1. Introduction

Non-stationary signals occur in many fields, such as radar system, sonar, speech and mechanical systems [

1]. Effective nonstationary signal processing methods are important for industrial applications. In recent years, scholars have developed some effective methods to characterize time-varying signal properties.

Time-frequency analysis (TFA) [

2] is an effective method to display time-varying instantaneous frequencies (IFs) and time-varying instantaneous amplitudes of nonstationary signal. The traditional TFA methods include linear TFA such as the short-time Fourier transform (STFT), the wavelet transform (WT), and the bilinear/quadratic TFA such as the Wigner Ville distribution (WVD). However, these methods are restricted by the Heisenberg uncertainty principle and cross terms. Time frequency representation (TFR) with insufficient time-frequency resolutions are not providing accurate estimations of nonstationary signal, which essentially restrict their engineering applications. For improving the time-frequency resolutions, the time-frequency reassignment methods are developed, e.g., the synchrosqueezing transform (SST), demodulated SST and synchro-extracting transform (SET) [

3]. The reassignment methods reduce energy spread via assigning the average of energy in a domain to the gravity center of these energy contributions.

It is well known that synchrosqueezed time–frequency representations are concentrated on an IF. However, it is also known that [

4] synchrosqueezed time–frequency representations do not provide better time–frequency resolutions for components that have high time variability, as compared to the original STFT or the WT. The synchrosqueezing just sums all the interferences, presented in the original STFT and the WT, into a more compact frequency region. However, even if the components appear to be more compact, as a result of synchrosqueezed time–frequency representations, this does not mean, that their parameters can be better evaluated. The SST is similar to the original STFT and the WT and, although being perfectly concentrated, does not necessarily provide better resolution properties than the respective original STFT and WT.

Therefore, the “correct” amplitude peaks cannot be identified more easily in SST than in the original STFT and WT. This is due to a serious drawback of synchrosqueezed representations in that, in contrast to the STFT and WT, the peak amplitudes in the synchrosqueezed time–frequency representations are not proportional to the amplitudes of the corresponding spectral component; instead, they are largely determined by the parameters of the used frequency discretization. Therefore, it is known that, even if one estimated component has a smaller amplitude than another, it may still have a much higher peak in the synchrosqueezed time–frequency representations.

Generally, the relationships between the peak amplitudes of synchrosqueezed representation amplitudes of the corresponding spectral component depend on the frequency discretization and these relationships are nonlinear, time-varying, and are dependent on many factors, e.g., possible amplitude and frequency modulation of the component and noise. Hence, the outcomes of IF estimation by SST will also depend on the frequency discretization, amplitude modulation (AM), frequency modulation (FM), and the presence of noise.

This effect is additionally aggravated by the following factor: due to the non-smoothness of the SST, it is hard to apply peak interpolation, so, amplitude peaks remain discrete, and this amplitude discretization also affects the performance of IF evaluation. Due to the above factors, employing SST peak amplitudes for IF estimation can lead to unpredictable unstable results.

Finally, if the SST is used as the postprocessing technique of the STFT, which is not able to efficiently analyze nonstationary signals, the energy concentration of SET spectra will be essentially influenced by time–frequency resolution drawbacks of the STFT, when processing data.

In order to overcome the drawbacks of the SST method and obtain a better time–frequency resolution for strong FM signals, various methods have been developed in recent decades. A generalized SST was proposed [

5] by demodulating the time-varying signal into a purely harmonic version. An iterative generalized SST [

6] was developed to address multi-component signals with distinct FM laws. A matching SST demodulated transform [

7], based on the polynomial or the Fourier series, was proposed to match time-varying IF. For all the above demodulated methods, the exact time-varying FM dependency of the signal is needed in advance. However, due to the complexity of practice diagnosis cases, it is hard to estimate the exact demodulated parameters, especially for AM-FM signals [

8].

A popular method is to use the high-order information of the signal, such as the chirp rate, or frequency acceleration, to enhance the energy concentration for strong FM, which involves second-order SST [

9] and higher order SST [

10]. However, higher-order SST techniques are easy to be affected by noise because they are computed by the high-order derivative of the STFT and the WT. Recently, a new multi-SST (MSST) technique [

11] was presented, which employs an iterative reassignment procedure to concentrate the blurry energy in a step-wise manner. MSST squeezes the time–frequency coefficients into the ridge, i.e., the curve along which the signal energy is locally maximum. However, for the ridge, MSST gives a biased estimate of an IF when dealing with nonlinear frequency modulations; therefore, it is difficult for MSST to estimate IF for nonlinear frequency modulations.

Recently, two methods were proposed to analyze the impulse signals: time-reassigned SST (TSST) [

12] and transient-extracting transform (TET) [

13]. TSST can achieve a concentrated time–frequency representation for strong FM, whose ridge curves are almost parallel to the frequency axis. TET uses a transient-extracting operator that gives a sharper time–frequency representation than the TSST. However, both the TSST and the TET are not suitable for a signal consisting of FM IFs in the presence of noise.

The high-order SST (HSST) was proposed for IF estimation [

14]. However, the computation cost is very high due to the high-order approximation of the FM function.

Synchrosqueezed wavelet transform (SWT) [

15] is a new method. It is called an empirical mode decomposition (EMD)-like tool. The anti-noise ability and time–frequency resolution of the SWT are improved on the basis of the WT. After the WT, the corresponding frequency of each scale is given by the derivative of the WT coefficients with respect to time. The SWT greatly improves the energy divergence and time–frequency resolution of the WT. The SWT retains the advantages of both EMD and WT.

The SWT has been widely studied. Yang analyzed the statistical features of the SWT [

16]. Reconstruction of the SWT was developed by Meignen [

17]. The SWT was extended to the STFT [

18], the wave packet transform [

19], the S-transform [

20], and the curvelet transform [

21]. Nevertheless, the SWT and its extensions are suitable only for signals consisting of weak frequency modulated modes [

22].

It is shown in [

23] that in spite of the improvement in resolution, the SWT fails to identify closely spaced IFs. Their study showed that if the difference in frequency of the two closely spaced IFs is below the sampling rate, the SWT fails to separate them and demands finer sampling of the original signal.

So, in summary, the use of various synchrosqueezing time–frequency representations to IF estimation has multiple essential drawbacks that outweigh its advantage.

In addition, the parameterized TFA methods have been proposed to characterize time–frequency signals using signal-dependent parameters [

24]. These TFA methods provide a way to qualitatively analyze the nonstationary signals. However, qualitative analysis cannot be effectively applied to applications such as IF estimation.

The order analysis has been widely applied in nonstationary signal processing and engineering application [

25]. In traditional order analysis, the data are measured, using special analogue hardware to sample at a rate proportional to the shaft speed. For the computed order analysis (COA), nonstationary signal and rotational speed are measured at a constant rate, and then use a software to resample the signal at constant angular increments. As a result, the time-domain nonstationary signal is transformed into an angular-domain stationary signal, and characteristic components can be quantitatively evaluated via the order spectrum, generated by the fast Fourier transform. The speed sensors require installation space, extra wiring, delicate calibration, regular maintenance, and therefore have additional cost [

26], which seriously limit applications of the COA. For removing restrictions, related to usage of a speed sensors, the IF estimation based COA is developed [

27], in which nonstationary instantaneous rotational frequency (RF) is extracted from TFA of nonstationary signals.

However, the RF related IF is difficult to extract in noise environment. In addition, the essential disadvantage of the COA, is errors in the estimation of the shaft angular position and resampled amplitude [

28], which affects its accuracy.

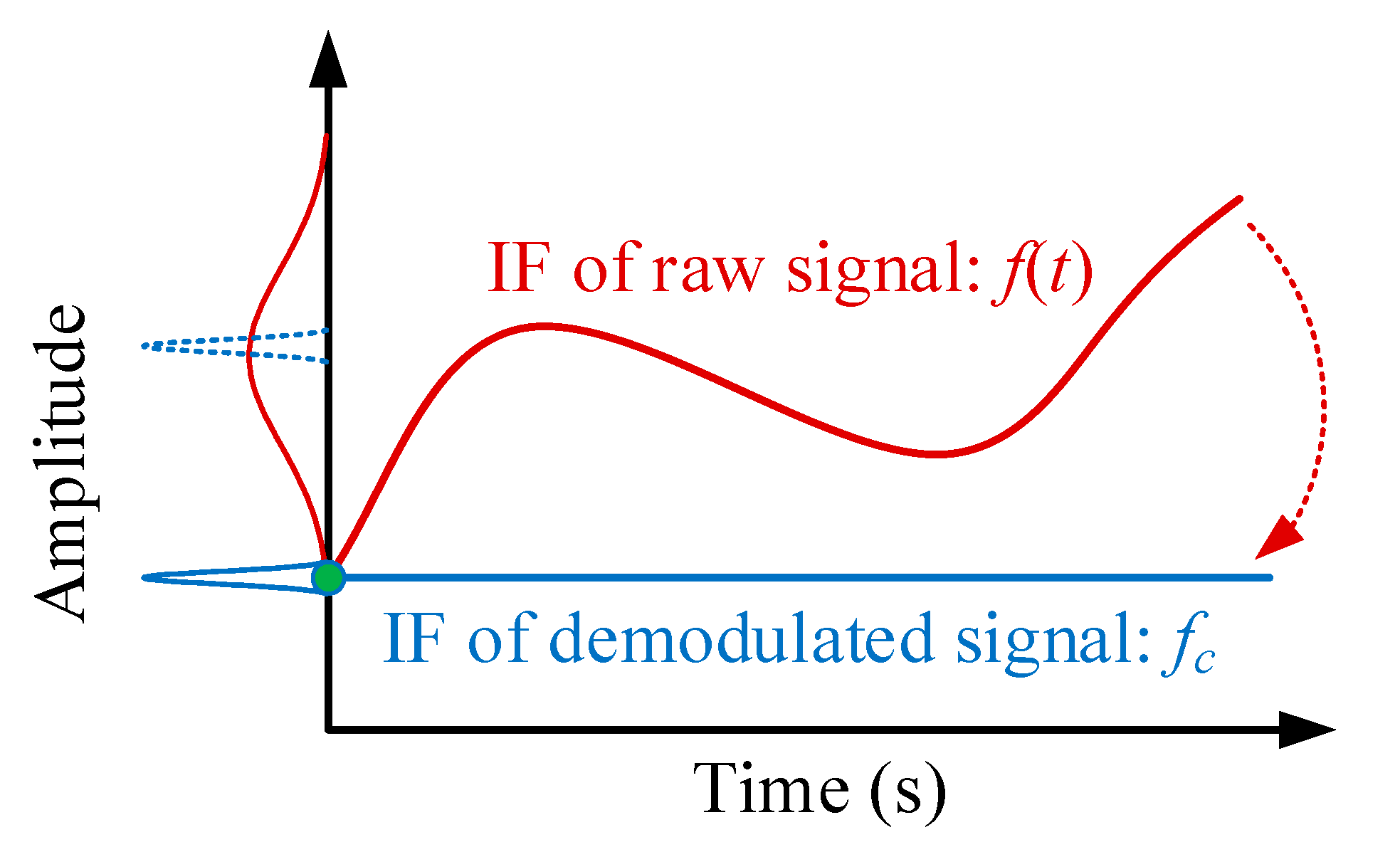

The generalized demodulation transform (GDT) is another non-stationary signal processing method, which is proposed by Olhede [

29]. The GDT can be used to transform a signal with time-varying frequency component into a signal with constant frequency component. Different to the resample in the COA, the conversion process of the GDT is based on the demodulation operator. Hence, the errors, resulting from estimation of the shaft angular position and resampled amplitude can be avoided [

30]. The demodulation operator is calculated via the measured RF or estimated RF. Considering the challenges to separate the overlapped nonstationary multi-component signals, a novel GDT is proposed, based on the GDT [

31].

Cheng [

32] improved the GDT, and it can be used for multi-component signal decomposition. The iterative GDT is developed to transform multi-frequency components [

33]. In the iterative GDT, the true IF curve functions are required, and the multi-frequency curves are transformed into the constant frequency curves. In recent years, the GDT is widely applied in industrial applications, such as fault frequencies detection of bearings and planetary gearboxes under nonstationary conditions [

34]. Cheng [

35] proposed an envelope order spectrum-based GDT to detect gear fault frequencies. In the proposed method, time-varying fault frequencies are transformed into lines, and are also decomposed into some mono-component. However, the demodulation operator is difficult to obtain without a speed sensor. For example, if the signal component with IF, which is used to calculate the demodulation operator, is polluted by noise, it therefore cannot be extracted from the TFR of the original signal.

Based on the above analysis, the IF estimation technique is important for machineries’ fault frequencies detection under nonstationary conditions. The tachometer-free-based methods have attracted scholars’ attention. Feng proposed [

36] an iterative GDT-based energy separation method; the method can be used to process rotational machinery signals with knowledge of true IF dependency. In this method, the GDT is used to separate an interested harmonic, and the harmonic frequency can be extracted. The GDT is applied only one time to the same specific harmonic, and the number of harmonics in a signal defines the number of GDT iterations. These methods are facing the following challenge. In addition to the time-varying IFs, nonstationary signals normally exhibit time-varying instantaneous amplitudes. As a result, frequency components with relatively low amplitudes are easily contaminated by noise, and they therefore cannot be accurately extracted from the TFA by the GDT. The above GDT methods do not consider IFs of components with relatively low amplitudes that are difficult to accurately estimate.

Another challenge is as follows. The GDT transforms a time-varying frequency curve into a constant frequency one, which can be quantitatively characterized by a peak in the spectrum. The transformed frequency curve has a better time–frequency concentration. However, without knowledge of a true IF curve function, the GDT does not produce IF estimations.

In order to address the above-mentioned challenges, the novel IF estimation technology, named multi-generalized demodulation transform (MGDT), is proposed here. The main innovations of the paper are as follows:

A novel IF estimation technology is proposed for IF estimation. The proposed novel technology, MGDT, is based on the GDT and employs the novel proposition of multiple adaptive iterations of the GDT for a specific signal component to concentrate blurry TFR energy in a step-wise manner. A theoretical basis of the novel IF estimation technology is created. A novel termination criterion, that could control iterations of the MGDT method, is also proposed. By iteratively and adaptively applying multiple GDT operations to the same specific signal component, the energy of the TFR result should be concentrated in a step-wise manner. The technology does not require a priori knowledge of true IF time dependency in contrast to other advanced IF estimation technologies. This feature is important for industrial applications of the proposed technology.

The main difference between the proposed MGDT and previously proposed transforms, e.g., [

36], is that the MGDT is performing multiple adaptive GDT iterations for the same specific signal component and the previously proposed transforms are performing just one (initial) GDT iteration for the same specific signal component. Other differences are highlighted below. The important feature of the novel MGDT is that every new iteration of the GDT is adaptive, i.e., it is based on previous iteration results.

Our extensive literature search clearly shows that nobody, in worldwide terms, has previously proposed the main important novelty of the MGDT: an adaptive iterative application of the GDT for the same signal component of a multi-component signal.

Novel IF estimation results, obtained by simulation, for four types of AM-FM nonstationary signals under a strong background noise (signal to noise ratio is -5dB): (i) single-component signal with nonstationary amplitude and nonstationary, nonlinear (quadratic) variation of the instantaneous frequency; (ii) multi-component signal with components that have nonstationary amplitudes and nonstationary linear instantaneous frequencies with different chirp rates; (iii) multi-component signal with components that have nonstationary amplitudes and nonstationary, nonlinear (quadratic) instantaneous frequencies with different chirp rates and frequency accelerations; and (iv) multi-component signal with components that have nonstationary amplitudes and nonstationary, nonlinear (cubic) instantaneous frequencies with different chirp rates, frequency accelerations, and the first derivatives of frequency accelerations.

Novel experimental IF estimation results for defect frequency of rolling bearings for multiple defect frequency harmonics, using the proposed technology in non-stationary conditions and in conditions of six different levels of a noise interference, including of two levels of a strong noise interference.

The objectives of the research are as follows:

To develop, investigate, and create the theoretical basis of the novel IF estimation technology.

To perform a novel validation of the proposed technology by simulation for four types of AM-FM nonstationary signals.

To perform comparisons of the proposed IF estimation technology with four traditional TFAs technologies by simulation.

To perform a novel experimental validation of the proposed technology for IF estimation for multiple harmonics of bearing defect frequency in non-stationary conditions and in conditions of different levels of noise interference, including a strong noise interference.

The rest of the paper is structured as follows.

Section 2 presents the developed theoretical bases of the IF estimation technology, including brief review of the GDT, and details of the proposed technology.

Section 3 presents novel validation of the proposed method, using four types of the simulated signals, and comparisons of the proposed IF estimation technology with four traditional TFAs technologies by simulation.

Section 4 presents a novel experimental validation of the proposed technology for IF estimation for multiple harmonics of a bearing defect frequency in nonstationary conditions and in conditions of different levels of noise interference, including a strong noise interference. Finally, the conclusions are drawn in

Section 5.

4. Validation of the Proposed IF Estimation Technology via Experimental Trials

In this section, experimental validation of the proposed IF estimation technology for a nonstationary multi-component signal from the rolling element bearing is performed.

The rolling bearing is one of the most widely used mechanical parts in rotating machinery. Its faults are important reasons of shutdowns of machines. For reducing economic losses and avoiding disastrous accidents, novel IF estimations for rolling bearing has become an important topic [

44,

45,

46,

47].

The captured nonstationary bearing vibration signal from a faulty bearing is considered for experimental MGDT validation. The main purpose of the validation is to estimate the non-stationary instantaneous bearing defect frequencies for the fundamental harmonic and the higher harmonics, using the proposed IF estimation technology for different levels of noise interference at a very early stage of damage development.

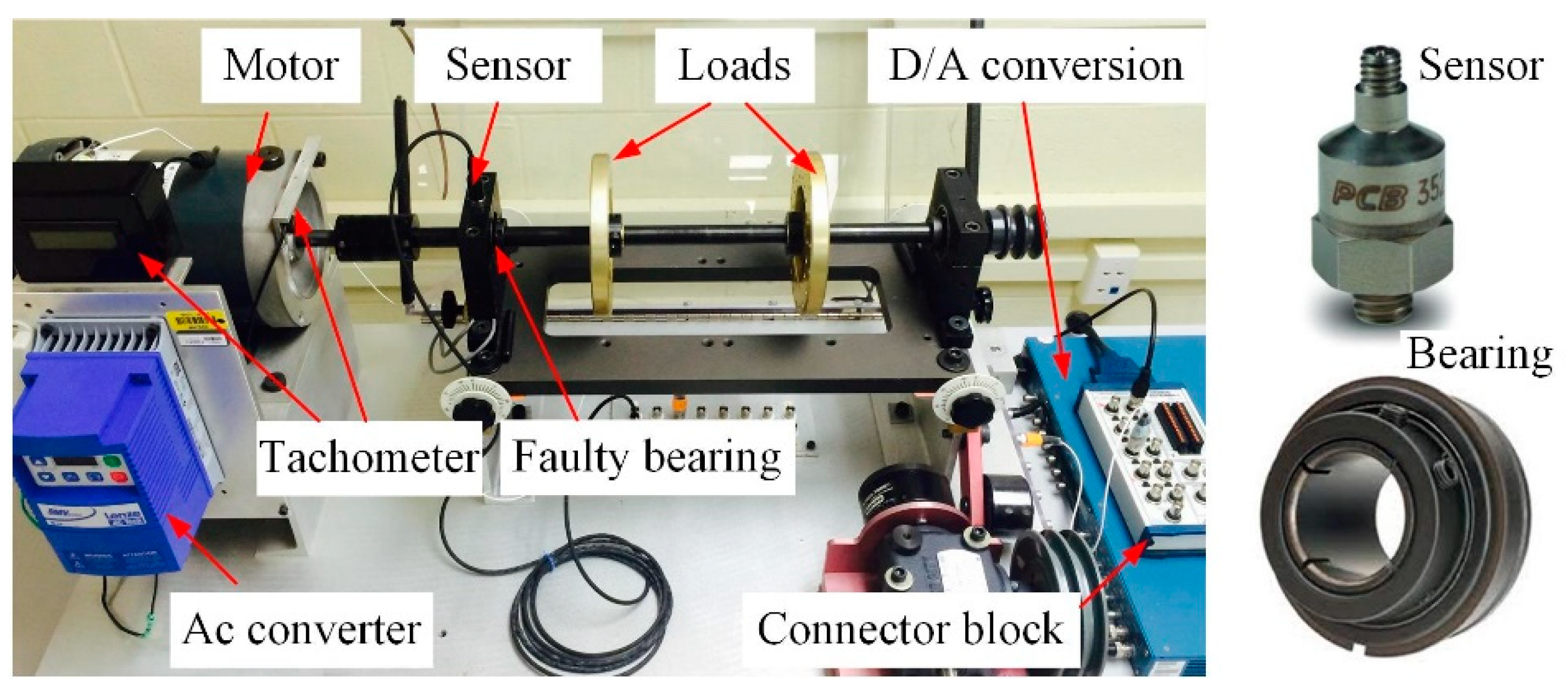

Figure 16 shows the structural sketch of the experimental set-up. The AC motor (Marathon, Beloit, WI, USA )(3 phase, Hz: 60/50, RPM: 3450/2850, voltage: 208–230/460) is used to drive the steel shaft, which is supported by two bearings (Rexnord, Milwaukee, WI, USA), including a faulty one.

The employed motor has a star connection. In delta connection, each winding will get phase to phase voltage. Alternatively, in star connection, there will be two windings in series across two phases. Hence, motor windings get a higher voltage in delta connection. In star connection, the stator phase voltage is about 58 % of the line voltage. The torque of the motor is directly proportional to the square of the applied voltage. In star connection, the torque of the motor is about 33 % of the maximum rated torque of the motor. The torque delivering capacity of the motor in the delta connection is more than the torque-delivering capacity in the star connection, i.e., torque (star connection) = 33 % of torque (delta connection). Motor vibration amplitudes are propositional to the motor torque. Therefore, it is easier to estimate IFs of narrowband motor components in the delta connection, compared with the star connection.

Two flywheels (SpectraQuest, Richmond, VA, USA) are installed on the shaft to apply load to the system. The RF is measured by a built-in tachometer (SpectraQuest, Richmond, VA, USA) (one pulse per revolution analogue transistor-transistor logic output for DAQ purposes) and the RF can be adjusted by the AC converter.

An accelerometer (PCB, Depew, NY, USA) (PCB 352A60) is mounted on the top surface of the faulty bearing housing by a tapped hole to capture the vibration signal. This miniature accelerometer achieves an extremely high frequency response from 5 Hz to 60 kHz. The sensitivity of the accelerometer is 10 mV/g; electrical filter corner frequency is 45 kHz; electrical filter roll-off is 10 dB/decade; resonant frequency is

kHz; measurement range is up to 500 g; broadband resolution is 0.002 g rms; nonlinearity is

; transverse sensitivity is

; overload limit is 5000 g pk; temperature response is −54 to +121℃; base strain sensitivity is

; excitation voltage is 18 to 30 VDC; constant current excitation is 2 to 20 mA; output impedance is

; output bias voltage is from 8 to 12 VDC; discharge time constant is from 0.02 to 0.06 s; spectral noise (10 Hz) is 160

; spectral noise (100 Hz) is 40

; spectral noise (1 kHz) is 15

; spectral noise (10 kHz) is 10

; height is 21.6 mm; weight is 6 gm; sensing element is ceramic; size-hex is 3/8in; sensing geometry is shear; housing material is stainless steel; sealing is welded hermetic; electrical connector is 5-44 coaxial; electrical connection position is the top; mounting is integral stud; and mounting thread is 10-32 male. The accelerometer is shown in

Figure 16.

The signal collecting system is mainly consisted of a DAQ card (Model: NI-PCI6259, number of channels is 16 differential or 32 single-ended, ADC resolution is 16 bits, single channel maximum is 1.25 MS/s, and multichannel maximal sample rate is 1 MS/s) and the NI-DAQmx software.

The bearing type is ER-10K, number of balls is 8, ball diameter is 8.94 mm, pitch diameter is 33.5 mm, contact angle is 0, and its FCCs of the outer race, inner race, and ball are 3.05, 4.95, and 1.99, respectively. A defect in the form of a 0.1 mm diameter hole is considered in the outer raceway of the bearing; the relative damage size, related to the outer race circumference, is 0.2%. The bearing is shown in

Figure 16.

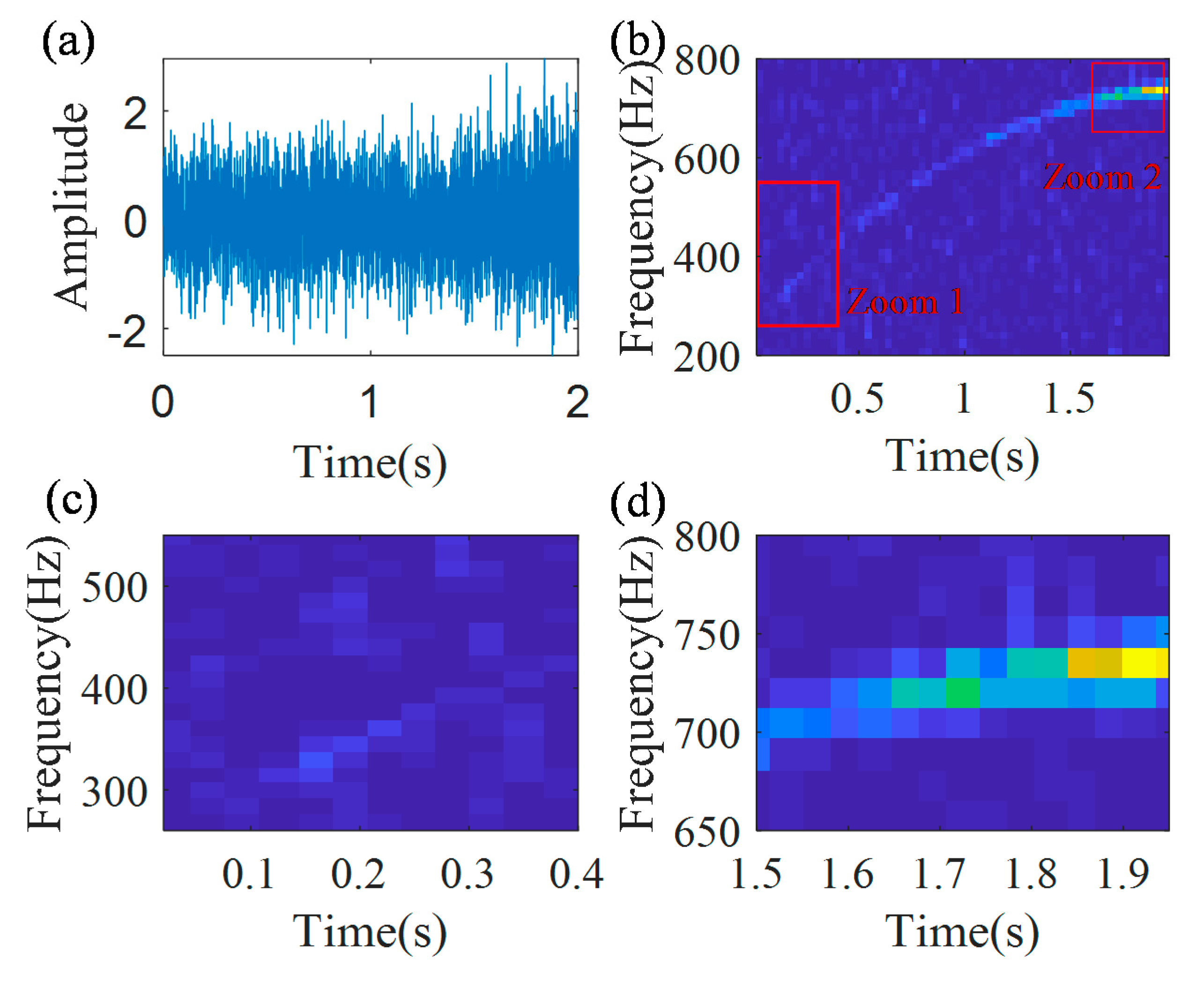

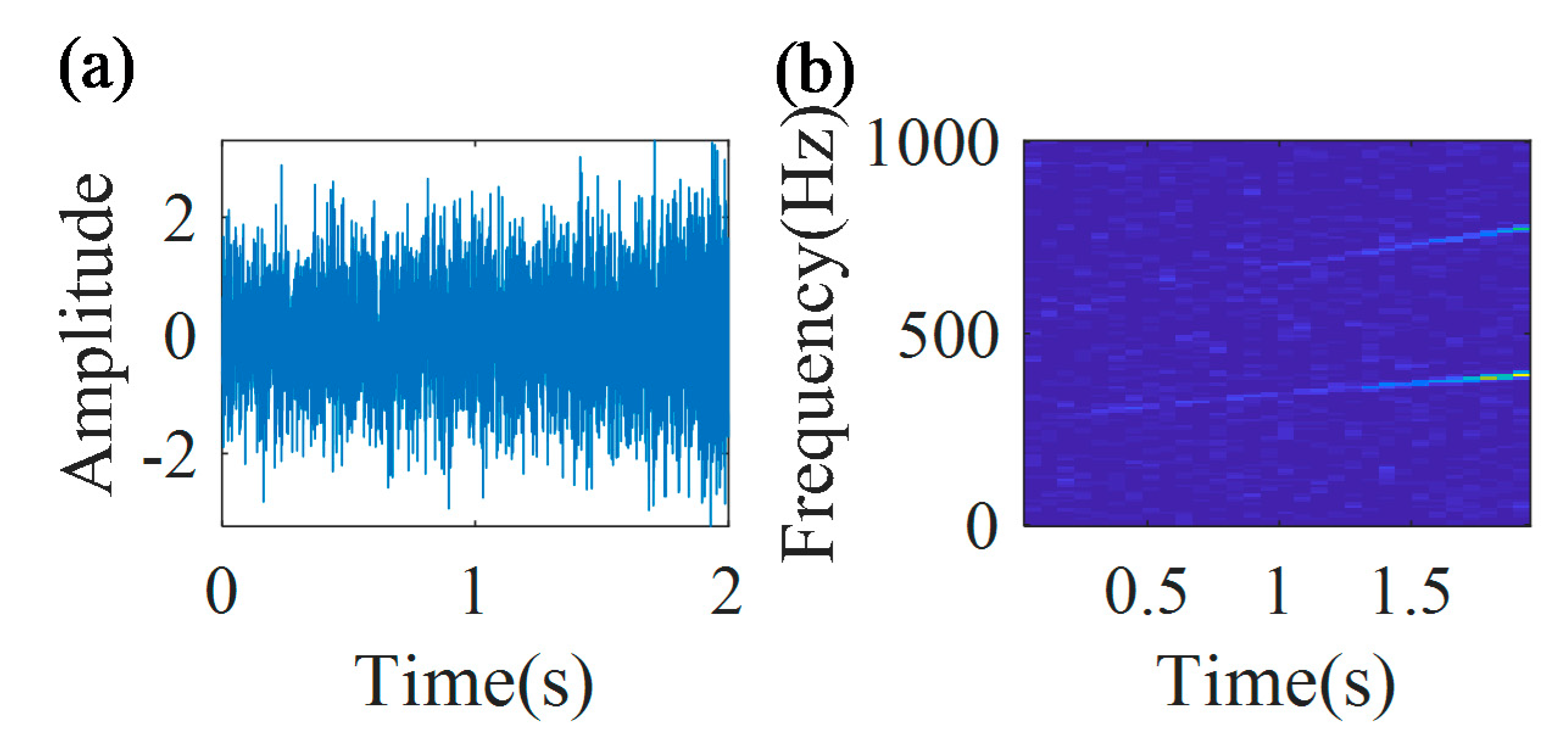

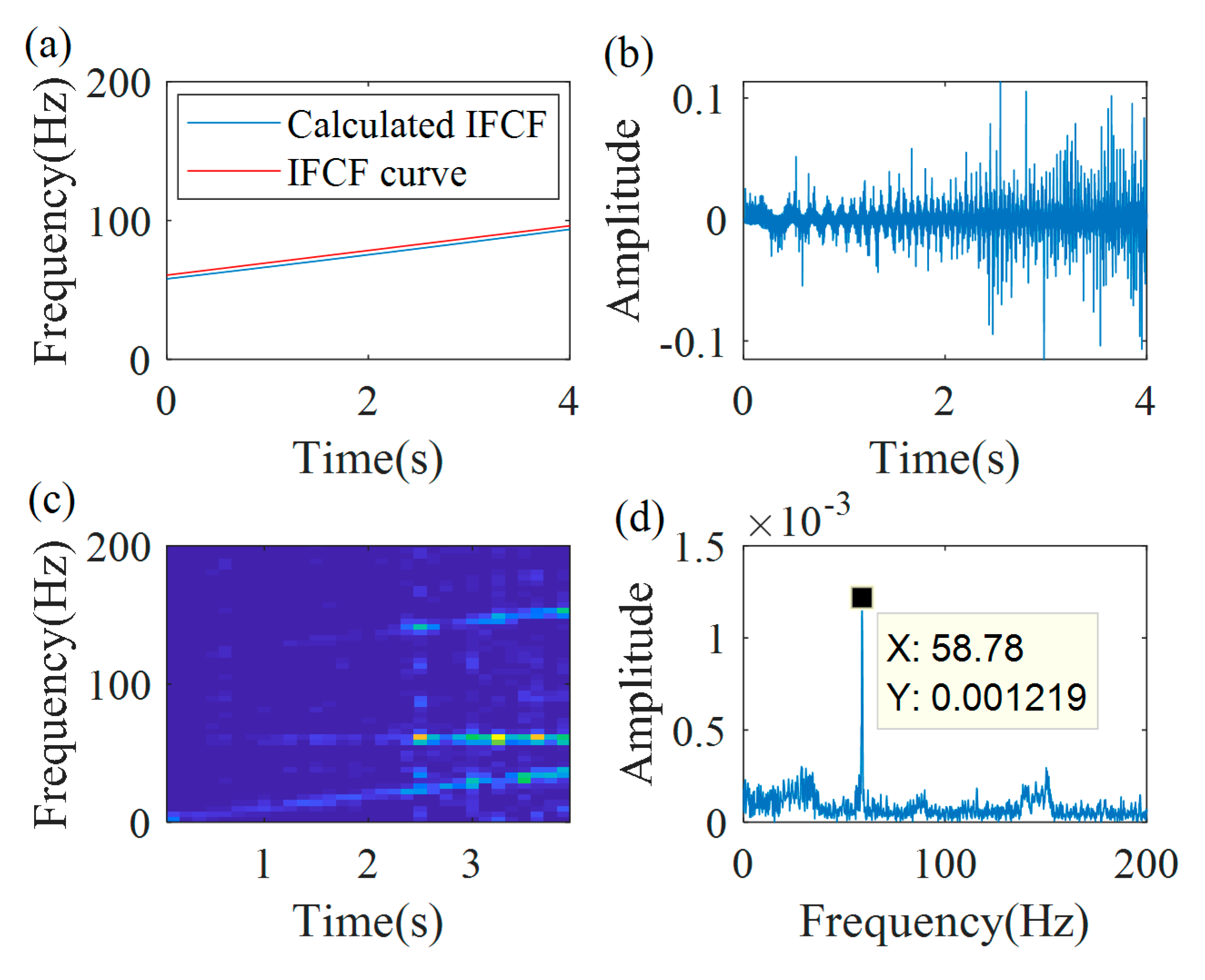

First, the raw bearing vibration signal is collected. The collected vibration signal from the bearing with outer race fault is presented in

Figure 17a; the estimated from speed sensor RF function is

Hz; the RF increases from 19.9 to 31.5 Hz over 4 s. The sampling frequency is 48,000 Hz and the time duration is 4 s. It should be noted that speed sensor data are not used for the proposed estimation technology, as the technology does not require a priori knowledge of a true time-varying IF dependency. These data are used only for IF error estimations for the proposed technology.

For selection of the sampling frequency, the following frequencies should be taken into account: the fundamental outer race bearing defect frequency that varies from 60.7 to 96.1 Hz and a frequency band that is related to transient impulses, generated by a bearing outer race local fault. Before the final selection of the sampling frequency, a preliminary assessment of a frequency band that is related to transient impulses, generated by a bearing local outer race fault, was performed by spectral kurtosis [

48,

49,

50], and it was found that this band is (9–12) kHz. So, based on the estimated frequency band, it is clear that the bearing outer race defect frequency is not critical in the selection of the sampling frequency, and the estimated frequency band is critical in sampling frequency selection. In order to avoid aliasing, the sampling frequency is selected as four times the maximum frequency of a frequency band that is related to transient impulses, generated by bearing local faults, i.e., 48 kHz.

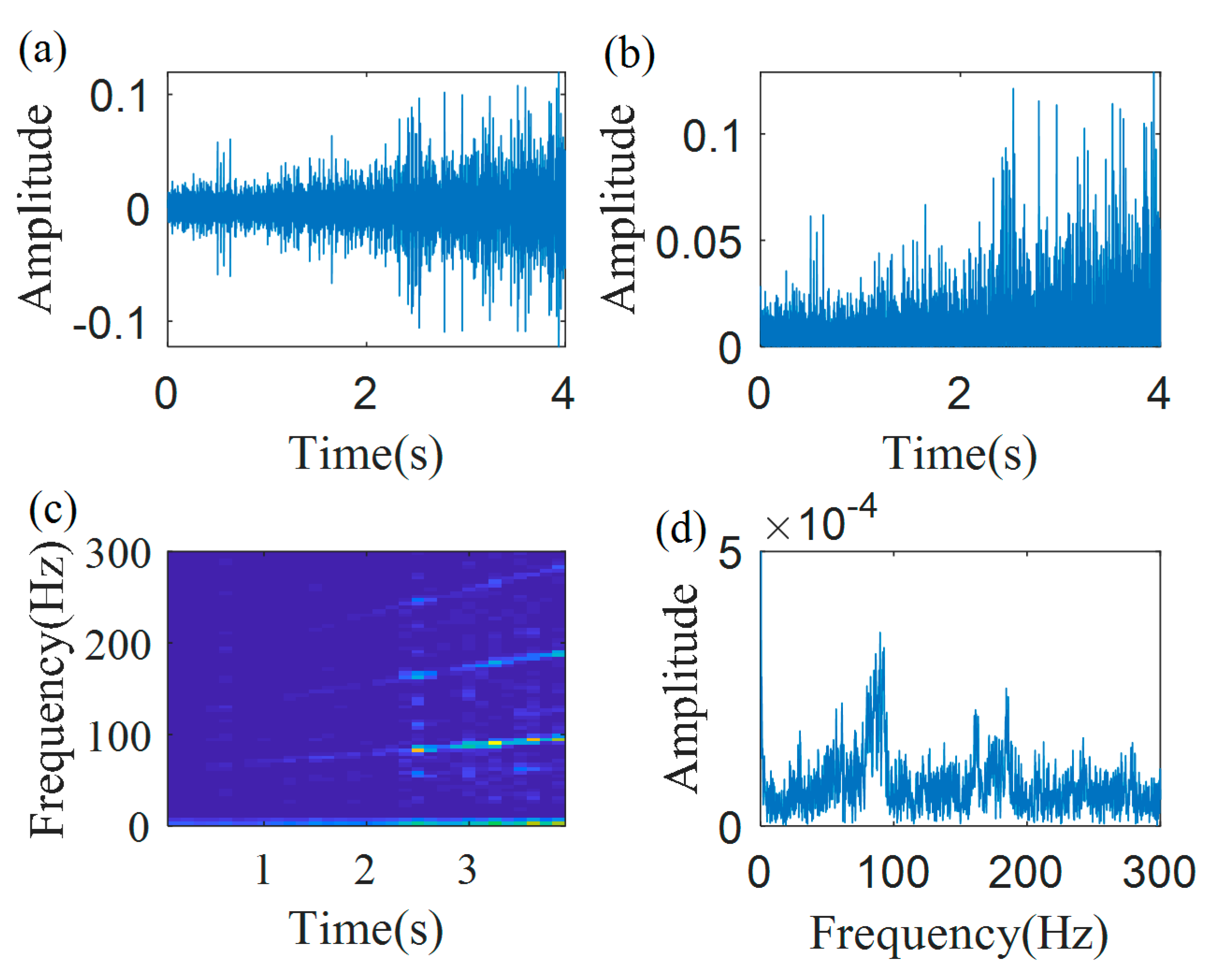

Firstly, the proposed technology is validated for IF estimation of the first harmonic of the outer race defect frequency. The envelope signal, shown in

Figure 17b, is estimated by the Hilbert transform.

Figure 17c,d show the TFR and the spectrum of the envelope signal, respectively. From the TFR, it can be found that due to the noise, the weak IFCFs in the initial duration of the signal are polluted by noise. In addition, because of the time-varying operation condition, the IFCF curve is time-varying and cannot be quantitatively characterized by the classical Fourier spectrum, as shown in

Figure 17d.

The proposed IF estimation technology is employed to the envelope signal for obtaining the IFCF. Here, the length of the Gaussian window is L = 12000, 50% overlap, the local search range .

The main criterion for window length selection depends on an instantaneous frequency change, characterized by the chirp rate in the case of linear frequency variation and by the chirp rate and the frequency acceleration in the case of quadratic frequency variation, and so on [

51,

52,

53,

54].

The employed criterion of window length selection is clearly explained below on the basis of the two main cases of combinations of the instantaneous frequency change of the components and frequency resolution, defined by a window length.

Case 1. The instantaneous frequency change of IF of component during the duration of the selected window is within the frequency limits (; ), defined by the frequency resolution f at a particular central frequency of a frequency bin of the STFT. The considered case could be viewed as a quasi-stationary case within a window length and no additional errors are provided that are related to STFT estimation for a nonstationary signal, because the time-variable IF is not moving from one frequency bin to another during the selected window length.

Case 2. The instantaneous frequency change of IF of component during the duration of the selected window is more than the frequency limits (; ), defined by the frequency resolution f at the particular central frequency of a frequency bin.

This case is definitely not a quasi-stationary case and additional errors are provided that are related to STFT estimation for a nonstationary signal, as the time-variable IF is moving from one frequency bin to another during the selected window length, i.e., the IF will be, at least, in two different frequency bins (or even more, depending on the speed of the frequency change) for the selected duration of the window.

Based on the considered two cases, the clear criterion for window selection that we employed is as follows: the instantaneous frequency change of IF of component during the duration of the selected window should be within the frequency limit (; ), defined by the frequency resolution with a “safety factor” within the threshold range (1.5–3) for a “safety factor”, where a safety factor is defined as .

The threshold range (1.5–3) is defined as follows: it is a danger to select a threshold around 1, as an IF still could move from one frequency bin to another during the selected window length. If the selected threshold range is (1.5–3), then the IF will not move from one frequency bin to another during the selected window length. It is possible to have a safety factor of more than 3; however, a drawback of such a big safety factor is that the frequency resolution for this case becomes poorer and this will potentially compromise an IF estimation.

It is discussed here how this criterion was employed for the considered experimental trials.

As the main effort is for estimation, firstly, the IF of the first harmonic of the bearing outer race defect frequency is considered a time variation of the IF of this harmonic, which is , where is the time variation of the fundamental rotation frequency, and the coefficient of 3.05 is the FCC of the bearing outer race.

For the selected window length of 12000 (i.e., time duration of this window length is 0.25 s), the instantaneous frequency change fch1 of the IF of the first harmonic of the bearing outer race defect frequency is = (0.25s x 2.9Hz/s x 3.05) = 2.21 Hz and the frequency resolution related to this window length is f = (1/0.25Hz) = 4 Hz. So, for this selection of the window, the instantaneous frequency change (i.e., 2.21 Hz) during the duration of the window is within the frequency resolution (i.e., 4 Hz) and, therefore, it is possible to avoid additional errors related to STFT estimation for the first harmonic of the bearing outer race defect frequency. This avoidance is because the time-variable IF is not moving from one frequency bin to another during window length. The “safety factor” for this estimation is S = (4 Hz/2.21 Hz) = 1.81 and it is inside the specified threshold range (1.5–3).

It is possible to select a window length, e.g., of 6000 (i.e., the time duration of this window length is 0.125s). In this case, the instantaneous frequency change fch1 of the IF of the first harmonic of the bearing outer race defect frequency is = (0.125s x 2.9 Hz/s x 3.05) = 1.11 Hz and the frequency resolution related to this window length is f = (1/0.125 Hz) = 8 Hz. So, in this case, the instantaneous frequency change during the duration of the window (i.e., 1.11 Hz) is also within the frequency resolution (8 Hz) and it is also possible to avoid additional errors related to STFT estimation for the first harmonic of the bearing outer race defect frequency.

However, the “safety factor” for this estimation is too big at S = (8 Hz/1.11 Hz) = 7.21. A drawback of this big safety is that the frequency resolution for this case (8 Hz) is poorer, compared with window length of 12000 that, potentially, will compromise an IF estimation.

If a longer window length, e.g., 18000, is selected, then the instantaneous frequency change of the IF of the first harmonic of the bearing outer race defect frequency is (0.3755s x 2.9 Hz/s x 3.05) = 3.32 Hz, and the frequency resolution related to this window length is f = (1/0.375 Hz) = 2.67 Hz. In this case, the instantaneous frequency change during the duration of the window (i.e. 3.32 Hz) is not within the frequency resolution (2.67 Hz) and it is not possible to avoid additional errors related to STFT estimation for the first harmonic of the bearing outer race defect frequency. This non-avoidance is because the time-variable IF is moving from one frequency bin to another during the window length. So, the selection of a longer window length of 18000 is not acceptable.

The same criterion was used for the selection of the window length for simulation trials. For the simulation of two harmonics with nonlinear frequency modulation, the selected window length is 128. For the selected window length of 128 (i.e., the time duration of this window length is 0.064 s), the instantaneous frequency change fch1 of the IF of the first harmonic is 5.72 Hz and the frequency resolution related to this window length is f = (1/0.064 Hz) = 15.625 Hz. So, for this selection of the window, the instantaneous frequency change during the duration of the window (i.e., 5.72 Hz) is within the frequency resolution (i.e., 15.625 Hz) and it is possible to avoid additional errors related to STFT estimation for the first harmonic. The “safety factor” for this estimation S = (15.625 Hz /5.72 Hz) = 2.73 which is inside the specified threshold range (1.5–3).

So, in order to implement the described criterion for the proposed method, what need to be known, approximately, are the maximum chirp rates for signals with linear variation of the IF and the maximum chirp rates and frequency accelerations for quadratic variation of the IF, etc.

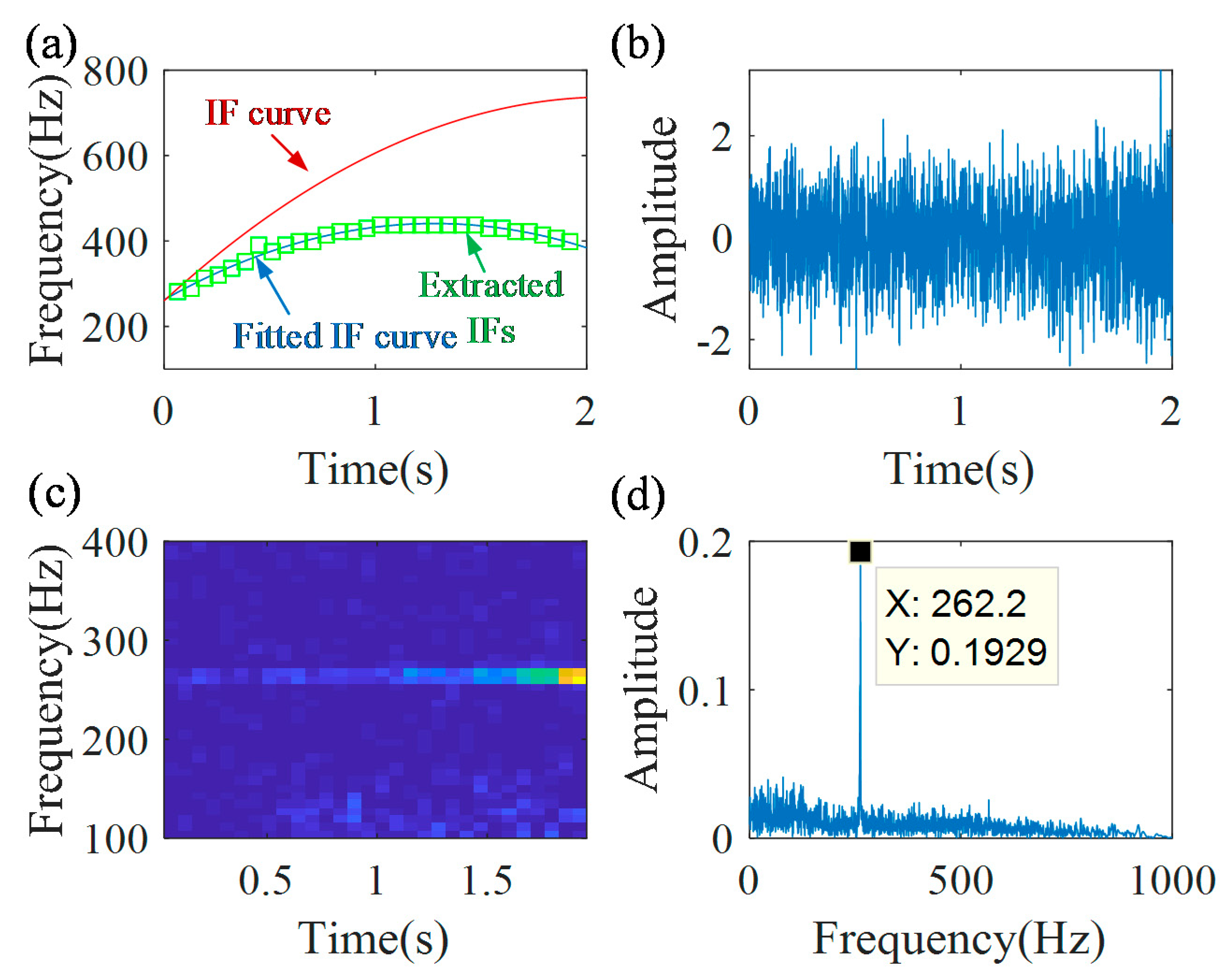

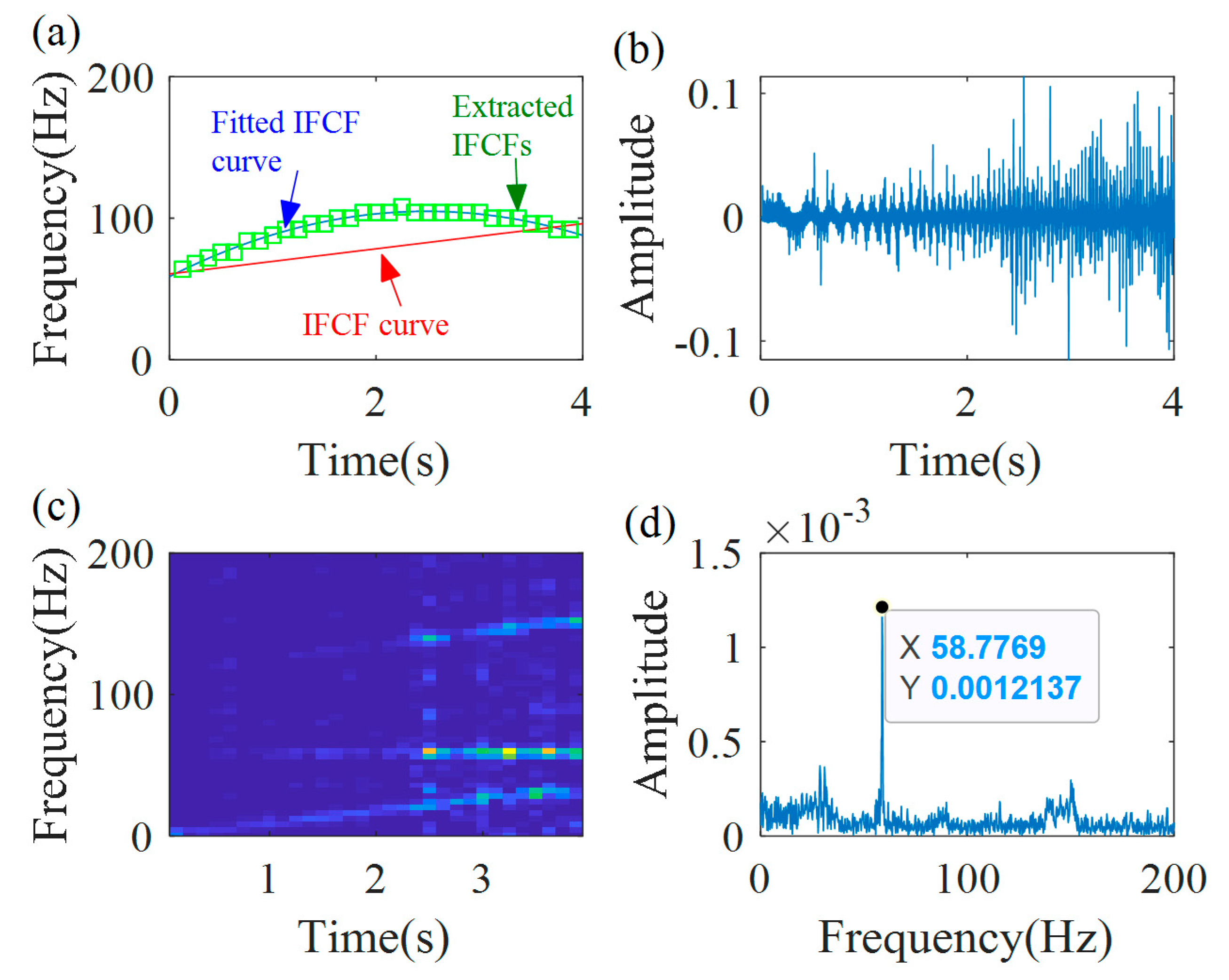

Figure 18 shows the first iteration demodulation results. As shown in

Figure 18a, the first extracted IFCF has a relatively big error; the error between the first fitted IFCF curve (

) and the actual IFCF curve (

) is 63.1%. A clear peak, without smearing, cannot be captured in the spectrum, as shown in

Figure 18d. The second iteration demodulation results are shown in

Figure 19. From

Figure 19a, it can be found that the extracted IFCF is coincident with the fitted IFCF curve (

). There is a clear non-smeared peak in the spectrum, presented in

Figure 19d, and the frequency of that peak is very close to the starting frequency of

.

Based on , and Equation (16), the estimated IFCF curve function is , and the IF estimation error between the estimated IF function and the obtained one from the speed sensor function is 4.4%. Applying the termination threshold of 0.01, the third iteration is not needed.

Based on Equation (17), the demodulation operator is estimated as

. With the obtained demodulation operator, the demodulated signal is estimated and is shown in

Figure 20b.

Figure 20c,d are the TFR and the spectrum of the demodulated signal. From the TFR, a constant time–frequency curve can be found, and its value is 58.8 Hz, which is a peak frequency in the spectrum, as shown in

Figure 20d.

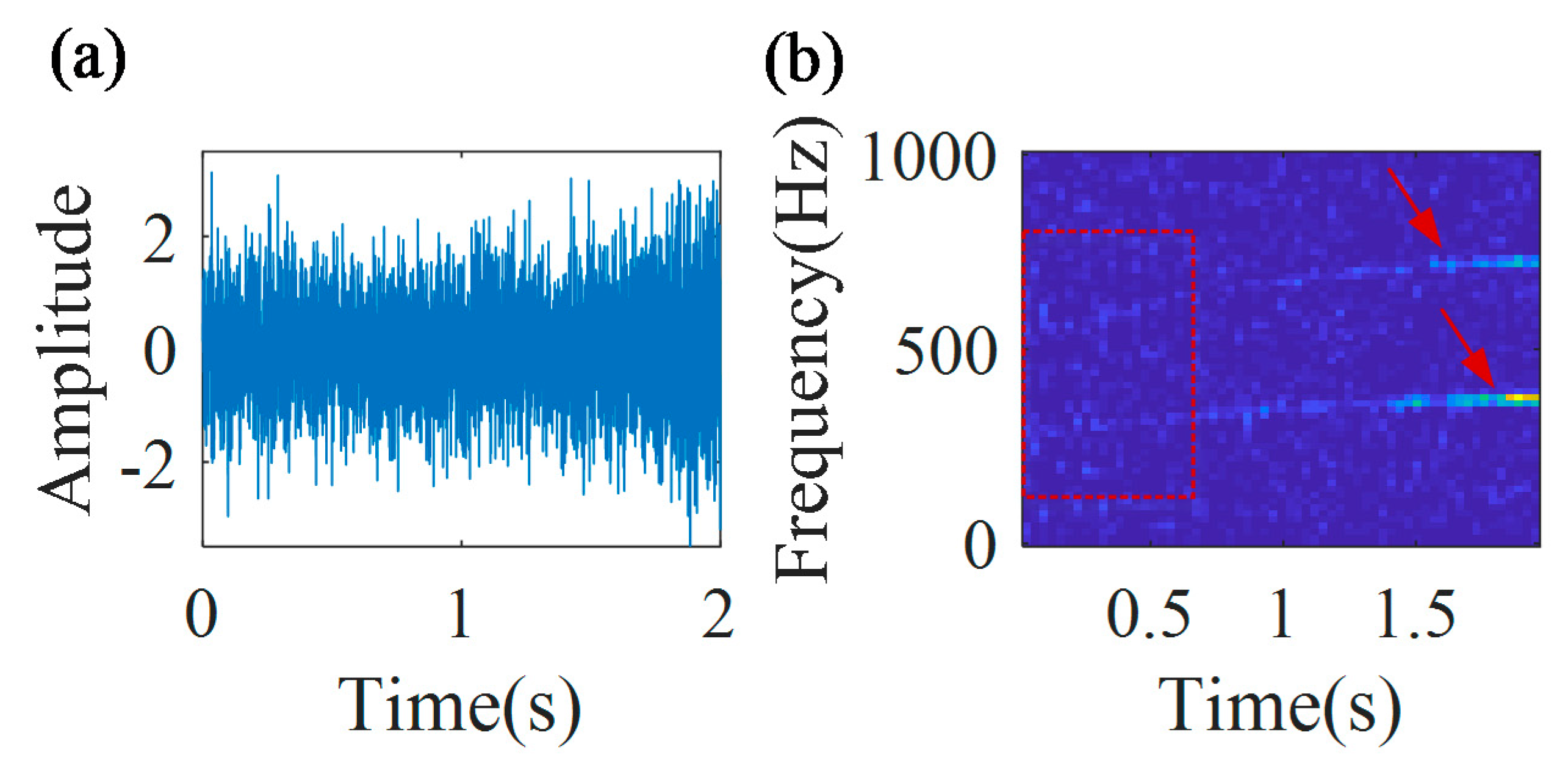

Then, the proposed technology is further validated for estimation of IFs of the second and third harmonics of the outer race defect frequency.

Figure 21a,b is the TFR and the spectrum of the demodulated signal, related to the second harmonic.

Figure 21c,d is the TFR and the spectrum of the demodulated signal, related to the third harmonic.

A constant time-frequency ridge and a peak can be detected in the TFR and the spectrum of demodulated signal, related to the second harmonic (

Figure 21a,b). The peak frequency is 117.7 Hz, which is very close to the value 121.4 Hz, estimated by the speed sensor. Similarly, a constant time-frequency ridge and a peak can be detected in the TFR and the spectrum of the demodulated signal, related to the 3 third harmonic (

Figure 21c,d). The peak frequency is 176.7 Hz, which is very close to the value 182.1 Hz, estimated by the speed sensor.

The IF estimation technology is further experimentally validated at different added noise levels. The Gaussian white noise is added to the experimental vibration signal and the SNRs are −4 (strong background interference), 2 (strong background interference), 8, 30, 40, and 50 dB.

The IF estimation technology is applied to these signals. All technology parameters remain the same. The obtained IFCF estimation errors under different noise levels are listed in

Table 2. It can be found that the results have no change under noise levels from 50 to 8 dB compared with the experimental signal without additional noise. The estimation error slightly increases to 5.8% for noise level 2 dB. The estimation error further increases to 7.6%, for noise level −4 dB. Hence, it is experimentally confirmed that a high immunity level against noise is provided by the proposed technology in nonstationary conditions of the very early stage of local bearing damage development, and the relative damage size is 0.2%.

It should be noted that the experimental raw signal has an initial noise level.

As a result of the experimental investigation at different SNRs of the interference, it is obtained that a satisfactory estimation error of 5.8% is achieved at the additional noise level of 2 dB SNR. As experimental vibration data are already contaminated by noise, it is believed that a 5.8% error is achieved, at least, in the range of (0–2 dB) SNR. Thus, the (0–2) dB SNR range is a successful immunity level against interference achieved by the proposed method via experiments.

It is also shown that the −5 dB SNR is a successful immunity level against noise achieved by the proposed method via simulation, and the simulation error range is (1.2%–4.46%).

In the current experimental setup, the investigated faulty bearing does not slip. In the majority of bearing operation conditions under nominal loads, bearing slippage is insignificant and it is not needed to make any changes to the proposed method.

However, at high speeds and light loads or at no loads, bearing slippage may be essential. A minimum load must be applied to a bearing in order to avoid slippage. The value of this minimum load increases with speed.

If bearing slippage appears, the fault characteristic periods change and, therefore, the bearing defect frequencies are affected by the slippage. Bearing slippage needs to be taken into account for IF estimation of bearing defect frequencies. For bearing slippage conditions, a novel signal segmentation approach by slicing the bearing vibrations into small realizations (periods), considering simultaneously the relatively small number, e.g., 5–10, of these realizations (i.e., groups of realizations) for IF estimation/fault diagnosis purposes, and then tracking IF estimations/fault diagnosis results via multiple groups has been proposed, developed, investigated, and comprehensively experimentally validated [

55,

56,

57,

58,

59,

60]. This approach takes into account that bearing slippage is not a very fast developing process and, therefore, allows to consider simultaneously 5–10 realizations. It is possible to apply this novel approach for the proposed method for bearing slippage conditions by considering the STFT of a small number of realizations (i.e., groups), applying the method for multiple STFTs of groups, starting with groups characterized by relatively high SNR regions, and tracking the obtained estimation results via multiple groups in order to obtain the overall IF estimation for the whole nonstationary bearing vibration signal.

The proposed method is developed, firstly, as a generic IF estimation method and, secondly, with a specific view of application for IF estimation related to the bearing defect frequencies, for the purpose of bearing fault diagnosis. It is well known that all bearing defect frequencies, i.e., outer race defect frequencies, inner race defect frequencies, rolling element defect frequencies, and cage defect frequencies, are directly proportional to the fundamental rotational frequency and constants of proportionalities which are known as fault characteristic coefficients (FCCs).

Therefore, taking into account these direct proportionalities, it is known that for both stationary and nonstationary conditions of bearing operations and for a simultaneous appearance of multiple bearing local faults (e.g., outer race faults, inner race faults, etc.), the bearing defect frequencies of all harmonics are not intersecting. Even if a rotating shaft with two different rolling element bearings is considered, the bearing defect frequencies of all harmonics are also not intersecting.

Thus, the current version of the proposed IF estimation method is designed for non-intersecting IFs. Other known GDT approaches are also designed for non-intersecting IFs.

Taking into account the nature of the proposed method, the method does not have any limitations on the number of non-intersecting harmonics. It is shown above that the proposed method can successfully estimate multiple IFs for the following cases in a very noisy environment, where the SNR is −5 dB:

Multi-component signal with three harmonic components with time-variable amplitudes and linear FMs.

Multi-component signal with two harmonic components with time-variable amplitudes and nonlinear (quadratic) FMs.

Multi-component signal with two harmonic components with time-variable amplitudes and nonlinear (cubic) FMs.

Therefore, the proposed technology has the potential ability to diagnose multiple bearing faults by IF estimations of bearing defect frequencies, related to local faults of outer race, inner race, cage, and roller elements. As the proposed technology has good immunity against interference, it allows to diagnose early stages of local bearing defects. In the performed experiment, the IF of the outer race defect is successfully estimated at the very early stage of outer race damage development, and the relative damage size is 0.2%.

As the proposed method does not require a priori knowledge about “true IF time dependency”, it could be applied to two scenarios: (i) where bearing defect frequencies are known; and (ii) where bearing defect frequencies are unknown. The last case is very important for industrial applications.

It is possible to apply the proposed method for IF estimations also for induction motors, including inverter-fed induction motors. The proposed method could be used for IF estimations for harmonics related to issues other than bearing faults, such as mechanical faults in induction motors in stationary and nonstationary conditions. In most cases, such an application will be related to IF estimations for variable rotation speed harmonics. In nonstationary conditions of motor operations, these harmonics, normally, have time-variable amplitudes and time-variable nonlinear frequency modulations (pure linear frequency modulations do not often appear in the exploitation of induction motors). Therefore, the three important advantages of the proposed method: the ability of effective IF estimation in conditions of time-variable harmonic amplitude, the ability of effective IF estimation in conditions of time-variable nonlinear frequency modulations, and the ability of the estimation of IF of multiple harmonics, could be exploited for IF estimations for harmonics related to mechanical faults in induction motors.

The effects of inverter harmonics on motor vibration signatures are studied in detail in the literature. It is shown theoretically and experimentally that the vibration signatures, caused by the inverter, are related to the multiple harmonics of the grid supply frequency. It is a possibility that those harmonics will affect the reliability of IF estimations for induction motors as strong inverter-induced harmonics could dominate in vibration spectra and, therefore, will mask weaker harmonics of bearing defect frequencies. However, it is possible to eliminate the influence of inverter-induced harmonics from motor raw vibrations in the same way as gearbox mesh harmonics are removed from gearbox raw vibrations in order to obtain gearbox vibration residual signals, e.g., [

48]. In these motor vibration residual signals, masking effects of inverter-induced harmonics will be essentially reduced and, thus, effective IF estimations of motor narrowband harmonics could be performed by the proposed technology.