Damage Localization in Composite Plates Using Wavelet Transform and 2-D Convolutional Neural Networks

Abstract

:1. Introduction

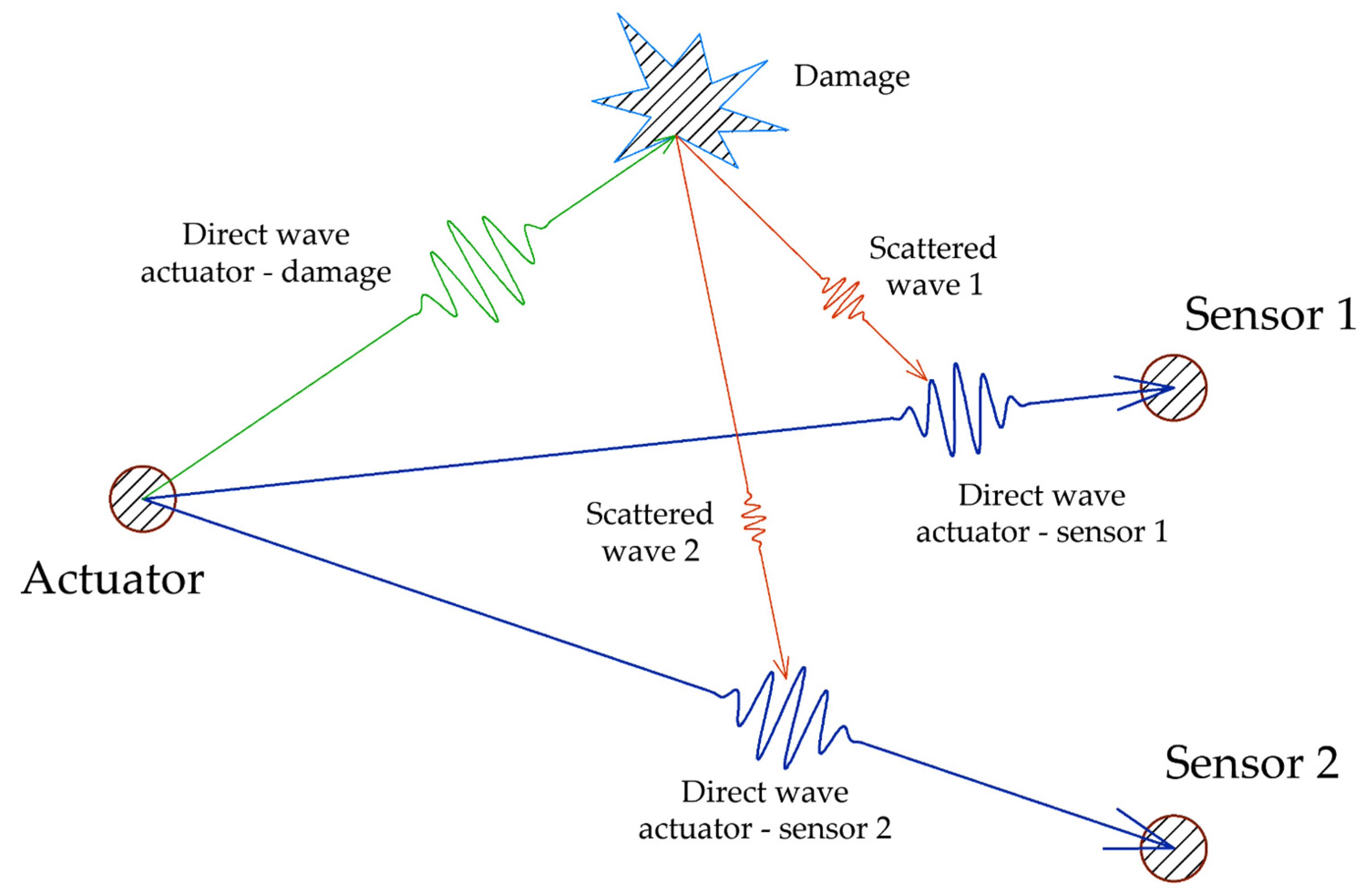

2. Physical Background

3. Methodology

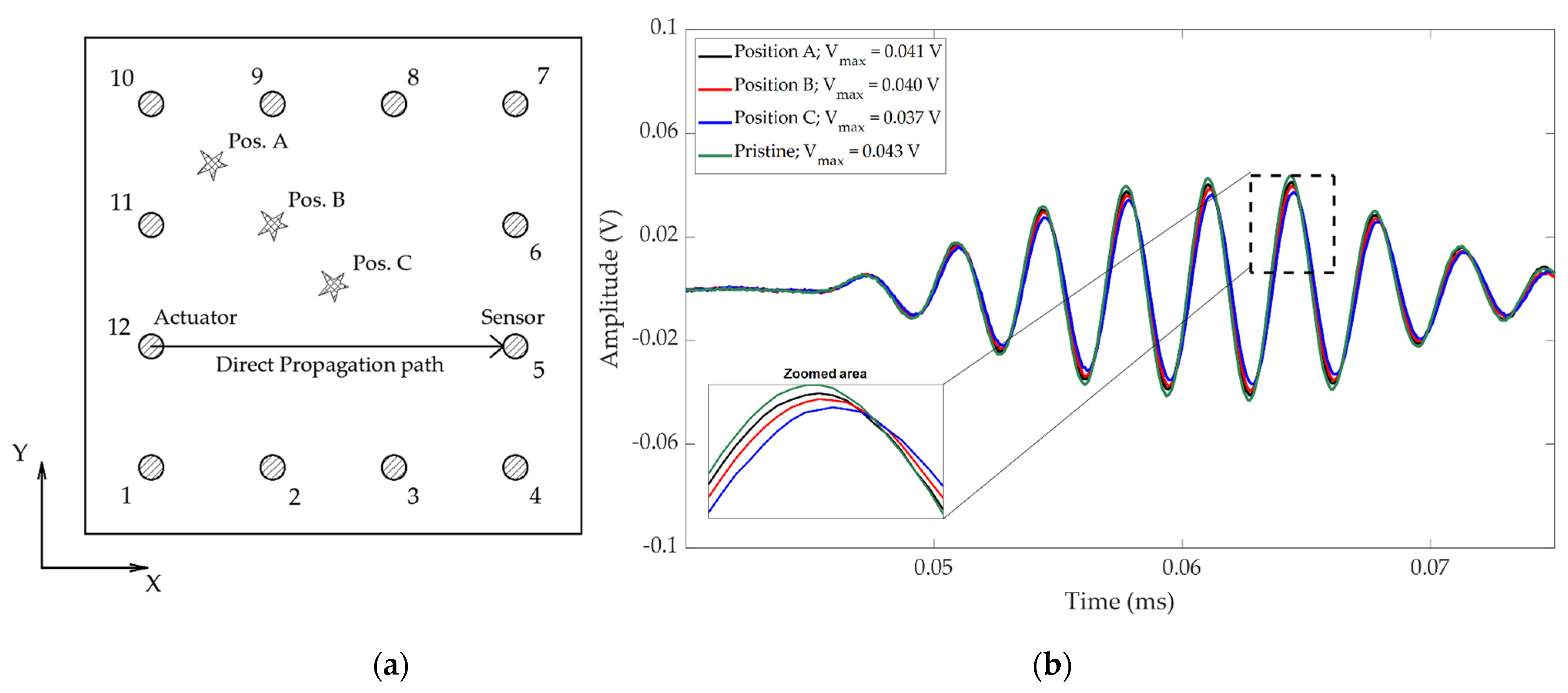

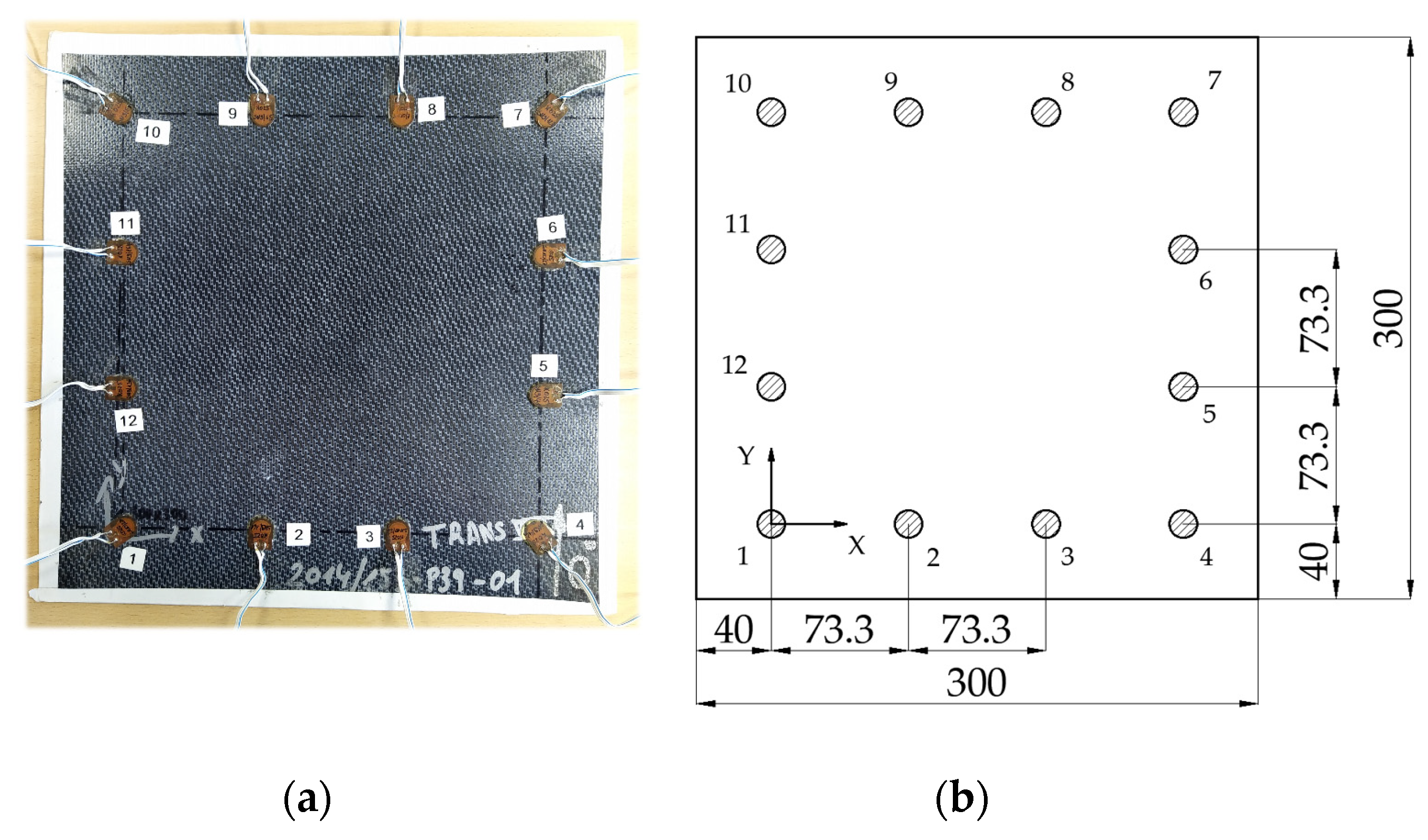

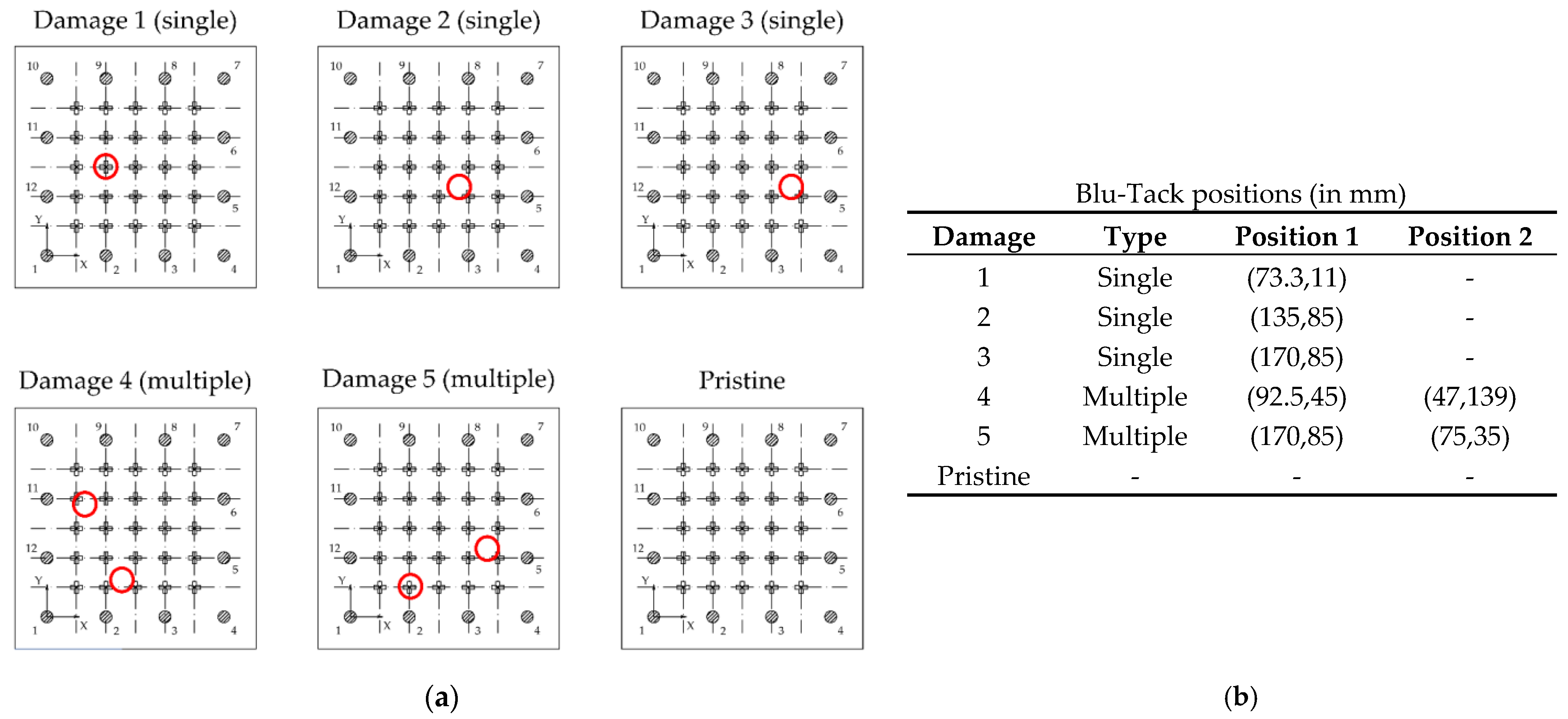

3.1. Experimental Setup Configuration

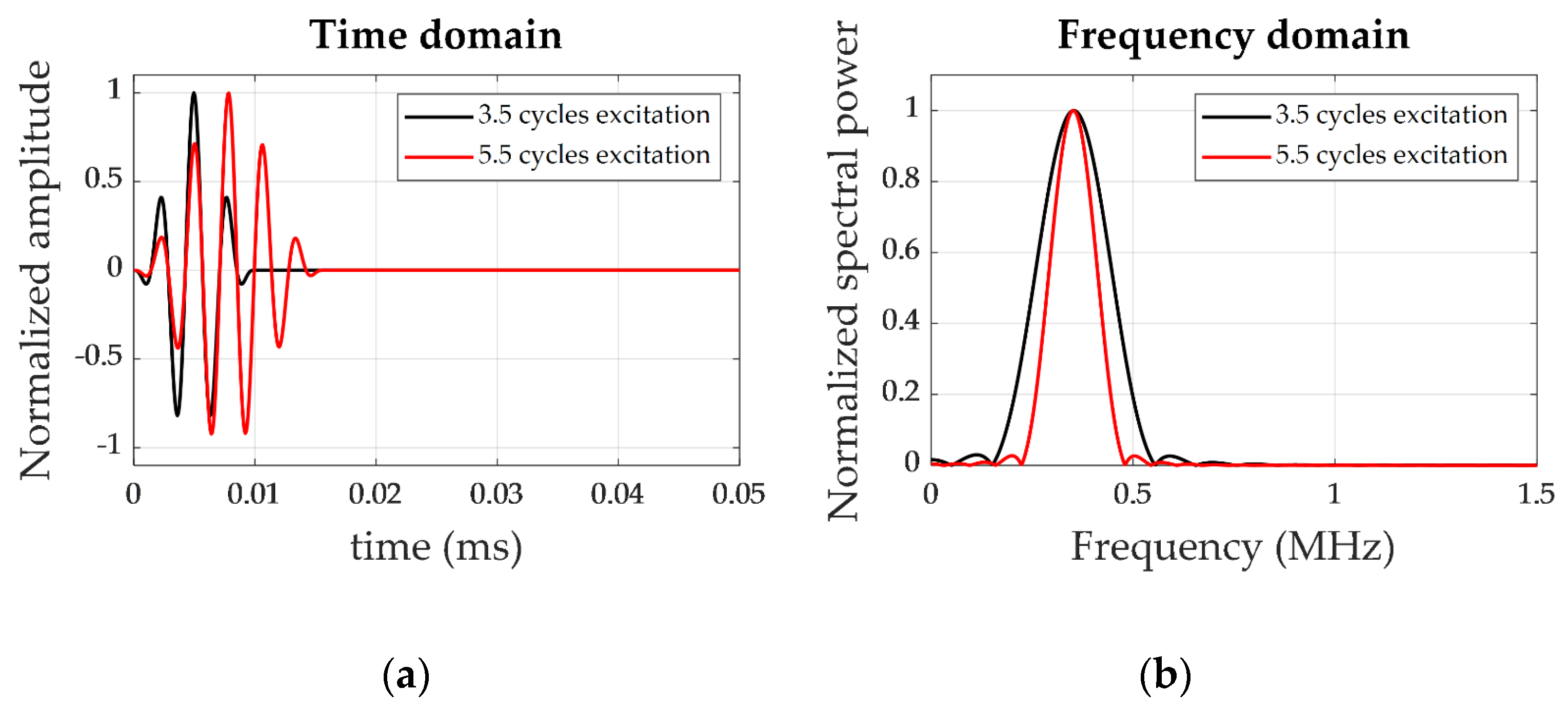

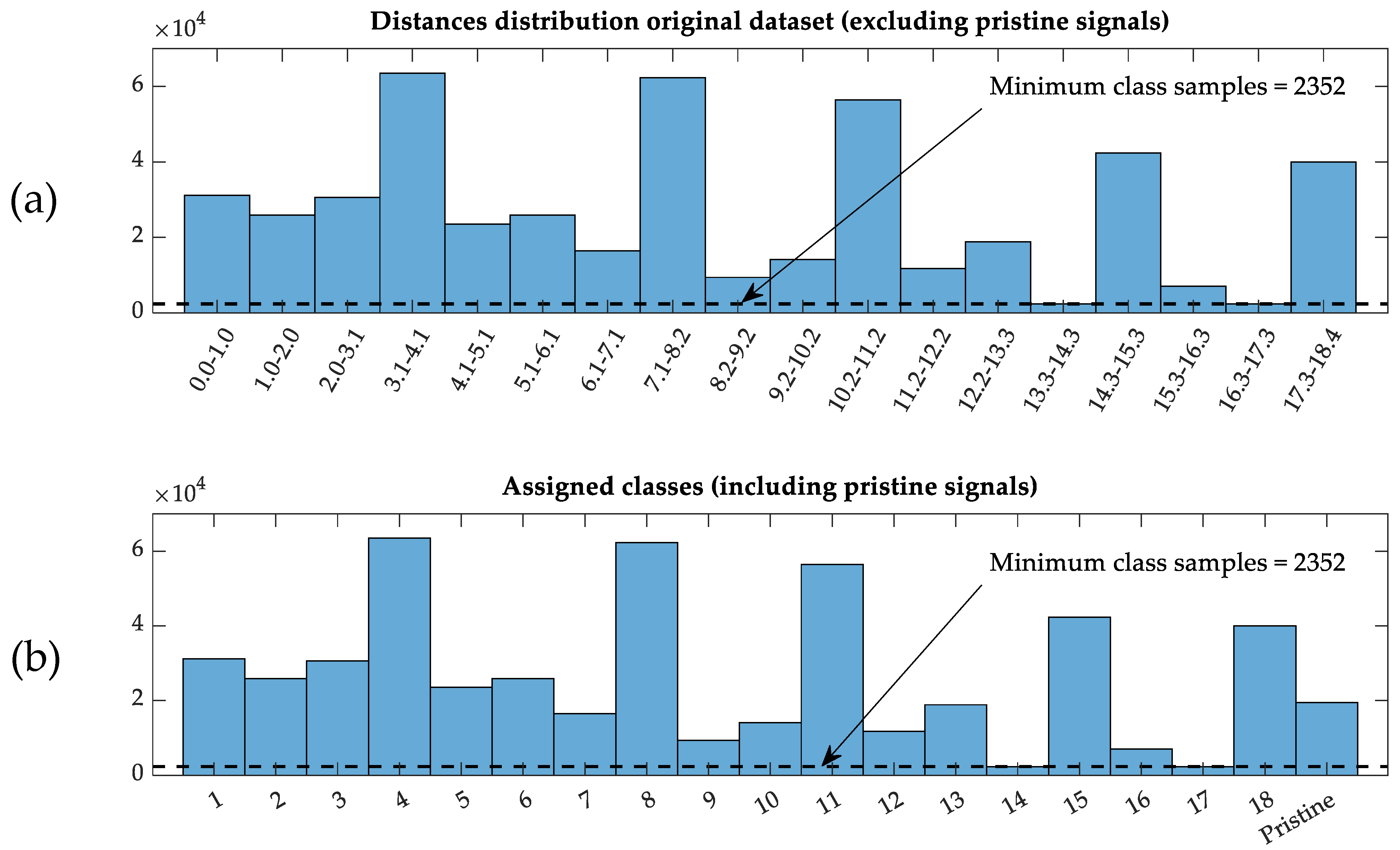

3.2. Data Acquisition Process for Generating the Training Dataset

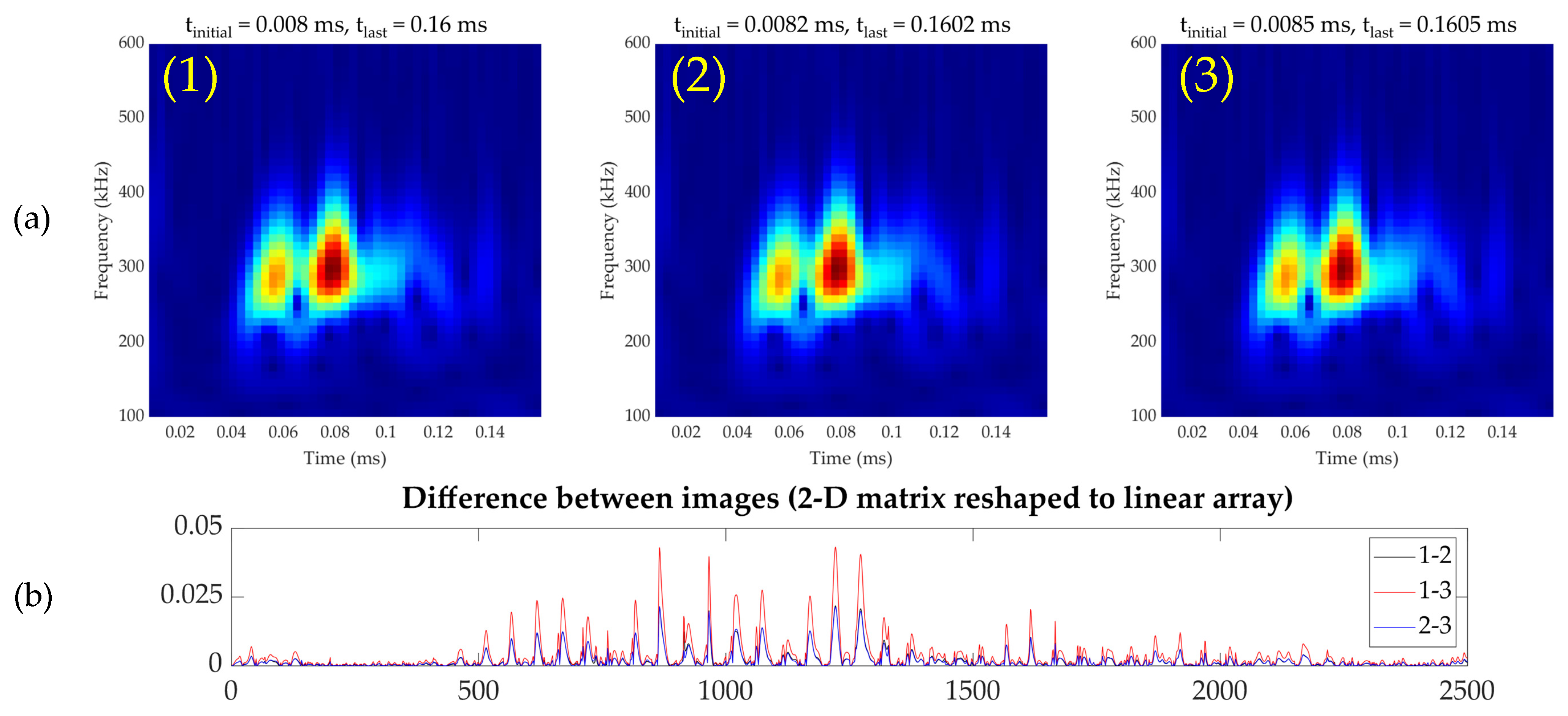

3.3. Conversion of 1-D Waveforms to 2-D Arrays Using Wavelet Transform

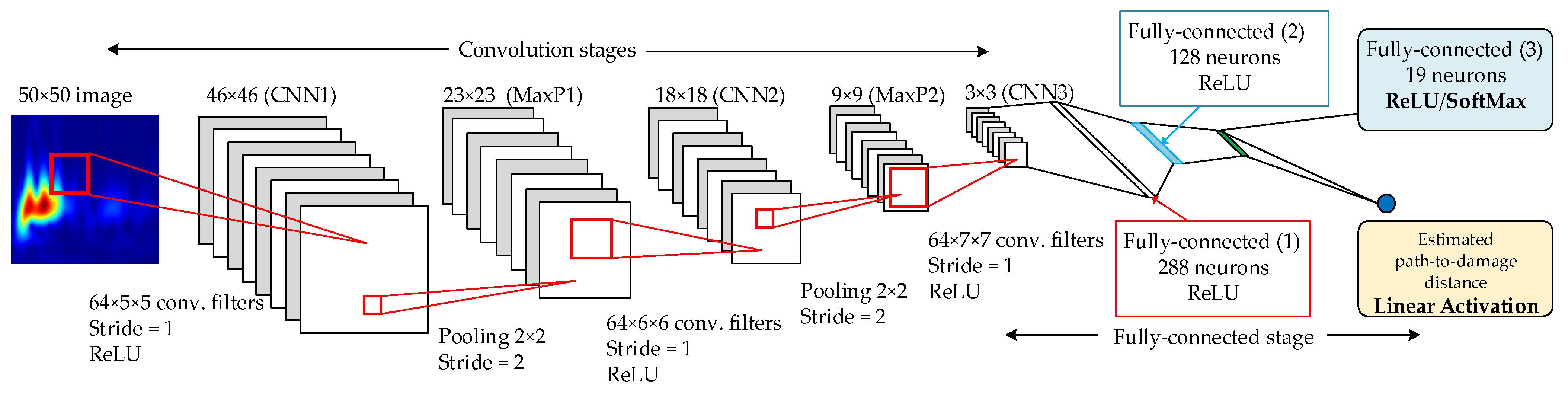

3.4. Convolutional Neural Networks Design

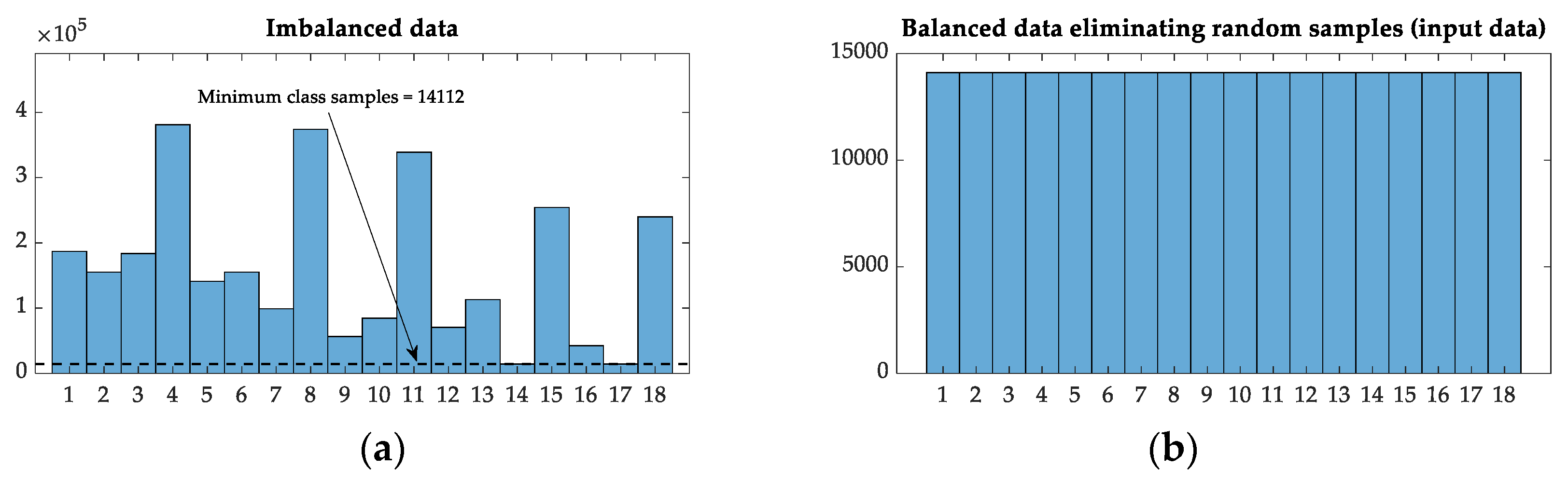

3.4.1. Improvement of the Training Dataset Using Data Augmentation

3.4.2. Hyperparameters Tuning and Model Training

3.4.3. Training Software Tools

3.5. Distance Estimation-Based Imaging Algorithm

- : damage index for the analyzed point.

- N: number of attached transducers.

- : normal distance from the analysis point (x,y) to the line which intersects the transmitter and receiver transducers (t and r) path.

- : predicted distance (corresponding distance-class value, in case of classification-based CNN) for the input signal (wavelet-transformed image).

- : standard deviation of the exponential-Gaussian distribution. This value controls the influence of the propagation path on the analyzed point.

- : probability value for each b class in the t-r path signal prediction (only for classification-based CNN; otherwise, ). The value is obtained as output from the SoftMax layer of the model.

- B: number of classes (only for classification-based CNN—18 distance classes, the pristine class has no associated distance value; otherwise, ).

4. Results

4.1. Training Process

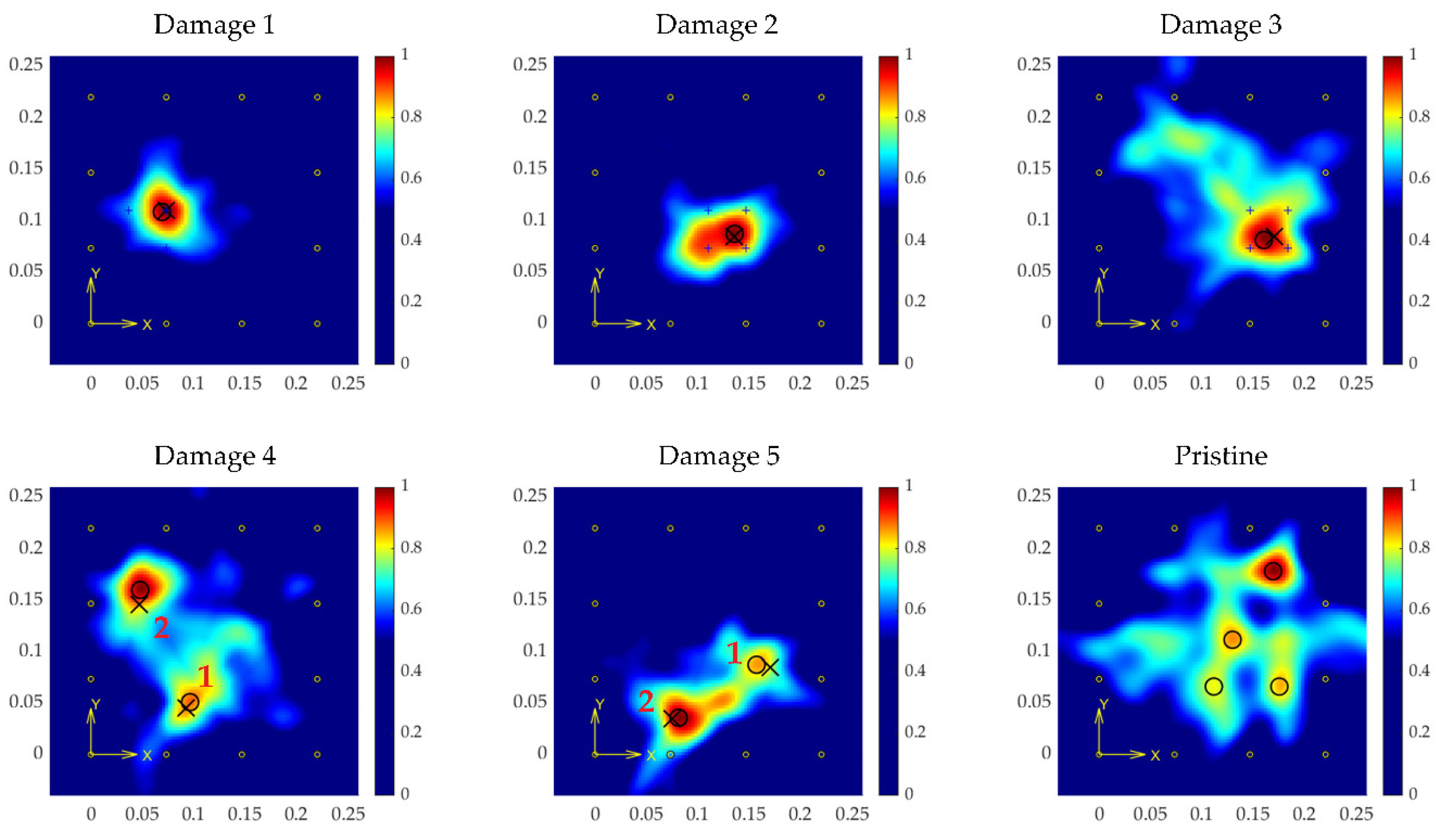

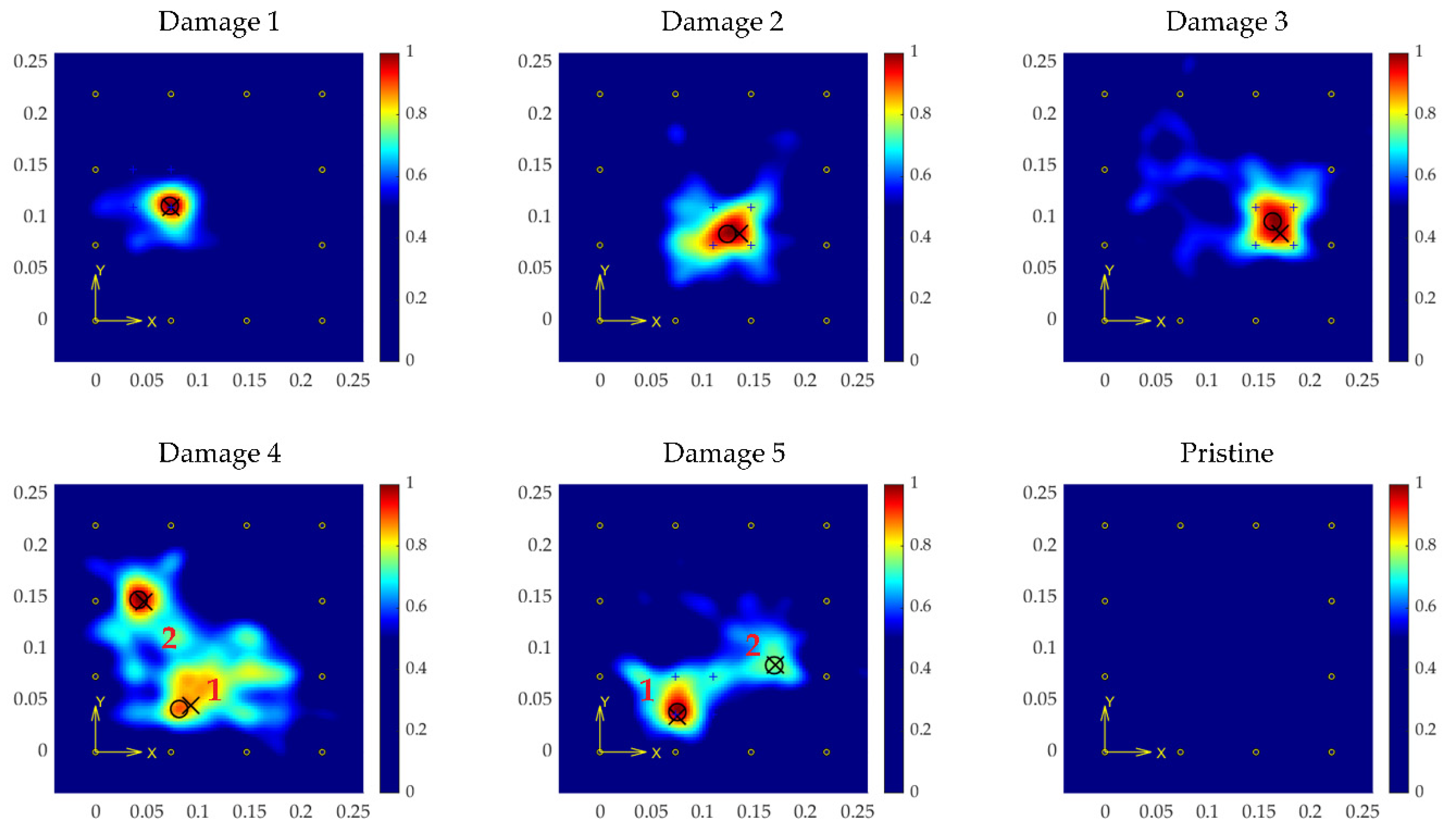

4.2. Imaging Results

5. Discussion

6. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AERO—Boeing 787 from the Ground Up. Available online: https://www.boeing.com/commercial/aeromagazine/articles/qtr_4_06/article_04_2.html (accessed on 16 April 2021).

- Jerome, P.O.R.A. Composite materials in the airbus A380-from history to future. In Proceedings of the 13th International Conference on Composite Materials (ICCM-13), Beijing, China, 25–29 June 2001. [Google Scholar]

- Kassapoglou, C. Design and Analysis of Composite Structures: With Applications to Aerospace Structures; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Staszewski, W.; Mahzan, S.; Traynor, R. Health monitoring of aerospace composite structures—Active and passive approach. Compos. Sci. Technol. 2009, 69, 1678–1685. [Google Scholar] [CrossRef]

- Worden, K.; Farrar, C.; Manson, G.; Park, G. The fundamental axioms of structural health monitoring. Proc. R. Soc. A Math. Phys. Eng. Sci. 2007, 463, 1639–1664. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Structural Health Monitoring with Piezoelectric Wafer Active Sensors; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Hellier, C.J. Handbook of Nondestructive Evaluation, 3rd ed.; McGraw-Hill Education: New York, NY, USA, 2020. [Google Scholar]

- Mitchell, T.M. Machine Learning; McGraw-Hill Education: New York, NY, USA, 1997. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A.; Bengio, Y. Deep Learning; MIT Press Cambridge: Cambridge, MA, USA, 2016; Volume 1. [Google Scholar]

- LeCun, Y.; Boser, B.; Denker, J.S.; Henderson, D.; Howard, R.E.; Hubbard, W.; Jackel, L.D. Backpropagation Applied to Handwritten Zip Code Recognition. Neural Comput. 1989, 1, 541–551. [Google Scholar] [CrossRef]

- Stetco, A.; Dinmohammadi, F.; Zhao, X.; Robu, V.; Flynn, D.; Barnes, M.; Keane, J.; Nenadic, G. Machine learning methods for wind turbine condition monitoring: A review. Renew. Energy 2018, 133, 620–635. [Google Scholar] [CrossRef]

- Luo, H.; Huang, M.; Zhou, Z. A dual-tree complex wavelet enhanced convolutional LSTM neural network for structural health monitoring of automotive suspension. Measurement 2019, 137, 14–27. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Ye, X.W.; Jin, T.; Yun, C.B. A review on deep learning-based structural health monitoring of civil infrastructures. Smart Struct. Syst. 2019, 24, 567–585. [Google Scholar]

- Flah, M.; Nunez, I.; Ben Chaabene, W.; Nehdi, M.L. Machine Learning Algorithms in Civil Structural Health Monitoring: A Systematic Review. Arch. Comput. Methods Eng. 2020, 28, 2621–2643. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, W.; Gu, J.; Lei, Y. Damage Identification of a Steel Frame Based on Integration of Time Series and Neural Network under Varying Temperatures. Adv. Civ. Eng. 2020, 2020, 1–15. [Google Scholar] [CrossRef]

- Avci, O.; Abdeljaber, O.; Kiranyaz, S.; Hussein, M.; Gabbouj, M.; Inman, D.J. A review of vibration-based damage detection in civil structures: From traditional methods to Machine Learning and Deep Learning applications. Mech. Syst. Signal Process. 2020, 147, 107077. [Google Scholar] [CrossRef]

- Ebrahimkhanlou, A.; Salamone, S. Single-Sensor Acoustic Emission Source Localization in Plate-Like Structures Using Deep Learning. Aerospace 2018, 5, 50. [Google Scholar] [CrossRef] [Green Version]

- Tabian, I.; Fu, H.; Khodaei, Z.S. A Convolutional Neural Network for Impact Detection and Characterization of Complex Composite Structures. Sensors 2019, 19, 4933. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hesser, D.F.; Kocur, G.K.; Markert, B. Active source localization in wave guides based on machine learning. Ultrasonics 2020, 106, 106144. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, S.; Gabbouj, M.; Inman, D.J. Real-Time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 2017, 388, 154–170. [Google Scholar] [CrossRef]

- Su, C.; Jiang, M.; Lv, S.; Lu, S.; Zhang, L.; Zhang, F.; Sui, Q. Improved Damage Localization and Quantification of CFRP Using Lamb Waves and Convolution Neural Network. IEEE Sens. J. 2019, 19, 5784–5791. [Google Scholar] [CrossRef]

- Zhang, S.; Li, C.M.; Ye, W. Damage localization in plate-like structures using time-varying feature and one-dimensional convolutional neural network. Mech. Syst. Signal Process. 2020, 147, 107107. [Google Scholar] [CrossRef]

- Ewald, V.; Groves, R.M.; Benedictus, R. DeepSHM: A deep learning approach for structural health monitoring based on guided Lamb wave technique. Sens. Smart Struct. Technol. Civ. Mech. Aerosp. Syst. 2019, 10970, 109700H. [Google Scholar] [CrossRef] [Green Version]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Gou, L.; Li, H.; Zheng, H.; Li, H.; Pei, X. Aeroengine Control System Sensor Fault Diagnosis Based on CWT and CNN. Math. Probl. Eng. 2020, 2020, 5357146. [Google Scholar] [CrossRef] [Green Version]

- Gao, D.; Zhu, Y.; Wang, X.; Yan, K.; Hong, J. A Fault Diagnosis Method of Rolling Bearing Based on Complex Morlet CWT and CNN. In Proceedings of the Prognostics and System Health Management Conference (PHM-Chongqing), Chongqing, China, 26–28 October 2018; pp. 1101–1105. [Google Scholar] [CrossRef]

- Migot, A.; Bhuiyan, Y.; Giurgiutiu, V. Impact localization on composite plates using two developed imaging methods. In Proceedings of the Active and Passive Smart Structures and Integrated Systems XIV, San Diego, CA, USA, 11–14 March 2020; Volume 11376, p. 113760V. [Google Scholar] [CrossRef]

- Hameed, M.S.; Li, Z.; Zheng, K. Damage Size Estimation for Composite Laminates Based on an Anisotropic Wavefront Expression. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Virtual Conference, Online, 16–19 November 2020; Volume 84607, p. V012T12A056. [Google Scholar] [CrossRef]

- Legendre, S.; Massicotte, D.; Goyette, J.; Bose, T.K. Wavelet-transform-based method of analysis for Lamb-wave ultrasonic NDE signals. IEEE Trans. Instrum. Meas. 2003, 49, 524–530. [Google Scholar] [CrossRef]

- Li, F.; Meng, G.; Kageyama, K.; Su, Z.; Ye, L. Optimal Mother Wavelet Selection for Lamb Wave Analyses. J. Intell. Mater. Syst. Struct. 2009, 20, 1147–1161. [Google Scholar] [CrossRef]

- Joglekar, D. Analysis of nonlinear frequency mixing in Timoshenko beams with a breathing crack using wavelet spectral finite element method. J. Sound Vib. 2020, 488, 115532. [Google Scholar] [CrossRef]

- Lamb, H. On waves in an elastic plate. Proc. R. Soc. London. Ser. A Contain. Pap. A Math. Phys. Character 1917, 93, 114–128. [Google Scholar]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- Mallardo, V.; Aliabadi, M.H.; Khodaei, Z.S. Optimal sensor positioning for impact localization in smart composite panels. J. Intell. Mater. Syst. Struct. 2012, 24, 559–573. [Google Scholar] [CrossRef]

- Thiene, M.; Khodaei, Z.S.; Aliabadi, M.H. Optimal sensor placement for maximum area coverage (MAC) for damage localization in composite structures. Smart Mater. Struct. 2016, 25, 095037. [Google Scholar] [CrossRef]

- Ostachowicz, W.; Soman, R.; Malinowski, P. Optimization of sensor placement for structural health monitoring: A review. Struct. Health Monit. 2019, 18, 963–988. [Google Scholar] [CrossRef]

- Liu, Z.; Zhong, X.; Dong, T.; He, C.; Wu, B. Delamination detection in composite plates by synthesizing time-reversed Lamb waves and a modified damage imaging algorithm based on RAPID. Struct. Control. Health Monit. 2016, 24, e1919. [Google Scholar] [CrossRef]

- Azuara, G.; Barrera, E.; Ruiz, M.; Bekas, D. Damage Detection and Characterization in Composites Using a Geometric Modification of the RAPID Algorithm. IEEE Sens. J. 2019, 20, 2084–2093. [Google Scholar] [CrossRef]

- Wang, S.; Wu, W.; Shen, Y.; Liu, Y.; Jiang, S. Influence of the PZT Sensor Array Configuration on Lamb Wave Tomography Imaging with the RAPID Algorithm for Hole and Crack Detection. Sensors 2020, 20, 860. [Google Scholar] [CrossRef] [Green Version]

- Tan, Y.; Zhang, L. Computational methodologies for optimal sensor placement in structural health monitoring: A review. Struct. Health Monit. 2019, 19, 1287–1308. [Google Scholar] [CrossRef]

- Alleyne, D.; Cawley, P. The interaction of Lamb waves with defects. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 1992, 39, 381–397. [Google Scholar] [CrossRef] [PubMed]

- Scalerandi, M. Power laws and elastic nonlinearity in materials with complex microstructure. Phys. Lett. A 2016, 380, 413–421. [Google Scholar] [CrossRef]

- Aranguren, G.; Monje, P.M.; Cokonaj, V.; Barrera, E.; Ruiz, M. Ultrasonic wave-based structural health monitoring embedded instrument. Rev. Sci. Instrum. 2013, 84, 125106. [Google Scholar] [CrossRef]

- Hettler, J.; Tabatabaeipour, M.; Delrue, S.; Abeele, K.V.D. Linear and Nonlinear Guided Wave Imaging of Impact Damage in CFRP Using a Probabilistic Approach. Materials 2016, 9, 901. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Giurgiutiu, V. Tuned Lamb Wave Excitation and Detection with Piezoelectric Wafer Active Sensors for Structural Health Monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

- Azuara, G.; Barrera, E. Influence and Compensation of Temperature Effects for Damage Detection and Localization in Aerospace Composites. Sensors 2020, 20, 4153. [Google Scholar] [CrossRef]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

- Yu, K.; Xu, W.; Gong, Y. Deep learning with kernel regularization for visual recognition. Adv. Neural Inf. Process. Syst. 2008, 21, 1889–1896. [Google Scholar]

- Glorot, X.; Bengio, Y. Understanding the difficulty of training deep feedforward neural networks. In Proceedings of the thirteenth international conference on artificial intelligence and statistics, Sardinia, Italy, 13–15 May 2010; pp. 249–256. [Google Scholar]

- Michaels, J.E.; Michaels, T.E. Guided wave signal processing and image fusion for in situ damage localization in plates. Wave Motion 2007, 44, 482–492. [Google Scholar] [CrossRef]

- Ruiz, M.; Barrera, E.; Fernández, N.; Meléndez, R.; Alcaide, A.; Aranguren, G.; Monje, P.M. Integration of Embedded Data Processing Algorithms Inside PAMELA Devices. In Proceedings of the EWSHM-7th European Workshop on Structural Health Monitoring, Nantes, France, 8–11 July 2014. [Google Scholar]

- Azuara, G.; Barrera, E.; Ruiz, M. Integration of algorithms for damage detection in thermoplastic materials inside electronic embedded devices. In Proceedings of the EWSHM-9th European Workshop on Structural Health Monitoring, Manchester, UK, 10–13 July 2018. [Google Scholar]

| Matrix Polymer/Carbon Fiber | Layers | Ply/Total Thickness (mm) | Stacking Sequence |

|---|---|---|---|

| Tenax-E TPCL PEEK-HTA40/ Tenax-E HTA40 3K | 9 | 0.31/2.79 | [0/90/+45/ −45/0/90/+45/−45/0] |

| Layer Type | Operation Size | Channels | Stride | Activation | Input Size | Output Size | Weights |

|---|---|---|---|---|---|---|---|

| Convolution (1) | 5 × 5 | 64 | 1 | ReLU | 50 × 50 × 1 | 46 × 46 × 64 | 1664 |

| Max-Pooling (1) | 2 × 2 | 64 | 2 | - | 46 × 46 × 64 | 23 × 23 × 64 | 0 |

| Convolution (2) | 6 × 6 | 64 | 1 | ReLU | 23 × 23 × 64 | 18 × 18 × 64 | 147,520 |

| Max-Pooling (2) | 2 × 2 | 64 | 2 | - | 18 × 18 × 64 | 9 × 9 × 64 | 0 |

| Convolution (3) | 7 × 7 | 64 | 1 | ReLU | 9 × 9 × 64 | 3 × 3 × 64 | 200,768 |

| Fully-Connected (1) | 576 × 288 | - | - | ReLU | 3 × 3 × 64 | 288 × 1 | 166,176 |

| Fully-Connected (2) | 288 × 128 | - | - | ReLU | 288 × 1 | 128 × 1 | 36,992 |

| Fully-Connected (3) | 128 × 19 | - | - | ReLU 1/SoftMax 2 | 128 × 1 | 19 × 1 | 2451 |

| Fully-Connected (4) | 19 × 1 | - | - | Linear 1 | 19 × 1 | 1 × 1 | 20 |

| Regression-Based Model | Classification-Based Model | ||||

|---|---|---|---|---|---|

| Damage | Actual Location (mm) | Predicted Location (mm) | Deviation (mm) | Predicted Location (mm) | Deviation (mm) |

| 1 | (73.3,110) | (69.09,108.5) | 4.47 | (72.12,111.5) | 1.92 |

| 2 | (135,85) | (135.8,87.27) | 2.39 | (123.6,84.24) | 11.39 |

| 3 | (170,85) | (160,81.21) | 10.69 | (163,96.36) | 13.33 |

| Regression-Based Model | Classification-Based Model | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dam. | Actual (1) | Actual (2) | Predicted (1) | Predicted (2) | Dev. (1) | Dev. (2) | Predicted (1) | Predicted (2) | Dev. (1) | Dev. (2) |

| 4 | (92.5,45) | (47,146) | (96.36,50.91) | (47.88,160) | 7.06 | 14.02 | (81.21,41.82) | (41.82,147.9) | 11.72 | 5.51 |

| 5 | (170,85) | (75,35) | (157,87.27) | (81.21,35.76) | 13.22 | 6.25 | (169.1,84.24) | (75.15,38.79) | 1.18 | 3.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azuara, G.; Ruiz, M.; Barrera, E. Damage Localization in Composite Plates Using Wavelet Transform and 2-D Convolutional Neural Networks. Sensors 2021, 21, 5825. https://doi.org/10.3390/s21175825

Azuara G, Ruiz M, Barrera E. Damage Localization in Composite Plates Using Wavelet Transform and 2-D Convolutional Neural Networks. Sensors. 2021; 21(17):5825. https://doi.org/10.3390/s21175825

Chicago/Turabian StyleAzuara, Guillermo, Mariano Ruiz, and Eduardo Barrera. 2021. "Damage Localization in Composite Plates Using Wavelet Transform and 2-D Convolutional Neural Networks" Sensors 21, no. 17: 5825. https://doi.org/10.3390/s21175825

APA StyleAzuara, G., Ruiz, M., & Barrera, E. (2021). Damage Localization in Composite Plates Using Wavelet Transform and 2-D Convolutional Neural Networks. Sensors, 21(17), 5825. https://doi.org/10.3390/s21175825