A Survey on the Application of WirelessHART for Industrial Process Monitoring and Control

Abstract

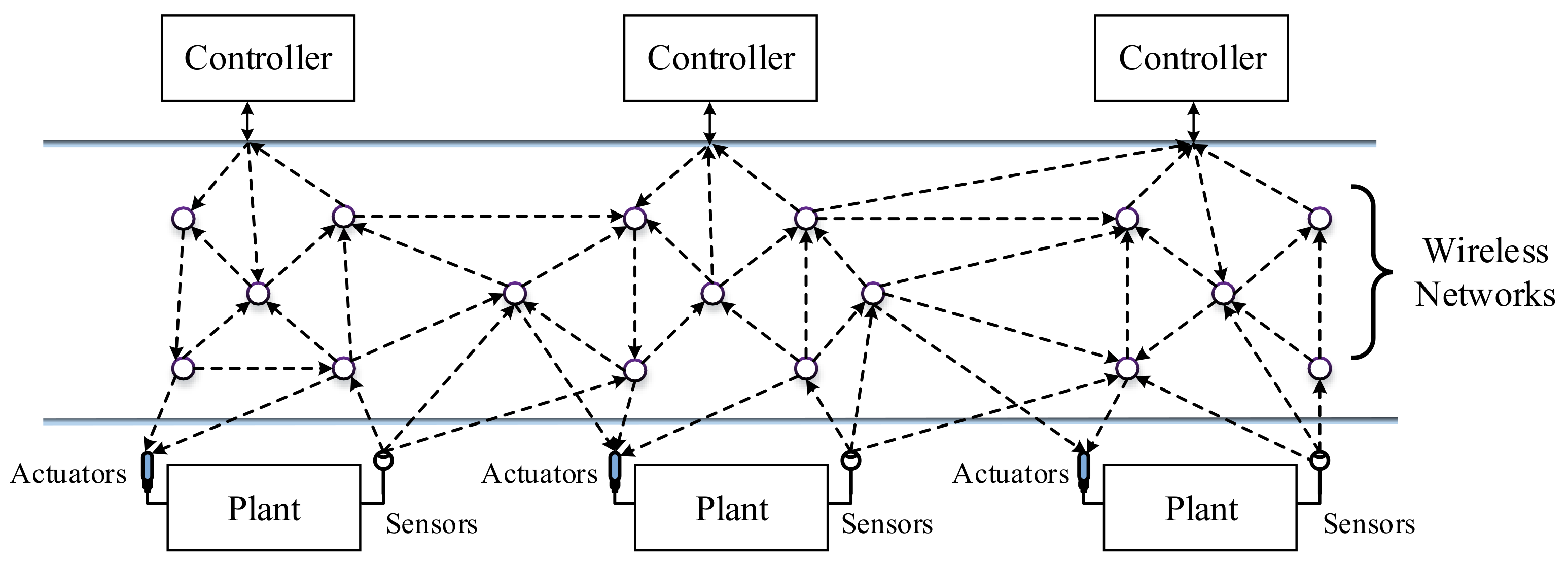

:1. Introduction

- They can eliminate the costly and bulky cabling used to connect the various field devices [7];

- They will dramatically reduce the deployment, redeployment, installation, and commissioning times, thus avoiding the problem of frequent cable maintenance [8];

- They will be self-organized and support a large number of battery-powered wireless nodes [9];

- They can be installed at any location irrespective of the surrounding environmental conditions [10].

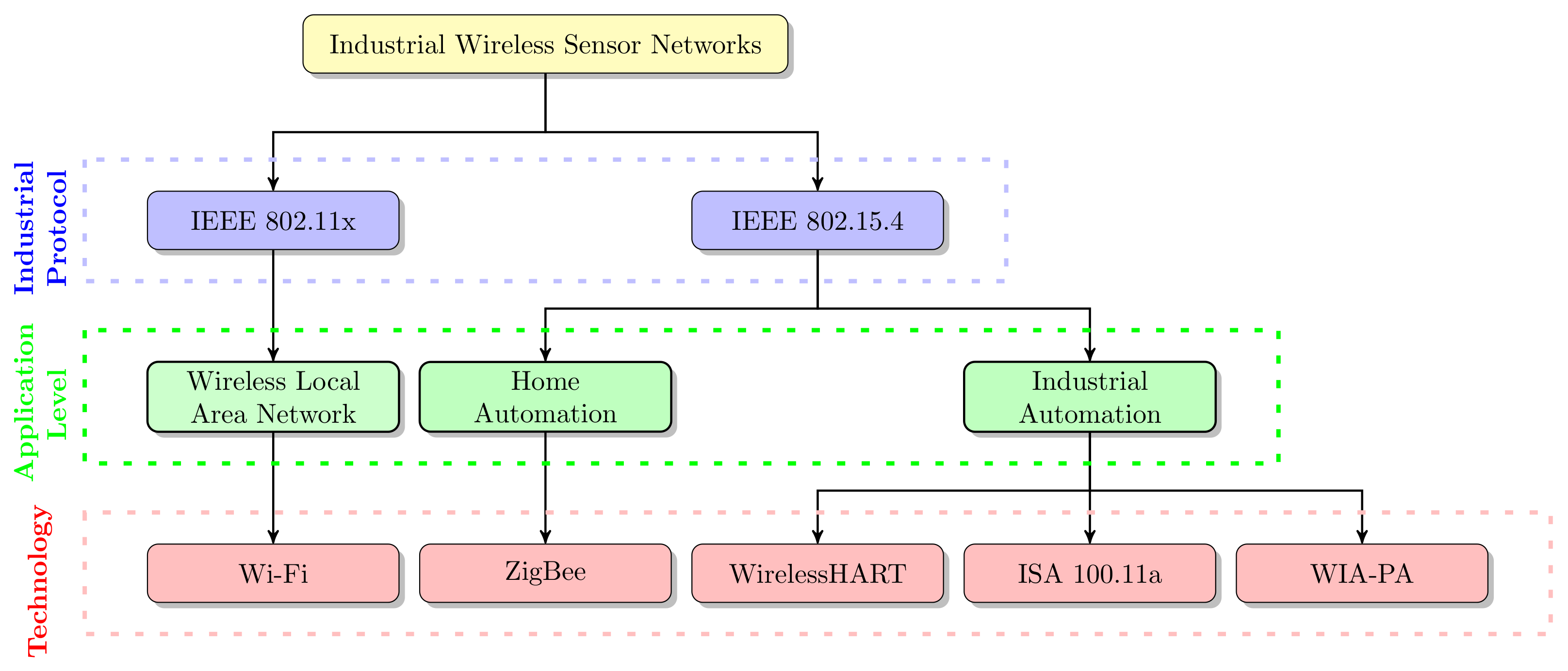

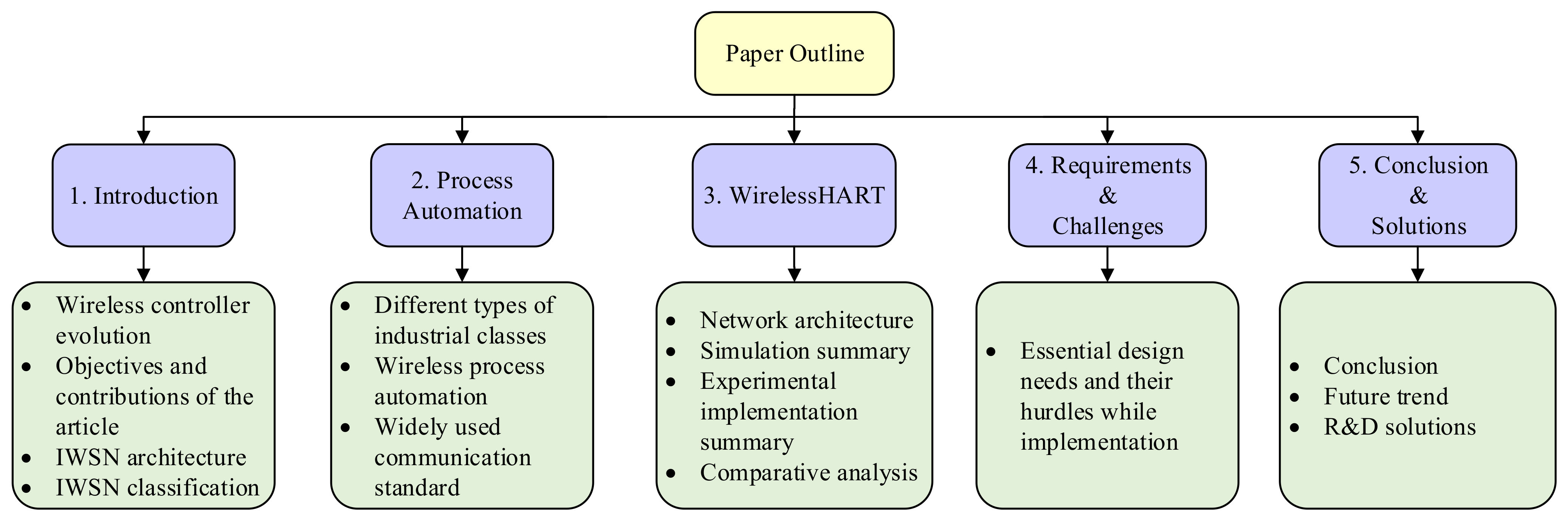

- Evolution of the IWSN with its architecture and classification;

- Progression of the industrial process automation using IWSN;

- How the WirelessHART protocol dominates the process control industries;

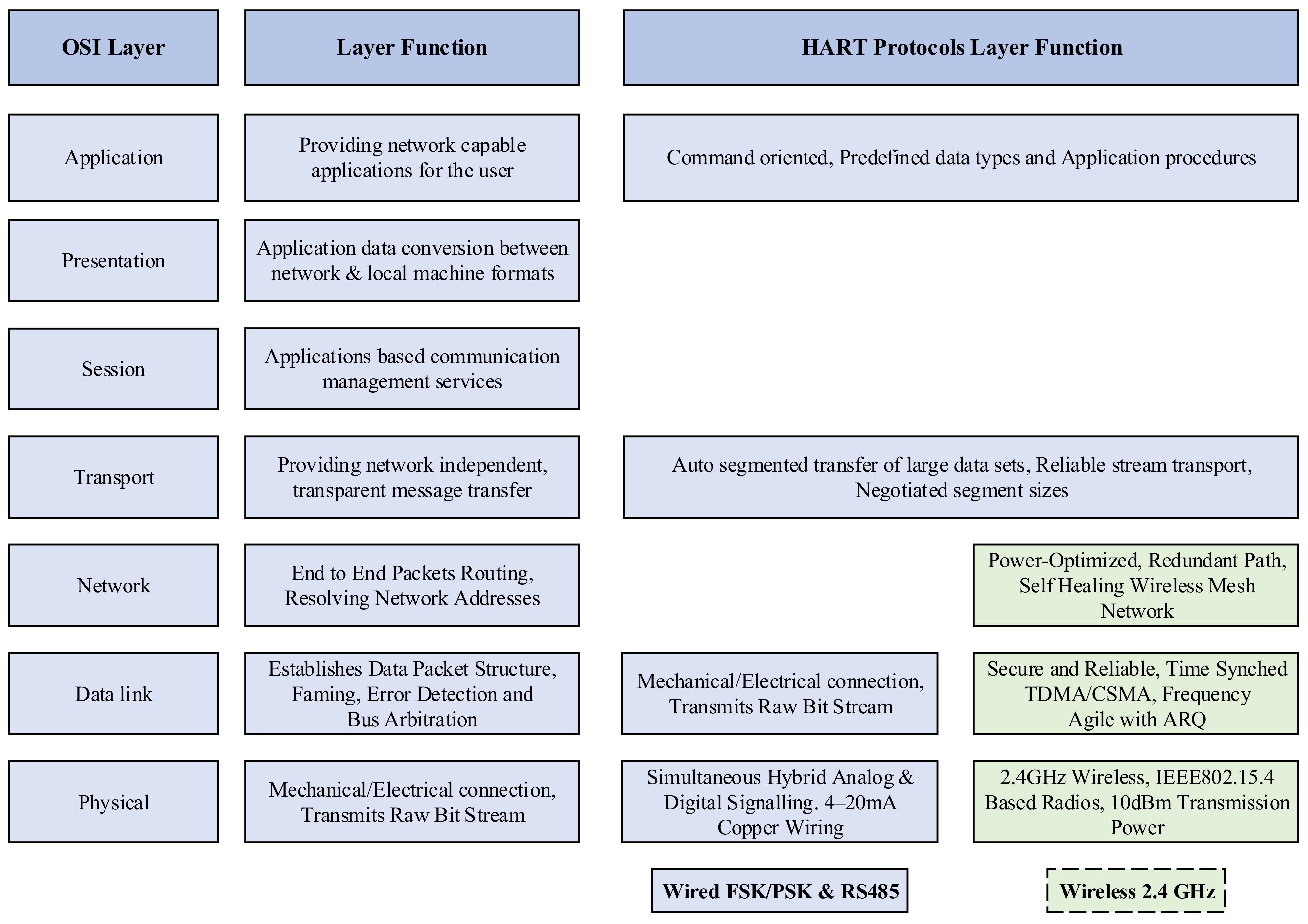

- WirelessHART network architecture with its OSI layer structure;

- Detailed survey of the utilization of WirelessHART for industrial process control in simulation and real-time implementation;

- Design challenges and application-based requirements for the WirelessHART network;

- Possible research and development solutions for the WirelessHART network requirements and challenges.

2. Background of Process Automation

2.1. Process Control Automation

2.1.1. Safety and Supervisory Control

2.1.2. Closed-Loop Control

2.1.3. Monitoring and Control

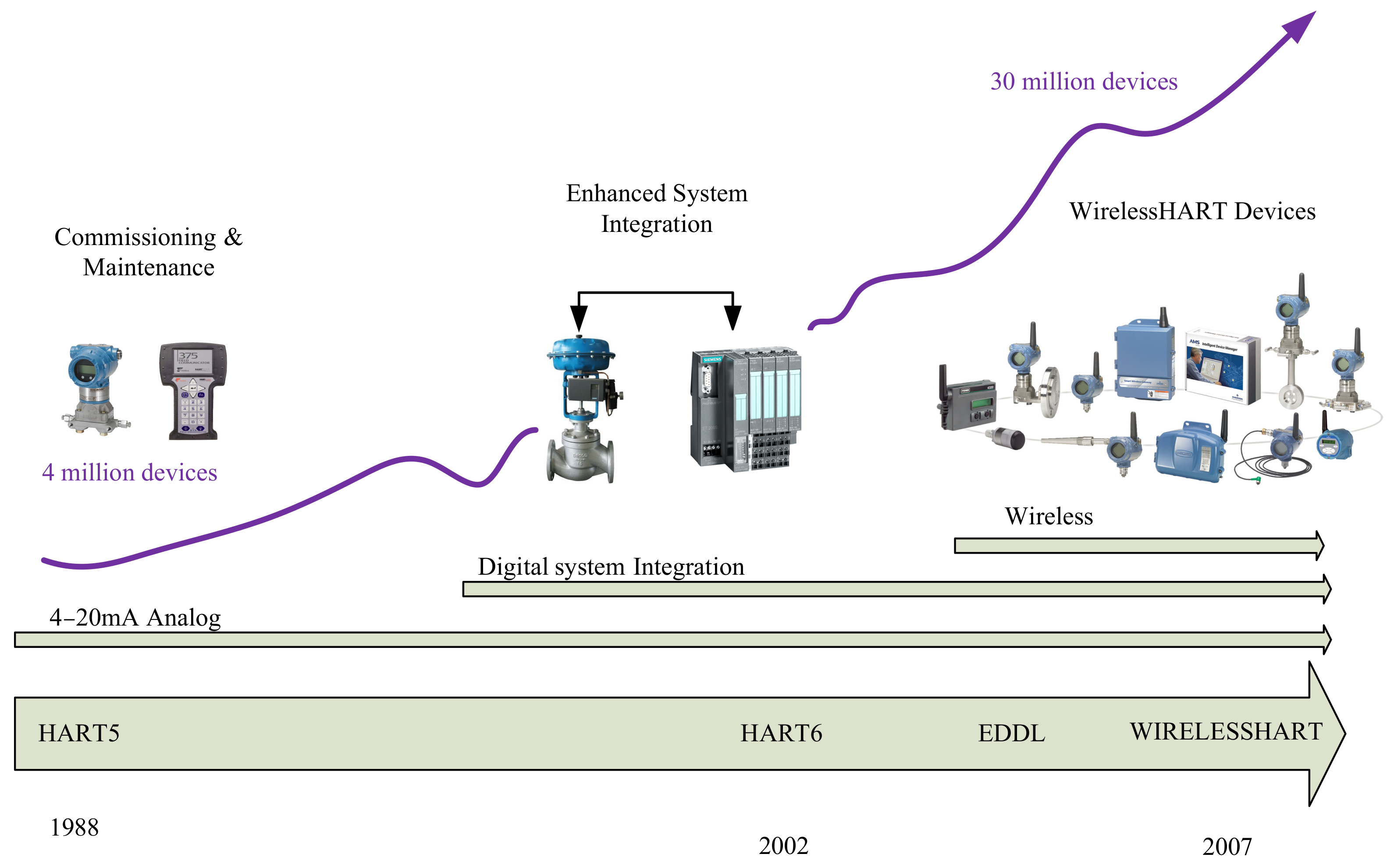

2.2. Evolution of Wireless Networks in Process Automation

3. Industrial Applications of WirelessHART

3.1. WirelessHART

- Wireless mesh networking;

- Time synchronization and stamping;

- Network and transport layer;

- Security encryption and decryption;

- Enhanced burst mode messaging;

- Pipes for high-speed file transfer.

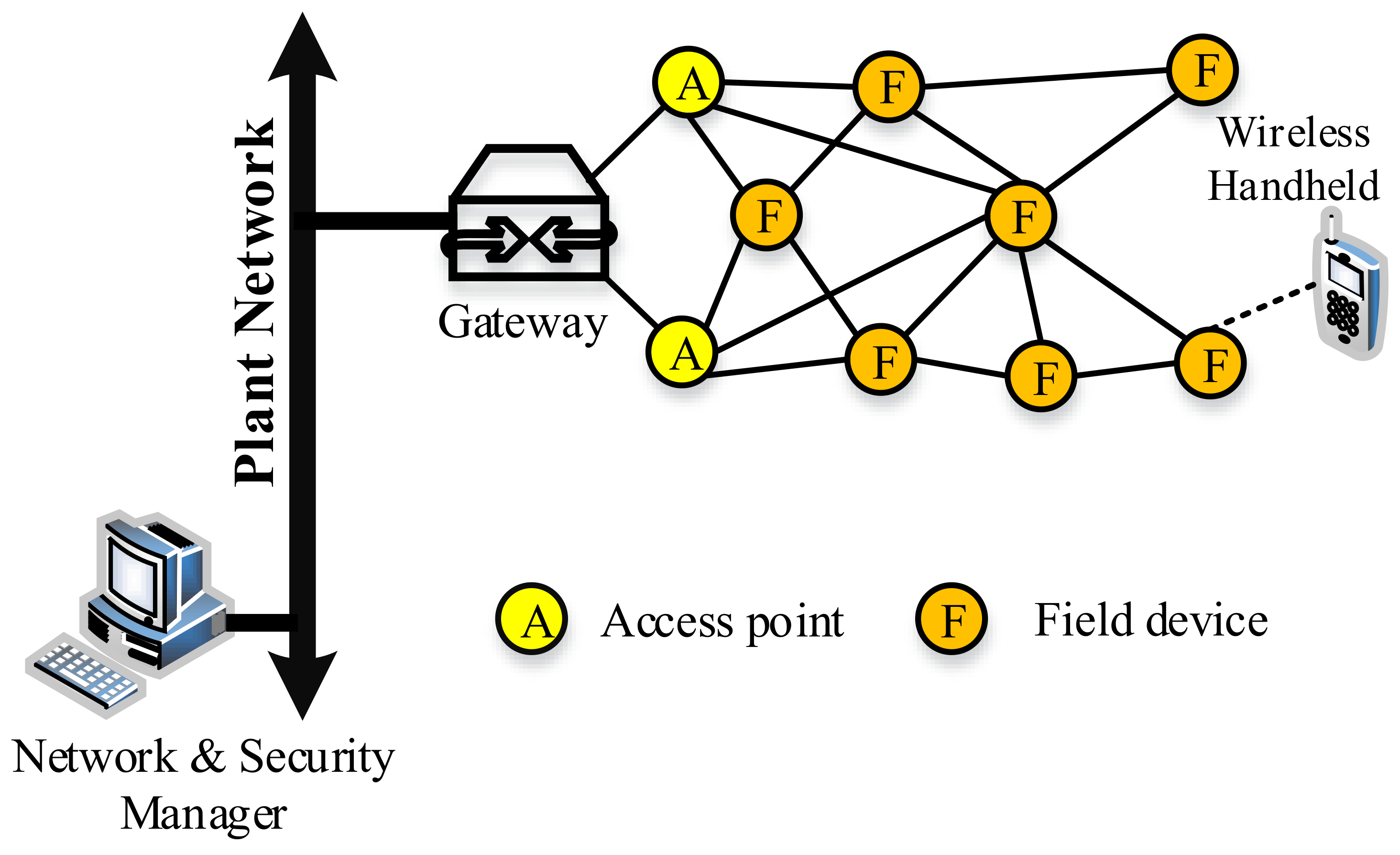

- Field device: connected to the industrial process plant.

- Wireless handheld: employed for diagnostics, device configuration, and calibration from a remote location.

- Gateway: acts as a bridging device to connect host applications and field devices.

- Network manager: accountable for configuring the network, scheduling, routing, and managing communication.

- Security manager: managing and allocating security encryption keys and keeping track of authorized devices to connect to the network.

3.2. Simulation Environment

3.3. Real-Time Implementation

4. Challenges and Design Requirements

4.1. Security

4.2. Reliability and Interference

4.3. Latency

4.4. Interoperability

4.5. Cost Effectiveness and Resource Utilization

4.6. Power Consumption and Battery lifetime

4.7. Fault Tolerance

4.8. Data Accessibility

4.9. Autonomous and Predictive Characteristics

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DoS | Denial-of-Service |

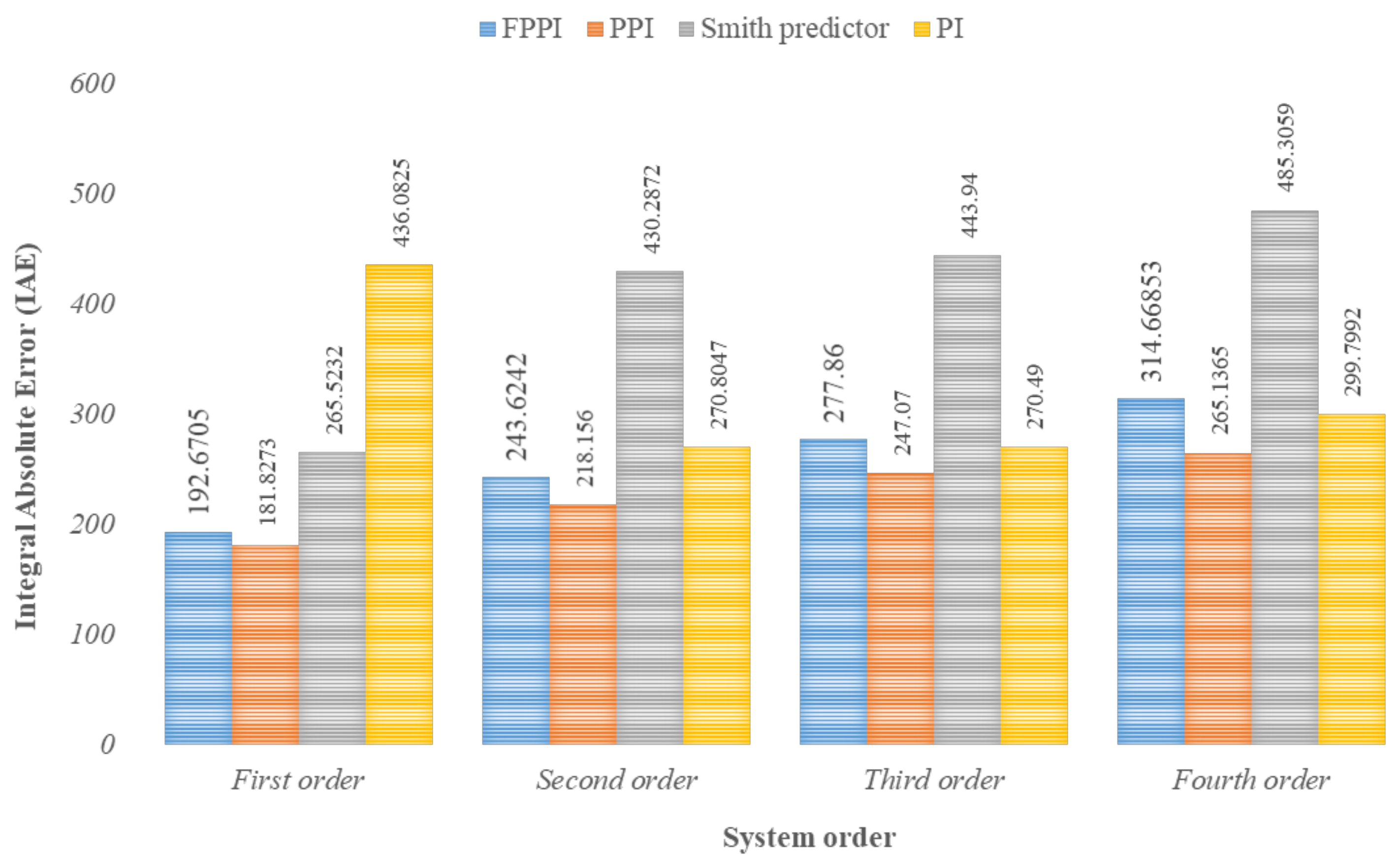

| FPPI | Filtered Predictive PI |

| FoPPI | Fractional-order Predictive PI |

| HART | Highway Addressable Remote Transducer |

| IWSN | Industrial Wireless Sensor Network |

| IAE | Integral Absolute Error |

| IMC | Internal Model Control |

| MAC | Medium Access Control |

| MPC | Model Predictive Control |

| PI | Proportional Integral |

| PPI | Predictive PI |

| PID | Proportional Integral Derivative |

| TITO | Two Input Two Output |

| UWSN | Underwater Wireless Sensor Networks |

| WIA-PA | Wireless network for Industrial Automation-Process Automation |

| WHNCS | WirelessHART Network Control Systems |

References

- Åström, K.J.; Murray, R.M. Feedback Systems: An Introduction for Scientists and Engineers; Princeton University Press: Princeton, NJ, USA, 2021. [Google Scholar]

- Garpinger, O.; Hägglund, T.; Åström, K.J. Performance and robustness trade-offs in PID control. J. Process Control 2014, 24, 568–577. [Google Scholar] [CrossRef]

- Raza, M.; Aslam, N.; Le-Minh, H.; Hussain, S.; Cao, Y.; Khan, N.M. A critical analysis of research potential, challenges, and future directives in industrial wireless sensor networks. IEEE Commun. Surv. Tutor. 2017, 20, 39–95. [Google Scholar] [CrossRef]

- Raposo, D.; Rodrigues, A.; Sinche, S.; Sá Silva, J.; Boavida, F. Industrial IoT monitoring: Technologies and architecture proposal. Sensors 2018, 18, 3568. [Google Scholar] [CrossRef] [Green Version]

- Zou, Y.; Zhu, J.; Wang, X.; Hanzo, L. A survey on wireless security: Technical challenges, recent advances, and future trends. Proc. IEEE 2016, 104, 1727–1765. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Jiang, J. Comparative examination on architecture and protocol of industrial wireless sensor network standards. IEEE Commun. Surv. Tutor. 2016, 18, 2197–2219. [Google Scholar] [CrossRef]

- Salam, H.A.; Khan, B.M. IWSN-standards, challenges and future. IEEE Potentials 2016, 35, 9–16. [Google Scholar] [CrossRef]

- Luvisotto, M.; Pang, Z.; Dzung, D. Ultra high performance wireless control for critical applications: Challenges and directions. IEEE Trans. Ind. Inform. 2016, 13, 1448–1459. [Google Scholar] [CrossRef]

- Menezes, M. Wireless HART® Minimizes Cost of New Energy Measurements. Energy Eng. 2015, 112, 69–77. [Google Scholar] [CrossRef]

- Blevins, T.; Chen, D.; Nixon, M.; Wojsznis, W. Wireless Control Foundation: Continuous and Discrete Control for the Process Industry; International Society of Automation: Research Triangle Park, NC, USA, 2015; Volume 4. [Google Scholar]

- Chung, T.D.; Ibrahim, R.B.; Asirvadam, V.S.; Saad, N.B.; Hassan, S.M. Adopting ewma filter on a fast sampling wired link contention in wirelesshart control system. IEEE Trans. Instrum. Meas. 2016, 65, 836–845. [Google Scholar] [CrossRef]

- Hatler, M. Industrial wireless sensor networks: Trends and developments. Retrieved 2013, 11, 2013. [Google Scholar]

- Gavel, S.; Raghuvanshi, A.S.; Tiwari, S. A multilevel hybrid anomaly detection scheme for industrial wireless sensor networks. Int. J. Netw. Manag. 2020, e2144. [Google Scholar] [CrossRef]

- Hassan, S.M.; Ibrahim, R.; Saad, N.; Bingi, K.; Asirvadam, V.S. Hybrid PID Based Predictive Control Strategies for WirelessHART Networked Control Systems; Springer Nature: Berlin/Heidelberg, Germany, 2020; Volume 293. [Google Scholar]

- Park, P.; Ergen, S.C.; Fischione, C.; Lu, C.; Johansson, K.H. Wireless network design for control systems: A survey. IEEE Commun. Surv. Tutor. 2017, 20, 978–1013. [Google Scholar] [CrossRef]

- Ovsthus, K.; Kristensen, L.M. An industrial perspective on wireless sensor networks—A survey of requirements, protocols, and challenges. IEEE Commun. Surv. Tutor. 2014, 16, 1391–1412. [Google Scholar]

- Li, X.; Li, D.; Wan, J.; Vasilakos, A.V.; Lai, C.F.; Wang, S. A review of industrial wireless networks in the context of industry 4.0. Wirel. Netw. 2017, 23, 23–41. [Google Scholar] [CrossRef]

- Kandris, D.; Nakas, C.; Vomvas, D.; Koulouras, G. Applications of wireless sensor networks: An up-to-date survey. Appl. Syst. Innov. 2020, 3, 14. [Google Scholar] [CrossRef] [Green Version]

- Mishra, A.; Agrawal, D.P. Evaluation of Suitability of Current Industrial Standards in Designing Control Applications for Internet of Things Healthcare Sensor Networks. J. Sens. Actuator Netw. 2019, 8, 54. [Google Scholar] [CrossRef] [Green Version]

- Ghayvat, H.; Mukhopadhyay, S.; Gui, X.; Suryadevara, N. WSN-and IOT-based smart homes and their extension to smart buildings. Sensors 2015, 15, 10350–10379. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Croce, S.; Tondini, S. Urban Microclimate Monitoring and Modeling through an Open-Source Distributed Network of Wireless Low-Cost Sensors and Numerical Simulations; Engineering Proceedings; Multidisciplinary Digital Publishing Institute: Basel, Switzerland, 2020; Volume 2, p. 18. [Google Scholar]

- Baire, M.; Melis, A.; Lodi, M.B.; Dachena, C.; Fanti, A.; Farris, S.; Pisanu, T.; Mazzarella, G. WSN Hardware for Automotive Applications: Preliminary Results for the Case of Public Transportation. Electronics 2019, 8, 1483. [Google Scholar] [CrossRef] [Green Version]

- Islam, S.; Park, S.Y.; Zheng, S.; Han, S.; Park, S.M. Supervisory Control for Wireless Networked Power Converters in Residential Applications. Energies 2019, 12, 1911. [Google Scholar] [CrossRef] [Green Version]

- Fadel, E.; Gungor, V.C.; Nassef, L.; Akkari, N.; Malik, M.A.; Almasri, S.; Akyildiz, I.F. A survey on wireless sensor networks for smart grid. Comput. Commun. 2015, 71, 22–33. [Google Scholar] [CrossRef]

- Tang, X.; Wang, X.; Cattley, R.; Gu, F.; Ball, A.D. Energy harvesting technologies for achieving self-powered wireless sensor networks in machine condition monitoring: A review. Sensors 2018, 18, 4113. [Google Scholar] [CrossRef] [Green Version]

- Ullah, R.; Faheem, Y.; Kim, B.S. Energy and congestion-aware routing metric for smart grid AMI networks in smart city. IEEE Access 2017, 5, 13799–13810. [Google Scholar] [CrossRef]

- Ojha, T.; Misra, S.; Raghuwanshi, N.S. Wireless sensor networks for agriculture: The state-of-the-art in practice and future challenges. Comput. Electron. Agric. 2015, 118, 66–84. [Google Scholar] [CrossRef]

- Baire, M.; Melis, A.; Lodi, M.B.; Tuveri, P.; Dachena, C.; Simone, M.; Fanti, A.; Fumera, G.; Pisanu, T.; Mazzarella, G. A wireless sensors network for monitoring the Carasau bread manufacturing process. Electronics 2019, 8, 1541. [Google Scholar] [CrossRef] [Green Version]

- Fattah, S.; Gani, A.; Ahmedy, I.; Idris, M.Y.I.; Targio Hashem, I.A. A Survey on Underwater Wireless Sensor Networks: Requirements, Taxonomy, Recent Advances, and Open Research Challenges. Sensors 2020, 20, 5393. [Google Scholar] [CrossRef] [PubMed]

- Santana Abril, J.; Santana Sosa, G.; Sosa, J.; Bautista, T.; Montiel-Nelson, J.A. A Novel Charging Method for Underwater Batteryless Sensor Node Networks. Sensors 2021, 21, 557. [Google Scholar] [CrossRef]

- Al-Turjman, F.M.; Hassanein, H.S.; Ibnkahla, M.A. Efficient deployment of wireless sensor networks targeting environment monitoring applications. Comput. Commun. 2013, 36, 135–148. [Google Scholar] [CrossRef]

- Zhao, G. Wireless Sensor Networks for Industrial Process Monitoring and Control: A Survey. Netw. Protoc. Algorithms 2011, 3, 46–63. [Google Scholar] [CrossRef]

- Zhao, G.; Imran, M.A.; Pang, Z.; Chen, Z.; Li, L. Toward real-time control in future wireless networks: Communication-control co-design. IEEE Commun. Mag. 2018, 57, 138–144. [Google Scholar] [CrossRef] [Green Version]

- Sparks, R. Reduce Costs with Wireless Instrumentation, Emerson Process Management; 2009. Available online: https://www.powermag.com/reduce-costs-with-wireless-instrumentation/ (accessed on 7 May 2021).

- Hassan, S.M.; Ibrahim, R.; Bingi, K.; Chung, T.D.; Saad, N. Application of wireless technology for control: A WirelessHART perspective. Procedia Comput. Sci. 2017, 105, 240–247. [Google Scholar] [CrossRef]

- Zand, P.; Chatterjea, S.; Das, K.; Havinga, P. Wireless industrial monitoring and control networks: The journey so far and the road ahead. J. Sens. Actuator Netw. 2012, 1, 123–152. [Google Scholar] [CrossRef] [Green Version]

- Hassan, S.M.; Ibrahim, R.; Saad, N.; Asirvadam, V.S.; Bingi, K. Adopting setpoint weighting strategy for WirelessHART networked control systems characterised by stochastic delay. IEEE Access 2017, 5, 25885–25896. [Google Scholar] [CrossRef]

- Zand, P.; Mathews, E.; Havinga, P.; Stojanovski, S.; Sisinni, E.; Ferrari, P. Implementation of wirelesshart in the ns-2 simulator and validation of its correctness. Sensors 2014, 14, 8633–8668. [Google Scholar] [CrossRef] [Green Version]

- Nobre, M.; Silva, I.; Guedes, L.A. Routing and scheduling algorithms for WirelessHARTNetworks: A survey. Sensors 2015, 15, 9703–9740. [Google Scholar] [CrossRef] [Green Version]

- Kobo, H.I.; Abu-Mahfouz, A.M.; Hancke, G.P. A survey on software-defined wireless sensor networks: Challenges and design requirements. IEEE Access 2017, 5, 1872–1899. [Google Scholar] [CrossRef]

- Maass, A.I.; Nešić, D.; Postoyan, R.; Dower, P.M.; Varma, V.S. Emulation-based stabilisation of networked control systems over WirelessHART. In Proceedings of the 2017 IEEE 56th Annual Conference on Decision and Control (CDC), Melbourne, VIC, Australia, 12–15 December 2017; pp. 6628–6633. [Google Scholar]

- Oliveira, L.; Rodrigues, J.J.; Kozlov, S.A.; Rabêlo, R.A.; Albuquerque, V.H.C.D. MAC layer protocols for Internet of Things: A survey. Future Internet 2019, 11, 16. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Nixon, M.; Chen, D.; Mok, A.; Muston, P. WirelessHART™ sensor networks. In Industrial Wireless Sensor Networks; Elsevier: Amsterdam, The Netherlands, 2016; pp. 79–103. [Google Scholar]

- Kwon, S.; Jeong, J.; Shon, T. Toward security enhanced provisioning in industrial IoT systems. Sensors 2018, 18, 4372. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.Q.; Yu, F.R.; Deng, G.; Luo, C.; Ming, Z.; Yan, Q. Industrial internet: A survey on the enabling technologies, applications, and challenges. IEEE Commun. Surv. Tutor. 2017, 19, 1504–1526. [Google Scholar] [CrossRef]

- Tramarin, F.; Mok, A.K.; Han, S. Real-time and reliable industrial control over wireless lans: Algorithms, protocols, and future directions. Proc. IEEE 2019, 107, 1027–1052. [Google Scholar] [CrossRef]

- Jin, X.; Kong, F.; Kong, L.; Liu, W.; Zeng, P. Reliability and temporality optimization for multiple coexisting WirelessHART networks in industrial environments. IEEE Trans. Ind. Electron. 2017, 64, 6591–6602. [Google Scholar] [CrossRef]

- Tran, C.D.; Ibrahim, R.; Asirvadam, V.S.; Saad, N.; Miya, H.S. Internal model control for industrial wireless plant using WirelessHART hardware-in-the-loop simulator. ISA Trans. 2018, 75, 236–246. [Google Scholar] [CrossRef] [PubMed]

- Pyotsia, J.; Simula, M.; Cederlof, H. Wireless Control of a Field Device in an Industrial Process. U.S. Patent 7,010,294, 7 March 2006. [Google Scholar]

- Petersen, S.; Carlsen, S. Performance evaluation of WirelessHART for factory automation. In Proceedings of the 2009 IEEE Conference on Emerging Technologies & Factory Automation, Palma de Mallorca, Spain, 22–25 September 2009; pp. 1–9. [Google Scholar]

- Winter, J.M.; Kunzel, G.; Muller, I.; Pereira, C.E.; Netto, J.C. Study of routing mechanisms in a WirelessHART network. In Proceedings of the 2013 IEEE International Conference on Industrial Technology (ICIT), Cape Town, South Africa, 25–28 February 2013; pp. 1540–1545. [Google Scholar]

- Huang, Q.; Sikora, A.; Groza, V.F.; Zand, P. Simulation & analysis of WirelessHART nodes for real-time actuator application. In Proceedings of the 2014 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Montevideo, Uruguay, 12–15 May 2014; pp. 1590–1594. [Google Scholar]

- Nawaz, F.; Jeoti, V. Performance assessment of WirelessHART technology for its implementation in dense reader environment. Computing 2016, 98, 257–277. [Google Scholar] [CrossRef]

- Cervin, A.; Henriksson, D.; Lincoln, B.; Eker, J.; Arzen, K.E. How does control timing affect performance? Analysis and simulation of timing using Jitterbug and TrueTime. IEEE Control Syst. Mag. 2003, 23, 16–30. [Google Scholar]

- De Biasi, M.; Snickars, C.; Landernäs, K.; Isaksson, A. Simulation of process control with WirelessHART networks subject to clock drift. In Proceedings of the 2008 32nd Annual IEEE International Computer Software and Applications Conference, Turku, Finland, 28 July–1 August 2008; pp. 1355–1360. [Google Scholar]

- De Biasi, M.; Snickars, C.; Landernas, K.; Isaksson, A.J. Simulation of process control with WirelessHART networks subject to packet losses. In Proceedings of the 2008 IEEE International Conference on Automation Science and Engineering, Arlington, VA, USA, 23–26 August 2008; pp. 548–553. [Google Scholar]

- Snickars, C. Design of a WirelessHART Simulator for Studying Delay Compensation in Networked Control Systems. Masters’ Degree Project, KTH Royal Institute of Technology, Stockholm, Sweden 2008. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.542.1127&rep=rep1&type=pdf (accessed on 7 May 2020).

- Pesonen, J.; Zhang, H.; Soldati, P.; Johansson, M. Methodology and tools for controller-networking codesign in WirelessHART. In Proceedings of the 2009 IEEE Conference on Emerging Technologies & Factory Automation, Palma de Mallorca, Spain, 22–25 September 2009; pp. 1–8. [Google Scholar]

- Shah, K.; Seceleanu, T.; Gidlund, M. Design and implementation of a WirelessHART simulator for process control. In Proceedings of the International Symposium on Industrial Embedded System (SIES), Trento, Italy, 7–9 July 2010; pp. 221–224. [Google Scholar]

- Gustafsson, D. Wirelesshart-Implementation and Evaluation on Wireless Sensors. Masters’s Thesis, KTH University, Electrical Engineering, Stockholm, Sweden, 2009; pp. 1–39. [Google Scholar]

- Ferrari, P.; Flammini, A.; Rizzi, M.; Sisinni, E. Improving simulation of wireless networked control systems based on WirelessHART. Comput. Stand. Interfaces 2013, 35, 605–615. [Google Scholar] [CrossRef]

- Maass, A.I.; Nešić, D.; Dower, P.M. A hybrid model of networked control systems implemented on WirelessHART networks under source routing configuration. In Proceedings of the 2016 Australian Control Conference (AuCC), Newcastle, NSW, Australia, 3–4 November 2016; pp. 60–65. [Google Scholar]

- Modekurthy, V.P.; Saifullah, A.; Madria, S. DistributedHART: A distributed real-time scheduling system for WirelessHART networks. In Proceedings of the 2019 IEEE Real-Time and Embedded Technology and Applications Symposium (RTAS), Montreal, QC, Canada, 16–18 April 2019; pp. 216–227. [Google Scholar]

- Song, J.; Han, S.; Mok, A.; Chen, D.; Lucas, M.; Nixon, M.; Pratt, W. WirelessHART: Applying wireless technology in real-time industrial process control. In Proceedings of the 2008 IEEE Real-Time and Embedded Technology and Applications Symposium, St. Louis, MO, USA, 22–24 April 2008; pp. 377–386. [Google Scholar]

- Han, S.; Zhu, X.; Aloysius, K.M.; Nixon, M.; Blevins, T.; Chen, D. Control over WirelessHART network. In Proceedings of the IECON 2010-36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 2114–2119. [Google Scholar]

- Seibert, F.; Belvins, T. Wireless HART successfully handles control. Chem. Process. ER-000148-Jan. 2011. Available online: https://www.emerson.com/documents/automation/article-wirelesshart-successfully-handles-control-deltav-en-37778.pdf (accessed on 7 May 2020).

- Mahmoud, M.S.; Sabih, M. Experimental investigations for distributed networked control systems. IEEE Syst. J. 2013, 8, 717–725. [Google Scholar] [CrossRef]

- Blevins, T.; Nixon, M.; Wojsznis, W. PID control using wireless measurements. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 790–795. [Google Scholar]

- Blevins, T.; Wojsznis, W.K.; Nixon, M.J.; Roach, B. Wireless model predictive control applied for dividing wall column control. In Proceedings of the 2016 Second International Conference on Event-based Control, Communication, and Signal Processing (EBCCSP), Krakow, Poland, 13–15 June 2016; pp. 1–7. [Google Scholar]

- Devan, P.A.M.; Hussin, F.A.B.; Ibrahim, R.; Bingi, K.; Abdulrab, H.Q. Fractional-Order Predictive PI Controller for Dead-Time Processes With Set-Point and Noise Filtering. IEEE Access 2020, 8, 183759–183773. [Google Scholar] [CrossRef]

- Chung, T.D.; Ibrahim, R.B.; Asirvadam, V.S.; Saad, N.B.; Hassan, S.M. Simulation of WirelessHART networked control system with packet dropout. In Proceedings of the 2015 10th Asian Control Conference (ASCC), Kota Kinabalu, Malaysia, 31 May–3 June 2015; pp. 1–6. [Google Scholar]

- Chung, T.D.; Ibrahim, R.; Asirvadam, V.S.; Saad, N.; Hassan, S.M. Effect of network induced delays on WirelessHART control system. In Proceedings of the 2016 6th International Conference on Intelligent and Advanced Systems (ICIAS), Kuala Lumpur, Malaysia, 15–17 August 2016; pp. 1–5. [Google Scholar]

- Hassan, S.M.; Ibrahim, R.; Saad, N.; Asirvadam, V.S.; Chung, T.D. Implementation of real-time WirelessHART network for control application. In Proceedings of the 2016 6th International Conference on Intelligent and Advanced Systems (ICIAS), Kuala Lumpur, Malaysia, 15–17 August 2016; pp. 1–6. [Google Scholar]

- Chien, L.J.; Ibrahim, R.; Hassan, S.M.; Bingi, K.; Supramaniam, T. Comparison Between Wired and WirelessHART Networked PID Control of Process Flow. In Proceedings of the 2018 International Conference on Intelligent and Advanced System (ICIAS), Kuala Lumpur, Malaysia, 13–14 August 2018; pp. 1–5. [Google Scholar]

- Liu, Y.; Candell, R.; Lee, K.; Moayeri, N. A simulation framework for industrial wireless networks and process control systems. In Proceedings of the 2016 IEEE World Conference on Factory Communication Systems (WFCS), Aveiro, Portugal, 3–6 May 2016; pp. 1–11. [Google Scholar]

- Somkane, P.; Kongratana, V.; Gulpanich, S.; Tipsuwanporn, V.; Wongvanich, N. A study of flow-level cascade control with WirelessHART TM transmitter using LabVIEW. In Proceedings of the 2017 17th International Conference on Control, Automation and Systems (ICCAS), Jeju, Korea, 18–21 October 2017; pp. 856–861. [Google Scholar]

- Quaglia, D.; Muradore, R.; Fiorini, P. A SystemC/MATLAB Co-simulation Tool for Networked Control Systems. In Coordination Control of Distributed Systems; Springer: Berlin/Heidelberg, Germany, 2015; pp. 283–290. [Google Scholar]

- Di Girolamo, G.D.; D’Innocenzo, A. Codesign of controller, routing and scheduling in WirelessHART networked control systems. Int. J. Robust Nonlinear Control 2019, 29, 2171–2187. [Google Scholar] [CrossRef]

- Soto, V.S.; Muller, I.; Winter, J.M.; Pereira, C.E.; Netto, J.C. Control over wirelesshart network through a host application: A wirelesshart network control proposal. In Proceedings of the 2014 Brazilian Symposium on Computing Systems Engineering, Manaus, Brazil, 3–7 November 2014; pp. 91–96. [Google Scholar]

- Saifullah, A.; Xu, Y.; Lu, C.; Chen, Y. End-to-end communication delay analysis in industrial wireless networks. IEEE Trans. Comput. 2014, 64, 1361–1374. [Google Scholar] [CrossRef]

- Chen, G.; Cao, X.; Liu, L.; Sun, C.; Cheng, Y. Joint scheduling and channel allocation for end-to-end delay minimization in industrial WirelessHART networks. IEEE Internet Things J. 2018, 6, 2829–2842. [Google Scholar] [CrossRef]

- Battsh, J.A.; Sheltami, T.R.; Mhamoud, A.S.H.; Barnawi, A.Y. Performance Evaluation of Industrial Wireless Sensor Network Technologies: ZigBee, WirelessHART, and Isa100. Int. J. Interdiscip. Telecommun. Netw. 2018, 10, 77–97. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, H.; Ibrahim, R.; Hassan, S.M.; Chung, T.D. Filtered feedback PID control for WirelessHART networked plant. In Proceedings of the 2016 6th International Conference on Intelligent and Advanced Systems (ICIAS), Kuala Lumpur, Malaysia, 15–17 August 2016; pp. 1–5. [Google Scholar]

- Hassan, S.M.; Ibrahim, R.; Saad, N.; Asirvadam, V.S.; Bingi, K.; Chung, T.D. Fuzzy Adaptive Setpoint Weighting Controller for WirelessHART Networked Control Systems. In Wireless Sensor Networks-Insights and Innovations; IntechOpen: London, UK, 2017. [Google Scholar]

- Hassan, S.M.; Bingi, K.; Ibrahim, R.; Chein, L.J.; Supramaniam, T. Implementation of flow control over wirelessHART sensor network using wirelessHART adaptors. Indones. J. Electr. Eng. Comput. Sci. 2019, 15, 910–919. [Google Scholar] [CrossRef]

- Chung, T.D.; Ibrahim, R.; Asirvadam, V.S.; Saad, N.; Hassan, S.M. Latency analysis of WirelessHART control message with variable payload. In Proceedings of the 2016 2nd IEEE International Symposium on Robotics and Manufacturing Automation (ROMA), Ipoh, Malaysia, 25–27 September 2016; pp. 1–5. [Google Scholar]

- Hassan, S.M.; Ibrahim, R.; Saad, N.; Asirvadam, V.S.; Chung, T.D. Predictive PI controller for wireless control system with variable network delay and disturbance. In Proceedings of the 2016 2nd IEEE International Symposium on Robotics and Manufacturing Automation (ROMA), Ipoh, Malaysia, 25–27 September 2016; pp. 1–6. [Google Scholar]

- Zhu, X.; Lin, T.; Han, S.; Mok, A.; Chen, D.; Nixon, M.; Rotvold, E. Measuring WirelessHART against wired fieldbus for control. In Proceedings of the IEEE 10th INTERNATIONAL Conference on Industrial Informatics, Beijing, China, 25–27 July 2012; pp. 270–275. [Google Scholar]

- Blevins, T.; Nixon, M.; Wojsznis, W. Event based control applied to wireless throttling valves. In Proceedings of the 2015 International Conference on Event-based Control, Communication, and Signal Processing (EBCCSP), Krakow, Poland, 17–19 June 2015; pp. 1–6. [Google Scholar]

- Liu, J.; Lin, J. Design optimization of WirelessHART networks in Cyber-Physical Systems. J. Syst. Archit. 2019, 97, 168–184. [Google Scholar] [CrossRef]

- Wongvanich, N.; Pongsumpun, P. Simplified Modeling Approach to Characterize Sudden Load Disturbances in WirelessHART FOPDT Systems. In Proceedings of the 2018 15th International Conference on Control, Automation, Robotics and Vision (ICARCV), Singapore, 18–21 November 2018; pp. 1567–1572. [Google Scholar]

- Huang, V.K.; Pang, Z.; Chen, C.J.A.; Tsang, K.F. New trends in the practical deployment of industrial wireless: From noncritical to critical use cases. IEEE Ind. Electron. Mag. 2018, 12, 50–58. [Google Scholar] [CrossRef]

- Igarashi, Y.; Nakano, R.; Wakamiya, N. A Polling-Based Transmission Scheme Using a Network Traffic Uniformity Metric for Industrial IoT Applications. Sensors 2019, 19, 187. [Google Scholar] [CrossRef] [Green Version]

- Suto, K.; Nishiyama, H.; Kato, N.; Huang, C.W. An energy-efficient and delay-aware wireless computing system for industrial wireless sensor networks. IEEE Access 2015, 3, 1026–1035. [Google Scholar] [CrossRef] [Green Version]

- Seferagić, A.; Famaey, J.; De Poorter, E.; Hoebeke, J. Survey on wireless technology trade-offs for the industrial internet of things. Sensors 2020, 20, 488. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Queiroz, D.V.; Alencar, M.S.; Gomes, R.D.; Fonseca, I.E.; Benavente-Peces, C. Survey and systematic mapping of industrial Wireless Sensor Networks. J. Netw. Comput. Appl. 2017, 97, 96–125. [Google Scholar] [CrossRef]

- Bayou, L.; Espes, D.; Cuppens-Boulahia, N.; Cuppens, F. Security analysis of WirelessHART communication scheme. In International Symposium on Foundations and Practice of Security; Springer: Berlin/Heidelberg, Germany, 2016; pp. 223–238. [Google Scholar]

- Gavrić, Ž.; Simić, D. Overview of DOS attacks on wireless sensor networks and experimental results for simulation of interference attacks. Ing. Investig. 2018, 38, 130–138. [Google Scholar] [CrossRef]

- Nikolidakis, S.A.; Kandris, D.; Vergados, D.D.; Douligeris, C. Energy efficient routing in wireless sensor networks through balanced clustering. Algorithms 2013, 6, 29–42. [Google Scholar] [CrossRef]

- Habib, G.; Haddad, N.; El Khoury, R. Case study: WIRELESSHART vs ZIGBEE network. In Proceedings of the 2015 Third International Conference on Technological Advances in Electrical, Electronics and Computer Engineering (TAEECE), Beirut, Lebanon, 29 April–1 May 2015; pp. 135–138. [Google Scholar]

- Karakaya, A.; Akleylek, S. A survey on security threats and authentication approaches in wireless sensor networks. In Proceedings of the 2018 6th International Symposium on Digital Forensic and Security (ISDFS), Antalya, Turkey, 22–25 March 2018; pp. 1–4. [Google Scholar]

- Zhang, Q.; Li, F.; Ju, L.; Jia, Z.; Zhang, Z. Reliable and energy efficient routing algorithm for WirelessHART. In International Conference on Algorithms and Architectures for Parallel Processing; Springer: Berlin/Heidelberg, Germany, 2014; pp. 192–203. [Google Scholar]

- Ramos, B.; Savazzi, S.; Winter, J.; Ojeda, V.; Chalen, M.; Del Rosario, E.; Á lvarez, M.A. A Perfomance Comparison of WirelessHART and ZigBee in Oil Refinery. In Proceedings of the 2018 IEEE-APS Topical Conference on Antennas and Propagation in Wireless Communications (APWC), Cartagena, Colombia, 10–14 September 2018; pp. 846–849. [Google Scholar]

- Ma, J.; Yang, D.; Zhang, H.; Gidlund, M. A reliable handoff mechanism for mobile industrial wireless sensor networks. Sensors 2017, 17, 1797. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Gunatilaka, D.; Saifullah, A.; Sha, M.; Tiwari, P.B.; Lu, C.; Chen, Y. Maximizing network lifetime of WirelessHART networks under graph routing. In Proceedings of the 2016 IEEE First International Conference on Internet-of-Things Design and Implementation (IoTDI), Berlin, Germany, 4–8 April 2016; pp. 176–186. [Google Scholar]

- Nobre, M.; Silva, I.; Guedes, L.A. Performance evaluation of WirelessHART networks using a new network simulator 3 module. Comput. Electr. Eng. 2015, 41, 325–341. [Google Scholar] [CrossRef]

- Xiao, X.; Huang, H.; Wang, W. Underwater Wireless Sensor Networks: An Energy-Efficient Clustering Routing Protocol Based on Data Fusion and Genetic Algorithms. Appl. Sci. 2021, 11, 312. [Google Scholar]

- Devan, P.A.M.; Hussin, F.A.; Ibrahim, R.; Bingi, K.; Abdulrab, H. Fractional-order Predictive PI Controller for Process Plants with Deadtime. In Proceedings of the 2020 IEEE 8th R10 Humanitarian Technology Conference (R10-HTC), Kuching, Malaysia, 1–3 December 2020; pp. 1–6. [Google Scholar]

- Raza, S.; Faheem, M.; Guenes, M. Industrial wireless sensor and actuator networks in industry 4.0: Exploring requirements, protocols, and challenges—A MAC survey. Int. J. Commun. Syst. 2019, 32, e4074. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, W.; He, H.; Liu, Y. A New Method of Priority Assignment for Real-Time Flows in the WirelessHART Network by the TDMA Protocol. Sensors 2018, 18, 4242. [Google Scholar] [CrossRef] [Green Version]

- Givehchi, O.; Landsdorf, K.; Simoens, P.; Colombo, A.W. Interoperability for industrial cyber-physical systems: An approach for legacy systems. IEEE Trans. Ind. Inform. 2017, 13, 3370–3378. [Google Scholar] [CrossRef]

- Oyewobi, S.S.; Hancke, G.P. A survey of cognitive radio handoff schemes, challenges and issues for industrial wireless sensor networks (CR-IWSN). J. Netw. Comput. Appl. 2017, 97, 140–156. [Google Scholar] [CrossRef] [Green Version]

- Karray, F.; Jmal, M.W.; Garcia-Ortiz, A.; Abid, M.; Obeid, A.M. A comprehensive survey on wireless sensor node hardware platforms. Comput. Networks 2018, 144, 89–110. [Google Scholar] [CrossRef]

- Bergmann, N.W.; Hou, L. Machine condition monitoring with industrial wireless sensor networks. In Industrial Wireless Sensor Networks; CRC Press: Boca Raton, FL, USA, 2017; pp. 23–45. [Google Scholar] [CrossRef] [Green Version]

- Kharb, S.; Singhrova, A. Review of industrial standards for wireless sensor networks. In Next-Generation Networks; Springer: Berlin/Heidelberg, Germany, 2018; pp. 77–87. [Google Scholar]

- He, X.; Fu, X.; Yang, Y. Energy-efficient trajectory planning algorithm based on multi-objective PSO for the mobile sink in wireless sensor networks. IEEE Access 2019, 7, 176204–176217. [Google Scholar] [CrossRef]

- Goyal, N.; Dave, M.; Verma, A.K. Improved data aggregation for cluster based underwater wireless sensor networks. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2017, 87, 235–245. [Google Scholar] [CrossRef]

- Nakas, C.; Kandris, D.; Visvardis, G. Energy efficient routing in wireless sensor networks: A comprehensive survey. Algorithms 2020, 13, 72. [Google Scholar] [CrossRef] [Green Version]

- Xiao, G.; Shi, J.; Sun, N.; Chen, Y.; Zhang, Y. Adaptive Freeshape Clustering for Balanced Energy Saving in the WirelessHART Networks. Complexity 2019, 2019, 2836981. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, R.; Chung, T.D.; Hassan, S.M.; Bingi, K.; binti Salahuddin, S.K. Solar energy harvester for industrial wireless sensor nodes. Procedia Comput. Sci. 2017, 105, 111–118. [Google Scholar] [CrossRef]

- Shaikh, F.K.; Zeadally, S. Energy harvesting in wireless sensor networks: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 55, 1041–1054. [Google Scholar] [CrossRef]

- Sha, K.; Gehlot, J.; Greve, R. Multipath routing techniques in wireless sensor networks: A survey. Wirel. Pers. Commun. 2013, 70, 807–829. [Google Scholar] [CrossRef]

- Fanian, F.; Rafsanjani, M.K. Cluster-based routing protocols in wireless sensor networks: A survey based on methodology. J. Netw. Comput. Appl. 2019, 142, 111–142. [Google Scholar] [CrossRef]

- Patel, H.; Singh Rajput, D.; Thippa Reddy, G.; Iwendi, C.; Kashif Bashir, A.; Jo, O. A review on classification of imbalanced data for wireless sensor networks. Int. J. Distrib. Sens. Netw. 2020, 16, 1550147720916404. [Google Scholar] [CrossRef]

- Boubiche, S.; Boubiche, D.E.; Bilami, A.; Toral-Cruz, H. Big data challenges and data aggregation strategies in wireless sensor networks. IEEE Access 2018, 6, 20558–20571. [Google Scholar] [CrossRef]

- Randhawa, S.; Jain, S. Data aggregation in wireless sensor networks: Previous research, current status and future directions. Wirel. Pers. Commun. 2017, 97, 3355–3425. [Google Scholar] [CrossRef]

- Chouikhi, S.; El Korbi, I.; Ghamri-Doudane, Y.; Saidane, L.A. A survey on fault tolerance in small and large scale wireless sensor networks. Comput. Commun. 2015, 69, 22–37. [Google Scholar] [CrossRef]

- Geng, Z.; Dong, J.; Chen, J.; Han, Y. A new self-organizing extreme learning machine soft sensor model and its applications in complicated chemical processes. Eng. Appl. Artif. Intell. 2017, 62, 38–50. [Google Scholar] [CrossRef]

- Kamimura, A.; Tomita, K. A self-organizing network coordination framework enabling collision-free and congestion-less wireless sensor networks. J. Netw. Comput. Appl. 2017, 93, 228–244. [Google Scholar] [CrossRef]

- Kostadinovic, M.; Stjepanovic, A.; Kuzmic, G.; Stojcic, M.; Kostadinovic, T. Quality Analysis of Data Transferring Through the Process of Modeling WirelessHART Network. In Proceedings of the 2020 19th International Symposium INFOTEH-JAHORINA (INFOTEH), East Sarajevo, Bosnia and Herzegovina, 18–20 March 2020; pp. 1–5. [Google Scholar]

- Li, F.; Zhang, Z.; Jia, Z.; Ju, L. Superframe scheduling for data aggregation in WirelessHART networks. In Proceedings of the 2015 IEEE 17th International Conference on High Performance Computing and Communications, 2015 IEEE 7th International Symposium on Cyberspace Safety and Security, and 2015 IEEE 12th International Conference on Embedded Software and Systems, New York, NY, USA, 24–26 August 2015; pp. 1540–1545. [Google Scholar]

- Jindal, V.; Verma, A. The underlying technologies in WSNs: ZigBee vs. wireless HART. In Proceedings of the 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2208–2213. [Google Scholar]

- Künzel, G.; Cainelli, G.P.; Pereira, C.E. A weighted broadcast routing algorithm for wirelesshart networks. In Proceedings of the 2017 VII Brazilian Symposium on Computing Systems Engineering (SBESC), Curitiba, PR, Brazil, 6–10 November 2017; pp. 187–192. [Google Scholar]

- Supramaniam, T.; Ibrahim, R.; Hassan, S.M.; Bingi, K. Development of WirelessHART adapter with industrial transmitter for process monitoring. In Proceedings of the 2017 IEEE International Conference on Signal and Image Processing Applications (ICSIPA), Kuching, Malaysia, 12–14 September 2017; pp. 294–298. [Google Scholar]

- Chen, G.; Cao, X.; Jin, J. Joint Scheduling and Channel Allocation for Kalman Filtering over Multihop WirelessHART Networks. IEEE Trans. Ind. Inform. 2020, 17, 3555–3565. [Google Scholar] [CrossRef]

- Benoit, J.; Yao, A.; Saladis, L.; Zheng, Y. Performance evaluations of multi-hop wirelessHART network and 6LoWPAN using different topologies. In Proceedings of the 2018 Global Smart Industry Conference (GloSIC), Chelyabinsk, Russia, 13–15 November 2018; pp. 1–5. [Google Scholar]

- Modekurthy, V.P.; Saifullah, A.; Madria, S. Distributed graph routing for wirelesshart networks. In Proceedings of the 19th International Conference on Distributed Computing and Networking (ICDCN ’18), Varanasi, India, 4 –7 January 2018; pp. 1–10. [Google Scholar]

- Saifullah, A.; Gunatilaka, D.; Tiwari, P.; Sha, M.; Lu, C.; Li, B.; Wu, C.; Chen, Y. Schedulability analysis under graph routing in WirelessHART networks. In Proceedings of the 2015 IEEE Real-Time Systems Symposium, San Antonio, TX, USA, 1–4 December 2015; pp. 165–174. [Google Scholar]

- Li, F.; Ju, L.; Jia, Z. Data aggregation framework for energy-efficient WirelessHART networks. J. Syst. Archit. 2016, 63, 70–79. [Google Scholar] [CrossRef]

- Ji, M.; Cao, X. Joint Design of Routing and Scheduling for Maximizing Reliability of Multihop Transmissions in WirelessHART Networks. In Proceedings of the 2020 35th Youth Academic Annual Conference of Chinese Association of Automation (YAC), Zhanjiang, China, 16–18 October 2020; pp. 269–275. [Google Scholar]

- Paul, P.; Ram, N.; Usha, M. Symmetric key encryption for secure communication using wireless hart in wireless sensor networks (WSN). Aust. J. Basic Appl. Sci. 2016, 10, 625–630. [Google Scholar]

- Mota, A.V.; Azam, S.; Shanmugam, B.; Yeo, K.C.; Kannoorpatti, K. Comparative analysis of different techniques of encryption for secured data transmission. In Proceedings of the 2017 IEEE International Conference on Power, Control, Signals and Instrumentation Engineering (ICPCSI), Chennai, Tamil Nadu, India, 21–22 September 2017; pp. 231–237. [Google Scholar]

- Bayou, L.; Espes, D.; Cuppens-Boulahia, N.; Cuppens, F. Security issue of wirelesshart based SCADA systems. In International Conference on Risks and Security of Internet and Systems; Springer: Berlin/Heidelberg, Germany, 2015; pp. 225–241. [Google Scholar]

- Adriano, J.D.; do Rosario, E.C.; Rodrigues, J.J. Wireless sensor networks in industry 4.0: WirelessHART and ISA100.11a. In Proceedings of the 2018 13th IEEE International Conference on Industry Applications (INDUSCON), Sao Paulo, Brazil, 12–14 November 2018; pp. 924–929. [Google Scholar]

- Noura, M.; Atiquzzaman, M.; Gaedke, M. Interoperability in internet of things: Taxonomies and open challenges. Mob. Netw. Appl. 2019, 24, 796–809. [Google Scholar] [CrossRef] [Green Version]

| Factors | 2012 (%) | 2014 (%) |

|---|---|---|

| Data Accuracy | 96 | 96 |

| Data Protection | 89 | 87 |

| Data Accessibility | 71 | 69 |

| Industrial Standards | 68 | 62 |

| Cost Effective | 61 | 59 |

| IP Compatibility | 45 | 54 |

| Battery Lifetime | 68 | 51 |

| Features | Standard | |||

|---|---|---|---|---|

| ZigBee | WirelessHART | ISA100.11a | WIA-PA | |

| Data Security | High | Very High | Very High | Very High |

| Scalability | Medium | High | High | High |

| Power Usage | Low | Low | Low | Low |

| Data Transfer Rate | Low (20–250 kbps) | |||

| Network Topology | Star/Mesh/Tree | Star/Mesh | Star/Mesh | Hybrid |

| Data Reliability | Low | Very High | Very High | Very High |

| Routing Capability | Limited | Full | Full/Limited | Limited |

| Channel Hopping | No | Yes | Yes | Yes |

| Frequency channels | 27 (All Bands) | 15 (2.4 GHz) | 16 (2.4 GHz) | 16 (2.4 GHz) |

| Manager Architecture | Centralized/ Distributed | Centralized | Centralized | Centralized/ Distributed |

| Category | Latency | Class | Description | End Function | Field Devices |

|---|---|---|---|---|---|

| Safety and Supervisory | 10 ms | Emergency control | Always critical | Emergency shutdown | Vibration sensor Gas sensor Sprinklers |

| Closed-loop Control | 10–100 ms | Regulatory control | Often critical | Field device control | Control valve Flow meter |

| Supervisory control | Mostly non-critical | Control loops optimization | |||

| Monitoring and Control | 100–1000 ms | Open-loop control | Corrective maintenance | Manual process shutdown | Proximity sensor DC motor Relays |

| Alerting systems | Preventive maintenance | Regular maintenance, Field device examinations | |||

| Monitoring systems | Periodic maintenance | Record maintenance, Event sequence recording |

| Wireless Standard | 2012 (%) | 2014 (%) |

|---|---|---|

| WirelessHART | 27 | 25 |

| ISA 100.11a | 10 | 11 |

| Hybrid | 22 | 16 |

| Others (WIA-PA and ZigBee) | 23 | 28 |

| Factory Automation | 13 | 13 |

| Ref. | Process | Field device | T | ST | C | Mo | Challenges Addressed | Results |

|---|---|---|---|---|---|---|---|---|

| [50] | Network analysis | Temperature and Pressure Sensors | M | Network simulator (NS-1) | - | SI | Security (Signal Jamming), Interoperability | WirelessHART and WLAN coexistence investigation and network performance examination |

| [51] | Emerson Smart Wireless Gateway | S | Emerson (AMS Snap-on) | - | RT | Packet loss | Data scheduling and routing analysis for packet drop mitigation | |

| [52] | Sensor nodes | M | Network simulator (NS-2) | - | SI | Latency, Noise | Effects of packet error rate and packet drop analysis | |

| [53] | Sensor node networking experiment | Temperature sensor, XDM2510HE Dust network gateway | L, M, S | WirelessHART network simulator | - | SI, RT | Signal reliability, Latency | WirelessHART network for Dense Reader Environment in industrial monitoring |

| [56] | Laboratory scale open loop process | ABB AC800M | M | TrueTime with MATLAB | PI, PPI | SI | Latency | Reduced the problems caused by clock drift |

| [55] | DC Motor control | Sensor nodes | M | TrueTime with MATLAB | PD | SI | Packet loss, Channel hopping | WirelessHART implementation for sluggish processes |

| [58] | Level Process | Sensor nodes | M | Jitterbug toolbox | LQG | SI | Data reliability | Improving the network reliability and controller design |

| Controller | Model Parameters | Controller Parameters | ||||

|---|---|---|---|---|---|---|

| PI | - | - | - | - | ||

| FOPI | - | - | - | |||

| PPI | - | - | - | |||

| FPPI | - | |||||

| FOPPI | - | - | - | |||

| Smith predictor | K | T | - | |||

| IMC | K | T | - | - | ||

| Ref. | Process | Field Device | T | ST | C | Mo | Challenges Addressed | Results |

|---|---|---|---|---|---|---|---|---|

| [59] | Actuator to sensor communication | Sensor nodes | - | WirelessHART simulator in MATLAB | - | SI | Reliability (Interference minimization) | WirelessHART simulator for large scale networks |

| [61] | DC servo motor control | Virtual sensor nodes | M | TrueTime with OMNET++ in MATLAB | PI | SI | Interoperability | Improving coexistence management for WirelessHART and ISA100.11a |

| [62] | Unstable batch reactor | Sensor nodes | L | Network simulator | PI | SI | Stability | Stabilized routing configuration using a hybrid approach for non-linear systems and time-varying transmissions |

| [11] | Network analysis on industrial process models | XDM2510H WirelessHART RF Module | - | WirelessHART simulator in MATLAB | PID | SI | Link reliability, Latency | Effective design of an EWMA filter to mitigate packet dropout and link delay |

| [63] | Test bed of TelosB mote | Chipcon CC2420 | M | TinyOS 2.2, TOSSIM | - | SI | Link reliability, Channel Hopping | Time window allocation for real-time scheduling to reduce resource usage and enhancing the scalability |

| [64] | Laboratory scale testing | Freescale MC1321x evaluation toolkit | M | ANSI C in HCS08 | - | RT | Security | Data scheduling and transmission between the field devices to indicate the possibility of monitoring and data transfer |

| [65] | WirelessHART test bench | Rosemount 648 TT | M | Wi-Analys | - | RT | - | Achieving data transfer between the field nodes and the controller via gateway |

| [66] | Steam flow and pressure of Distillation column | Raschig Jaeger RSP-250 | - | PID | RT | Latency analysis, Data reliability | To control the industrial process in WirelessHART network | |

| [67] | DC servo motor | NI-DAC control cards | - | LabVIEW | P | RT | Delay, Packet loss | Performance investigation for the effect of different networks on the control with a simulation study for fixed packet loss case |

| [68] | Industrial process plant | - | - | DeltaV control system | PID, PIDPlus | RT | Data reliability | Designing a control strategy for non-periodic measurement updates from the processes |

| [14] | Pressure process plant | Linear tech Smart Mesh WirelessHART (XG2510HE gateway and XDM2510H node) | M | MATLAB | PI, PPI, FPPI | SI, RT | Predictive characteristics, Packet delay | Controlling a real-time process plant even in presence of noise and packet delay |

| [69] | Distillation column control | Wireless field devices | - | DeltaV PredictPro | PID, MPC | RT | Predictive characteristics | To control the industrial process with real-time data prediction for packet loss compensation |

| [71] | Network simulation | Sensor nodes | - | TrueTime with MATLAB | PID | SI | Packet drop | Simulation study on wired and wireless networked control system under various packet loss conditions |

| [72] | WirelessHART mote (DC9003A) Eterna Interface card (DC9006A) | M | SmartMesh API Explorer stack with MATLAB | PID | SI | Network delay | Network induced delays measurement technique and its effects on a pilot process plant | |

| [48] | Level Flow, Heat and pressure process plants | Linear Technology WirelessHART Modules | M | MATLAB | PID, MPC | SI, RT | Latency, Data reliability | Even under model mismatch and packet delay variation, the controller is designed to keep the process control loop as a stable one |

| [73] | Network analysis | AwiaTech WirelessHART evaluation kit | L, M, S | AwiaTech WirelessHART simulator | - | SI, RT | Latency, Data reliability, Interference | Examined the joining time for each node and their effect on the distance between them |

| [37] | Industrial processes transfer functions | Linear tech Smart Mesh WirelessHART (XG2510HE gateway, XDM2510H node) | - | WirelessHART hardware-in- the-loop simulator with MATLAB | PI, Smith predictor, Set-point weighted PI | SI, RT | Stochastic delay, Noise | Controller implementation in WirelessHART network under model mismatch, stochastic delay, and noise conditions |

| [74] | Flow process | SmartMesh WirelessHART kit | - | SmartMesh API Explorer stack with MATLAB | PI, PID, Fuzzy PID | RT | Network delay | Investigations on the effects of using wired and WirelessHART motes on the control performance on pilot process plant |

| [75] | Tennessee Eastman (TE) Plant | Sensor nodes | M | OMNET++ wireless network simulator | - | SI | Packet errors, Packet drop, Link failure | Performance study of WirelessHART networks on a TE plant in the presence of packet errors and packet drop |

| [76] | Flow and Level process | WirelessTHUM adaptor | - | LabVIEW and Emerson Smart Wireless Gateway | PID | RT | Network delay | Cascaded PID controller is designed and experimented to handle network induced delay and disturbance |

| [77] | Teleoperated system | - | - | MATLAB and SystemC | - | SI | Packet loss, Delay | Networked control systems co-simulations for time synchronization and error tracking |

| [78] | Batch reactor | - | M | WirelessHART simulator | LQR | SI | Packet scheduling and transmission | Scheduling and routing in a WirelessHART networked control system with controller co-design |

| [79] | Valve actuation control | Emerson 1420A | M | HART UDP interface with C++ | PID | RT | Latency | Investigation of control valve positioning using a PID controller in a WirelessHART environment |

| [80] | Wireless sensor network testbed | TelosB motes with Chipcon CC2420 | M | WirelessHART network simulator | - | SI | Latency, Interference | Determining the packet schedulability of real-time data flow based on new network model map |

| [81] | Network analysis | Virtual sensor nodes | Random | MATLAB | - | SI | Data scheduling, Latency | Examination of the problem in joint transmission scheduling and channel allocation to minimize end-to-end delay |

| [82] | S, M, T | NS-2 simulator and OPNET simulator | - | SI | Delay, Energy consumption | Performance comparison of different industrial wireless sensor network protocols | ||

| [83] | Rosemount —1420 Rosemount —3051S | S, M | DeltaV and Emerson Smart Wireless Gateway | PID | SI, RT | Latency, Packet drop, Noise | New controller design to overcome network delay and packet dropout even in a noisy environment | |

| [84] | Industrial process transfer functions | WirelessHART mote (DC9003A) Eterna Interface card (DC9006A) | M | SmartMesh API Explorer with MATLAB | Fuzzy Set-point weighted PI | SI | Latency, Packet drop | Mitigation of network delay and packet drop in the closed-loop process using a Fuzzy Adaptive Set-point Weighting Controller |

| [85] | Flow process | SmartMesh WirelessHART kit, T-click board with Arduino | - | MATLAB | PI, Smith predictor, Fuzzy PID | RT | Packet delay, Latency | Implementation of locally developed WirelessHART adaptors in the pilot process plant and performance comparison of various controllers |

| [86] | Industrial process transfer functions | Virtual sensor nodes | M | Python | PID | SI | Network load, Link reliability, Latency | Examination of variable payload message length effects in round trip delay measurements |

| [87] | Transfer function of thermal chamber process | Linear tech Smart Mesh WirelessHART kit (XG2510HE gateway, XDM2510H node) | - | MATLAB | Smith predictor, PI, PPI | SI | Delay, Noise, Disturbance | New controller performance analysis over a variable network delay, external noise, and process dead-time |

| [88] | Valve control | Rosemount 702, Fisher 4320 on/off valve, AwiaTech WirelessHART Evaluation Kit | S | Emerson Process Management | P | RT | Latency, Data Reliability, Signal Interference | Comparative study of WirelessHART and wired Foundation Fieldbus for valve control |

| [89] | Flow process | Fisher 4320 wireless position transmitter | - | DeltaV control system | PID, PIDPlus | RT | Delay | Experimentation of valve position control using a PIDPlus controller in a WirelessHART network for the flow process |

| [90] | Production decision and supporting system (PDSS) | 34 TelosB motes with Chipcon CC2410 | M | TinyOS 2.1 with CC2420x radio driver | LQR | RT | Latency, Data transmission | Co-design strategies for a small industrial Cyber–Physical System to enhance communication reliability |

| [91] | Two tank system | Emerson Smart Wireless Gateway kit | - | LabVIEW | - | RT | Delay | Modeling and flow measurement of a coupled tank process based on Laplace transformation with simple linear optimizations to reduce sudden load disturbance and errors |

| Challenges | Limitations/ Problems | Possible Research and Development Solutions |

|---|---|---|

| Battery | Limited power supply Price is proportional to capacity and durability | Sleep scheduling [63,78] Passive data transfer [130,131] Effective data redundancy [78] |

| Memory | Limited memory power for complex processes | Memory optimization and additional memory allocation [63,132,133] |

| Computational power | Confined traditional processor | Usage of modern SRAM and DRAM [134] Current generation processor co-design [58,78,90] |

| Data transmission | Interference Overlapping | Adaptive channeling and multi-hop communication [135,136] Distribute routing protocol [39,137] |

| Delay | Process instability Stochastic delay | Slotted retransmission and scheduled transmissions [138] Priority data access [139] Fault tolerant [53,127] |

| Network traffic | Random transmission Interference and overlapping Data aggregation | Channel scheduling and TDMA slotting [51,81] Estimation and filtering [37,135] (e.g., Kalman, Particle) |

| Controlling | Delay Network/ mote failure | Multi-hop transmission [135,140] Delay compensators [85,87] Model-based predictive controllers [14,48] |

| Security | DoS, QoS Data theft Channel flooding Hacking Signal interference | Data and Network encryption and authentication [71,141,142] Cryptographic keying [100,143] |

| Interoperability | Inadequate standardization Existing numerous protocols | IPv6-based enhancement [47,144] Interoperable node and network development [50,61,145] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Devan, P.A.M.; Hussin, F.A.; Ibrahim, R.; Bingi, K.; Khanday, F.A. A Survey on the Application of WirelessHART for Industrial Process Monitoring and Control. Sensors 2021, 21, 4951. https://doi.org/10.3390/s21154951

Devan PAM, Hussin FA, Ibrahim R, Bingi K, Khanday FA. A Survey on the Application of WirelessHART for Industrial Process Monitoring and Control. Sensors. 2021; 21(15):4951. https://doi.org/10.3390/s21154951

Chicago/Turabian StyleDevan, P. Arun Mozhi, Fawnizu Azmadi Hussin, Rosdiazli Ibrahim, Kishore Bingi, and Farooq Ahmad Khanday. 2021. "A Survey on the Application of WirelessHART for Industrial Process Monitoring and Control" Sensors 21, no. 15: 4951. https://doi.org/10.3390/s21154951

APA StyleDevan, P. A. M., Hussin, F. A., Ibrahim, R., Bingi, K., & Khanday, F. A. (2021). A Survey on the Application of WirelessHART for Industrial Process Monitoring and Control. Sensors, 21(15), 4951. https://doi.org/10.3390/s21154951