Bragg Grating Assisted Sagnac Interferometer in SiO2-Al2O3-La2O3 Polarization-Maintaining Fiber for Strain–Temperature Discrimination

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

3.1. Transmission Spectra of Fabricated Device

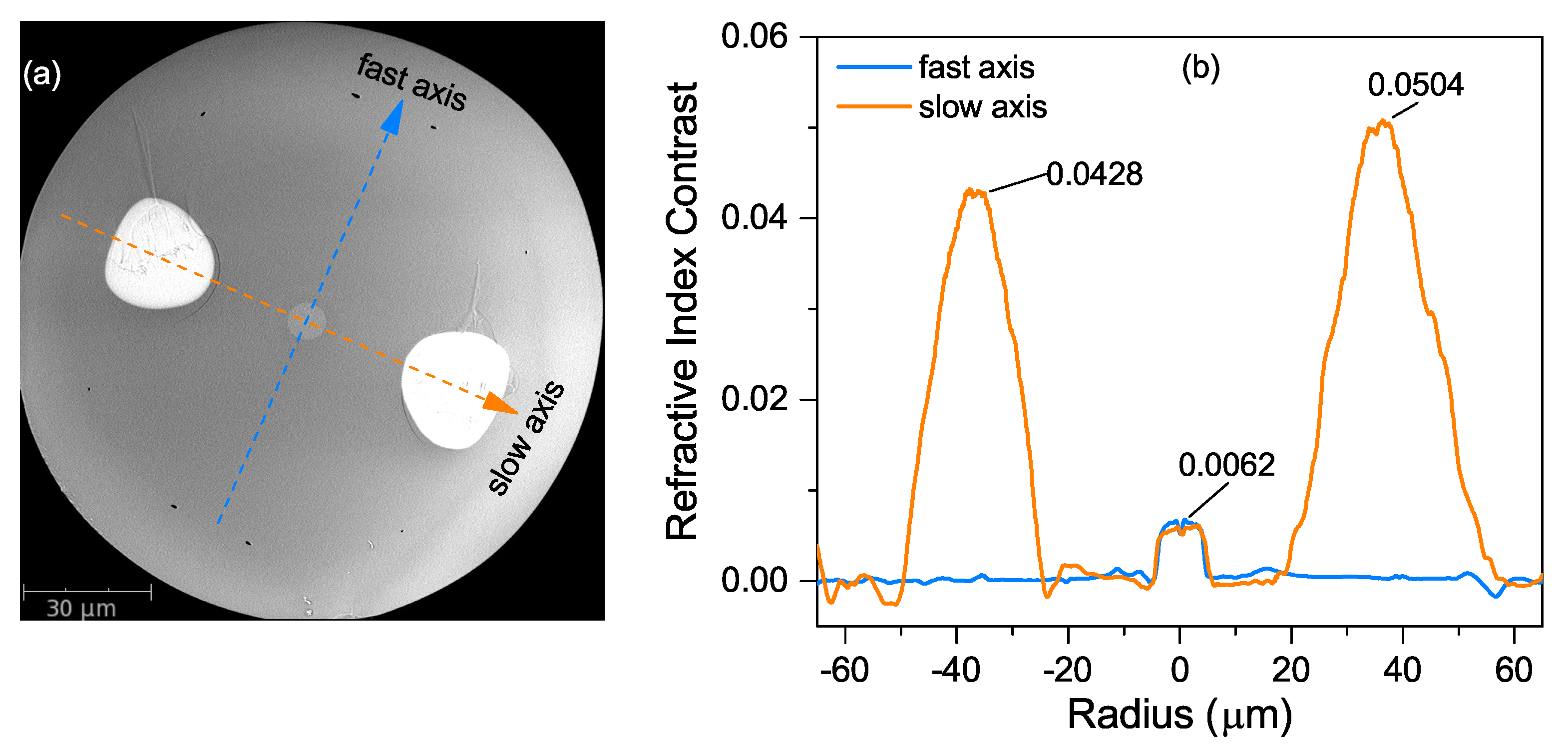

3.2. Stress and Birefringence Simulation

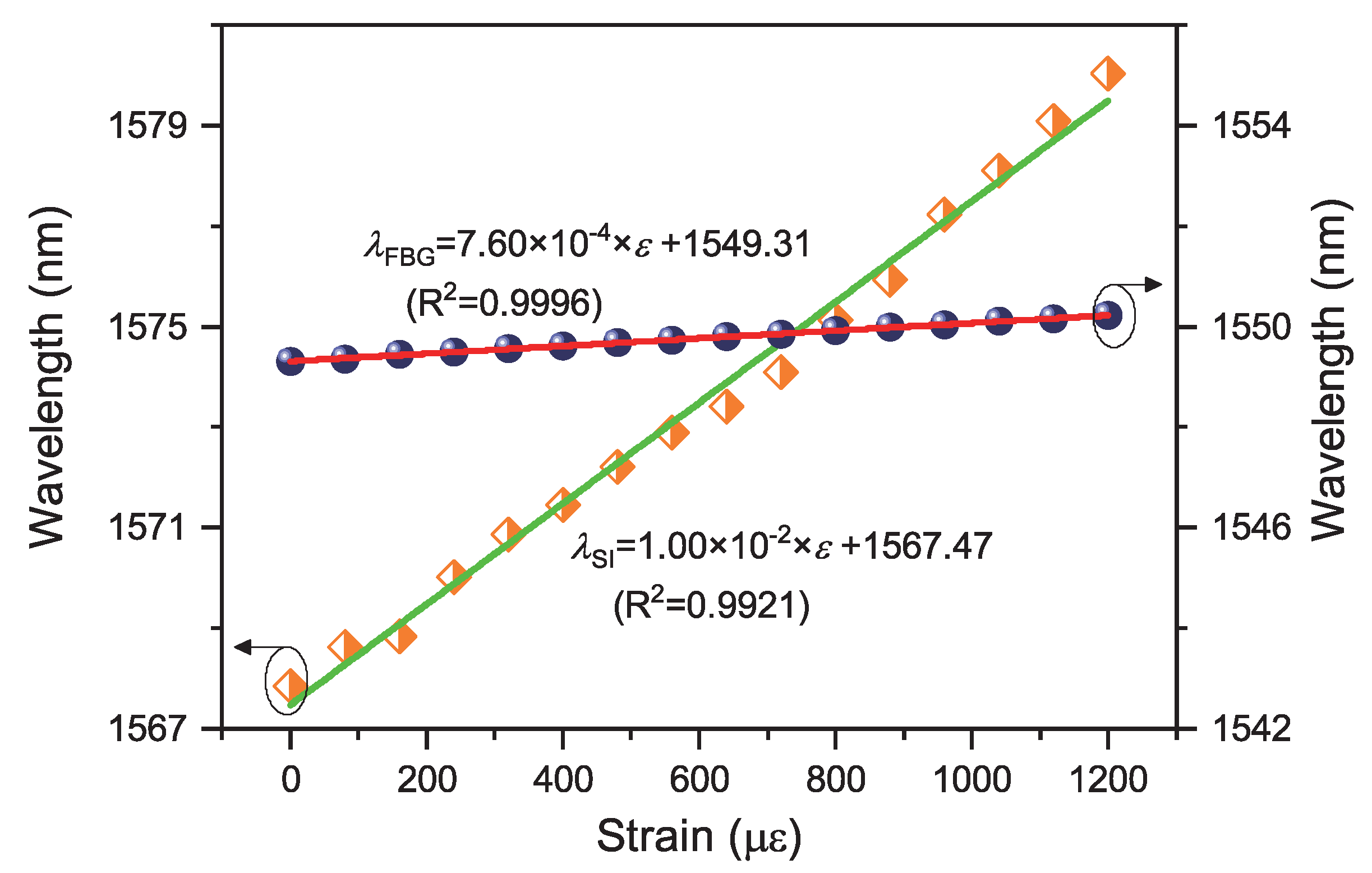

3.3. Sensing Performance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Méndez, A.; Morse, T.F. Specialty Optical Fibers Handbook; Elsevier Academic Press: Cambridge, MA, USA, 2007; pp. 243–276. [Google Scholar] [CrossRef]

- Noda, J.; Okamoto, K.; Sasaki, Y. Polarization-maintaining fibers and their applications. J. Lightw. Technol. 1986, 4, 1071–1089. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, B.; Feng, X.; Zhang, W.; Zhou, G.; Yuan, S.; Kai, G.; Dong, X. High-birefringence fiber loop mirrors and their applications as sensors. Appl. Opt. 2005, 44, 2382–2390. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Tam, H.Y.; Shum, P.P. Temperature-insensitive strain sensor with polarization-maintaining photonic crystal fiber based Sagnac interferometer. Appl. Phys. Lett. 2007, 90, 151113. [Google Scholar] [CrossRef]

- Gouveia, C.; Chesini, G.; Cordeiro, C.M.B.; Baptista, J.M.; Jorge, P.A.S. Simultaneous measurement of refractive index and temperature using multimode interference inside a high birefringence fiber loop mirror. Sens. Actuators B 2013, 177, 717–723. [Google Scholar] [CrossRef]

- Frazão, O.; Baptista, M.J.; Santos, L.J. Recent Advances in High-Birefringence Fiber Loop Mirror Sensors. Sensors 2007, 7, 2970. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.P.; Wei, L.; Liu, W.K.; Lit, J.W.Y. Simultaneous measurement of strain and temperature based on a fiber Bragg grating combined with a high-birefringence fiber loop mirror. Opt. Commun. 2008, 281, 4640–4643. [Google Scholar] [CrossRef]

- Wang, S.S.; Hu, Z.F.; Li, Y.H.; Tong, L.M. All-fiber Fabry-Perot resonators based on microfiber Sagnac loop mirrors. Opt. Lett. 2009, 34, 253–255. [Google Scholar] [CrossRef]

- Zheng, Y.; Wu, Z.; Shum, P.P.; Xu, Z.; Keiser, G.; Humbert, G.; Zhang, H.; Zeng, S.; Dinh, X.Q. Sensing and lasing applications of whispering gallery mode microresonators. Opto-Electronic Advances 2018, 1, 180015. [Google Scholar] [CrossRef]

- Chu, P.; Sammut, R. Analytical method for calculation of stresses and material birefringence in polarization-maintaining optical fiber. J. Lightw. Technol. 1984, 2, 650–662. [Google Scholar] [CrossRef]

- Frazão, O.; Silva, S.O.; Baptista, J.M.; Santos, J.L.; Statkiewicz-Barabach, G.; Urbanczyk, W.; Wojcik, J. Simultaneous measurement of multiparameters using a Sagnac interferometer with polarization maintaining side-hole fiber. Appl. Opt. 2008, 47, 4841–4848. [Google Scholar] [CrossRef]

- Ramaswamy, V.; French, W.G.; Standley, R.D. Polarization characteristics of noncircular core single-mode fibers. Appl. Opt. 1978, 17, 3014–3017. [Google Scholar] [CrossRef] [PubMed]

- Adams, M.J.; Payne, D.N.; Ragdale, C.M. Birefringence in optical fibres with elliptical cross-section. Electron. Lett. 1979, 15, 298–299. [Google Scholar] [CrossRef]

- Knight, J.C.; Birks, T.A.; Russell, P.S.J.; Atkin, D.M. All-silica single-mode optical fiber with photonic crystal cladding. Opt. Lett. 1996, 21, 1547–1549. [Google Scholar] [CrossRef] [PubMed]

- Russell, P. Photonic Crystal Fibers. Science 2003, 299, 358–362. [Google Scholar] [CrossRef]

- Suzuki, K.; Kubota, H.; Kawanishi, S.; Tanaka, M.; Fujita, M. Optical properties of a low-loss polarization-maintaining photonic crystal fiber. Opt. Express 2001, 9, 676–680. [Google Scholar] [CrossRef]

- Steel, M.J.; Osgood, R.M. Polarization and Dispersive Properties of Elliptical-Hole Photonic Crystal Fibers. J. Lightw. Technol. 2001, 19, 495. [Google Scholar] [CrossRef]

- Varnham, M.; Payne, D.N.; Barlow, A.; Birch, R. Analytic solution for the birefringence produced by thermal stress in polarization-maintaining optical fibers. J. Lightw. Technol. 1983, 1, 332–339. [Google Scholar] [CrossRef]

- Ramaswamy, V.; Stolen, R.H.; Divino, M.D.; Pleibel, W. Birefringence in elliptically clad borosilicate single-mode fibers. Appl. Opt. 1979, 18, 4080–4084. [Google Scholar] [CrossRef]

- Kudinova, M.; Humbert, G.; Auguste, J.L.; Delaizir, G. Multimaterial polarization maintaining optical fibers fabricated with the powder-in-tube technology. Opt. Mater. Express 2017, 7, 3780–3790. [Google Scholar] [CrossRef]

- Litzkendorf, D.; Grimm, S.; Schuster, K.; Kobelke, J.; Schwuchow, A.; Ludwig, A.; Kirchhof, J.; Leich, M.; Jetschke, S.; Dellith, J.; et al. Study of Lanthanum Aluminum Silicate Glasses for Passive and Active Optical Fibers. Int. J. Appl. Glass Sci. 2012, 3, 321–331. [Google Scholar] [CrossRef]

- Dragic, P.D.; Kucera, C.; Ballato, J.; Litzkendorf, D.; Dellith, J.; Schuster, K. Brillouin scattering properties of lanthano-aluminosilicate optical fiber. Appl. Opt. 2014, 53, 5660. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; Wu, Z.; Shum, P.P.; Dinh, X.; Humbert, G. Investigation on the Impact of Hi-Bi Fiber Length on the Sensitivity of Sagnac Interferometer. IEEE Sens. J. 2014, 14, 1952–1956. [Google Scholar] [CrossRef][Green Version]

- Kim, H.M.; Nam, H.; Moon, D.S.; Kim, Y.H.; Lee, B.H.; Chung, Y. Simultaneous measurement of strain and temperature with high sensing accuracy. In Proceedings of the 2009 14th OptoElectronics and Communications Conference, Vienna, Austria, 13–17 July 2009; pp. 1–2. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, H.; Shum, P.P.; Shao, X.; Huang, T.; Seow, Y.M.; Liu, Y.G.; Wei, H.; Wang, Z. Supermode Bragg grating combined Mach-Zehnder interferometer for temperature-strain discrimination. Opt. Express 2015, 23, 33001–33007. [Google Scholar] [CrossRef] [PubMed]

- Guan, R.; Zhu, F.; Gan, Z.; Huang, D.; Liu, S. Stress birefringence analysis of polarization maintaining optical fibers. Opt. Fiber Technol. 2005, 11, 240–254. [Google Scholar] [CrossRef]

- Zhao, J.; Tang, M.; Oh, K.; Feng, Z.; Zhao, C.; Liao, R.; Fu, S.; Shum, P.P.; Liu, D. Polarization-maintaining few mode fiber composed of a central circular-hole and an elliptical-ring core. Photon. Res. 2017, 5, 261–266. [Google Scholar] [CrossRef]

- Fleming, J.W. Dispersion in GeO2-SiO2 glasses. Appl. Opt. 1984, 23, 4486–4493. [Google Scholar] [CrossRef] [PubMed]

- Dianov, E.M.; Mashinsky, V.M. Germania-Based Core Optical Fibers. J. Lightw. Technol. 2005, 23, 3500. [Google Scholar] [CrossRef]

- Guan, B.; Tam, H.Y.; Tao, X.M.; Dong, X.Y. Simultaneous strain and temperature measurement using a superstructure fiber Bragg grating. IEEE Photon. Techno. Lett. 2000, 12, 675–677. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, Y.G.; Wang, Z.; Jiang, M.; Ji, W.; Han, T.; Li, S.; Shao, X.; Dinh, X.Q.; Tjin, S.C.; et al. Simultaneous measurement of curvature and strain based on fiber Bragg grating in two-dimensional waveguide array fiber. Opt. Lett. 2013, 38, 4070–4073. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Z.; Shum, P.P.; Shao, X.; Wang, R.; Dinh, X.Q.; Fu, S.; Tong, W.; Tang, M. Directional torsion and temperature discrimination based on a multicore fiber with a helical structure. Opt. Express 2018, 26, 544–551. [Google Scholar] [CrossRef]

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; LeBlanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber grating sensors. J. Lightwave Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

| Cladding | Core | SAL Rods | |

|---|---|---|---|

| Material | pure silica | GeO2 doped silica | La2O3-Al2O3 doped silica |

| Diameter (μm) | 140 | 8.4 | 24.2 |

| Young’s modulus (GPa) | 78.3 | 78.3 | 110.7 |

| Poisson’s ratio | 0.186 | 0.186 | 0.282 |

| Relative density (kg/m3) | 2203 | 2203 | 3346.7 |

| Thermal expansion coefficient (K−1) | 5.4 × | 1.0 × | 5.32 × |

| First stress optical coefficient (/N) | 0.65 × | ||

| Second stress optical coefficient (m2/N) | 4.2 × | ||

| Operating temperature (°C) | 20 | ||

| Reference temperature (°C) | 1100 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Wu, P.; Kudinova, M.; Zhang, H.; Shum, P.P.; Shao, X.; Humbert, G.; Auguste, J.-L.; Dinh, X.Q.; Pu, J. Bragg Grating Assisted Sagnac Interferometer in SiO2-Al2O3-La2O3 Polarization-Maintaining Fiber for Strain–Temperature Discrimination. Sensors 2020, 20, 4772. https://doi.org/10.3390/s20174772

Wu Z, Wu P, Kudinova M, Zhang H, Shum PP, Shao X, Humbert G, Auguste J-L, Dinh XQ, Pu J. Bragg Grating Assisted Sagnac Interferometer in SiO2-Al2O3-La2O3 Polarization-Maintaining Fiber for Strain–Temperature Discrimination. Sensors. 2020; 20(17):4772. https://doi.org/10.3390/s20174772

Chicago/Turabian StyleWu, Zhifang, Peili Wu, Maryna Kudinova, Hailiang Zhang, Perry Ping Shum, Xuguang Shao, Georges Humbert, Jean-Louis Auguste, Xuan Quyen Dinh, and Jixiong Pu. 2020. "Bragg Grating Assisted Sagnac Interferometer in SiO2-Al2O3-La2O3 Polarization-Maintaining Fiber for Strain–Temperature Discrimination" Sensors 20, no. 17: 4772. https://doi.org/10.3390/s20174772

APA StyleWu, Z., Wu, P., Kudinova, M., Zhang, H., Shum, P. P., Shao, X., Humbert, G., Auguste, J.-L., Dinh, X. Q., & Pu, J. (2020). Bragg Grating Assisted Sagnac Interferometer in SiO2-Al2O3-La2O3 Polarization-Maintaining Fiber for Strain–Temperature Discrimination. Sensors, 20(17), 4772. https://doi.org/10.3390/s20174772