Development of Wrist Interface Based on Fully Actuated Coaxial Spherical Parallel Mechanism for Force Interaction

Abstract

1. Introduction

2. Kinematic Analysis of the CSPM

2.1. Forward Kinematics

2.2. Inverse Kinematics

2.3. Jacobian Analysis

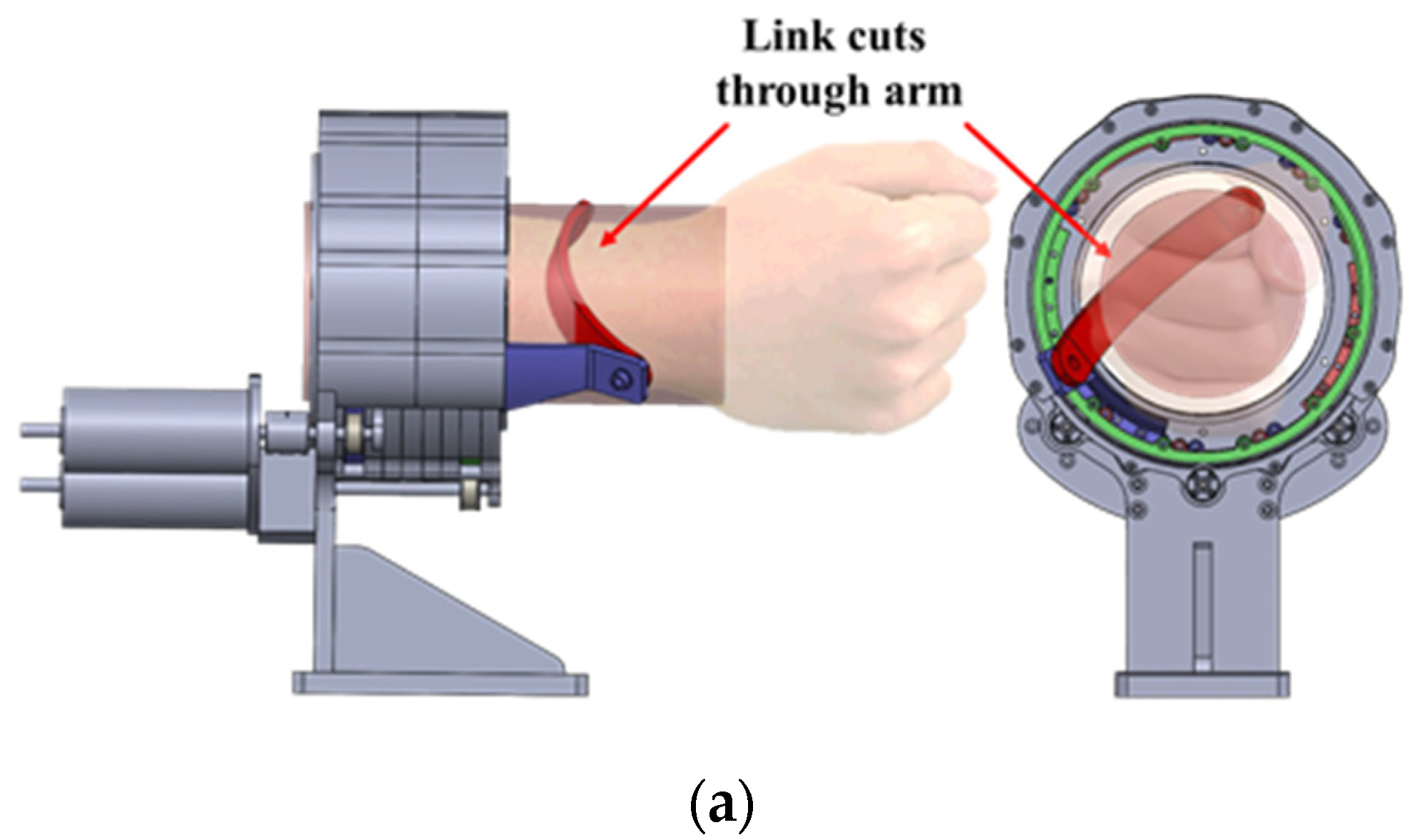

3. Interference Safety of the C-WERI

4. Design Optimization

4.1. Design Parameters and Bounds

4.2. Performance Measures

4.2.1. Condition Index

4.2.2. Interference Safety Margin

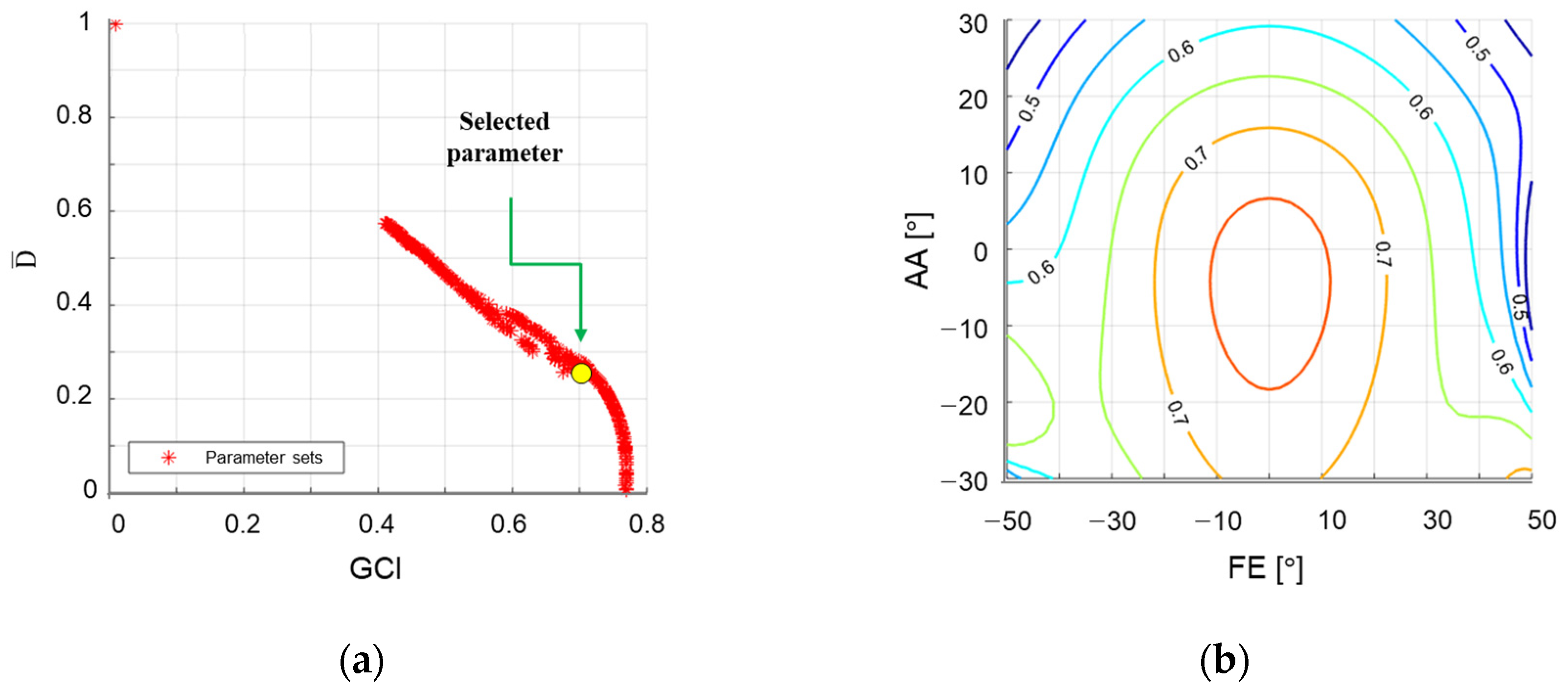

4.3. Design Optimization

4.4. Actuator Capacity Design

5. Verification

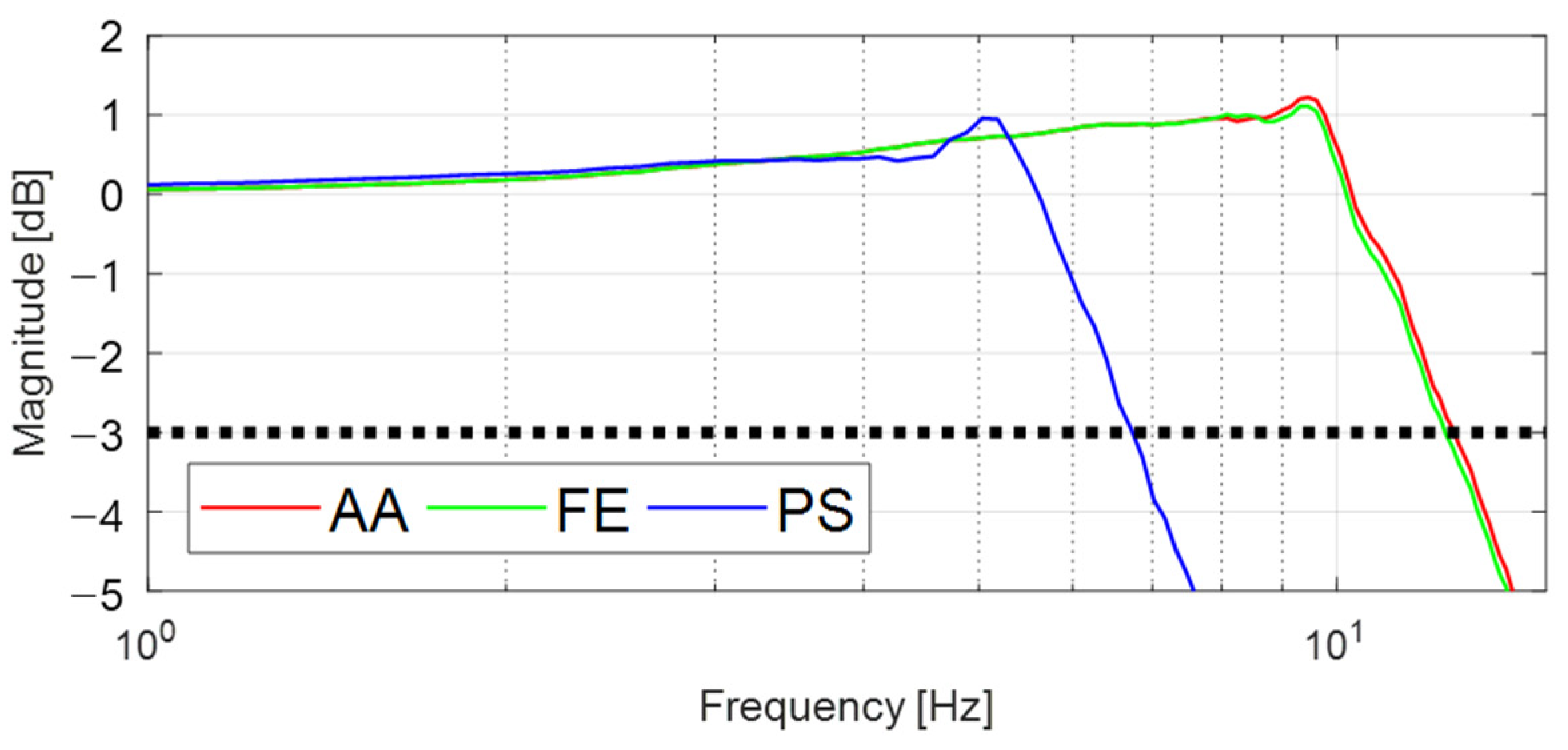

5.1. Motion Control Experiment

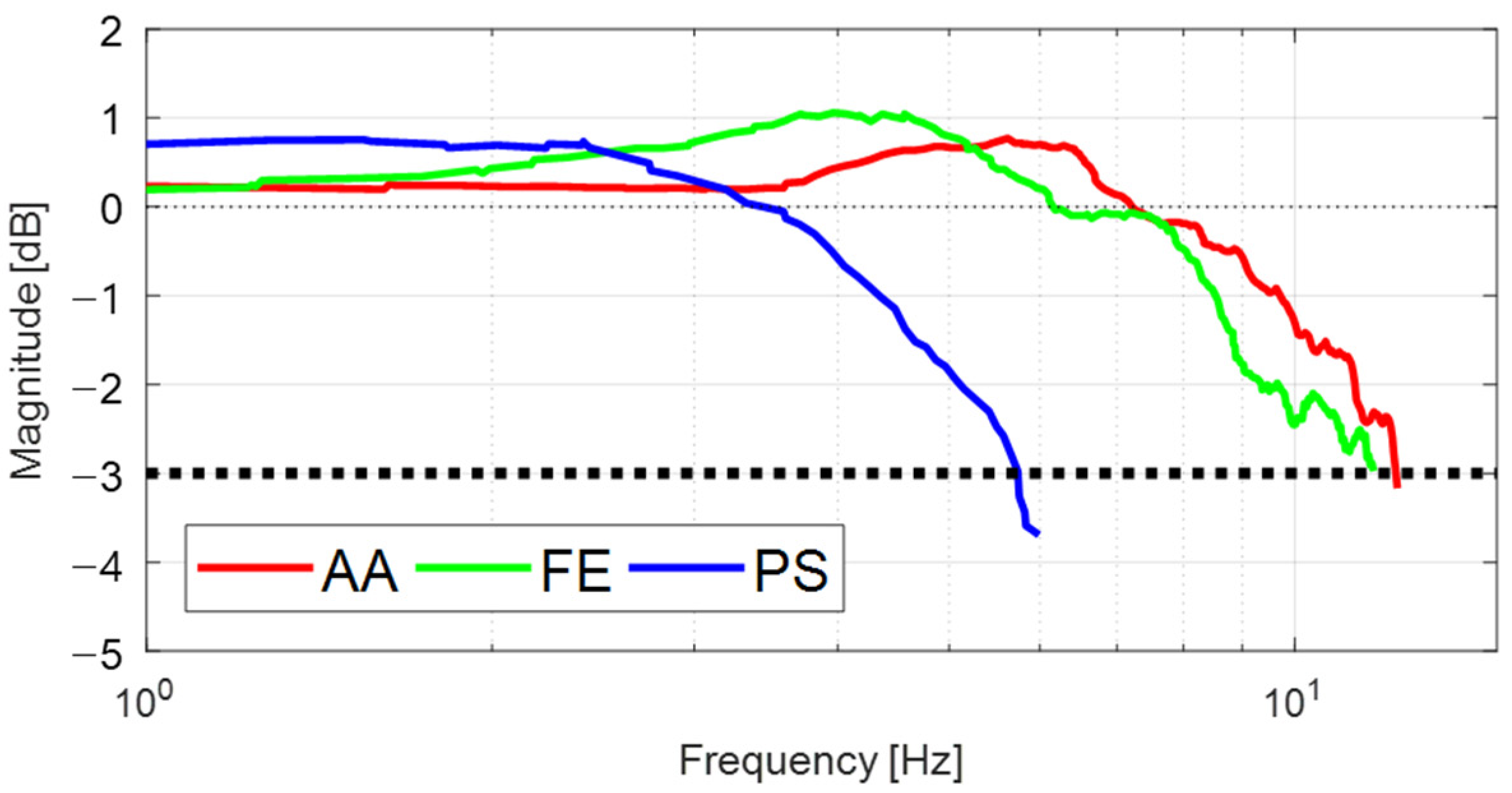

5.2. Force Control Experiment

5.3. Dynamic Response Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goodrich, M.A.; Schultz, A.C. Human-Robot Interaction: A Survey; Now Publishers Inc.: Boston, MA, USA, 2008. [Google Scholar]

- Tejima, N. Rehabilitation robotics: A review. Adv. Robot. 2001, 14, 551–564. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, G.; Cho, D.Y.; Kim, H.Y.; Lee, J.Y.; Kim, S.; Park, S.B.; Shin, J.H. Comparisons between end-effector and exoskeleton rehabilitation robots regarding upper extremity function among chronic stroke patients with moderate-to-severe upper limb impairment. Sci. Rep. 2020, 10, 1806. [Google Scholar] [CrossRef]

- Pehlivan, A.U.; Lee, S.; O’Malley, M.K. Mechanical design of ricewrist-s: A forearm-wrist exoskeleton for stroke and spinal cord injury rehabilitation. In Proceedings of the 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; pp. 1573–1578. [Google Scholar]

- Oblak, J.; Cikajlo, I.; Matjacic, Z. Universal haptic drive: A robot for arm and wrist rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2010, 18, 293–302. [Google Scholar] [CrossRef] [PubMed]

- Lo, H.S.; Xie, S.Q. Exoskeleton robots for upper-limb rehabilitation: State of the art and future prospects. Med. Eng. Phys. 2012, 34, 261–268. [Google Scholar] [CrossRef]

- Jeong, Y.; Lee, Y.; Kim, K.; Hong, Y.S.; Park, J.O. A 7 DOF wearable robotic arm using pneumatic actuators. In Proceedings of the 32nd International Symposium on Robotics (ISR), Seoul, Korea, 19–21 April 2001; pp. 388–393. [Google Scholar]

- French, J.A.; Rose, C.G.; O’Malley, M.K. System characterization of MAHI Exo-II: A robotic exoskeleton for upper extremity rehabilitation. In Proceedings of the ASME Dynamic Systems and Control Conference, San Antonio, TX, USA, 22–24 October 2014; p. V003T43A006. [Google Scholar]

- Gupta, A.; O’Malley, M.K.; Patoglu, V.; Burgar, C. Design, control and performance of RiceWrist: A force feedback wrist exoskeleton for rehabilitation and training. Int. J. Robot. Res. 2008, 27, 233–251. [Google Scholar] [CrossRef]

- Pehlivan, A.U.; Sergi, F.; Erwin, A.; Yozbatiran, N.; Francisco, G.E.; O’Malley, M.K. Design and validation of the RiceWrist-S exoskeleton for robotic rehabilitation after incomplete spinal cord injury. Robotica 2014, 32, 1415–1431. [Google Scholar] [CrossRef]

- Schiele, A.; Van Der Helm, F.C.T. Kinematic design to improve ergonomics in human machine interaction. IEEE Trans. Neural Syst. Rehabil. Eng. 2006, 14, 456–469. [Google Scholar] [CrossRef]

- Lu, Y.; Chang, Z.; Lu, Y.; Wang, Y. Development and kinematics/statics analysis of rigid-flexible-soft hybrid finger mechanism with standard force sensor. Robot. Comput.-Integr. Manuf. 2021, 67, 101978. [Google Scholar] [CrossRef]

- Chiaradia, D.; Tiseni, L.; Xiloyannis, M.; Solazzi, M.; Masia, L.; Frisoli, A. An assistive soft wrist exosuit for flexion movements with an ergonomic reinforced glove. Front. Robot. AI 2021, 7, 182. [Google Scholar] [CrossRef]

- Mihlj, M.; Tobias, N.; Robert, R. ARMin II-7 DoF rehabilitation robot: Mechanics and kinematics. In Proceedings of the IEEE International Conference on Robotics and Automation, Rome, Italy, 10–14 April 2007; pp. 4120–4125. [Google Scholar]

- Martinez, J.A.; Ng, P.; Lu, S.; Campagna, M.S.; Celik, O. Design of wrist gimbal: A forearm and wrist exoskeleton for stroke rehabilitation. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Seattle, WA, USA, 24–26 June 2013; pp. 1–6. [Google Scholar]

- Cappello, L.; Elangovan, N.; Contu, S.; Khosravani, S.; Konczak, J.; Masia, L. Robot-aided assessment of wrist proprioception. Front. Hum. Neurosci. 2015, 9, 198. [Google Scholar] [CrossRef]

- Rahman, M.H.; Saad, M.; Kenne, J.P.; Archambault, P.S. Modeling and development of an exoskeleton robot for rehabilitation of wrist movements. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Montreal, QC, Canada, 6–9 July 2010; pp. 25–30. [Google Scholar]

- Pezent, E.; Rose, C.G.; Deshpande, A.D.; O’Malley, M.K. Design and characterization of the Openwrist: A robotic wrist exoskeleton for coordinated hand-wrist rehabilitation. In Proceedings of the IEEE International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 720–725. [Google Scholar]

- Buongiorno, D.; Sotgiu, E.; Leonardis, D.; Marcheschi, S.; Solazzi, M.; Frisoli, A. WRES: A novel 3 DoF WRist ExoSkeleton with tendon-driven differential transmission for neuro-rehabilitation and teleoperation. IEEE Robot. Autom. Lett. 2018, 3, 2152–2159. [Google Scholar] [CrossRef]

- Hayward, V.; Astley, O.R. Performance Measures for Haptic Interfaces; Robotics Research; Springer: London, UK, 1996. [Google Scholar]

- Lee, J.; Song, B.W.; Yang, W. Design of exoskeleton-type wrist human–machine interface based on over-actuated coaxial spherical parallel mechanism. Adv. Mech. Eng. 2018, 10, 168781401775389. [Google Scholar] [CrossRef]

- Birglen, L.; Gosselin, C.; Pouliot, N.; Mosarrat, B.; Laliberte, T. SHaDe, a new 3 DOF haptic device. IEEE Trans. Robot. Autom. 2002, 18, 166–175. [Google Scholar] [CrossRef]

- Bai, S.; Hansen, M.R.; Angeles, J. A robust forward-displacement analysis of spherical parallel robots. Mech. Mach. Theory 2009, 44, 2204–2216. [Google Scholar] [CrossRef]

- Jeong, Y.A.; Min, J.H.; Yun, Y.D.; Choi, J.H.; Yoo, K.T. Analysis on the change of hand grip strength as per the circumference of upper arm and forearm and the muscle activity of upper arm and forearm as per the duration of gripping. J. Int. Acad. Phys. Ther. Res. 2013, 4, 532–538. [Google Scholar] [CrossRef][Green Version]

- Wang, J.S.; Wu, C.; Liu, X.J. Performance evaluation of parallel manipulators: Motion/force transmissibility and its index. Mech. Mach. Theory 2010, 45, 1462–1476. [Google Scholar] [CrossRef]

- Wu, G. Multiobjective optimum design of a 3-RRR spherical parallel manipulator with kinematic and dynamic dexterities. Modeling Identif. Control. 2012, 33, 111–121. [Google Scholar] [CrossRef]

- Bai, S. Optimum design of spherical parallel manipulators for a prescribed workspace. Mech. Mach. Theory 2010, 45, 200–211. [Google Scholar] [CrossRef]

- Kucuk, S.; Bingul, Z. Comparative study of performance indices for fundamental robot manipulators. Robot. Autom. Syst. 2006, 54, 567–573. [Google Scholar] [CrossRef]

- Liu, X.J.; Jin, Z.L.; Gao, F. Optimum design of 3-DOF spherical parallel manipulators with respect to the conditioning and stiffness indices. Mech. Mach. Theory 2000, 35, 1257–1267. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T.A.M.T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Ryu, J.; Cooney, W.P.; Askew, L.J.; An, K.N.; Chao, E.Y.S. Functional ranges of motion of the wrist joint. J. Hand Surg. 1991, 16, 409–419. [Google Scholar] [CrossRef]

- Mann, K.A.; Wernere, F.W.; Palmer, A.K. Frequency spectrum analysis of wrist motion for activities of daily living. J. Orthop. Res. 1989, 7, 304–306. [Google Scholar] [CrossRef] [PubMed]

- Tsagarakis, N.; Caldwell, D.G.; Medrano-Cerda, G.A. A 7 DOF pneumatic muscle actuator (pMA) powered exoskeleton. In Proceedings of the 8th IEEE International Workshop on Robot Human Interaction, Pisa, Italy, 27–29 September 1999; pp. 327–333. [Google Scholar]

- Liang, J.W.; Feeny, B.F. Identifying Coulomb and viscous friction from free-vibration decrements. Nonlinear Dyn. 1998, 16, 337–347. [Google Scholar] [CrossRef]

- Douglass, B.P. Agile Systems Engineering; Morgan Kaufmann Publishers: San Francisco, CA, USA, 2015. [Google Scholar]

| Parameters (°) | |||||

| Upper bound | 90 | 120 | 120 | −30 | 150 |

| Lower bound | 30 | 60 | 60 | 30 | 90 |

| Wrist Motion | Pronation–Supination (PS) | Flexion–Extension (FE) | Adduction–Abduction (AA) | |||

|---|---|---|---|---|---|---|

| ROM (°) | Torque (Nm) | ROM (°) | Torque (Nm) | ROM (°) | Torque (Nm) | |

| ADL | 150 | 0.06 | 115 | 0.35 | 70 | 0.35 |

| Functional ROM and Isometric torque | - | 9.1 | 80 | 19.8 | 40 | 20.8 |

| FC-WREI | 160 | 11.87 | 100 | 14.34 | 60 | 11.75 |

| MAHI EXO-II [8] | 180 | 2.3 | 72 | 1.67 | 72 | 1.93 |

| RiceWrist-S [8] | 180 | 1.69 | 130 | 3.37 | 75 | 2.11 |

| OpenWrist [18] | 170 | 3.5 | 135 | 3.6 | 75 | 2.3 |

| Wrist gimbal [15] | 180 | 2.87 | 180 | 1.77 | 60 | 1.77 |

| IIT wrist robot [16] | 160 | 2.77 | 144 | 1.53 | 72 | 1.63 |

| WRES [19] | 140 | 6.52 | 75 | 1.62 | 40 | 1.62 |

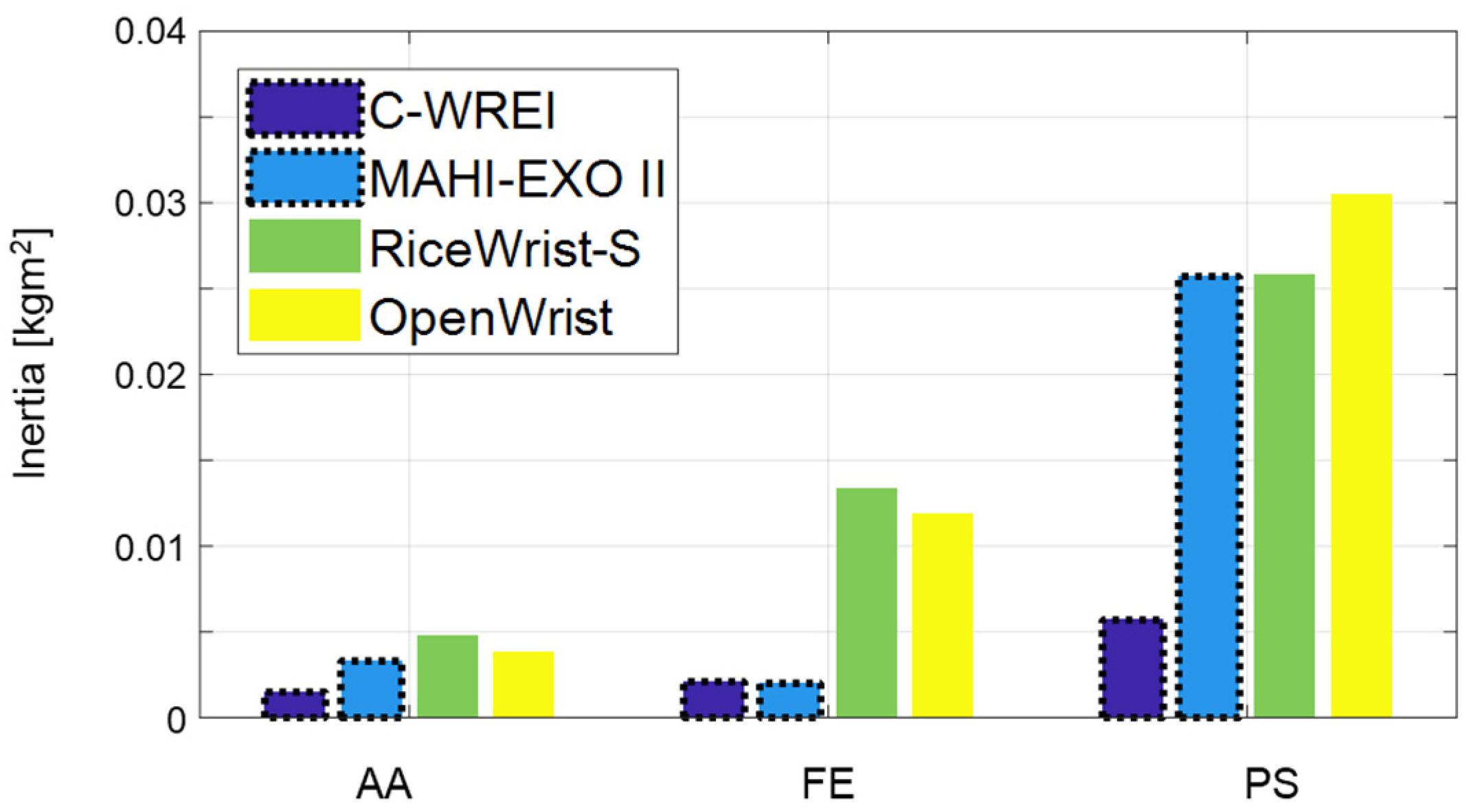

| FC-WREI | MAHI-EXO II | RiceWrist-S | OpenWrist | |||||

|---|---|---|---|---|---|---|---|---|

| DOF |

CLBW (Hz) |

Inertia (kgm2) |

CLBW (Hz) |

Inertia (kgm2) |

CLBW (Hz) |

Inertia (kgm2) |

CLBW (Hz) |

Inertia (kgm2) |

| AA | 11.83 | 0.0015 | 10.6 | 0.0033 | 8.3 | 0.0048 | 9.8 | 0.0038 |

| FE | 12.24 | 0.0021 | 13.3 | 0.002 | 6.0 | 0.0134 | 7.0 | 0.0119 |

| PS | 5.73 | 0.0057 | 4.2 | 0.0257 | 3.5 | 0.0258 | 4.6 | 0.0305 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, H.; Yang, W. Development of Wrist Interface Based on Fully Actuated Coaxial Spherical Parallel Mechanism for Force Interaction. Sensors 2021, 21, 8073. https://doi.org/10.3390/s21238073

Lee J, Kim H, Yang W. Development of Wrist Interface Based on Fully Actuated Coaxial Spherical Parallel Mechanism for Force Interaction. Sensors. 2021; 21(23):8073. https://doi.org/10.3390/s21238073

Chicago/Turabian StyleLee, Jaeyong, Hyungjoo Kim, and Woosung Yang. 2021. "Development of Wrist Interface Based on Fully Actuated Coaxial Spherical Parallel Mechanism for Force Interaction" Sensors 21, no. 23: 8073. https://doi.org/10.3390/s21238073

APA StyleLee, J., Kim, H., & Yang, W. (2021). Development of Wrist Interface Based on Fully Actuated Coaxial Spherical Parallel Mechanism for Force Interaction. Sensors, 21(23), 8073. https://doi.org/10.3390/s21238073