Behavioral Modeling of DC/DC Converters in Self-Powered Sensor Systems with Modelica

Abstract

:1. Introduction

1.1. Simulation: Level of Detail vs. Time Scale

1.2. Cycle-to-Cycle vs. Behavioral Modeling

1.3. Power Class of Self-Powered Sensor Systems

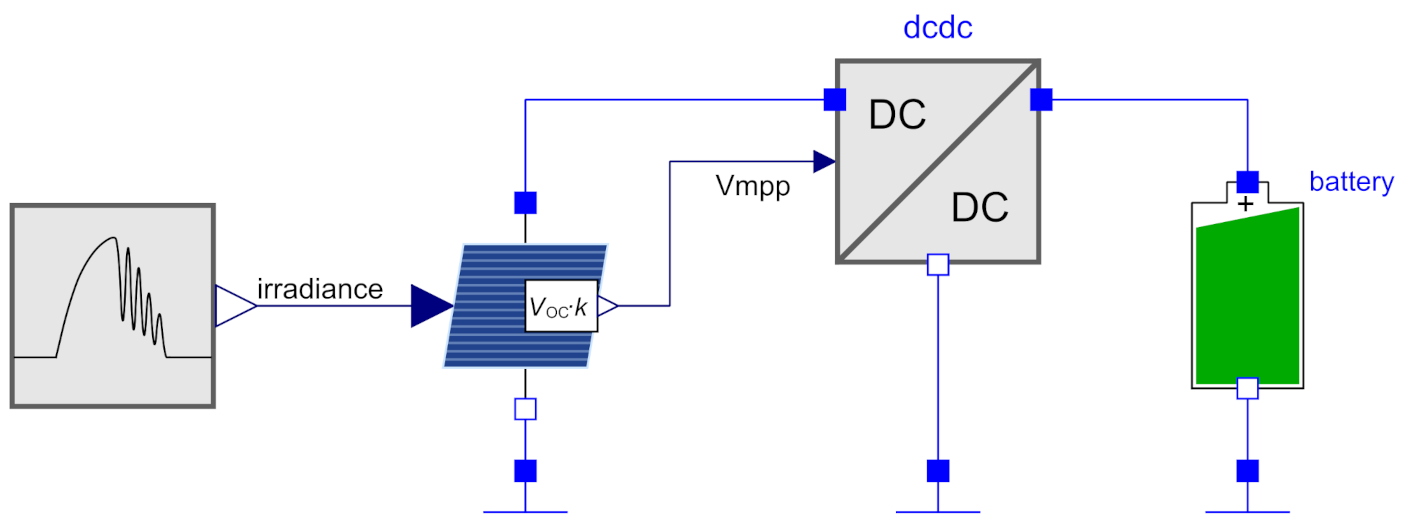

2. Fundamentals of Self-Powered Systems and Power Converters

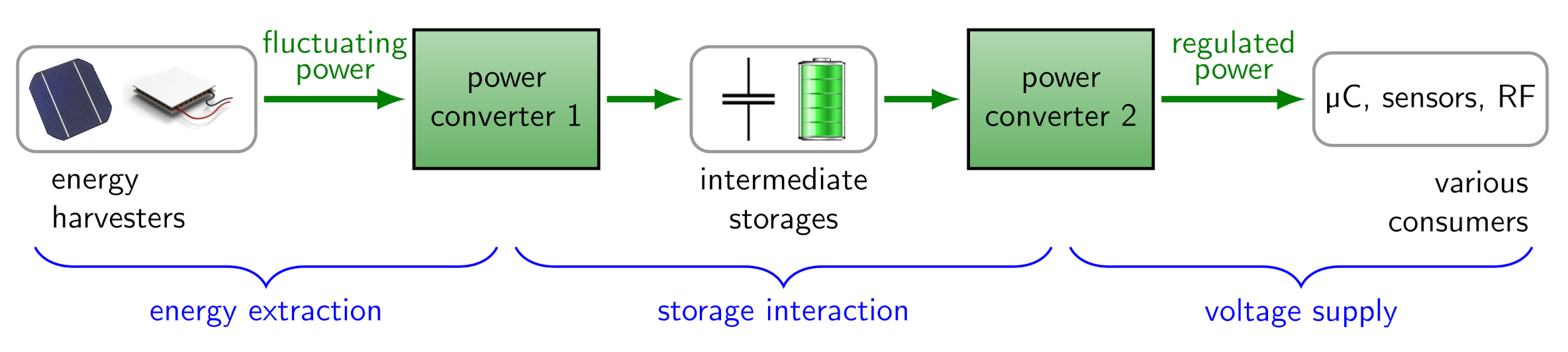

2.1. Structure and Functions a Micro Power Management

- Energy extraction: The output impedance of the harvester varies with the input power due to the environmental fluctuations. To extract as much energy from a harvester as possible, a continuous matching called maximum power point tracking (MPPT) is needed. The first power converter in Figure 1 is typically a step-up converter. For instance, a single solar cell only offers a voltage of about V at the MPP, but a Li-Ion battery has an open-circuit voltage of V.

- Storage interaction (charge and protect): Most secondary batteries (e.g., Li-ion) need a constant-current, constant-voltage charging scheme (CCCV). Due to power fluctuations, this scheme cannot be followed completely, but at least a voltage limiting to prevent under- and over-charge must be implemented in both converters.

- Voltage supply: A regulated constant voltage is required to supply the consumers. The second power converter is typically a step-down converter, as e.g., a low-power microcontroller needs a stable voltage of V, which is below the battery voltage.

2.2. Power Management Integrated Circuits (PMICs)

2.3. Structure of PMIC vs. the Presented Model

3. Related Work

4. Model Scope and Discussion Based upon Modeling Aspects

4.1. Electrical Representation

4.2. Causal Connection of Input and Output

4.3. Efficiency Function and Power Losses

4.4. Feedback Control

4.5. Converter Start-Up and Shutdown

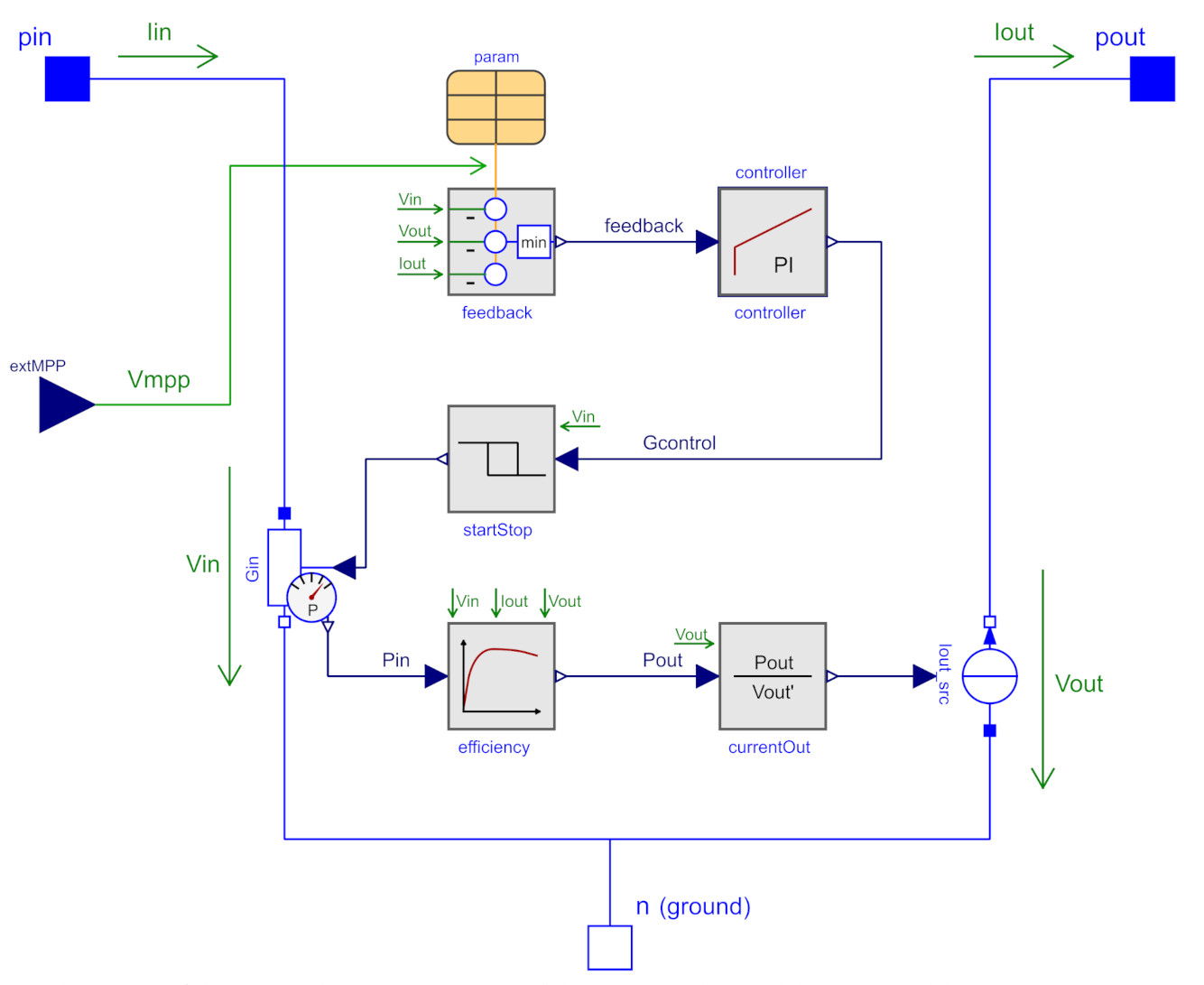

5. The Proposed Behavioral Model

5.1. Overview of the Power Path

5.2. Electrical Representation and Working Principle

5.3. Determination of the Output Current

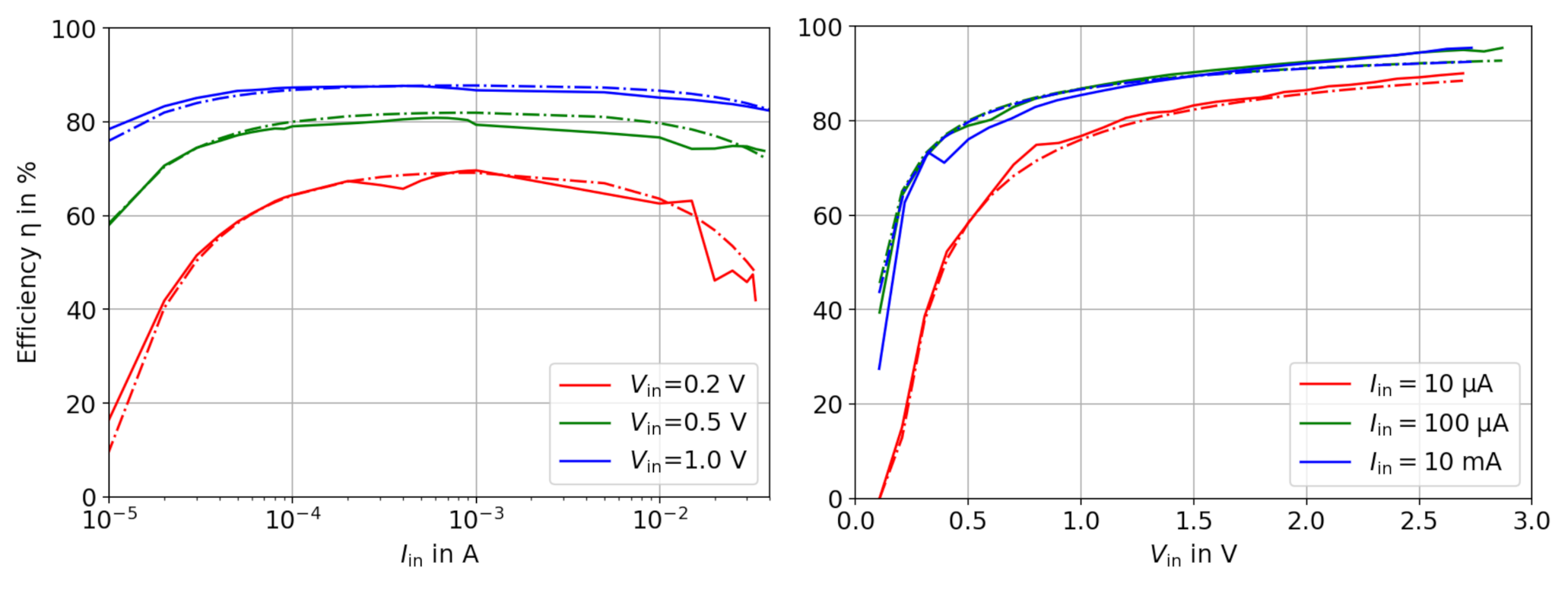

5.4. Efficiency Calculation Based on Power Losses

- The input current sweep shows a plateau with a flat maximum (i.e., ≈ 1 mA for the ADP5090), whereas the input voltage sweep is monotonically increasing without a clear maximum.

- The curves in the current sweep show a similar shape, but the higher Vin, the higher the efficiency. This can be explained by the fact that the -to- ratio moves closer to 1, which causes fewer losses.

- In both graphs, the efficiency drops rapidly for very small input powers. The behavior is similar even if and are swept independently of each other.

- Only in the sweep, the efficiency decreases for high input currents. It will be especially dominant if the input voltage is small. There is no comparable slope at the ”right side” in the graph.

5.4.1. Power Loss Proportional to

5.4.2. Power Loss Proportional to

5.4.3. Constant Power Loss

5.4.4. Power Loss Proportional to

5.5. Overview of the Control Path

5.6. Minimum Start-Up and Working Voltage

5.7. Feedback Error Determination and Setpoints

5.8. Closed-Loop Feedback by a PI Controller

5.9. Operation at the Maximum Power Point

6. Simulation Setup

7. Results

7.1. Simulation Performance

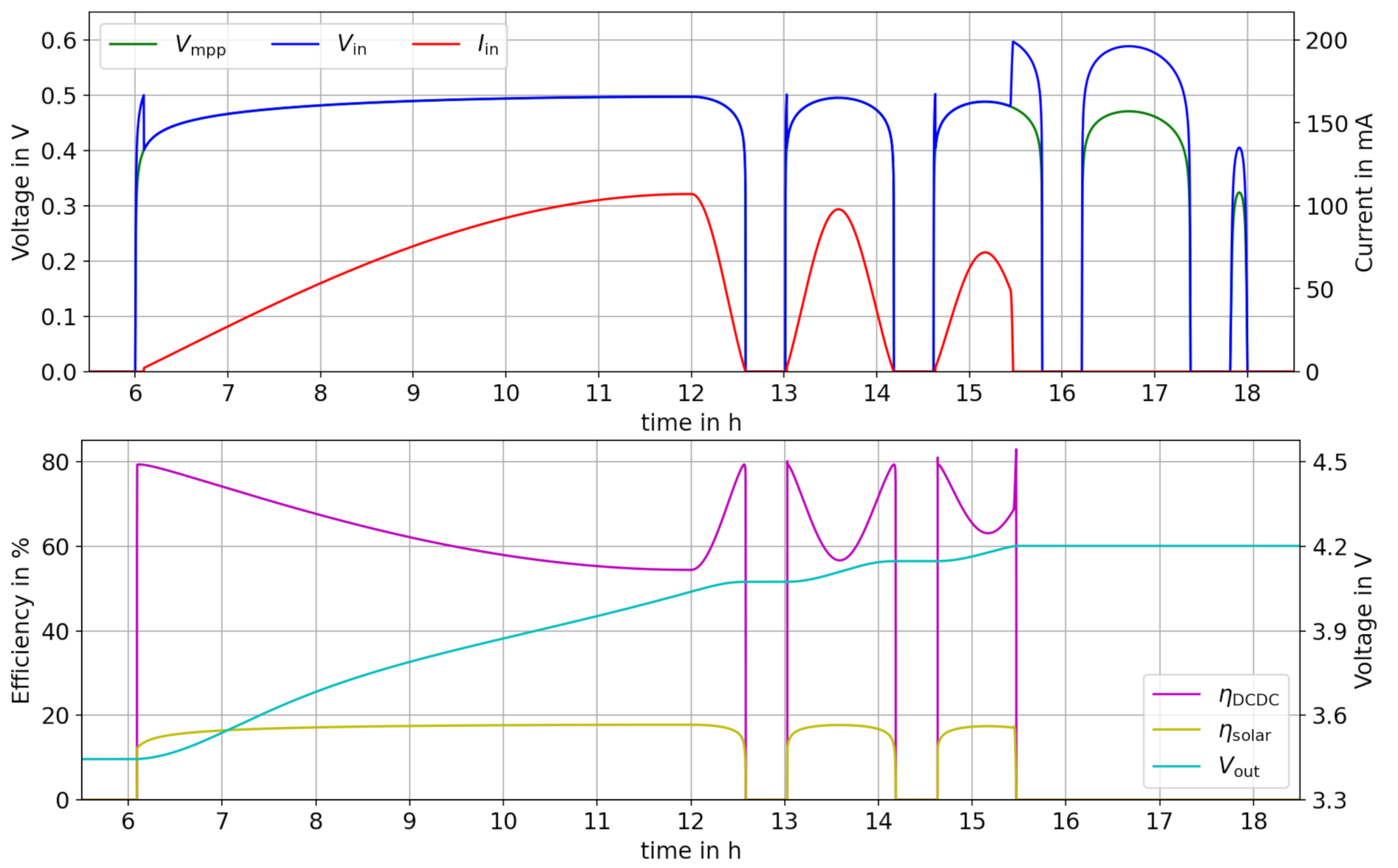

7.2. Behavior Discussion

8. Discussion

9. Conclusions

- The model implements a complete start-stop behavior with minimum working voltage and the cold-start voltage .

- The converter efficiency is modeled as a function, which is based on losses and depends on and . The loss terms are carefully selected to easily extract the parameters from the manufacturer’s datasheet.

- The closed-loop controller allows three modes of operation: CV (constant-voltage output), CC (constant-current output) and MPP (following the maximum power point by regulating Vin).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCCV | constant-current, constant-voltage (charging scheme) |

| DAE | differential algebraic equation |

| DC | direct current (opposite of AC = alternating current) |

| EH | energy harvesting |

| FOCV | fractional open-circuit voltage (method) |

| MPP | maximum power point |

| PMIC | power management integrated circuit |

| PI | proportional–integral (controller) |

| P&O | perturb and observe (method) |

| WSN | wireless sensor nodes |

References

- Tang, X.; Wang, X.; Cattley, R.; Gu, F.; Ball, A.D. Energy harvesting technologies for achieving self-powered wireless sensor networks in machine condition monitoring: A review. Sensors 2018, 18, 4113. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Magno, M.; Brunelli, D.; Sigrist, L.; Andri, R.; Cavigelli, L.; Gomez, A.; Benini, L. InfiniTime: Multi-sensor wearable bracelet with human body harvesting. Sustain. Comput. Inform. Syst. 2016, 11, 38–49. [Google Scholar] [CrossRef]

- Kim, J.; Lynch, J.P. Experimental analysis of vehiclebridge interaction using a wireless monitoring system and a two-stage system identification technique. Mech. Syst. Signal Process. 2012, 28, 3–19. [Google Scholar] [CrossRef]

- Raghunathan, V.; Kansal, A.; Hsu, J.; Friedman, J.; Srivastava, M. Design considerations for solar energy harvesting wireless embedded systems. In Proceedings of the 4th International Symposium on Information Processing in Sensor Networks, IPSN, Boise, ID, USA, 15 April 2005; Volume 2005, pp. 457–462. [Google Scholar]

- Kokert, J.; Beckedahl, T.; Reindl, L.M. Evaluating Micro-Power Management of Solar Energy Harvesting using a Novel Modular Platform. J. Phys. Conf. Ser. 2016, 773, 12042. [Google Scholar] [CrossRef]

- Kokert, J.; Beckedahl, T.; Reindl, L.M. Medlay: A reconfigurable micro-power management to investigate self-powered systems. Sensors 2018, 18, 259. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dondi, D.; Bertacchini, A.; Brunelli, D.; Larcher, L.; Benini, L. Modeling and optimization of a solar energy harvester system for self-powered wireless sensor networks. IEEE Trans. Ind. Electron. 2008, 55, 2759–2766. [Google Scholar] [CrossRef]

- Mellit, A.; Rezzouk, H.; Messai, A.; Medjahed, B. FPGA-based real time implementation of MPPT-controller for photovoltaic systems. Renew. Energy 2011, 36, 1652–1661. [Google Scholar] [CrossRef]

- Stoecklin, S.; Yousaf, A.; Gidion, G.; Reindl, L.; Rupitsch, S.J. Simultaneous power feedback and maximum efficiency point tracking for miniaturized rf wireless power transfer systems. Sensors 2021, 21, 2023. [Google Scholar] [CrossRef] [PubMed]

- Jirgl, M.; Bradac, Z.; Fiedler, P. Testing the E-PEAS Energy Management circuit for Embedded Systems. IFAC-PapersOnLine 2018, 51, 432–437. [Google Scholar] [CrossRef]

- Modelica Association. The Modelica Standard Library v4.0. 2020. Available online: https://modelica.org/ (accessed on 4 July 2021).

- Torrey, D.; Selamogullari, U. A Behavioral Model for DC-DC Converter using Modelica. In Proceedings of the 2nd International Modelica Conference, Oberpfaffenhofen, Germany, 18–19 March 2002; pp. 167–172. [Google Scholar]

- Brkic, J.; Ceran, M.; Elmoghazy, M.; Kavlak, R.; Haumer, A.; Kral, C. Open Source PhotoVoltaics Library for Systemic Investigations. In Proceedings of the 13th International Modelica Conference, Regensburg, Germany, 4–6 March 2019; Volume 157, pp. 41–50. [Google Scholar]

- Haumer, A.; Kral, C. The New EDrives Library: A Modular Tool for Engineering of Electric Drives. In Proceedings of the 10th International Modelica Conference, Lund, Sweden, 10–12 March 2014; Volume 96, pp. 155–163. [Google Scholar]

- Oliver, J.A.; Prieto, R.; Romero, V.; Cobos, J.A. Behavioral modeling of multi-output DC-DC converters for large-signal simulation of distributed power systems. In Proceeding of the 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006. [Google Scholar]

- Behrmann, T.; Budelmann, C.; Bosse, S.; Lehmhus, D.; Lemmel, M.C. Tool chain for harvesting, simulation and management of energy in Sensorial Materials. J. Intell. Mater. Syst. Struct. 2013, 24, 2245–2254. [Google Scholar] [CrossRef]

- Gragger, J.V.; Giuliani, H.; Kral, C.; Bauml, T.; Kapeller, H.; Pirker, F. The SmartElectricDrives Library—Powerful Models for Fast Simulations of Electric Drives. In Proceedings of the 5th International Modelica Conference, Vienna, Austria, 4–5 September 2006. [Google Scholar]

- Shrivastava, A.; Calhoun, B.H. A DC-DC Converter Efficiency Model for System Level Analysis in Ultra Low Power Applications. J. Low Power Electron. Appl. 2013, 3, 215–232. [Google Scholar] [CrossRef] [Green Version]

- Aloisi, W.; Palumbo, G. Efficiency model of boost dc-dc PWM converters. Int. J. Circuit Theory Appl. 2005, 33, 419–432. [Google Scholar] [CrossRef]

- Texas Instruments. BQ25570 Datasheet—Nano Powerboost Charger and Buck Converter for Energy Harvester Powered Applications; Texas Instruments: Dallas, TX, USA, 2013. [Google Scholar]

- Kokert, J. A Modelica Library to Model and Simulate Energy Harvesting Powered Wireless Sensor Nodes (EH-WSN). 2021. Available online: https://github.com/jankokert/EnergyHarvestingWSN (accessed on 4 July 2021).

- Analog Devices. ADP5090 Datasheet—Ultralow Power Boost Regulator with MPPT and Charge Management; Analog Devices: Norwood, MA, USA, 2015. [Google Scholar]

- Tremblay, O.; Dessaint, L.A.; Dekkiche, A.I. A generic battery model for the dynamic simulation of hybrid electric vehicles. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 284–289. [Google Scholar]

- Tiller, M.; Winkler, D. A Searchable Index of All Known Freely Available Modelica Libraries. 2021. Available online: https://modelica.org/ (accessed on 4 July 2021).

- Felgner, F.; Exel, L.; Nesarajah, M.; Frey, G. Component-oriented modeling of thermoelectric devices for energy system design. IEEE Trans. Ind. Electron. 2014, 61, 1301–1310. [Google Scholar] [CrossRef]

| Authors | Electrical Representation | Input Behavior and Start-Up | Feedback Control | Efficiency | Operation at MPP |

|---|---|---|---|---|---|

| Torrey et al. [12] | In: current sink Out: current source | ; but no start-up | commanded ; limited | const. value + input resistor | n/a |

| Brkic et al. [13] | In: voltage source Out: current source | not modeled | commanded | const., 100% | by external vDCRef |

| Haumer et al. [14] | In: current sink Out: voltage source | not modeled | commanded | const., 100% | n/a |

| Oliver et al. [15] | In: current sink Out: voltage source | remote on/off by state diagram | n/a | look-up table | n/a |

| Behrmann et al. [16] | In/Out: generic power ports | not modeled | n/a | look-up table | n/a |

| this work | In: conductance Out: current source | and | commanded , , | function based on power losses | by external |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kokert, J.; Reindl, L.M.; Rupitsch, S.J. Behavioral Modeling of DC/DC Converters in Self-Powered Sensor Systems with Modelica. Sensors 2021, 21, 4599. https://doi.org/10.3390/s21134599

Kokert J, Reindl LM, Rupitsch SJ. Behavioral Modeling of DC/DC Converters in Self-Powered Sensor Systems with Modelica. Sensors. 2021; 21(13):4599. https://doi.org/10.3390/s21134599

Chicago/Turabian StyleKokert, Jan, Leonhard M. Reindl, and Stefan J. Rupitsch. 2021. "Behavioral Modeling of DC/DC Converters in Self-Powered Sensor Systems with Modelica" Sensors 21, no. 13: 4599. https://doi.org/10.3390/s21134599

APA StyleKokert, J., Reindl, L. M., & Rupitsch, S. J. (2021). Behavioral Modeling of DC/DC Converters in Self-Powered Sensor Systems with Modelica. Sensors, 21(13), 4599. https://doi.org/10.3390/s21134599