An Integrated Wireless Multi-Sensor System for Monitoring the Water Quality of Aquaculture

Abstract

:1. Introduction

2. Wireless Multi-Sensor IoT System Design

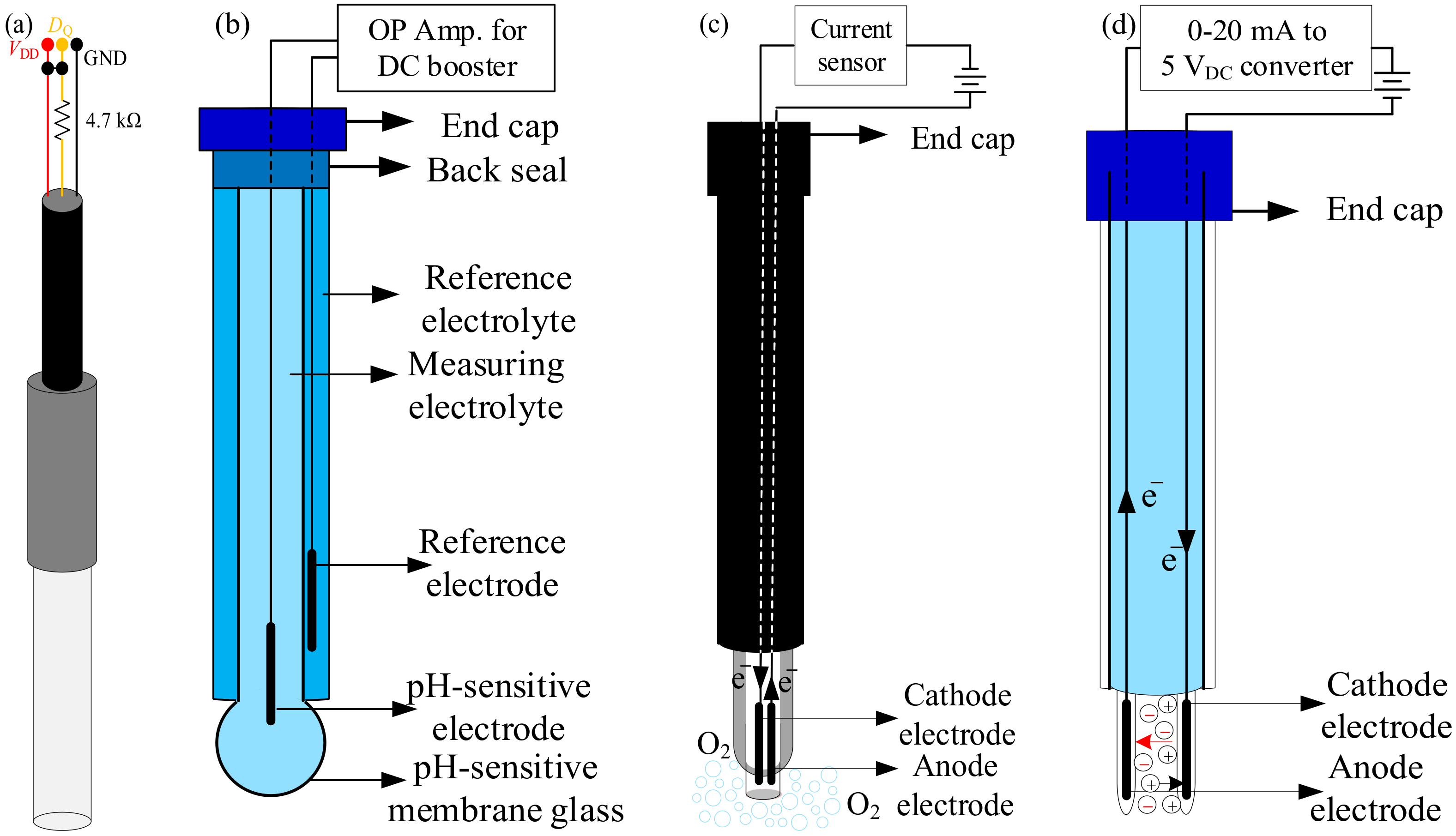

2.1. Sensors Description for Aquaculture

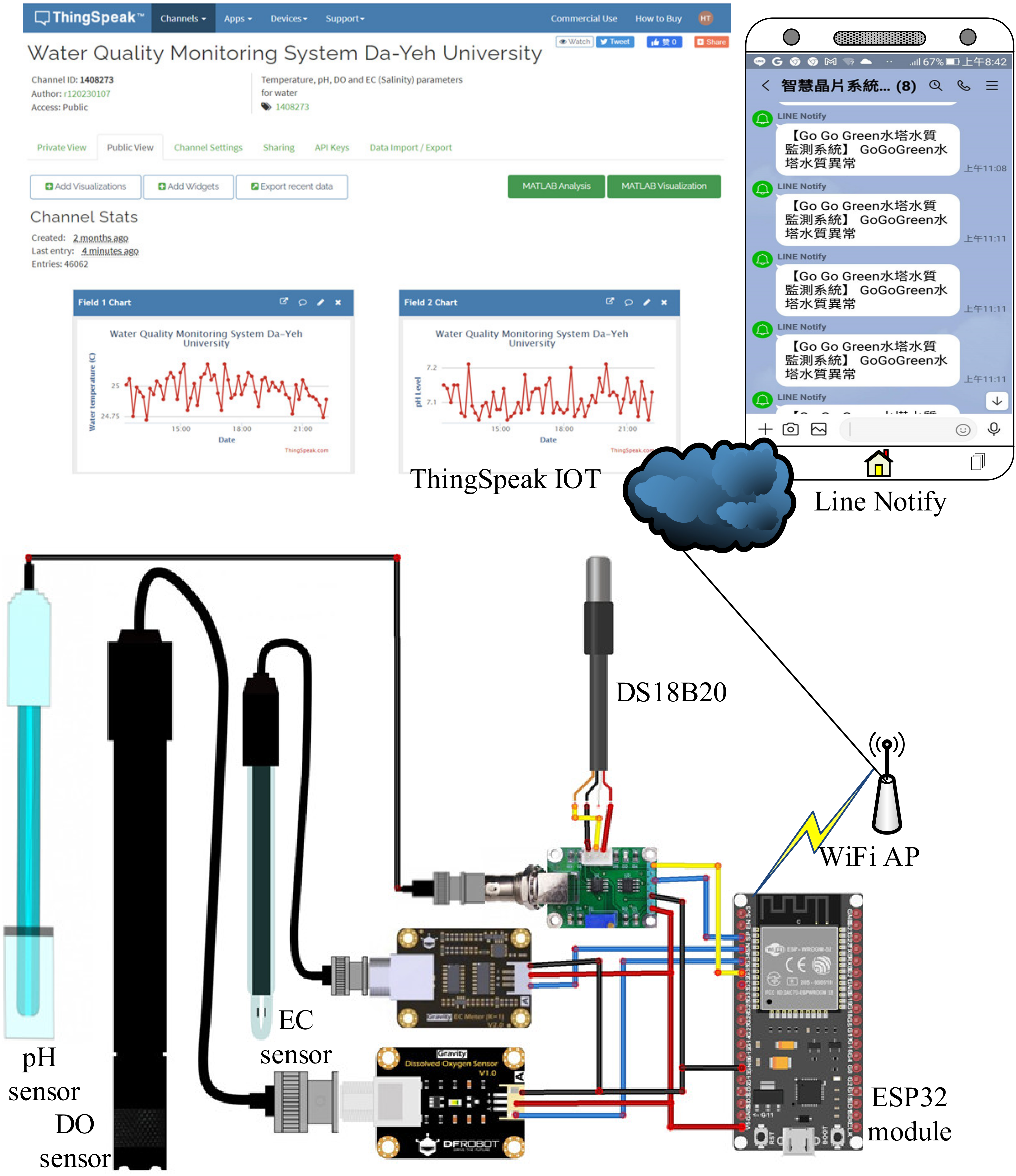

2.2. Hardware Description for the Wireless MCU and IoT System

3. System Implementation

3.1. Hardware Implementation for the Wireless Multi-Sensor IoT System

3.2. Software Design for the Wireless Multi-Sensor IoT System

4. Results and Discussion

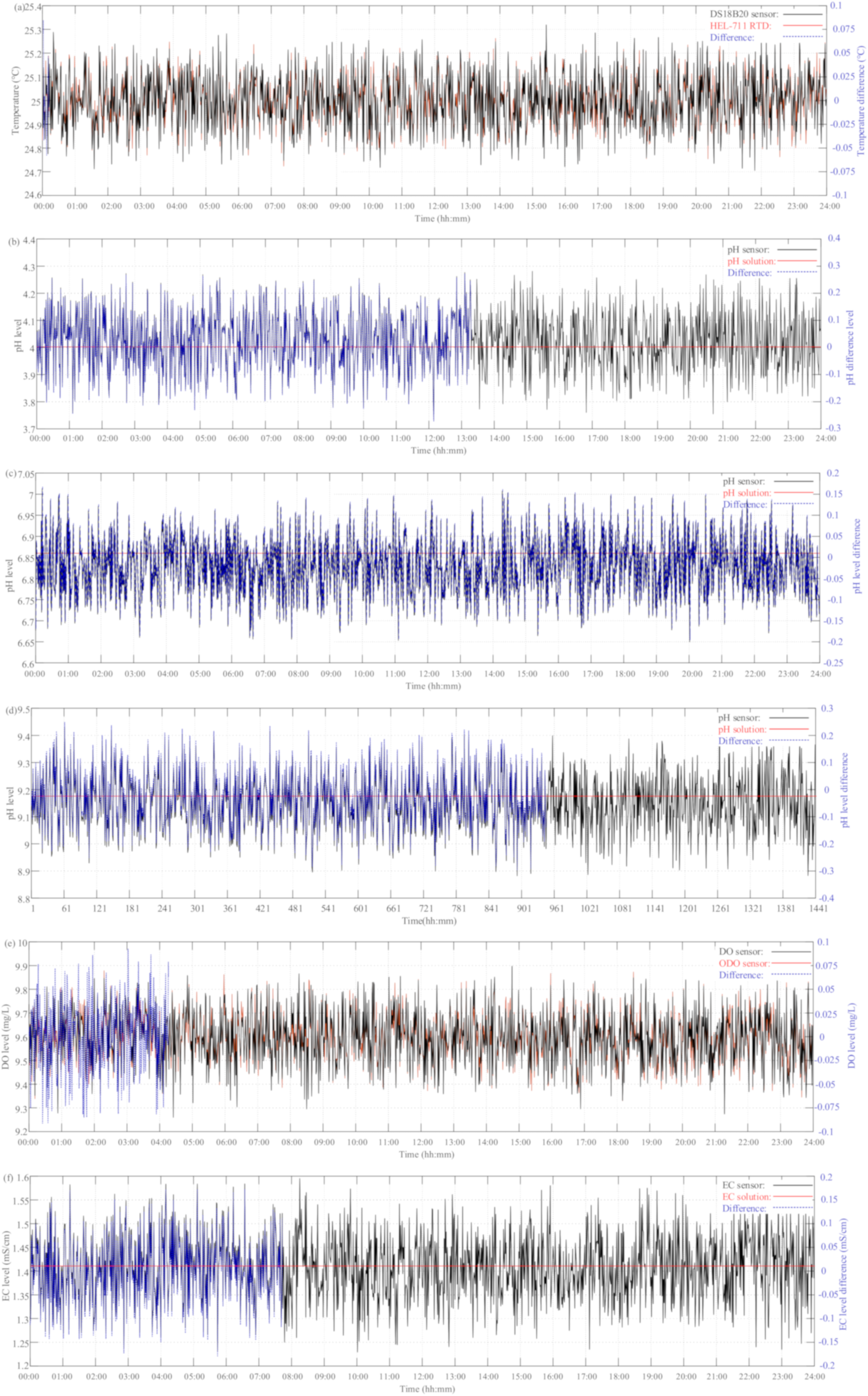

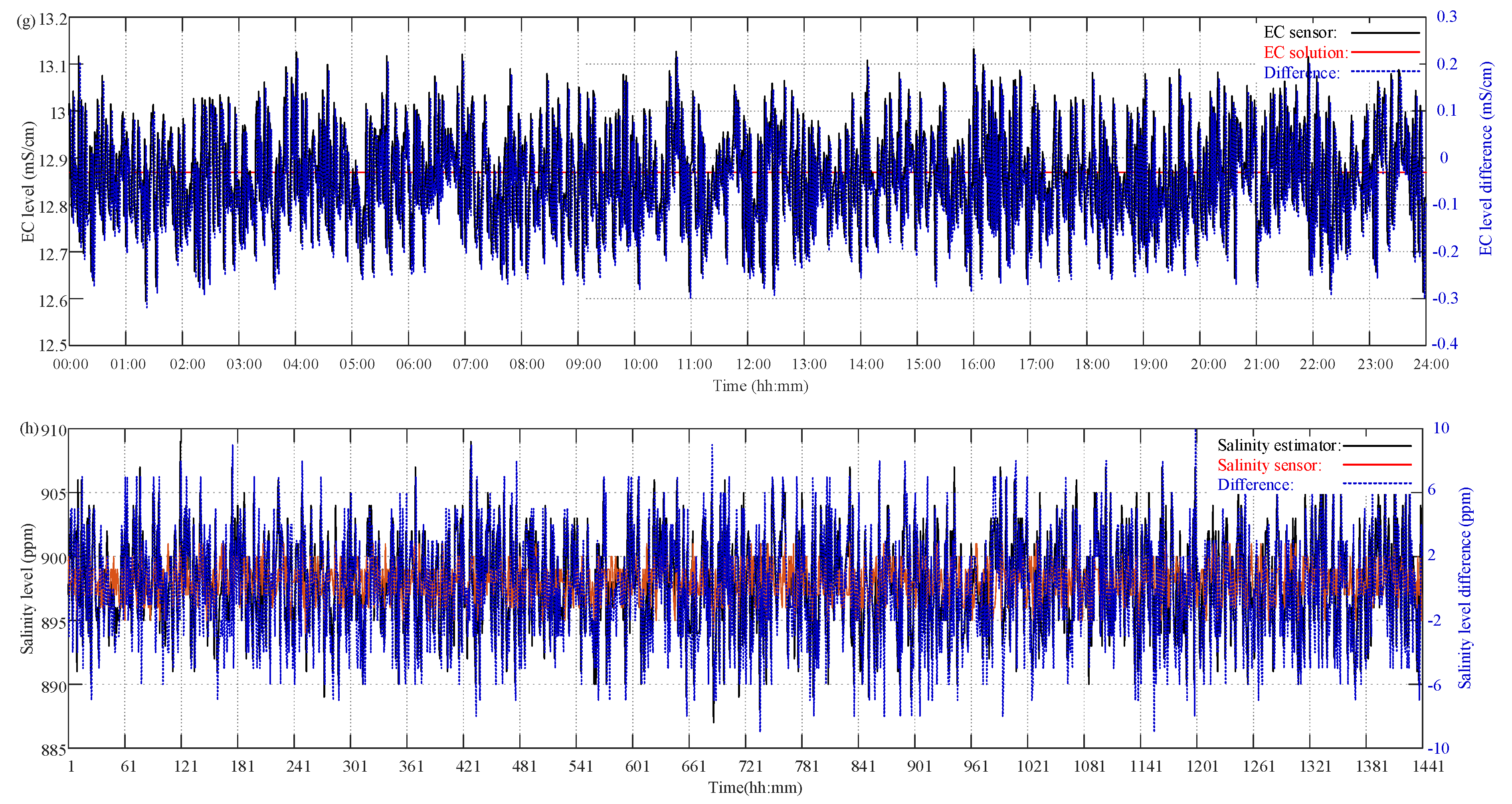

4.1. Pre-Calibration Process

4.2. In Situ Monitoring Results

4.3. Post-Calibration Results

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations (FAO). The State of World Fisheries and Aquaculture 2020; Food and Agriculture Organization of the United Nations (FAO): Roma, Italy, 2020. [Google Scholar] [CrossRef]

- Zhua, X.; Lia, D.; Heb, D.; Wanga, J.; Maa, D.; Li, F. A remote wireless system for water quality online monitoring in intensive fish culture. Comput. Electron. Agric. 2010, 71S, S3–S9. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Li, G.; Wua, H.B.; Liu, X.G.; Yao, Y.H.; Tao, L.; Liu, H. An integrated recirculating aquaculture system (RAS) for land-based fish farming: The effects on water quality and fish production. Aquacult. Eng. 2011, 45, 93–102. [Google Scholar] [CrossRef]

- Odey, A.J.; Li, D. AquaMesh—design and implementation of smart wireless mesh sensor networks for aquaculture. Am. J. Netw. Commun. 2013, 2, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Simbeye, D.S.; Yang, S.F. Water quality monitoring and control for aquaculture based on wireless sensor networks. J. Netw. 2014, 9, 840–849. [Google Scholar] [CrossRef]

- Schmidt, W.; Raymondb, D.; Parishb, D.; Ashton, I.G.C.; Millerc, P.I.; Camposd, C.J.A.; Shutler, J.D. Design and operation of a low-cost and compact autonomous buoy system for use in coastal aquaculture and water quality monitoring. Aquacult. Eng. 2018, 80, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Saparudin, F.A.; Chee, T.C.; Ab Ghafar, A.S.; Majid, H.A.; Katiran, N. Wireless water quality monitoring system for high density aquaculture application. Indones. J. Electr. Eng. Comput. Sci. 2019, 13, 507–513. [Google Scholar] [CrossRef]

- Danh, L.V.Q.; Dung, D.V.M.; Danh, T.H.; Ngon, N.C. Design and deployment of an IoT-based water quality monitoring system for aquaculture in Mekong Delta. Int. J. Mech. Eng. Robot. Res. 2020, 9, 1170–1175. [Google Scholar] [CrossRef]

- Quick-Teck. DS18B20 Waterproof Temperature Sensor. Available online: https://www.quick-teck.co.uk/Management/EEUploadFile/1420644897.pdf (accessed on 7 July 2021).

- International Organization of Standards (ISO). ISO 10523 Water Quality Determination of pH; International Organization of Standards (ISO): Geneva, Switzerland, 2008. [Google Scholar]

- DFRobot. Analog pH Sensor/Meter Kit V2. Available online: https://media.digikey.com/pdf/Data%20Sheets/DFRobot%20PDFs/SEN0161-V2_Web.pdf (accessed on 21 March 2021).

- Environmental Protection Administration (EPA) United States. Chesapeake Bay Total Maximum Daily Load for Nitrogen, Phosphorus and Sediment. 29 December 2010, pp. 3–9, 3–10. Available online: https://www.epa.gov/sites/default/files/2014-12/documents/cbay_final_tmdl_exec_sum_section_1_through_3_final_0.pdf (accessed on 7 July 2021).

- DFRobot. Analog Dissolved Oxygen Sensor/Meter Kit for Arduino. Available online: https://media.digikey.com/pdf/Data%20Sheets/DFRobot%20PDFs/SEN0237-A_Web.pdf (accessed on 21 March 2021).

- Fondriest Environmental, Inc. “Measuring Dissolved Oxygen.” Fundamentals of Environmental Measurements. 2014. Available online: https://www.fondriest.com/environmental-measurements/measurements/measuring-water-quality/dissolved-oxygen-sensors-and-methods/ (accessed on 7 July 2021).

- Richards, L.A. (Ed.) Diagnosis and Improvement of Saline and Alkali Soils; United States Salinity Laboratory Staff: Riverside, CA, USA, 1954; pp. 16–17. [Google Scholar]

- DFRobot. Analog Electrical Conductivity Sensor/Meter (K = 1). Available online: https://media.digikey.com/pdf/Data%20Sheets/DFRobot%20PDFs/DFR0300-H_Web.pdf (accessed on 21 March 2021).

- Environmental Protection Administration (EPA) United States. Indicators Used in the National Aquatic Resource Surveys. Available online: https://www.epa.gov/national-aquatic-resource-surveys/indicators-used-national-aquatic-resource-surveys (accessed on 14 May 2021).

- Swann, L. A Fish Farmer’s Guide to Understanding Water Quality. Available online: https://southcenters.osu.edu/sites/southc/files/site-library/site-images/FishFarmersGuideToWaterQuality.pdf (accessed on 7 July 2021).

- Espressif Systems. ESP32 Series Datasheet, Ver. 3.7. 2021. Available online: https://www.espressif.com/sites/default/files/documentation/esp32_datasheet_en.pdf (accessed on 14 May 2021).

- ThingSpeak. Available online: https://thingspeak.com/channels/1408273 (accessed on 14 May 2021).

- Honeywell. Thin Film Platinum RTDs: HEL-700 Series. Available online: https://sensing.honeywell.com/honeywell-sensing-hel-700-series-thin-film-platinum-rtd-productsheet-009080-1-en.pdf (accessed on 14 May 2021).

- FOPTOD. FOPTOD Optical Dissolved Oxygen. Available online: http://www.jetec.com.tw/pdf/6/english/FOPTOD_E_data.pdf (accessed on 14 May 2021).

- Vernier. Salinity Sensor. Available online: https://www.vernier.com/files/manuals/sal-bta/sal-bta.pdf (accessed on 14 May 2021).

| No. | Sensors | Processor | Communication | Information Platform | References | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T | pH | DO | EC | TD | ORP | Sal | |||||

| 1 | 2 | 1 | 1 | 1 | 0 | 0 | * | PICNIC 2.0 | CDMA | Intranet Platform | Zhua et al. (2010) |

| 2 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | Multimeter | × | × | Zhang et al. (2011) |

| 3 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | Wastmode | ZeeBee/WiFi/GPRS | DiGi International | Odey & Li (2013) |

| 4 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | ATMega | ZeeBee | LabVIEW | Simbeye & Yang (2018) |

| 5 | 3 | 0 | 1 | 0 | 0 | 0 | 0 | Dataloger | Manual offload | HOBO | Schmidt et al. (2019) |

| 6 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | Raspberry Pi | WiFi/CDMA | ThingSpeak | Saparudin et al. (2019) |

| 7 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | Embeded MCU | RoLa/WiFi | ThingSpeak | Dahn et al. (2020) |

| 8 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | ESP-32 | WiFi | ThingSpeak | Proposed |

| pH | pH Buffer Solutions @25 °C | ||||||

|---|---|---|---|---|---|---|---|

| °C | 1.68 | 4.01 | 6.86 | 7.00 | 9.18 | 10.10 | 12.46 |

| 0 | 1.67 | 4.01 | 6.98 | 7.12 | 9.46 | 10.32 | 13.47 |

| 5 | 1.67 | 4.01 | 6.95 | 7.09 | 9.39 | 10.25 | 13.25 |

| 10 | 1.67 | 4.00 | 6.92 | 7.06 | 9.32 | 10.18 | 13.03 |

| 15 | 1.67 | 4.00 | 6.90 | 7.04 | 9.27 | 10.12 | 12.83 |

| 20 | 1.68 | 4.00 | 6.88 | 7.02 | 9.22 | 10.06 | 12.64 |

| 25 | 1.68 | 4.01 | 6.86 | 7.00 | 9.18 | 10.01 | 12.46 |

| 30 | 1.69 | 4.01 | 6.85 | 6.98 | 9.14 | 9.97 | 12.29 |

| 35 | 1.69 | 4.02 | 6.84 | 6.98 | 9.10 | 9.93 | 12.14 |

| 40 | 1.70 | 4.03 | 6.84 | 6.97 | 9.07 | 9.89 | 11.99 |

| 45 | 1.70 | 4.04 | 6.83 | 6.97 | 9.04 | 9.86 | 11.86 |

| 50 | 1.71 | 4.06 | 6.83 | 6.97 | 9.01 | 9.83 | 11.73 |

| 55 | 1.72 | 4.08 | 6.83 | 6.97 | 8.99 | 9.81 | 11.61 |

| Sensors | Measuring Range | Measuring Accuracy | Operating Temperature | Warning Range |

|---|---|---|---|---|

| Temperature | −55–125 °C | ±0.5 °C @ −10–85 °C | −55–125 °C | ≤0 °C or ≥40 |

| pH | 0–14 | ±0.1 @ 25 °C | 0–60 °C | <6.5 or >8.5 |

| DO | 0–20 mg/L | NA | 0–50 °C | ≤6 mg/L |

| EC | 0–20 mS/cm | ±5% F.S. | 0–40 °C | ≥5 mS/cm |

| Pin No. | Pin Function | Function | Remark |

|---|---|---|---|

| 3 | GPIO36 (ADC0) | pH reading | Input only |

| 4 | GPIO39 (ADC3) | DO reading | Input only |

| 5 | GPIO34 (ADC6) | EC reading | Input only |

| 6 | GPIO35 (ADC7) | Temperature reading | Input only |

| 14 | GND | Ground | |

| 19 | 5 VDC | Power supply |

| Items | Reference | Accuracy Analysis | ||

|---|---|---|---|---|

| Difference Range | MAE | RMSE | ||

| Temperature sensor | HEL-711 RTD | −0.10–0.10 °C | 0.0331 °C | 0.0403 °C |

| pH sensor | pH 4.0 buffer solution | −0.26–0.31 | 0.0899 | 0.1094 |

| pH 6.86 buffer solution | −0.20–0.16 | 0.0624 | 0.0755 | |

| pH 9.18 buffer solution | −0.31–0.23 | 0.0920 | 0.1119 | |

| DO sensor | FOPTOD ODO | −0.10–0.10 mg/L | 0.0339 mg/L | 0.414 mg/L |

| EC sensor | 1413 μS/cm conductivity solution | −0.19–0.17 mS/cm | 0.0574 mS/cm | 0.0698 mS/cm |

| 12.88 mS/cm conductivity solution | −0.28–0.26 mS/cm | 0.0882 mS/cm | 0.1082 mS/cm | |

| Salinity estimation | Vernier Salinity Sensor | −10–9 ppm | 3.0285 ppm | 3.6451 ppm |

| Items | Accuracy Analysis | |||

|---|---|---|---|---|

| Mean | Difference Range | MAE | RMSE | |

| Temperature sensor | 25.0951 °C | −0.31–0.34 °C | 0.0961 °C | 0.1178 °C |

| pH sensor | 7.1755 | −0.20–0.20 | 0.0640 | 0.782 |

| DO sensor | 9.5228 mg/L | −0.35–0.33 mg/L | 0.0990 mg/L | 0.1217 mg/L |

| EC sensor | 0.7923 mS/cm | −0.18–0.18 mS/cm | 0.0571 mS/cm | 0.0694 mS/cm |

| Salinity estimation | 464 ppm | −2–2 ppm | 0.5337 ppm | 0.7557 ppm |

| Items | Reference | Accuracy Analysis | ||

|---|---|---|---|---|

| Difference Range | MAE | RMSE | ||

| Temperature sensor | HEL-711 RTD | −0.10–0.10 °C | 0.0339 °C | 0.0417 °C |

| pH sensor | pH 6.86 buffer solution | −0.23–0.15 | 0.0603 | 0.0738 |

| DO sensor | FOPTOD ODO | −0.10–0.10 mg/L | 0.0329 mg/L | 0.401 mg/L |

| EC sensor | 1413 μS/cm conductivity solution | −0.19–0.17 mS/cm | 0.0574 mS/cm | 0.0698 mS/cm |

| Salinity estimation | Vernier Salinity Sensor | −10–10 ppm | 2.9743 ppm | 3.6078 ppm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.-Y.; Tsai, H.-L.; Lyu, W.-H. An Integrated Wireless Multi-Sensor System for Monitoring the Water Quality of Aquaculture. Sensors 2021, 21, 8179. https://doi.org/10.3390/s21248179

Lin J-Y, Tsai H-L, Lyu W-H. An Integrated Wireless Multi-Sensor System for Monitoring the Water Quality of Aquaculture. Sensors. 2021; 21(24):8179. https://doi.org/10.3390/s21248179

Chicago/Turabian StyleLin, Jen-Yung, Huan-Liang Tsai, and Wei-Hong Lyu. 2021. "An Integrated Wireless Multi-Sensor System for Monitoring the Water Quality of Aquaculture" Sensors 21, no. 24: 8179. https://doi.org/10.3390/s21248179

APA StyleLin, J.-Y., Tsai, H.-L., & Lyu, W.-H. (2021). An Integrated Wireless Multi-Sensor System for Monitoring the Water Quality of Aquaculture. Sensors, 21(24), 8179. https://doi.org/10.3390/s21248179