Design of a Digital 3D Model of Transport–Technological Environment of Open-Pit Mines Based on the Common Use of Telemetric and Geospatial Information

Abstract

:1. Introduction

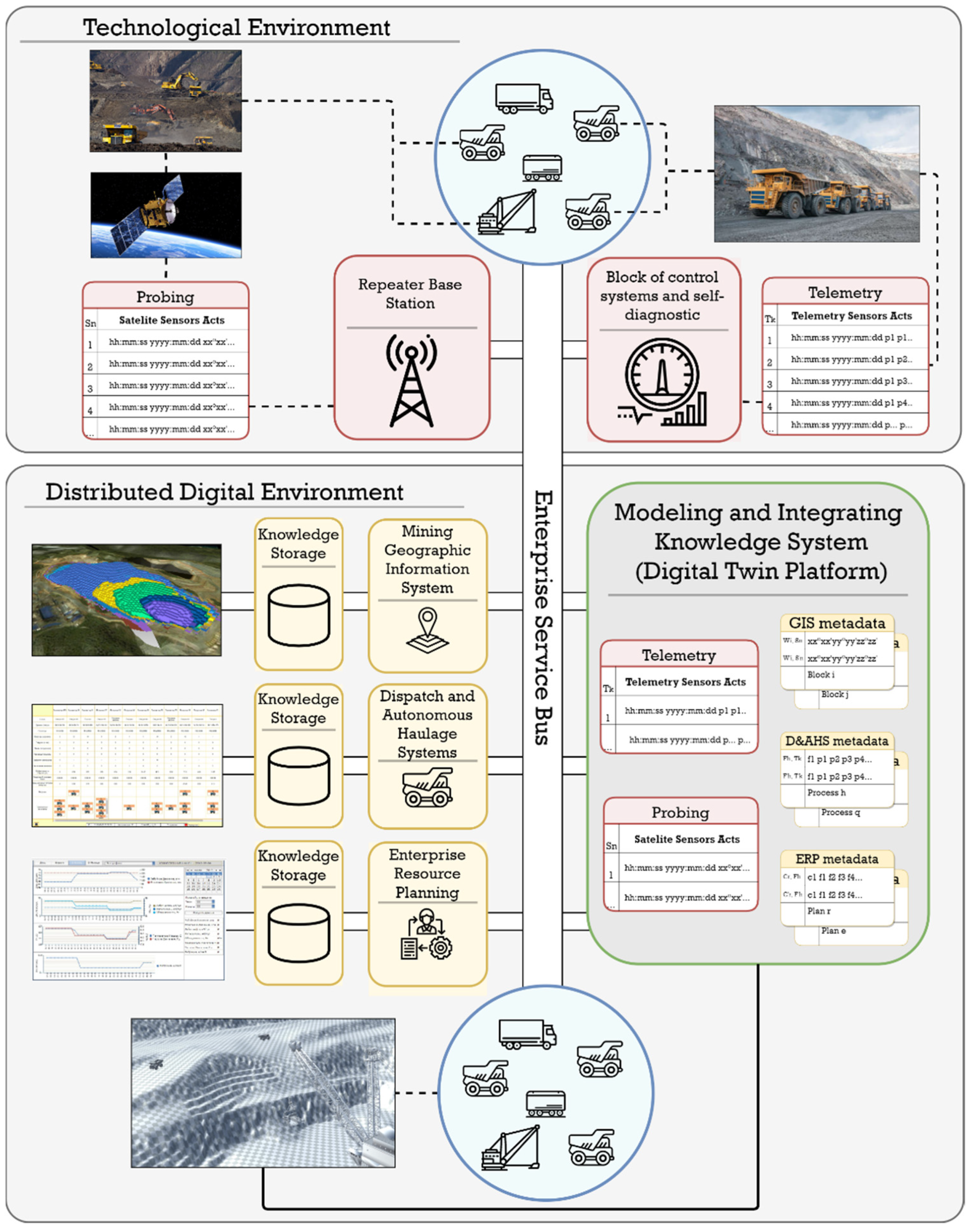

2. Conceptual Architecture and Mechanisms of Functioning of an Intelligent Geoinformation Control Platform

- Mineral resource excavation and loading operations at the excavator site;

- Movement along certain routes from the excavator site to the points of unloading;

- Unloading of rock mass in the special areas;

- Movement of empty dump trucks to excavator sites;

- Maneuvering on excavator sites.

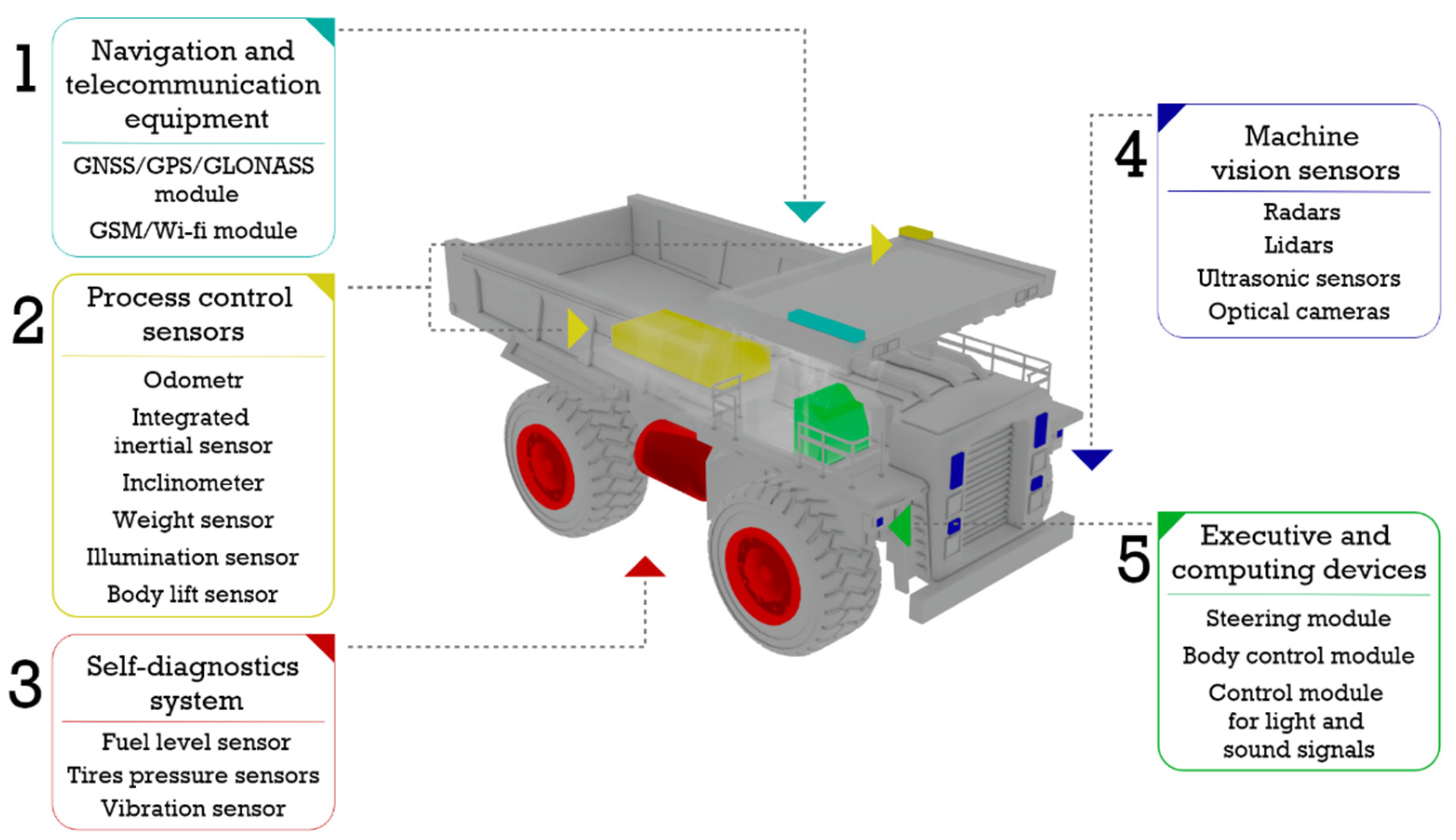

- Data of the onboard monitoring system, which provides information about the current location and technical condition of the agent;

- Tasks for execution received from the dispatching system;

- Digital models of the chosen routes;

- Sensory information obtained when interacting with other agents.

- Current traffic intensity;

- Number of dump tracks passing through the section of the road per unit of time;

- Speed of movement for which the road is designed;

- Permissible weight and dimensions of the fleet;

- Bandwidth;

- Stability of the quarry ledge sides.

- Enterprise Service Bus is a software unified platform interface (Application Programming Interface) that supports standard data transfer protocols used in mining enterprises and Industrial Internet of Things protocols for organizing the interaction of enterprise systems, functional agents, and platform modules.

- Brokers of messages of the technological environment, which are necessary for organizing the transfer of data between agents of the same or different classes within the technological environment and their switching with the service bus of the enterprise. These smart devices should be located on stationary repeaters in the quarry, and their main purpose is to aggregate telemetry information from agents of uniform technological or geographic groups, transmit control commands from the enterprise service bus to agents, and transfer telemetry data and command execution results back to the service bus. The second task of these brokers is to organize information interaction between agents within the groups in the implementation of complex automatic operations, which involves maneuvering a dump truck when approaching an excavator loading or maneuvering when passing while on a transport site. For example, MQTT brokers provide fast and reliable transmission of measured telemetry to minimize errors in the determination of mutual approach distances, which was confirmed using laboratory physical modeling.

- Automatic registration of requests and proposals for specific types of information by listening for and detecting incoming messages (data, requests, and commands) from information entities to the service bus.

- Automatically manage information flows by sorting, grouping, and cataloging data by queue.

- Monitoring the quality of information and feedback in order to maintain the relevance and reliability of control processes during data transmission.

- Optimization of databases by removing redundant, inaccurate, or outdated information.

- End-to-end modeling and visualization to ensure high-precision virtual display of the technological environment using data aggregation and integration at different time horizons (archive, real, and forecast).

- Module for the automatic construction of infrastructure agents using inhomogeneous information: telemetry data, data from a mining and geological system, remote sensing systems, satellite and aerial photographs: quarry—road schemes—routes—technological zones—block model GIS.

- Module for automatic construction of mobile agents using archived and up-to-date telemetry data, technical passports, and regulatory documents: dump trucks, excavators, loaders, etc.

- Module for monitoring and predicting the operational (technical) state of functional agents, which implements an algorithm for monitoring and predicting the state of infrastructure agents (quality of the roadway, changes in the actual coordinates of edges, and terminal vertices of the route graph).

- Module for monitoring and forecasting production indicators.

- Module of intelligent control that generates adjustments of control commands for agents of the technological environment, controls and tests instances of metadata and telemetry data for transmission to enterprise systems; the monitoring and predictive analysis module in order to increase the generalizing capabilities of control models, including intelligent routing of mobile agents with multiparameter criteria optimizations and constraints.

3. The Conception of the Quarry Technological Environment Dynamic Digital Model Building

- Dynamic integration and aggregation of heterogeneous mining information;

- Construction of a dynamic, three-dimensional visualization of the production environment;

- Optimization modeling of technological processes.

- Dividing the infrastructure agent “quarry” into atomic elements along the surface in order to identify the main technological zones, their geometric orientation in space, and the possibility of assigning quality properties of the soil (roadbed).

- Dividing the open pit into the depths in the form of a block model to determine the geological composition of the field and the accompanying geophysical properties of individual infrastructural parts.

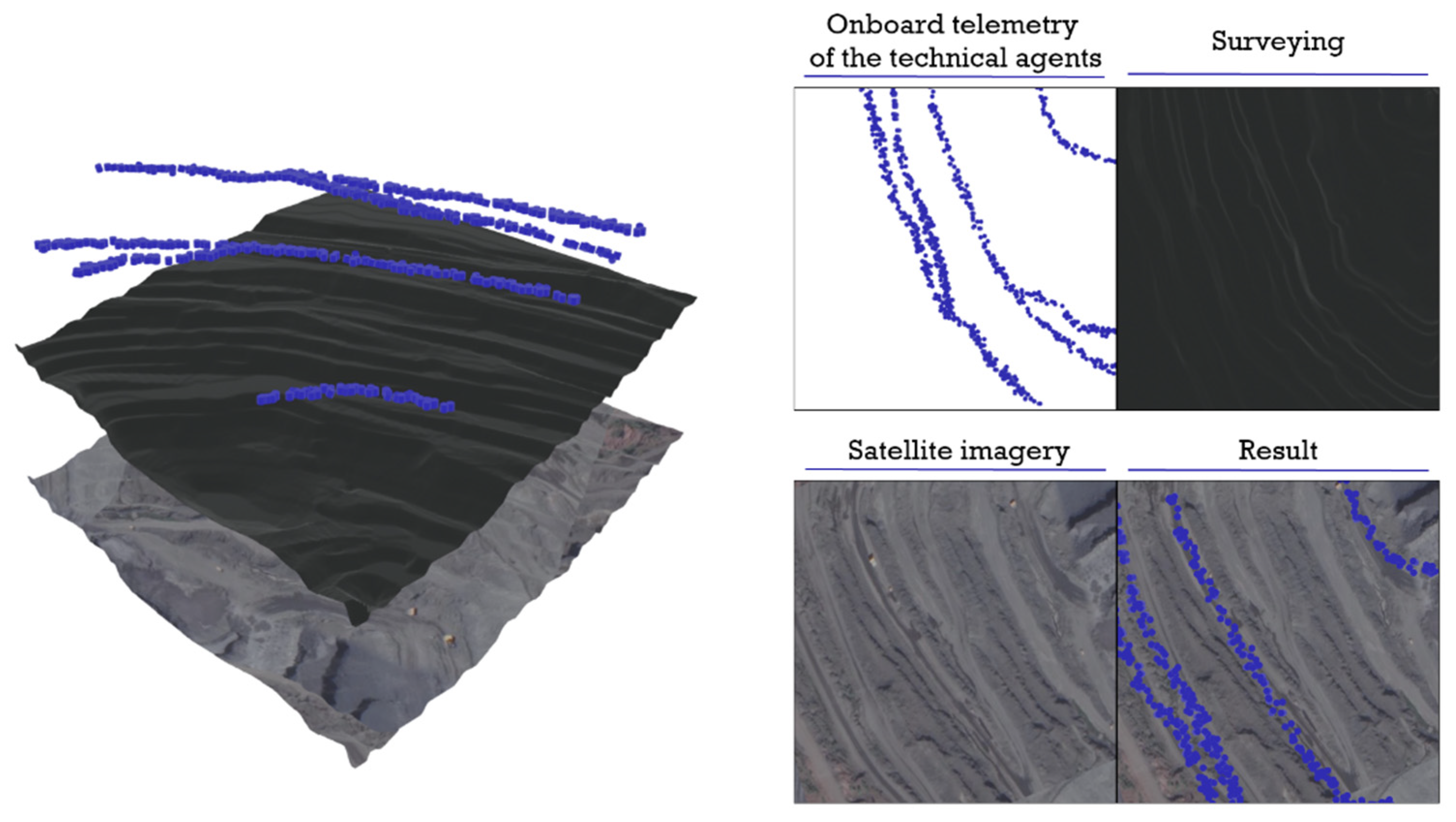

- Results of mine-surveying;

- Satellite or aerial photographs of the area;

- Telemetry measurements of onboard mining equipment.

- Aggregation of information in a distributed data warehouse.

- Determination of coordinates of the initial boundaries of technological zones.

- Setting of the algorithm for calculating the boundary points of the technological zone (contour restoration).

- Accumulation of coordinates of moving mobile agents and the formation of a cloud of points in the space of technological zones.

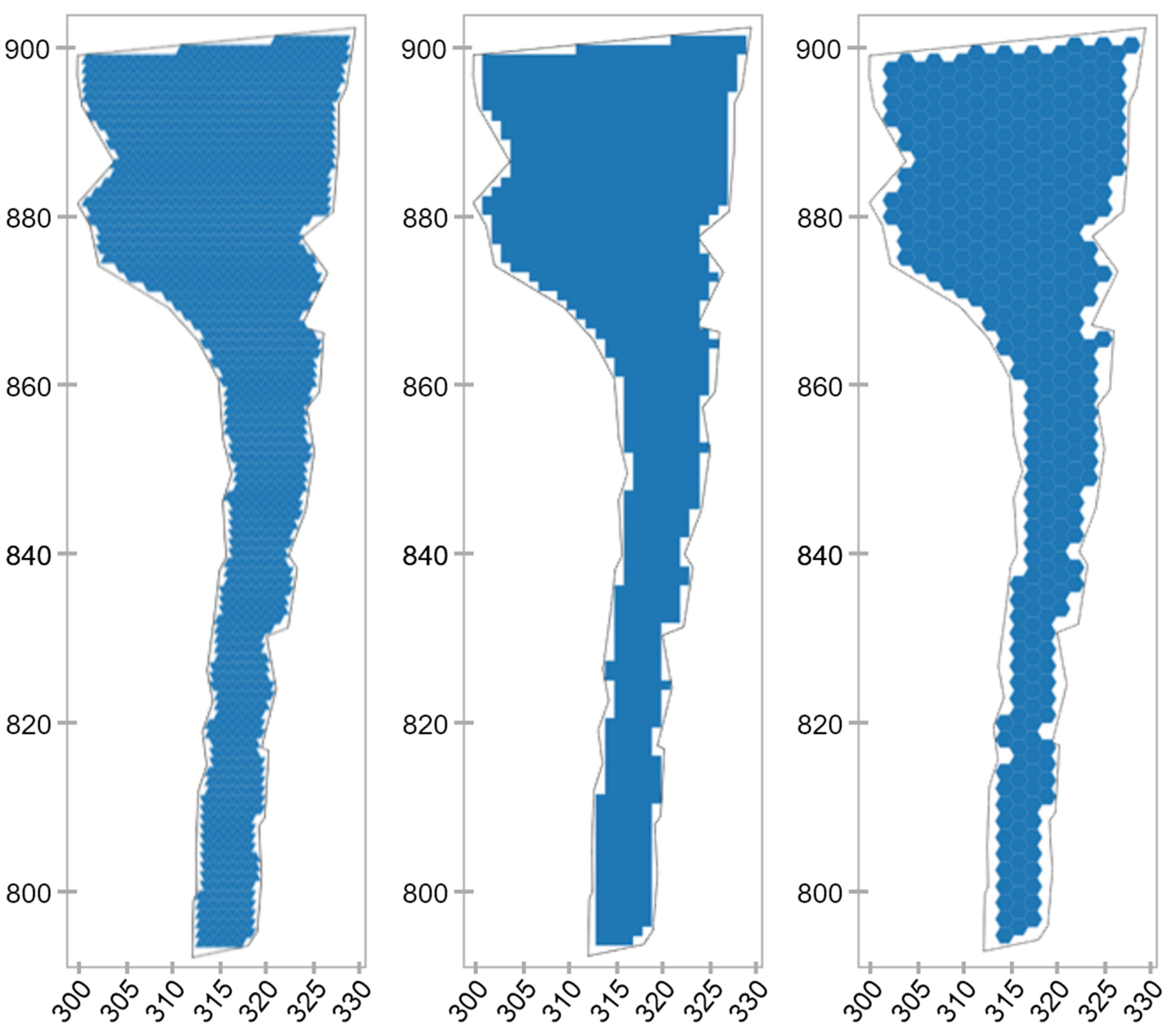

- Partitioning the space of technological zones into atomic elements (tessellation paving).

- Formation of a digital model of technological zones.

- Updating the coordinates of the boundaries of technological zones (delineation).

4. The Structure of a Dynamic Digital Model

- Unique identification number;

- Belonging to a certain technological zone;

- Type of road surface;

- A set of coordinates of the vertices and the center of an atomic element;

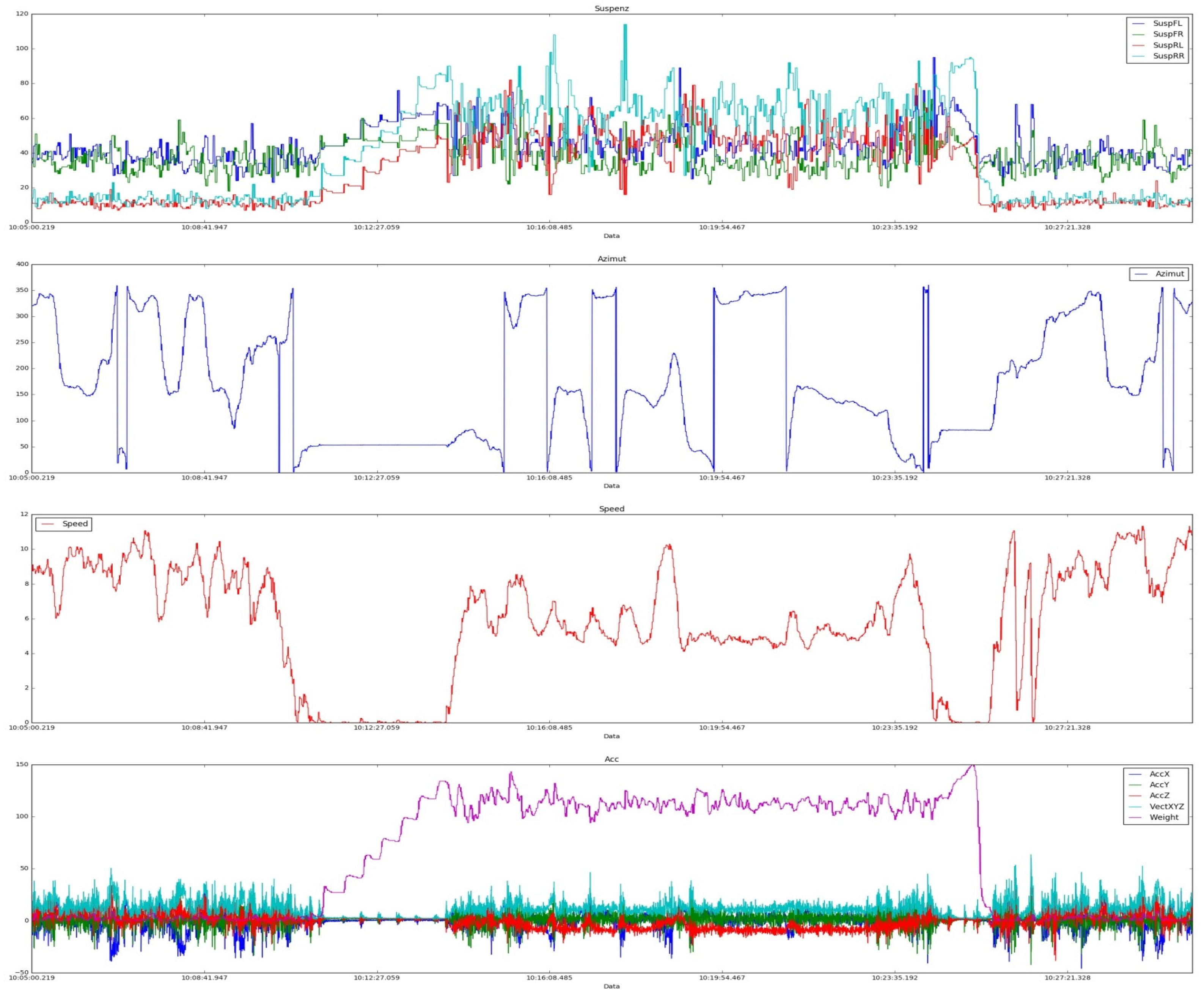

- —quality index of an atomic element (calculated coefficient).

- is the location within the technological space (for example, “close–far” from the border of the technological zone);

- is the location of the plane of an atomic element in space (the best option is for all vertices of an atomic element);

- is an evaluation function characterizing the current state of an atomic element (stone, pit, pothole, track trough, etc.), which is formed on the basis of expert statistical analysis of data received from onboard sensors (examples of such implementations are shown in Figure 6). Data from the load sensors on the springs of all wheels of the dump truck, as well as the speedometers, accelerometers, and inclinometers are used. As a result, for each atomic element using a fuzzy rule base, the integral estimate is calculated.

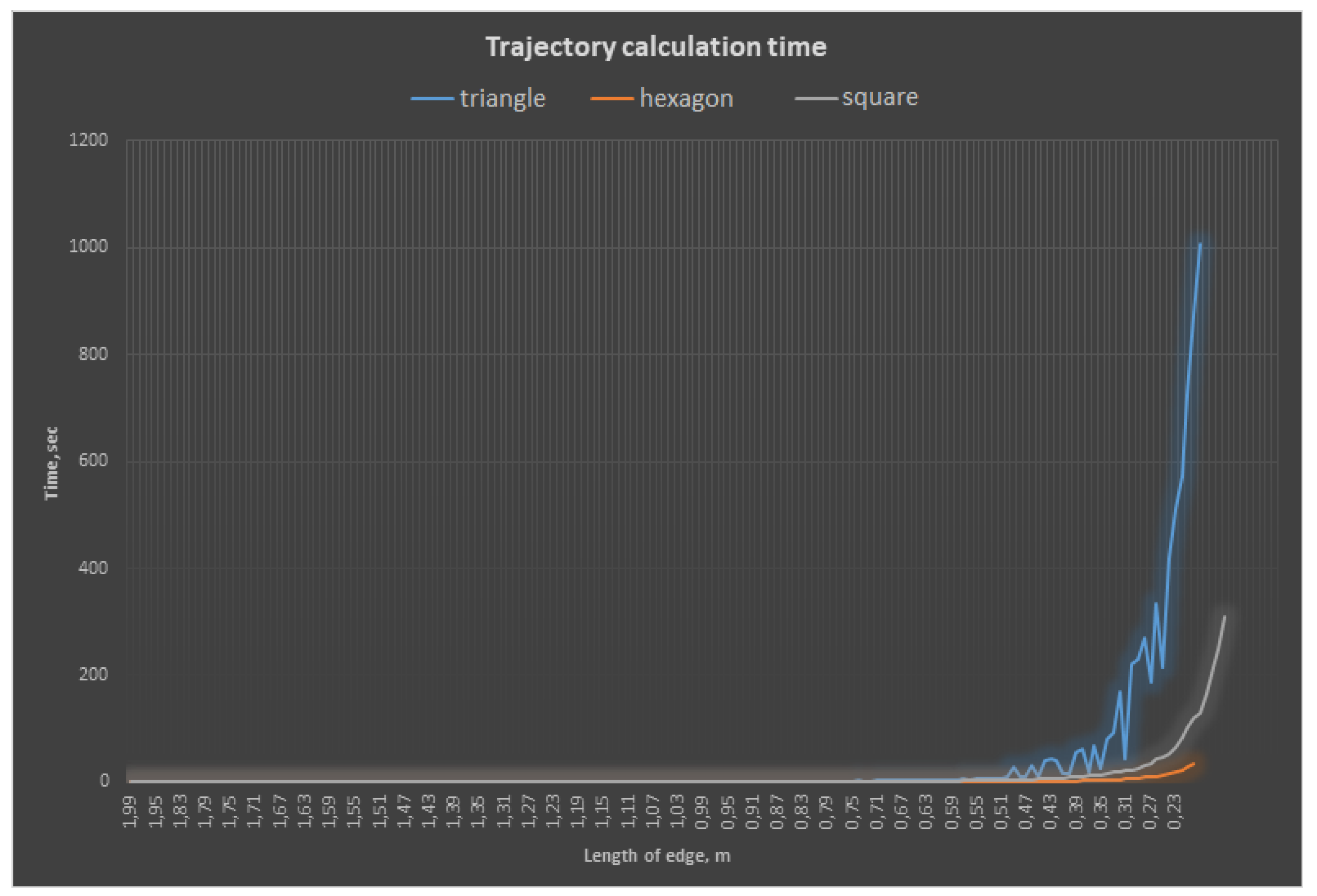

5. Computational Experiments with a Digital Model—Determination of Model Parameters

6. Results

7. Discussion

8. Conclusions

- A brief overview of the landscape defining today’s approaches to the implementation of open-pit mining technologies within the framework of the functioning of modern automated process control systems with the use of robotic or fully autonomous mining and transport equipment was performed.

- The analysis of modern approaches to the implementation of autonomous haulage systems allows us to conclude that a wide range of predictive analytics and machine learning methods have been successfully used to solve the problems of coordinating actions and managing the coordinated movement of autonomous transport objects.

- It was noted that industrial transport and technological systems, which certainly include mining technologies of open-pit mining, have a number of distinctive features associated with the peculiarities of the operating environment and the tasks to be solved. This refers to heterogeneous autonomous systems that must function in a constantly changing technological environment.

- Taking into account the multicriteria and nonstationarity of transport and technological processes in quarries, it is proposed to move to a new qualitative level of modeling with the use of technological Digital Twin. The possible problems that may arise during the process of constructing this class of models in the conditions of a continuous, stochastic, and nonstationary modeling object are shown.

- The possibilities of using modern monitoring tools, and onboard and stationary telemetry systems operating within the framework of modern automated control systems are considered.

- An approach to modeling the processes of open-pit mining is proposed, which consists in the decomposition of the entire technological complex into three agent systems, which are defined as: technical mobile, infrastructural–technological, and geostructural.

- A methodology and an appropriate set of algorithms have been developed aimed at integrating heterogeneous geospatial and telemetric information in order to build a digital 3D model of the technological environment of the quarry (infrastructure and technological system). The basis of the methodology is the structure of the digital model of transport and technological zones of the quarry.

- A set of computational experiments was carried out, which confirmed the efficiency of the proposed method. Based on the analysis of the simulation results, specific recommendations can be formulated for the implementation of the proposed methodology at any mining facility with robotic equipment equipped with modern sensor equipment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y. Design and implementation of the management information system for Chain business corporation. In Proceedings of the 8th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Macau, China, 11–12 March 2016; pp. 195–198. [Google Scholar] [CrossRef]

- Moreno, G.A.; Cámara, J.; Garlan, D.; Schmerl, B. Flexible and Efficient Decision-Making for Proactive Latency-Aware Self-Adaptation. ACM Trans. Auton. Adapt. Syst. 2018, 13, 36. [Google Scholar] [CrossRef]

- Kammoun, H.M.; Kallel, I.; Casillas, J.; Abraham, A.; Alimi, A.M. Adapt-Traf: An adaptive multiagent road traffic management system based on hybrid ant-hierarchical fuzzy model. Transp. Res. Part C Emerg. Technol. 2014, 42, 147–167. [Google Scholar] [CrossRef]

- Nowakowski, C.; Shladover, S.E.; Tan, H.-S. Heavy Vehicle Automation: Human Factors Lessons Learned. Proc. Manuf. 2015, 3, 2945–2952. [Google Scholar] [CrossRef] [Green Version]

- Marshall, J.A.; Bonchis, A.; Nebot, E.; Scheding, S. Robotics in mining. In Springer Handbook of Robotics; Siciliano, B., Khatib, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1549–1576. [Google Scholar] [CrossRef] [Green Version]

- Klebanov, A.F. Information systems of mining production and the main directions of development of automation of open pit mining. Min. Ind. 2015, 2, 93–95. [Google Scholar]

- Deryabin, S.A.; Temkin, I.O.; Zykov, S.V. About some issues of developing Digital Twins for the intelligent process control in quarries. Proc. Comput. Sci. 2020, 176, 3210–3216. [Google Scholar] [CrossRef]

- Dadhich, S.; Bodin, U.; Anderson, U. Key challenges in automation of earth-moving machines. Autom. Constr. 2016, 68, 212–222. [Google Scholar] [CrossRef] [Green Version]

- Yan, Z.; Jouandeau, N.; Cherif, A.A. A survey and analysis of multi-robot coordination. Int. J. Adv. Robot. Syst. 2013, 10, 399. [Google Scholar] [CrossRef]

- Goodin, C.; Prevost, Z. Simulation of Biologically-Inspired Control Algorithms for Teams of Ground Vehicles. In Proceedings of the 2015 Conference on Autonomous and Robotic Construction of Infrastructure, Ames, IA, USA, 2–3 June 2015; pp. 105–111. [Google Scholar]

- Temkin, I.O.; Myaskov, A.V.; Deryabin, S.A.; Rzazade, U.A. Digital twins and modeling of the transporting-technological processes for on-line dispatch control in open pit mining. Eurasian Min. 2020, 2, 55–58. [Google Scholar] [CrossRef]

- Jhavian, R.; Brito, L.; Behzadan, A. Integrated Mobile Sensor-Based Activity Recognition of Construction Equipment and Human Crews. In Proceedings of the 2015 Conference on Autonomous and Robotic Construction of Infrastructure, Ames, IA, USA, 2–3 June 2015; pp. 1–20. [Google Scholar]

- Borangiu, T.; Trentesaux, D.; Thomas, A.; Leitão, P.; Barata, J. Digital transformation of manufacturing through cloud services and resource virtualization. Comput. Ind. 2019, 108, 150–162. [Google Scholar] [CrossRef]

- Oyekan, J.; Farnsworth, M.; Hutabarat, W.; Miller, D.; Tiwari, A. Applying a 6 DoF Robotic Arm and Digital Twin to Automate Fan-Blade Reconditioning for Aerospace Maintenance, Repair, and Overhaul. Sensors 2020, 20, 4637. [Google Scholar] [CrossRef]

- Sahal, R.; Breslin, J.G.; Ali, M.I. Big data and stream processing platforms for industry 4.0 requirements mapping for a predictive maintenance use case. J. Manuf. Syst. 2020, 54, 138–151. [Google Scholar] [CrossRef]

- Resende, C.; Folgado, D.; Oliveira, J.; Franco, B.; Moreira, W.; Oliveira-Jr, A.; Cavaleiro, A.; Carvalho, R. TIP4.0: Industrial Internet of Things Platform for Predictive Maintenance. Sensors 2021, 21, 4676. [Google Scholar] [CrossRef]

- Thoben, K.-D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and smart manufacturing—A review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef] [Green Version]

- Fiosina, J. Decentralized regression model for intelligent forecasting in multi-agent traffic networks. In Proceedings of the AISC—9th International Confernce on Distributed Computing and Artificial Intelligence (DCAI’12), Salamanca, Spain, 28–30 March 2012; Omatu, S., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 255–263. [Google Scholar] [CrossRef]

- Jiang, B.; Fei, Y. Vehicle Speed Prediction by Two-Level Data Driven Models in Vehicular Networks. IEEE Trans. Intell. Transp. Syst. 2017, 18, 1793–1801. [Google Scholar] [CrossRef]

- Cámara, J.; Moreno, G.A.; Garlan, D.; Schmerl, B. Analyzing Latency-Aware Self-Adaptation Using Stochastic Games and Simulations. ACM Trans. Auton. Adapt. Syst. (TAAS) 2016, 10, 1–28. [Google Scholar] [CrossRef] [Green Version]

- Vennapusa, P.K.R.; White, J.D.; Jahren, C.T. Impacts of Automated Machine Guidance on Earth-work Operation. In Proceedings of the 2015 Conference on Autonomous and Robotic Construction of Infrastructure, Ames, IA, USA, 2–3 June 2015; pp. 207–216. [Google Scholar]

- Al Ghifari, N.T.; Jati, A.N.; Saputra, R.E. Coordination control for simple autonomous mobile robot. In Proceedings of the 5th International Conference on Instrumentation, Control and Automation (ICA), Yogyakarta, Indonesia, 9–11 August 2017; pp. 93–98. [Google Scholar] [CrossRef]

- Zhu, Q.; Hu, J.; Cai, W.; Henchen, L. A new robot navigation algorithm for dynamic unknown environment based on dynamic path re-computation and an improved scout ant algorithm. Appl. Soft Comput. 2011, 11, 4667–4676. [Google Scholar] [CrossRef]

- Sukhorukova, M.A.; Ivannikov, A.L. Vehicle accident risk assessment in mines. Min. Inf. Anal. Bull. 2020, 2020, 224–232. [Google Scholar] [CrossRef]

- Rybak, J.; Kongar-Syuryun, C.; Tyulyaeva, Y.; Khayrutdinov, A.M. Creation of Backfill Materials Based on Industrial Waste. Minerals 2021, 11, 739. [Google Scholar] [CrossRef]

- Lopez-Arevalo, I.; Gonzalez-Compean, J.L.; Hinojosa-Tijerina, M.; Martinez-Rendon, C.; Montella, R.; Martinez-Rodriguez, J.L. A WoT-Based Method for Creating Digital Sentinel Twins of IoT Devices. Sensors 2021, 21, 5531. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Kunath, M.; Winkler, H. Integrating the Digital Twin of the manufacturing system into a decision support system for improving the order management process. Proc. CIRP 2018, 72, 225–231. [Google Scholar] [CrossRef]

- Stary, C. Digital Twin Generation: Re-Conceptualizing Agent Systems for Behavior-Centered Cyber-Physical System Development. Sensors 2021, 21, 1096. [Google Scholar] [CrossRef]

- Savolainen, J.; Urbani, M. Maintenance optimization for a multi-unit system with digital twin simulation. Intell. Manuf. 2021, 32, 1953–1973. [Google Scholar] [CrossRef]

- Martínez, P.L.; Dintén, R.; Drake, J.M.; Zorrilla, M. A big data-centric architecture metamodel for Industry 4.0. Future Gener. Comput. Syst. 2021, 125, 263–284. [Google Scholar] [CrossRef]

- Velásquez, N.; Estevez, E.; Pesado, P. Cloud computing, big data and the industry 4.0 reference architectures. J. Comput. Sci. Technol. 2018, 18, e29. [Google Scholar] [CrossRef]

- Al-Gumaei, K.; Schuba, K.; Friesen, A.; Heymann, S.; Pieper, C.; Pethig, F.; Schriegel, S. A survey of internet of things and big data integrated solutions for industrie 4.0. In Proceedings of the 2018 IEEE 23rd International Conference on Emerging Technologies and Factory Automation (ETFA), Torino, Italy, 4–7 September 2018; pp. 1417–1424. [Google Scholar] [CrossRef]

- Liua, C.; Su, Z.; Xu, X.; Lu, Y. Service-oriented industrial internet of things gateway for cloud manufacturing. Robot. Comput. Integr. Manuf. 2022, 73, 102217. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, H.; Tao, F.; Juang, C.-F. DT-II: Digital twin enhanced Industrial Internet reference framework towards smart manufacturing. Robot. Comput. Integr. Manuf. 2020, 62, 101881. [Google Scholar] [CrossRef]

- Tuli, S.; Poojara, S.R.; Srirama, S.N.; Casale, G. COSCO: Container Orchestration Using Co-Simulation and Gradient Based Optimization for Fog Computing Environments. IEEE Trans. Parallel Distrib. Syst. 2021, 33, 101–116. [Google Scholar] [CrossRef]

- Petrasch, R.; Hentschke, R. Process Modeling for Industry 4.0 Applications: Towards an Industry 4.0 Process Modeling Language and Method. In Proceedings of the 13th International Joint Conference on Computer Science and Software Engineering (JCSSE), Khon Kaen, Thailand, 13–15 July 2016. [Google Scholar] [CrossRef]

| Characteristics | Mine-Surveying | Satellite Imagery | On Board Telemetry |

|---|---|---|---|

| Accuracy | 1 cm | 100 cm | 50 cm |

| Completeness of the data | High | High | Medium |

| Update frequency | Once a week | Discretely nondeterministic | Continuous |

| ) accuracy | 1 m | 10 m | 2 m |

| Type of Atomic Element | Length of Edge, m | ||

|---|---|---|---|

| square | 1 | 1114 | 92.83 |

| triangle | 1 | 2270 | 94.58 |

| hexagon | 1 | 394 | 85 |

| Type of Atomic Element | Length of Edge, m | Complexity, n | Time of Calculation, sec | Square, m2 | ||

|---|---|---|---|---|---|---|

| square | 2 | 245 | 54 | 0.041955 | 980 | 81.67 |

| square | 1 | 1114 | 111 | 0.375658 | 1114 | 92.83 |

| square | 0.5 | 4723 | 226 | 5.399732 | 1180.75 | 98.40 |

| square | 0.25 | 19.466 | 458 | 118.5997 | 1216.63 | 99.39 |

| triangle | 2 | 535 | 96 | 0.081783 | 1070 | 89.17 |

| triangle | 1 | 2270 | 192 | 0.660409 | 1135 | 94.58 |

| triangle | 0.5 | 9352 | 381 | 40.54165 | 1169 | 97.42 |

| triangle | 0.25 | 37.988 | 758 | 1208.144 | 1187.13 | 98.93 |

| hexagon | 2 | 77 | 28 | 0.019948 | 800.21 | 66.68 |

| hexagon | 1 | 394 | 60 | 0.088249 | 1023.64 | 85.30 |

| hexagon | 0.5 | 1754 | 121 | 0.874117 | 1139.26 | 94.93 |

| hexagon | 0.25 | 7355 | 247 | 13.87281 | 1194.30 | 99.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Temkin, I.; Myaskov, A.; Deryabin, S.; Konov, I.; Ivannikov, A. Design of a Digital 3D Model of Transport–Technological Environment of Open-Pit Mines Based on the Common Use of Telemetric and Geospatial Information. Sensors 2021, 21, 6277. https://doi.org/10.3390/s21186277

Temkin I, Myaskov A, Deryabin S, Konov I, Ivannikov A. Design of a Digital 3D Model of Transport–Technological Environment of Open-Pit Mines Based on the Common Use of Telemetric and Geospatial Information. Sensors. 2021; 21(18):6277. https://doi.org/10.3390/s21186277

Chicago/Turabian StyleTemkin, Igor, Alexander Myaskov, Sergey Deryabin, Iliya Konov, and Alexander Ivannikov. 2021. "Design of a Digital 3D Model of Transport–Technological Environment of Open-Pit Mines Based on the Common Use of Telemetric and Geospatial Information" Sensors 21, no. 18: 6277. https://doi.org/10.3390/s21186277

APA StyleTemkin, I., Myaskov, A., Deryabin, S., Konov, I., & Ivannikov, A. (2021). Design of a Digital 3D Model of Transport–Technological Environment of Open-Pit Mines Based on the Common Use of Telemetric and Geospatial Information. Sensors, 21(18), 6277. https://doi.org/10.3390/s21186277