; Zhan, Z.; Li, Y.; Zheng, L.; Huang, W.; Sun, G.; Kim, Y.-J. All-Graphene-Based Highly Flexible Noncontact Electronic Skin. ACS Appl. Mater. Interfaces 2017, 9, 44593–44601. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Fan, W.; Yang, X.; Ge, S.; Xia, C.; Foong, S.Y.; Liew, R.K.; Wang, S.; Van Le, Q.; Lam, S.S. Piezoelectric PAN/BaTiO3 nanofiber membranes sensor for structural health monitoring of real-time damage detection in composite. Compos. Commun. 2021, 25, 100680. [Google Scholar] [CrossRef]

- Wang, H.S.; Hong, S.K.; Han, J.H.; Jung, Y.H.; Jeong, H.K.; Im, T.H.; Jeong, C.K.; Lee, B.-Y.; Kim, G.; Yoo, C.D.; et al. Biomimetic and flexible piezoelectric mobile acoustic sensors with multiresonant ultrathin structures for machine learning biometrics. Sci. Adv. 2021, 7, eabe5683. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Zhao, N.; Liu, J.; Yang, B. Coupling piezoelectric and piezoresistive effects in flexible pressure sensors for human motion detection from zero to high frequency. J. Mater. Chem. C 2021, 9, 9309–9318. [Google Scholar] [CrossRef]

- Turdakyn, N.; Medeubayev, A.; Abay, I.; Adair, D.; Kalimuldina, G. Preparation of a piezoelectric PVDF sensor via electrospinning. Mater. Today Proc. 2022, 49, 2478–2481. [Google Scholar] [CrossRef]

- Claver, U.P.; Zhao, G. Recent Progress in Flexible Pressure Sensors Based Electronic Skin. Adv. Eng. Mater. 2021, 23, 2001187. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Adhikary, P.; Jana, S.; Biswas, A.; Sencadas, V.; Gupta, S.D.; Tudu, B.; Mandal, D. Electrospun gelatin nanofiber based self-powered bio-e-skin for health care monitoring. Nano Energy 2017, 36, 166–175. [Google Scholar] [CrossRef]

- Sultana, A.; Ghosh, S.K.; Sencadas, V.; Zheng, T.; Higgins, M.J.; Middya, T.R.; Mandal, D. Human skin interactive self-powered wearable piezoelectric bio-e-skin by electrospun poly-l-lactic acid nanofibers for non-invasive physiological signal monitoring. J. Mater. Chem. B 2017, 5, 7352–7359. [Google Scholar] [CrossRef] [Green Version]

- Dutta, B.; Kar, E.; Bose, N.; Mukherjee, S. NiO@SiO2/PVDF: A flexible polymer nanocomposite for a high performance human body motion-based energy harvester and tactile e-skin mechanosensor. ACS Sustain. Chem. Eng. 2018, 6, 10505–10516. [Google Scholar] [CrossRef]

- Huang, X.; Li, J.; Liu, Y.; Wong, T.; Su, J.; Yao, K.; Zhou, J.; Huang, Y.; Li, H.; Li, D.; et al. Epidermal self-powered sweat sensors for glucose and lactate monitoring. Bio-Design Manuf. 2022, 5, 201–209. [Google Scholar] [CrossRef]

- Lei, H.; Chen, Y.; Gao, Z.; Wen, Z.; Sun, X. Advances in self-powered triboelectric pressure sensors. J. Mater. Chem. A 2021, 9, 20100–20130. [Google Scholar] [CrossRef]

- Shin, Y.-E.; Sohn, S.-D.; Han, H.; Park, Y.; Shin, H.-J.; Ko, H. Self-powered triboelectric/pyroelectric multimodal sensors with enhanced performances and decoupled multiple stimuli. Nano Energy 2020, 72, 104671. [Google Scholar] [CrossRef]

- Pu, X.; An, S.; Tang, Q.; Guo, H.; Hu, C. Wearable triboelectric sensors for biomedical monitoring and human-machine interface. iScience 2021, 24, 102027. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Gao, W.; Wang, Z.L. The Triboelectric Nanogenerator as an Innovative Technology toward Intelligent Sports. Adv. Mater. 2021, 33, 2004178. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Liu, D.; Wang, J.; Wang, Z.L. Triboelectric nanogenerators: Fundamental physics and potential applications. Friction 2020, 8, 481–506. [Google Scholar] [CrossRef]

- Yang, D.; Guo, H.; Chen, X.; Wang, L.; Jiang, P.; Zhang, W.; Zhang, L.; Wang, Z.L. A flexible and wide pressure range triboelectric sensor array for real-time pressure detection and distribution mapping. J. Mater. Chem. A 2020, 8, 23827–23833. [Google Scholar] [CrossRef]

- Jin, T.; Sun, Z.; Li, L.; Zhang, Q.; Zhu, M.; Zhang, Z.; Yuan, G.; Chen, T.; Tian, Y.; Hou, X.; et al. Triboelectric nanogenerator sensors for soft robotics aiming at digital twin applications. Nat. Commun. 2020, 11, 5381. [Google Scholar] [CrossRef]

- Chen, X.; Xie, X.; Liu, Y.; Zhao, C.; Wen, M.; Wen, Z. Advances in Healthcare Electronics Enabled by Triboelectric Nanogenerators. Adv. Funct. Mater. 2020, 30, 2004673. [Google Scholar] [CrossRef]

- Chen, X.; Ren, Z.; Han, M.; Wan, J.; Zhang, H. Hybrid energy cells based on triboelectric nanogenerator: From principle to system. Nano Energy 2020, 75, 104980. [Google Scholar] [CrossRef]

- Jiang, X.-Z.; Sun, Y.-J.; Fan, Z.; Zhang, T.-Y. Integrated Flexible, Waterproof, Transparent, and Self-Powered Tactile Sensing Panel. ACS Nano 2016, 10, 7696–7704. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, S.; Li, N.; Yao, T.; Lv, D. Triboelectric Self-Powered Three-Dimensional Tactile Sensor. IEEE Access 2020, 8, 172076–172085. [Google Scholar] [CrossRef]

- Wang, X.; Dong, L.; Zhang, H.; Yu, R.; Pan, C.; Wang, Z.L. Recent Progress in Electronic Skin. Adv. Sci. 2015, 2, 1500169. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Song, Y.; Cheng, X.; Zhang, H. Self-powered electronic skin based on the triboelectric generator. Nano Energy 2019, 56, 252–268. [Google Scholar] [CrossRef]

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material aspects of triboelectric energy generation and sensors. NPG Asia Mater. 2020, 12, 6. [Google Scholar] [CrossRef]

- Yang, A.; Yan, F. Flexible Electrochemical Biosensors for Health Monitoring. ACS Appl. Electron. Mater. 2020, 3, 53–67. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, L.; Yeo, J.C.; Lim, C.T. Wearable Sensors: Flexible Hybrid Sensors for Health Monitoring: Materials and Mechanisms to Render Wearability. Adv. Mater. 2020, 32, 2070117. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Ke, K.; Jia, J.; Pu, J.; Zhao, X.; Bao, R.; Liu, Z.; Bai, L.; Zhang, K.; Yang, M.; et al. Recent Advances in Multiresponsive Flexible Sensors towards E-skin: A Delicate Design for Versatile Sensing. Small 2022, 18, 2103734. [Google Scholar] [CrossRef]

- Wang, H.; Li, Z.; Liu, Z.; Fu, J.; Shan, T.; Yang, X.; Lei, Q.; Yang, Y.; Li, D. Flexible capacitive pressure sensors for wearable electronics. J. Mater. Chem. C 2022, 10, 1594–1605. [Google Scholar] [CrossRef]

- Lim, H.R.; Kim, H.S.; Qazi, R.; Kwon, Y.T.; Jeong, J.W.; Yeo, W.H. Advanced soft materials, sensor integrations, and applications of wearable flexible hybrid electronics in healthcare, energy, and environment. Adv. Mater. 2020, 32, 1901924. [Google Scholar] [CrossRef]

- McNichol, L.; Lund, C.; Rosen, T.; Gray, M. Medical adhesives and patient safety: State of the scienceconsensus statements for the assessment, prevention, and treatment of adhesive-related skin injuries. J. Wound Ostomy Cont. Nurs. 2013, 40, 365–380. [Google Scholar] [CrossRef]

- Nawrocki, R.A.; Jin, H.; Lee, S.; Yokota, T.; Sekino, M.; Someya, T. Self-adhesive and ultra-conformable, Sub-300 nm dry thin-film electrodes for surface monitoring of biopotentials. Adv. Funct. Mater. 2018, 28, 1803279. [Google Scholar] [CrossRef]

- Duan, P.; Ma, T.; Yue, Y.; Li, Y.; Zhang, X.; Shang, Y.; Gao, B.; Zhang, Q.; Yue, Q.; Xu, X. Fe/Mn nanoparticles encapsulated in nitrogen-doped carbon nanotubes as a peroxymonosulfate activator for acetamiprid degradation. Environ. Sci. Nano 2019, 6, 1799–1811. [Google Scholar] [CrossRef]

- Pang, C.; Koo, J.H.; Nguyen, A.; Caves, J.M.; Kim, M.G.; Chortos, A.; Bao, Z. Sensors: Highly Skin-Conformal Microhairy Sensor for Pulse Signal Amplification. Adv. Mater. 2015, 27, 589. [Google Scholar] [CrossRef]

- Wang, J.-C.; Karmakar, R.S.; Lu, Y.J.; Chan, S.H.; Wu, M.C.; Lin, K.J.; Hsu, Y.H. Miniaturized flexible piezoresistive pressure sensors: Poly (3, 4-ethylenedioxythiophene): Poly (styrenesulfonate) copolymers blended with graphene oxide for biomedical applications. ACS Appl. Mater. Interfaces 2019, 11, 34305–34315. [Google Scholar] [CrossRef] [PubMed]

- Ha, M.; Lim, S.; Ko, H. Wearable and flexible sensors for user-interactive health-monitoring devices. J. Mater. Chem. B 2018, 6, 4043–4064. [Google Scholar] [CrossRef]

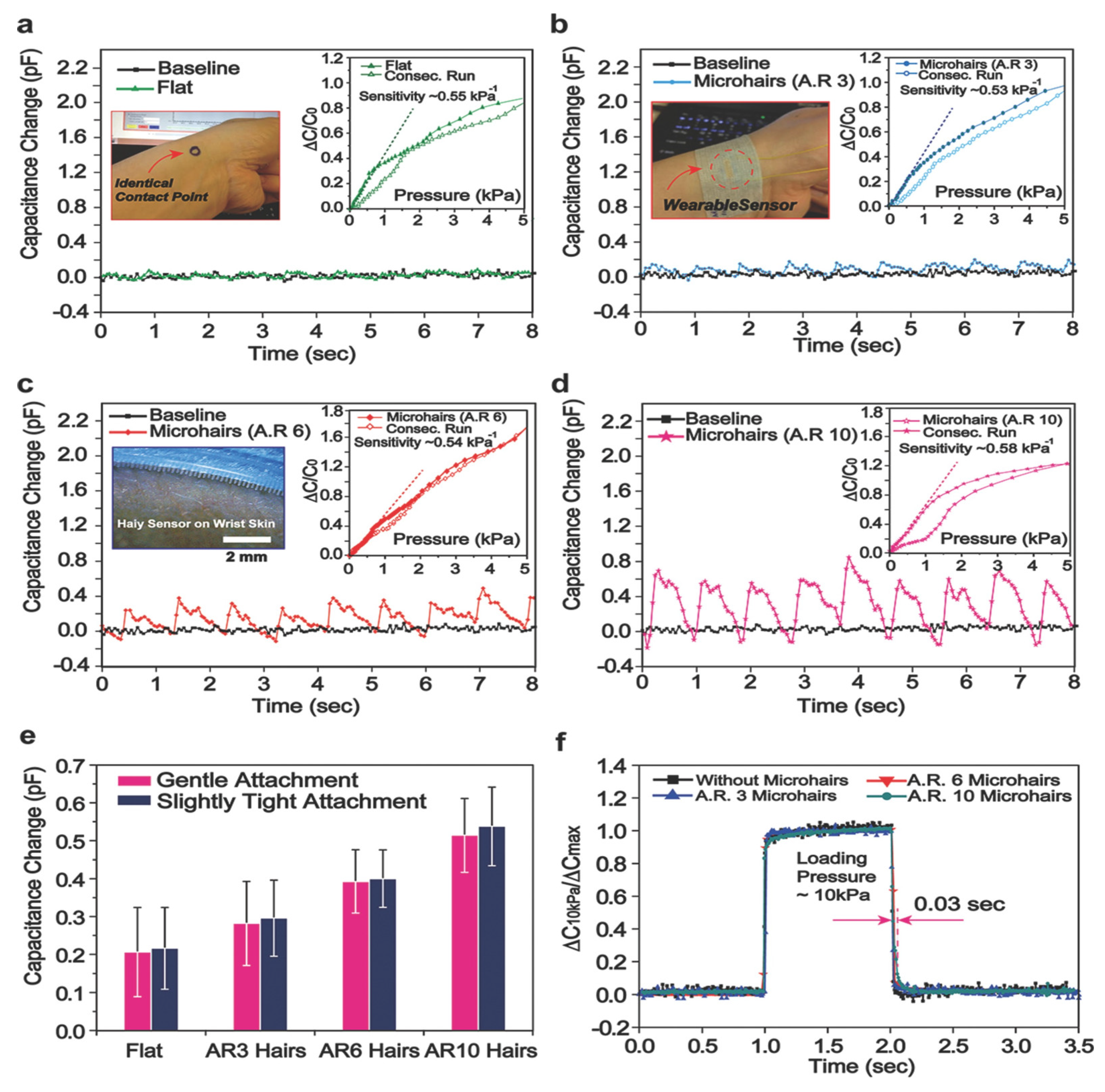

- Pang, C.; Koo, J.H.; Nguyen, A.; Caves, J.M.; Kim, M.-G.; Chortos, A.; Kim, K.; Wang, P.J.; Tok, J.B.-H.; Bao, Z. Highly Skin-Conformal Microhairy Sensor for Pulse Signal Amplification. Adv. Mater. 2015, 27, 634–640. [Google Scholar] [CrossRef]

- Khalid, M.A.U.; Chang, S.H. Flexible strain sensors for wearable applications fabricated using novel functional nanocomposites: A review. Compos. Struct. 2022, 284, 115214. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Wearable Flexible Sensors: A Review. IEEE Sens. J. 2017, 17, 3949–3960. [Google Scholar] [CrossRef] [Green Version]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly Stretchable and Wearable Graphene Strain Sensors with Controllable Sensitivity for Human Motion Monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef]

- Ryu, S.; Lee, P.; Chou, J.B.; Xu, R.; Zhao, R.; Hart, A.J.; Kim, S.-G. Extremely Elastic Wearable Carbon Nanotube Fiber Strain Sensor for Monitoring of Human Motion. ACS Nano 2015, 9, 5929–5936. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Lee, K.H.; Anjum, D.H.; Sougrat, R.; Jiang, Q.; Kim, H.; Alshareef, H.N. MXenes stretch hydrogel sensor performance to new limits. Sci. Adv. 2018, 4, eaat0098. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roh, E.; Hwang, B.U.; Kim, D.; Kim, B.Y.; Lee, N.E. Stretchable, transparent, ultrasensitive, and patchable strain sensor for human–machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers. ACS Nano. 2015, 9, 6252–6261. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Gu, Y.; Xiong, Z.; Cui, Z.; Zhang, T. Electronic Skin: Silk-Molded Flexible, Ultrasensitive, and Highly Stable Electronic Skin for Monitoring Human Physiological Signals. Adv. Mater. 2014, 26, 1309. [Google Scholar] [CrossRef] [Green Version]

- Sim, K.; Rao, Z.; Zou, Z.; Ershad, F.; Lei, J.; Thukral, A.; Chen, J.; Huang, Q.-A.; Xiao, J.; Yu, C. Metal oxide semiconductor nanomembrane–based soft unnoticeable multifunctional electronics for wearable human-machine interfaces. Sci. Adv. 2019, 5, eaav9653. [Google Scholar] [CrossRef] [PubMed]

- Eppner, C.; Deimel, R.; Álvarez-Ruiz, J.; Maertens, M.; Brock, O. Exploitation of environmental constraints in human and robotic grasping. Int. J. Robot. Res. 2015, 34, 1021–1038. [Google Scholar] [CrossRef] [Green Version]

- He, Q.; Wang, Z.; Wang, Y.; Minori, A.; Tolley, M.T.; Cai, S. Electrically controlled liquid crystal elastomer–based soft tubular actuator with multimodal actuation. Sci. Adv. 2019, 5, eaax5746. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Sun, Z.; Zhao, Y.; Zuo, L. A highly stretchable hydrogel sensor for soft robot multi-modal perception. Sens. Actuators A Phys. 2021, 331, 113006. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zazoum, B.; Batoo, K.M.; Khan, M.A.A. Recent Advances in Flexible Sensors and Their Applications. Sensors 2022, 22, 4653. https://doi.org/10.3390/s22124653

Zazoum B, Batoo KM, Khan MAA. Recent Advances in Flexible Sensors and Their Applications. Sensors. 2022; 22(12):4653. https://doi.org/10.3390/s22124653

Chicago/Turabian StyleZazoum, Bouchaib, Khalid Mujasam Batoo, and Muhammad Azhar Ali Khan. 2022. "Recent Advances in Flexible Sensors and Their Applications" Sensors 22, no. 12: 4653. https://doi.org/10.3390/s22124653

APA StyleZazoum, B., Batoo, K. M., & Khan, M. A. A. (2022). Recent Advances in Flexible Sensors and Their Applications. Sensors, 22(12), 4653. https://doi.org/10.3390/s22124653