Diagnosis Methodology Based on Deep Feature Learning for Fault Identification in Metallic, Hybrid and Ceramic Bearings

Abstract

:1. Introduction

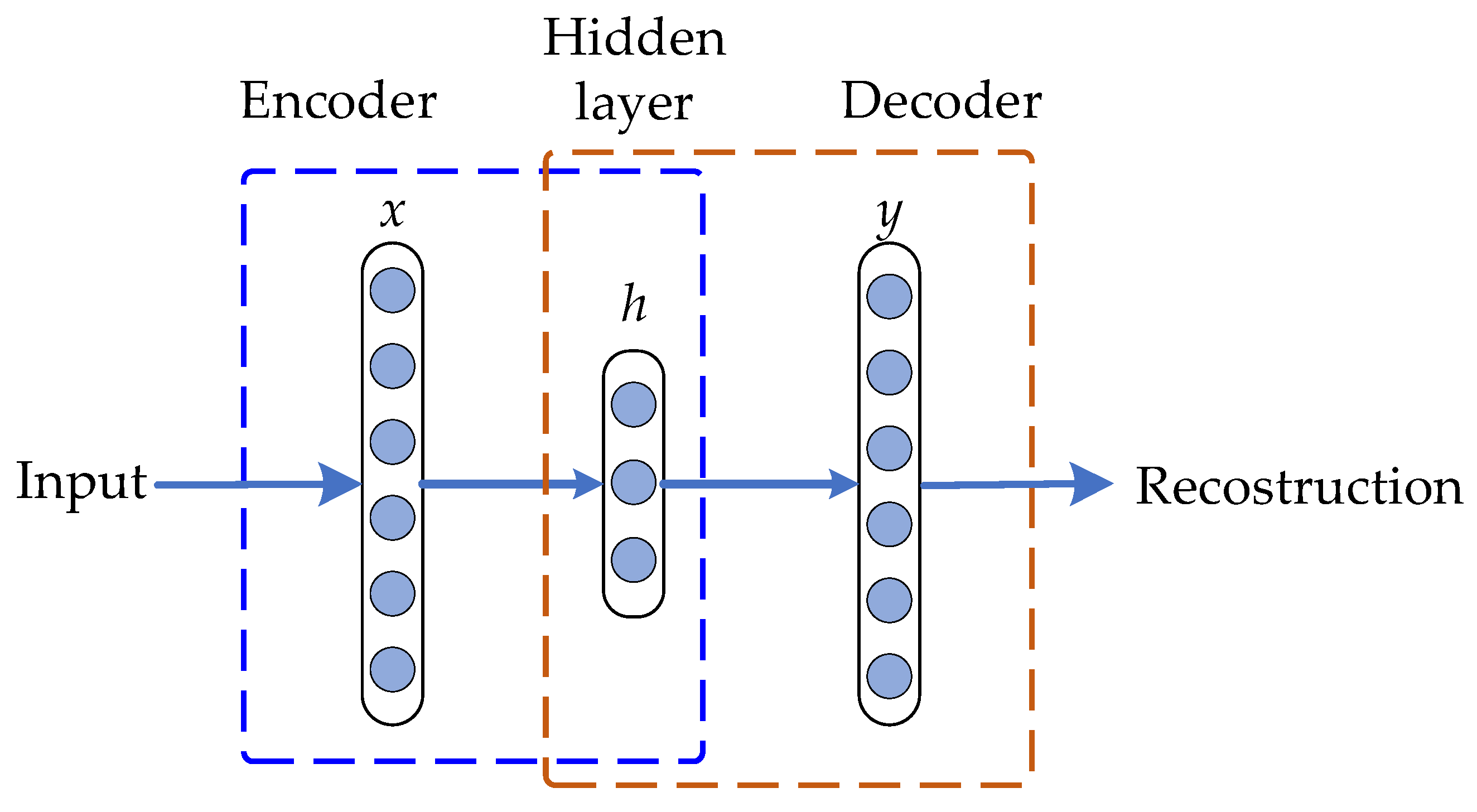

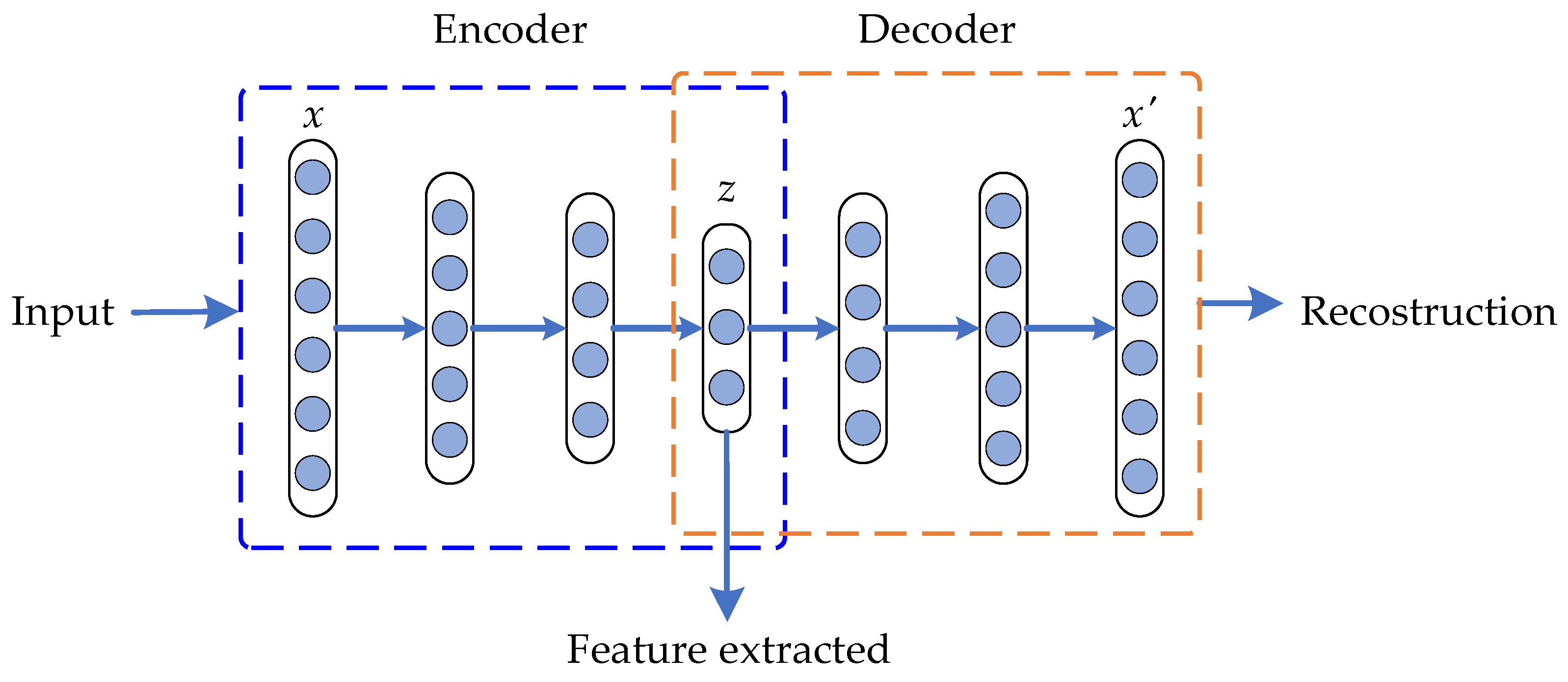

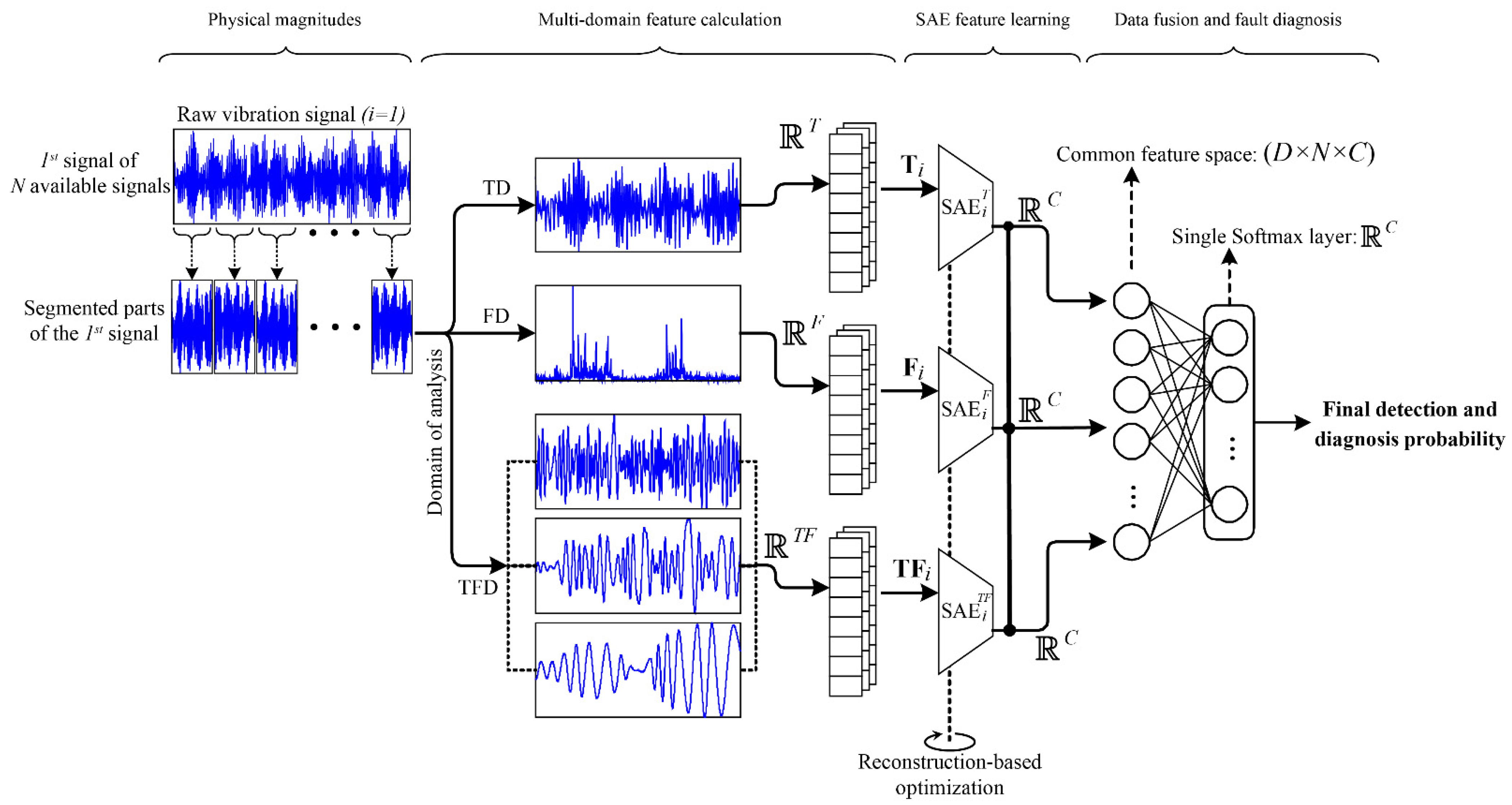

2. Autoencoder-Based Deep Feature Learning

3. Deep Feature Learning Based Methodology

3.1. Multi-Domain Feature Calculation

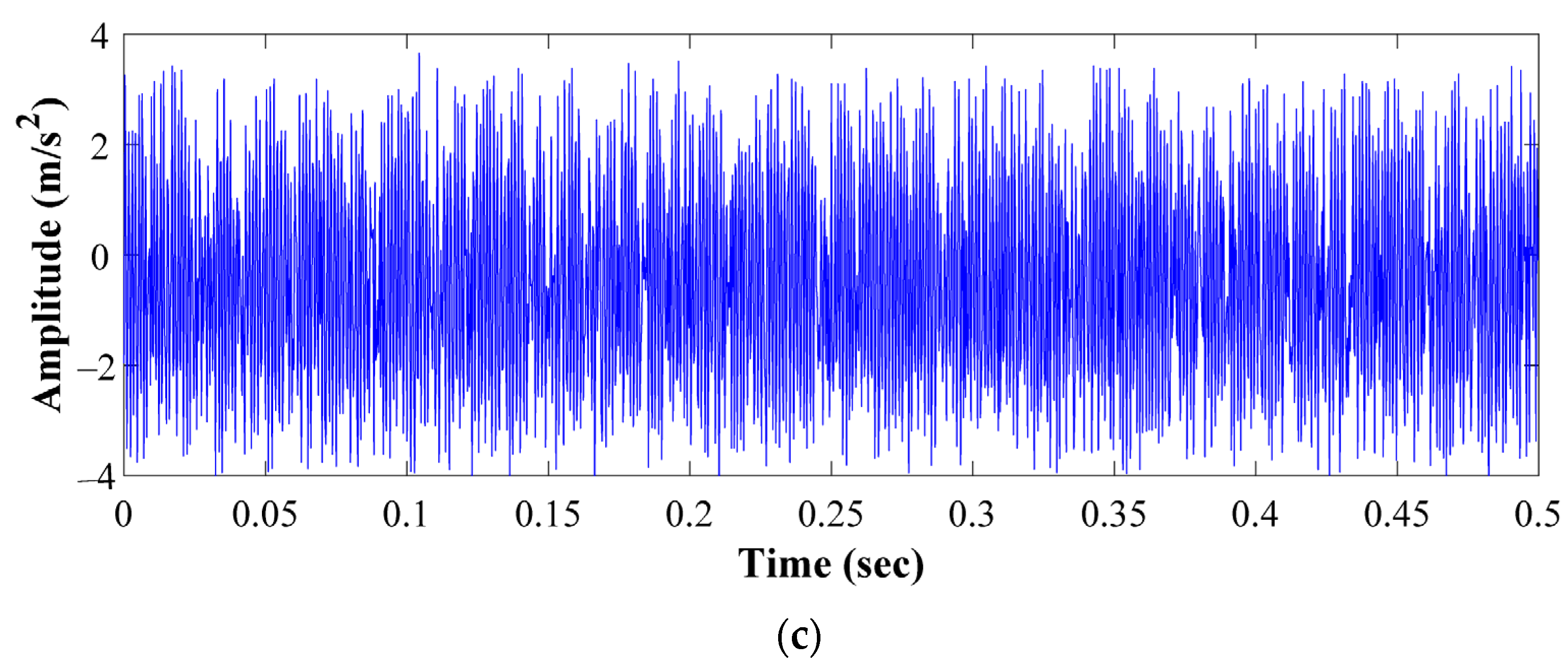

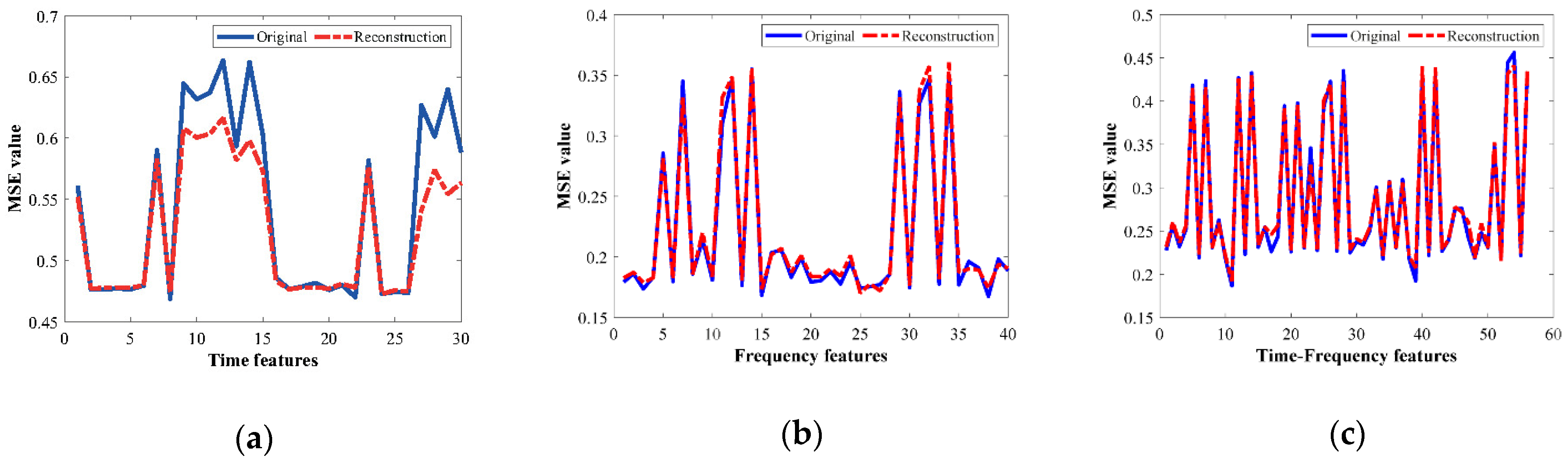

3.2. SAE Feature Learning

- Step 1: Initialization of the population: the chromosomes of the GA are initially defined with a logical vector containing three elements, where each element represents each one of the hyperparameters. Subsequently, a random initialization of the population is performed by assigning a specific value to each particular hyperparameter; in fact, the values assigned to each hyperparameter are within a predefined range of values. Once the initialization of the population is achieved, the procedure continues in step 2.

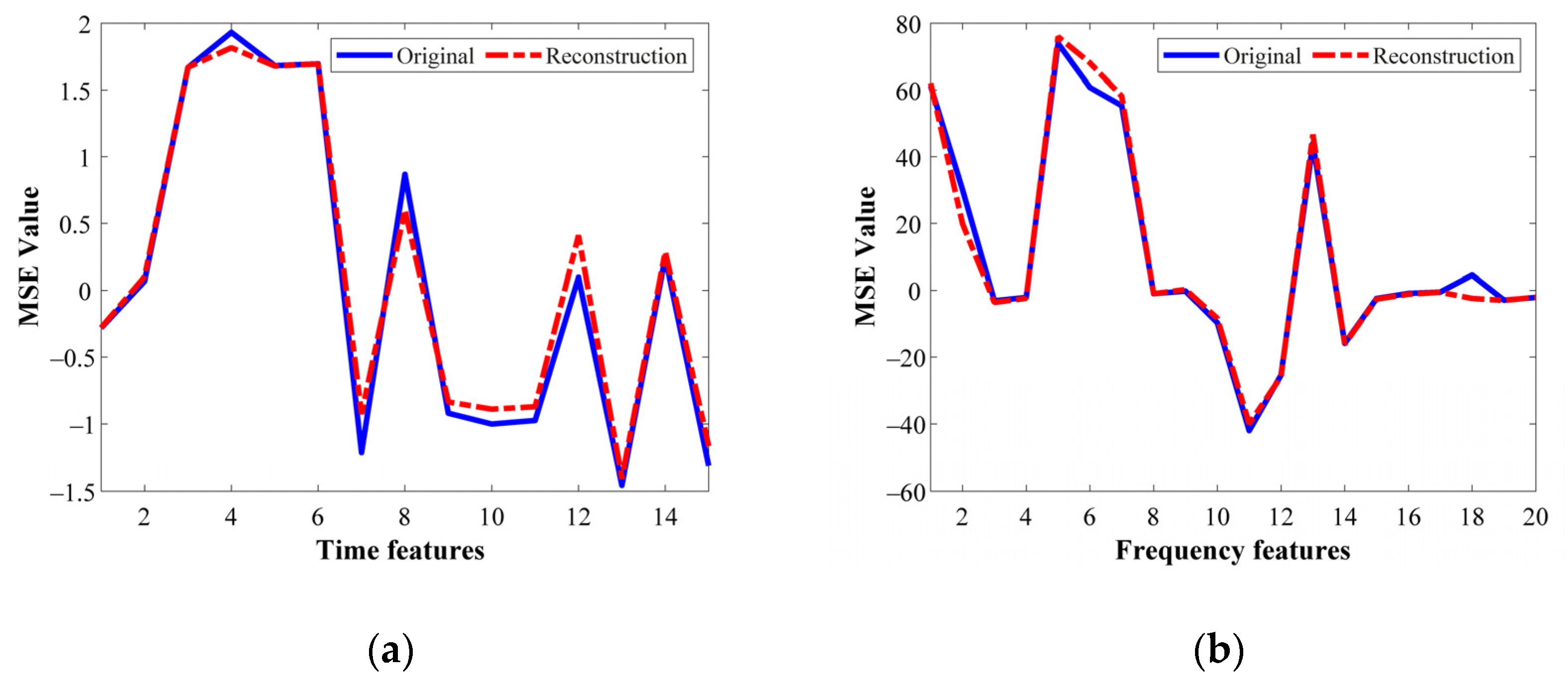

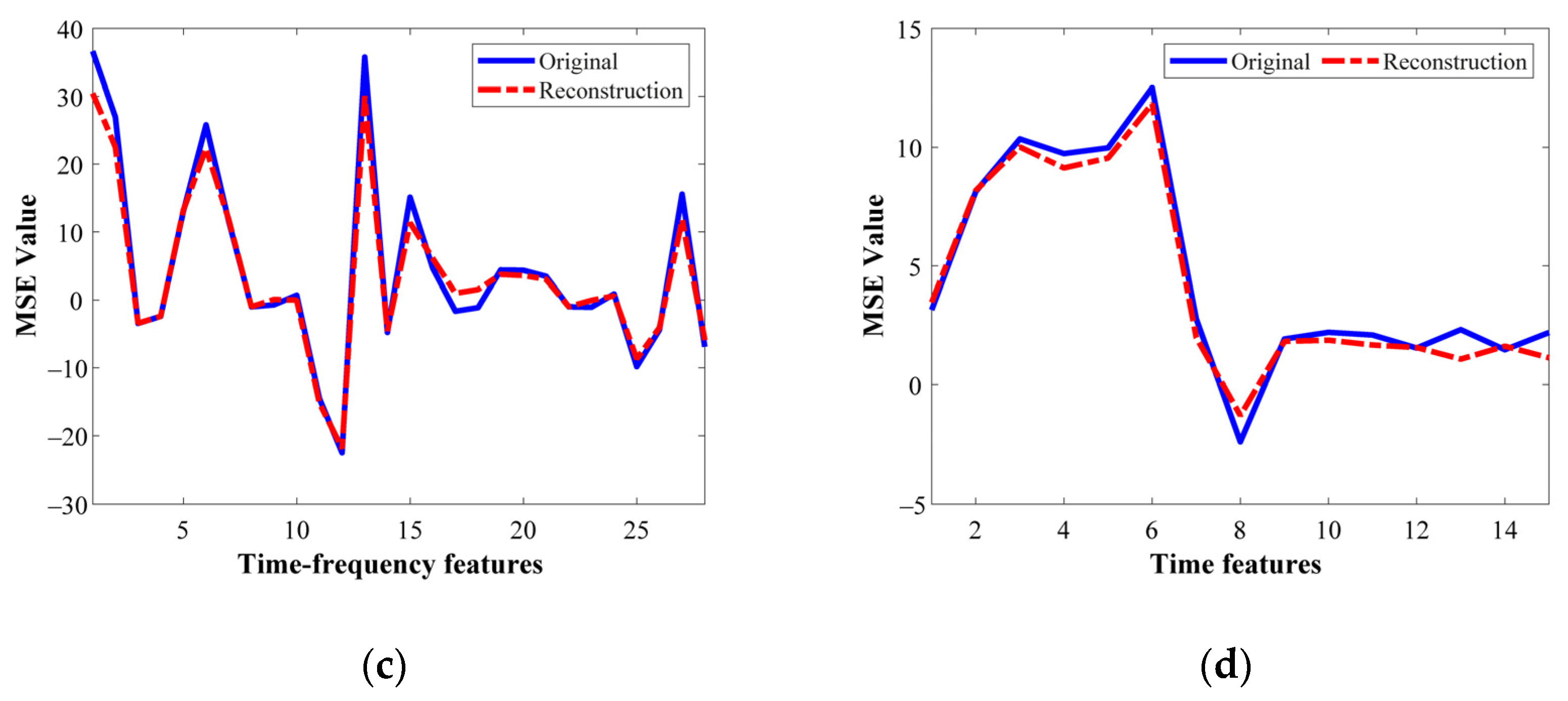

- Step 2: Evaluation of the population: in this step the fitness function is evaluated based on the minimization of the reconstruction error between the input and the output features. Specifically, the minimization of the reconstruction error is evaluated in terms of the MSE value following Equation (3), as mentioned in Section 2. Thereby, the optimization problem to be solved by the GA involves the search of those specific hyperparameter values that leads a high-performance feature mapping. Then, once the whole population is evaluated under a wide range of values, the condition of best hyperparameter values is analyzed and the procedure continues in step 4.

- Step 3: Mutation operation: the mutation of the GA produces a new population by means of the roulette wheel selection; the newly generated population takes into account the choice of the best fitness value achieved by the previously evaluated population. Moreover, a mutation operation that is based on the Gaussian distribution is applied during the generation of the new population. Subsequently, the procedure continues in step 2.

- Step 4: Stop criteria: there are two stop criteria for the GA: (i) the obtention of a reconstruction MSE value lower than a predefined threshold, 5%, and/or, (ii) reaching the maximum number of iterations, 1000. In the case of the first stop criterion, (i), the procedure is repeated iteratively until those optimal hyperparameter values are found until the GA evolves, then the procedure continues in step 3.

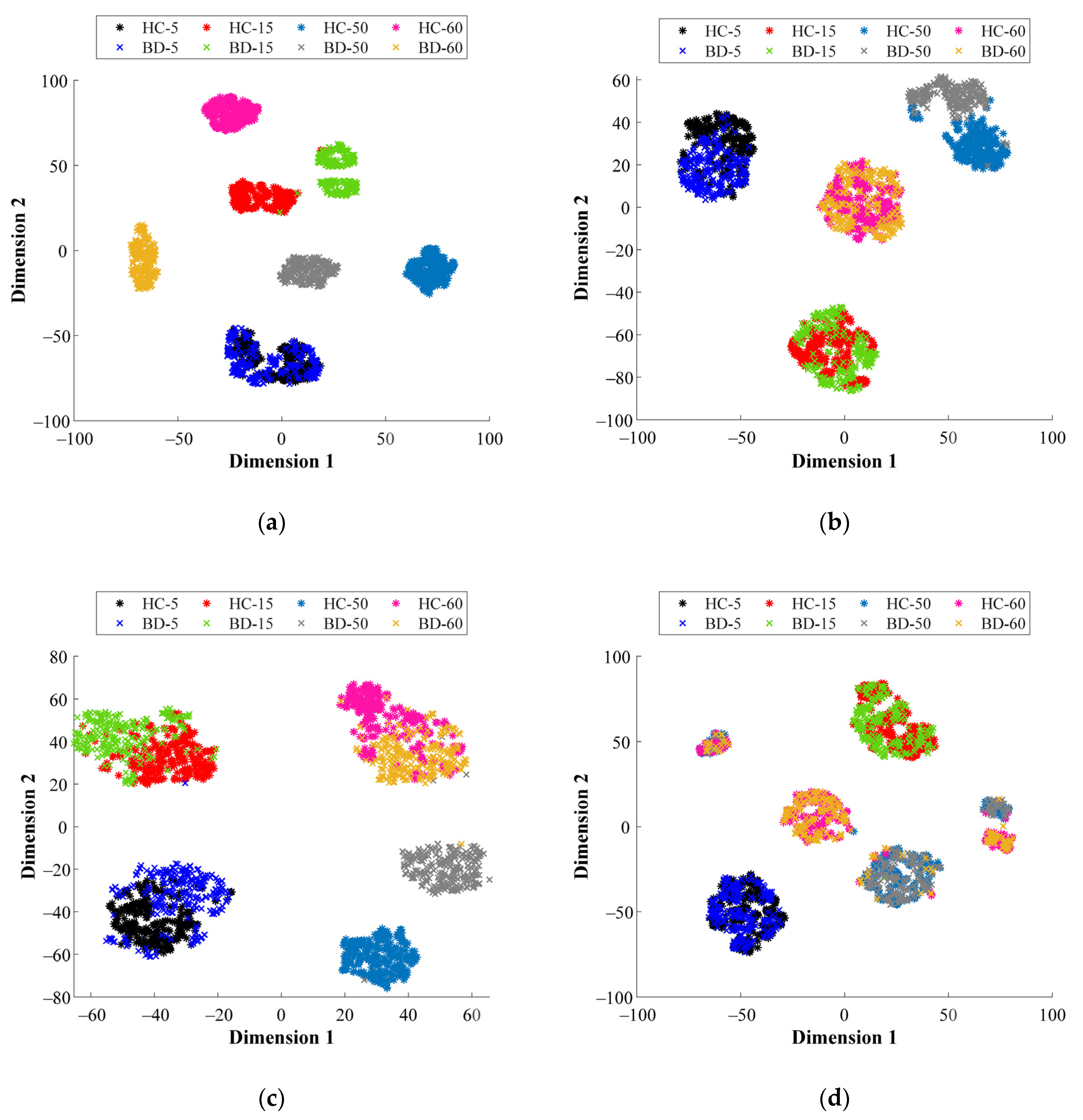

3.3. Data Fusion and Fault Diagnosis

4. Experimental Validation

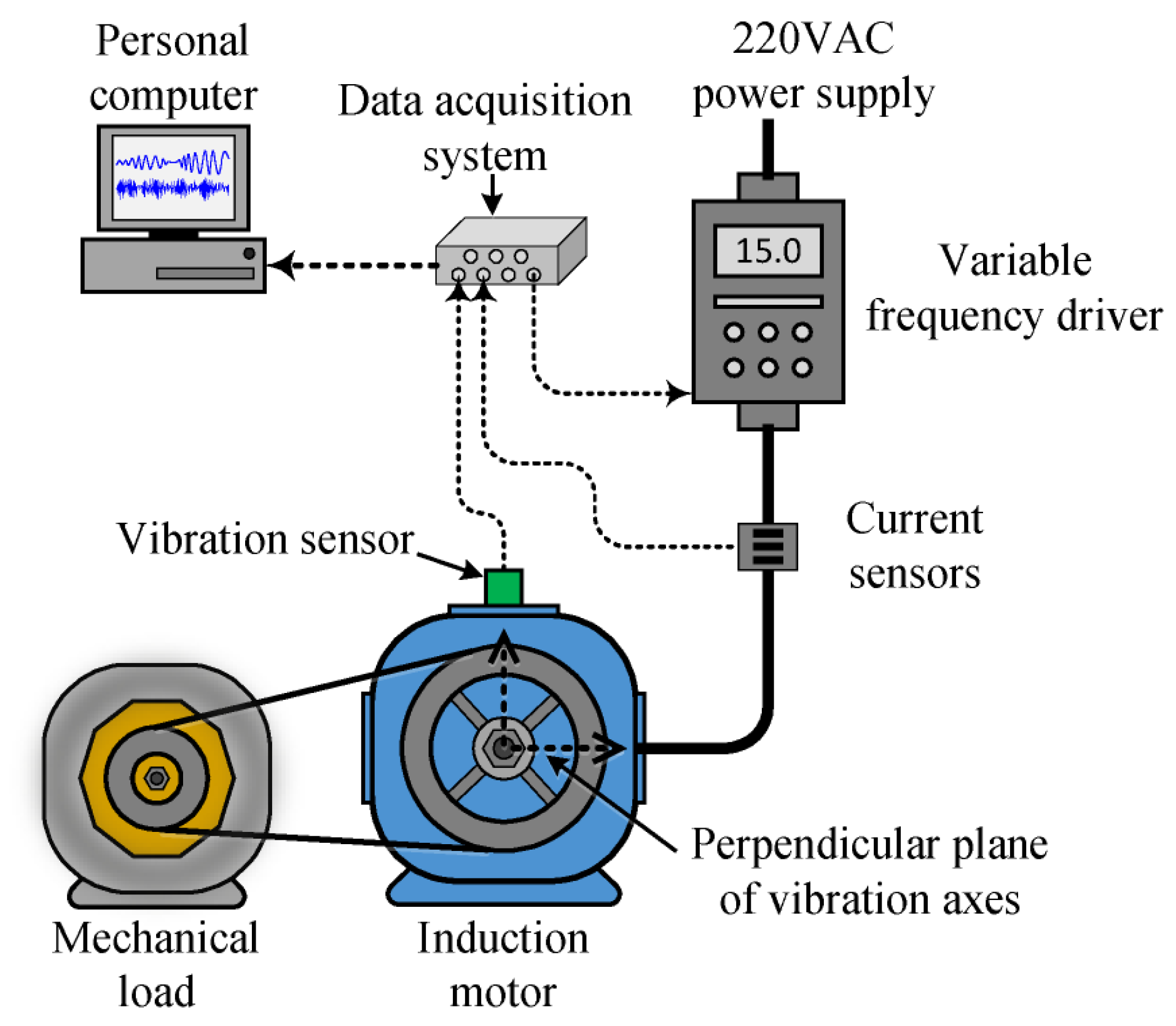

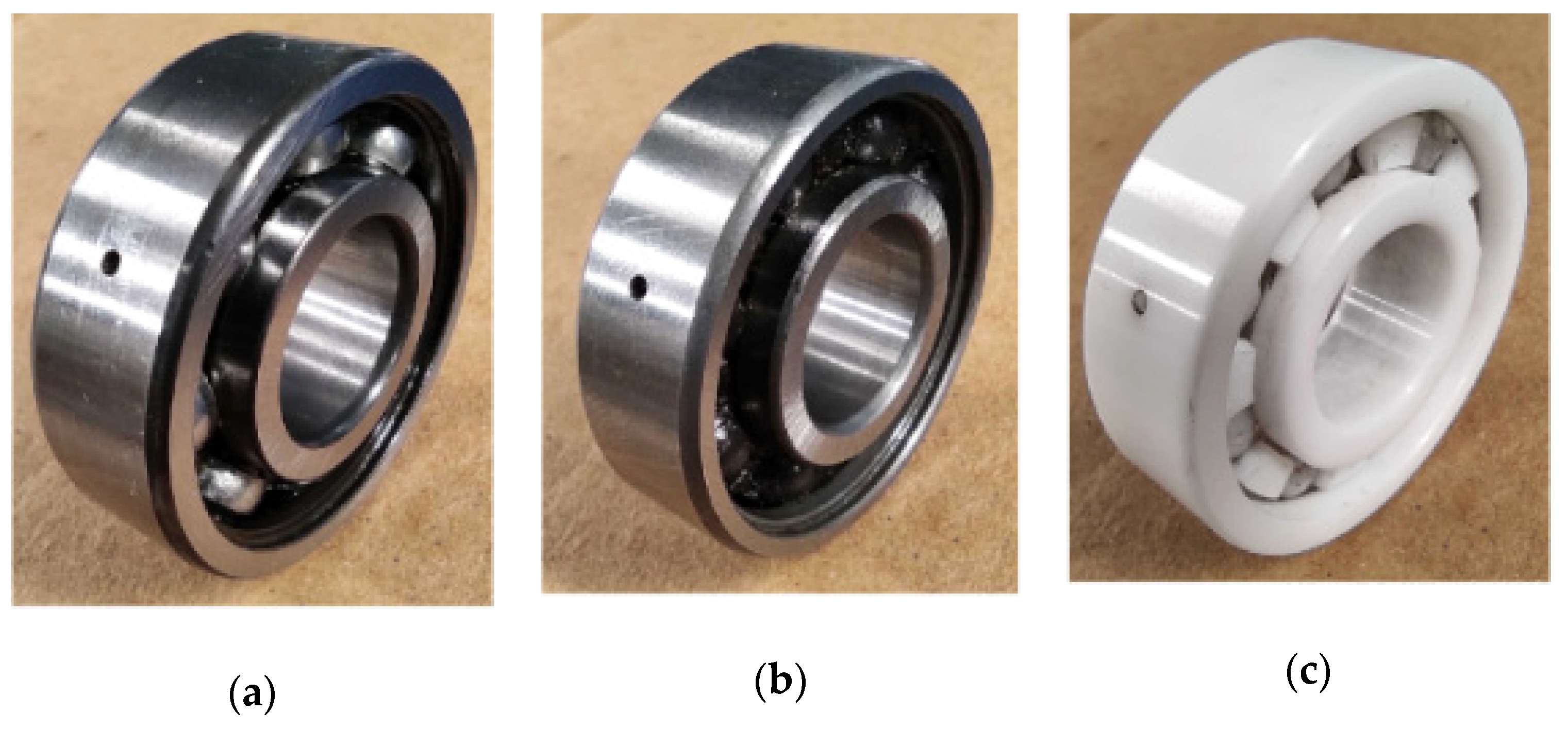

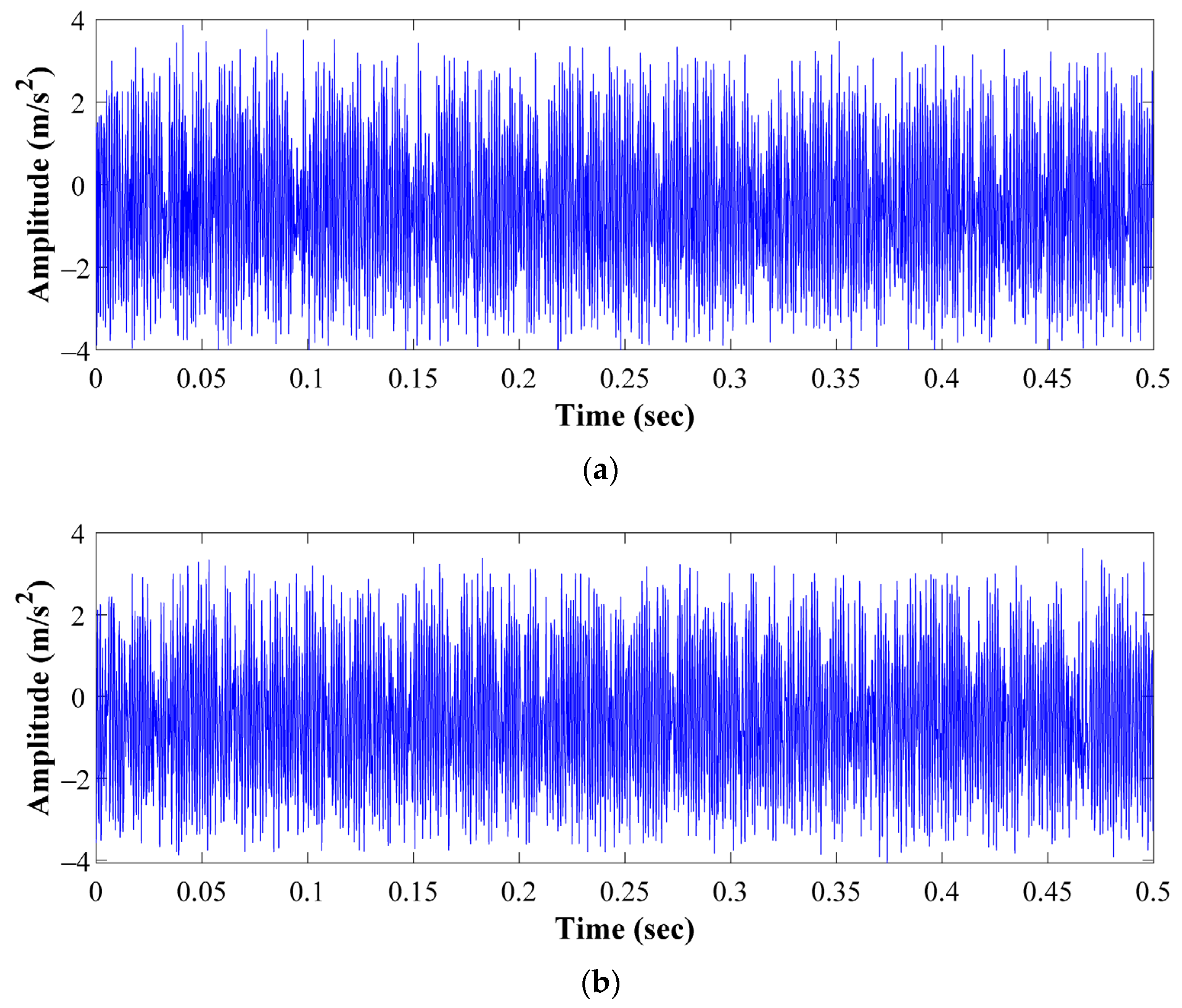

4.1. Pulley-Belt Electromechanical System

4.2. Rolling Bearing CWRU Dataset

5. Results and Validation

5.1. Evaluation of the Diagnostic Model in the Pulley-Belt Electromechanical System

5.2. Evaluation of the Diagnostic Model in the CWRU Database

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- You, L.; Hu, J.; Fang, F.; Duan, L. Fault Diagnosis System of Rotating Machinery Vibration Signal. Procedia Eng. 2011, 15, 671–675. [Google Scholar] [CrossRef] [Green Version]

- Glowacz, A. Ventilation Diagnosis of Angle Grinder Using Thermal Imaging. Sensors 2021, 21, 2853. [Google Scholar] [CrossRef]

- Shi, H.; Liu, Z.; Bai, X.; Li, Y.; Wu, Y. A Theoretical Model with the Effect of Cracks in the Local Spalling of Full Ceramic Ball Bearings. Appl. Sci. 2019, 9, 4142. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Wang, H.; Liu, H.; He, T.; Xie, T. Health Monitoring on the Spacecraft Bearings in High-Speed Rotating Systems by Using the Clustering Fusion of Normal Acoustic Parameters. Appl. Sci. 2019, 9, 3246. [Google Scholar] [CrossRef] [Green Version]

- Cui, L.; Wang, X.; Wang, H.; Wu, N. Improved Fault Size Estimation Method for Rolling Element Bearings Based on Concatenation Dictionary. IEEE Access 2019, 7, 22710–22718. [Google Scholar] [CrossRef]

- Cui, L.; Wang, X.; Wang, H.; Ma, J. Research on Remaining Useful Life Prediction of Rolling Element Bearings Based on Time-Varying Kalman Filter. IEEE Trans. Instrum. Meas. 2019, 69, 2858–2867. [Google Scholar] [CrossRef]

- Belinha, J.; Azevedo, J.M.C.; Dinis, L.; Jorge, R.N. Simulating fracture propagation in brittle materials using a meshless approach. Eng. Comput. 2017, 34, 503–522. [Google Scholar] [CrossRef]

- Ma, D.; Wang, J.; Sun, L. Methodology for measuring fracture toughness of ceramic materials by instrumented indentation test with vickers indenter. J. Am. Ceram. Soc. 2017, 16, 695–2308. [Google Scholar] [CrossRef]

- Vieillard, C. Observation of subsurface rolling contact fatigue cracks in silicon nitride and comparison of their location to Hertzian contact subsurface stresses. Int. J. Fatigue 2017, 96, 283–292. [Google Scholar] [CrossRef]

- Sun, L.; Ma, D.; Wang, L.; Shi, X.; Wang, J.; Chen, W. Determining indentation fracture toughness of ceramics by finite element method using virtual crack closure technique. Eng. Fract. Mech. 2018, 197, 151–159. [Google Scholar] [CrossRef]

- Li, B.; Ma, H.; Yu, X.; Zeng, J.; Guo, X.; Wen, B. Nonlinear vibration and dynamic stability analysis of rotor-blade system with nonlinear supports. Arch. Appl. Mech. 2019, 89, 1375–1402. [Google Scholar] [CrossRef]

- Cui, L.; Jin, Z.; Huang, J.; Wang, H. Fault Severity Classification and Size Estimation for Ball Bearings Based on Vibration Mechanism. IEEE Access 2019, 7, 56107–56116. [Google Scholar] [CrossRef]

- Ohta, H.; Satake, S. Vibrations of the All-Ceramic Ball Bearing. J. Tribol. 2002, 124, 448–460. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, Z.; Shi, H.; Bai, X.; Wang, Z. Research on Vibration Characteristics of a Ceramic Spindle Based on the Reverse Magnetic Effect. Shock. Vib. 2019, 2019, 1–15. [Google Scholar] [CrossRef]

- Dai, J.; Tang, J.; Shao, F.; Huang, S.; Wang, Y. Fault Diagnosis of Rolling Bearing Based on Multiscale Intrinsic Mode Function Permutation Entropy and a Stacked Sparse Denoising Autoencoder. Appl. Sci. 2019, 9, 2743. [Google Scholar] [CrossRef] [Green Version]

- Sohaib, M.; Kim, J.-M. Reliable Fault Diagnosis of Rotary Machine Bearings Using a Stacked Sparse Autoencoder-Based Deep Neural Network. Shock. Vib. 2018, 2018, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Sohaib, M.; Kim, C.-H.; Kim, J.-M. A Hybrid Feature Model and Deep-Learning-Based Bearing Fault Diagnosis. Sensors 2017, 17, 2876. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ren, L.; Sun, Y.; Cui, J.; Zhang, L. Bearing remaining useful life prediction based on deep autoencoder and deep neural networks. J. Manuf. Syst. 2018, 48, 71–77. [Google Scholar] [CrossRef]

- Prieto, M.D.; Cirrincione, G.; Espinosa, A.G.; Ortega, J.A.; Henao, H. Bearing Fault Detection by a Novel Condition-Monitoring Scheme Based on Statistical-Time Features and Neural Networks. IEEE Trans. Ind. Electron. 2012, 60, 3398–3407. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J. Early fault diagnosis of bearing and stator faults of the single-phase induction motor using acoustic signals. Measurement 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72-73, 303–315. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis. Measurement 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Soualhi, A.; Medjaher, K.; Zerhouni, N. Bearing health monitoring based on Hilbert–Huang transform, support vector machine, and regression. IEEE Trans. Instrum. Meas. 2015, 64, 52–62. [Google Scholar] [CrossRef] [Green Version]

- Saucedo, J.J.; Delgado, M.; Osornio, R.A.; Romero, R.J. Multifault Diagnosis Method Applied to an Electric Machine Based on High-Dimensional Feature Reduction. IEEE Trans. Ind. Appl. 2017, 53, 3086–3097. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Liu, G.; Zuo, Y.; Wu, J. An Anomaly Detection Framework Based on Autoencoder and Nearest Neighbor. In Proceedings of the 15th International Conference ICSSSM, Hangzhou, China, 21–22 July 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; De Silva, C.W. Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks. IEEE/ASME Trans. Mechatron. 2017, 23, 101–110. [Google Scholar] [CrossRef]

- Huang, G.; Song, S.; Gupta, J.N.D.; Wu, C. Semi-Supervised and Unsupervised Extreme Learning Machines. IEEE Trans. Cybern. 2014, 44, 2405–2417. [Google Scholar] [CrossRef]

- Zohuri, B.; Moghaddam, M. Deep Learning Limitations and Flaws. Mod. Approaches Mater. Sci. 2020, 2, 241–250. [Google Scholar]

- Smith, W.; Randall, R. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64-65, 100–131. [Google Scholar] [CrossRef]

- Jian, X.; Li, W.; Guo, X.; Wang, R. Fault Diagnosis of Motor Bearings Based on a One-Dimensional Fusion Neural Network. Sensors 2019, 19, 122. [Google Scholar] [CrossRef] [Green Version]

- Ou, J.; Li, H.; Huang, G.; Zhou, Q. A Novel Order Analysis and Stacked Sparse Auto-Encoder Feature Learning Method for Milling Tool Wear Condition Monitoring. Sensors 2020, 20, 2878. [Google Scholar] [CrossRef] [PubMed]

- Hinton, G.E.; Osindero, S.; Teh, Y.-W. A Fast Learning Algorithm for Deep Belief Nets. Neural Comput. 2006, 18, 1527–1554. [Google Scholar] [CrossRef] [PubMed]

- Nayana, B.R.; Geethanjali, P. Analysis of Statistical Time-Domain Features Effectiveness in Identification of Bearing Faults From Vibration Signal. IEEE Sens. J. 2017, 17, 5618–5625. [Google Scholar] [CrossRef]

- Gangsar, P.; Pandey, R.K.; Chouksey, M. Unbalance detection in rotating machinery based on support vector machine using time and frequency domain vibration features. Noise Vib. Worldw. 2021, 52, 75–85. [Google Scholar] [CrossRef]

- Neupane, D.; Seok, J. Bearing Fault Detection and Diagnosis Using Case Western Reserve University Dataset With Deep Learning Approaches: A Review. IEEE Access 2020, 8, 93155–93178. [Google Scholar] [CrossRef]

| Statistical Feature | Mathematical Equation | |

|---|---|---|

| Mean | (9) | |

| Maximum value | (10) | |

| Root mean square | (11) | |

| Square root mean | (12) | |

| Standard deviation | (13) | |

| Variance | (14) | |

| RMS Shape factor | (15) | |

| SRM Shape factor | (16) | |

| Crest factor | (17) | |

| Latitude factor | (18) | |

| Impulse factor | (19) | |

| Skewness | (20) | |

| Kurtosis | (21) | |

| Fifth moment | (22) | |

| Sixth moment | (23) |

| Statistical Feature | Mathematical Equation | |

|---|---|---|

| Mean | (24) | |

| Variance | (25) | |

| Third moment | (26) | |

| Fourth moment | (27) | |

| Grand mean | (28) | |

| Standard deviation 1 | (29) | |

| C Factor | (30) | |

| D Factor | (31) | |

| E Factor | (32) | |

| G Factor | (33) | |

| Third moment 1 | (34) | |

| Fourth moment 1 | (35) | |

| H Factor | (36) | |

| J Factor | (37) |

| Feature Domain | ||||

|---|---|---|---|---|

| Time | Frequency | Time–Frequency | ||

| Related condition | Normal | T1 @5Hz@HC | F1 @5Hz@HC | TF1 @5Hz@HC |

| T1 @15Hz@HC | F1 @15Hz@HC | TF1 @15Hz@HC | ||

| T1 @50Hz@HC | F1 @50Hz@HC | TF1 @50Hz@HC | ||

| T1 @60Hz@HC | F1 @60Hz@HC | TF1 @60Hz@HC | ||

| Damaged | T1 @5Hz@BD | F1 @5Hz@BD | TF1 @5Hz@BD | |

| T1 @15Hz@BD | F1 @15Hz@BD | TF1 @15Hz@BD | ||

| T1 @50Hz@BD | F1 @50Hz@BD | TF1 @50Hz@BD | ||

| T1 @60Hz@BD | F1 @60Hz@BD | TF1 @60Hz@BD | ||

| Grouped matrices | T1 group | F1 group | TF1 group | |

| Material | Feature Domain | Hyperparameters | ||

|---|---|---|---|---|

| L2 Regularization | Sparsity Regularizatio | Sparsity Proportion | ||

| Metallic | Time (T1 group) | 1.31 × 10−5 | 7.384 × 10−5 | 0.664 |

| Frequency (F1 group) | 1.616 × 10−5 | 5.761 × 10−5 | 0.655 | |

| Time–Frequency (TF1 group) | 3.250 × 10−5 | 7.164 × 10−5 | 0.779 | |

| Ceramic | Time (T1 group) | 2.090 × 10−5 | 8.037 × 10−5 | 0.132 |

| Frequency (F1 group) | 2.879 × 10−5 | 1.407 × 10−5 | 0.479 | |

| Time–Frequency (TF1 group) | 2.213 × 10−5 | 5.277 × 10−5 | 0.854 | |

| Hybrid | Time (T1 group) | 2.212 × 10−5 | 7.785 × 10−5 | 0.176 |

| Frequency (F1 group) | 1.276 × 10−5 | 2.406 × 10−5 | 0.560 | |

| Time–Frequency (TF1 group) | 1.064 × 10−5 | 4.435 × 10−5 | 0.240 | |

| Material | Feature Domain | Hyperparameters | ||

|---|---|---|---|---|

| L2 Regularization | Sparsity Regularizatio | Sparsity Proportion | ||

| Metallic | Time (T2 group) | 2.277 × 10−5 | 7.108 × 10−5 | 0.3228 |

| Frequency (F2 group) | 1.077 × 10−5 | 8.433 × 10−5 | 0.2026 | |

| Time–Frequency (TF2 group) | 2.277 × 10−5 | 7.108 × 10−5 | 0.3228 | |

| Ceramic | Time (T2 group) | 1.675 × 10−5 | 6.944 × 10−5 | 0.4743 |

| Frequency (F2 group) | 1.320 × 10−5 | 4.897 × 10−5 | 0.546 | |

| Time–Frequency (TF2 group) | 1.821 × 10−5 | 4.950 × 10−5 | 0.678 | |

| Hybrid | Time (T2 group) | 2.228 × 10−5 | 2.824 × 10−5 | 0.332 |

| Frequency (F2 group) | 1.625 × 10−5 | 4.365 × 10−5 | 0.391 | |

| Time–Frequency (TF2 group) | 3.384 × 10−5 | 7.621 × 10−5 | 0.4227 | |

| Material | Feature Domain | MSE Error | |

|---|---|---|---|

| Vibrations (i = 1) | Current (i = 2) | ||

| Metallic | Time (Ti group) | 1.071 × 10−4 | 3.689 × 10−4 |

| Frequency (Fi group) | 3.113 × 10−4 | 4.451 × 10−4 | |

| Time–Frequency (TFi group) | 4.348 × 10−4 | 1.137 × 10−4 | |

| Ceramic | Time (Ti group) | 7.8202 × 10−5 | 1.990 × 10−4 |

| Frequency (Fi group) | 1.894 × 10−4 | 2.786 × 10−4 | |

| Time–Frequency (TFi group) | 1.794 × 10−4 | 1.464 × 10−4 | |

| Hybrid | Time (Ti group) | 6.550 × 10−5 | 1.995 × 10−4 |

| Frequency (Fi group) | 3.543 × 10−4 | 2.778 × 10−4 | |

| Time–Frequency (TFi group) | 1.230 × 10−4 | 4.882 × 10−4 | |

| Material | Feature Domain | Proposed Method | PCA + NN | LDA + NN | |||

|---|---|---|---|---|---|---|---|

| Training | Test | Training | Test | Training | Test | ||

| Metallic | Time (T1,2 group) | 99.1% | 99.3% | 60.5% | 62.1% | 73.3% | 73.5% |

| Frequency (F1,2 group) | 96.5% | 95.8% | 68.6% | 70.7% | 78.3% | 79.9% | |

| Time–Frequency (TF1,2 group) | 95.3% | 96% | 78.9% | 80.8% | 71.5% | 65.8% | |

| Fusion scheme (T1,2 group + F1,2 group + TF1,2 group) | 100% | 100% | 81.2% | 83.1% | 62.5% | 62.7% | |

| Ceramic | Time (T1,2 group) | 97% | 96.5% | 69.5% | 70.8% | 69.0% | 71.9% |

| Frequency (F1,2 group) | 100% | 100% | 72.8% | 73.9% | 86.9% | 88.6% | |

| Time–Frequency (TF1,2 group) | 98.8% | 98.8% | 84.7% | 88.8% | 87.5% | 87.9% | |

| Fusion scheme (T1,2 group + F1,2 group + TF1,2 group) | 100% | 100% | 73.0% | 73.2% | 75.0% | 75.0% | |

| Hybrid | Time (T1,2 group) | 99.8% | 99.3% | 81.0% | 81.9% | 87.4% | 87.5% |

| Frequency (F1,2 group) | 100% | 100% | 84.2% | 84.4% | 87.9% | 88.0% | |

| Time–Frequency (TF1,2 group) | 99.9 | 99.8% | 81.1% | 86.7% | 82.8% | 84.0% | |

| Fusion scheme (T1,2 group + F1,2 group + TF1,2 group) | 100% | 100% | 75.2% | 75.3% | 70.3% | 71.4% | |

| Material | Accuracy | Precision | Recall | F1 Score | |||||

|---|---|---|---|---|---|---|---|---|---|

| Training | Test | Training | Test | Training | Test | Training | Test | ||

| Metallic | Time | 0.98 | 0.97 | 0.99 | 0.98 | 0.99 | 0.97 | 0.99 | 0.97 |

| Frequency | 0.93 | 0.91 | 0.98 | 0.98 | 0.94 | 0.92 | 0.95 | 0.94 | |

| Time–Frequency | 0.95 | 0.96 | 0.97 | 0.98 | 0.97 | 0.97 | 0.97 | 0.97 | |

| Fusion scheme | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | |

| Ceramic | Time | 0.96 | 0.96 | 0.98 | 0.98 | 0.98 | 0.97 | 0.98 | 0.97 |

| Frequency | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Time–Frequency | 0.99 | 0.98 | 0.99 | 0.98 | 0.99 | 0.99 | 0.99 | 0.98 | |

| Fusion scheme | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Hybrid | Time | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 1 | 0.99 | 0.99 |

| Frequency | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Time–Frequency | 0.99 | 0.99 | 0.99 | 1 | 0.99 | 0.99 | 0.99 | 0.99 | |

| Fusion scheme | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Feature Domain | Hyperparameters | ||

|---|---|---|---|

| L2 Regularization | Sparsity Regularization | Sparsity Proportion | |

| Time (T1) | 8.0 × 10−5 | 8.0 × 10−5 | 0.55 |

| Frequency (F1) | 8.0 × 10−5 | 8.0 × 10−5 | 0.45 |

| Time–Frequency (TF1) | 8.0 × 10−5 | 8.0 × 10−5 | 0.50 |

| Feature Domain | Average Accuracy | |

|---|---|---|

| Training | Test | |

| Time | 96.2% | 94.5% |

| Frequency | 99.8% | 98.5% |

| Time–Frequency | 98.4% | 96.8% |

| Fusion Scheme | 100.0% | 99.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saucedo-Dorantes, J.J.; Arellano-Espitia, F.; Delgado-Prieto, M.; Osornio-Rios, R.A. Diagnosis Methodology Based on Deep Feature Learning for Fault Identification in Metallic, Hybrid and Ceramic Bearings. Sensors 2021, 21, 5832. https://doi.org/10.3390/s21175832

Saucedo-Dorantes JJ, Arellano-Espitia F, Delgado-Prieto M, Osornio-Rios RA. Diagnosis Methodology Based on Deep Feature Learning for Fault Identification in Metallic, Hybrid and Ceramic Bearings. Sensors. 2021; 21(17):5832. https://doi.org/10.3390/s21175832

Chicago/Turabian StyleSaucedo-Dorantes, Juan Jose, Francisco Arellano-Espitia, Miguel Delgado-Prieto, and Roque Alfredo Osornio-Rios. 2021. "Diagnosis Methodology Based on Deep Feature Learning for Fault Identification in Metallic, Hybrid and Ceramic Bearings" Sensors 21, no. 17: 5832. https://doi.org/10.3390/s21175832

APA StyleSaucedo-Dorantes, J. J., Arellano-Espitia, F., Delgado-Prieto, M., & Osornio-Rios, R. A. (2021). Diagnosis Methodology Based on Deep Feature Learning for Fault Identification in Metallic, Hybrid and Ceramic Bearings. Sensors, 21(17), 5832. https://doi.org/10.3390/s21175832