Sensor Fusion with NARX Neural Network to Predict the Mass Flow in a Sugarcane Harvester

Abstract

1. Introduction

2. Materials and Methods

2.1. Mass Flow Prediction

2.1.1. Sensor Calibration

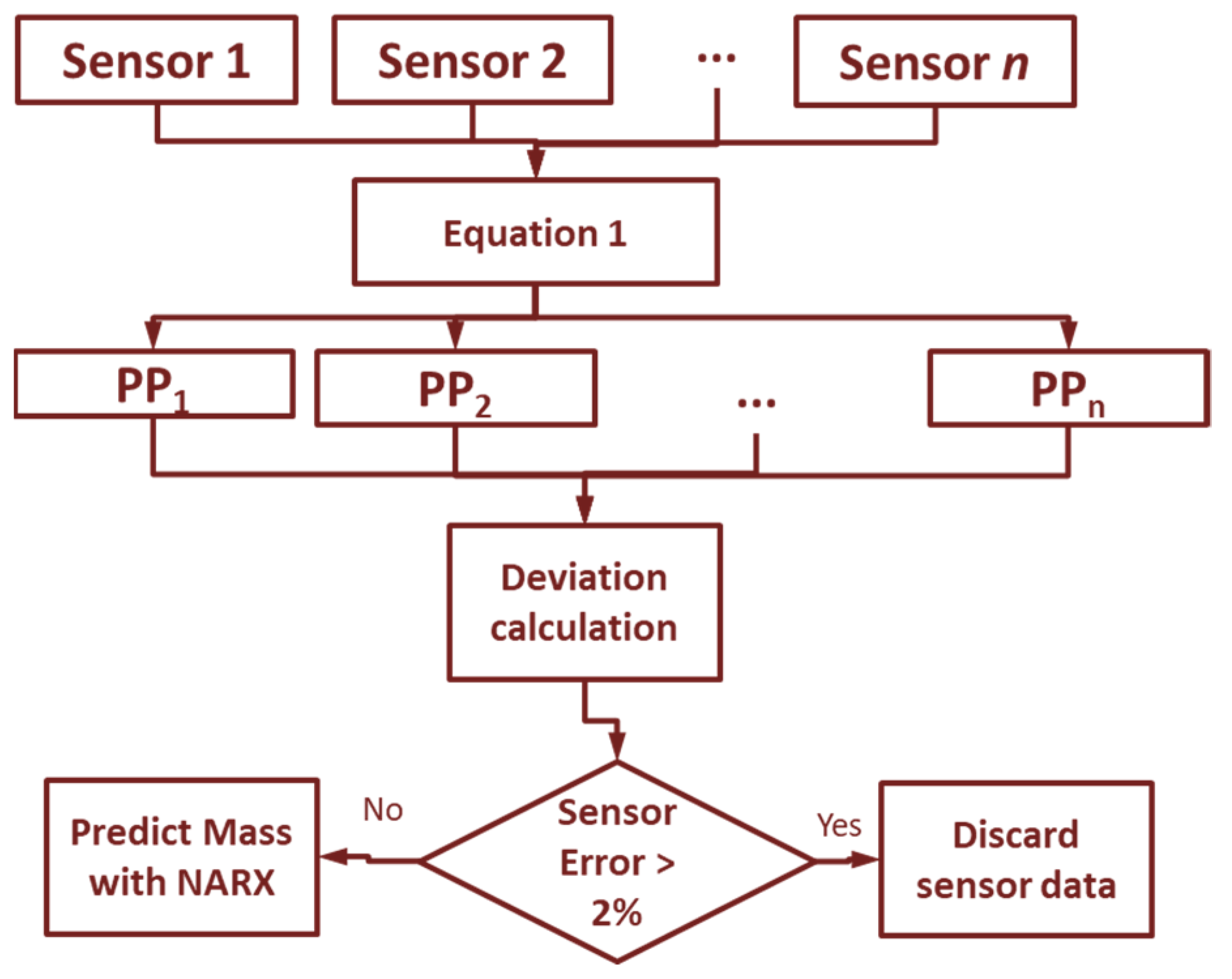

2.1.2. Sensor Self-Calibration Approach

2.1.3. Sensor Fusion

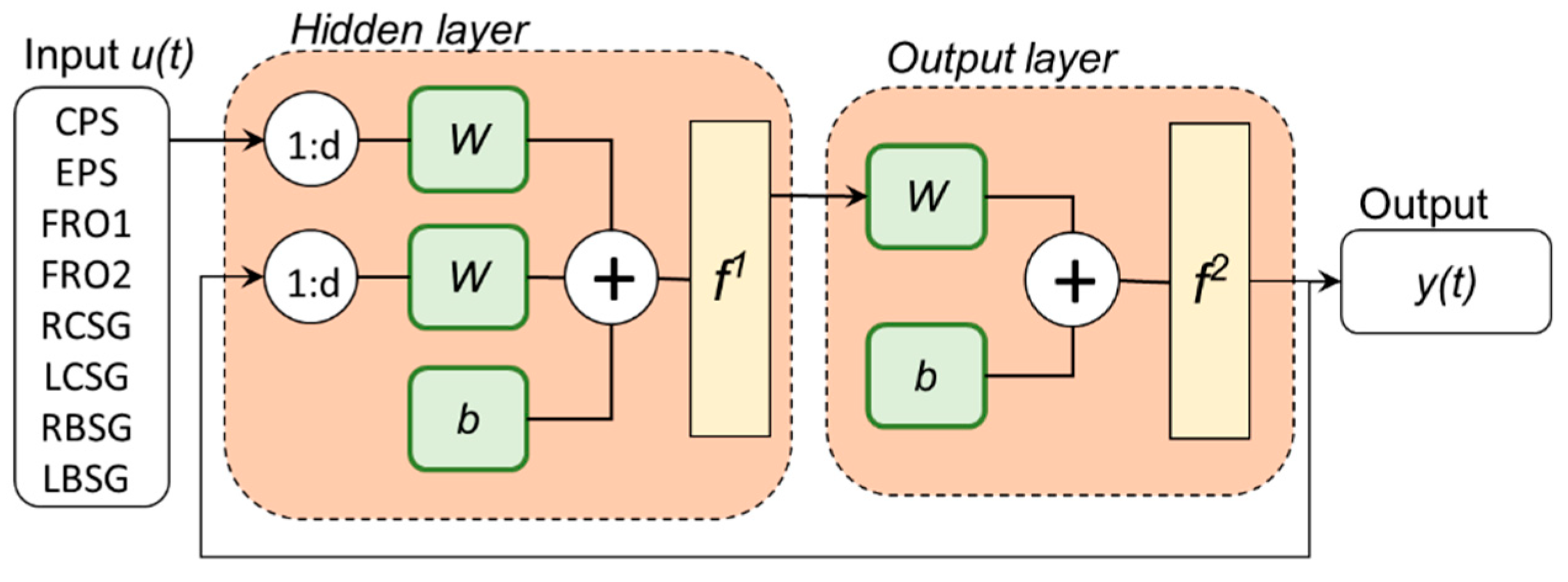

NARX Neural Network

Multiple Linear Regression

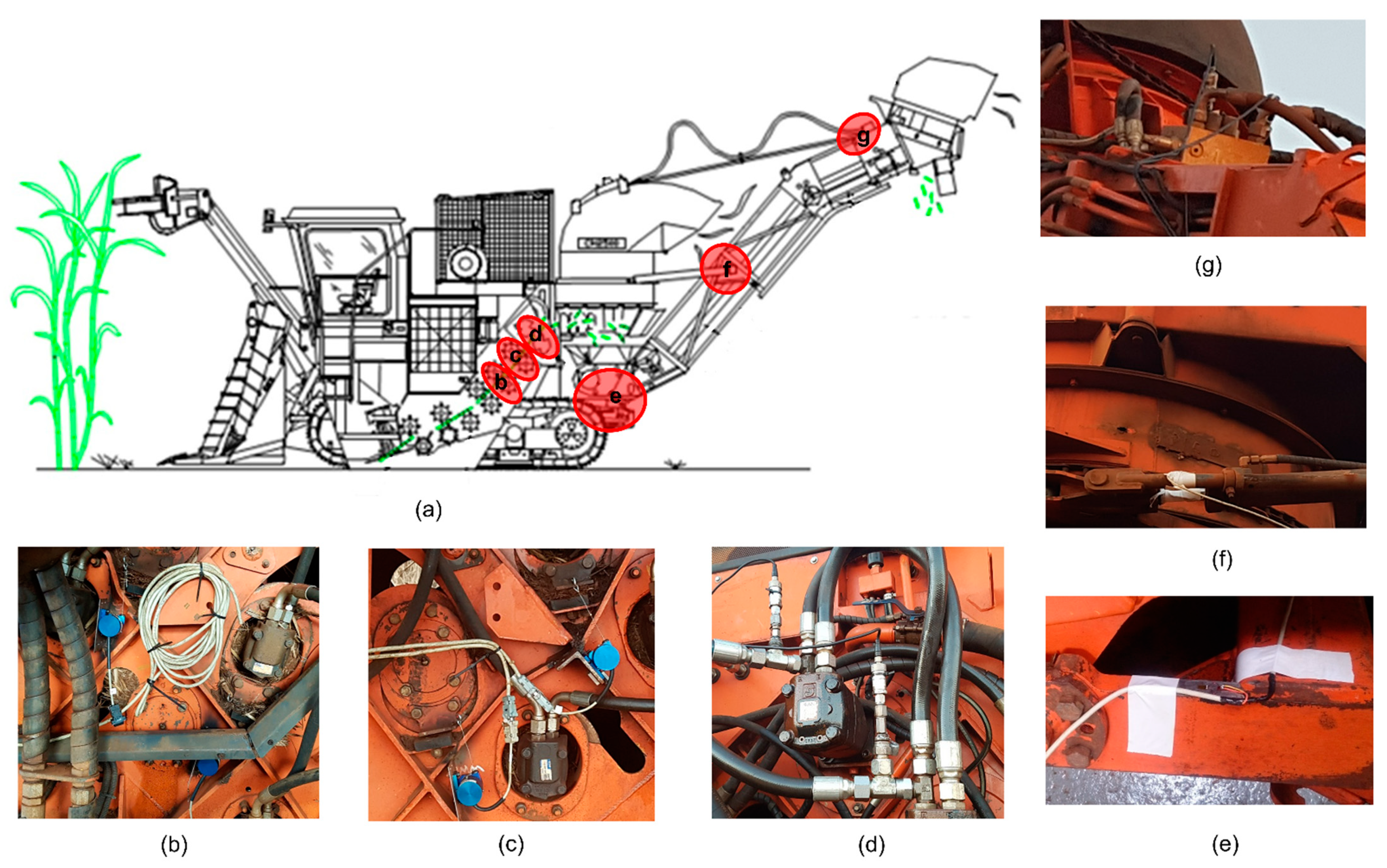

2.2. Harvester Instrumentation

2.2.1. Pressure Sensor

2.2.2. Strain Gauges Sensor

2.2.3. Displacement Sensor

2.3. Data Collection

2.4. Pre-Processing and Training Models

2.5. Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramos, C.R.G.; Pereira Lanças, K.; Albuquerque de Lyra, G.; Millani, T.M. Qualidade da colheita mecanizada de cana-de-açúcar em função da velocidade de deslocamento e rotação do motor da colhedora. Rev. Energ. Agric. 2014, 29, 87–94. [Google Scholar] [CrossRef]

- Ma, S.; Karkee, M.; Scharf, P.A.; Zhang, Q. Sugarcane harvester technology: A critical overview. Appl. Eng. Agric. 2014, 30, 727–739. [Google Scholar] [CrossRef]

- Xavier, W.D.; Silva, D.C.; da Costa, R.B.; Ribeiro, D.O.; Sousa, V.S.; João, J.V. Losses in the mechanized harvesting of sugarcane as of speed function of two harvester models in tropical savanna environment. Aust. J. Crop Sci. 2020, 14, 675–682. [Google Scholar] [CrossRef]

- da Silva, M.J.; de Lucas, L.; Correa, M.H.F.; de Souza, C.H.W. Quality Indexes and Performance in Mechanized Harvesting of Sugarcane at a Burnt Cane and Green Cane. Sugar Tech 2021. [Google Scholar] [CrossRef]

- Sanches, G.M.; Graziano Magalhães, P.S.; Junqueira Franco, H.C. Site-specific assessment of spatial and temporal variability of sugarcane yield related to soil attributes. Geoderma 2019, 334, 90–98. [Google Scholar] [CrossRef]

- Canata, T.F.; Chan, M.; Wei, F.; Maldaner, L.F.; Molin, J.P. Sugarcane Yield Mapping Using High-Resolution Imagery Data and Machine Learning Technique. Remote Sens. 2021, 13, 232. [Google Scholar] [CrossRef]

- Cox, G.; Cox, D.R.V.; Zillman, S.R.; Pax, R.A.; Bakker, D.M.; Harris, H.D. Mass Flow Rate Sensor for Sugar Cane Harvester. U.S. Patent No. 6,508,049, 21 January 2003. [Google Scholar]

- Cox, G.J. A Yield Mapping System for Sugar Cane Chopper Harvesters. Ph.D. Thesis, Uiversity of Southern Queensland, Toowoomba, Austrlia, 2002. [Google Scholar]

- Magalhães, P.S.G.; Cerri, D.G.P. Yield Monitoring of Sugar Cane. Biosyst. Eng. 2007, 96, 1–6. [Google Scholar] [CrossRef]

- Price, R.R.; Johnson, R.M.; Viator, R.P.; Larsen, J.; Peters, A. Fiber Optic Yield Monitor for a Sugarcane Harvester. Trans. ASABE 2011, 54, 31–39. [Google Scholar] [CrossRef]

- Quaderer, J.G.; Cash, M.F. Sugarcane Yield Mapping. U.S. Patent n. 8,955,402, 17 February 2015. [Google Scholar]

- Darr, M.J.; Corbett, D.J.; Herman, H.; Vallespi-Gonzalez, C.; Dugas, B.E.; Badino, H. Yield Measurement and Base Cutter Height Control Systems for a Harvester. U.S. Patent n. 10,371,561, 6 August 2019. [Google Scholar]

- Momin, M.A.; Grift, T.E.; Valente, D.S.; Hansen, A.C. Sugarcane yield mapping based on vehicle tracking. Precis. Agric. 2019, 20, 896–910. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Corrêdo, L.d.P.; Canata, T.F.; Molin, J.P. Predicting the sugarcane yield in real-time by harvester engine parameters and machine learning approaches. Comput. Electron. Agric. 2021, 181, 105945. [Google Scholar] [CrossRef]

- Abbas, I.; Liu, J.; Faheem, M.; Noor, R.S.; Shaikh, S.A.; Solangi, K.A.; Raza, S.M. Different sensor based intelligent spraying systems in Agriculture. Sens. Actuators A Phys. 2020, 316, 112265. [Google Scholar] [CrossRef]

- Emmi, L.; Le Flécher, E.; Cadenat, V.; Devy, M. A hybrid representation of the environment to improve autonomous navigation of mobile robots in agriculture. Precis. Agric. 2021. [Google Scholar] [CrossRef]

- Kanagasingham, S.; Ekpanyapong, M.; Chaihan, R. Integrating machine vision-based row guidance with GPS and compass-based routing to achieve autonomous navigation for a rice field weeding robot. Precis. Agric. 2020, 21, 831–855. [Google Scholar] [CrossRef]

- Milella, A.; Reina, G.; Nielsen, M. A multi-sensor robotic platform for ground mapping and estimation beyond the visible spectrum. Precis. Agric. 2019, 20, 423–444. [Google Scholar] [CrossRef]

- Jang, J.S.R.; Sun, C.T. Neuro-Fuzzy Modeling and Control. Proc. IEEE 1995, 83, 378–406. [Google Scholar] [CrossRef]

- Thai, C.N.; Shewfelt, R.L. Modeling sensory color quality of tomato and peach. Neural networks and statistical regression. Trans. Am. Soc. Agric. Eng. 1991, 34, 950–955. [Google Scholar] [CrossRef]

- Pham, H.T.; Tran, V.T.; Yang, B.S. A hybrid of nonlinear autoregressive model with exogenous input and autoregressive moving average model for long-term machine state forecasting. Expert Syst. Appl. 2010, 37, 3310–3317. [Google Scholar] [CrossRef]

- Runge, J.; Zmeureanu, R. Forecasting energy use in buildings using artificial neural networks: A review. Energies 2019, 12, 3254. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Chan, C.; Li, B.; Song, X. Multi-sensor fusion methodology for enhanced land vehicle positioning. Inf. Fusion 2019, 46, 51–62. [Google Scholar] [CrossRef]

- Aslinezhad, M.; Malekijavan, A.; Abbasi, P. ANN-assisted robust GPS/INS information fusion to bridge GPS outage. Eurasip J. Wirel. Commun. Netw. 2020, 2020, 1–18. [Google Scholar] [CrossRef]

- Andrade, A.; Lopes, K.; Lima, B.; Maitelli, A. Development of a methodology using artificial neural network in the detection and diagnosis of faults for pneumatic control valves. Sensors (Switzerland) 2021, 21, 853. [Google Scholar] [CrossRef]

- Raptodimos, Y.; Lazakis, I. Application of NARX neural network for predicting marine engine performance parameters. Ships Offshore Struct. 2020, 15, 443–452. [Google Scholar] [CrossRef]

- Ali, W.; Khan, W.U.; Raja, M.A.Z.; He, Y.; Li, Y. Design of Nonlinear Autoregressive Exogenous Model Based Intelligence Computing for Efficient State Estimation of Underwater Passive Target. Entropy 2021, 23, 550. [Google Scholar] [CrossRef]

- Ang, M.R.C.O.; Gonzalez, R.M.; Castro, P.P.M. Multiple data fusion for rainfall estimation using a NARX-based recurrent neural network-the development of the REIINN model. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Beijing, China, 2014; Volume 17, p. 012019. [Google Scholar]

- Le, V.M.; Pham, B.T.; Le, T.T.; Ly, H.B.; Le, L.M. Daily Rainfall Prediction Using Nonlinear Autoregressive Neural Network. In Lecture Notes in Networks and Systems; Springer: Singapore, 2020; Volume 106, pp. 213–221. [Google Scholar] [CrossRef]

- Corrêdo, L.d.P.; Canata, T.F.; Maldaner, L.F.; de Lima, J.d.J.A.; Molin, J.P. Sugarcane Harvester for In-field Data Collection: State of the Art, Its Applicability and Future Perspectives. Sugar Tech 2020, 23, 1–14. [Google Scholar] [CrossRef]

- Barcelo-Ordinas, J.M.; Doudou, M.; Garcia-Vidal, J.; Badache, N. Self-calibration methods for uncontrolled environments in sensor networks: A reference survey. Ad Hoc Netw. 2019, 88, 142–159. [Google Scholar] [CrossRef]

- Ferrer-Cid, P.; Barcelo-Ordinas, J.M.; Garcia-Vidal, J.; Ripoll, A.; Viana, M. A Comparative Study of Calibration Methods for Low-Cost Ozone Sensors in IoT Platforms. IEEE Internet Things J. 2019, 6, 9563–9571. [Google Scholar] [CrossRef]

- Chen, S.; Billings, S.A. Neural networks for nonlinear dynamic system modelling and identification. Int. J. Control 1992, 56, 319–346. [Google Scholar] [CrossRef]

- Di Piazza, A.; Di Piazza, M.C.; Vitale, G. Solar and wind forecasting by NARX neural networks. Renew. Energy Environ. Sustain. 2016, 1, 39. [Google Scholar] [CrossRef]

- Xiu, Y.; Zhang, W. Multivariate Chaotic Time Series Prediction Based on NARX Neural Networks. In Advances in Engineering Research; Atlantis Press: Paris, France, 2017; pp. 164–167. [Google Scholar] [CrossRef][Green Version]

- Jung, D.H.; Kim, H.S.; Jhin, C.; Kim, H.J.; Park, S.H. Time-serial analysis of deep neural network models for prediction of climatic conditions inside a greenhouse. Comput. Electron. Agric. 2020, 173, 105402. [Google Scholar] [CrossRef]

- Wendte, K.W.; Skotnikov, A.; Thomas, K.K. Sugar Cane Yield Monitor. U.S. Patent n. 6,272,819, 14 August 2001. [Google Scholar]

- Hernandez, B.; Fernandez, F.; Ponce, E.; Esquivel, M.; Rodriguez, J.; Quintana, L.; Interian, S.; Alvarez, R. Application of precision farming technologies for sugarcane crop. In Proceedings of the 5th European Conference on Precision Agriculture; Heemskerk, C., Engval, M., Eds.; Wageningen Academic Publishers: Wageningen, The Netherlands, 2005; pp. 9–12. [Google Scholar]

- Fernandez, F.; Hernandez, B.; Esquivel, M.; Marrrereo, S.; Ponce, E.; Quintana, L. Yield mapping sugarcane in Australia. In Proceedings of the 6th European Conference on Precision Agriculture, Skiathos, Greece, 7 July 2007; pp. 3–6. [Google Scholar]

- Tukey, J.W. Exploratory Data Analysis; Addison-Wesley Publishing Company: London, UK, 1977. [Google Scholar]

- Zounemat-Kermani, M.; Stephan, D.; Hinkelmann, R. Multivariate NARX neural network in prediction gaseous emissions within the influent chamber of wastewater treatment plants. Atmos. Pollut. Res. 2019, 10, 1812–1822. [Google Scholar] [CrossRef]

- Mustapa, R.F.; Dahlan, N.Y.; Yassin, A.I.M.; Nordin, A.H.M. Quantification of energy savings from an awareness program using NARX-ANN in an educational building. Energy Build. 2020, 215, 109899. [Google Scholar] [CrossRef]

- Zhang, F.; Murphy, M.D.; Shalloo, L.; Ruelle, E.; Upton, J. An automatic model configuration and optimization system for milk production forecasting. Comput. Electron. Agric. 2016, 128, 100–111. [Google Scholar] [CrossRef]

- Murphy, M.D.; O’Mahony, M.J.; Shalloo, L.; French, P.; Upton, J. Comparison of modelling techniques for milk-production forecasting. J. Dairy Sci. 2014, 97, 3352–3363. [Google Scholar] [CrossRef]

- Maldaner, L.F.; Molin, J.P. Data processing within rows for sugarcane yield mapping. Sci. Agrícola 2020, 77, e20180391. [Google Scholar] [CrossRef]

- Xie, L.; Wang, J.; Cheng, S.; Zeng, B.; Yang, Z. Performance Evaluation of a Chopper System for Sugarcane Harvester. Sugar Tech 2019, 21, 825–837. [Google Scholar] [CrossRef]

- Kent, G.A. Issues Associated with Using Trash as a Cogeneration Fuel. Sugar Tech 2014, 16, 227–234. [Google Scholar] [CrossRef]

- Alencastre-Miranda, M.; Davidson, J.R.; Johnson, R.M.; Waguespack, H.; Krebs, H.I. Robotics for Sugarcane Cultivation: Analysis of Billet Quality using Computer Vision. IEEE Robot. Autom. Lett. 2018, 3, 3828–3835. [Google Scholar] [CrossRef]

- Siegelmann, H.T. Stochastic analog networks and computational complexity. J. Complex. 1999, 15, 451–475. [Google Scholar] [CrossRef]

- Sams, B.; Litchfield, C.; Sanchez, L.; Dokoozlian, N. Two methods for processing yield maps from multiple sensors in large vineyards in California. Adv. Anim. Biosci. 2017, 8, 530–533. [Google Scholar] [CrossRef]

- Leroux, C.; Jones, H.; Pichon, L.; Taylor, J.; Tisseyre, B. Automatic harmonization of heterogeneous agronomic and environmental spatial data. Precis. Agric. 2019, 20, 1211–1230. [Google Scholar] [CrossRef]

| Row Number | Train and Test | Validation |

|---|---|---|

| 1 | 389 | 69 |

| 2 | 358 | 63 |

| 3 | 301 | 53 |

| 4 | 309 | 55 |

| 5 | 351 | 62 |

| 6 | 331 | 58 |

| 7 | 344 | 61 |

| 8 | 332 | 59 |

| 9 | 343 | 60 |

| Models Input Variables | Sensor |

|---|---|

| Fusion 1 = {CPS, EPS, FRO1, FRO2, RCSG, LCSG, RBSG, LBSG} | PS, SGS, DPS |

| Fusion 2 = {CPS, EPS, FRO1, FRO2, RCSG, LCSG} | PS, SGS, DPS |

| Fusion 3 = {EPS, RCSG, LCSG} | PS, SGS |

| Fusion 4 = {CPS, FRO1, FRO2} | PS, DPS |

| Fusion 5 = {FRO1, FRO2} | DPS |

| Fusion 6 = {CPS, EPS} | PS |

| Fusion 7 = {RCSG, LCSG, RBSG, LBSG} | SGS |

| Fusion 8 = {EPS} | PS |

| Fusion 9 = {CPS} | PS |

| Models Input Variables | Correlation | RMSE (kg s−1) | MAPE (%) | |||

|---|---|---|---|---|---|---|

| MLR | NARX | MLR | NARX | MLR | NARX | |

| CPS, EPS, FRO1, FRO2, RCSG, LCSG, RBSG, LBSG | 0.63 | 0.99 | 1.6 | 0.3 | 4.9 | 0.7 |

| CPS, EPS, FRO1, FRO2, RCSG, LCSG | 0.62 | 0.98 | 1.6 | 0.4 | 4.9 | 0.8 |

| EPS, RCSG, LCSG | 0.56 | 0.96 | 1.7 | 0.5 | 6.3 | 2.4 |

| CPS, FRO1, FRO2 | 0.50 | 0.97 | 1.8 | 0.5 | 5.4 | 1.3 |

| FRO1, FRO2 | 0.32 | 0.96 | 1.9 | 0.5 | 7.3 | 1.0 |

| CPS, EPS | 0.61 | 0.97 | 1.6 | 0.4 | 5.1 | 1.6 |

| RCSG, LCSG, RBSG, LBSG | 0.17 | 0.93 | 2.0 | 0.7 | 8.8 | 1.2 |

| EPS | 0.49 | 0.95 | 1.8 | 0.6 | 5.7 | 1.2 |

| CPS | 0.56 | 0.94 | 1.7 | 0.6 | 6.5 | 2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lima, J.d.J.A.d.; Maldaner, L.F.; Molin, J.P. Sensor Fusion with NARX Neural Network to Predict the Mass Flow in a Sugarcane Harvester. Sensors 2021, 21, 4530. https://doi.org/10.3390/s21134530

Lima JdJAd, Maldaner LF, Molin JP. Sensor Fusion with NARX Neural Network to Predict the Mass Flow in a Sugarcane Harvester. Sensors. 2021; 21(13):4530. https://doi.org/10.3390/s21134530

Chicago/Turabian StyleLima, Jeovano de Jesus Alves de, Leonardo Felipe Maldaner, and José Paulo Molin. 2021. "Sensor Fusion with NARX Neural Network to Predict the Mass Flow in a Sugarcane Harvester" Sensors 21, no. 13: 4530. https://doi.org/10.3390/s21134530

APA StyleLima, J. d. J. A. d., Maldaner, L. F., & Molin, J. P. (2021). Sensor Fusion with NARX Neural Network to Predict the Mass Flow in a Sugarcane Harvester. Sensors, 21(13), 4530. https://doi.org/10.3390/s21134530