Robotic Railway Multi-Sensing and Profiling Unit Based on Artificial Intelligence and Data Fusion

Abstract

1. Introduction

2. Related Work

2.1. Context

2.2. Literature Survey

- -

- Autonomy of the method: the robotic cart can travel alone, collect position-referenced information regarding tracks gauges, deviations from standards, presence of foreign objects on the rails, imaging and external gauge profiling;

- -

- Collected data can be either transmitted via Wi-Fi to dedicated access points, or locally stored for off-line analysis;

- -

- Integrates various machine learning techniques for data fusion;

- -

- Has the possibility to fine tune a wide variety of measurements parameters and speed increments;

- -

- Is designed especially for subway lines with no GPS positioning signals, but can be adapted to work in external environments, using additional GPS information for position of a location;

- -

- Reduces stress of maintenance personnel by overtaking some tasks in usual maintenance activities during subway off-service periods;

- -

- The following are comparisons with other previously published works related to the railway inspection approaches:

- -

- Rowshandel, H. [6] proposes in his doctorate thesis a robotic inspection system for discovering fatigue cracks in the rolling system of a surface railway. The system employs an alternating current field measurement (ACFM) sensor combined with a rule-based expert system. The solution is dedicated for collecting a single type of data, only detecting cracks, and not inspecting railway gauges, for example;

- -

- Only 3% of the maintenance operations in railway tunnels (including subway) are recently subject of robotic activities [45]—therefore, the benefits of such a solution;

- -

- -

- Killian, K [48] proposes a vision system based on wayside sensors for inspecting integrity of train wheels and rails (no mobility involved here for the automatic measuring system);

- -

- Railway catenary and power line automatic inspection are proposed via a system with laser beams and imagistic analysis simultaneously for four wires [49]—the solution is intended to be mounted on the engine of a train and is operational for speeds up to 90 km/h. No other parameters are envisaged to be measured;

- -

- Railway robotic inspection in tracks maintenance operations: machine vision and classification algorithms are used to detect and/or localize cracks in the rolling surface of tracks. It is employed a laser scanner mounted on a car that uses a random Forest classification learning algorithm [50] and for tracks geometry [51]. No other parameters are envisaged to be measured;

- -

- Ground penetrating radar is also used for some robotic inspections in tunnels [52].

3. Design of the Proposed Solution for Mobile Autonomous Data Collection

3.1. Rail Defects

- -

- Rail fracturing (might be early detected employing ultrasonic and/or video solutions). In case of complete fracture, the track circuits might be also able to detect this type of defect via electric control and interdict the entrance of a train on the specific section via the covering signal;

- -

- Intensive burring of insulating joints from neighboring rail coupons might induce short-circuits between adjacent track circuits, producing delaying in trains operations;

- -

- Mechanical deformations of gauges (between parallel rails, or between elements of a switching point, or a crossing)—this can be caused by exceeding the allowed weight per axle, mud under the rails, or other types of phenomena. It can also be caused by falling of heavy objects on the respective parts, especially from freight trains. In intense and prolonged warm summers, the temperature on the rails level might exceed 50 °C, causing mechanical deformations due to dilatation. This is a very dangerous defect, that must be early detected. Therefore, in very hot summers railway administrations impose speed and weight restrictions;

- -

- Intensive erosion, rust, or wear of the rail rolling surface. This type of defect might be considered from two points of view: firstly, if the line is intensively eroded, the electrical contact between the rail and the train wheel is imperfect and might cause malfunctioning of the track circuit, which might also trigger false response on the railway signaling, with possible catastrophic effects leading to trains collisions. It is very important to use safe track circuits from this point of view (based on high voltage pulses) on such lines, or to perform regular traffic to reduce erosion by mechanical friction. On the other hand, if the rails exhibit intensively wear, the surface becomes irregular, or with undulations, causing vibrations on the rolling stock or possible loss of electrical contact at high speeds. Therefore, also these types of mechanical deformations should be detected and resolved in due time.

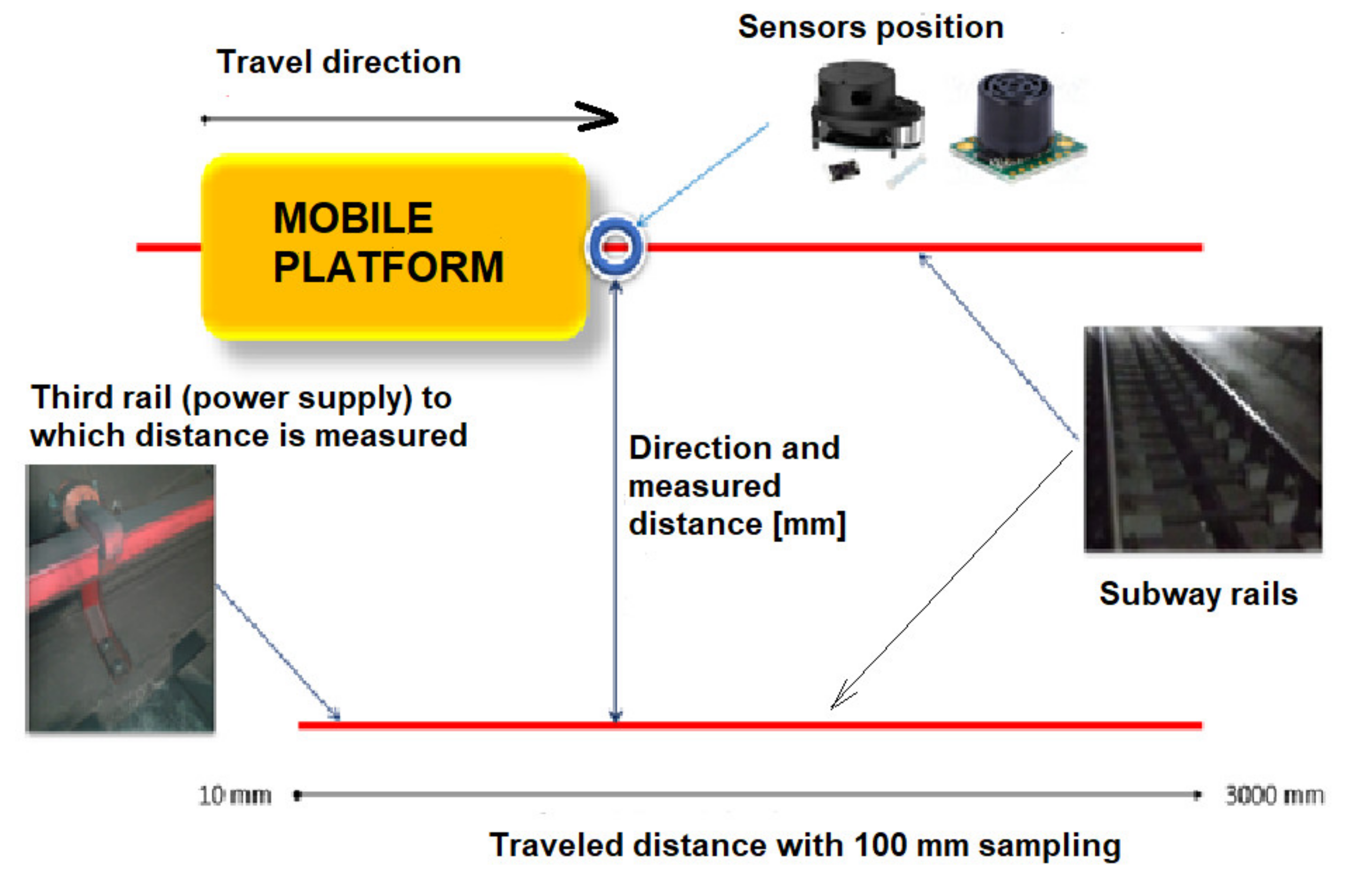

3.2. Rail Diagnostics Techniques. Description of Hardware

- Central processing unit (CPU) based on myRIO—holds all the controls and commands for the mobile platform, programmable via a notebook;

- Odometry module (OM)—responsible with counting pulses from the wheels, measuring traveled distance, speed and updating the information about position of the automated platform to the CPU. For computing traveled distance and speed, a NPN Hall-Effect sensor has been employed. The following formula is employed for determining velocity:

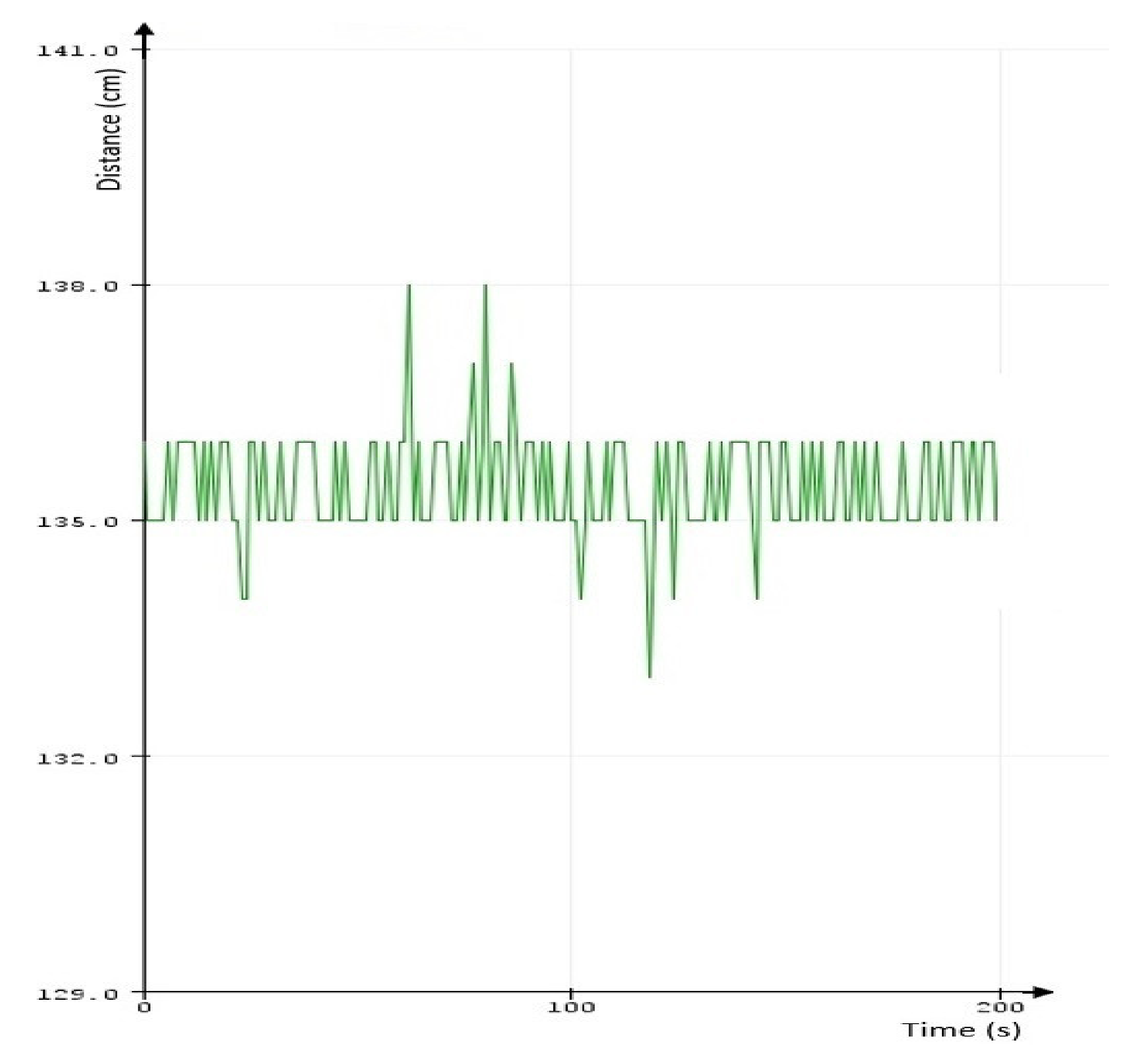

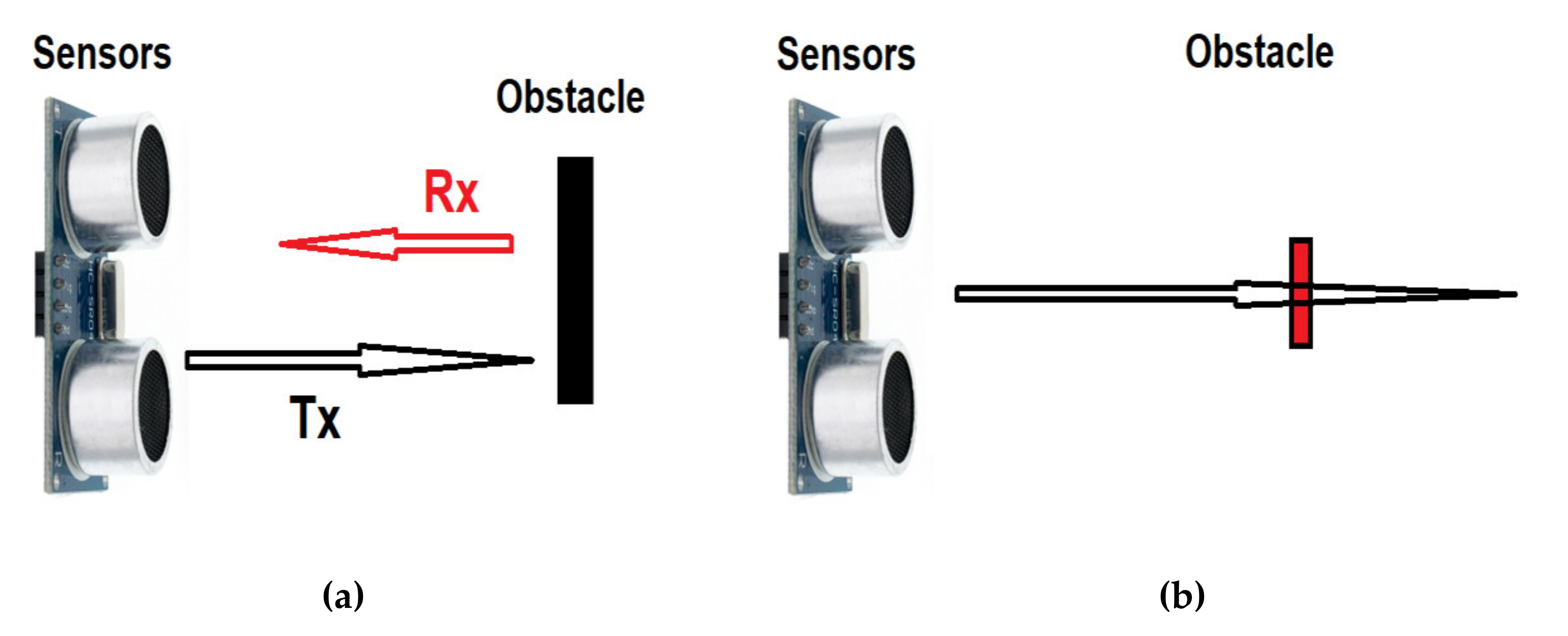

- Obstacle detection module (ODM)—it is composed of an infrared sensor and an ultrasonic sensor combination mounted in the front of the mobile platform for rapidly detecting and/or identifying obstacles on tracks. The detection of obstacles that are present in the front of the platform is performed through an IR sensor type Sharp GP2YOA710KOF and an ultrasonic sensor XL Maxbotix EZ0. Sharp GP2YOA710KOF is an integrated distance sensor for front obstacles, that ensures IR LED detection at λ = 850 nm. Operating distance is comprised between 100 and 550 cm. Its sensitivity diagram is presented in Figure 2. A 90% reflection coefficient was considered for the white paper set as a reference target. The dimensions, quality, and ease of use of the ultrasonic sensor XL Maxbotix EZ0 also allow high accuracy readings from 0 to 765 cm with a resolution of 1 cm. The sensor can be supplied with a voltage between 3.3 and 5 V D.C.

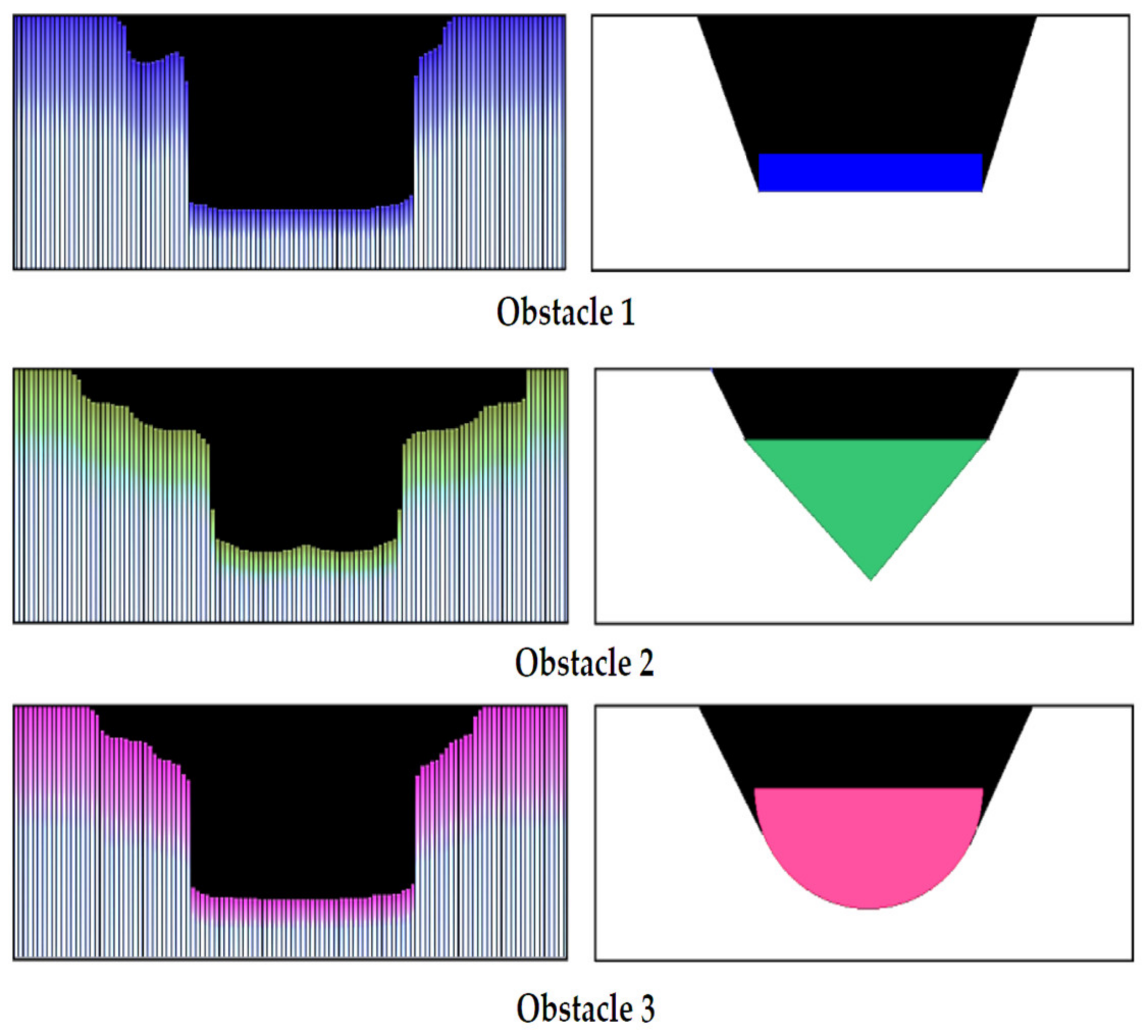

- Gauge assessment module (GAM)—composed of ultrasonic and laser sensors to check the dimensions of the external gauge of tunnels, detect and locate eventual obstacles, or protruding objects. For a much more precise gauge check, an RPLIDAR A1M8-360 laser kit with a maximum reading frequency of 10 Hz and a detection distance of approximately 6 m was also introduced. The Bucharest underground free pass gauge shape is presented in Figure 3.

- Fire detection module (FDM)—composed of dedicated IR sensor and cooperating with GAM for fire detection, heated cabling location and alarming.

4. Test Bed Setup and Results

4.1. Introduction

- -

- Merging sensor measurements of different categories;

- -

- Merging measurements from different positions and angles;

- -

- Merging measurements taken at different time intervals.

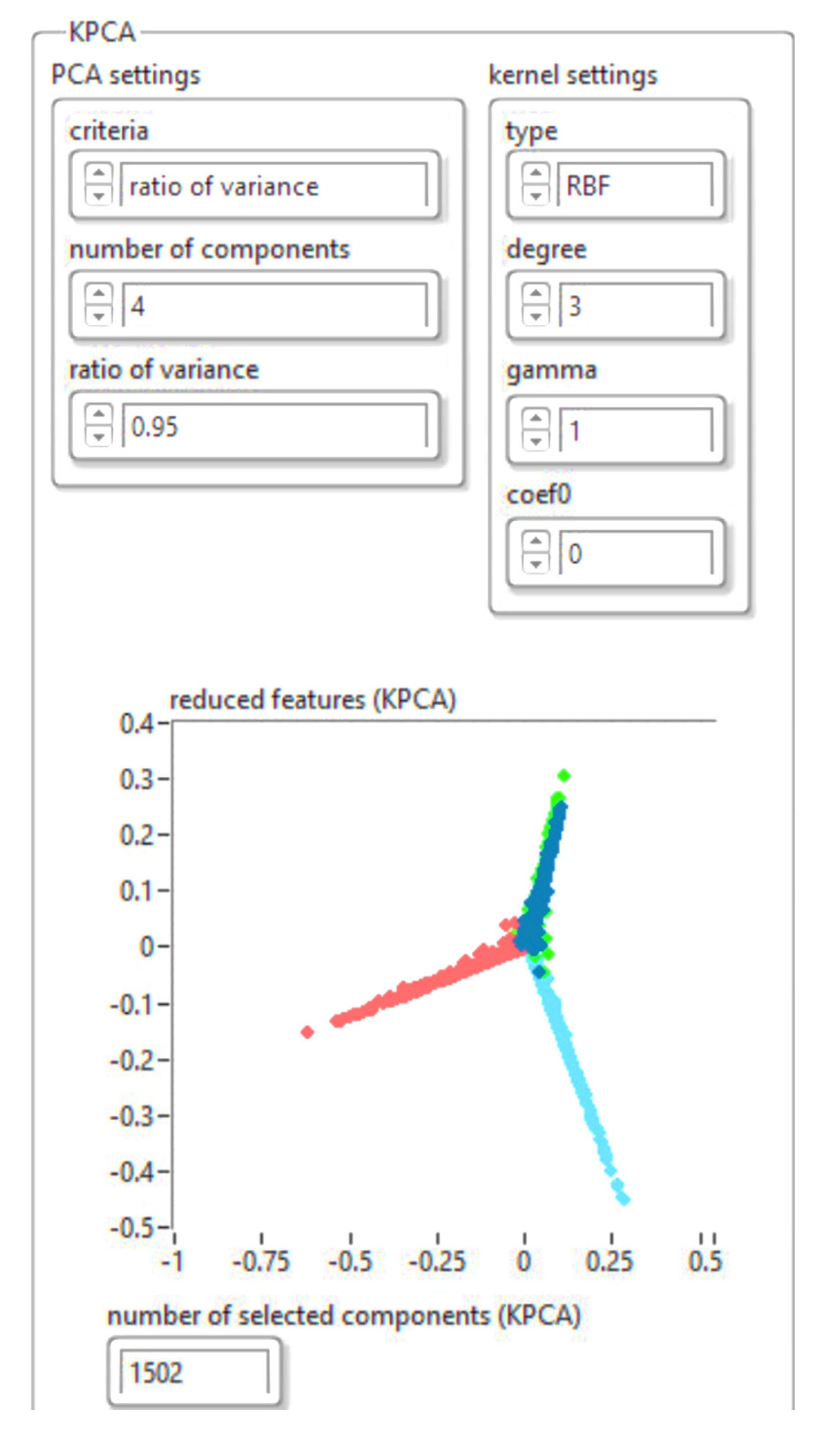

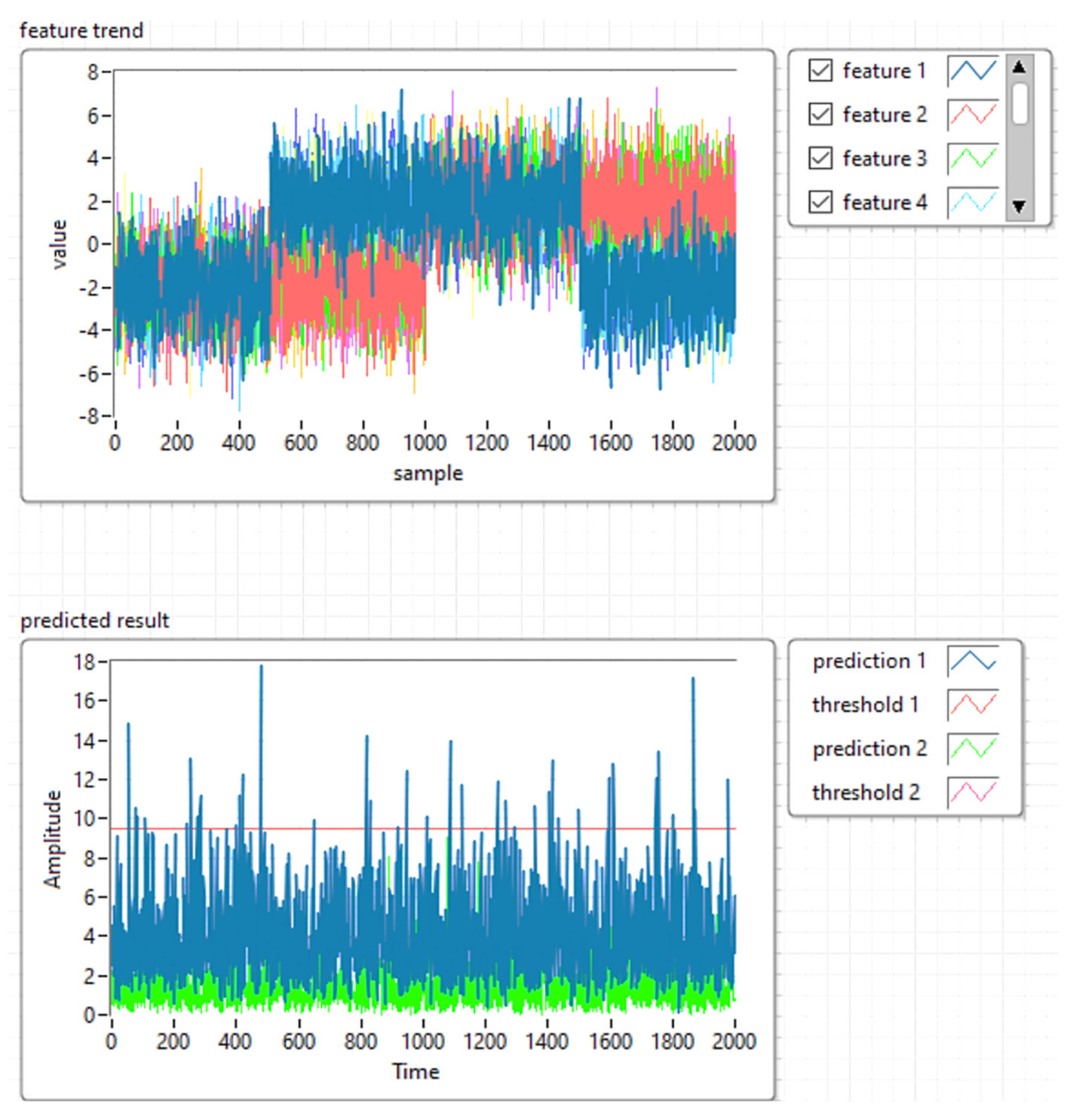

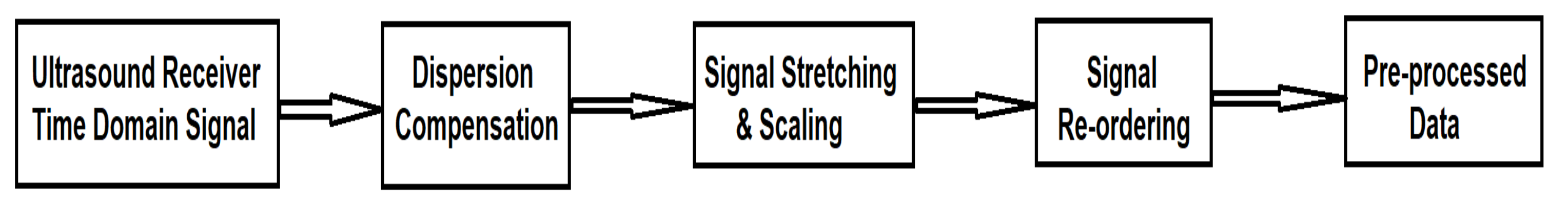

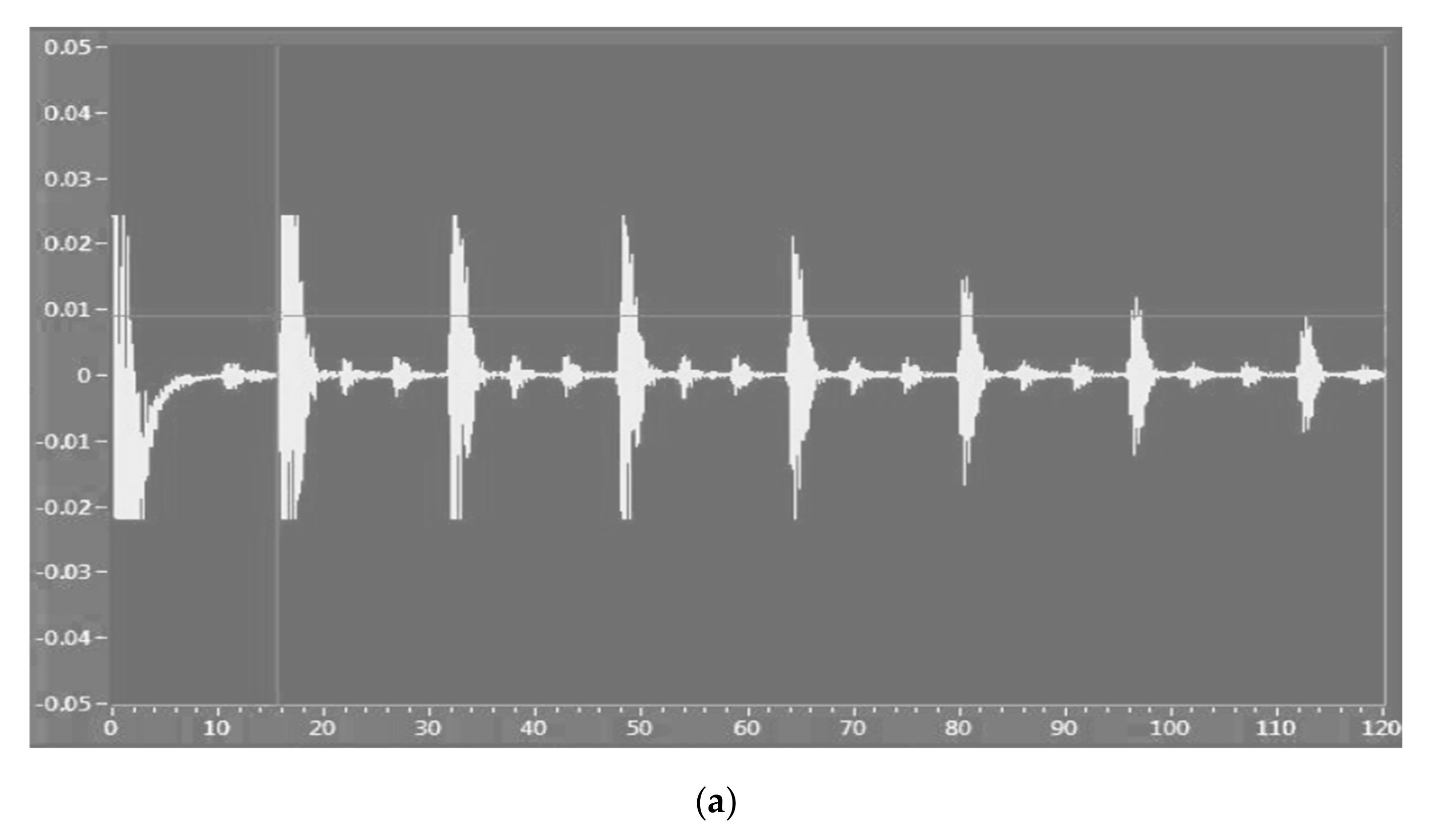

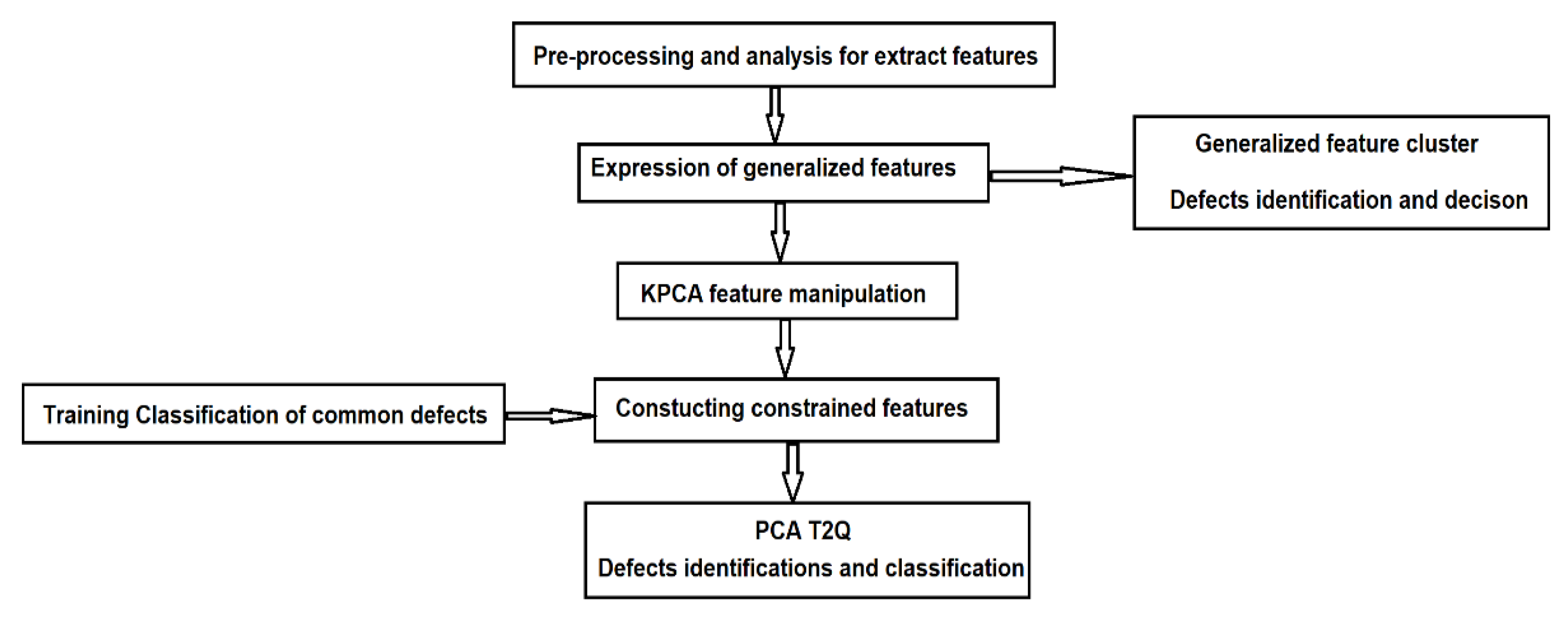

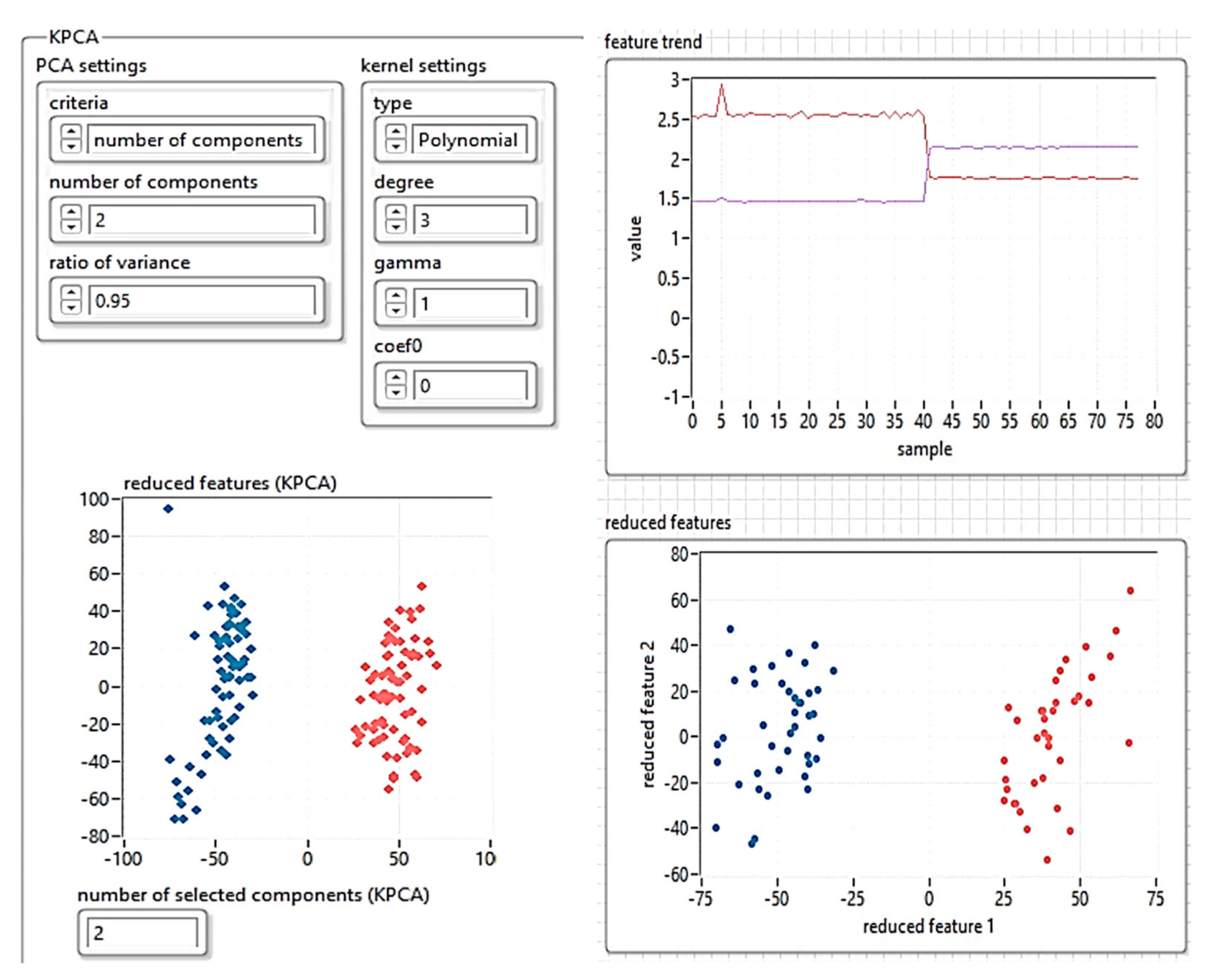

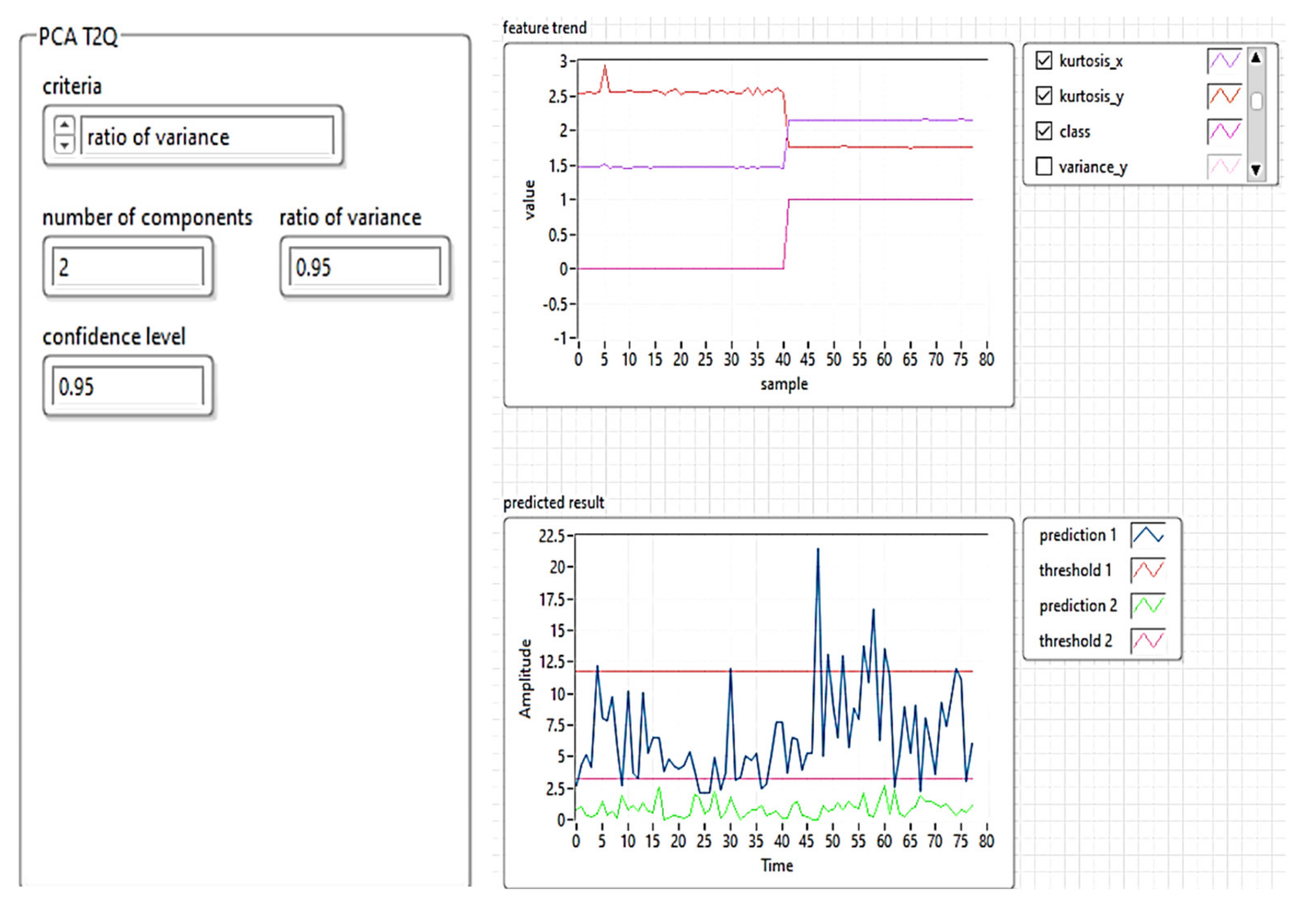

4.2. Development of the Machine Learning Model with PCA T2Q

4.3. Simulation and Experimental Verification of the Model

4.4. Case Study

- -

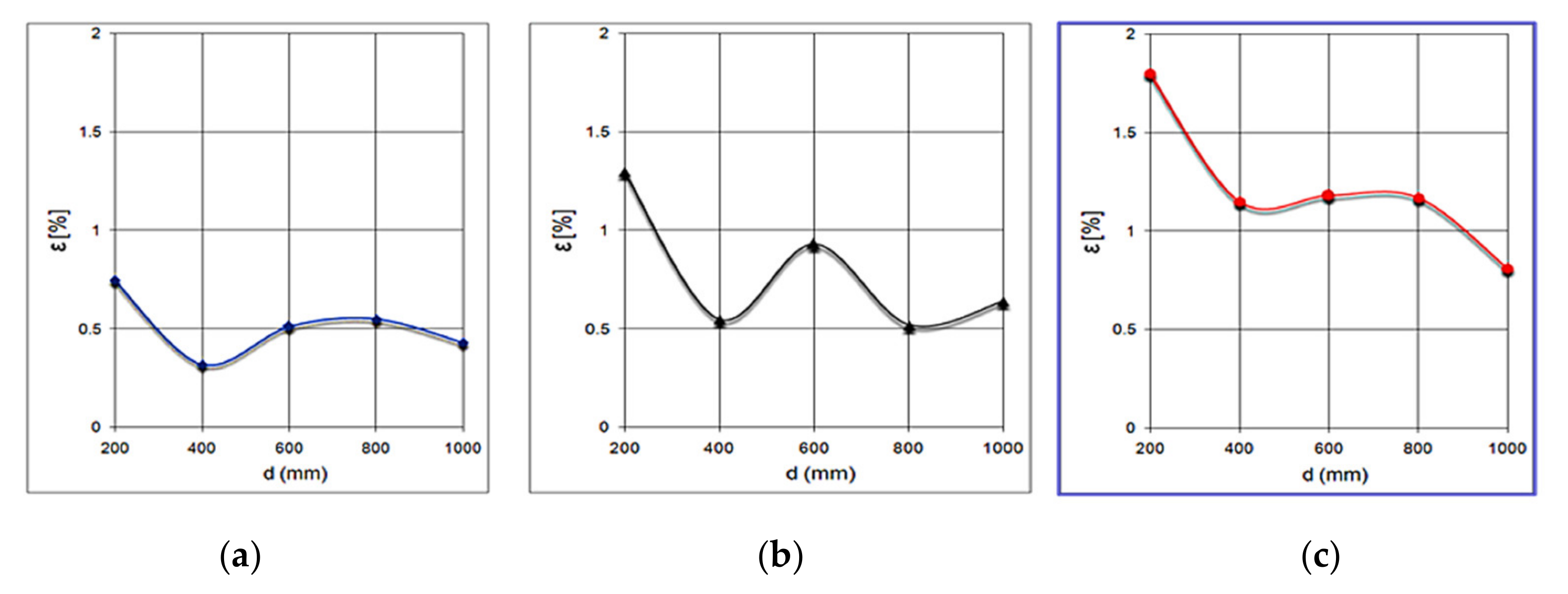

- Rail defect detection techniques based on ultrasonic waves analysis and machine learning. Experimental research on the behavior of ultrasonic sensors in the detection process.

- The placement of the sensor very close to the target for minimizing air attenuation;

- Placing the sensory assembly on a stabilized platform, or with good mechanical attenuation to vibrations is required;

- A deeper experimental analysis of the performances that higher-frequency ultransonic scanner has on different materials, in different conditions is required.

- -

- Measurement errors

- Gross errors that result from misreading or inattention and must be eliminated;

- Systematic errors that occur due to some constructive characteristics of equipment, or may be caused by external factors (temperature, pressure, humidity, noise etc);

- Random errors that occur as a result of the diversity of processes and phenomena as well as a the interactions of the experiment with other processes and phenomena that take place simultaneously.

- -

- Determining the distance to obstacles of different sizes

- -

- Determining the distance from obstacles of different shapes

- -

- Determining the distance to obstacles from materials with different textures

- Stainless steel;

- Aluminum;

- Copper;

- Wood;

- Rubber;

- Plastic.

- -

- Determining the distance with a sensor mounted on a rotating platform (radar)

5. Discussion

- Ultrasonic investigations allow the evaluation of the amplitude in volume, in metal components, with an acceptable accuracy. To obtain the stress values, it is necessary to consider the elastic constants of the material. Further investigations and field tests are necessary in this direction, to also determine the feasibility of using high-frequency ultrasound imaging for subway practical applications.

- Some manufacturing and/or operating and stressing processes (casting, plastic deformation, welding, machining) might introduce into the material of the parts residual stresses that substantially change their operating performance. These are difficult to detect with classic setup of ultrasonic sensors, a deeper investigation is necessary, probably using closer ultrasonic sensing and higher frequencies.

- The great advantages of ultrasonic techniques are the fast data collection, portability of instrumentation, radiation-free control, the possibility of measuring the geometric location of points or continuous time and the low costs. However, to obtain quantitative values of signal amplitude, ultrasonic techniques require the evaluation of elastic properties. Therefore, it is important to precisely know the mission of sound amplitude state analysis.

- Ultrasonic techniques allow the estimation of surface and volume stresses of the parts under investigation.

- The ultrasonic investigation method can be applied to metallic and non-metallic materials, capable of propagating ultrasonic waves with frequencies up to 20 MHz.

- In the analysis of internal structure stresses, decreased propagation time can be interpreted as a decrease in tension or an increase in compression stresses, the change in stress can be approximated using the relative change in time and the appropriate elastic constants.

6. Conclusions

- (1)

- The proposed method avoids the instability, upper or lower constraints caused by the characteristics of the rails during the processing of anomaly detection. The experimental results showed that the proposed method can work better than similar methods presented, with an accuracy of 98.65% and an average detection time of 0.15 s. However, for better results, the speed of the automated cart should be limited and sampling intervals shortened (for 100 mm sampling intervals, a speed of 0.36 km/h is recommended);

- (2)

- The PCA T2Q method is used to group the generalized characteristics constrained after size reduction using KPCA. In addition, the kurtosis index, and the accuracy of the PCA T2Q algorithm are used to evaluate the results, and the detection results are obtained with an accuracy of over 95%;

- (3)

- The experimental results show that the proposed method has a higher detection accuracy for rails defects (fracturing, mechanical deformation, and intensive erosion due to rust) and present better application perspectives than the methods reported in the literature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fact Sheets on the European Union—2021. Available online: https://www.europarl.europa.eu/ftu/pdf/en/FTU_3.4.5.pdf (accessed on 22 July 2021).

- Fact Sheet | High Speed Rail Development Worldwide. Available online: https://www.eesi.org/papers/view/fact-sheet-high-speed-rail-development-worldwide (accessed on 25 July 2021).

- Odziemczyk, W.; Woźniak, M. Analysis of railway track geometry measurement methods usability. Transp. Overv.-Przeglad Komun. 2018, 2018, 40–50. [Google Scholar] [CrossRef]

- Pan, P.; Hu, H.; Yang, X.; Blaabjerg, F.; Wang, X.; He, Z. Impedance Measurement of Traction Network and Electric Train for Stability Analysis in High-Speed Railways. IEEE Trans. Power Electron. 2018, 33, 10086–10100. [Google Scholar] [CrossRef]

- Dolara, A.; Leva, S. Calculation of Rail Internal Impedance by Using Finite Elements Methods and Complex Magnetic Permeability. Int. J. Veh. Technol. 2009, 2009, 1–10. [Google Scholar] [CrossRef]

- Rowshandel, H. The Development of an Autonomous Robotic Inspection System to Detect and Characterize Rolling Contact Fatigue Cracks in Railway Track. Ph.D. Thesis, University of Birmingham, Birmingham, UK, September 2013. [Google Scholar]

- Lamas, D.; Soilán, M.; Grandío, J.; Riveiro, B. Automatic Point Cloud Semantic Segmentation of Complex Railway Environments. Remote Sens. 2021, 13, 2332. [Google Scholar] [CrossRef]

- Zhang, X.; Cui, X.; Huang, B. The Design and Implementation of an Inertial GNSS Odometer Integrated Navigation System Based on a Federated Kalman Filter for High-Speed Railway Track Inspection. Appl. Sci. 2021, 11, 5244. [Google Scholar] [CrossRef]

- Skrickij, V.; Šabanovič, E.; Shi, D.; Ricci, S.; Rizzetto, L.; Bureika, G. Visual Measurement System for Wheel–Rail Lateral Position Evaluation. Sensors 2021, 21, 1297. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Niu, X.; Zuo, L.; Zhang, T.; Xiao, F.; Liu, Y.; Liu, J. A Railway Track Geometry Measuring Trolley System Based on Aided INS. Sensors 2018, 18, 538. [Google Scholar] [CrossRef]

- Kampczyk, A. Magnetic-Measuring Square in the Measurement of the Circular Curve of Rail Transport Tracks. Sensors 2020, 20, 560. [Google Scholar] [CrossRef]

- Jeong, W.; Jeong, D. Acoustic Roughness Measurement of Railhead Surface Using an Optimal Sensor Batch Algorithm. Appl. Sci. 2020, 10, 2110. [Google Scholar] [CrossRef]

- Jeong, W.; Jeon, S.; Jeong, D.; Choi, H.S. Effect of Design variables of Rail Surface Measuring Device on Acoustic Roughness and Spectral Analysis. J. Korean Soc. Railway 2017, 20, 440–447. [Google Scholar] [CrossRef]

- Jeong, D.; Choi, H.S.; Choi, Y.J.; Jeong, W. Measuring acoustic roughness of a longitudinal railhead profile using a multi-sensor integration technique. Sensors 2019, 19, 1610. [Google Scholar] [CrossRef] [PubMed]

- Han, Q.; Wang, S.; Fang, Y.; Wang, L.; Du, X.; Li, H.; He, Q.; Feng, Q. A Rail Fastener Tightness Detection Approach Using Multi-source Visual Sensor. Sensors 2020, 20, 1367. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.Q. Railway Obstacle Detection Algorithm Based on Deep Neural Network. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

- Zhao, X.X. Railway Fastener Detection Based on Convolution Neural Network. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

- Shankar, S.; Roth, M.; Schubert, L.A.; Verstegen, J.A. Automatic Mapping of Center Line of Railway Tracks using Global Navigation Satellite System, Inertial Measurement Unit and Laser Scanner. Remote Sens. 2020, 12, 411. [Google Scholar] [CrossRef]

- Elberink, S.O.; Khoshelham, K. Automatic Extraction of Railroad Centerlines from Mobile Laser Scanning Data. Remote Sens. 2015, 7, 5565–5583. [Google Scholar] [CrossRef]

- Neubert, M.; Hecht, R.; Gedrange, C.; Trommler, M.; Herold, H.; Krüger, T.; Brimmer, F. Extraction of Railroad Objects from Very High Resolution Helicopter-borne Lidar and Ortho-image Data. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2008, 38, 25–30. [Google Scholar]

- Zhu, L.; Hyyppa, J. The Use of Airborne and Mobile Laser Scanning for Modeling Railway Environments in 3D. Remote Sens. 2014, 6, 3075–3100. [Google Scholar] [CrossRef]

- Kaasalainen, S.; Jaakkola, A.; Kaasalainen, M.; Krooks, A.; Kukko, A. Analysis of Incidence Angle and Distance Effects on Terrestrial Laser Scanner Intensity: Search for Correction Methods. Remote Sens. 2011, 3, 2207–2221. [Google Scholar] [CrossRef]

- Höfle, B.; Pfeifer, N. Correction of laser scanning intensity data: Data and model-driven approaches. ISPRS J. Photogramm. Remote Sens. 2007, 62, 415–433. [Google Scholar] [CrossRef]

- Krooks, A.; Kaasalainen, S.; Hakala, T.; Nevalainen, O. Correction of Intensity Incidence Angle Effect in Terrestrial Laser Scanning. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, 2, 145–150. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, C.; Dong, C.; Mao, Q.; Tang, F.; Chen, J.; Hou, H.; Xiong, Y. Absolute Positioning and Orientation of MLSS in a Subway Tunnel Based on Sparse Point-Assisted DR. Sensors 2020, 20, 645. [Google Scholar] [CrossRef] [PubMed]

- Larsen, M.B. High performance Doppler-inertial navigation-experimental results. In Proceedings of the OCEANS 2000 MTS/IEEE Conference and Exhibition, Providence, RI, USA, 11–14 September 2000; Volume 2, pp. 1449–1456. [Google Scholar]

- Kampczyk, A. Measurement innovations in railway infrastructure safety. World Sci. News 2017, 89, 336–347. [Google Scholar]

- Turabimana, P.; Nkundineza, C. Development of an On-Board Measurement System for Railway Vehicle Wheel Flange Wear. Sensors 2020, 20, 303. [Google Scholar] [CrossRef]

- Alemi, A.; Corman, F.; Lodewijks, G. Condition monitoring approaches for the detection of railway wheel defects. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2016, 231, 961–981. [Google Scholar] [CrossRef]

- Bernal, E.; Spiryagin, M.; Cole, C. Onboard Condition Monitoring Sensors, Systems and Techniques for Freight Railway Vehi-cles: A Review. IEEE Sens. J. 2019, 19, 4–24. [Google Scholar] [CrossRef]

- Benito, D.D. Automatic 3D Modeling of Train Rails in a Lidar Point Cloud. Master’s Thesis, Geo-Information Science and Earth Observation of the University of Twente, Enschede, The Netherlands, February 2012. [Google Scholar]

- Li, Q.; Chen, Z.; Hu, Q.; Zhang, L. Laser-Aided INS and Odometer Navigation System for Subway Track Irregularity Meas-urement. J. Surv. Eng. 2017, 143, 04017014. [Google Scholar] [CrossRef]

- Jiang, Q.; Wu, W.; Jiang, M.; Li, Y. A New Filtering and Smoothing Algorithm for Railway Track Surveying Based on Landmark and IMU/Odometer. Sensors 2017, 17, 1438. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, M.; Hu, X.; Hu, D. Self-Calibration for Land Navigation Using Inertial Sensors and Odometer: Observability Analysis. In Proceedings of the AIAA Guidance, Navigation, and Control Conference, Chicago, IL, USA, 10–13 August 2009. [Google Scholar]

- Morris, J.; Robinson, M.; Palacin, R. Use of Dynamic Analysis to Investigate the Behaviour of Short Neutral Sections in the Overhead Line Electrification. Infrastructures 2021, 6, 62. [Google Scholar] [CrossRef]

- Chen, L.; Xu, C.; Lin, S.; Li, S.; Tu, X. A Deep Learning-Based Method for Overhead Contact System Component Recognition Using Mobile 2D LiDAR. Sensors 2020, 20, 2224. [Google Scholar] [CrossRef]

- Mosleh, A.; Montenegro, P.; Costa, P.; Calçada, R. Railway Vehicle Wheel Flat Detection with Multiple Records Using Spectral Kurtosis Analysis. Appl. Sci. 2021, 11, 4002. [Google Scholar] [CrossRef]

- Specht, C.; Wilk, A.; Koc, W.; Karwowski, K.; Dąbrowski, P.; Specht, M.; Grulkowski, S.; Chrostowski, P.; Szmagliński, J.; Czaplewski, K.; et al. Verification of GNSS Measurements of the Railway Track Using Standard Techniques for Determining Coordinates. Remote Sens. 2020, 12, 2874. [Google Scholar] [CrossRef]

- Wilk, A.; Koc, W.; Specht, C.; Judek, S.; Karwowski, K.; Chrostowski, P.; Czaplewski, K.; Dabrowski, P.S.; Grulkowski, S.; Licow, R.; et al. Digital Filtering of Railway Track Coordinates in Mobile Multi–Receiver GNSS Measurements. Sensors 2020, 20, 5018. [Google Scholar] [CrossRef]

- Czaplewski, K.; Wisniewski, Z.; Specht, C.; Wilk, A.; Koc, W.; Karwowski, K.; Skibicki, J.; Dabrowski, P.; Czaplewski, B.; Specht, M.; et al. Application of Least Squares with Conditional Equations Method for Railway Track Inventory Using GNSS Observations. Sensors 2020, 20, 4948. [Google Scholar] [CrossRef]

- Specht, M.; Specht, C.; Wilk, A.; Koc, W.; Smolarek, L.; Czaplewski, K.; Karwowski, K.; Dąbrowski, P.S.; Skibicki, J.; Chrostowski, P.; et al. Testing the Positioning Accuracy of GNSS Solutions during the Tramway Track Mobile Satellite Measurements in Diverse Urban Signal Reception Conditions. Energies 2020, 13, 3646. [Google Scholar] [CrossRef]

- Spinsante, S.; Stallo, C. Hybridized-GNSS Approaches to Train Positioning: Challenges and Open Issues on Uncertainty. Sensors 2020, 20, 1885. [Google Scholar] [CrossRef] [PubMed]

- Koc, W.; Specht, C.; Szmaglinski, J.; Chrostowski, P. A Method for Determination and Compensation of a Cant Influence in a Track Centerline Identification Using GNSS Methods and Inertial Measurement. Appl. Sci. 2019, 9, 4347. [Google Scholar] [CrossRef]

- Lou, Y.; Zhang, T.; Tang, J.; Song, W.; Zhang, Y.; Chen, L. A Fast Algorithm for Rail Extraction Using Mobile Laser Scanning Data. Remote Sens. 2018, 10, 1998. [Google Scholar] [CrossRef]

- Vithanage, R.K.W.; Harrison, C.S.; DeSilva, A.K.M. Importance and Applications of Robotic and Autonomous Systems (RAS) in Railway Maintenance Sector: A Review. Computers 2019, 8, 56. [Google Scholar] [CrossRef]

- Yaguchi, H. Robot Introduction to Cleaning Work in the East Japan Railway Company. Adv. Robot. 1995, 10, 403–414. [Google Scholar] [CrossRef]

- Farnsworth, M.; Tomiyama, T. Capturing, classification and concept generation for automated maintenance tasks. CIRP Ann. 2014, 63, 149–152. [Google Scholar] [CrossRef][Green Version]

- Kilian, K.; Kilian, M.; Mazur, V.; Phelan, J. Rethinking reliability engineering using machine vision systems. J. Rail Rapid Transit. 2016, 230, 1006–1014. [Google Scholar] [CrossRef]

- Smorenburg, C.; Van Valkenburg, A.L. Automatic Inspection of Railway Overhead Wires. In 1988 International Congress on Optical Science and Engineering; SPIE: Bellingham, WA, USA, 1989; pp. 107–117. [Google Scholar]

- Resendiz, E.; Hart, J.M.; Ahuja, N. Automated Visual Inspection of Railroad Tracks. IEEE Trans. Intell. Transp. Syst. 2013, 14, 751–760. [Google Scholar] [CrossRef]

- Madejski, J. Autonomous track geometry diagnostics system. J. Mater. Process. Technol. 2004, 157, 194–202. [Google Scholar] [CrossRef]

- Montero, R.; Victores, J.; Martínez, S.; Jardón, A.; Balaguer, C. Past, present and future of robotic tunnel inspection. Autom. Constr. 2015, 59, 99–112. [Google Scholar] [CrossRef]

- Tarulescu, R. Contribution to the Optimization of Sensors Used on Mobil Robots. Ph.D. Thesis, Technical University of Brasov, Brașov, Romania, 2014. [Google Scholar]

| Sample Interval [mm] | Measured Distance [mm] RP Lidar A1 | Measured Distance [mm] XL-Maxsonar EZ * | Measured Distance [mm] BOSCH Professional GLM 50C |

|---|---|---|---|

| 100 | 1403.1 | 1340 | 1391 |

| 200 | 1401.0 | 1350 | 1390 |

| 300 | 1400.0 | 1360 | 1390 |

| 400 | 1400.2 | 1350 | 1394 |

| 500 | 1395.8 | 1350 | 1394 |

| 600 | 1401.1 | 1340 | 1394 |

| 700 | 1403.2 | 1340 | 1392 |

| 800 | 1404.1 | 1340 | 1394 |

| 900 | 1401.4 | 1400 | 1393 |

| 1000 | 1402.8 | 1350 | 1393 |

| 1100 | 1403.1 | 1340 | 1392 |

| 1200 | 1397.6 | 1400 | 1390 |

| 1300 | 1398.3 | 1350 | 1390 |

| 1400 | 1400.1 | 1340 | 1390 |

| 1500 | 1404.6 | 1340 | 1391 |

| 1600 | 1403.6 | 1350 | 1390 |

| 1700 | 1402.8 | 1350 | 1393 |

| 1800 | 1398.7 | 1360 | 1393 |

| 1900 | 1402.3 | 1340 | 1390 |

| 2000 | 1400.0 | 1340 | 1394 |

| 2100 | 1398.1 | 1350 | 1391 |

| 2200 | 1401.2 | 1350 | 1391 |

| 2300 | 1399.0 | 1348 | 1394 |

| 2400 | 1405.9 | 1360 | 1394 |

| 2500 | 1406.3 | 1340 | 1393 |

| 2600 | 1404.1 | 1350 | 1394 |

| 2700 | 1400.2 | 1340 | 1391 |

| 2800 | 1399.1 | 1350 | 1392 |

| 2900 | 1401.0 | 1350 | 1392 |

| 3000 | 1406.0 | 1360 | 1394 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minea, M.; Dumitrescu, C.M.; Dima, M. Robotic Railway Multi-Sensing and Profiling Unit Based on Artificial Intelligence and Data Fusion. Sensors 2021, 21, 6876. https://doi.org/10.3390/s21206876

Minea M, Dumitrescu CM, Dima M. Robotic Railway Multi-Sensing and Profiling Unit Based on Artificial Intelligence and Data Fusion. Sensors. 2021; 21(20):6876. https://doi.org/10.3390/s21206876

Chicago/Turabian StyleMinea, Marius, Cătălin Marian Dumitrescu, and Mihai Dima. 2021. "Robotic Railway Multi-Sensing and Profiling Unit Based on Artificial Intelligence and Data Fusion" Sensors 21, no. 20: 6876. https://doi.org/10.3390/s21206876

APA StyleMinea, M., Dumitrescu, C. M., & Dima, M. (2021). Robotic Railway Multi-Sensing and Profiling Unit Based on Artificial Intelligence and Data Fusion. Sensors, 21(20), 6876. https://doi.org/10.3390/s21206876