Assessment of Cracking Widths in a Concrete Wall Based on TIR Radiances of Cracking

Abstract

1. Introduction

2. Study Site and TIR Dataset

2.1. Study Site

2.2. TIR Dataset

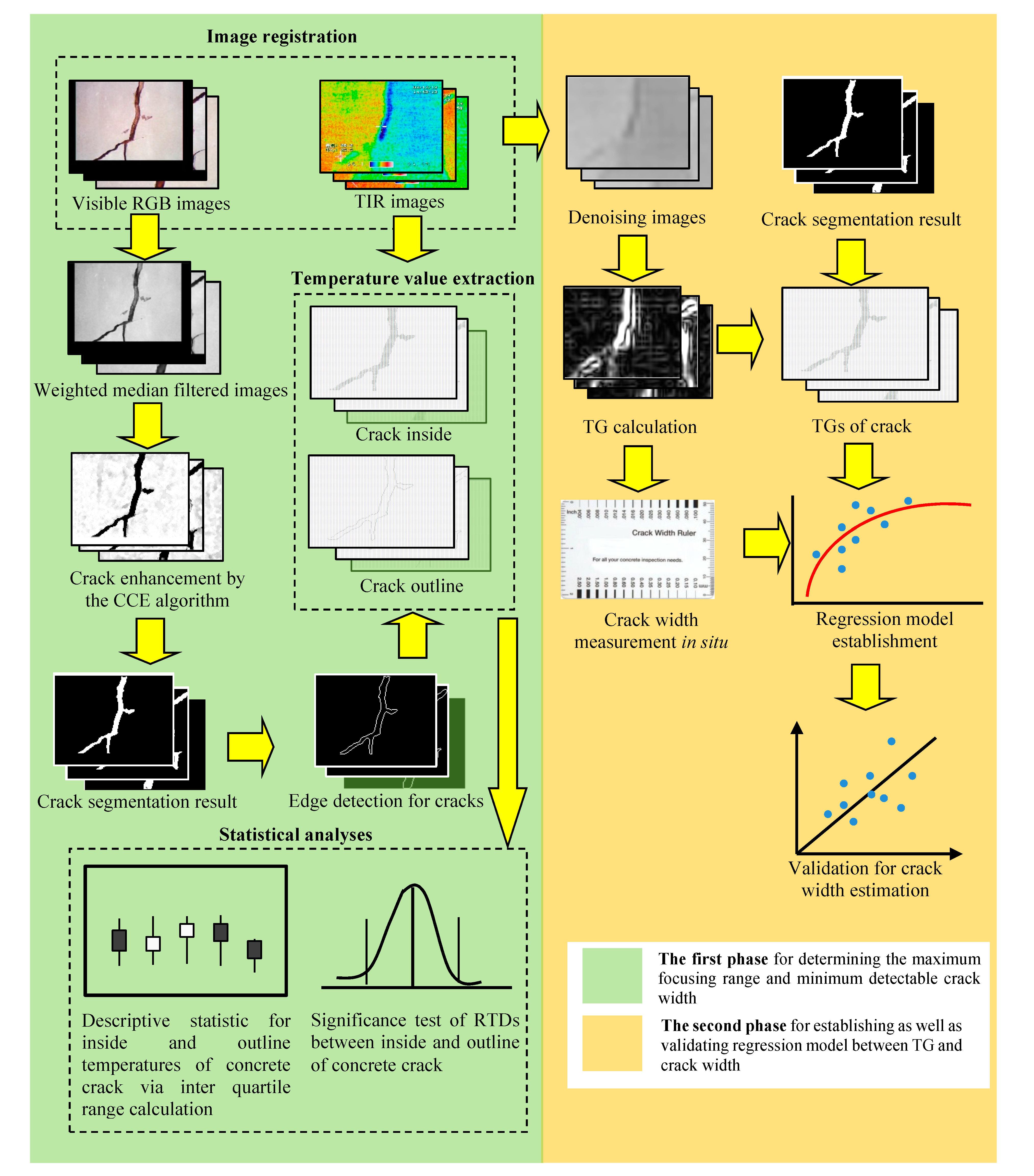

3. Methodology

3.1. Image Registration

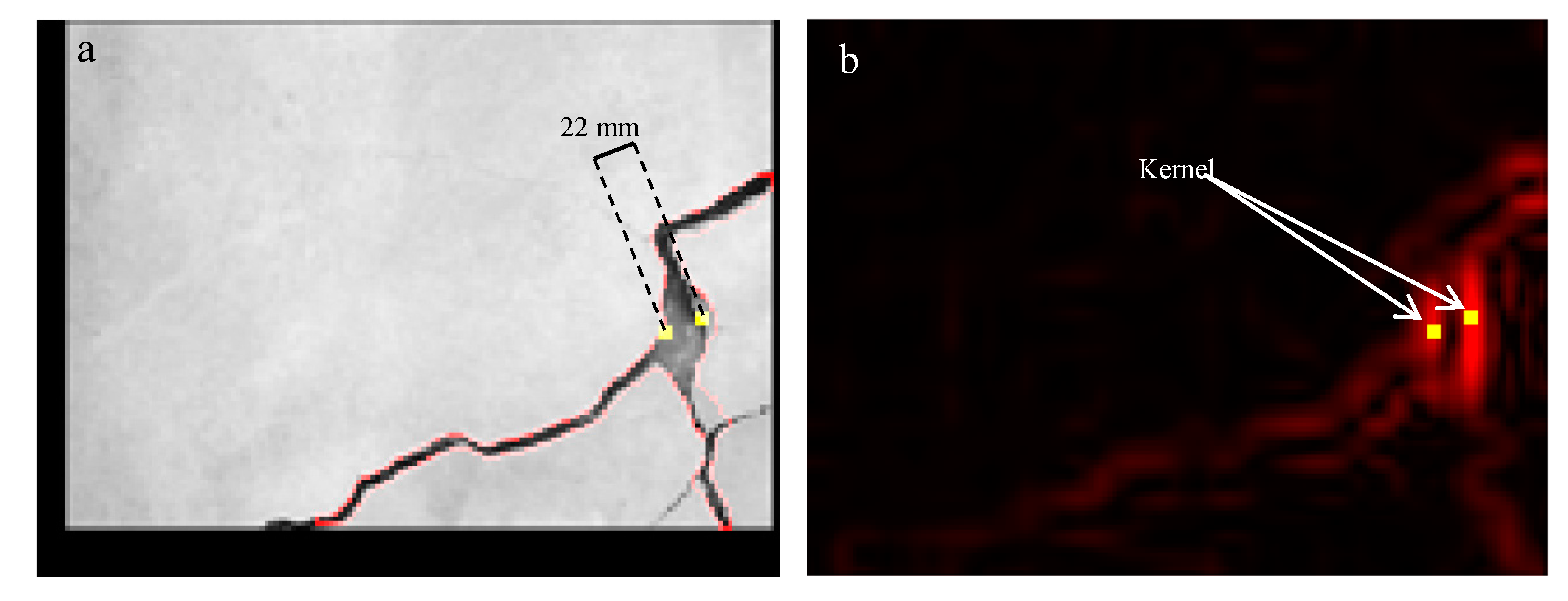

3.2. Crack Enhancement by CCE

| Algorithm 1 |

| begininitialize i ← 0, linear structural element B(12)i, filtered grayscale image F for i ← i + 10 ⊙ # image closing ç(), ç(F) # image complement do j ← j + 1 # image reconstruction until = RG() = end RG() ← RG() - # image subtraction (Top-hats transform) until i = 180 end. |

3.3. Statistical Analysis

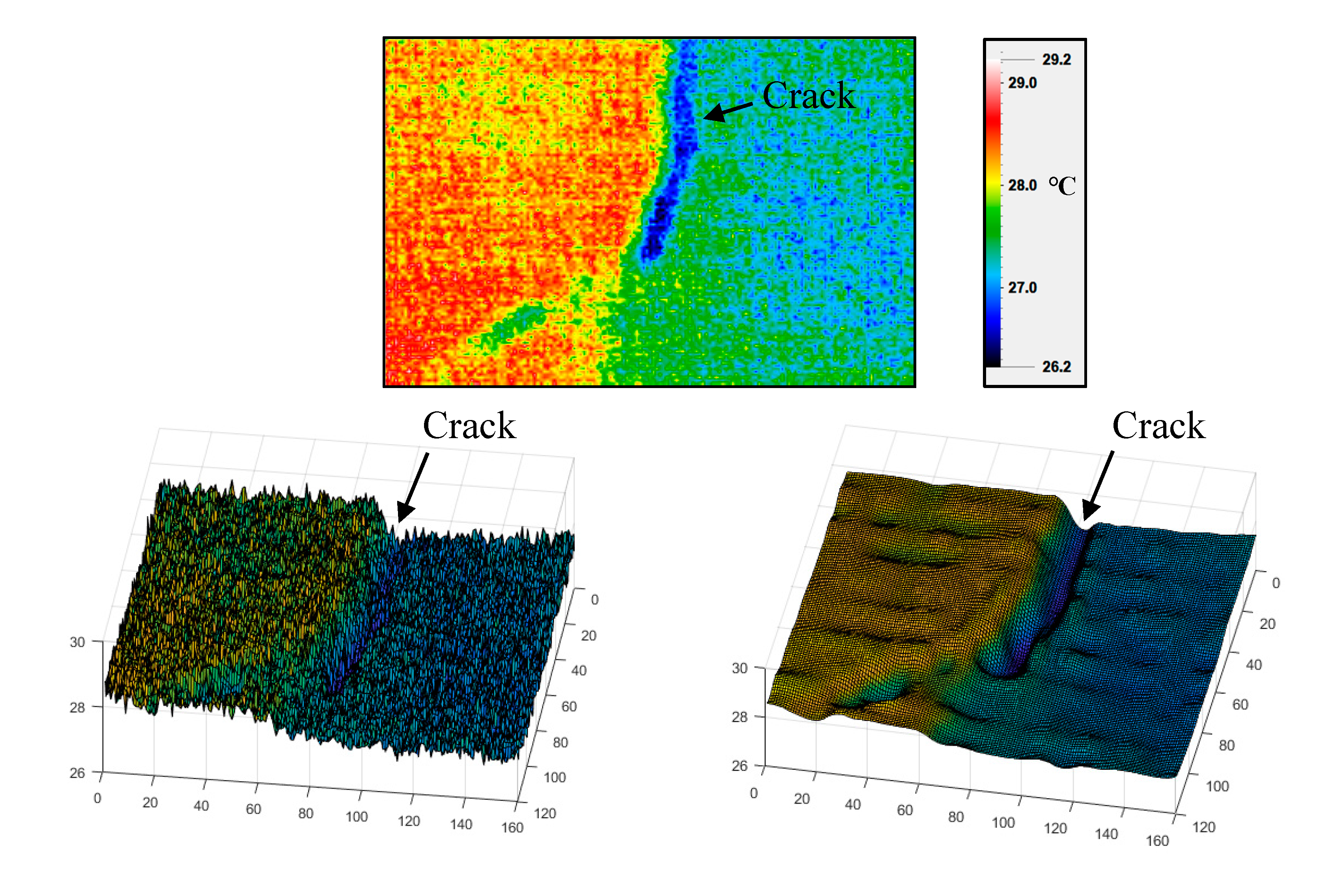

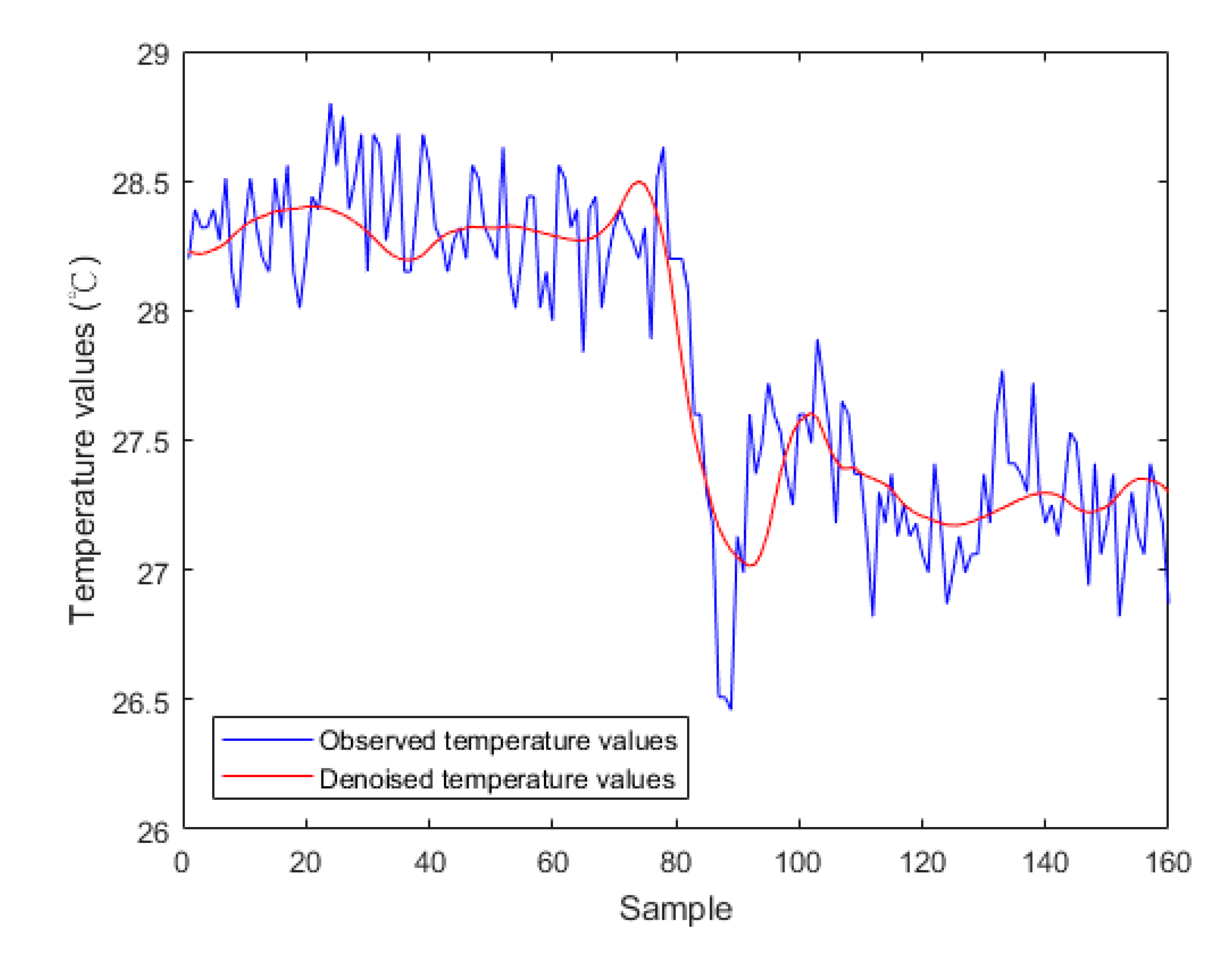

3.4. Denoising for TIR Image

3.5. TG Calculation

4. Results and Discussion

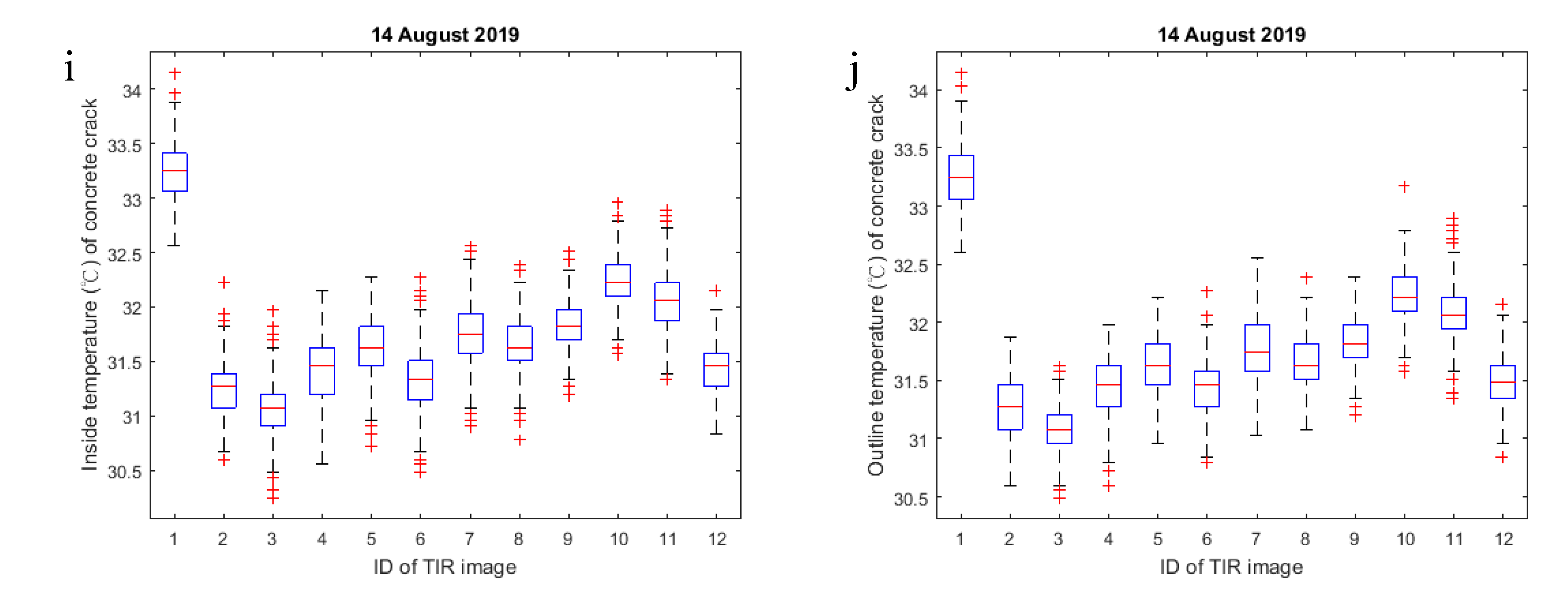

4.1. Descriptive Statistics for the Inside and Outline Temperatures of the Concrete Crack

4.2. Significance Test of RTD between the Inside and Outline of the Concrete Crack

4.3. Determination of Maximum Focusing Range and Minimum Detectable Crack Width

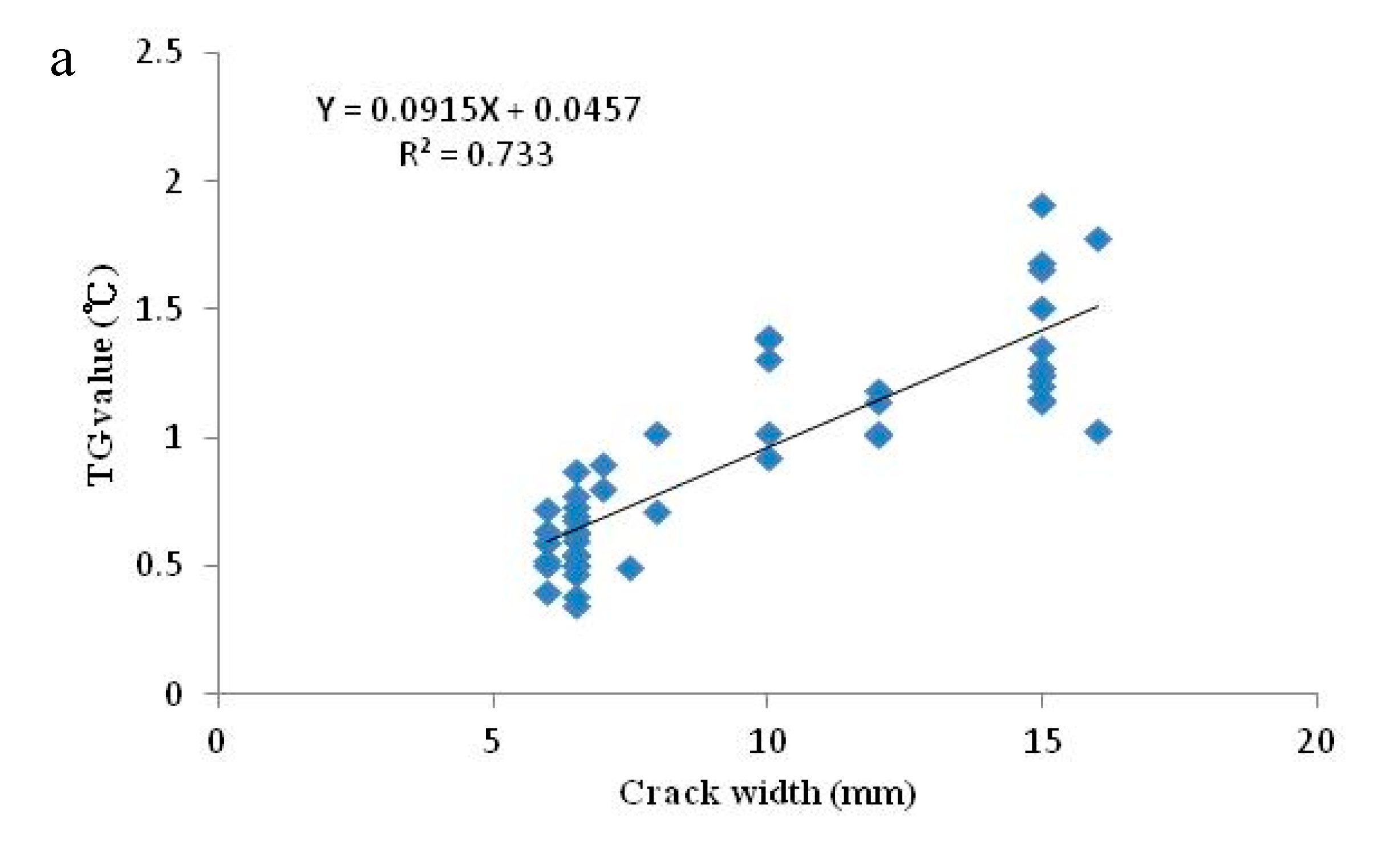

4.4. Regression Model Establishment between TG and Concrete Crack Width

5. Conclusions

- (1)

- The descriptive statistics of the inter-quartile range, coupled with the t-test, indicated that the difference between the inside and outline temperatures of the concrete crack would be insignificant as the seasonal temperature or relative humidity rose. In this study, multiple measurements were recorded from March to August 2019 in the subtropical climate of Kinmen, Taiwan. In future, multiple measurements should be recorded continuously over a number of years to observe the influence of climate change on the difference between the inside and outline temperatures of concrete cracks.

- (2)

- Wavelet-based image denoising is useful to smooth the TIR signals and facilitate the calculation of temperature gradients. The filtered waveform of the TIR radiances of a crack section (see Figure 4) was similar to the shape of the crack section. Based on the differences between the maximum and minimum temperatures of the crack sections, future regression models should also be established to estimate the depths of the crack sections.

- (3)

- The proposed operation procedure, based on a series of image processing and statistical analysis processes, not only effectively determined the maximum focusing range and minimum detectable crack width (1.0 m and 6.0 mm, respectively) but also successfully established a linear regression model between the temperature gradient and the crack width, with an R2 value of 0.733. Once a high-level TIR camera with a sufficient spatial resolution and thermal sensitivity for identifying concrete crack morphologies is obtained, the width estimation of sub-surface non-visible concrete cracks will be tested if the true widths are known.

- (4)

- According to the established linear regression model, the widths of several crack sections in the TIR images that were acquired in March and April 2019 were estimated. The derived R2 values between the estimated and observed crack widths were above 0.8, and the total RMSE was approximately ±2.5 mm. Nevertheless, in this paper, it was demonstrated that there was a greater proportional error for the width estimations of small crack sections than for large crack sections. A TIR dataset with a high spatial resolution is needed to reduce the proportional error of the width estimations of small crack sections, especially for detecting crack widths that are less than the current minimum limitation of 6.0 mm.

Funding

Acknowledgments

Conflicts of Interest

References

- Yuanxun, Z.; Zhang, P.; Cai, Y.; Jin, Z.; Moshtagh, E. Cracking resistance and mechanical properties of basalt fibers reinforced cement-stabilized macadam. Compos. Part B Eng. 2019, 165, 312–334. [Google Scholar]

- Kim, M.O.; Bordelon, A.C.; Lee, N.K. Early-age crack widths of thin fiber reinforced concrete overlays subjected to temperature gradients. Constr. Build. Mater. 2017, 148, 492–503. [Google Scholar] [CrossRef]

- Rajeev, P.; Sanjayan, J.G.; Seenuth, S.S. Assessment of thermal cracking in concrete roof tiles. Mater. Des. 2016, 107, 470–477. [Google Scholar] [CrossRef]

- Kim, S.; Kim, M.-J.; Yoon, H.; Yoo, D.-Y. Effect of cryogenic temperature on the flexural and cracking behaviors of ultra-high-performance fiber-reinforced concrete. Cryogenics 2018, 93, 75–85. [Google Scholar] [CrossRef]

- Fan, K.; Li, D.; Li, L.-Y.; Wu, J. Effect of temperature gradient on transient thermal creep of heated and stressed concrete in transient state tests. Constr. Build. Mater. 2019, 222, 839–851. [Google Scholar] [CrossRef]

- Yang, C.; Chen, J. Fully noncontact nonlinear ultrasonic characterization of thermal damage in concrete and correlation with microscopic evidence of material cracking. Cem. Concr. Res. 2019, 123, 105797. [Google Scholar] [CrossRef]

- Shen, D.; Jiang, J.; Wang, W.; Shen, J.; Jiang, G. Tensile creep and cracking resistance of concrete with different water-to-cement ratios at early age. Constr. Build. Mater. 2017, 146, 410–418. [Google Scholar] [CrossRef]

- Kobayashi, K.; Ahn, D.L.; Rokugo, K. Effects of crack properties and water-cement ratio on the chloride proofing performance of cracked SHCC suffering from chloride attack. Cem. Concr. Comp. 2016, 69, 18–27. [Google Scholar] [CrossRef]

- Kobayashi, K.; Kojima, Y. Effect of fine crack width and water cement ratio of SHCC on chloride ingress and rebar corrosion. Cem. Concr. Comp. 2017, 80, 235–244. [Google Scholar] [CrossRef]

- Ahn, E.; Shin, M.; Popovics, J.S.; Weaver, R.L. Effectiveness of diffuse ultrasound for evaluation of micro-cracking damage in concrete. Cem. Concr. Res. 2019, 124, 105862. [Google Scholar] [CrossRef]

- Jia, Y.; Tang, L.; Ming, P.; Xie, Y. Ultrasound-excited thermography for detecting microcracks in concrete materials. Ndt E Int. 2019, 101, 62–71. [Google Scholar] [CrossRef]

- Quiviger, A.; Payan, C.; Chaix, J.-F.; Garnier, V.; Salin, J. Effect of the presence and size of a real macro-crack on diffuse ultrasound in concrete. Ndt E Int. 2012, 45, 128–132. [Google Scholar] [CrossRef]

- Quiviger, A.; Girard, A.; Payan, C.; Chaix, J.F.; Garnier, V.; Salin, J. Influence of the depth and morphology of real cracks on diffuse ultrasound in concrete: A simulation study. Ndt E Int. 2013, 60, 11–16. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Kordatos, E.Z.; Soulioti, D.V.; Matikas, T.E. Combined use of thermography and ultrasound for the characterization of subsurface cracks in concrete. Constr. Build. Mater. 2010, 24, 1888–1897. [Google Scholar] [CrossRef]

- Loeb, A.; Earls, C. Optimized inspection design for the thermographic characterization of sub-pixel sized through cracks. Ndt E Int. 2016, 82, 44–55. [Google Scholar] [CrossRef]

- Abu-Nabah, B.A.; Al-Said, S.M.; Gouia-Zarrad, R. A simple heat diffusion model to avoid singularity in estimating a crack length using sonic infrared inspection technology. Sens. Actuat. A Phys. 2019, 293, 77–86. [Google Scholar] [CrossRef]

- Zhao, M.; Nie, Z.; Wang, K.; Liu, P.; Zhang, X. Nonlinear ultrasonic test of concrete cubes with induced crack. Ultrasonics 2019, 97, 1–10. [Google Scholar] [CrossRef]

- Iyer, S.; Sinha, S.K. A robust approach for automatic detection and segmentation of cracks in underground pipeline images. Image Vis. Comput. 2005, 23, 921–933. [Google Scholar] [CrossRef]

- Li, L.; Wang, Q.; Zhang, G.; Shi, L.; Dong, J.; Jia, P. A method of detecting the cracks of concrete undergo high-temperature. Constr. Build. Mater. 2018, 162, 345–358. [Google Scholar] [CrossRef]

- Su, T.-C.; Yang, M.-D. Morphological segmentation based on edge detection-II for automatic concrete crack measurement. Comput. Concr. 2018, 21, 727–739. [Google Scholar]

- Su, T.-C.; Yang, M.-D. Application of morphological segmentation to leaking defect detection in sewer pipelines. Sensors 2014, 14, 8686–8704. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. Comparison of deep convolutional neural networks and edge detectors for image-based crack detection in concrete. Constr. Build. Mater. 2018, 186, 1031–1045. [Google Scholar] [CrossRef]

- Dung, C.V.; Anh, L.D. Autonomous concrete crack detection using deep fully convolutional neural network. Automat. Constr. 2019, 99, 52–58. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, J.; Hong, Z.; Lu, W.; Yin, J.; Zou, L.; Shen, X. Image-based concrete crack detection in tunnels using deep fully convolutional networks. Constr. Build. Mater. 2020, 234, 117367. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Y.; Wang, Y.; Wang, W. Computer vision-based concrete crack detection using U-net fully convolutional networks. Automat. Constr. 2019, 104, 129–139. [Google Scholar] [CrossRef]

- Bayar, G.; Bilir, T. A novel study for the estimation of crack propagation in concrete using machine learning algorithms. Constr. Build. Mater. 2019, 215, 670–685. [Google Scholar] [CrossRef]

- Kabir, S. Imaging-based detection of AAR induced map-crack damage in concrete structure. Ndt E Int. 2010, 43, 461–469. [Google Scholar] [CrossRef]

- Yang, M.-D.; Su, T.-C.; Pan, N.-F.; Liu, P. Feature extraction of sewer pipe defects using wavelet transform and co-occurrence matrix. Int. J. Wavelets Multi. 2011, 9, 211–225. [Google Scholar] [CrossRef]

- Oh, B.H.; Choi, S.C.; Cha, S.W. Temperature and relative humidity analysis in early-age concrete decks of composite bridges. In Measuring, Monitoring and Modeling Concrete Properties, Proceedings of the 16th European Conference of Fracture (ECF16), Alexandroupolis, Greece, 3–7 July 2006; Springer: Dordrecht, The Netherlands, 2006; pp. 305–316. [Google Scholar]

- Erenoglu, R.C.; Akcay, O.; Erenoglu, O. An UAS-assisted multi-sensor approach for 3D modeling and reconstruction of cultural heritage site. J. Cult. Herit. 2017, 26, 79–90. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Sfarra, S.; Klein, M.; Maldague, X. Solar loading thermography: Time-lapsed thermographic survey and advanced thermographic signal processing for the inspection of civil engineering and cultural heritage structures. Infrared Phys. Technol. 2017, 82, 56–74. [Google Scholar] [CrossRef]

- FLIR Systems, Inc. 5 Factors Influencing Radiometric Temperature Measurements. Available online: https://www.cvl.isy.liu.se/education/undergraduate/tsbb09/lectures/Guidebook_Cores_5_Factors_Influencing_Radiometric_Temperature_Measurements.pdf (accessed on 17 August 2020).

- Tran, Q.H.; Han, D.; Kang, C.; Haldar, A.; Huh, J. Effects of ambient temperature and relative humidity on subsurface defect detection in concrete structures by active thermal imaging. Sensors 2017, 17, 1718. [Google Scholar] [CrossRef]

- Golrokh, A.J.; Lu, Y. An experimental study of the effects of climate conditions on thermography and pavement assessment. Int. J. Pavement Eng. 2019, 20. in press. [Google Scholar] [CrossRef]

- Lin, C.-L.; Kuo, C.-W.; Lai, C.-C.; Tsai, M.-D.; Chang, Y.-C.; Cheng, H.-Y. A novel approach to fast noise reduction of infrared image. Infrared Phys. Techn. 2011, 54, 1–9. [Google Scholar] [CrossRef]

- Washer, G.; Fenwick, R.; Bolleni, N. Effects of solar loading on infrared imaging of subsurface features in concrete. J. Bridge Eng. 2010, 15, 384–390. [Google Scholar] [CrossRef]

- Masciotta, M.; Ramos, L.F.; Lourenço, P.B. The importance of structural monitoring as a diagnosis and control tool in the restoration process of heritage structures: A case study in Portugal. J. Cult. Herit. 2017, 27, 36–47. [Google Scholar] [CrossRef]

- Islam, M.R.; Tarefder, R.A. Determining coefficients of thermal contraction and expansion of asphalt concrete using horizontal asphalt strain gage. Adv. Civ. Eng. Mater. 2014, 3, 204–219. [Google Scholar] [CrossRef]

- Islam, M.R.; Tarefder, R.A. Determining thermal properties of asphalt concrete using field data and laboratory testing. Constr. Build. Mater. 2014, 67, 297–306. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Guler, M. Thermal fatigue behavior of asphalt concrete: A laboratory-based investigation approach. Int. J. Fatigue 2019, 121, 229–236. [Google Scholar] [CrossRef]

- Barale, V.; Gade, M. Remote Sensing of the European Seas; Springer: New York, NY, USA, 2008; p. 245. [Google Scholar]

- Kaplan, Ç.D.; Murtezaoğlu, F.; İpekoğlu, B.; Böke, H. Weathering of andesite monuments in archaeological sites. J. Cult. Herit. 2013, 14, e77–e83. [Google Scholar] [CrossRef]

- Camuffo, D. Physical weathering of stones. Sci. Total Environ. 1995, 167, 1–14. [Google Scholar] [CrossRef]

- American Concrete Institute. Specifications for Structural Concrete ACI 301-05, with Selected ACI References; ACI: Farmington Hills, MI, USA, 2005; p. 257. Available online: https://openlibrary.org/works/OL3374611W/Specifications_for_structural_concrete_ACI_301-05_with_selected_ACI_references (accessed on 2 September 2020).

- Wendt, P.; Coyle, E.; Gallagher, N. Stack filters. IEEE Trans. Acoust. Speechand Signal Process. 1986, 34, 898–911. [Google Scholar] [CrossRef]

- Yli-Harja, O.; Astola, J.; Neuvo, Y. Analysis of the properties of median and weighted median filters using threshold logic and stack filter representation. IEEE T. Signal Proces. 1991, 39, 395–410. [Google Scholar] [CrossRef]

- Shih, F.Y. Image Processing and Pattern Recognition Fundamentals and Techniques; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; p. 133. [Google Scholar]

- Ching Hsing Computer Tech. LTD. Available online: http://www.chct.com.tw/ (accessed on 22 August 2020).

- Wolf, P.R.; Dewitt, B.A. Elements of Photogrammetry with Applications in GIS, 3rd ed.; McGraw-Hill: New York, NY, USA, 2000; pp. 518–521. [Google Scholar]

- Yan, H. Unified formulation of a class of image thresholding techniques. Pattern Recogn. 1996, 29, 2025–2032. [Google Scholar] [CrossRef]

- Budzan, S.; Wyżgolik, R. Noise Reduction in Thermal Images. In Proceedings of the International Conference on Computer Vision and Graphics (ICCVG 2014), Warsaw, Poland, 15–17 September 2014; pp. 116–123. [Google Scholar]

- Buades, A.; Coll, B.; Morel, J.M. A review of image denoising algorithms, with a new one. SIAM J. Multiscale Modeling Simul. 2005, 4, 490–530. [Google Scholar] [CrossRef]

- Goyal, B.; Dogra, A.; Agrawal, S.; Sohi, B.S.; Sharma, A. Image denoising review: From classical to state-of-the-art approaches. Inform. Fusion 2020, 55, 220–244. [Google Scholar] [CrossRef]

- Liu, L.; Xu, L.; Fang, H. Infrared and visible image fusion and denoising via ℓ2 − ℓp norm minimization. Signal Process. 2020, 172, 107546. [Google Scholar] [CrossRef]

- Xie, B.; Xiong, Z.; Wang, Z.; Zhang, L.; Zhnag, D.; Li, F. Gamma spectrum denoising method based on improved wavelet threshold. Nucl. Eng. Technol. 2020, 52, 1771–1776. [Google Scholar] [CrossRef]

- Misiti, M.; Misiti, Y.; Oppenheim, G.; Michel, J.P. Wavelet Toolbox: For Use with Matlab; The MathWorks, Inc.: Natick, MA, USA, 1996. [Google Scholar]

- Mallat, S.G. A theory for multiresolution signal decomposition: The wavelet representation. IEEE T. Pattern Anal. 1989, 11, 674–693. [Google Scholar] [CrossRef]

- Yaseen, A.S.; Zamel, R.S.; Khlaief, J.H. Wavelet-based denoising of images. Eng. Technol. J. 2019, 37, 54–60. [Google Scholar]

- Gonzalez, R.C.; Woods, R.E.; Eddins, S.L. Digital Image Processing Using Matlab, 2nd ed.; McGraw: New York, NY, USA, 2011; p. 339. [Google Scholar]

| Date | Time | No. of TIR Images | Focusing Ranges (m) | Weather | |

|---|---|---|---|---|---|

| Temperature (°C) | Relative Humidity (%) | ||||

| 12 March 2019 | 14:40~15:00 | 10 | 0.5 * | 24.1 | 49 |

| 30 April 2019 | 15:30~15:50 | 13 | 0.5, 0.6, 0.7,0.8 | 27.8 | 78 |

| 10 May 2019 | 10:50~11:10 | 13 | 0.5 | 22.7 | 71 |

| 20 June 2019 | 08:20~08:40 | 11 | 0.5, 1.1, 1.3, 1.5, 1.9 | 28.1 | 85 |

| 14 August 2019 | 08:40~09:00 | 12 | 0.6 | 28.9 | 86 |

| Total | 59 | ||||

| Date | Image ID | Focusing Range (m) | RCW * (mm) | Ti | To | MedTo—MedTi(°C) | Avg. of MedTo–MedTi (°C) | ||

|---|---|---|---|---|---|---|---|---|---|

| IQR (°C) | Avg. IQR (°C) | IQR (°C) | Avg. IQR (°C) | ||||||

| 12 March 2019 | 1 | 0.5 | 6~15 | 0.78 | 0.79 | 0.59 | 0.60 | 0.23 | 0.26 |

| 2 | 0.79 | 0.53 | 0.24 | ||||||

| 3 | 0.79 | 0.67 | 0.31 | ||||||

| 4 | 5~15↑ | 0.79 | - | 0.65 | - | 0.17 | - | ||

| 5 | 2~11 | 0.60 | 0.65 | 0.67 | 0.68 | 0.00 | 0.06 | ||

| 6 | 0.59 | 0.59 | 0.12 | ||||||

| 7 | 0.67 | 0.74 | 0.07 | ||||||

| 8 | 0.74 | 0.71 | 0.04 | ||||||

| 9 | 16~17 | 0.92 | - | 0.74 | - | 0.31 | - | ||

| 10 | 0.5 ↑ | 2~20↑ | 0.48 | - | 0.48 | - | 0.00 | - | |

| 30 April 2019 | 1 | 0.8 | 11~23 | 0.67 | - | 0.59 | - | 0.42 | - |

| 2 | 0.5 | 6~15 | 0.60 | 0.60 | 0.48 | 0.53 | 0.24 | 0.24 | |

| 3 | 0.54 | 0.55 | 0.23 | ||||||

| 4 | 0.67 | 0.55 | 0.24 | ||||||

| 5 | 0.7 | 3~20↑ | 0.74 | 0.72 | 0.62 | 0.59 | 0.14 | 0.18 | |

| 6 | 0.67 | 0.55 | 0.17 | ||||||

| 7 | 0.74 | 0.60 | 0.24 | ||||||

| 8 | 0.6 | 2~7.5 | 0.66 | 0.58 | 0.76 | 0.67 | 0.10 | 0.08 | |

| 9 | 0.54 | 0.59 | 0.07 | ||||||

| 10 | 0.54 | 0.66 | 0.07 | ||||||

| 11 | 0.5 | 4~5 | 0.41 | 0.40 | 0.41 | 0.36 | −0.07 | −0.02 | |

| 12 | 0.40 | 0.31 | 0.00 | ||||||

| 13 | 0.40 | 0.36 | 0.00 | ||||||

| 10 May 2019 | 1 | 0.5 | 1~3.5 | 0.29 | 0.36 | 0.31 | 0.35 | 0.00 | −0.02 |

| 2 | 0.47 | 0.50 | 0.03 | ||||||

| 3 | 0.31 | 0.24 | −0.07 | ||||||

| 4 | 1~4 | 0.26 | 0.26 | 0.33 | 0.30 | 0.00 | 0.00 | ||

| 5 | 0.26 | 0.26 | 0.00 | ||||||

| 6 | 1.5~6.5 | 0.50 | 0.47 | 0.47 | 0.42 | 0.00 | 0.00 | ||

| 7 | 0.43 | 0.38 | 0.00 | ||||||

| 8 | 1.5~4 | 0.38 | 0.38 | 0.36 | 0.37 | 0.00 | 0.00 | ||

| 9 | 0.38 | 0.38 | 0.00 | ||||||

| 10 | 0.38 | 0.38 | 0.00 | ||||||

| 11 | 2.5~3.5 | 0.38 | 0.36 | 0.38 | 0.37 | 0.00 | 0.00 | ||

| 12 | 0.31 | 0.36 | 0.00 | ||||||

| 13 | 0.38 | 0.38 | 0.00 | ||||||

| 20 June 2019 | 1 | 0.5 | 15~19 | 0.36 | - | 0.36 | - | 0.00 | - |

| 2 | 1.9 | 6~19 | 0.28 | - | 0.28 | - | −0.05 | - | |

| 3 | 1.5 | 6~20 | 0.26 | - | 0.31 | - | 0.07 | - | |

| 4 | 1.5 | 4~20↑ | 0.29 | - | 0.29 | - | 0.05 | - | |

| 5 | 1.3 | 1.5~6.5 | 0.29 | - | 0.24 | - | 0.00 | - | |

| 6 | 1.1 | 1~3.5 | 0.31 | 0.32 | 0.31 | 0.32 | 0.07 | 0.00 | |

| 7 | 0.34 | 0.31 | −0.07 | ||||||

| 8 | 0.31 | 0.35 | 0.00 | ||||||

| 9 | 1.1 | 4~15 | 0.55 | 0.53 | 0.47 | 0.55 | 0.07 | 0.05 | |

| 10 | 0.50 | 0.55 | 0.04 | ||||||

| 11 | 0.54 | 0.62 | 0.04 | ||||||

| 14 August 2019 | 1 | 0.6 | 11~25 | 0.35 | 0.32 | 0.38 | 0.33 | 0.00 | 0.00 |

| 2 | 0.31 | 0.38 | 0.00 | ||||||

| 3 | 0.29 | 0.24 | 0.00 | ||||||

| 4 | 3~12 | 0.43 | 0.38 | 0.36 | 0.34 | 0.00 | 0.04 | ||

| 5 | 0.36 | 0.36 | 0.00 | ||||||

| 6 | 0.36 | 0.31 | 0.12 | ||||||

| 7 | 1.5~6.5 | 0.36 | 0.32 | 0.40 | 0.33 | 0.00 | 0.00 | ||

| 8 | 0.31 | 0.31 | 0.00 | ||||||

| 9 | 0.28 | 0.28 | 0.00 | ||||||

| 10 | 2.5~3.5 | 0.29 | 0.32 | 0.29 | 0.29 | 0.00 | 0.01 | ||

| 11 | 0.35 | 0.28 | 0.00 | ||||||

| 12 | 0.31 | 0.29 | 0.03 | ||||||

| Date | Image ID | Pixel Number of Extracted Crack Temperature Values | Proportions of Ti Values Accepting Null (H0) and Alternative (H1) Hypotheses (%) | |||

|---|---|---|---|---|---|---|

| Ti | To | H0: Ti = To | H1: Ti > To | H1: Ti < To | ||

| 12 March 2019 | 1 | 1277 | 361 | 43.4 | 0.0 | 56.6 |

| 2 | 1083 | 322 | 29.8 | 0.0 | 70.2 | |

| 3 | 964 | 314 | 2.3 | 32.6 | 65.1 | |

| 4 | 1211 | 446 | 0.0 | 26.3 | 73.7 | |

| 5 | 1423 | 481 | 66.2 | 33.8 | 0.0 | |

| 6 | 1466 | 837 | 0.0 | 0.0 | 100.0 | |

| 7 | 932 | 428 | 54.1 | 0.0 | 45.9 | |

| 8 | 1189 | 638 | 46.3 | 0.0 | 53.7 | |

| 9 | 1324 | 251 | 5.2 | 19.0 | 75.8 | |

| 10 | 728 | 376 | 0.0 | 51.6 | 48.4 | |

| 30 April 2019 | 1 | 699 | 224 | 3.9 | 0.0 | 96.1 |

| 2 | 1461 | 377 | 22.6 | 0.0 | 77.4 | |

| 3 | 1483 | 377 | 0.0 | 0.0 | 100.0 | |

| 4 | 1534 | 378 | 1.4 | 0.0 | 98.6 | |

| 5 | 796 | 331 | 16.8 | 0.0 | 83.2 | |

| 6 | 753 | 336 | 10.8 | 0.0 | 89.2 | |

| 7 | 815 | 347 | 14.8 | 0.0 | 85.2 | |

| 8 | 820 | 370 | 0.0 | 45.1 | 54.9 | |

| 9 | 826 | 392 | 5.0 | 47.5 | 47.5 | |

| 10 | 810 | 398 | 0.0 | 49.1 | 50.9 | |

| 11 | 644 | 252 | 100.0 | 0.0 | 0.0 | |

| 12 | 638 | 243 | 76.2 | 0.0 | 23.8 | |

| 13 | 604 | 226 | 37.4 | 37.4 | 25.2 | |

| 10 May 2019 | 1 | 335 | 335 | 100.0 | 0.0 | 0.0 |

| 2 | 220 | 220 | 100.0 | 0.0 | 0.0 | |

| 3 | 245 | 245 | 100.0 | 0.0 | 0.0 | |

| 4 | 354 | 354 | 100.0 | 0.0 | 0.0 | |

| 5 | 287 | 287 | 100.0 | 0.0 | 0.0 | |

| 6 | 495 | 376 | 24.0 | 0.0 | 76.0 | |

| 7 | 487 | 363 | 25.5 | 0.0 | 74.5 | |

| 8 | 462 | 359 | 0.0 | 22.3 | 77.7 | |

| 9 | 452 | 359 | 20.6 | 0.0 | 79.4 | |

| 10 | 449 | 372 | 17.1 | 0.0 | 82.9 | |

| 11 | 386 | 287 | 25.6 | 0.0 | 74.4 | |

| 12 | 353 | 299 | 100.0 | 0.0 | 0.0 | |

| 13 | 379 | 278 | 26.6 | 0.0 | 73.4 | |

| 20 June 2019 | 1 | 867 | 229 | 47.2 | 26.4 | 26.4 |

| 2 | 434 | 274 | 100.0 | 0.0 | 0.0 | |

| 3 | 610 | 324 | 100.0 | 0.0 | 0.0 | |

| 4 | 494 | 304 | 100.0 | 0.0 | 0.0 | |

| 5 | 269 | 269 | 0.0 | 100.0 | 0.0 | |

| 6 | 183 | 183 | 100.0 | 0.0 | 0.0 | |

| 7 | 180 | 180 | 100.0 | 0.0 | 0.0 | |

| 8 | 193 | 193 | 100.0 | 0.0 | 0.0 | |

| 9 | 366 | 342 | 100.0 | 0.0 | 0.0 | |

| 10 | 345 | 345 | 100.0 | 0.0 | 0.0 | |

| 11 | 379 | 379 | 100.0 | 0.0 | 0.0 | |

| 14 August 2019 | 1 | 1040 | 236 | 68.1 | 0.0 | 31.9 |

| 2 | 979 | 238 | 100.0 | 0.0 | 0.0 | |

| 3 | 984 | 235 | 76.1 | 0.0 | 23.9 | |

| 4 | 1168 | 468 | 19.9 | 40.1 | 40.0 | |

| 5 | 1087 | 456 | 16.1 | 42.0 | 41.9 | |

| 6 | 1230 | 499 | 40.6 | 0.0 | 59.4 | |

| 7 | 450 | 350 | 22.2 | 0.0 | 77.8 | |

| 8 | 437 | 339 | 0.0 | 22.4 | 77.6 | |

| 9 | 442 | 339 | 23.3 | 0.0 | 76.7 | |

| 10 | 307 | 287 | 100.0 | 0.0 | 0.0 | |

| 11 | 311 | 285 | 100.0 | 0.0 | 0.0 | |

| 12 | 307 | 296 | 100.0 | 0.0 | 0.0 | |

| Crack Width Range (mm) | RMSE Obtained on (mm) | |

|---|---|---|

| 12 March 2019 | 30 April 2019 | |

| 6~10 | ±1.8 | ±2.2 |

| 11~15 | ±2.3 | ±2.2 |

| 15↑ | ±1.7 | ±2.2 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, T.-C. Assessment of Cracking Widths in a Concrete Wall Based on TIR Radiances of Cracking. Sensors 2020, 20, 4980. https://doi.org/10.3390/s20174980

Su T-C. Assessment of Cracking Widths in a Concrete Wall Based on TIR Radiances of Cracking. Sensors. 2020; 20(17):4980. https://doi.org/10.3390/s20174980

Chicago/Turabian StyleSu, Tung-Ching. 2020. "Assessment of Cracking Widths in a Concrete Wall Based on TIR Radiances of Cracking" Sensors 20, no. 17: 4980. https://doi.org/10.3390/s20174980

APA StyleSu, T.-C. (2020). Assessment of Cracking Widths in a Concrete Wall Based on TIR Radiances of Cracking. Sensors, 20(17), 4980. https://doi.org/10.3390/s20174980