Impact of Fabric Properties on Textile Pressure Sensors Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabric Chemical Characterization

2.3. Fabric Mechanical Characterization

2.4. Sensor Characterization

3. Results and Discussion

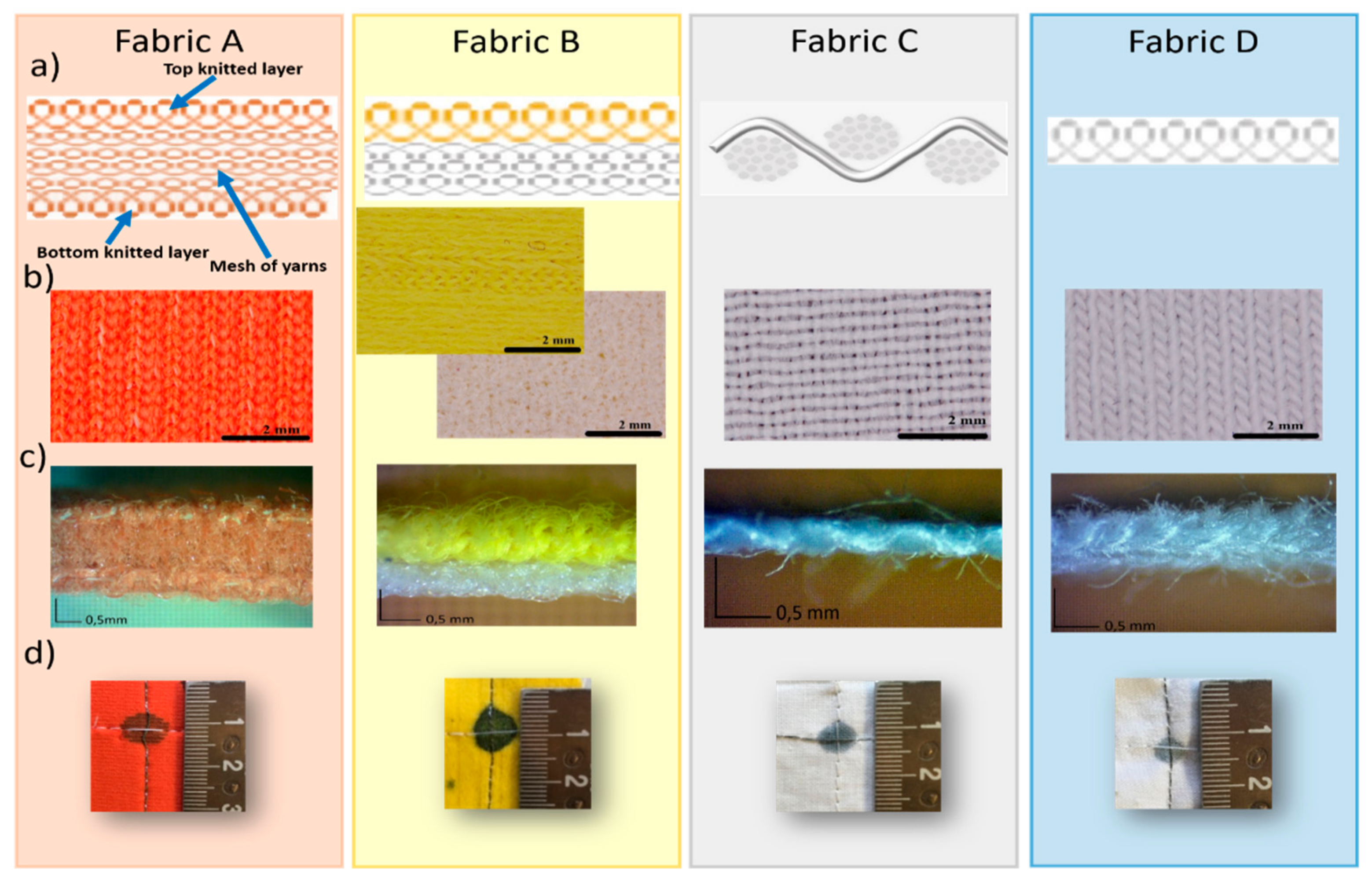

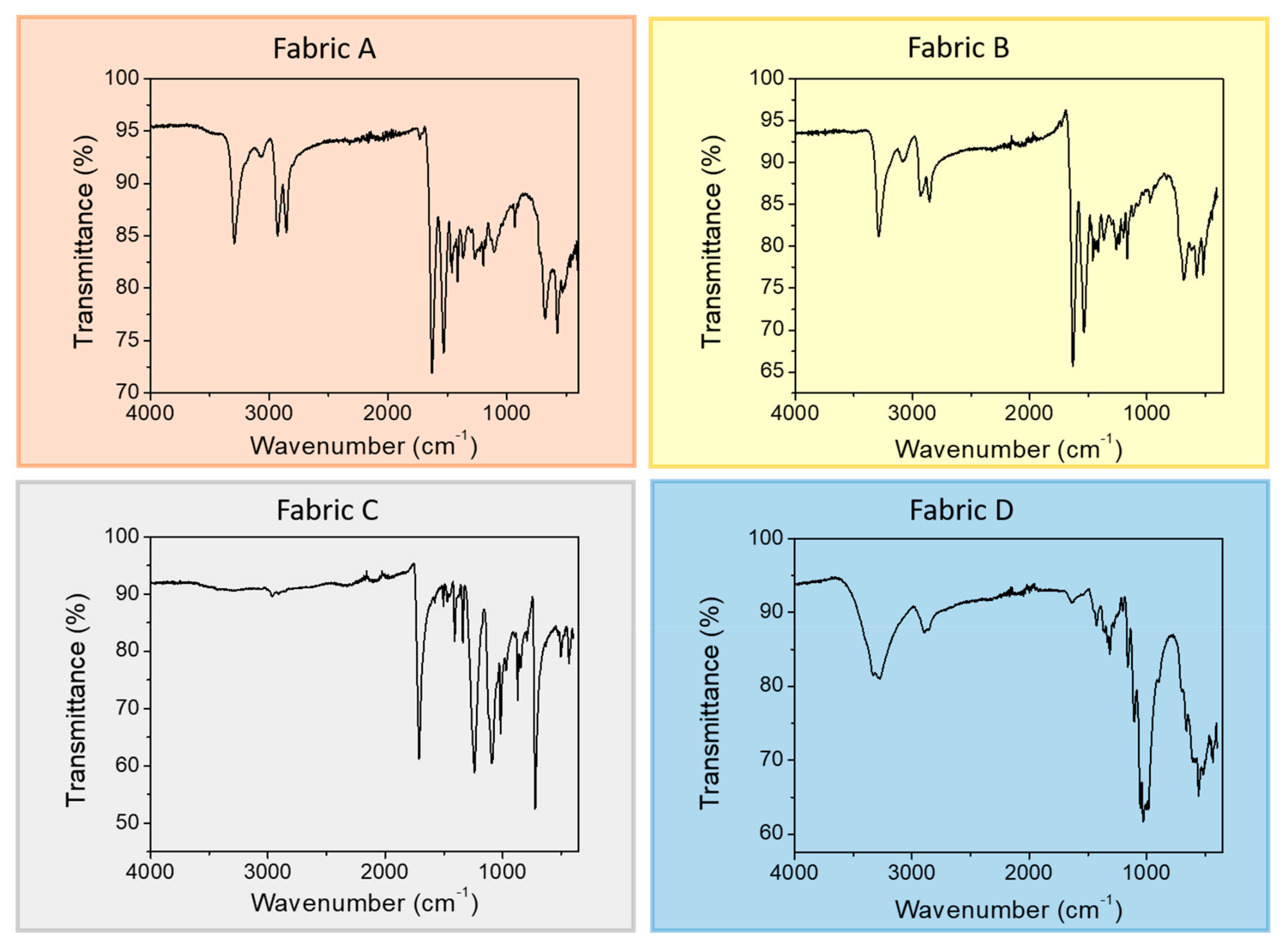

3.1. Characterization of Fabrics

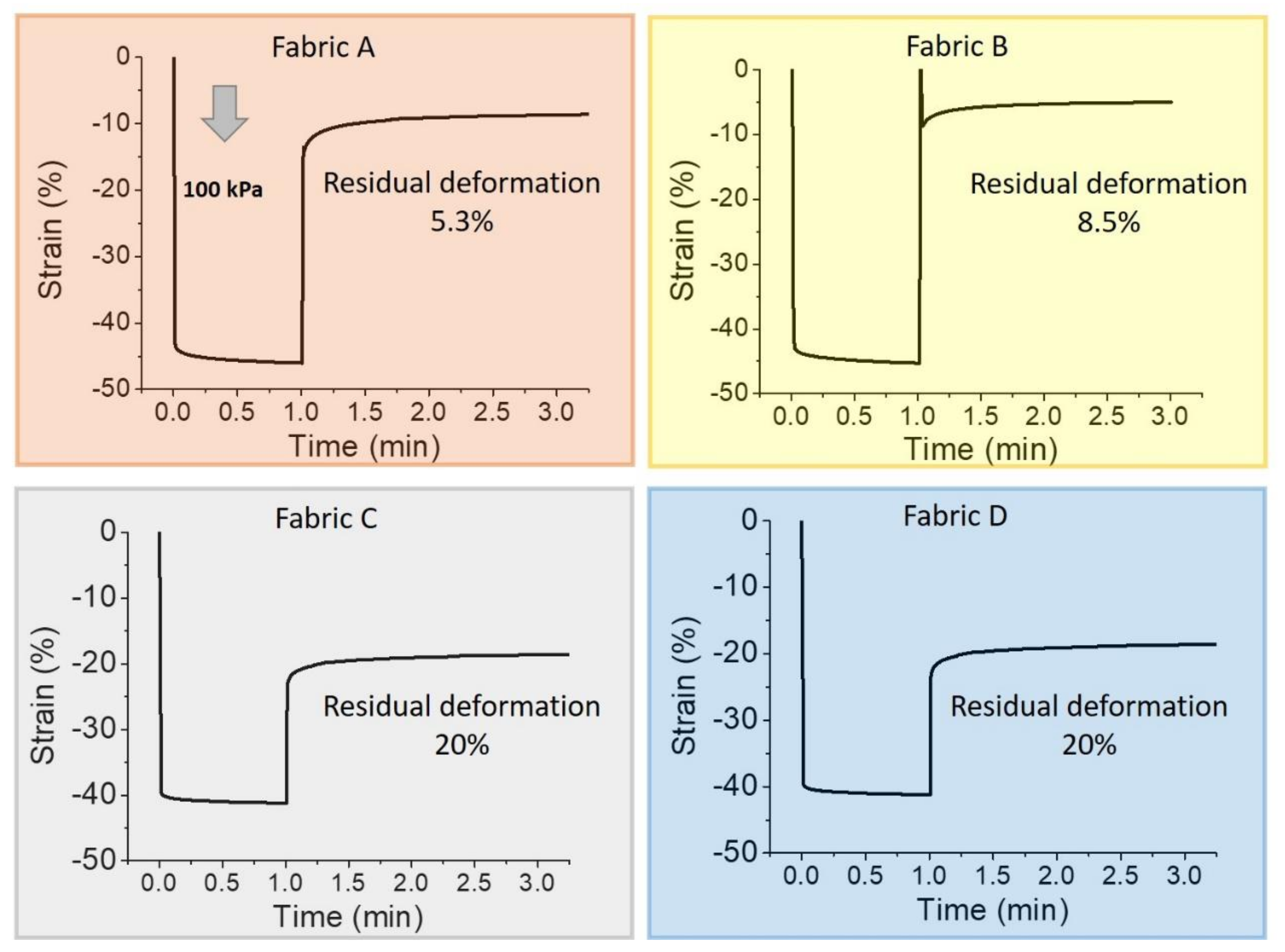

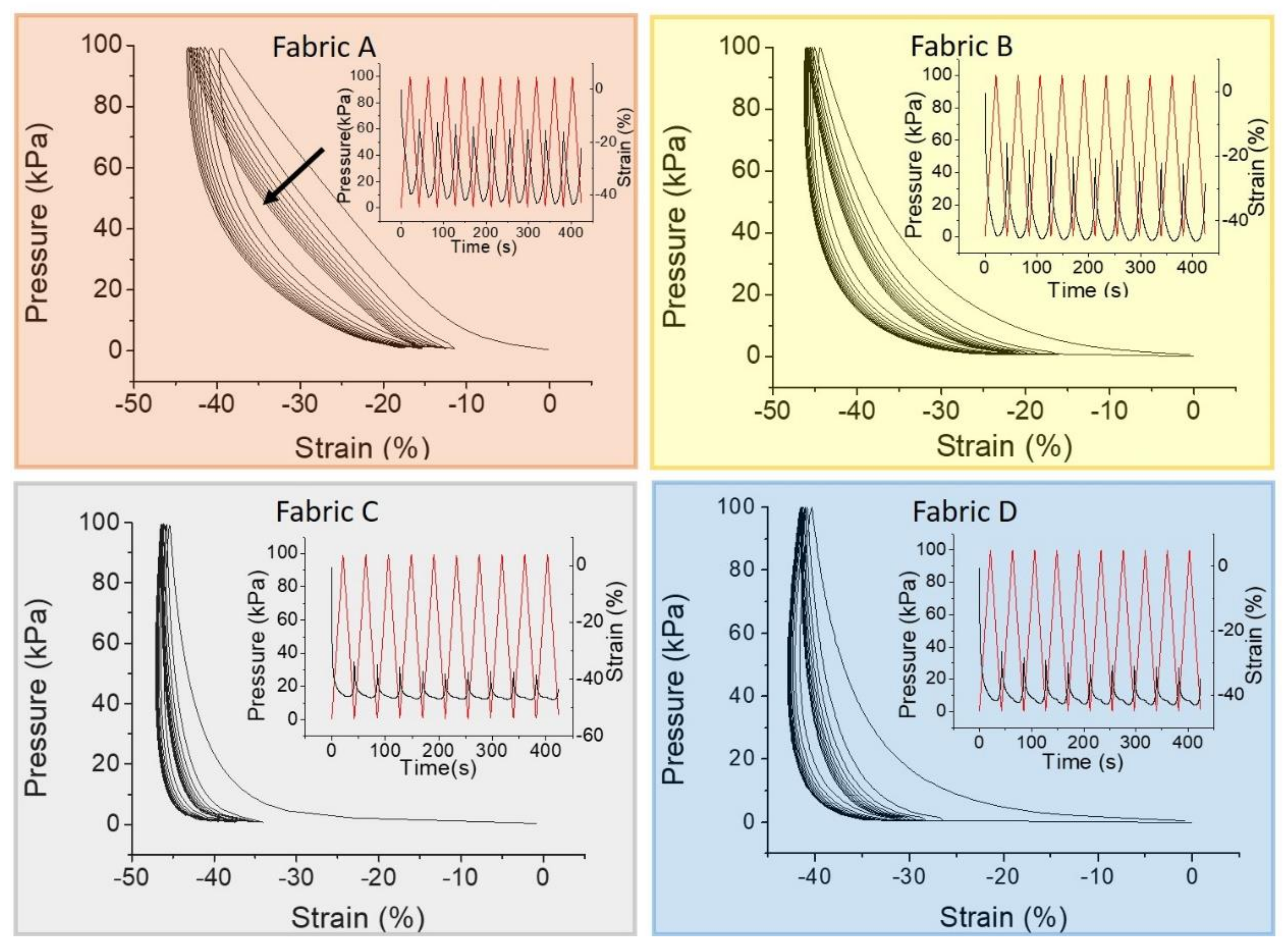

3.2. Mechanical Characterization of Fabrics

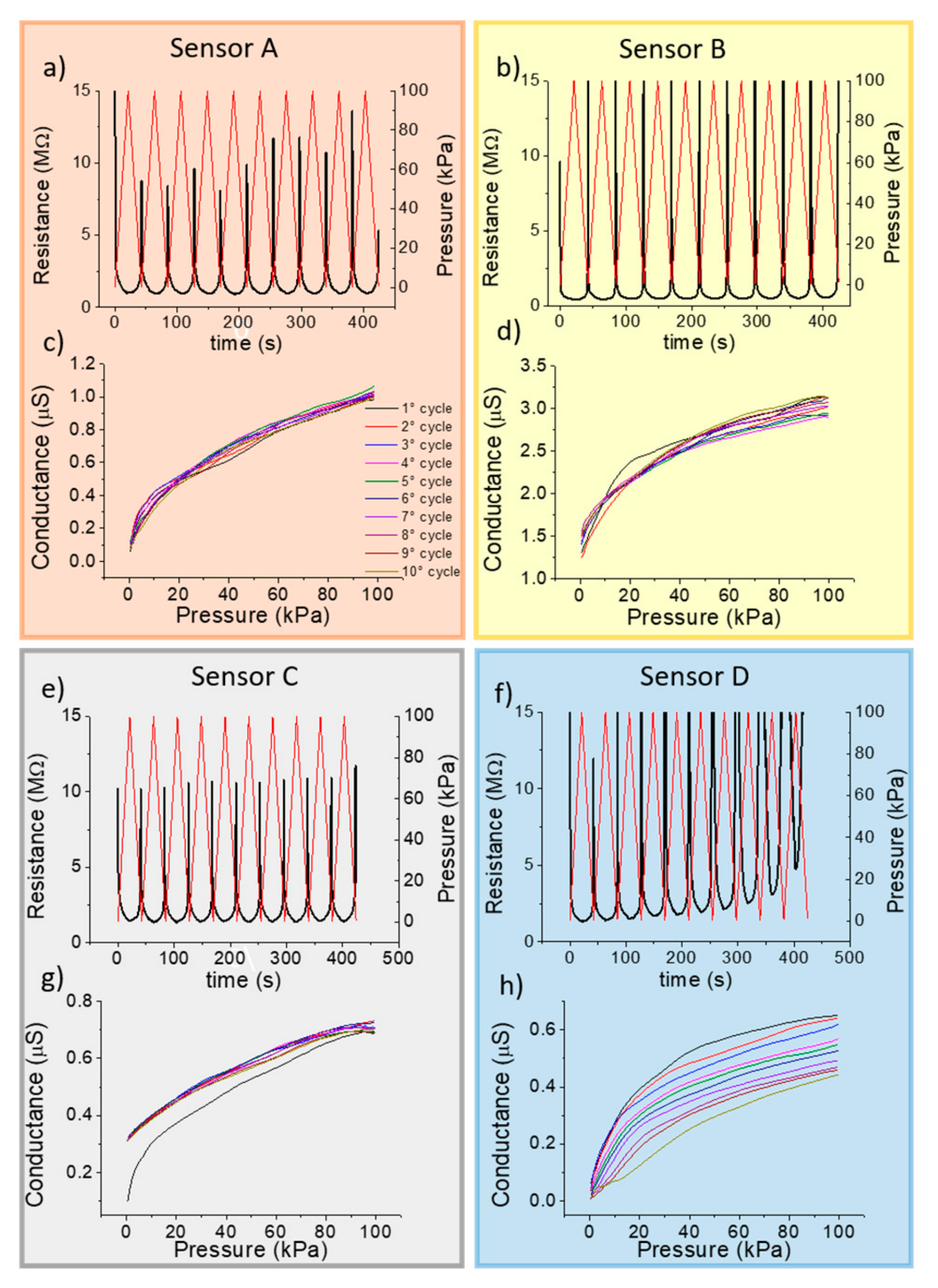

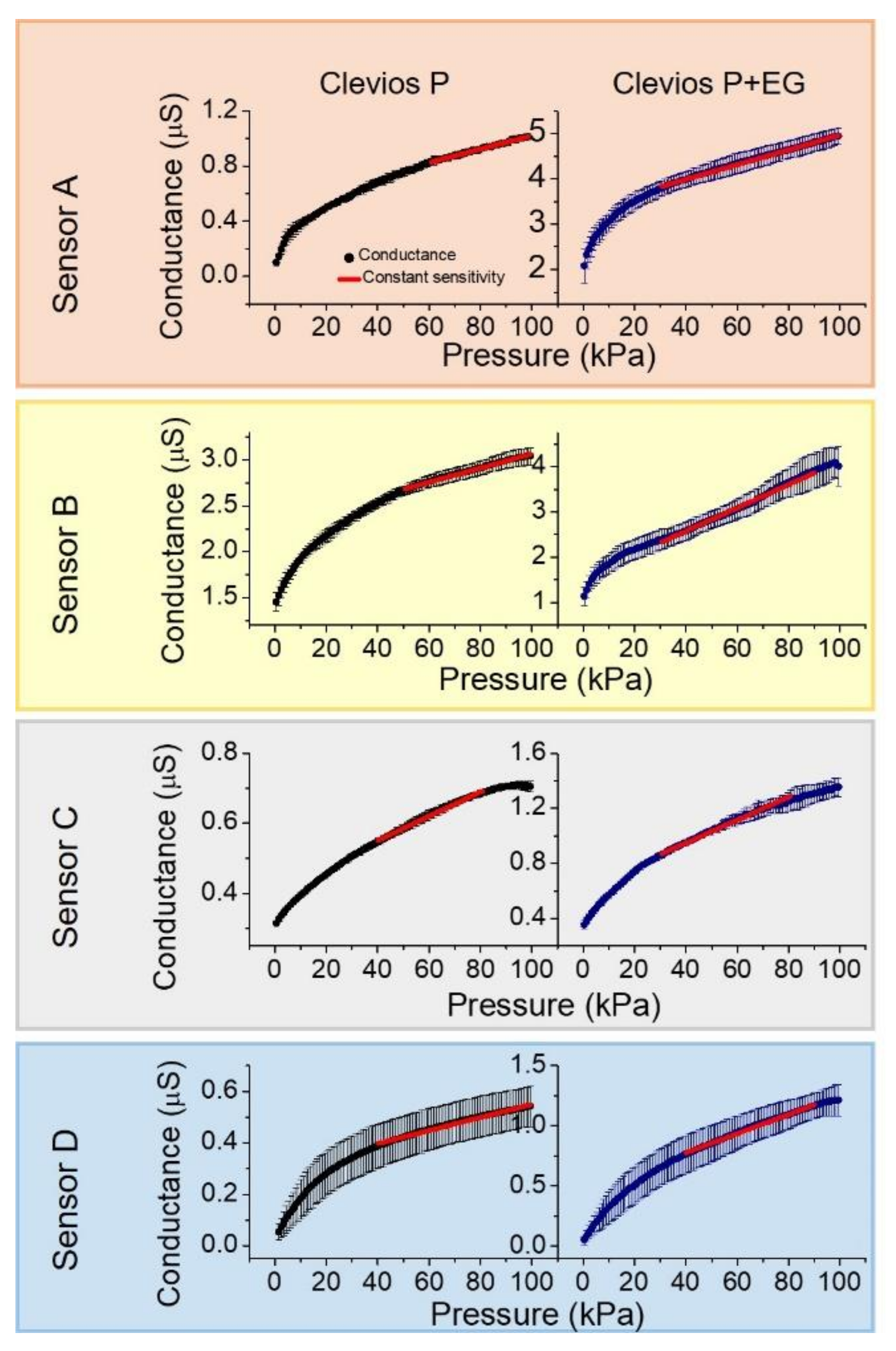

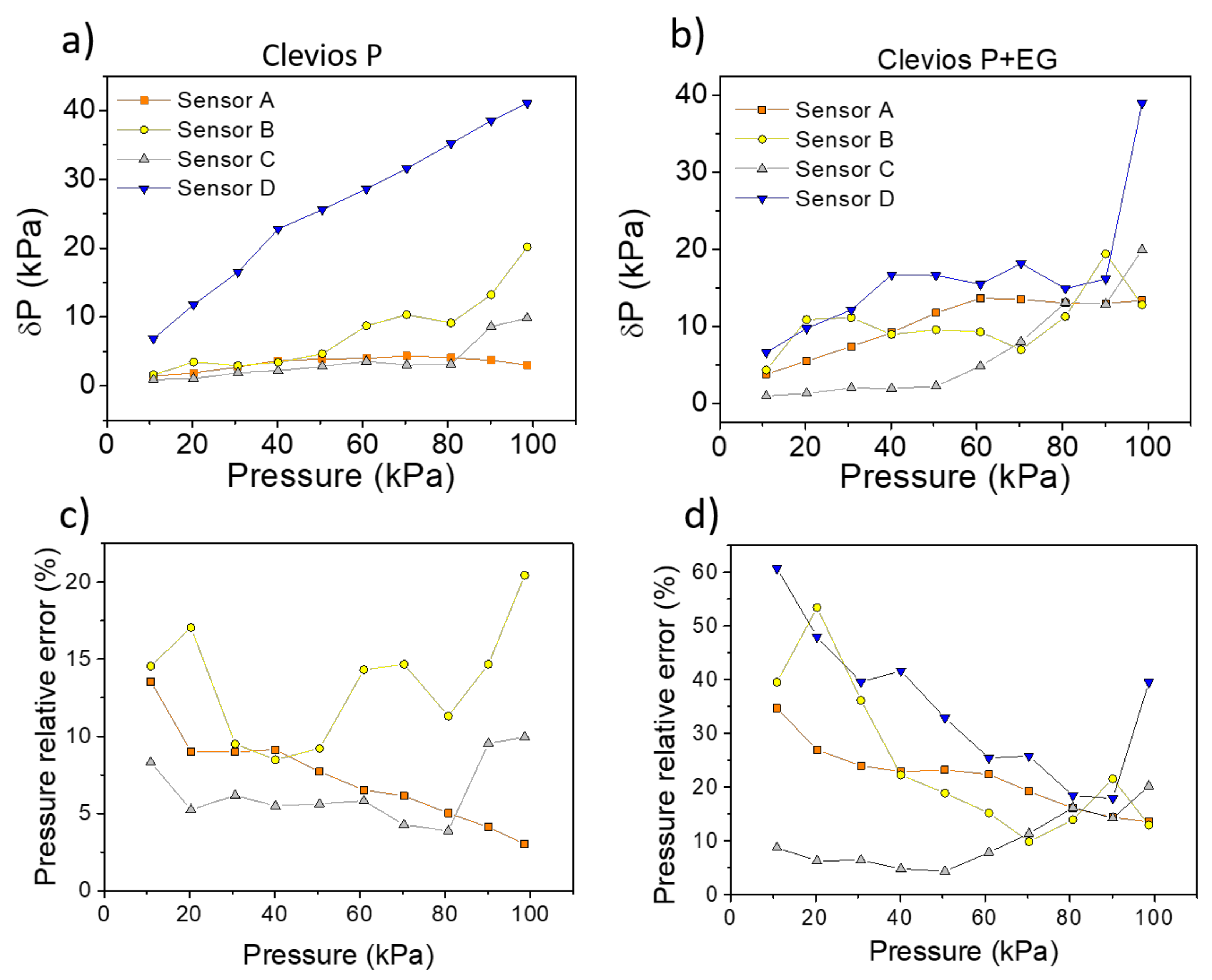

3.3. Pressure Sensor Performance in Dynamic Mode

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Xu, S.; Zhang, Y.; Jia, L.; Mathewson, E.K.; Jang, K.I.; Kim, J.; Fu, H.; Huang, X.; Chava, P.; Wang, R.; et al. Soft microfluidic assemblies of sensors, circuits, and radios for the skin. Science 2014, 344, 70–74. [Google Scholar] [CrossRef]

- Lee, H.; Song, C.; Hing, Y.S.; Kim, M.S.; Cho, H.R.; Kang, T.; Shin, K.; Choi, S.H.; Hyeon, T.; Kim, D.H.; et al. Wearable/disposable sweat-based glucose monitoring device with multistage transdermal drug delivery modul. Sci. Adv. 2017, 3, e1601314. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Emaminejad, S.; Yin, H.; Nyein, Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Hwang, B.U.; Lee, J.H.; Trung, T.Q.; Roh, E.; Kim, D.I.; Kim, S.W.; Lee, N.E. Transparent stretchable self-powered patchable sensor platform with ultrasensitive recognition of human activities. ACS Nano 2015, 9, 8801–8810. [Google Scholar] [CrossRef] [PubMed]

- Trindade, I.; Machado da Silva, J.; Miguel, R.; Pereira, M.; Luca, J.; Oliveira, L.; Valentim, B.; Barreto, J.; Santos Silva, M. Design and evaluation of novel textile wearable systems for the surveillance of vital signals. Sensors 2016, 10, 1573. [Google Scholar] [CrossRef]

- Lamberti, F.; Sanna, A.; Rokne, J. Sensors for Entertainment. Sensors 2016, 16, 1102. [Google Scholar] [CrossRef]

- Hwang, B.H.; Zabeeb, A.; Trung, T.Q.; Wen, L.; Lee, J.D.; Choi, Y.I.; Lee, H.B.; Kim, J.H.; Han, J.G.; Lee, N.E.L. A transparent stretchable sensor for distinguishable detection of touch and pressure by capacitive and piezoresistive signal transduction. NPG Asia Mater. 2019, 11, 23. [Google Scholar] [CrossRef]

- Jacobs, J.V.; Hettinger, L.J.; Huang, Y.H.; Jeffries, S.; Lesch, M.F.; Simons, L.A.; Verma, S.K.; Willetts, J.L. Employee acceptance of wearable technology in the workplace. Appl. Ergon. 2019, 78, 148–156. [Google Scholar] [CrossRef]

- Tessarolo, M.; Gualandi, I.; Fraboni, B. Recent progress in wearable fully textile chemical sensors. Adv. Mater. Technol. 2018, 3, 1700310. [Google Scholar] [CrossRef]

- Carvalho, H.; Yao, Y.; Gonçalves, L.M. Flexible force sensors for e-textiles. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 254, p. 072007. [Google Scholar]

- Zhou, B.; Sundholm, M.; Cheng, J.; Cruz, H.; Lukowicz, P. Measuring muscle activities during gym exercises with textile pressure mapping sensors. Pervasive Mob. Comput. 2017, 38, 331–345. [Google Scholar] [CrossRef]

- Lin, X.; Seet, B.-C. Battery-Free Smart Sock for Abnormal Relative Plantar Pressure Monitoring. IEEE Trans. Biomed. Circuits Syst. 2017, 11, 464–473. [Google Scholar] [CrossRef] [PubMed]

- Büscher, G.H.; Kõiva, R.; Schürmann, C.; Haschke, R.; Ritter, H.J. Flexible and stretchable fabric-based tactile sensor. Rob. Auton. Syst. 2015, 63, 244–252. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Ponraj, G.; Ren, H. Fabrication and Comparative Study on Sensing Characteristics of Soft Textile-Layered Tactile Sensors. IEEE Sens. Lett. 2017, 1, 1–4. [Google Scholar] [CrossRef]

- Maziz, A.; Concas, A.; Khaldi, A.; Stålhand, J.; Persson, N.K.; Jager, E.W.H. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327. [Google Scholar] [CrossRef]

- Kinkeldei, T.; Zysset, C.; Cherenack, K.H.; Troster, G. A textile integrated sensor system for monitoring humidity and temperature. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 1156–1159. [Google Scholar]

- Gualandi, I.; Marzocchi, M.; Achilli, A.; Cavedale, D.; Bonfiglio, A.; Fraboni, B. Textile Organic Electrochemical Transistors as a Platform for Wearable Biosensors. Sci. Rep. 2016, 6, 33637. [Google Scholar] [CrossRef]

- Gualandi, I.; Tessarolo, M.; Mariani, F.; Cramer, T.; Tonelli, D.; Scaveta, E.; Fraboni, B. Nanoparticle gated semiconducting polymer for a new generation of electrochemical sensors. Sens. Actuators B Chem. 2018, 273, 834–841. [Google Scholar] [CrossRef]

- Jia, J.; Xu, C.; Pan, S.; Xia, S.; Wei, S.; Noh, H.; Zhang, P.; Jiang, X. Conductive Thread-Based Textile Sensor for Continuous Perspiration Level Monitoring. Sensors 2018, 18, 3775. [Google Scholar] [CrossRef]

- Pani, D.; Dessi, A.; Gusai, E.; Saenz-Cogollo, J.F.; Barabino, G.; Fraboni, B.; Bonfiglio, M. Evaluation of novel textile electrodes for ECG signals monitoring based on PEDOT:PSS-treated woven fabrics. In Proceedings of the 2015 37th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Milan, Italy, 25–29 August 2015; pp. 3197–3200. [Google Scholar]

- Castrillón, R.; Pérez, J.J.; Andrade-Caicedo, H. Electrical performance of PEDOT: PSS-based textile electrodes for wearable ECG monitoring A comparative study. Biomed. Eng. Online 2018, 17, 38. [Google Scholar] [CrossRef]

- Saenz-Cogollo, J.; Pau, M.; Fraboni, B.; Bonfiglio, A. Pressure Mapping Mat for Tele-Home Care Applications. Sensors 2016, 16, 365. [Google Scholar] [CrossRef]

- Meyer, J.; Lukowicz, P.; Troster, G. Textile Pressure Sensor for Muscle Activity and Motion Detection. In Proceedings of the 2006 10th IEEE International Symposium on Wearable Computers, Montreux, Switzerland, 11–14 October 2006; pp. 69–72. [Google Scholar]

- Pizarro, F.; Villavicencio, P.; Yunge, D.; Rodriguez, M.; Hermosilla, G.; Leive, A. Easy-to-Build Textile Pressure Sensor. Sensors 2018, 18, 1190. [Google Scholar] [CrossRef]

- He, Y.; Li, W.; Yang, G.; Liu, G.; Lu, J.; Zheng, T.; Li, X.; He, Y.; Li, W.; Yang, G.; et al. A novel method for fabricating wearable, piezoresistive, and pressure sensors based on modified-graphite/polyurethane composite films. Materials 2017, 10, 684. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Shu, Y.; Wang, X.F.; Mohammad, M.A.; Bie, Z.; Xie, Q.Y.; Li, C.; Mi, W.T.; Yang, Y.; Ren, T.L. A graphene-based resistive pressure sensor with record-high sensitivity in a wide pressure range. Sci. Rep. 2015, 5, 8603. [Google Scholar] [CrossRef] [PubMed]

- Tessarolo, M.; Possanzini, L.; Campari, E.G.; Bonfiglioli, R.; Violante, F.S.; Bonfiglio, A.; Fraboni, B. Adaptable pressure textile sensors based on a conductive polymer. Flex. Print. Electron. 2018, 3, 034001. [Google Scholar] [CrossRef]

- Byrnes, C.; Horrocks, A.R.; Anand editors, S.C. Technical Textile Market–An Overview. In Handbook of Technical Textiles; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Silverstein, R.M.; Bassler, G.C.; Morrill, T.C. Spectrometric Identification of Organic Compounds, 7th ed.; John Wiley and Sons Inc.: New York, NY, USA, 2005. [Google Scholar]

- Strain, I.N.; Wu, Q.; Pourrahimi, A.M.; Hedenqvist, M.S.; Olsson, R.T.; Andersson, R.L. Electrospinning of recycled PET to generate tough mesomorphic fibre membranes for smoke filtration. J. Mater. Chem. A 2015, 3, 1632–1640. [Google Scholar] [CrossRef]

- Zhang, S.; Kumar, P.; Nouas, A.S.; Fontaine, L.; Tang, H.; Cicoira, F. Solvent-induced changes in PEDOT: PSS films for organic electrochemical transistors. APL Mater. 2015, 3, 014911. [Google Scholar] [CrossRef]

- Del Agua, I.; Mantione, D.; Ismailov, U.; Sanchez-Sanchex, A.; Aramburu, N.; Malliaras, G.G.; Mecerreyes, D.; Ismailova, E. DVS-Crosslinked PEDOT:PSS Free-Standing and Textile Electrodes toward Wearable Health Monitoring. Adv. Mater. Technol. 2018, 3, 1700322. [Google Scholar] [CrossRef]

| Creep Recovery | Stress-Strain Test | ||||

|---|---|---|---|---|---|

| Fabric | Initial Thickness (mm) | Thickness @100 kPa (mm) | Thickness after Release (mm) | Residual Deformation | Dynamic Strain Range |

| A | 2.49 * | 1.34 | 2.36 | 5.3% | 30% |

| B | 1.54 | 0.74 | 1.40 | 8.5% | 20% |

| C | 0.36 | 0.19 | 0.29 | 20% | 10% |

| D | 0.71 | 0.37 | 0.57 | 20% | 10% |

| Clevios P | Clevios P + EG | |||

|---|---|---|---|---|

| Sensor | G0 (µS) | G100 (µS) | G0 (µS) | G100 (µS) |

| A | 0.09 ± 0.02 | 1.01 ± 0.02 | 2.1 ± 0.4 | 4.4 ± 0.2 |

| B | 1.4 ± 0.1 | 3.03 ± 0.09 | 1.1 ± 0.2 | 4.0 ± 0.4 |

| C | 0.314 ± 0.003 | 0.70 ± 0.01 | 0.35 ± 0.03 | 1.35 ± 0.07 |

| D | 0.05 ± 0.03 | 0.54 ± 0.07 | 0.05 ± 0.03 | 1.2 ± 0.1 |

| SFIT (nS/kPa) | Linear Range | SFIT (nS/kPa) | Linear Range | |

| A | 4.90 ± 0.04 | 60–100 kPa | 16.2 ± 0.1 | 30–100 kPa |

| B | 7.70 ± 0.07 | 50–100 kPa | 25.6 ± 0.2 | 30–90 kPa |

| C | 3.47 ± 0.03 | 40–80 kPa | 8.3 ± 0.1 | 30–80 kPa |

| D | 2.54 ± 0.03 | 40–100 kPa | 7.9 ± 0.1 | 40–90 kPa |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Possanzini, L.; Tessarolo, M.; Mazzocchetti, L.; Campari, E.G.; Fraboni, B. Impact of Fabric Properties on Textile Pressure Sensors Performance. Sensors 2019, 19, 4686. https://doi.org/10.3390/s19214686

Possanzini L, Tessarolo M, Mazzocchetti L, Campari EG, Fraboni B. Impact of Fabric Properties on Textile Pressure Sensors Performance. Sensors. 2019; 19(21):4686. https://doi.org/10.3390/s19214686

Chicago/Turabian StylePossanzini, Luca, Marta Tessarolo, Laura Mazzocchetti, Enrico Gianfranco Campari, and Beatrice Fraboni. 2019. "Impact of Fabric Properties on Textile Pressure Sensors Performance" Sensors 19, no. 21: 4686. https://doi.org/10.3390/s19214686

APA StylePossanzini, L., Tessarolo, M., Mazzocchetti, L., Campari, E. G., & Fraboni, B. (2019). Impact of Fabric Properties on Textile Pressure Sensors Performance. Sensors, 19(21), 4686. https://doi.org/10.3390/s19214686