Research and Development of a Wireless Self-Powered Sensing Device Based on Bridge Vibration Energy Collection

Abstract

1. Introduction

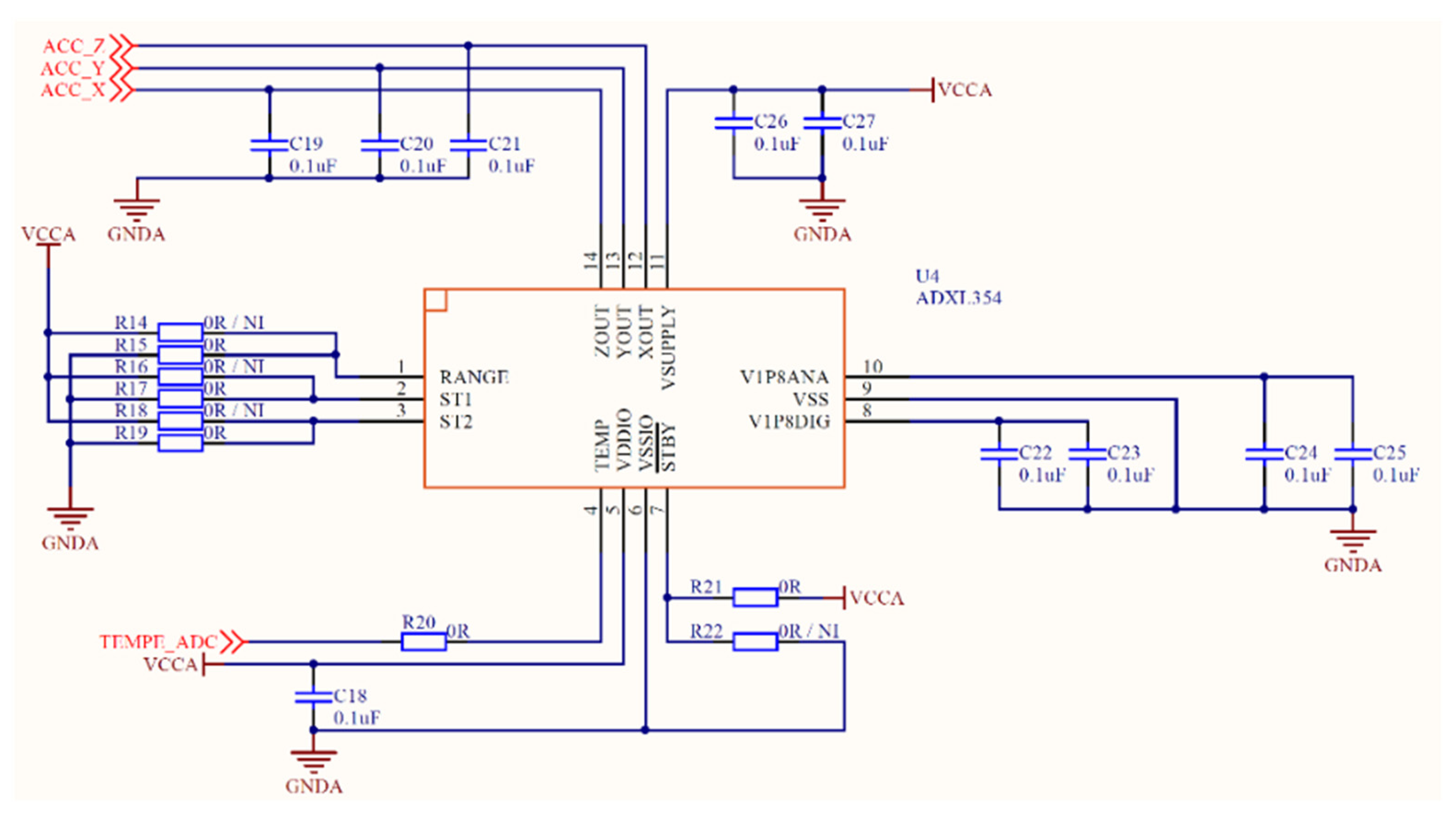

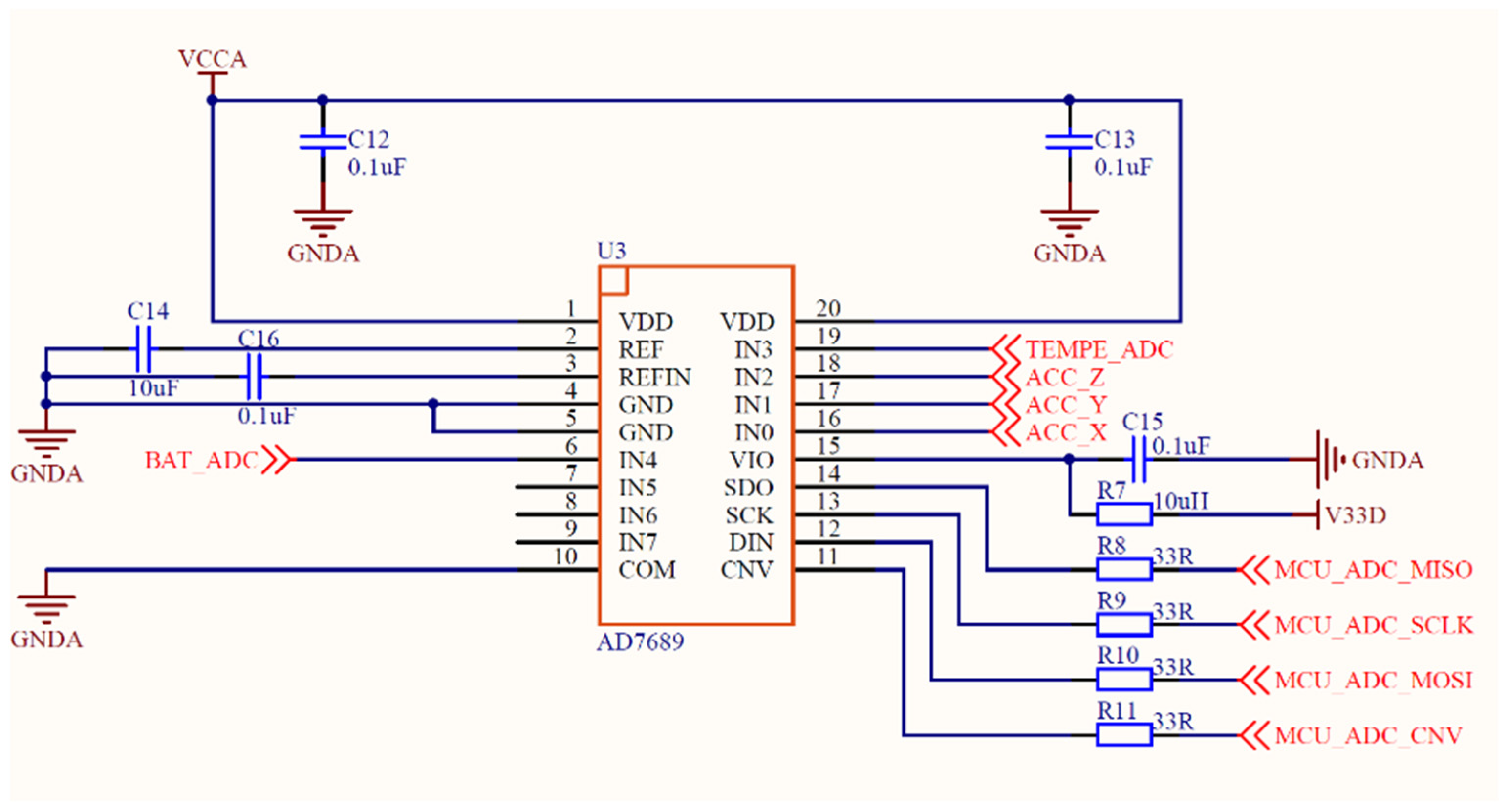

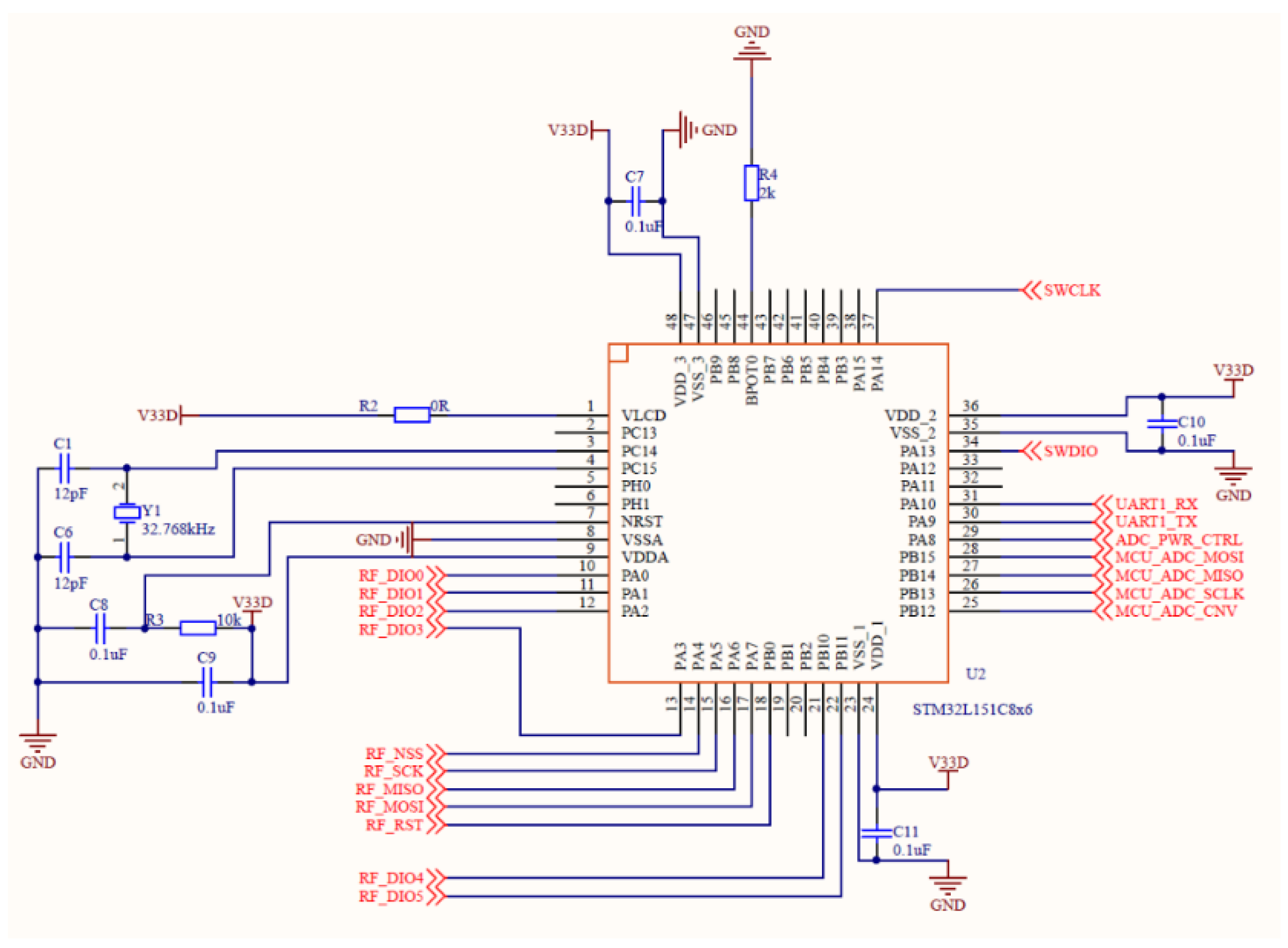

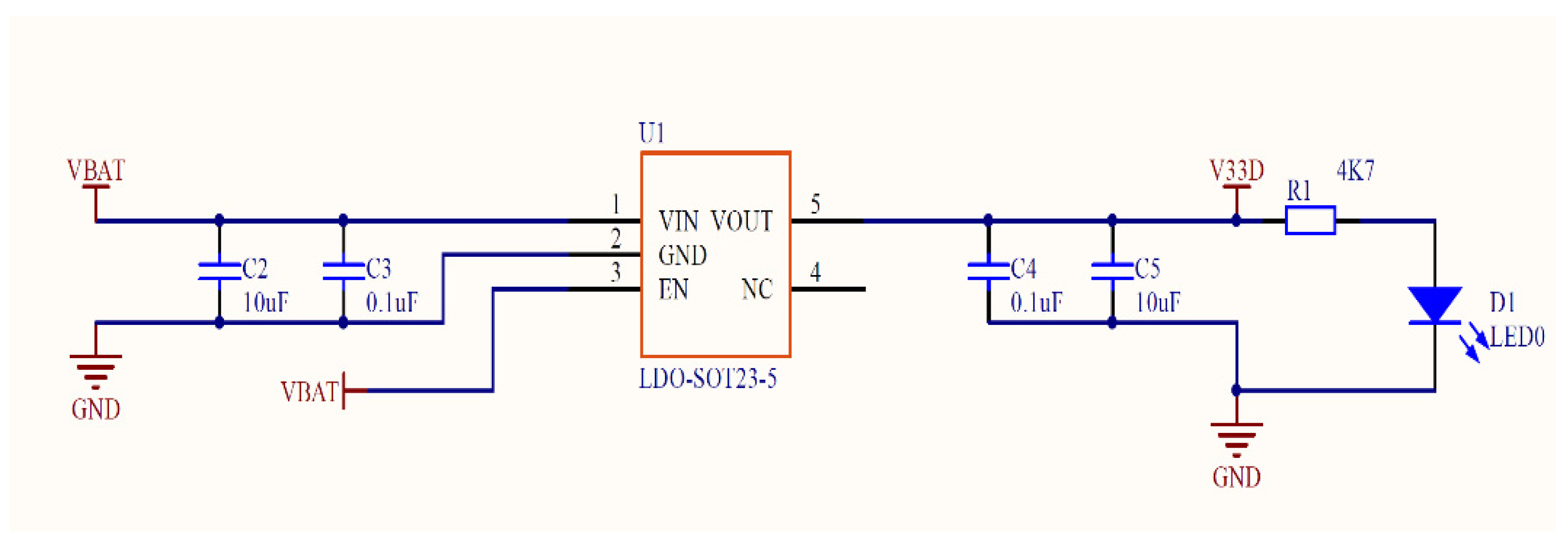

2. Wireless Acceleration Sensor

2.1. The Composition of Acceleration Sensor

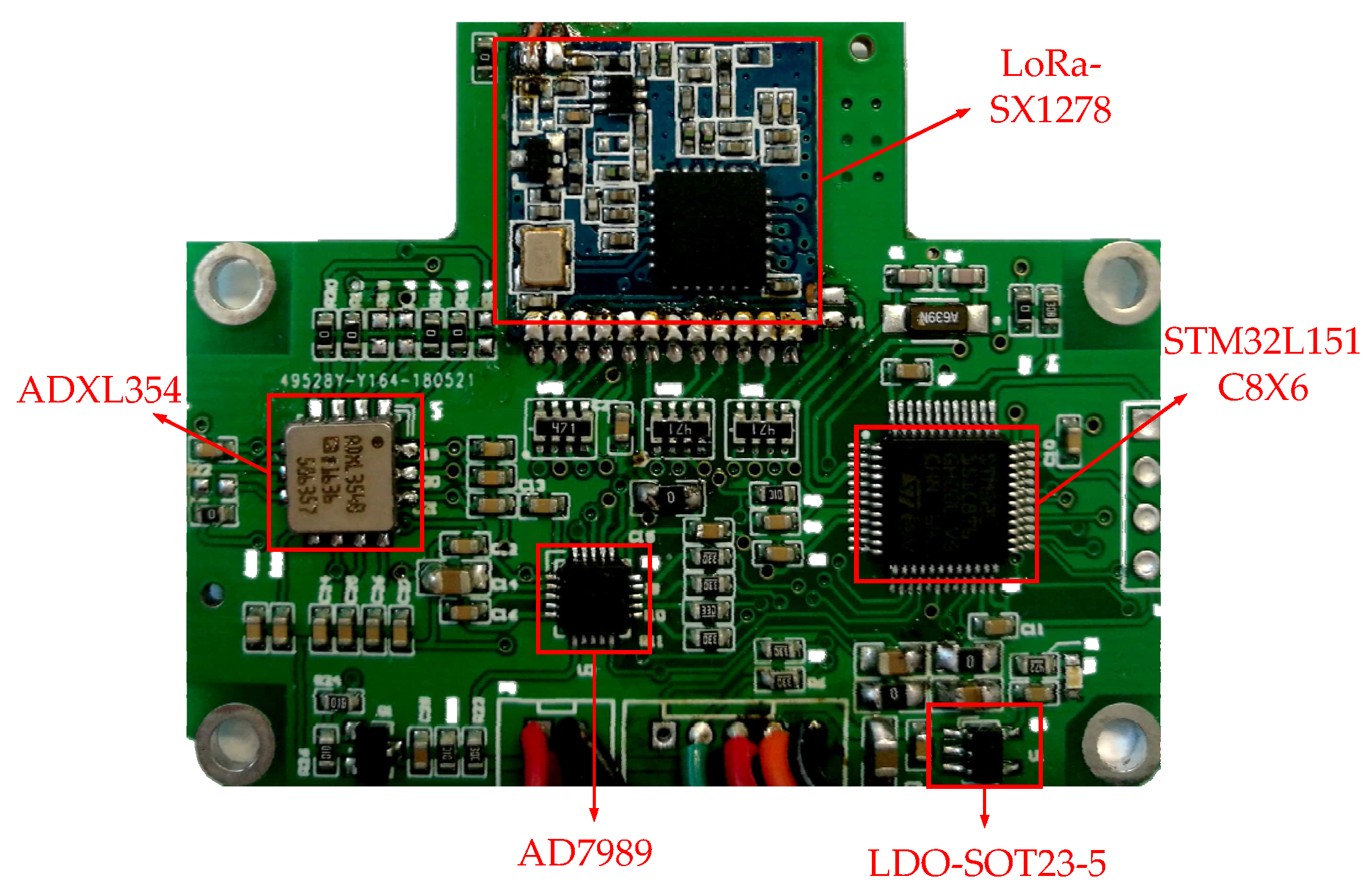

2.1.1. Circuit Diagram

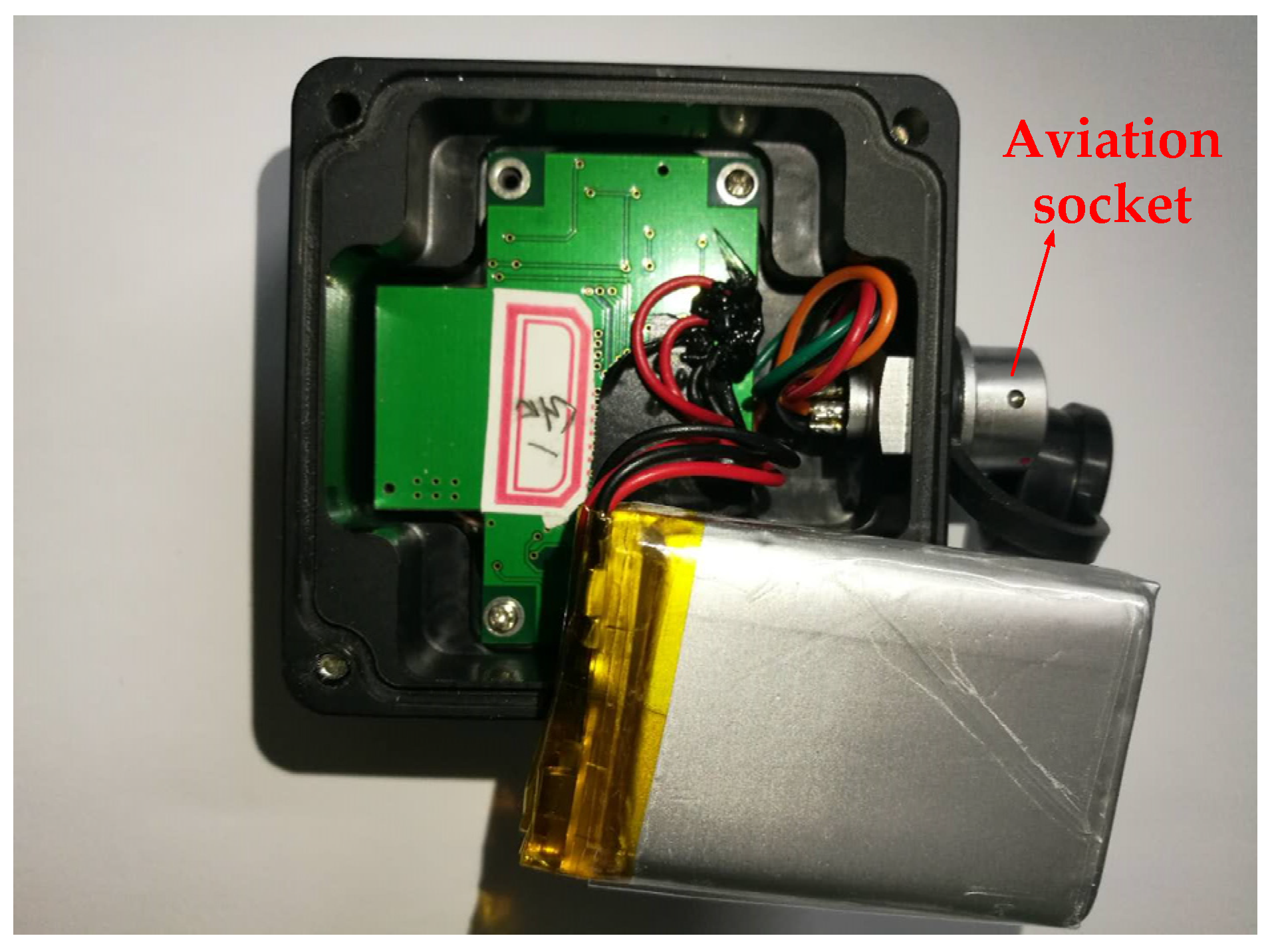

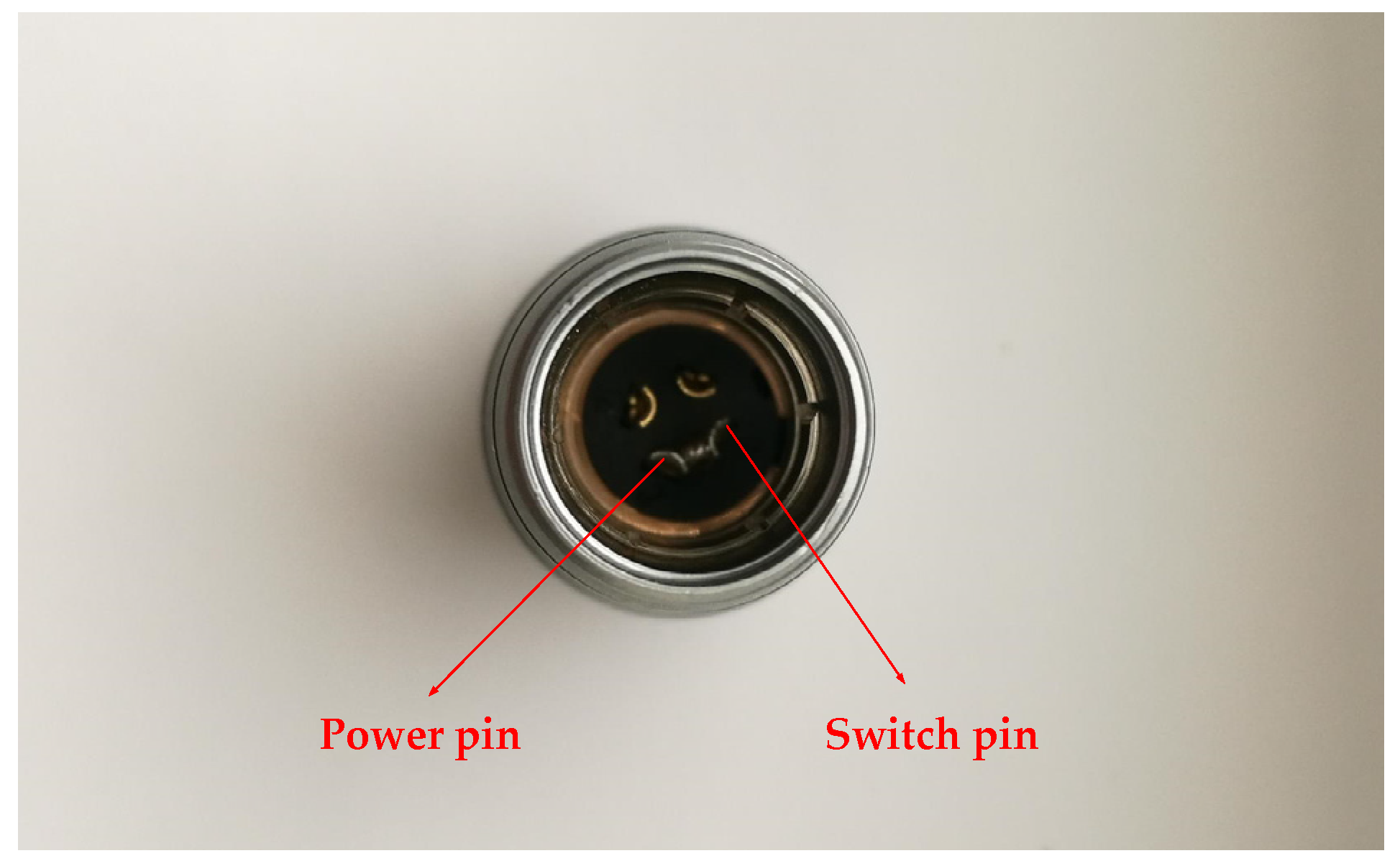

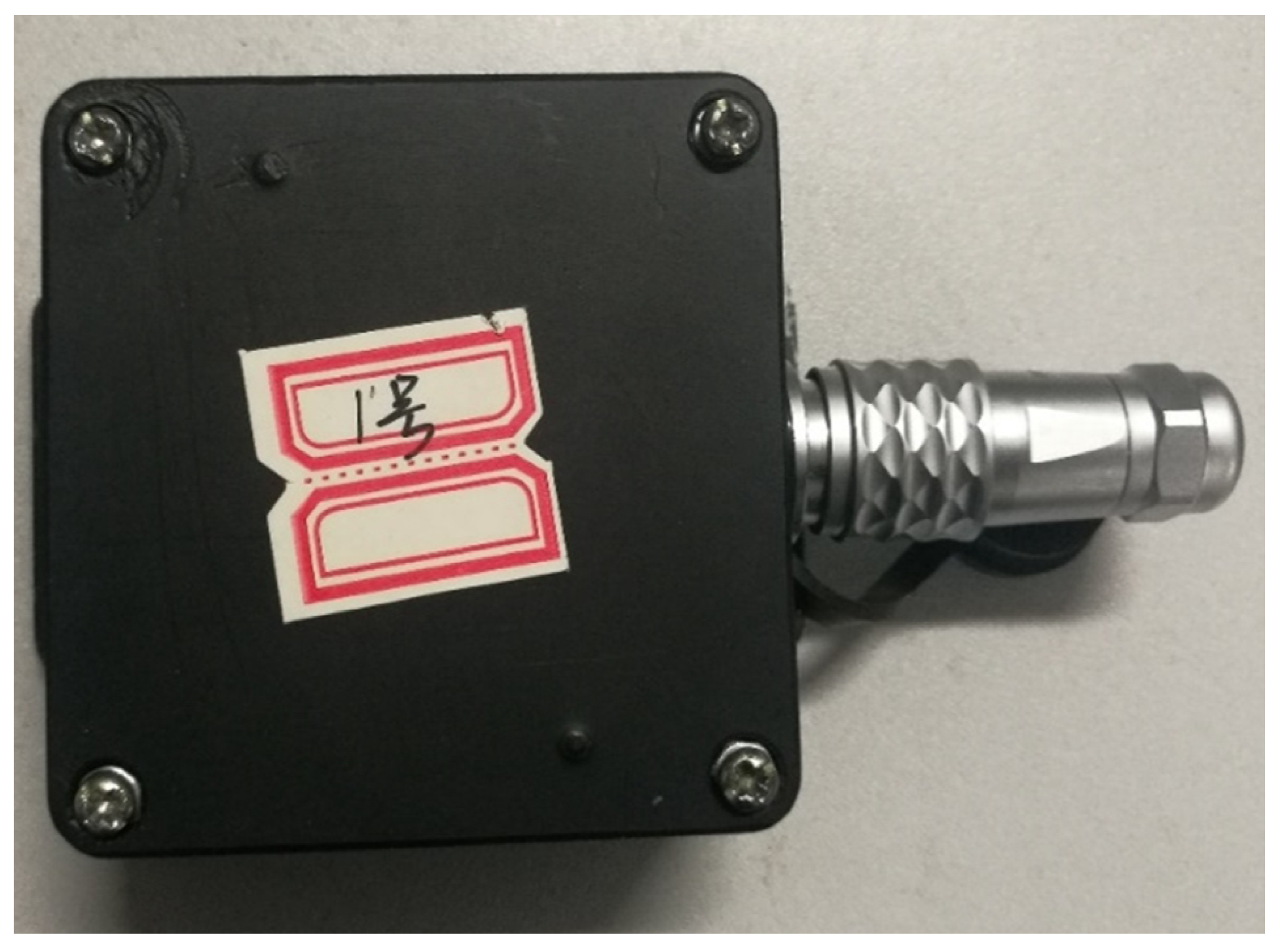

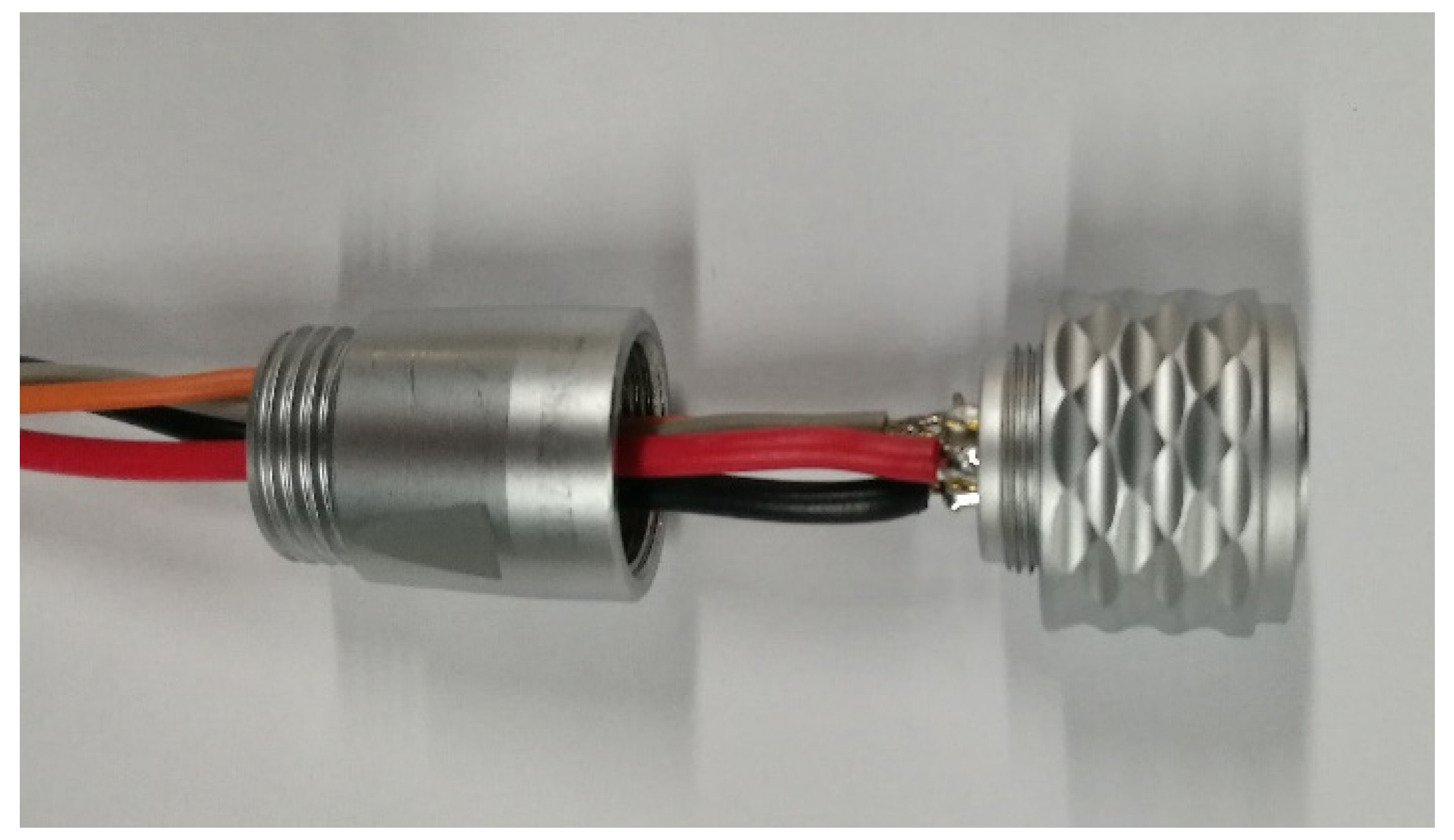

2.1.2. Production and Package of Circuit Board

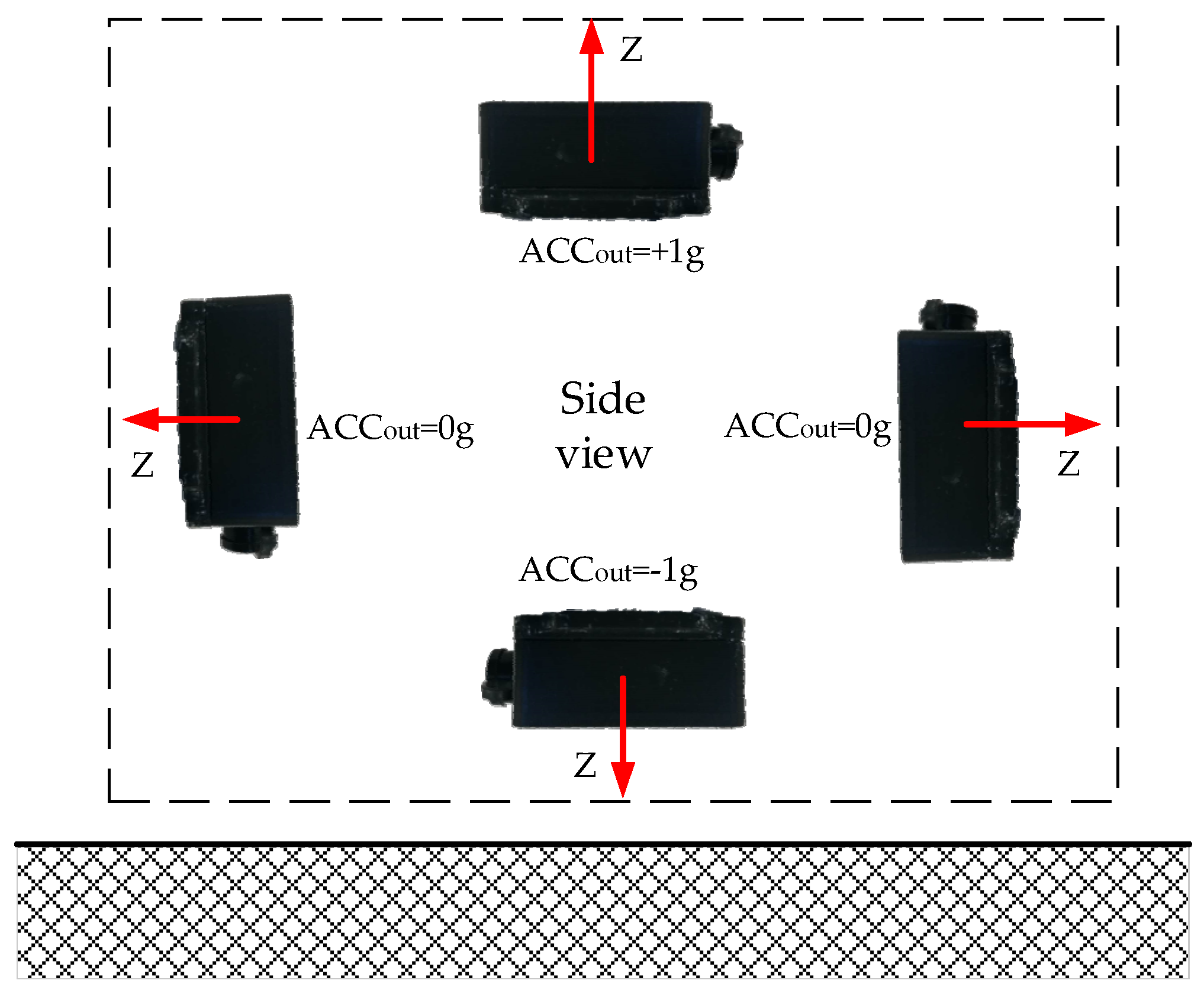

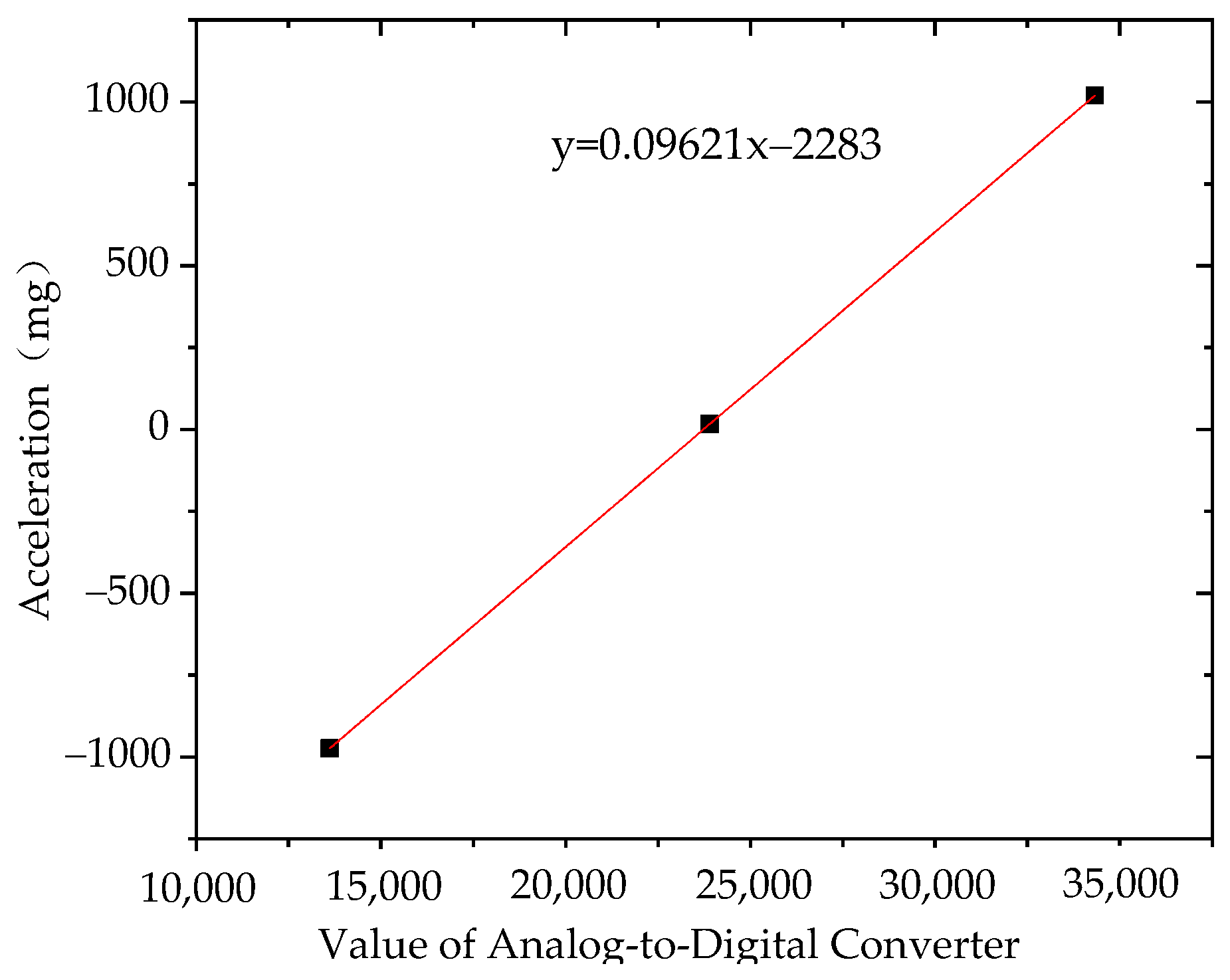

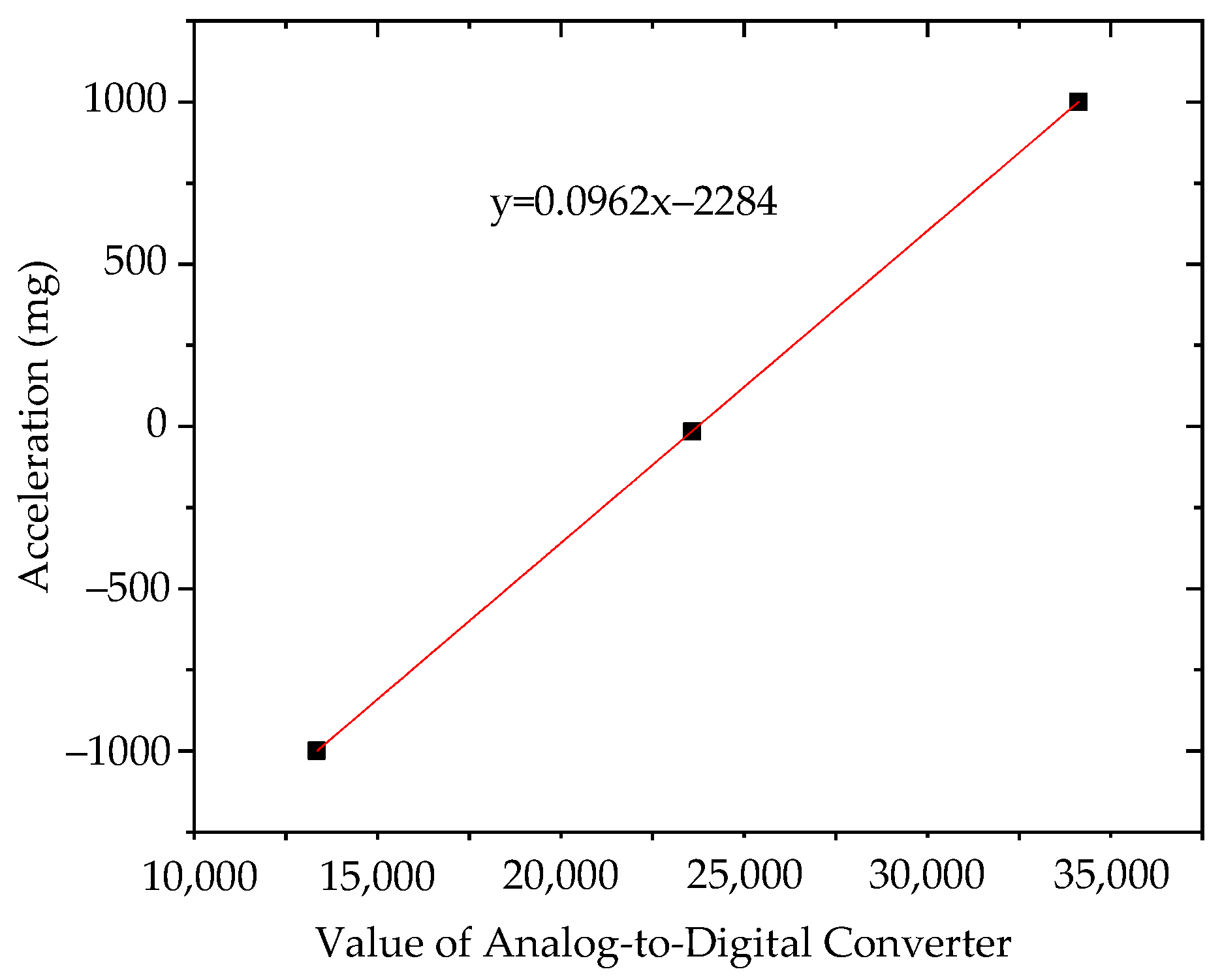

2.2. Calibration of Acceleration Sensor

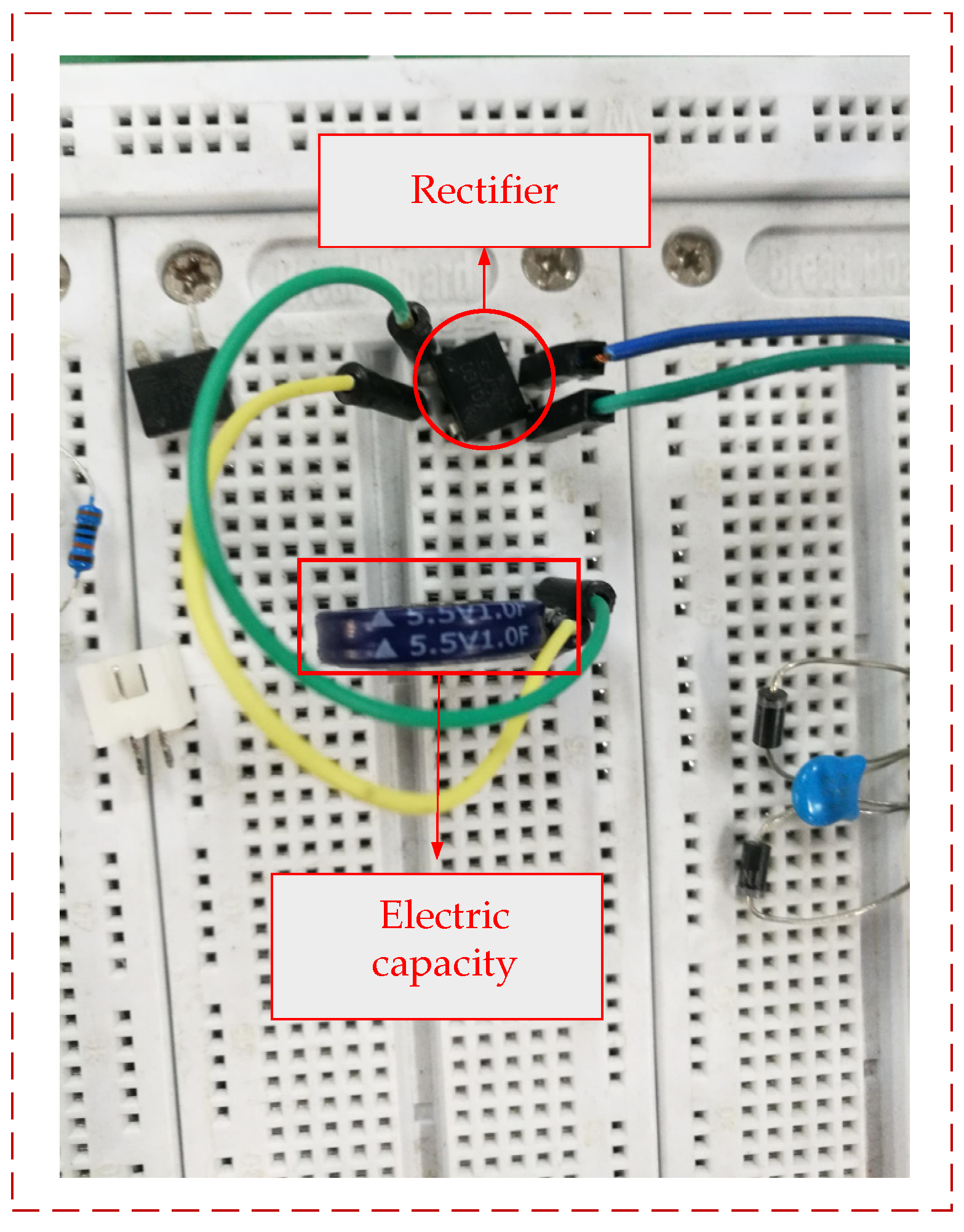

3. Vibration Energy Harvesting Device

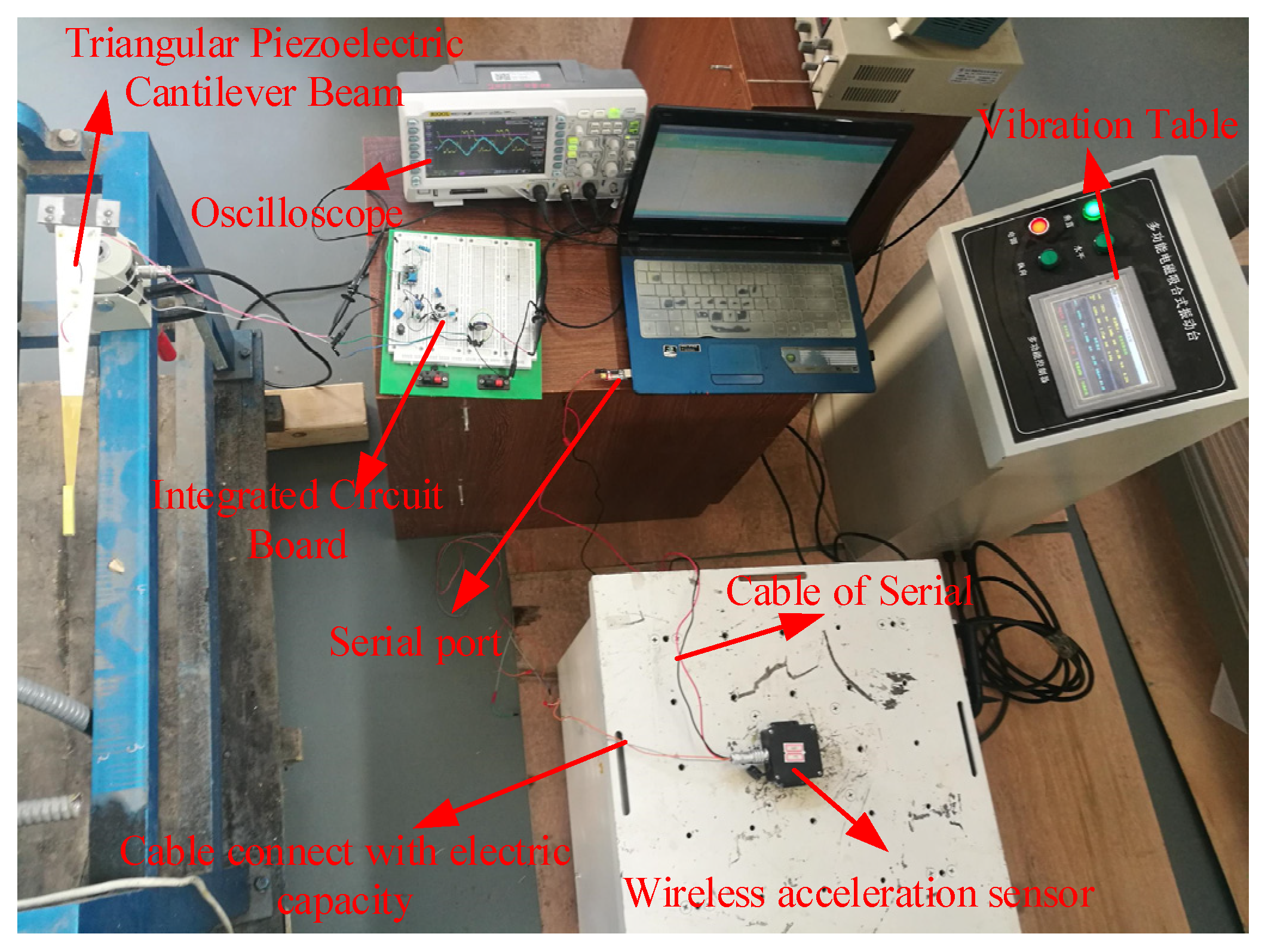

4. The Performance Test of Self-Power Sensor

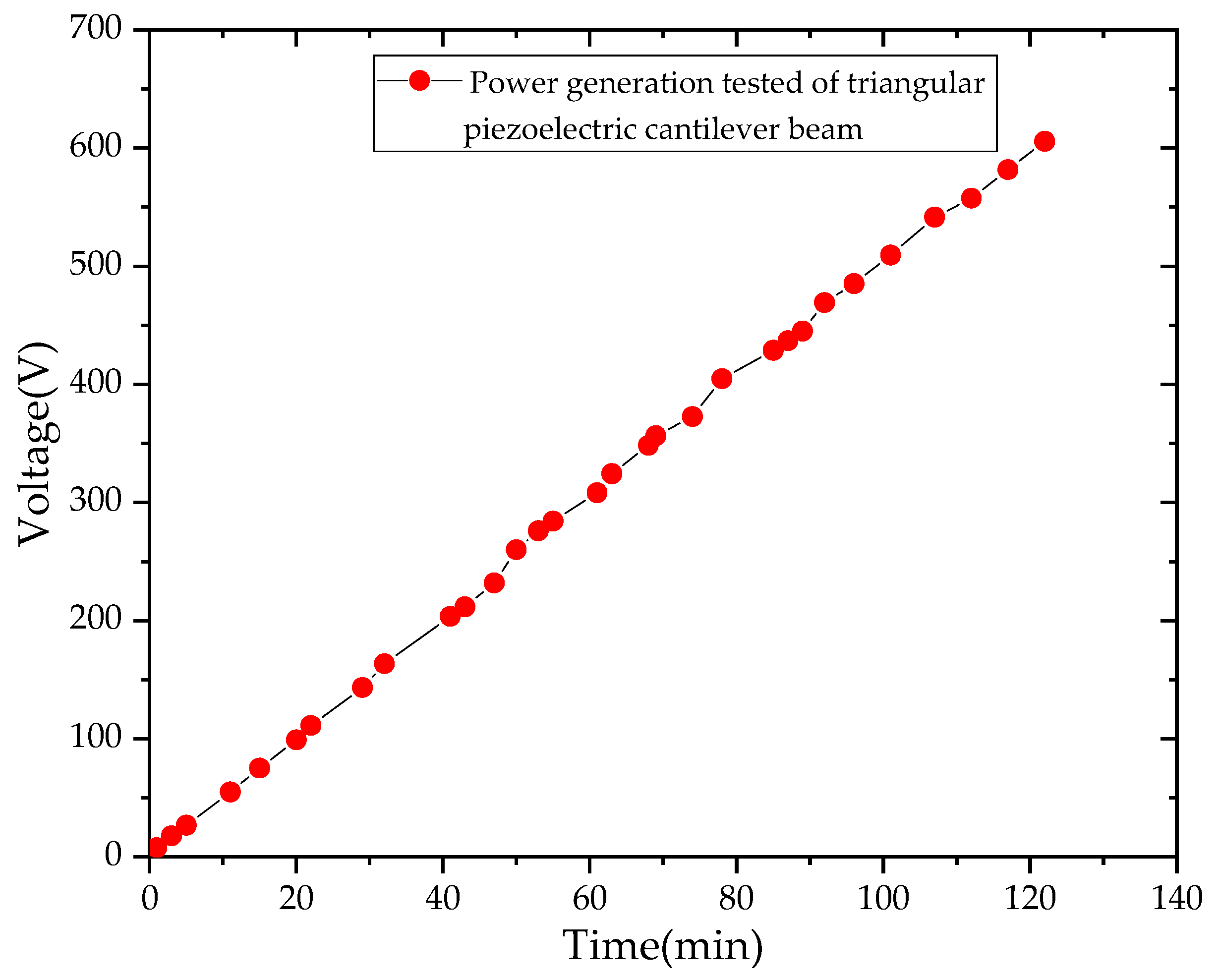

4.1. The Capacity Test of Piezoelectric Power Generation

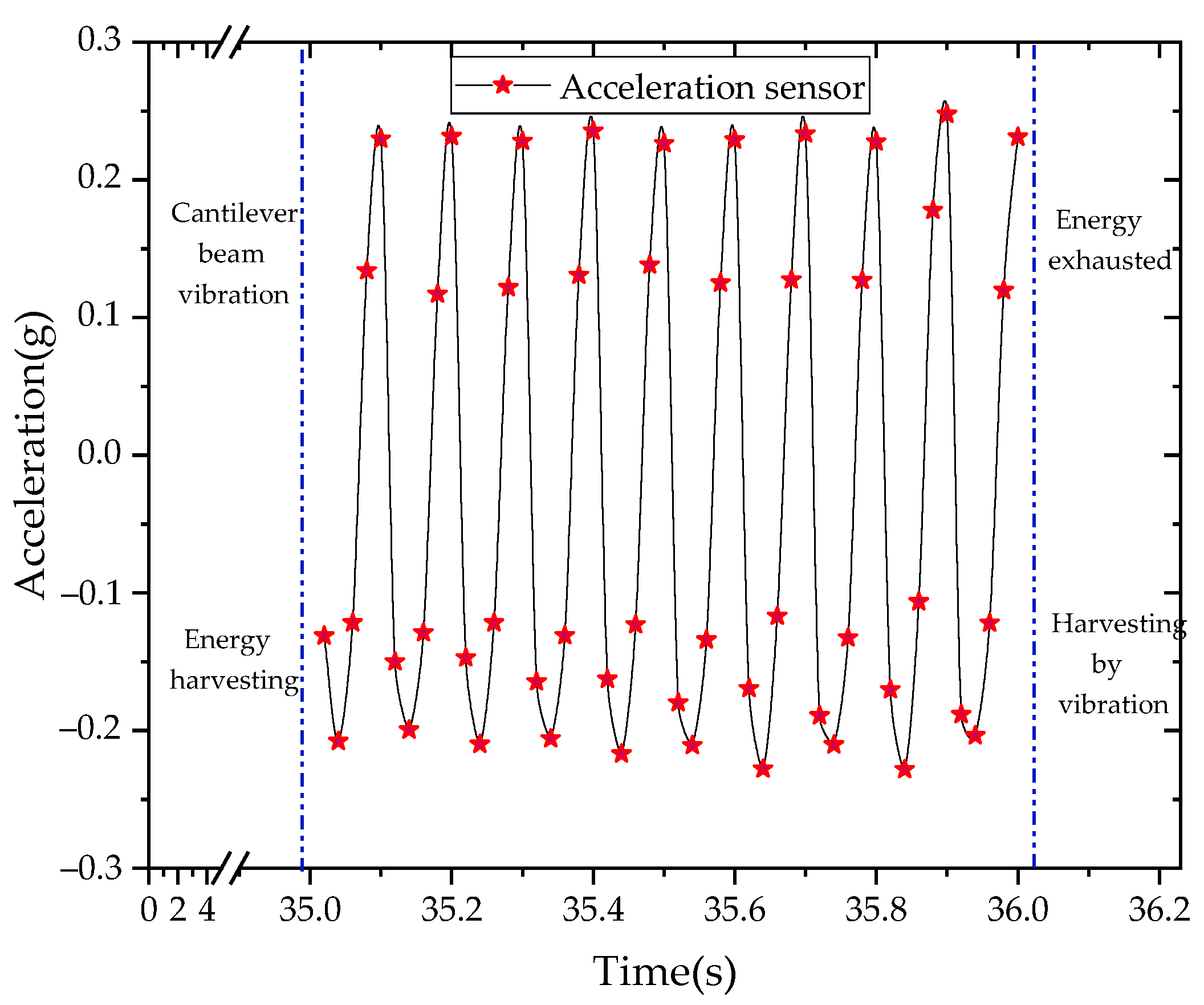

4.2. The Self-Powered Performance Test of Sensor

5. Summary

- A wireless acceleration sensor with low power consumption and high sensitivity for bridge vibration monitoring was developed, which solves the difficulties of traditional wiring monitoring. Calibration and performance comparison tests have verified the accuracy of the sensor in data collection.

- A triangular PCB was designed and fabricated based on the research results of different shapes of PCBs. It was shown that the triangular PCB has greater power generation capacity than the rectangular and trapezoidal PCBs, and the natural frequency is lower than the rectangular and trapezoidal PCBs.

- The acceleration sensor was integrated with the triangular PCB through the circuit, and its self-powered ability was tested. The experiment results showed that the single triangular PCB can generate 0.245 J within 1 h under excitation of 12 Hz, which proved the feasibility of installing piezoelectric energy harvesting devices on bridges to supply power for the sensors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xinlong, T.; Hailu, Y.; Linbing, W.; Yinghao, M. The development and field evaluation of an IoT system of low-power vibration for bridge health monitoring. Sensors 2019, 19, 1222. [Google Scholar]

- Cassandras, C.G.; Wang, T.; Pourazarm, S. Optimal routing and energy allocation for lifetime maximization of wireless sensor networks with Nonideal batteries. IEEE Trans. Control Netw. Syst. 2014, 1, 86–98. [Google Scholar] [CrossRef]

- Yang, H.; Cao, D. An investigation on stress distribution effect on multi-piezoelectric energy harvesters. Front. Struct. Civ. Eng. 2017, 11, 3. [Google Scholar] [CrossRef]

- Kempton, W.; Tomi, J. Vehicle-to-grid power implementation: From stabilizing the grid to supporting large-scale renewable energy. J. Power Sources 2005, 144, 280–294. [Google Scholar] [CrossRef]

- Charfi, S.; Atieh, A.; Chaabene, M. Modeling and cost analysis for different PV/battery/diesel operating options driving a load in Tunisia, Jordan and KSA. Sustain. Cities Soc. 2016, 25, 49–56. [Google Scholar] [CrossRef]

- Karami, A.; Basset, P.; Galayko, D. Electrostatic vibration energy harvester using an electret-charged mems transducer with an unstable auto-synchronous conditioning circuit. In Proceedings of the 15th International Conference on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS 2015), Boston, MA, USA, 1–4 December 2015. [Google Scholar]

- Xie, X.; Wang, Q. A mathematical model for piezoelectric ring energy harvesting technology from vehicle tires. Int. J. Eng. Sci. 2015, 94, 113–127. [Google Scholar] [CrossRef]

- Ng, T.H.; Liao, W.H. Sensitivity analysis and energy harvesting for a self-powered piezoelectric sensor. J. Intell. Mater. Syst. Struct. 2016, 16, 10. [Google Scholar] [CrossRef]

- Sharma, P.; Hajra, S.; Sahoo, S.; Rout, P.K.; Choudhary, N.R.P. Structural and electrical characteristics of gallium modified PZT ceramics. Process. Appl. Ceram. 2017, 11, 171–176. [Google Scholar] [CrossRef][Green Version]

- Sahu, M.; Vivekananthan, V.; Hajra, S.; Abisegapriyan, K.S.; Raj, N.P.M.J.; Kim, S.J. Synergetic enhancement of energy harvesting performance in triboelectric nanogenerator using ferroelectric polarization for self-powered IR signaling and body activity monitoring. J. Mater. Chem. A 2020, 8, 22257–22268. [Google Scholar] [CrossRef]

- Hosseini, R.; Hamedi, M.; Im, J.; Kim, J.; Dayou, J. Analytical and experimental investigation of partially covered piezoelectric cantilever energy harvester. Int. J. Eng. Manuf. 2017, 18, 415–424. [Google Scholar] [CrossRef]

- Lalthlamuana, R.; Talukdar, S. Conditions of visibility of bridge natural frequency in vehicle vertical acceleration. Procedia Eng. 2016, 144, 26–33. [Google Scholar] [CrossRef]

- Zhu, Q.; Yue, J.Z.; Liu, W.Q.; Wang, X.D.; Chen, J.; Hu, G.D. Active vibration control for piezoelectricity cantilever beam: An adaptive feedforward control method. Smart Mater. Struct. 2017, 26, 047003. [Google Scholar] [CrossRef]

- Liu, Y. Design Method of Piezoelectric Cantilever Beam in Bridge. Master’s Thesis, University of Science and Technology Beijing, Beijing, China, 2015. [Google Scholar]

- Xiong, Y.; Song, F.; Leng, X. A piezoelectric cantilever-beam energy harvester (PCEH) with a rectangular hole in the metal substrate. Microsyst. Technol. 2020, 26, 2–3. [Google Scholar] [CrossRef]

- Tong, X.; Song, S.; Wang, L.; Yang, H. A preliminary research on wireless cantilever beam vibration sensor in bridge health monitoring. Front. Struct. Civ. Eng. 2018, 12, 2. [Google Scholar] [CrossRef]

- Shi, F.; Tuo, X.; Yang, S.X.; Li, H.; Shi, R. Multiple two-way time message exchange (TTME) time synchronization for bridge monitoring wireless sensor networks. Sensors 2017, 17, 1027. [Google Scholar] [CrossRef]

- Kumalasari, A.D.; Tjondronegoro, S. Design of structural health monitoring using wireless sensor network case study pasupati bridge. Appl. Mech. Mater. 2016, 845, 293–298. [Google Scholar] [CrossRef]

- Li, C.; Cordovilla, F.; Ocana J, L. Design optimization and fabrication of a novel structural piezoresistive pressure sensor for micro-pressure measurement. Solid State Electron. 2018, 139, 39–47. [Google Scholar] [CrossRef]

- Dong, Q.; Wang, J.; Zhang, X.; Wang, H.; Jin, X. Development of virtual load rating method for taxiway bridge under aircraft taxiing. KSCE J. Civ. Eng. 2019, 23, 3030–3040. [Google Scholar] [CrossRef]

- Ye, Z.; Xiong, H.; Wang, L. Collecting comprehensive traffic information using pavement vibration monitoring data. Comput. Aided Civ. Infrastruct. Eng. 2020, 35, 134–149. [Google Scholar] [CrossRef]

- Yuan, Y.; Sun, X.; Liu, Z.; Li, Y.; Guan, X. Approach of Personnel Location in Roadway Environment Based on Multi-sensor Fusion and Activity Classification. Comput. Netw. 2018, 148, 34–45. [Google Scholar] [CrossRef]

- Aksel, E.; Jones, J.L. Advances in lead-free piezoelectric materials for sensors and actuators. Sensors 2010, 10, 1935–1954. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Tong, X.; Yang, H.; Wei, Y.; Miao, Y. Design and analysis of a hollow triangular piezoelectric cantilever beam harvester for vibration energy collection. Int. J. Pavement Res. Technol. 2019, 12, 259–268. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, X.; Hou, Y.; Dong, Y.; Zhang, Y.; Yang, H.; Qian, Z. Research and Development of a Wireless Self-Powered Sensing Device Based on Bridge Vibration Energy Collection. Sensors 2021, 21, 8319. https://doi.org/10.3390/s21248319

Tong X, Hou Y, Dong Y, Zhang Y, Yang H, Qian Z. Research and Development of a Wireless Self-Powered Sensing Device Based on Bridge Vibration Energy Collection. Sensors. 2021; 21(24):8319. https://doi.org/10.3390/s21248319

Chicago/Turabian StyleTong, Xinlong, Yun Hou, Yuanshuai Dong, Yanhong Zhang, Hailu Yang, and Zhenyu Qian. 2021. "Research and Development of a Wireless Self-Powered Sensing Device Based on Bridge Vibration Energy Collection" Sensors 21, no. 24: 8319. https://doi.org/10.3390/s21248319

APA StyleTong, X., Hou, Y., Dong, Y., Zhang, Y., Yang, H., & Qian, Z. (2021). Research and Development of a Wireless Self-Powered Sensing Device Based on Bridge Vibration Energy Collection. Sensors, 21(24), 8319. https://doi.org/10.3390/s21248319