Measuring Acoustic Roughness of a Longitudinal Railhead Profile Using a Multi-Sensor Integration Technique

Abstract

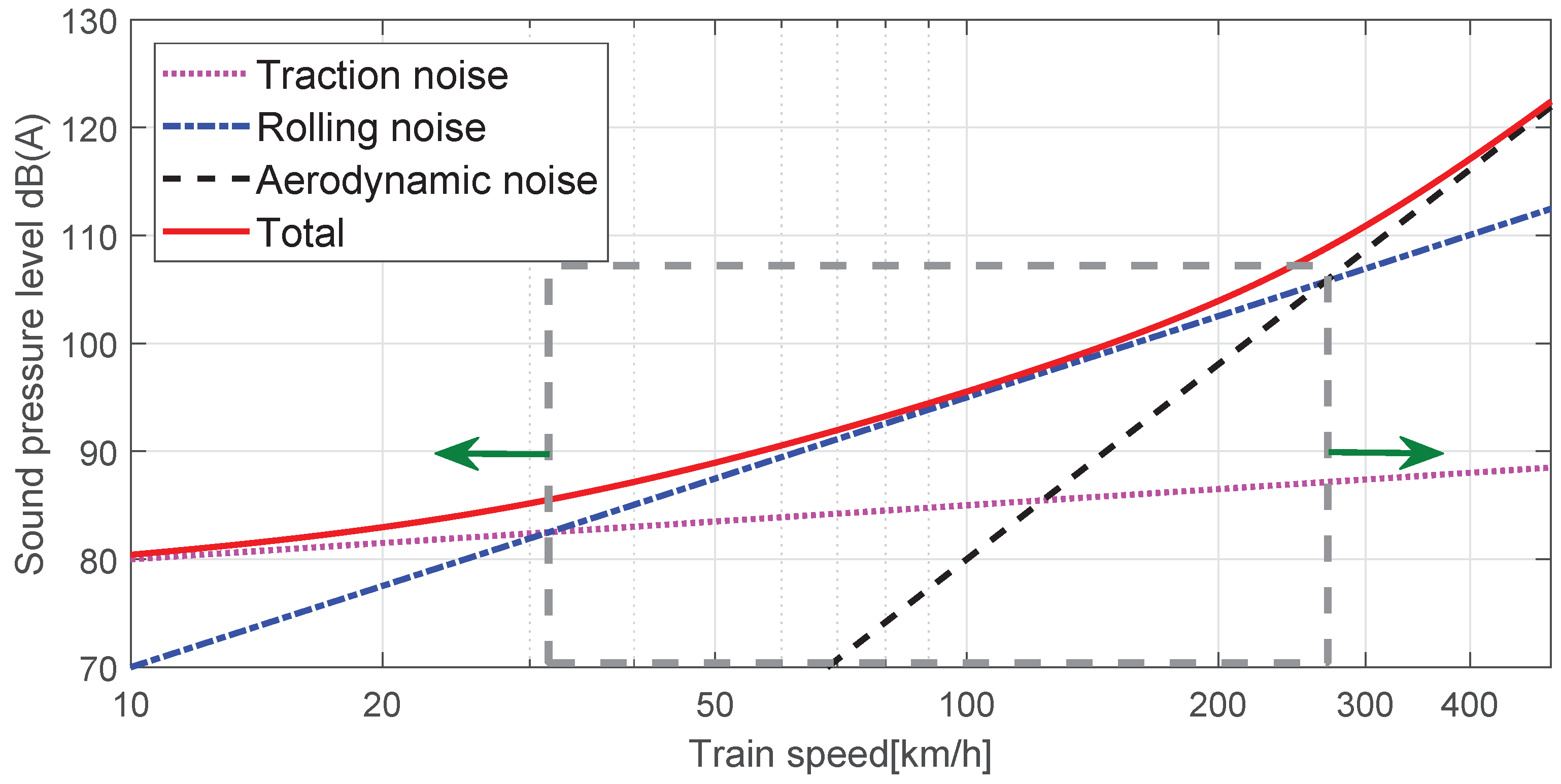

:1. Introduction

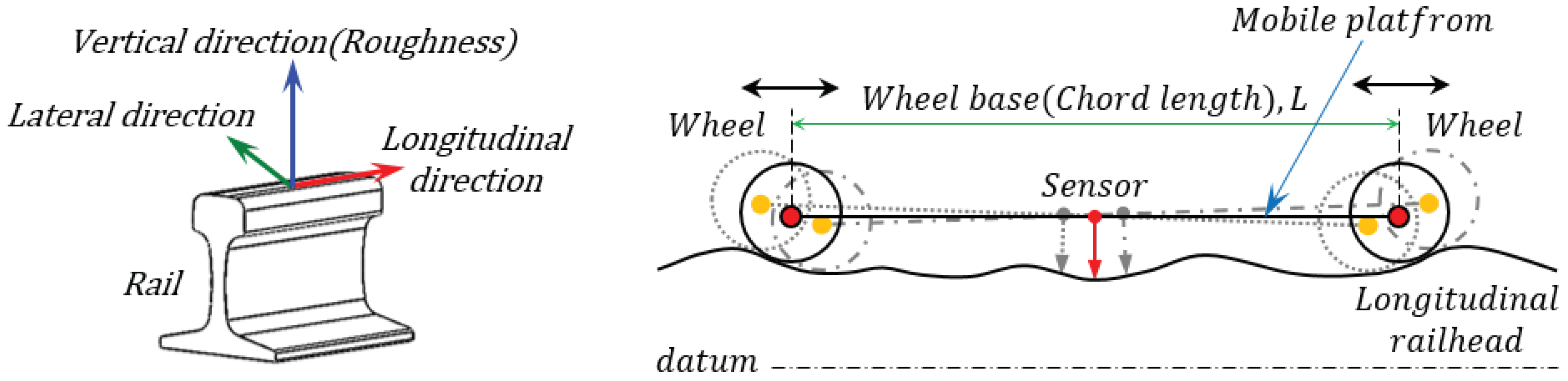

2. Measurement and Analysis of Rail Acoustic Roughness

2.1. Measurement of Acoustic Roughness Using an Acceleration Sensor

2.2. Measurement of Acoustic Roughness Using a Displacement Sensor

3. Chord Offset Synchronizing Method

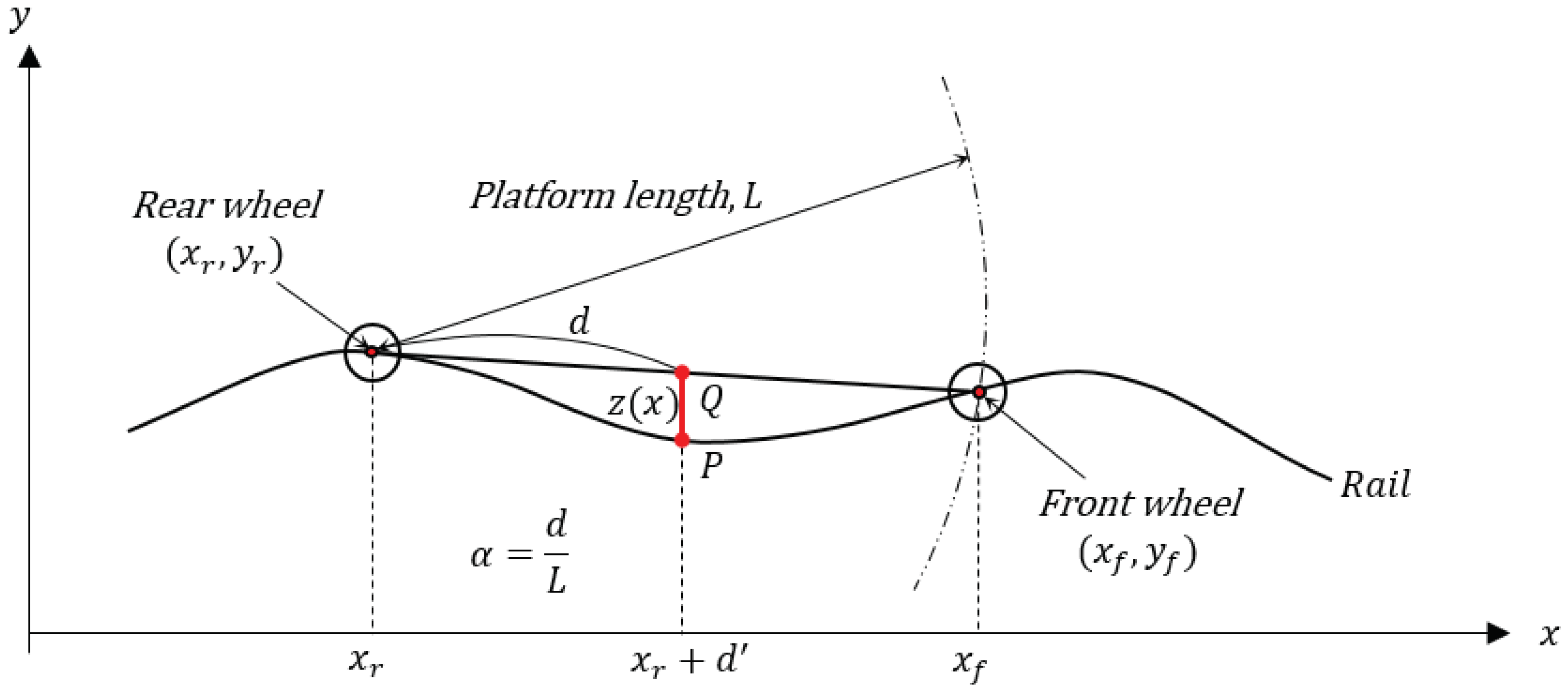

3.1. Single Sensor Measurement Compensation

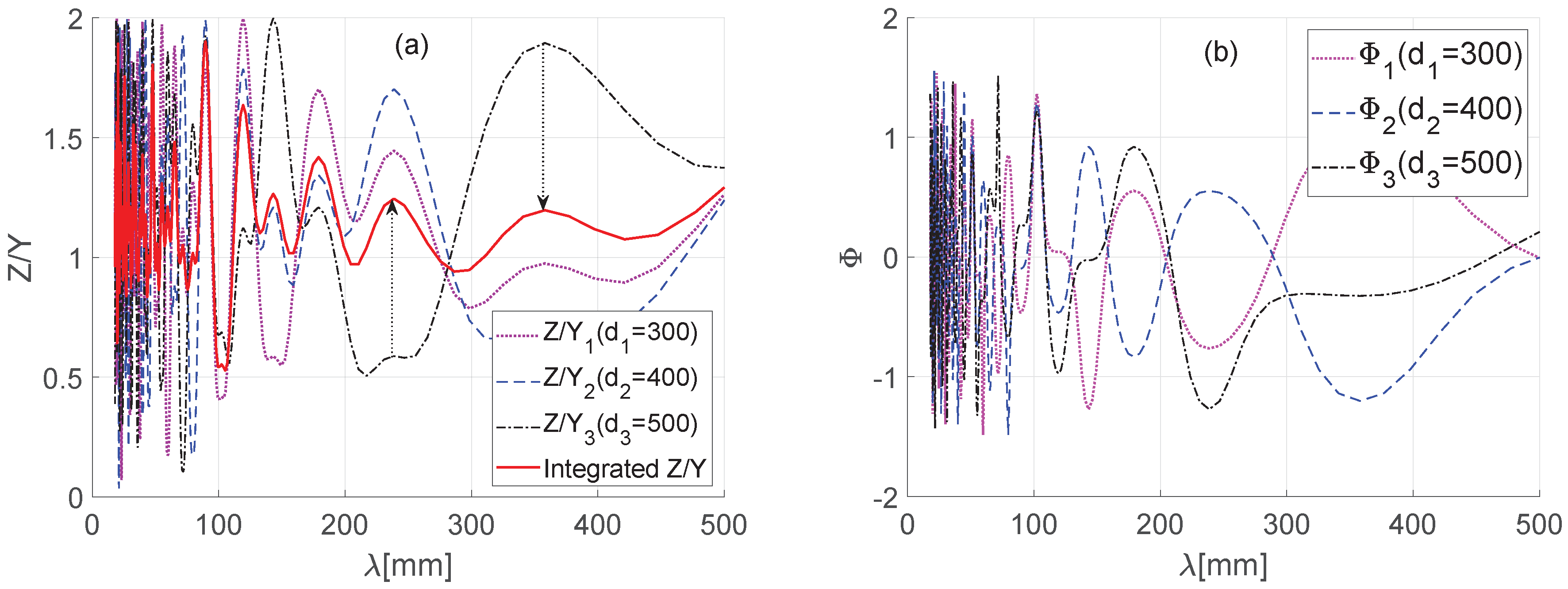

3.2. Analysis of Acoustic Roughness by a Convergence of Multiple Sensors

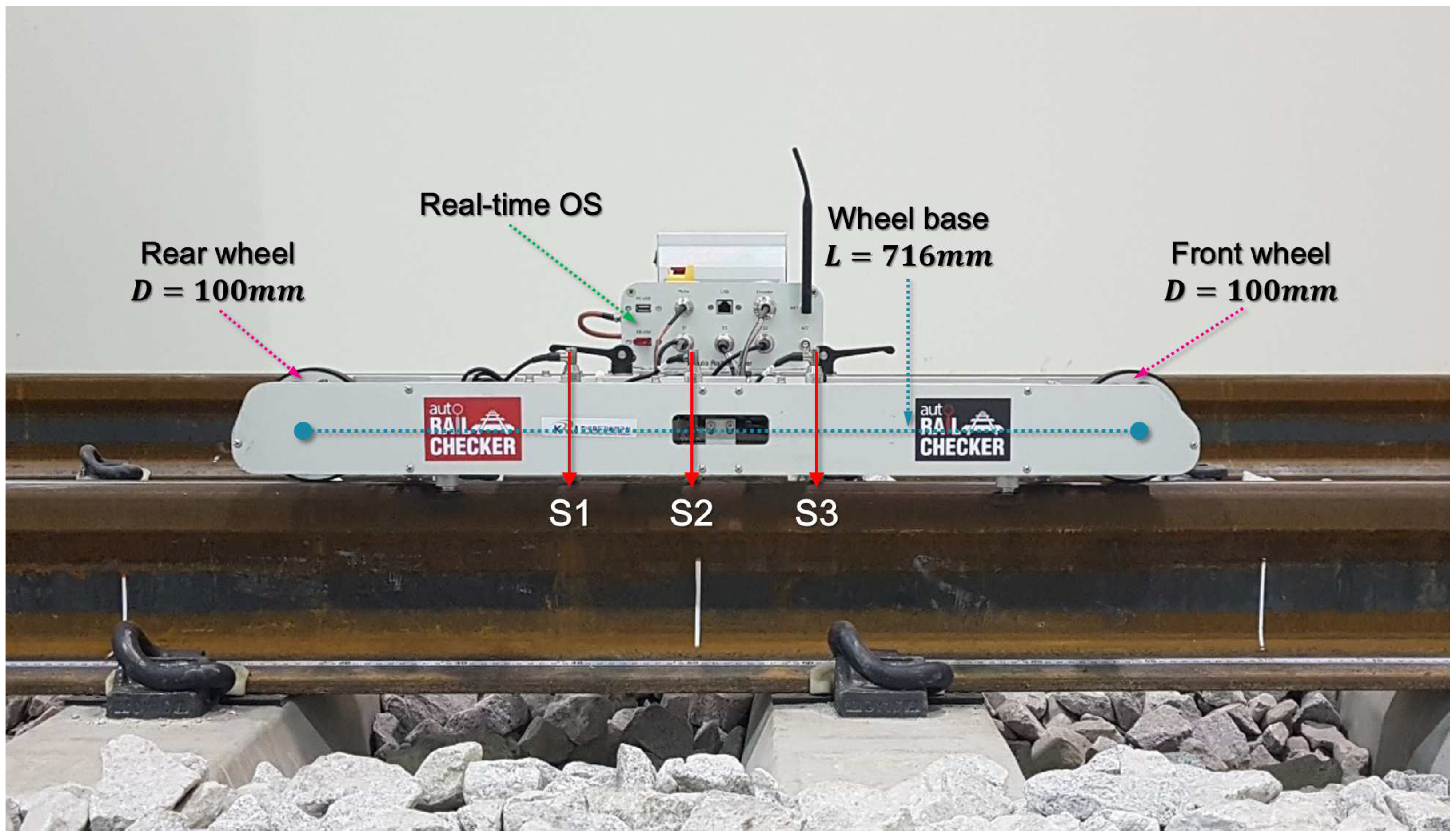

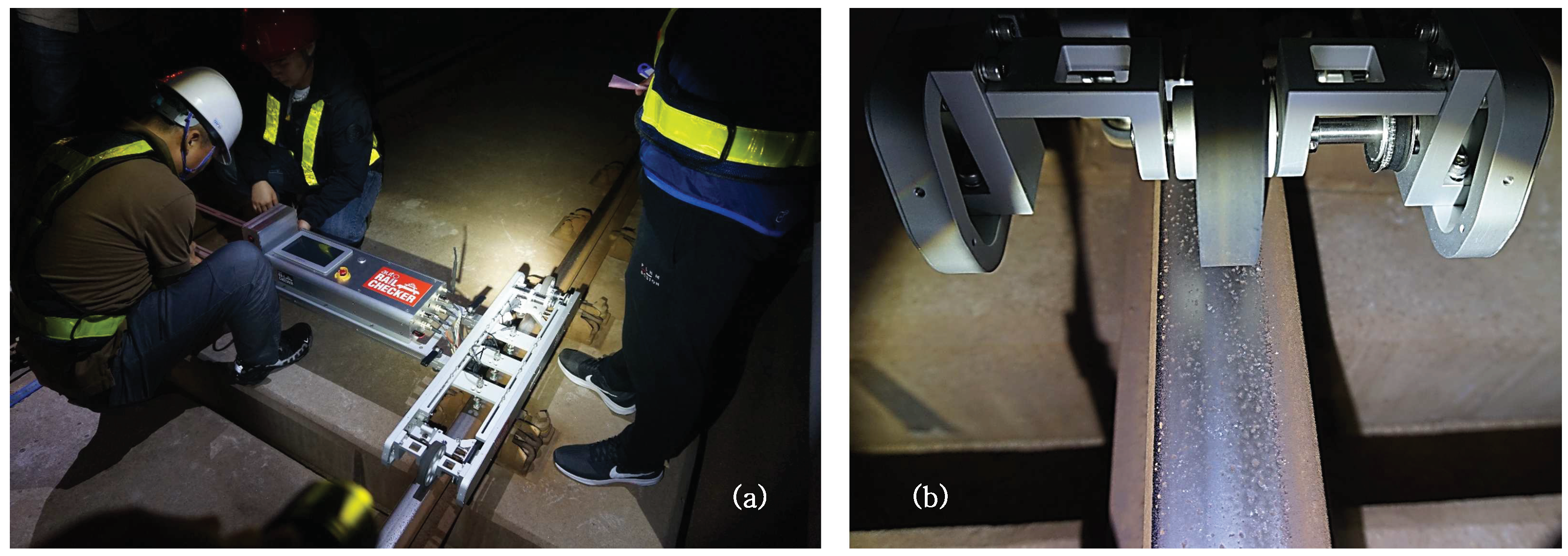

4. A Mobile System to Measure Rail Acoustic Roughness

4.1. Design of the Mobile Measurement System with Three Sensors

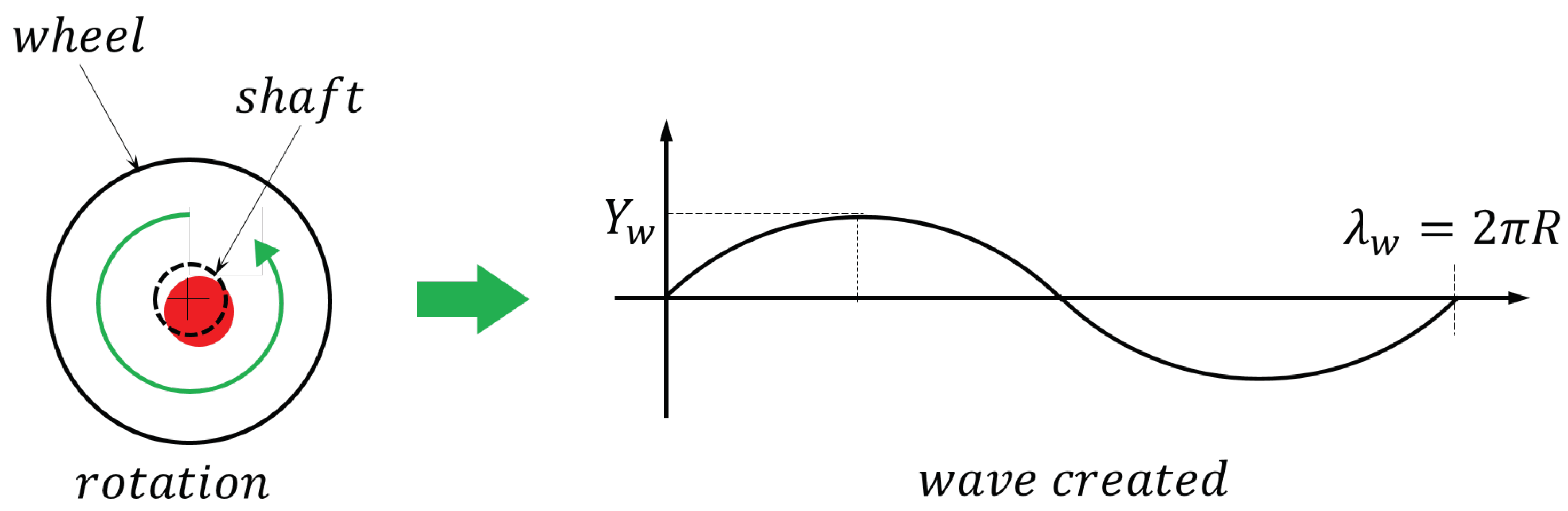

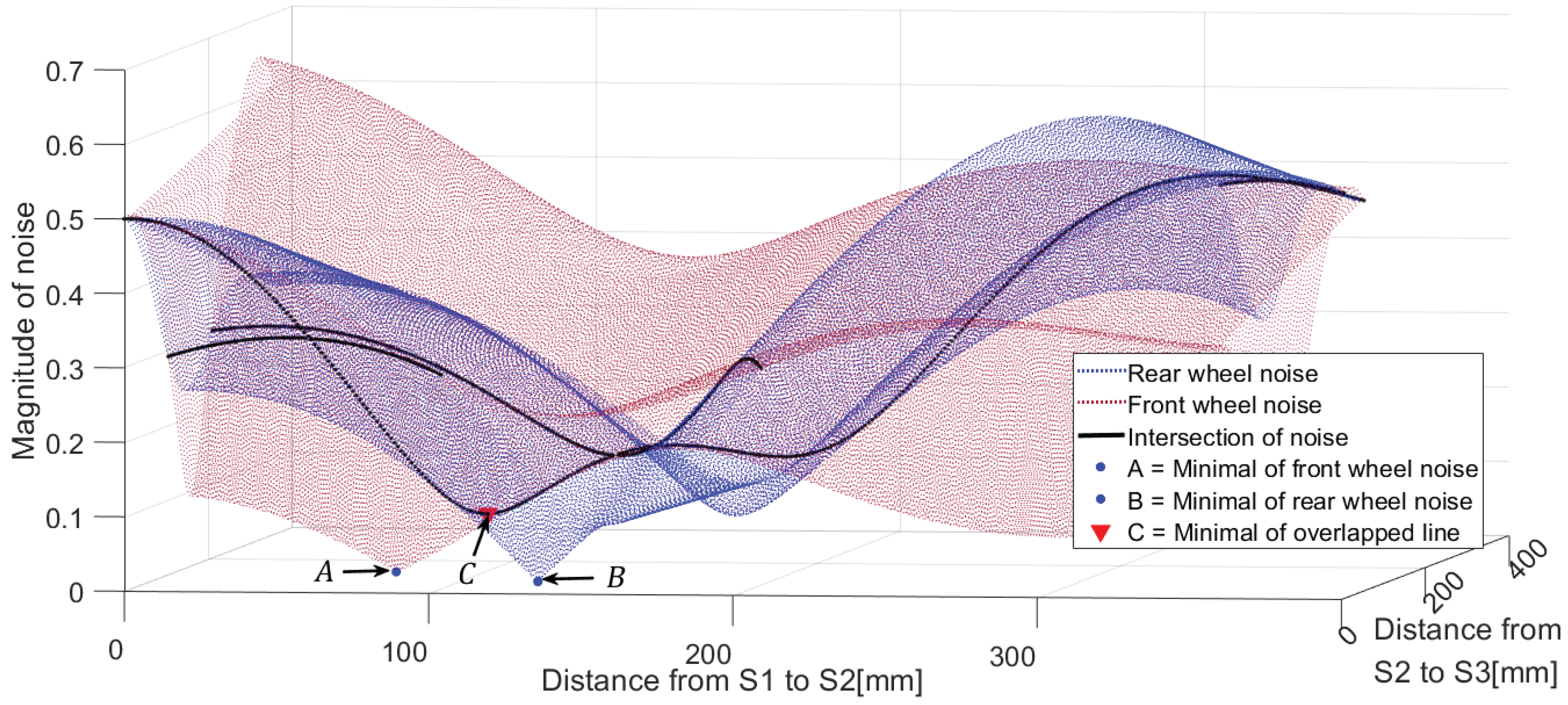

4.2. Sensor Position to Minimize the Impact of Driving Wheels

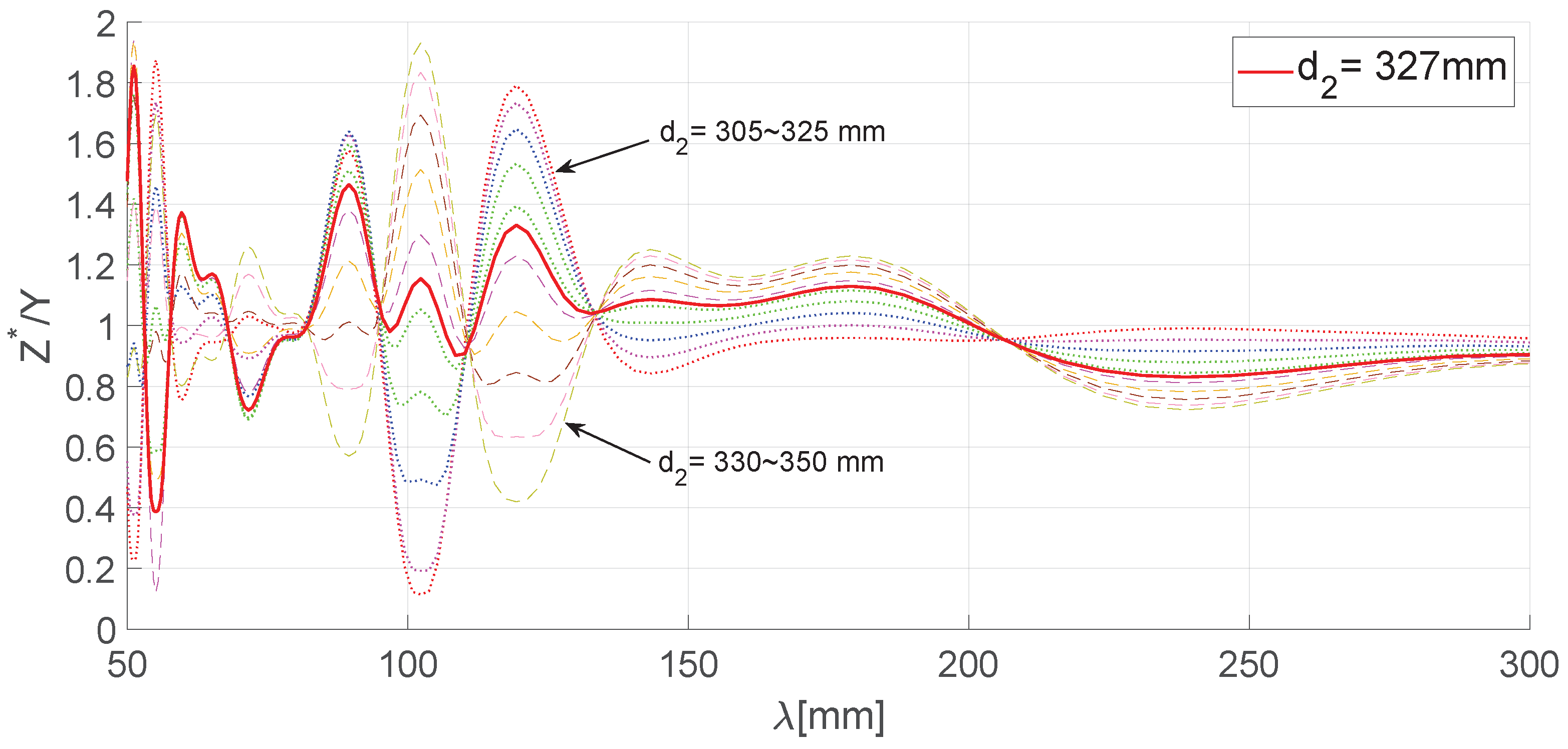

4.3. Sensor Position to Improve Measurement Accuracy

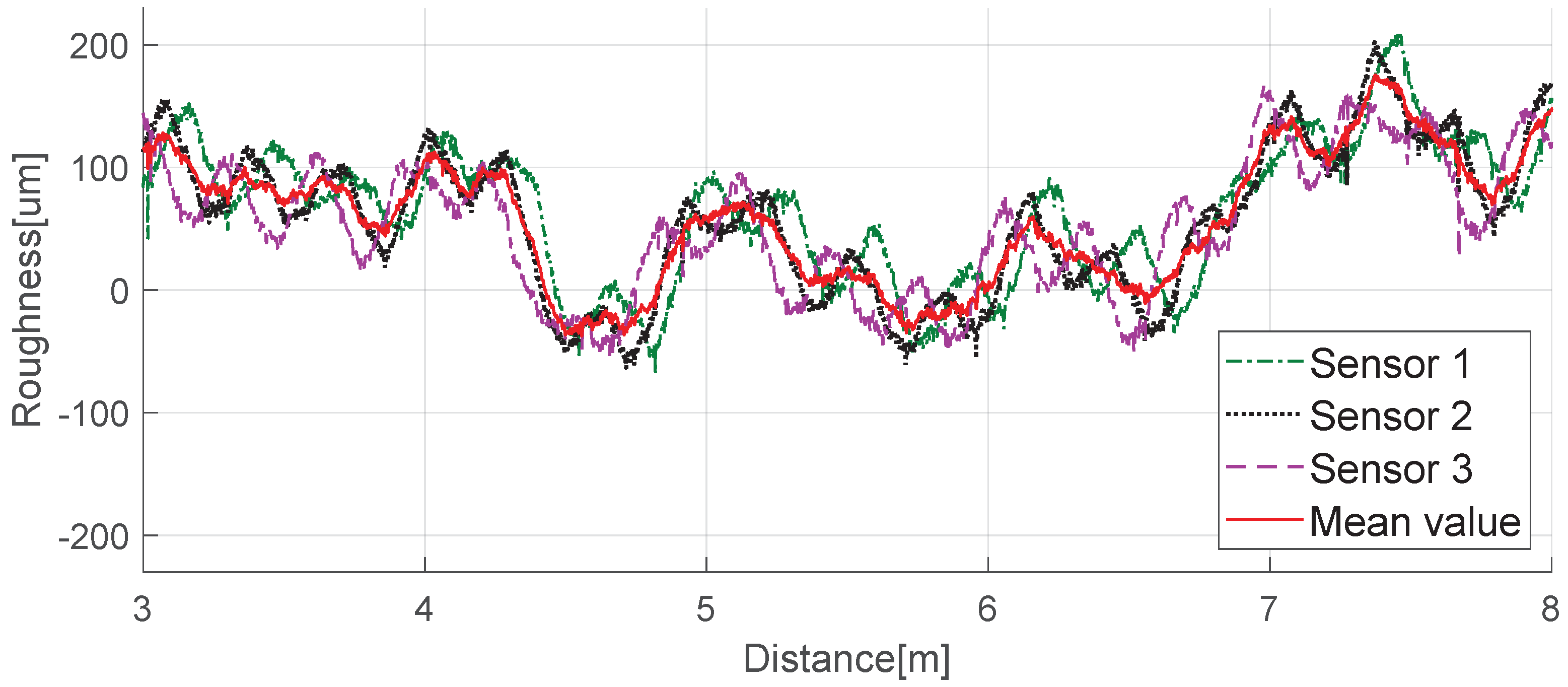

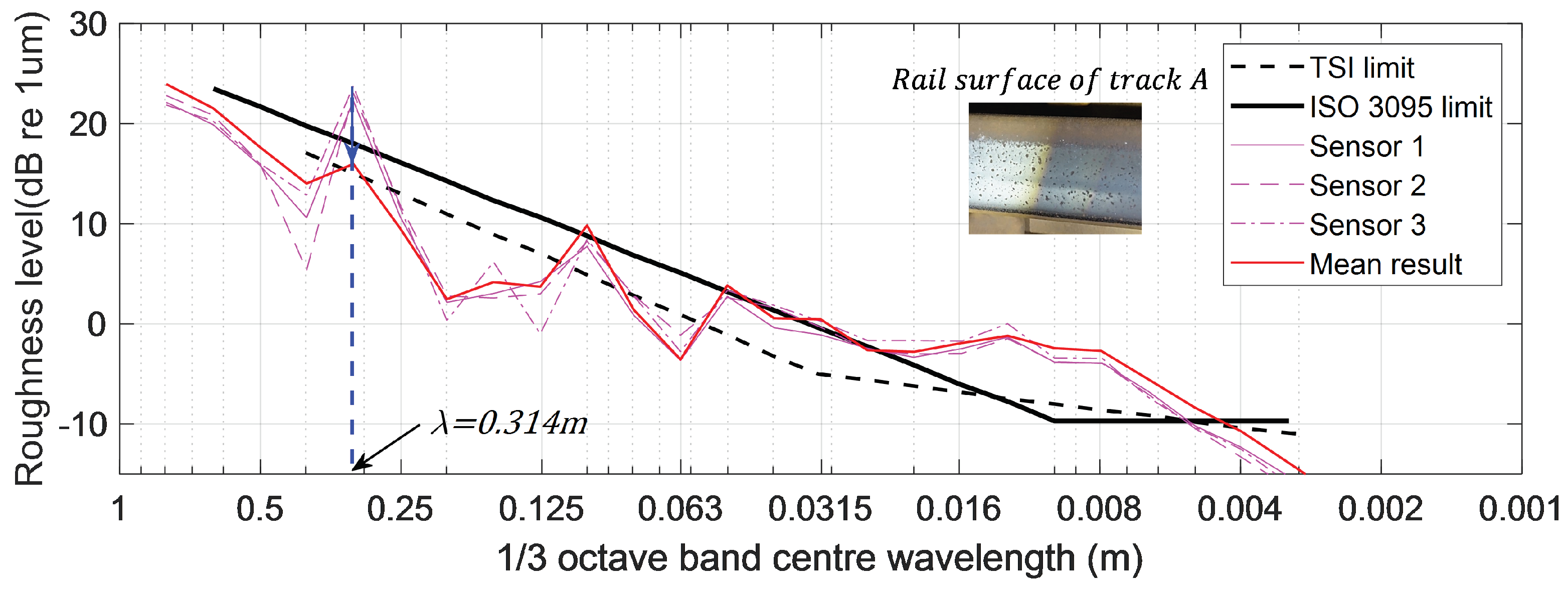

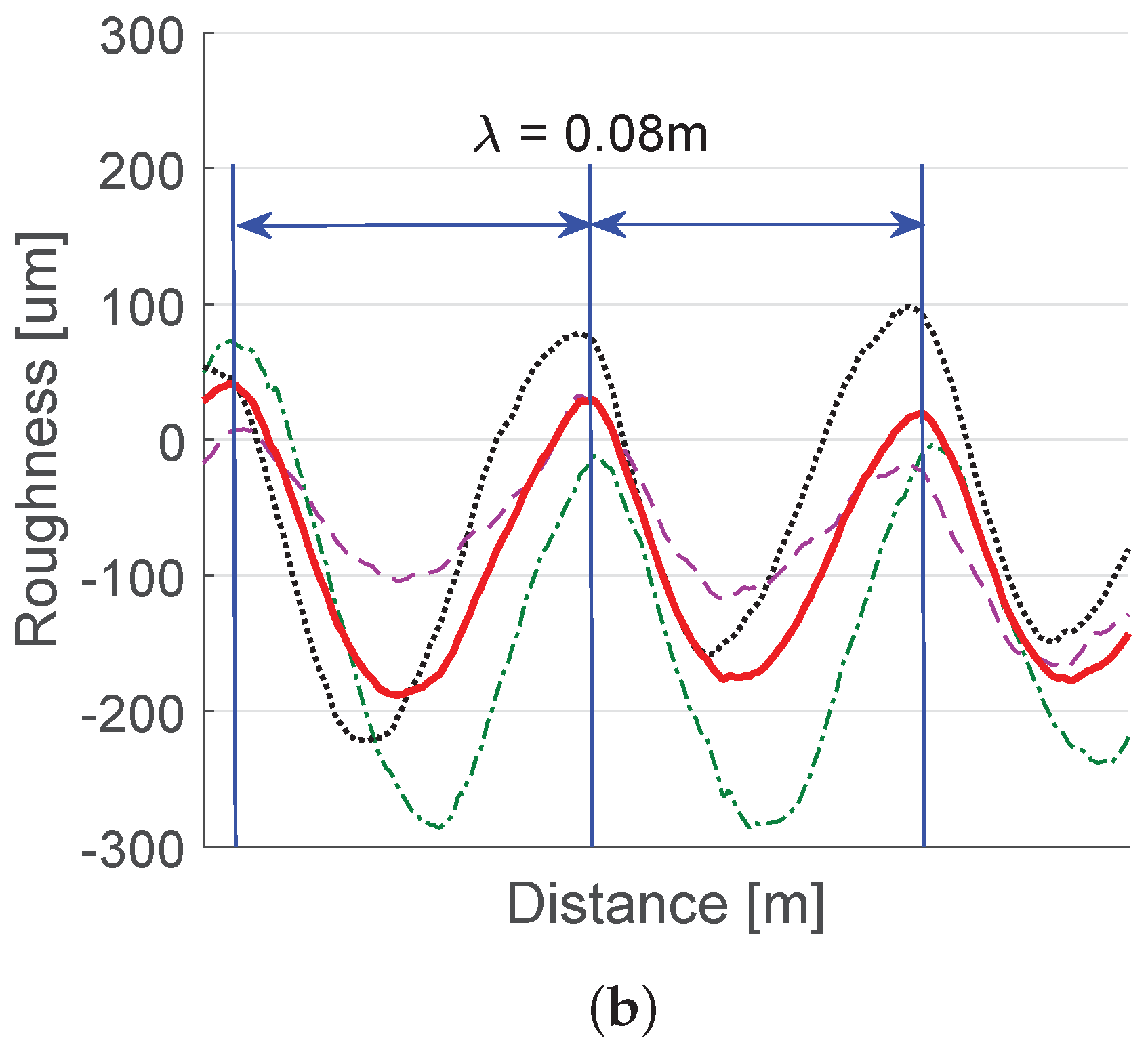

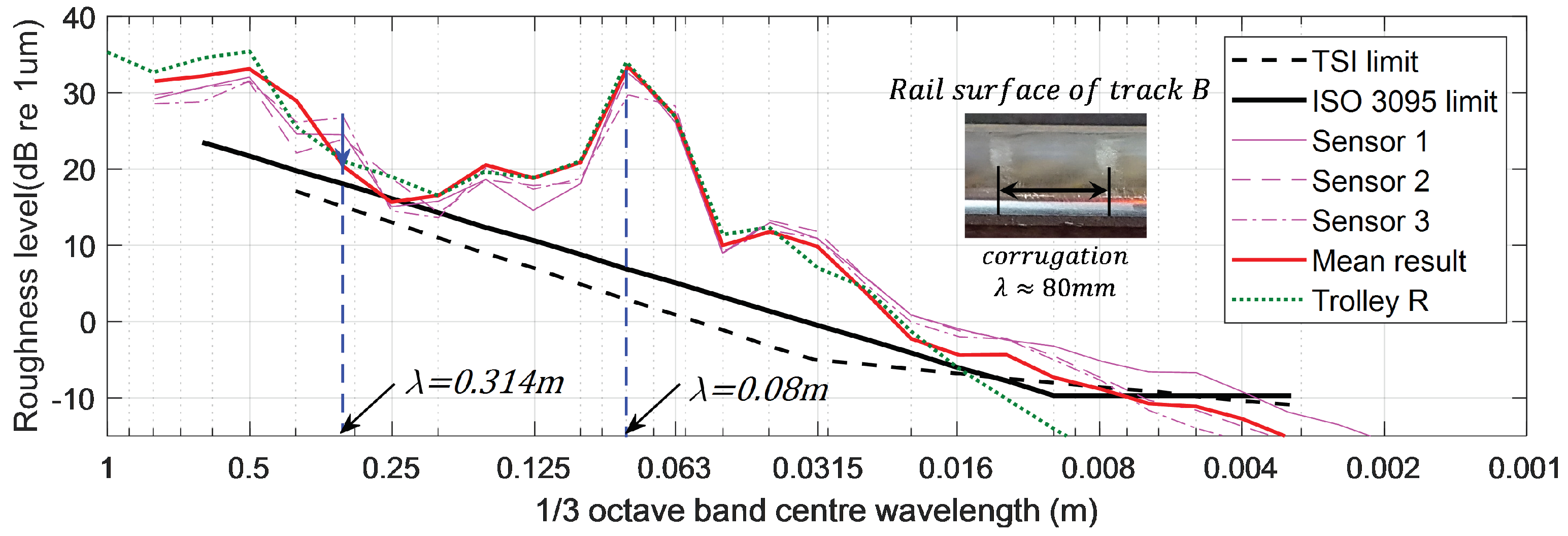

5. Testing and Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Thompson, D.; Jones, C. A review of the modelling of wheel/rail noise generation. J. Sound Vib. 2008, 231, 519–536. [Google Scholar] [CrossRef]

- Thompson, D. On the relationship between wheel and rail surface roughness and rolling noise. J. Sound Vib. 1996, 193, 149–160. [Google Scholar] [CrossRef]

- Jeong, W.; Jang, S.; Koh, H. Measuring technique for acoustic roughness of rail surface with homogeneous displacement sensors. Korea Acad.-Ind. Cooper. Soc. 2015, 16, 7941–7948. [Google Scholar]

- Jeong, W.; Jeon, S.; Jeong, D.; Choi, H. Effect of design variables of rail surface measuring device on acoustic roughness and spectral analysis. J. Korean Soc. Railway 2017, 20, 440–447. [Google Scholar] [CrossRef]

- Han, J.; Xiao, X.; Wu, Y.; Wen, Z.; Zhao, G. Effect of rail corrugation on metro interior noise and its control. Appl. Acoust. 2018, 130, 63–70. [Google Scholar] [CrossRef]

- ISO 3095: 2013 Acoustics-Railway Applications-Measurement of Noise Emitted by Railbound Vehicles. Available online: https://www.iso.org/standard/55726.html (accessed on 3 March 2019).

- BS EN 15610: 2009 Railway Applications-Noise Emission-Rail Roughness Measurement Related to Rolling Noise Generation. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030158837 (accessed on 3 March 2019).

- BS EN 13231-3: 2012 Railway Applications-Track-Acceptance of Works, Part 3; Acceptance of Reprofiling Rails in Track. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030209366 (accessed on 3 March 2019).

- Grassie, S.L. Rail corrugation: Advances in measurement, understanding and treatment. Wear 2005, 258, 1224–1234. [Google Scholar] [CrossRef]

- Verheijen, E. A survey on roughness measurements. J. Sound Vib. 2006, 293, 784–794. [Google Scholar] [CrossRef]

- Grassie, S.L. Measurement of railhead longitudinal profiles: A comparison of different techniques. Wear 1996, 191, 245–251. [Google Scholar] [CrossRef]

- Tanaka, H.; Shimizu, A. Practical application of portable trolley for the continuous measurement of rail surface roughness for rail corrugation maintenance. Q. Rep. RTRI 2016, 57, 118–124. [Google Scholar] [CrossRef]

- Diehl, R.; Holm, P. Roughness measurements have the necessities changed? J. Sound Vib. 2006, 293, 777–783. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, D.; Choi, H.S.; Choi, Y.J.; Jeong, W. Measuring Acoustic Roughness of a Longitudinal Railhead Profile Using a Multi-Sensor Integration Technique. Sensors 2019, 19, 1610. https://doi.org/10.3390/s19071610

Jeong D, Choi HS, Choi YJ, Jeong W. Measuring Acoustic Roughness of a Longitudinal Railhead Profile Using a Multi-Sensor Integration Technique. Sensors. 2019; 19(7):1610. https://doi.org/10.3390/s19071610

Chicago/Turabian StyleJeong, Dahae, Han Shin Choi, Yong Je Choi, and Wootae Jeong. 2019. "Measuring Acoustic Roughness of a Longitudinal Railhead Profile Using a Multi-Sensor Integration Technique" Sensors 19, no. 7: 1610. https://doi.org/10.3390/s19071610

APA StyleJeong, D., Choi, H. S., Choi, Y. J., & Jeong, W. (2019). Measuring Acoustic Roughness of a Longitudinal Railhead Profile Using a Multi-Sensor Integration Technique. Sensors, 19(7), 1610. https://doi.org/10.3390/s19071610