Real-Time Temperature Monitoring under Thermal Cycling Loading with Optical Fiber Sensor

Abstract

:1. Introduction

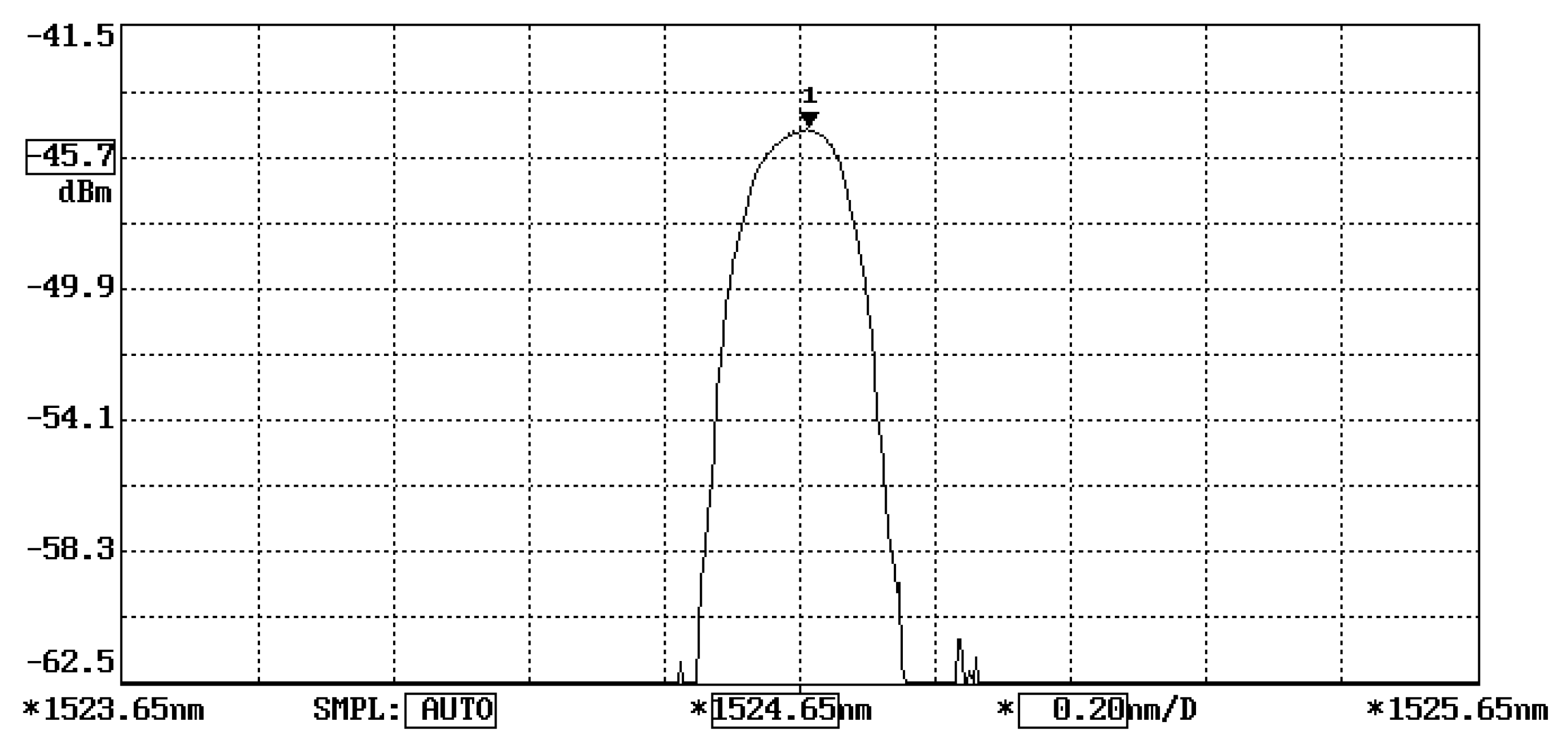

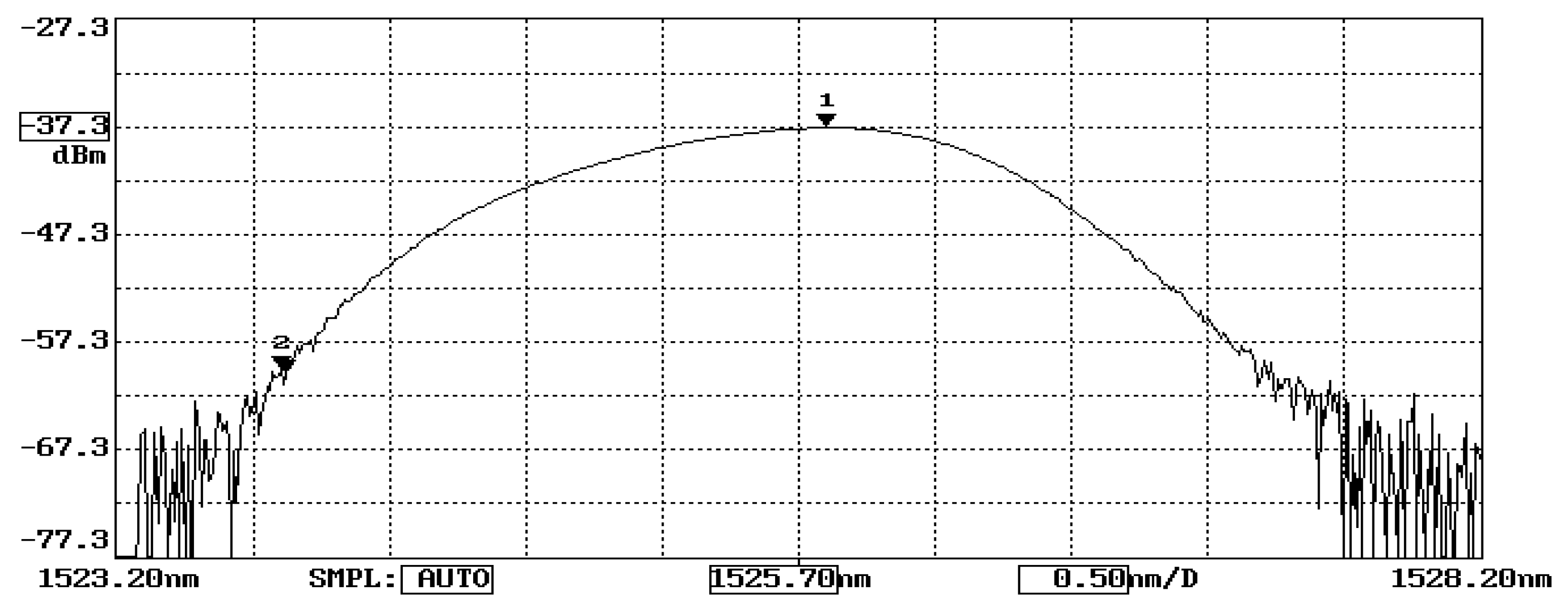

2. Bragg Wavelength Shift

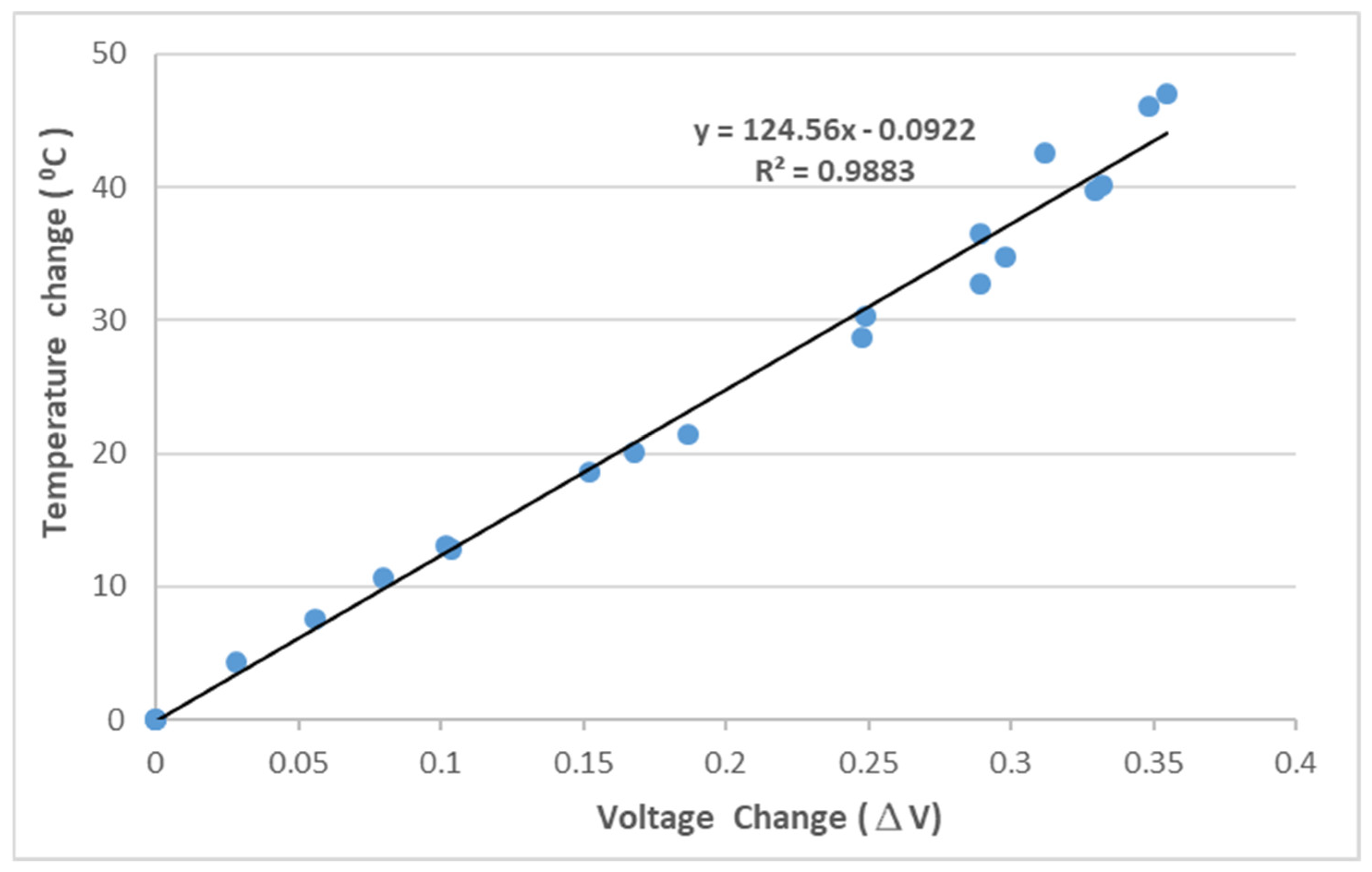

3. Temperature-IEEEnduced Light Power Variation

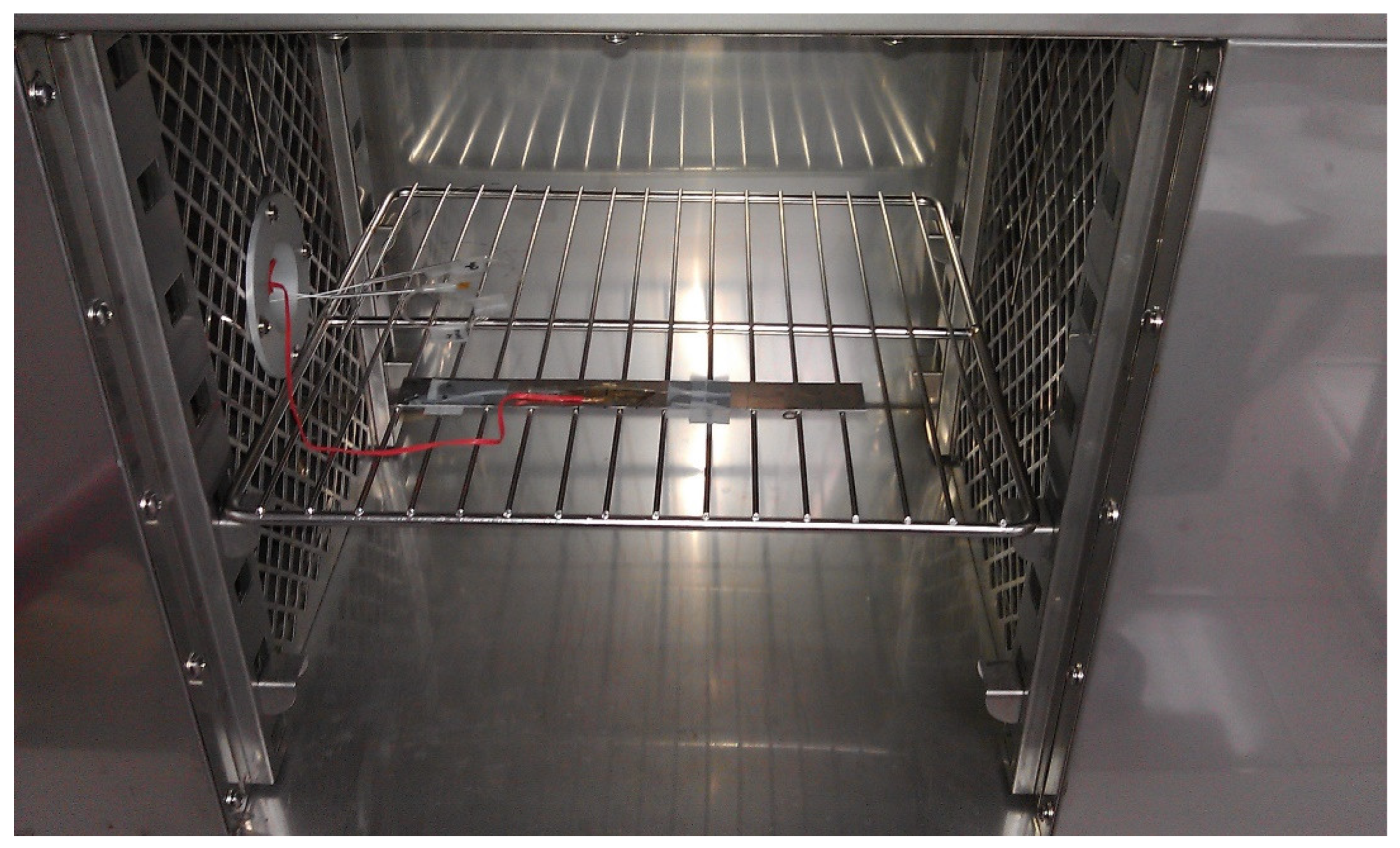

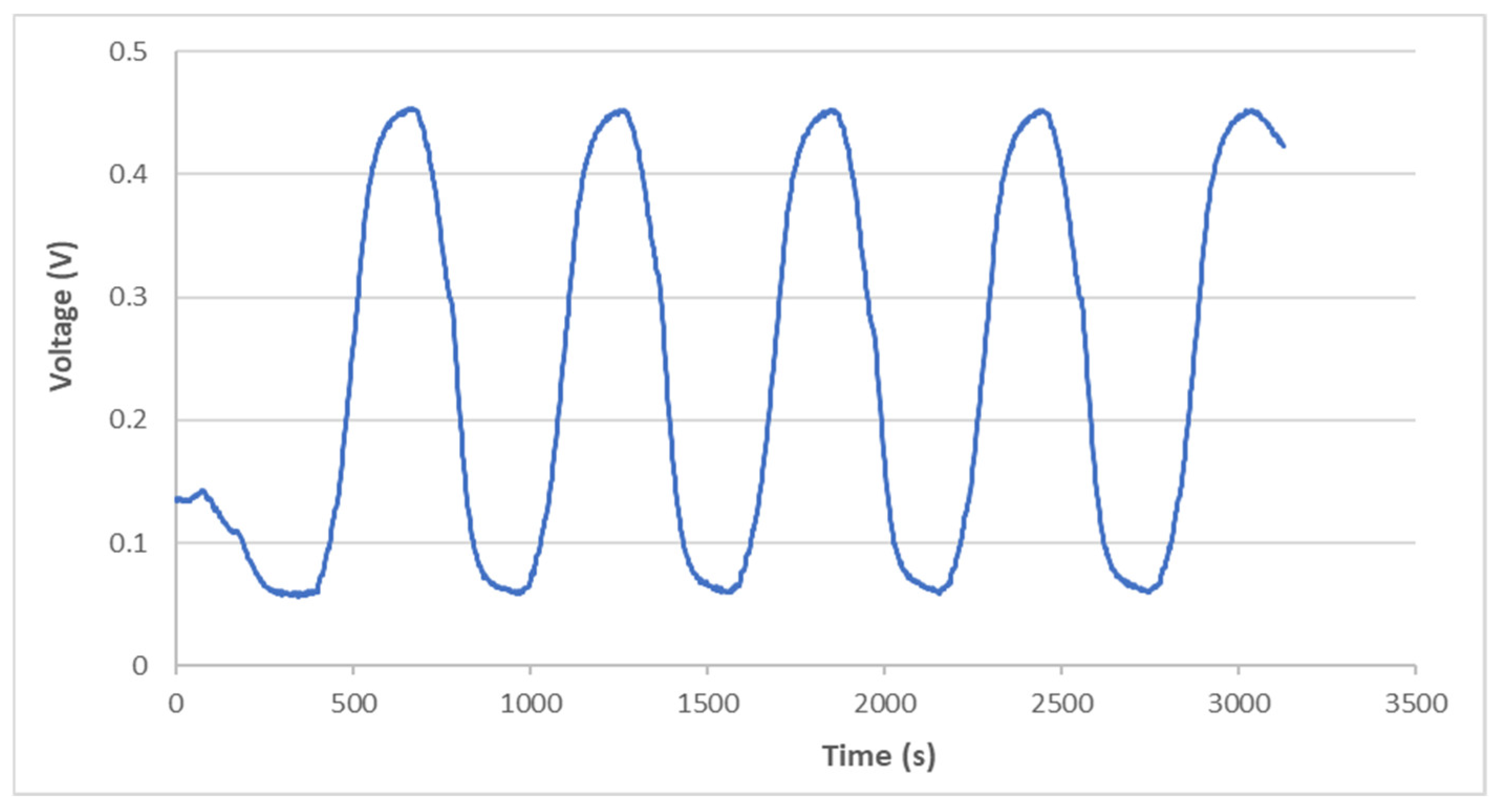

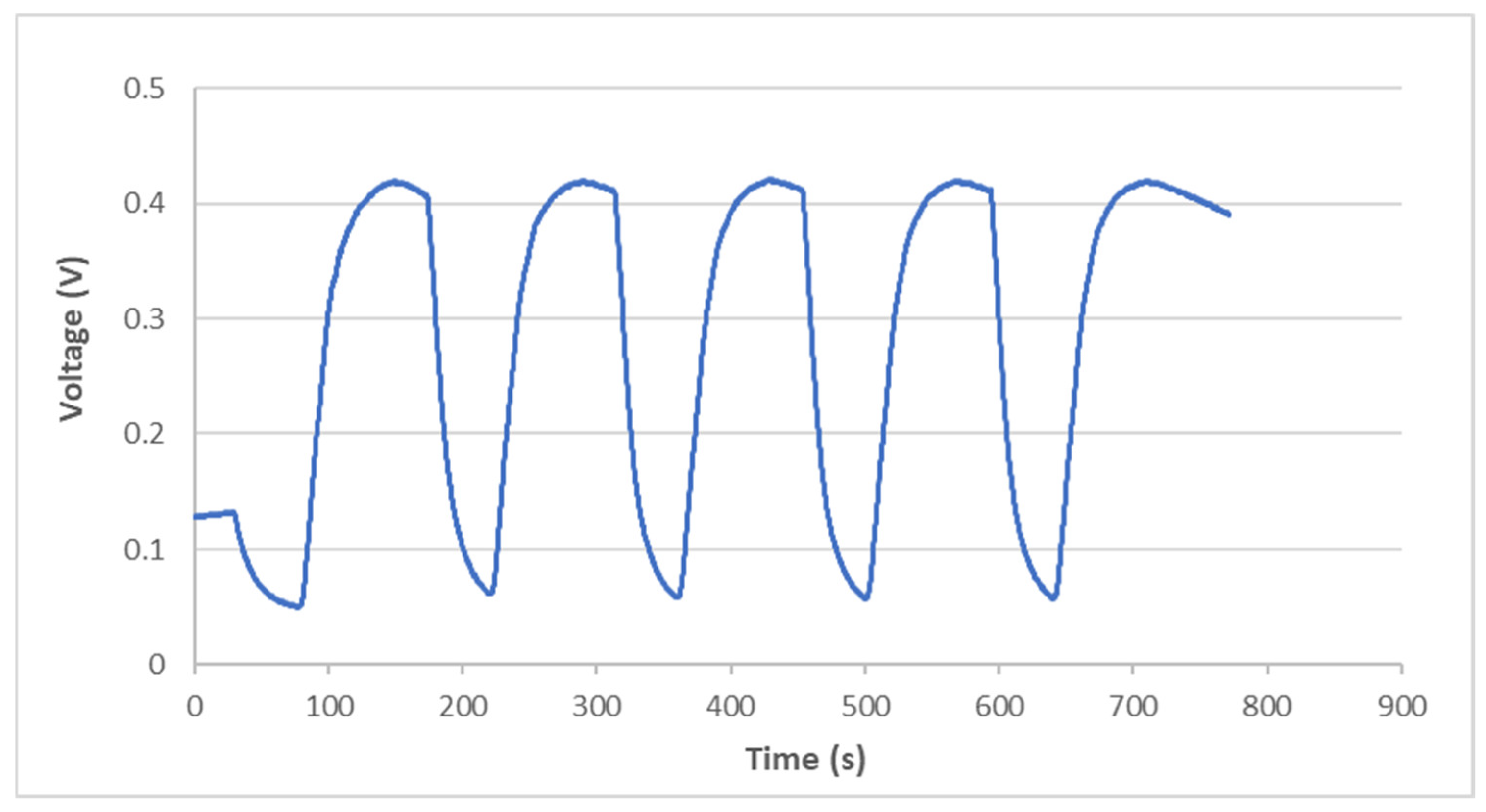

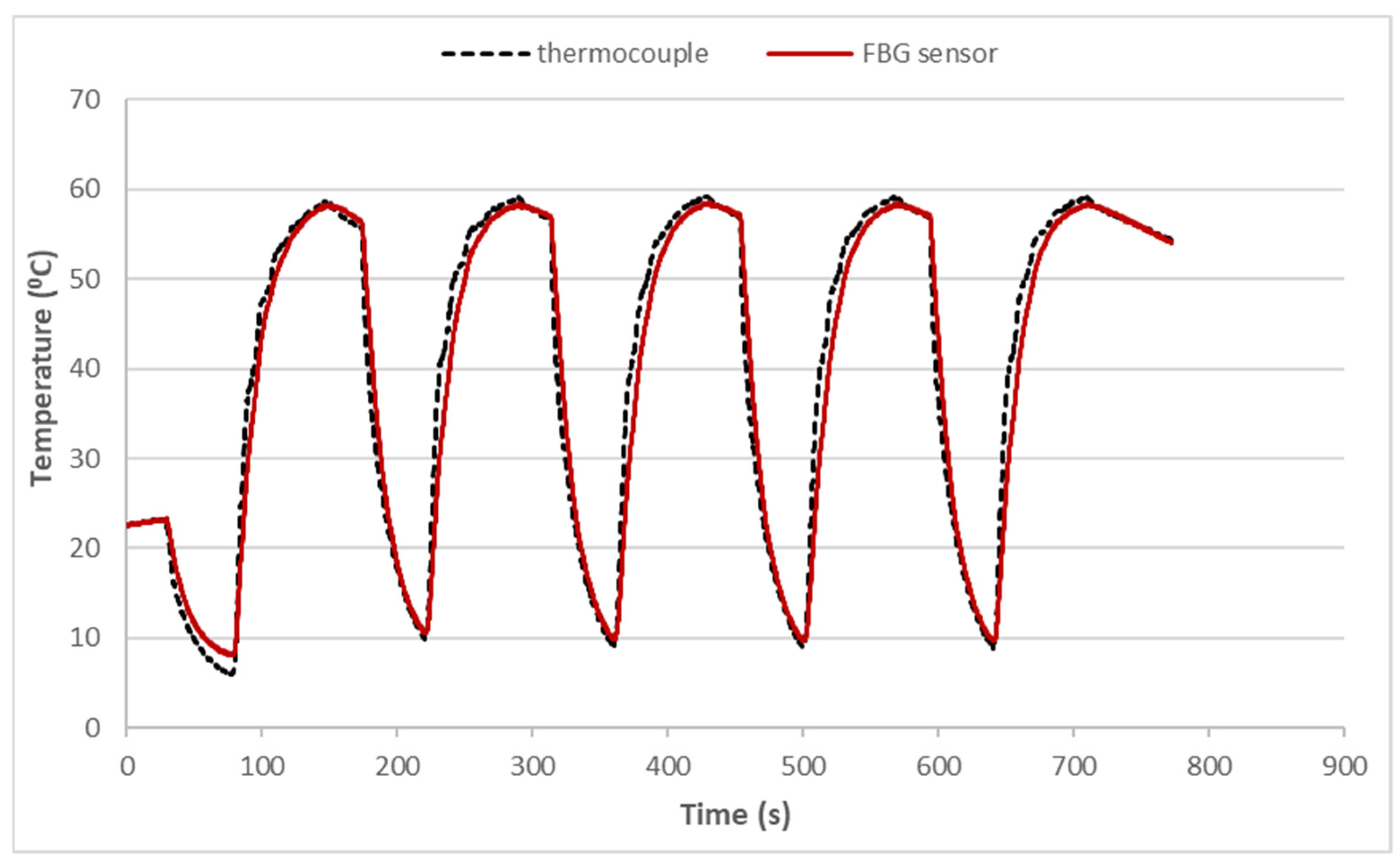

4. Thermal Cycling Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hegedus, G.; Sarkadi, T.; Czigany, T. Multifunctional composite: Reinforcing fibreglass bundle for deformation self-sensing. Compos. Sci. Technol. 2019, 180, 78–85. [Google Scholar] [CrossRef]

- Tripathi, K.M.; Vincent, F.; Castro, M.; Feller, J.F. Flax fibers – epoxy with embedded nanocomposite sensors to design lightweight smart bio-composites. Nanocomposites 2016, 2, 125–134. [Google Scholar] [CrossRef] [Green Version]

- Hoe, B.V.; Lee, G.; Bosman, E.; Missinne, J.; Kalathimekkad, S.; Maskery, O.; Webb, D.J.; Sugden, K.; Daele, P.V.; Steenberge, G.V. Ultra Small Integrated Optical Fiber Sensing System. Sensors 2012, 12, 12052–12069. [Google Scholar]

- Fang, J.X.; Taylor, H.F.; Choi, H.S. Fiber-optic Fabry-Perot flow sensor. Microwave Opt. Technol. Lett. 2015, 18, 209–211. [Google Scholar]

- Hu, R.P.; Huang, X.G. A simple fiber-optic flowmeter based on bending loss. IEEE Sens. J. 2009, 9, 1952–1955. [Google Scholar] [CrossRef]

- Falcetelli, F.; Rossi, L.; Di Sante, R.; Bolognini, G. Strain Transfer in Surface-Bonded Optical Fiber Sensors. Sensors 2020, 20, 3100. [Google Scholar] [CrossRef]

- Du, C.; Dutta, S.; Kurup, P.; Yu, T.; Wang, X. A review of railway infrastructure monitoring using fiber optic sensors. Sens. Actuators A 2020, 303, 111728. [Google Scholar] [CrossRef]

- Leung, C.K.Y.; Wan, K.T.; Inaudi, D.; Bao, X.; Habel, W.; Zhou, Z.; Ou, J.; Ghandehari, M.; Wu, H.C.; Imai, M. Review: Optical fiber sensors for civil engineering applications. Mater. Struct. 2015, 48, 871–906. [Google Scholar] [CrossRef] [Green Version]

- Choi, B.-H.; Seo, D.-C.; Kwon, I.-B. Detecting impact traces on a composite pressure vessel with aluminum-coating optical fiber using a phase-modulated BOCDA sensor. Compos. Sci. Technol. 2017, 142, 264–274. [Google Scholar] [CrossRef]

- Lu, X.; Soto, M.A.; Thévenaz, L. Temperature-strain discrimination in distributed optical fiber sensing using phase sensitive optical time-domain reflectometry. Voptics Express 2017, 25, 16059. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Xia, F.; Chen, M.-Q.; Lv, R.-Q. Optical fiber low-frequency vibration sensor based on Butterfly-Shape Mach-Zehnder Interferometer. Sens. Actuators A 2018, 273, 107–112. [Google Scholar] [CrossRef]

- Li, P.; Yan, H.; Zhang, H. Highly sensitive liquid level sensor based on an optical fiber Michelson interferometer with core-offset structure. Opt.-Int. J. Light Electron Opt. 2018, 171, 781–785. [Google Scholar] [CrossRef]

- Slattery, S.A.; Nikogosyan, D.N.; Brambilla, G. Fiber Bragg grating inscription by high intensity femtosecond UV laser light: Comparison with other existing methods of fabrication. J. Opt. Soc. Am. B 2005, 22, 354–361. [Google Scholar] [CrossRef]

- Szebenyi, G.; Blobl, Y.; Hegedüs, G.; Tabi, T.; Czigany, T.; Schledjewski, R. Fatigue monitoring of flax fibre reinforced epoxy composites using integrated fibre-optical FBG sensors. Compos. Sci. Technol. 2020, 199, 108317. [Google Scholar] [CrossRef]

- Zheng, H.-K.; Zhao, Y.; Zhao, Q.; Lv, R.-Q. High sensitivity optical fiber pressure sensor based on thin-walled oval cylinder. Sens. Actuators A 2020, 310, 112042. [Google Scholar]

- Lv, R.-Q.; Zheng, H.-K.; Zhao, Y.; Gu, Y.-F. An optical fiber sensor for simultaneous measurement of flow rate and temperature in the pipeline. Opt. Fiber Technol. 2018, 45, 313–318. [Google Scholar] [CrossRef]

- Jang, B.-W.; Kim, C.-G. Real-time estimation of delamination occurrence induced by low-velocity impact in composite plates using optical fiber sensing system. Compos. Struct. 2018, 189, 455–462. [Google Scholar] [CrossRef]

- Weisz-Patrault, D.; Maurin, L.; Legrand, N.; Salem, A.B.; Bengrir, A.A. Experimental evaluation of contact stress during cold rolling process with optical fiber Bragg gratings sensors measurements and fast inverse method. J. Mater. Process. Technol. 2015, 223, 105–123. [Google Scholar] [CrossRef] [Green Version]

- Tsukada, T.; Minakuchi, S.; Takeda, N. Identification of process-induced residual stress/strain distribution in thick thermoplastic composites based on in situ strain monitoring using optical fiber sensors. J. Compos. Mater. 2019, 53, 3445–3458. [Google Scholar] [CrossRef]

- Anastasopoulos, D.; Smedt, M.D.; Vandewalle, L.; Roeck, G.D.; Reynders, E.P.B. Damage identification using modal strains identified from operational fiber-optic Bragg grating data. Struct. Health Monit. 2018, 17, 1441–1459. [Google Scholar] [CrossRef]

- Fahim, A.; Hasan, S.M.K.; Suhling, J.C.; Lall, P. Creep Behavior of Various Materials Within PBGA Packages Subjected to Thermal Cycling Loading. In Proceedings of the ASME 2020 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, Anaheim, CA, USA, 27–29 October 2020. [Google Scholar]

- Fahim, A.; Hasan, S.M.K.; Suhling, J.C.; Lall, P. Nanoindentation Testing of Sac305 Solder Joints Subjected to Thermal Cycling Loading. In Proceedings of the ASME 2019 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems, Anaheim, CA, USA, 7–9 October 2019. [Google Scholar]

- Tosi, D. Review and Analysis of peak tracking techniques for fiber Bragg grating sensors. Sensors 2017, 17, 2368. [Google Scholar] [CrossRef] [PubMed]

- Her, S.-C.; Huang, S.-Y. Thermal Strain Measured by Fiber Bragg Grating Sensors. Sens. Mater. 2016, 28, 939–946. [Google Scholar]

- Her, S.-C.; Chung, S.-C. Dynamic Responses Measured by Optical Fiber Sensor for Structural Health Monitoring. Appl. Sci. 2019, 9, 2956. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Her, S.-C.; Tasi, J.-L. Real-Time Temperature Monitoring under Thermal Cycling Loading with Optical Fiber Sensor. Sensors 2022, 22, 4466. https://doi.org/10.3390/s22124466

Her S-C, Tasi J-L. Real-Time Temperature Monitoring under Thermal Cycling Loading with Optical Fiber Sensor. Sensors. 2022; 22(12):4466. https://doi.org/10.3390/s22124466

Chicago/Turabian StyleHer, Shiuh-Chuan, and Jr-Luen Tasi. 2022. "Real-Time Temperature Monitoring under Thermal Cycling Loading with Optical Fiber Sensor" Sensors 22, no. 12: 4466. https://doi.org/10.3390/s22124466

APA StyleHer, S.-C., & Tasi, J.-L. (2022). Real-Time Temperature Monitoring under Thermal Cycling Loading with Optical Fiber Sensor. Sensors, 22(12), 4466. https://doi.org/10.3390/s22124466