1. Introduction

In both three-dimensional (3D) and conventional two-dimensional (2D) imaging, acquiring digital image signals with full spatial resolution is redundant, particularly when the image is utilized only for the recognition of objects and the activation of functions. Instead, the frame difference can be acquired for the recognition and tracking of moving objects, as well as for motion-triggered awakening [

1,

2,

3]. Specifically, acquiring the frame difference suppresses the transmission of redundant information through the identification of moving objects and the elimination of repetitive frames in surveillance systems [

4]. In machine vision, successive functions such as the tracking of moving objects can be activated by the frame difference [

5]. Another application of the frame difference is the optic-flow sensor for the navigation of micro-vehicles [

6]. The on-chip optic-flow generation firstly requires the detection of the frame difference in order to provide the pattern of motion of objects.

For 2D imaging, several image sensors with integrated frame difference detection were reported [

1,

2,

3,

4,

5,

6]. The sensors generate the frame difference by simply subtracting signals of successive frames. However, the frame difference is determined by simply calculating the change in light intensity, which varies according to the ambient light. Thus, the absolute difference for moving objects cannot be acquired. A more critical problem is that the frame difference cannot be detected under dark conditions. Additionally, the optic-flow sensor reported in Reference [

6] generates only a 2D optic flow based on the frame difference of the light intensity, which is inaccurate when the ambient light intensity is extremely low or extremely high in outdoor applications.

Three-dimensional imaging that provides depth information, as well as 2D shape information, can be implemented with a variety of methods such as structured light projection (SLP), direct time-of-flight (dTOF), and indirect time-of-flight (iTOF) methods. These 3D imaging methods have the advantage of being immune to ambient light because they involve the detection of infrared (IR) light. Moreover, the 3D movement of objects can be detected. The SLP method provides high depth accuracy but involves complex post-processing in order to calculate the depth from the pattern matching [

7]. Even though the dTOF method offers simple post processing, it requires photodetectors with high sensitivity (such as avalanche photodiodes and single-photon avalanche diodes) and a large form factor in order to measure the time-of-flight with a small number of incident photons in a single measurement [

8,

9]. Therefore, high spatial resolution is difficult to be implemented. Among the 3D imaging methods, the iTOF method provides high depth accuracy, simple post processing, and high spatial resolution using small photodetectors (such as pinned photodiodes or photogates) that are widely used in 2D image sensors [

10,

11,

12,

13]. In the iTOF depth sensor, the four-phase modulation scheme is usually used to provide an accurate depth regardless of the reflectivity of objects while suppressing the offset from ambient lights. However, this four-phase modulation scheme requires two frames of modulation for acquisition of a single-frame depth image, power consuming modulation and analog-to-digital (A/D) conversion in two frames, and huge frame memory to store intermediate signals, which is illustrated in

Section 2.

In this paper, we propose a two-step comparison scheme for detecting an accurate depth frame difference regardless of the reflectivity. Without power-consuming four-phase modulation, A/D conversion, digital readout, and image signal processing, a depth frame difference can be simply generated via two-phase modulation with only column-parallel circuits in a single frame. Moreover, instead of frame memory, we implemented an over-pixel metal–insulator–metal (MIM) capacitor to store previous frame signals. Owing to the backside illumination (BSI) complementary metal–oxide–semiconductor (CMOS) image sensor (CIS) process [

3,

14], the over-pixel MIM capacitor as an analog memory (AM) did not reduce the sensitivity. Additionally, we reused the existing column-parallel amplifier circuit for the gain amplification of signals and reused the comparator of the column-parallel A/D converter (ADC) for acquiring the depth frame difference without a significant area overhead.

The remainder of this paper is organized as follows:

Section 2 introduces conventional four-phase modulation scheme.

Section 3 describes the operation principle of the proposed two-step comparison scheme for acquiring the depth frame difference.

Section 4 describes the structure and operation of the circuit.

Section 5 presents the experimental results. The paper is concluded in

Section 6.

2. Conventional Four-Phase Modulation Scheme

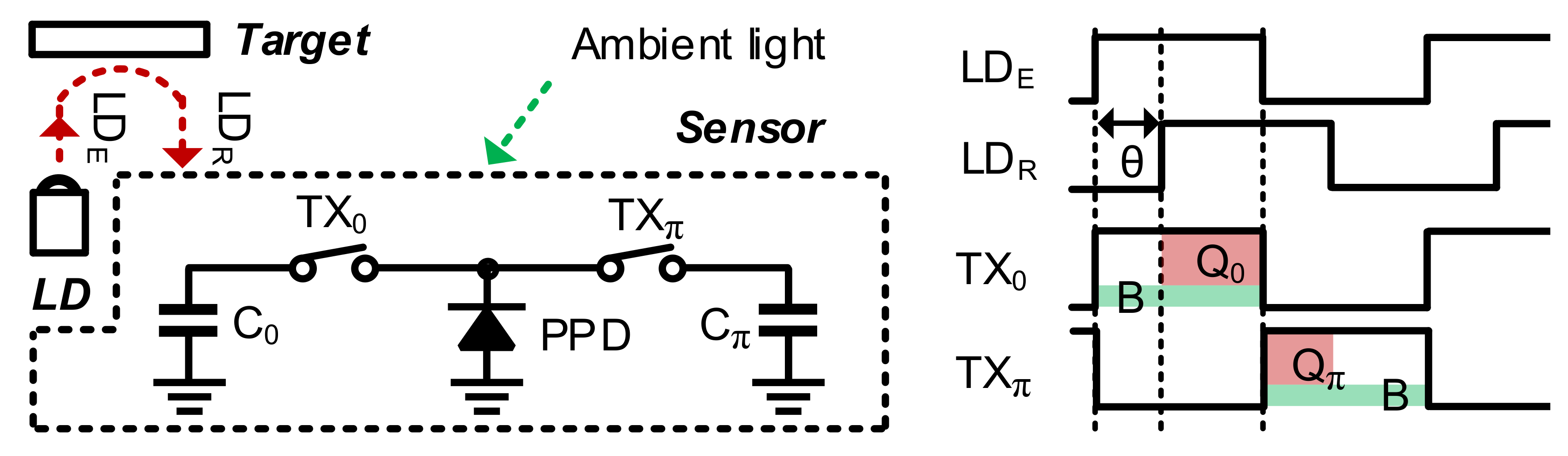

As shown in

Figure 1, an IR laser diode (LD) emits modulated light. The iTOF sensor calculates the depth according to the phase difference

θ between the emitted light LD

E and reflected light LD

R. Two electronic shutters TX

0 and TX

π in a pixel are modulated in-phase (synchronized with the LD) and out-of-phase, respectively. The typical modulation frequency is >10 MHz. The sensor detects a photogenerated current (I

PIX) in a pinned photodiode (PPD), which is integrated to obtain the charges

Q0 from TX

0 and

Qπ from TX

π. Then,

θ can be calculated as follows:

where

A represents the gain from different reflectivities and distances of the object. The total charge

QTOT that is the sum of

Q0 and

Qπ varies according to the distance and the reflectivity. However, the ratio

Qπ/

QTOT depends only on the distance. This operation is called two-phase modulation. Unfortunately, there is a strong background signal from ambient light, particularly in outdoor applications. This strong ambient light provides a common direct-current (DC) offset (

BG) to

Q0 and

Qπ, as shown in

Figure 1. Accordingly,

θ becomes erroneous, as shown in Equation (2).

Therefore, in the conventional iTOF sensor, four-phase modulation is commonly used. To cancel the background signal

BG, Δ

Q0 =

AQ0 −

AQπ is acquired. To cancel the gain term

A, we obtain another signal Δ

Qπ/2 =

AQπ/2 −

AQ3π/2 in the next frame. Finally, we can obtain the exact distance regardless of the reflectivity and ambient light [

13] by calculating the following ratio:

To calculate the depth frame difference, we must calculate and store

θ(1) in Frame #1, calculate

θ(2) in Frame #2, and then detect their difference. However, we have three critical problems. Firstly, we need two frames to obtain

θ(1) (and also

θ(2)) for the four-phase modulation. This two-frame operation (for each

θ(k)) requires a large power consumption, particularly for the modulation of pixels. Additionally, the calculation of

θ involves a digital readout of 10-bit signals and image signal processing, including division, which requires additional power consumption. Secondly, significant motion blur arises because of the two-frame operation, particularly for fast-moving objects. Thirdly, a frame memory with large area is needed to store the Δ

Q0 and Δ

Qπ/2 generated from the previous frame. In

Section 3, we illustrate the proposed two-step comparison scheme that generates the depth frame difference in a single frame without area overhead from the frame memories and power consumption overhead from the modulation in two frames.

3. Two-Step Comparison Scheme for Acquiring Depth Frame Difference

The main purpose of the proposed scheme is to provide on-chip depth frame difference regardless of reflectivity of objects. In ideal case, we can detect the depth frame difference by measuring only intensity of the reflected light from a single object because the light intensity decreases according to the distance. However, more than two objects with different reflectivities provide different intensity (according to the reflectivity). Therefore, a simple measurement of light intensity like a conventional proximity sensor in mobile devices will induce an error for calculating the absolute difference of depth in successive frames. Instead of light intensity, we can calculate the depth itself using the four-phase modulation scheme that is commonly used in an iTOF depth sensor. However, as mentioned in

Section 2, significant overhead of area, power consumption, and speed arise. Therefore, we propose the two-step comparison scheme to generate on-chip depth frame difference in a single frame without any additional memory and power consumption overhead from the modulation.

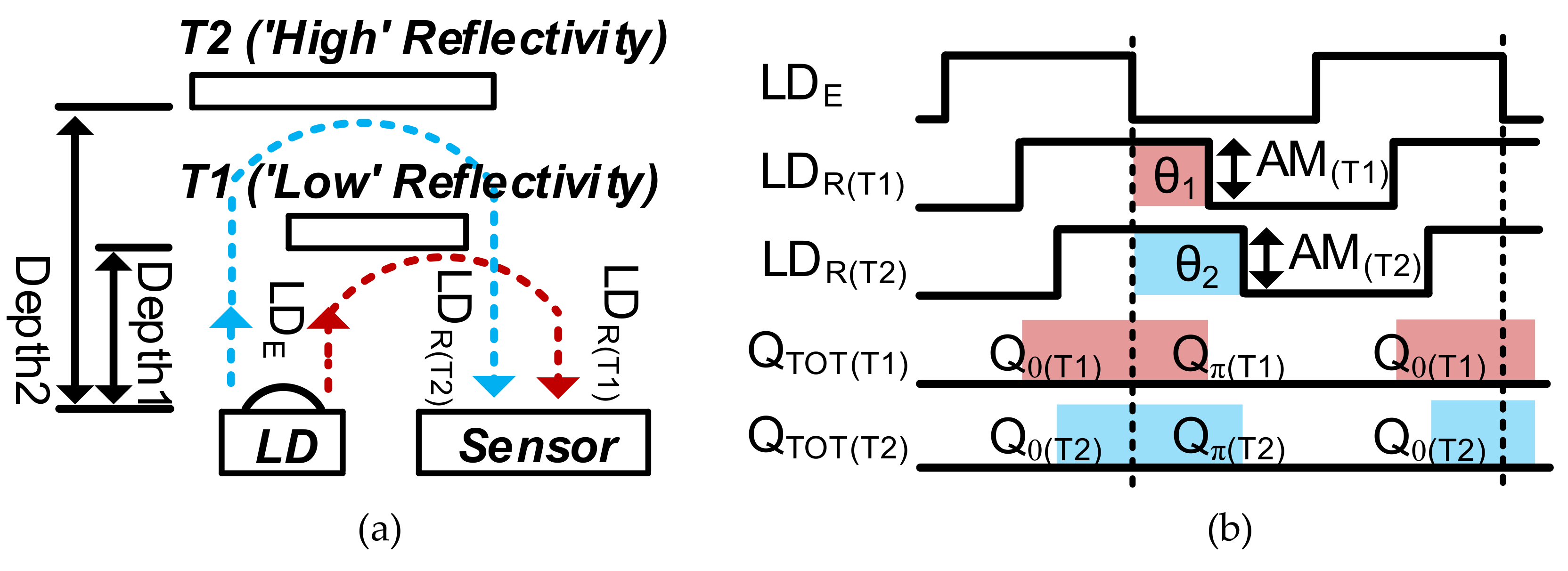

Figure 2 shows the operation principles of the proposed method for acquiring the depth frame difference. The main idea is that the change of

Qπ/

QTOT in successive frames is detected if the depth frame difference occurs. Because

QTOT varies according to the reflectivity, as well as the distance,

QTOT (and also

Qπ) is linearly adjusted to the fixed reference first. Then, the depth frame difference can be detected by simply detecting the change in

Qπ because the denominator

QTOT was adjusted to the fixed reference. For illustration, we assumed a special case in which Targets 1 (T1) and 2 (T2) are present in the first and second frames, respectively, as shown in

Figure 2a. The targets have different reflectivities and depths. We assumed this special case to show that the proposed scheme works regardless of the reflectivity of the objects. Assuming that the amplitude (AM

(T1)) of reflected light (LDR

(T1)) from T1 and the amplitude (AM

(T2)) of reflected light LDR

(T2) from T2 are equal, the total integrated charges

QTOT(T1) and

QTOT(T2) are the same, as shown in

Figure 2c. In the illustration of

Figure 2c, we describe the integrated charge at each sub-integration time

TSUB, where

TSUB is evenly divided over the whole integration time. The situation illustrated in

Figure 2c can occur even with different distances, because of differences in reflectivity. In this case, we cannot detect the depth difference by just calculating the change in the light intensity (

QTOT) even though

QTOT varies according to the distance, because the

QTOT values in successive frames are equal owing to reflectivity. However, using the proposed two-step comparison scheme, we can detect the depth difference for T1 and T2 without depth calculation in Equation (1) regardless of the

QTOT values. Assuming that

QTOT(T1) and

QTOT(T2) are different, as shown in case 2 of

Figure 2d, we equalize

QTOT(T1) and

QTOT(T2) using two phase operations. In the first phase, we integrate charges until

QTOT reaches the fixed reference

QREF for equalizing

QTOT(T1) and

QTOT(2). For this equalization process, the total integration time is divided into

N sub-integration times (

N·

TSUB). Each

TSUB consists of the modulation time (

TMOD) for accumulating photogenerated charge in the pixel and the accumulation time for accumulating the pixel output into the AM, as illustrated in detail in

Section 4. Therefore, the total charges integrated in the pixel (

QTOT(

N·

TSUB)) can be expressed as follows:

where

IPIX represents the photocurrent in a pixel. At each

TSUB,

QTOT is compared with

QREF. The integration of

QTOT is continued until the

k-th

TSUB (

k·

TSUB) that has a larger

QTOT than

QREF is reached. We can then obtain

where

A and

B are proportionality factors (PFs) based on the controlled integration time. This equalization process involves comparison in each

TSUB. We call this process the first comparison phase. In the second comparison phase, the values of

A·

Qπ(T1) and

B·

Qπ(T2) scaled with same PF used in the first comparison phase are compared. They have hte same PF because

Qπ experiences the same controlled integration time (

k·

TSUB) as

QTOT. According to the adjusted integration in the first comparison phase, we already have

A·

Qπ(T1) and

B·

Qπ(T2). Because the denominator

QTOT in Equation (1) is a constant in the first comparison phase, a simple comparison of the two

Qπ values provides the same result as a comparison of the

θ values. Therefore, we can effectively compare the ratios

Qπ(T1)/

QTOT(T1) and

Qπ(T2)/

QTOT(T2), where the reflectivity in both the numerator and denominator can be divided and cancelled. The

Qπ(1) and

Qπ(2) from Frames #1 and #2, respectively, are simply compared to determine whether a significant frame difference of the depth occurs, as follows:

where

Qth is the threshold of the depth frame difference. Using this two-step comparison scheme, we can simply generate the depth frame difference without accessing the A/D-converted digital signal and calculating the ratio in the image signal processor. More significantly, the two-phase modulation is sufficient; the power-consuming (and slow) four-phase modulation is not necessary.

However, the proposed two-step comparison scheme can induce an error because the integrated charge decreases significantly along the distance, particularly for a short distance, as shown in

Figure 3a. To illustrate this error, in

Figure 3b, we assume that the

QTOT(1) (marked with a blue line) of the first frame reaches

QREF (= 0.5) at the second

TSUB and that the

QTOT(2) of the second frame is exactly equal to

QTOT(1). Additionally, we assume that the

Qπ (marked with a blue dotted line) in both frames is half of the

QTOT. In this case, no frame difference should be detected. However, if

QTOT(2) is judged as a smaller value than

QREF in the second

TSUB owing to noise,

QTOT(2) is decided as 0.75 in the third

TSUB. In this case,

Qπ(2) is 0.375 owing to the error, whereas

Qπ(1) is 0.25. With this error (Δ

Qπ_err = 0.125), if

QTH is set as 0.1, the wrong frame difference (0.375 − 0.25 > 0.1) is detected, even though no frame difference occurs. In summary,

QTOT can be integrated with one more

TSUB via random noise or quantization noise during the first comparison phase. This induces significant error, particularly at a short distance, because

Q decreases significantly with an increase in the distance, as shown in

Figure 3b.

To suppress this error, we must reduce the increment of

Q in each

TSUB only for the short distance that induces significant error. This can be achieved by using the adaptive modulation time AF·

TMOD, where AF is an adaptive factor. Therefore, the decrement of

Q is reduced at a short distance, whereas the decrement of

Q is maintained (or increased) at a long distance. This effect is also shown in

Figure 3a,b. The increment of

Q (marked with a solid red line for

QTOT and a dotted red line for

Qπ) in each

TSUB is reduced by applying AF·

TMOD/

N in each

TSUB, where AF < 1. Then,

Qπ(2) is 0.28125 in the ninth

TSUB (owing to the error), and

Qπ(1) (0.25·

TMOD) is 0.25 in the eighth

TSUB. The depth frame difference (0.28125 − 0.25 < 0.1) is not detected, as desired.

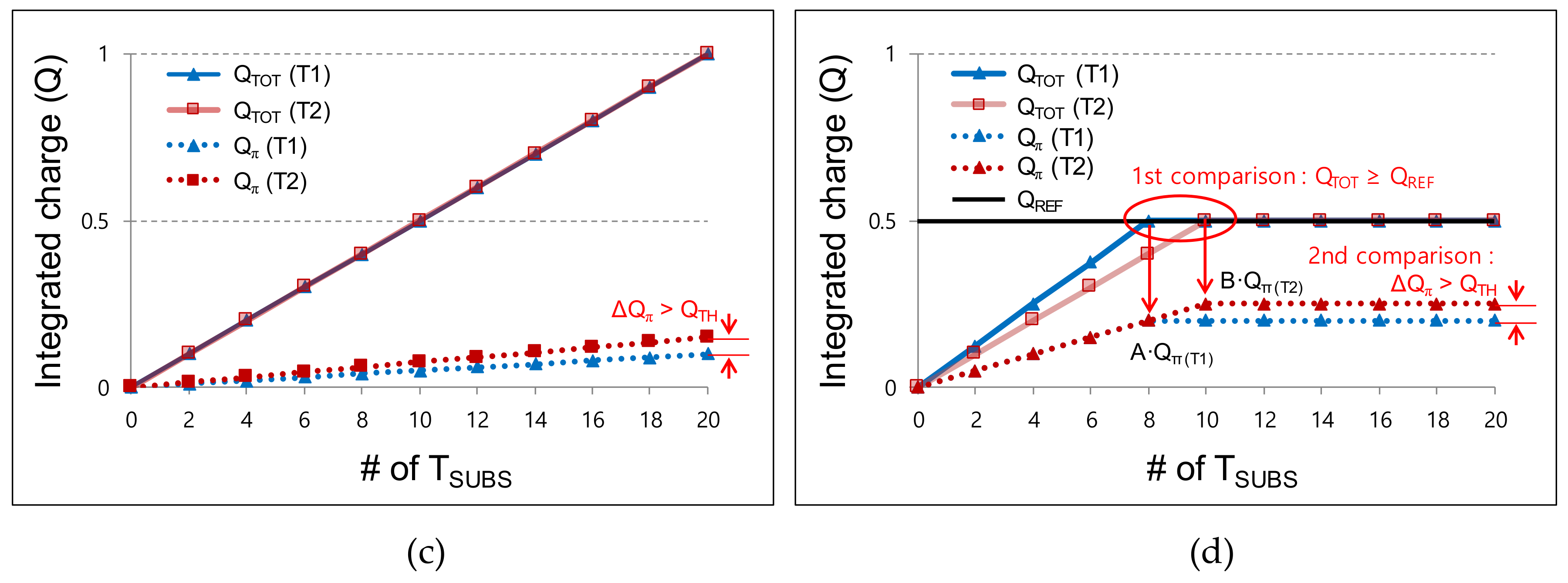

Figure 4a shows the integrated

QTOT along the sub-integration time. Both the cases with and without the adaptive modulation time are shown. We reduce the increment of

Q for the first 24

TSUBs by applying a small AF (

TMOD/4), because the integrated

QTOT generated from the short-distance objects has an abrupt transition along the distance. In this case, we have a large error that arises from the difference between the integrated

QTOT (at the 24th

TSUB) and the reference

QREF (

QTOT −

QREF). By reducing the

TMOD to

TMOD/4, the error can be suppressed owing to the decreased increment of

Q. However, for the long-distance objects, the rate of the charge integration is too low because of the reduced

TMOD. Therefore, from the 25th

TSUB to the 128th

TSUB, we gradually increase the

TMOD from

TMOD/2 to 2·

TMOD such that the integration of the small

Q reaches

QREF. Note that only the first

TSUB has a large AF (14.25). This is because the large initial

Q (integrated in the 1st

TSUB) accelerates the time to reach

QREF within 128·

TSUB. Without a large AF in the first

TSUB, the integration of the small

Q (in the case of long-distance objects) does not reach

QREF.

Figure 4b illustrates the PF·Δ

Qπ according to the distance. Using the proposed two-step comparison scheme, we acquire PF·

QTOT first (first comparison) from

N·

TSUB. The maximum

QTOT is set as 1 for simple illustration, as shown in

Figure 4a. As shown in

Figure 3a,

QTOT decreases proportionally to the square of the distance. Then, the PF·

QTOT and the resultant PF·Δ

Qπ are acquired according to the distance. We use Δ

Qπ (=

Q0 +

BG −

Qπ −

BG =

Q0 −

Qπ) instead of

Qπ in this calculation because we actually use Δ

Qπ in the prototype chip in order to cancel out the background term

BG, as in the four-phase modulation. As illustrated in

Figure 4b, allocating a larger number of

TSUBs in a given frame suppresses the depth error because the

TSUB is the effective resolution that determines Δ

Qπ. With the allocation of 128·

TSUB, the deviation in each

TSUB is suppressed. Without the adaptive modulation time, the error at the short distance (<1.5 m) is large (5.5% at maximum) because of the large decrement of

QTOT. Using the adaptive modulation time shown in

Figure 4a, the large decrement can be suppressed, and the error rate is reduced to 2.2% (maximum) over all distances. Thus, we can detect a frame difference larger than a certain threshold regardless of the distance of the objects. In this way, we suppress the nonlinearity-induced error using the adaptive modulation time and the allocation of 128·

TSUB.

In summary, the depth frame difference can be calculated in a single frame using the proposed two-step comparison scheme without generating four-phase images in two frames. Even though finite error in the depth calculation occurs owing to the quantization, the error can be suppressed below 2.2 % (<3.3 cm) by aid of the adaptive modulation. Because of the single-frame operation, no additional memory and power consumption overhead for the four-phase modulation are required. The detailed circuit implementation of the two-step comparison scheme is illustrated in the next section.

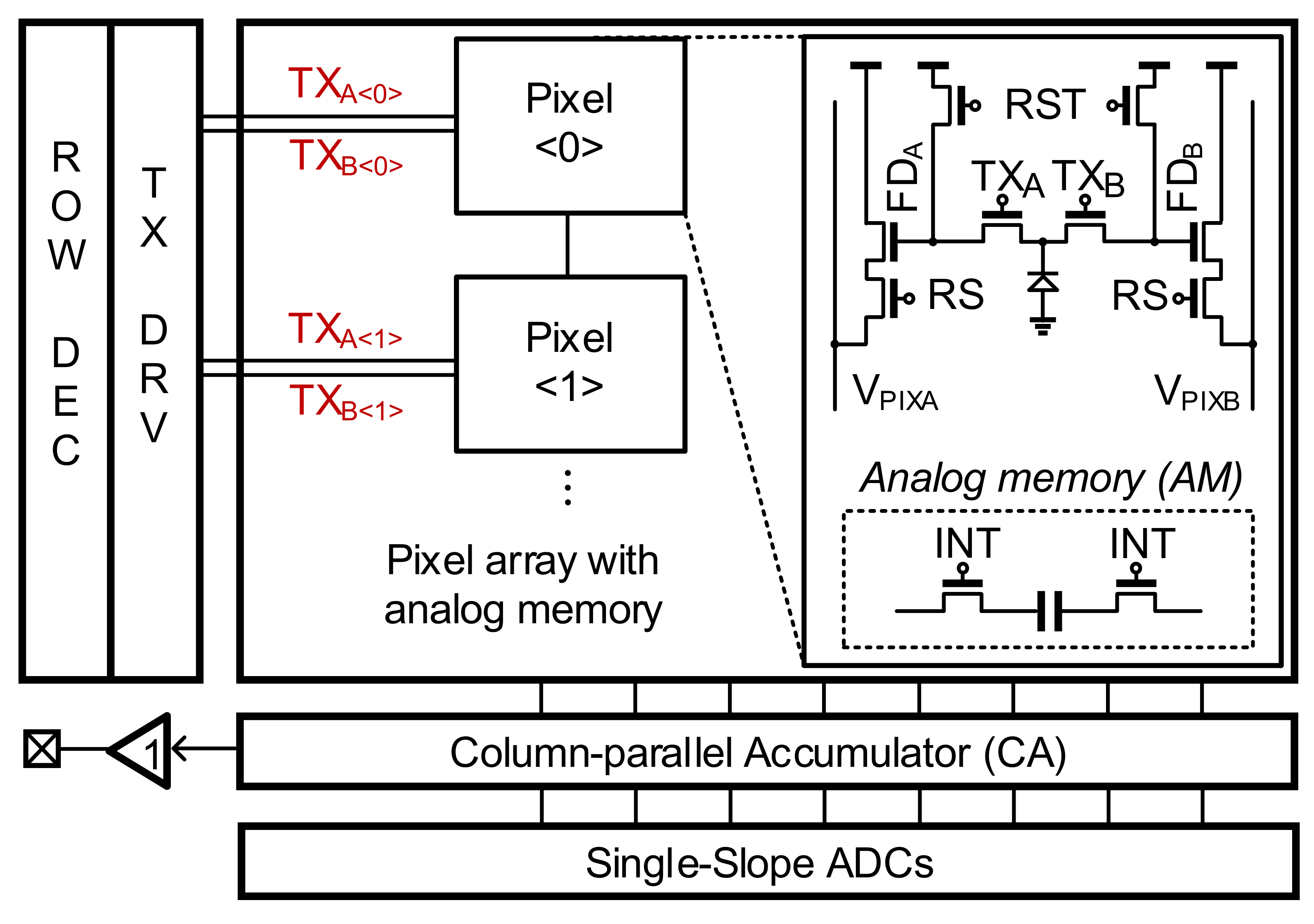

4. Circuit Implementation

Figure 5 shows the overall architecture of the proposed sensor chip. The sensor chip consists of an array of pixels with an over-pixel AM, a TX driver, and a row decoder for driving and selecting pixels, a column-parallel accumulator (CA) for accumulating charges from the pixels into the AM, and a unity-gain buffer for the output. The pixel consists of a PPD, two reset transistors (RST), two row-selection transistors (RS), two source follower transistors, and two electronic shutters (TX

0 and TX

π). Additionally, the AM (including one capacitor and two access transistors) is placed to store an intermediate

Q during the integration time. After the overall operation is finished in a frame, this AM stores the acquired Δ

Qπ in a given frame, which becomes the previous frame signal in the next frame.

The proposed two-step comparison scheme requires comparing the values of

QTOT and

Qπ. However, with strong ambient light, the DC offset

BG is added, as indicated by Equation (2). Therefore, instead of acquiring

QTOT and

Qπ, we must obtain Δ

QTOT = (

QTOT +

BG) − (0 +

BG) and Δ

Qπ = (

Q0 +

BG) − (

Qπ +

BG) in a single frame. Both

Qπ and Δ

Qπ provide phase information according to the depth [

2]. Therefore, the first comparison is performed as Δ

QTOT > Δ

QREF, and the second comparison is performed as |

A·Δ

Qπ(1) −

B·Δ

Qπ(2)| > Δ

QTH.

For a two-step comparison scheme, we grouped two adjacent pixels. The pixel<0> generates Δ

QTOT, and the pixel<1> generates Δ

Qπ. As shown in

Figure 6a, the modulation period of TX in pixel<1> is twice that of the even pixels, such that Δ

QTOT is generated in a single frame. Each pixel has an AM, i.e., AM<0> to AM<1>. The Δ

Qπ(1)s from Frame #1 are stored in AM<0>, and the Δ

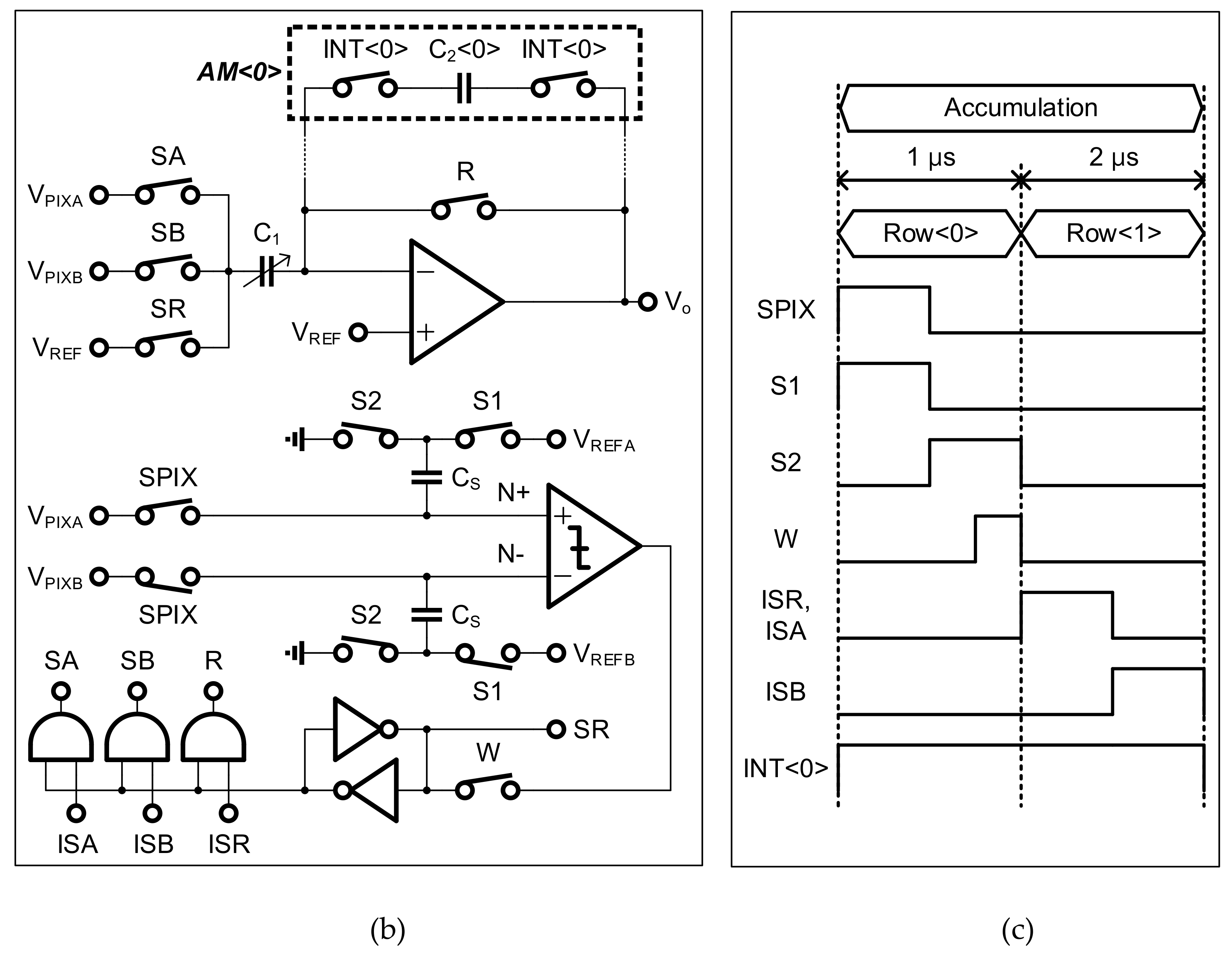

Qπ(2)s from Frame #2 are stored in AM<1>.

Figure 6b shows the CA circuit that accumulates the pixel output into the AM and reads the stored signal in the AM. The CA consists of an analog multiplexer, an amplifier, a static random-access memory (SRAM), and an input capacitor bank (C

1) for providing a high gain of >8. The comparator circuit that is originally used for the single-slope ADC is reused for the two-step comparison scheme. Additionally, the amplifier originally used for the column-parallel programmable-gain amplifier is reused for area efficiency.

The timing diagram of

Figure 6a illustrates the operation in a single

TSUB in one frame. Each

TSUB consists of two operation phases: (1) modulation, and (2) accumulation and the first comparison. The detailed operation is as follows: the first phase is the modulation phase, where

Q0,

Qπ, and

QTOT are integrated in the floating-diffusion (FD) nodes of pixels by modulating the electronic shutters TX

A and TX

B. After the modulation phase, four signals (

Q0 +

BG,

Qπ +

BG,

QTOT +

BG,

BG) are generated. These signals are stored in the FD nodes FD

A and FD

B of the two pixels. The second phase is the accumulation and first comparison phase. In the second phase, the integrated Δ

QTOT (from pixel<0>) until the current

TSUB and Δ

QREF are compared. If Δ

QTOT is larger than Δ

QREF, Δ

Qπ (from pixel<1>) is stored in the AM. In this case, Δ

Qπ is no longer stored in the AM from the next

TSUB. Therefore, the Δ

Qπ acquired when Δ

QTOT reaches Δ

QREF is preserved in the AM. When Δ

QTOT is smaller than Δ

QREF, Δ

Qπ is still stored in the AM. However, in this case, a new Δ

Qπ is stored in the AM in the next

TSUB. After 128∙

TSUB (= 1 frame), the Δ

Qπ stored in the current frame and the Δ

Qπ stored in the previous frame are accessed through the amplifier to be compared.

The circuit operation, along with a timing diagram, is shown in

Figure 6c. At

t1, even pixels (row<0>) are selected. The switches SA and SAD are enabled. Then, two outputs of the source followers (V

PIXA and V

PIXB) are sampled on

CS. At this time,

VPIXA is

VRST −

BG/

CFD, and

VPIXB is

VRST − (

QTOT +

BG)/

CFD. At

t2, the switch SB is enabled. Then, the comparator inputs N+ and N− experience voltage drops based on

VREFA and

VREFB. We set

VREFB as

VREFA +

QREF/

CFD, such that the comparator compares

QTOT with

QREF. Therefore, if

QTOT >

QREF, the comparator generates an output of “1”. At

t3, the switch SE is enabled to store the comparator output in the SRAM. At

t4, odd pixels (row<1>) are selected. Additionally, AM<0> is selected by enabling the INT<0>. Then, the switches RINT and ISM1 are enabled. If the SRAM is storing “0”, the accumulation of Δ

Qπ to the AM is required, because

QTOT has not reached

QREF yet. In this case,

VPIXA (=

VRST − (

Qπ +

BG)/

CFD) is sampled on

C1 for the accumulation. Simultaneously, the

C2 for AM<0> is reset by unity-gain feedback. If the SRAM is storing “0”, no accumulation of Δ

Qπ is required, because

QTOT already reached

QREF in the previous

TSUB, and the final Δ

Qπ is already stored in the AM. In this case, the reference voltage

VREF is sampled on

C1 instead of sampling the

VPIXA. By fixing the input as a constant

VREF, no accumulation is performed in the accumulator. Moreover, the AM is not reset, for preserving the stored Δ

Qπ. At

t5, ISM2 is enabled for the accumulation. Simultaneously,

VPIXB (=

VRST − (

Q0 +

BG)/

CFD) is input to the capacitor

C1. This accumulation is performed only when the SRAM is storing “1”. Finally, the output of the CA is

This operation is repeated during 128 sub-integration times. In this manner, Δ

Qπ is stored in one AM (AM<0>) out of the two AMs in the first frame. The other AM (AM<1>) is used for storing the next frame signals. After 128·

TSUB, both the stored

A·Δ

Qπ(1) in AM<0> and

B·Δ

Qπ(2) in AM<1> are read out through the unity-gain buffer, which is used only for testing purposes, such that the second comparison of the values of |

A·Δ

Qπ(1) −

B·Δ

Qπ(2)| > Δ

QTH can be performed in the external logic circuit. Even though we used the buffer circuit to read Δ

Qπ and performed the second comparison off-chip for the purpose of characterization, the second comparison can be easily performed using the existing comparator of the single-slope ADC. It is noteworthy that the binary quantization in the second comparison is mainly for simple post processing, e.g., optic-flow estimation [

6] or motion-triggered awakening [

1] that use binary information of the frame difference. In the case that analog frame difference is required to generate accurate 3D motion vectors,

A·Δ

Qπ(1) −

B·Δ

Qπ(2) can be simply generated through an additional amplifier circuit that is similar as the one used in the column amplifier.

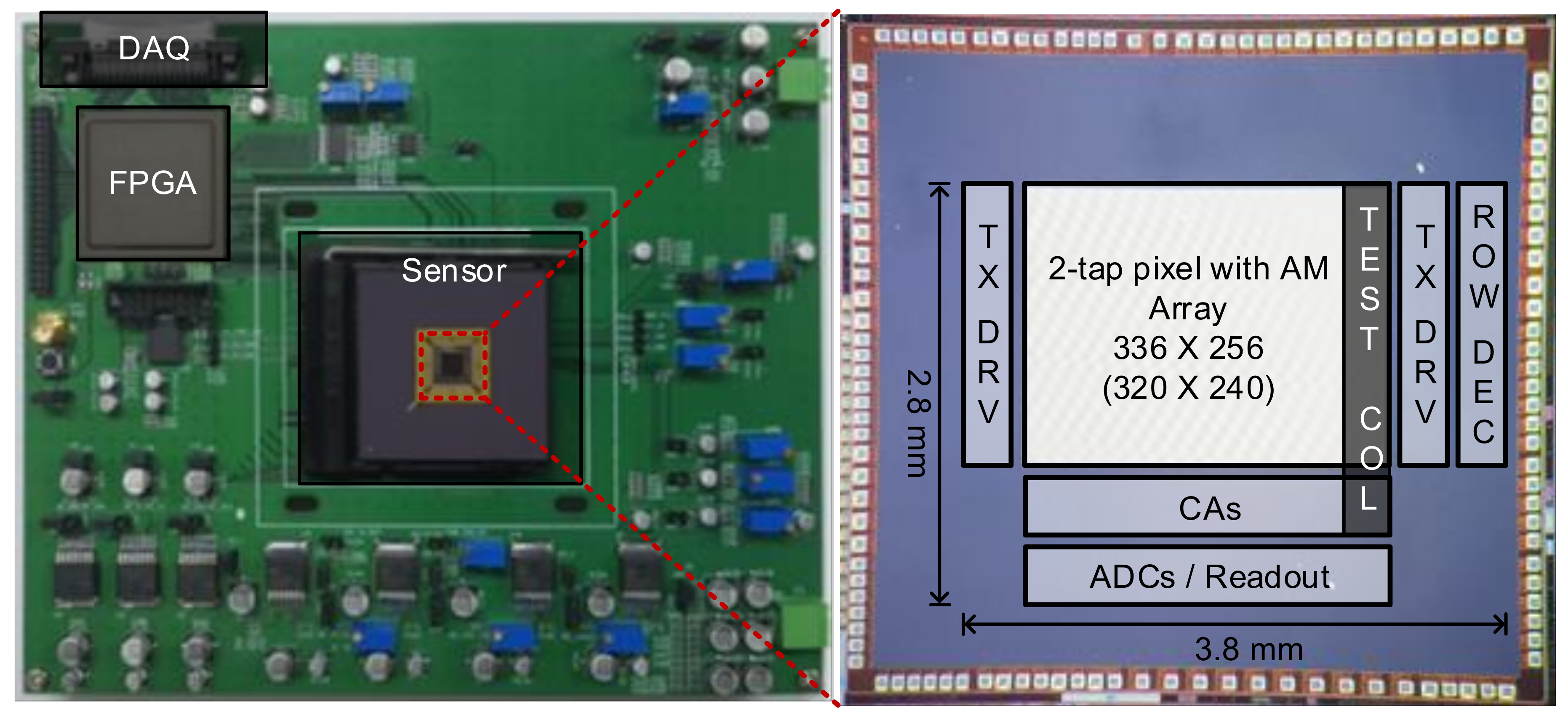

5. Experimental Results

A prototype chip was fabricated using a 90-nm BSI CIS process. The core size was 3.8 × 2.8 mm

2. The light source, which was composed of IR light-emitting diodes (LEDs), was modulated at 10 MHz with a power of 40 mW for each LED. This prototype chip was originally implemented to have a split pixel array for characterizing various PPDs and pixel layouts. The pixel split was performed in a row-by-row manner. To characterize the proposed two-step comparison scheme, we implemented the accumulator with comparison logic circuits only in one column, as shown in

Figure 7. The output of the accumulator was read through the unity-gain buffer.

Table 1 presents the chip characteristics.

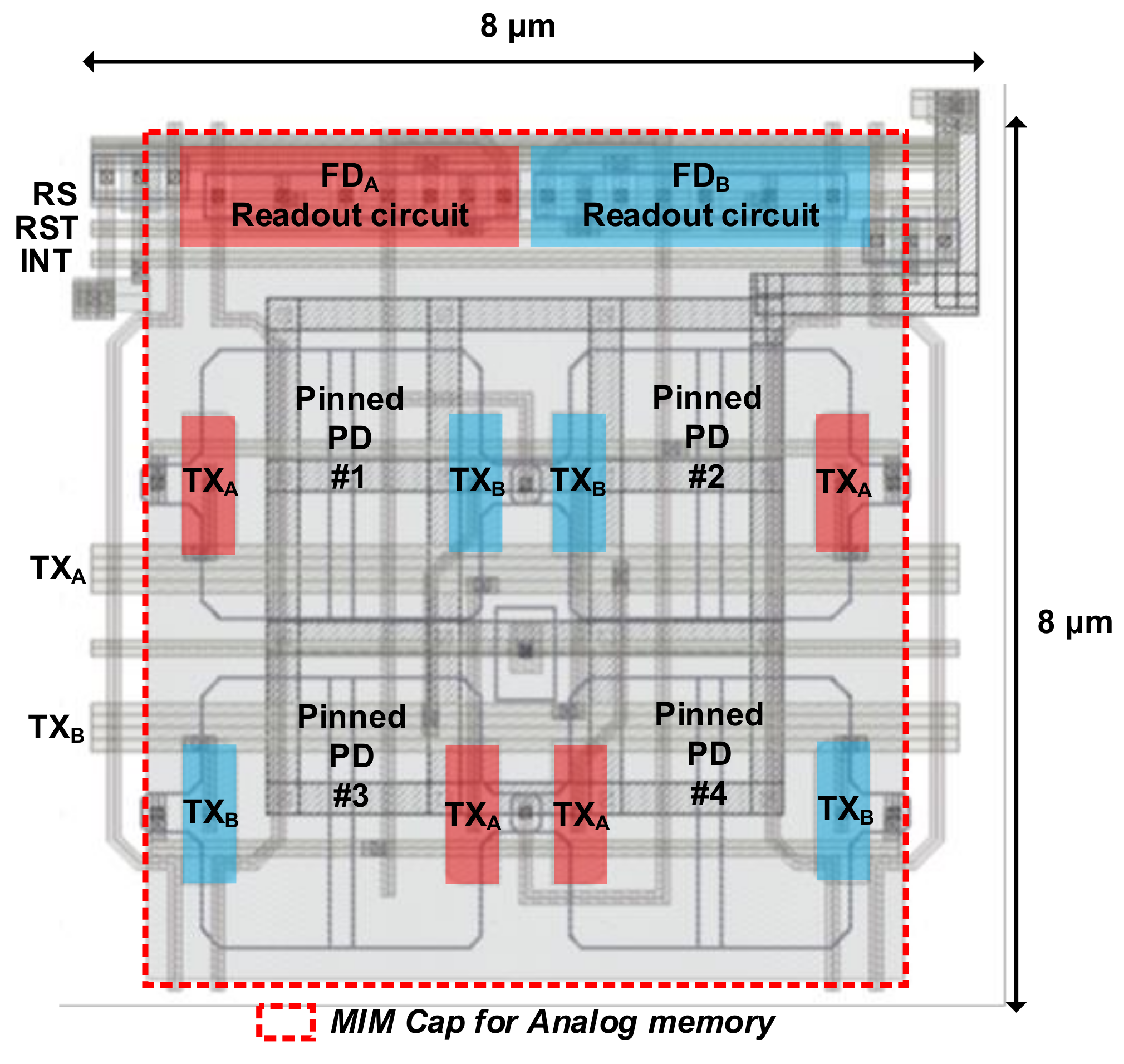

Figure 8 shows the pixel layout with an AM. To minimize the distance of charge transfer in the PPD within a short modulation period, the size of the PPD should be small enough while guaranteeing high sensitivity. Therefore, four small PPDs were shared to provide higher sensitivity [

15]. The size of each PPD was 2.3 × 2.3 μm

2. Because the AM was implemented with an MIM capacitor using the BSI CIS process, the AM on the front side did not degrade the sensitivity. In the proposed two-step comparison scheme, the AM must be accessed 128 times using a column amplifier. However, the column amplifier was designed with a low bias current of 2 μA for power-efficient operation. The average power consumption in a column was measured as 4 μW at 20 fps, which is even smaller than the power consumption in the column-parallel ADC of conventional image sensors [

16,

17,

18].

As illustrated in

Figure 6b, the AM operates as a feedback capacitor when Δ

Qπ is read out through the CA. Because of the gain amplification of 8 in the CA, the capacitance variation of the AM (C

1) affects gain term (C

1/C

2) in Equation (7) and induces gain fixed-pattern noise (FPN) in a column. Because the gain error from the gain FPN provides an error in the second comparison that compares the amplified Δ

Qπ, the result of the second comparison becomes erroneous. In order to suppress the gain FPN, the AM should be designed to have enough size such that mismatch between rows (and also between columns) are suppressed. The size of the MIM capacitor was designed to be 6.2 × 7 μm

2. The capacitance was 278 fF. In order to prove that the gain FPN does not provide significant error if enough capacitance is used, we measured the gain FPN in the test column. The measurement result shows 0.42% FPN that corresponds to an error of the depth frame difference below 0.1 cm.

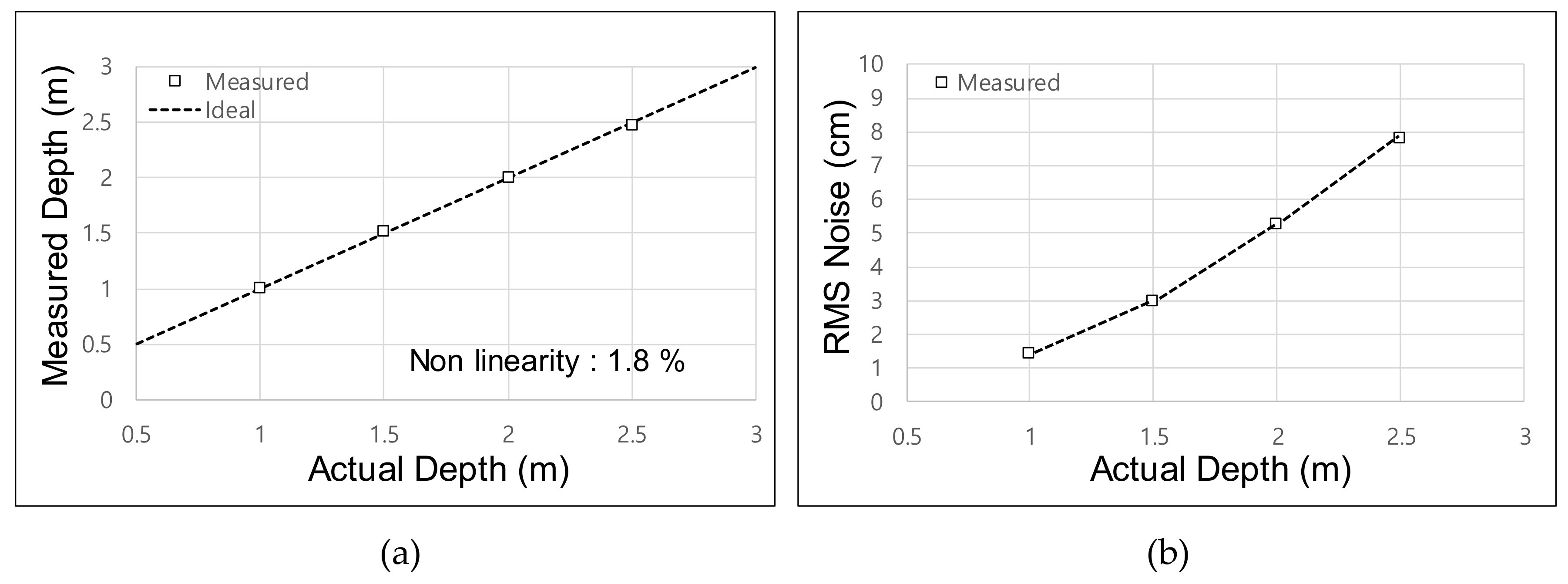

Figure 9a shows the measured depth over the range of 1–2.5 m. For the four-phase operation of depth acquisition, we had to acquire Δ

Qπ in the first frame and Δ

Qπ/2 in the second frame. Therefore, the effective frame rate was set as 10 fps for the depth-acquisition experiment. The measured nonlinearity was 1.8%. The minimum root-mean-square (RMS) noise was measured as 1.42 cm at a distance of 1 m, as shown in

Figure 9b. The frame rate of 10 fps was used only for the depth acquisition using the four-phase operation. The depth frame difference using the proposed two-step comparison scheme was measured at 20 fps because only a single frame of integration was needed to acquire Δ

Q. We allocated a modulation time of 25 ms for all 128 sub-integration times. Reducing the modulation time enhances the frame rate but degrades the depth accuracy. The frame rate is expected to be improved by optimizing the responsivity of the PPD in further research.

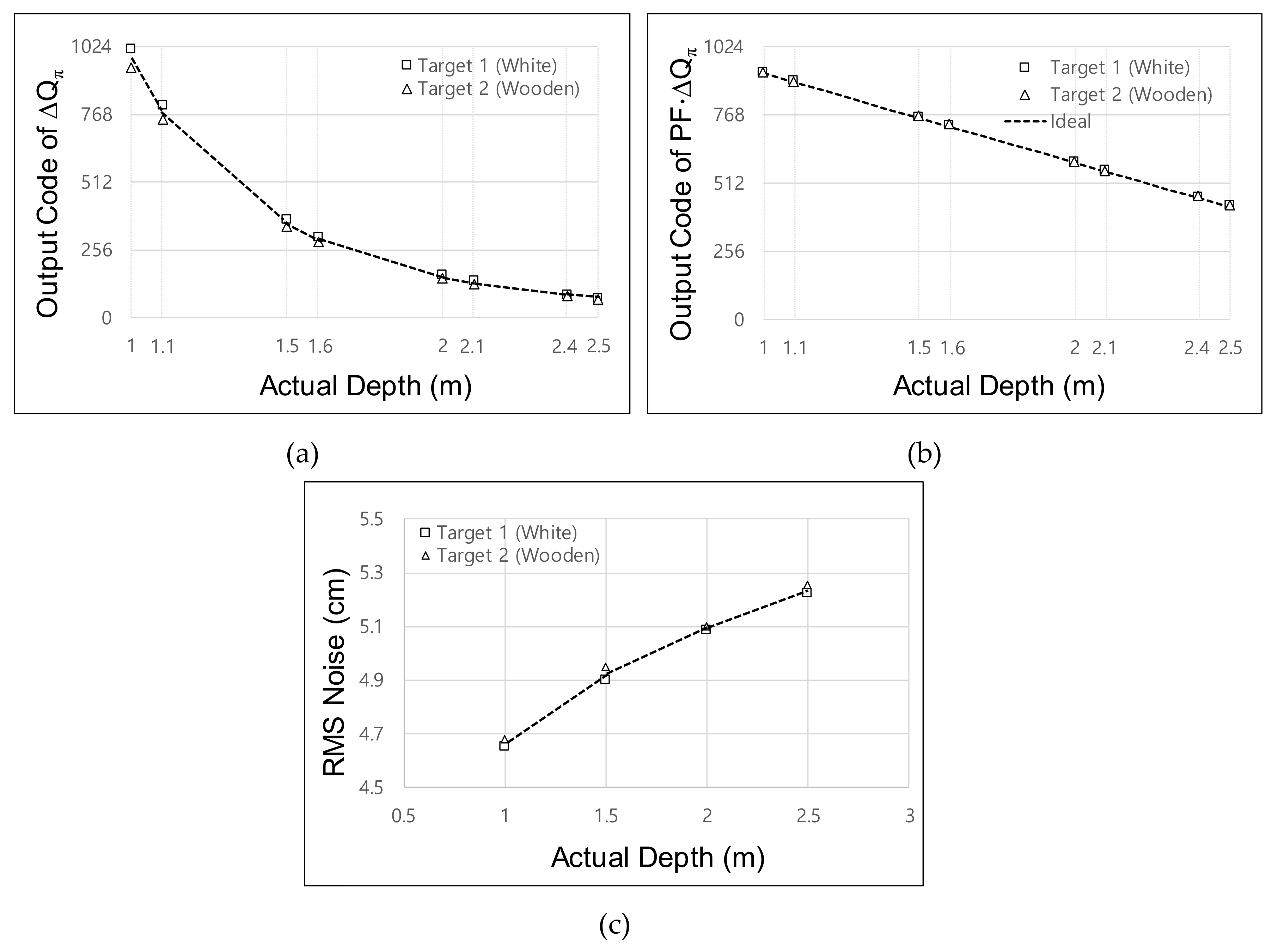

Figure 10 shows the measured Δ

Qπ for acquisition of the depth frame difference. To prove that the depth frame difference can be reliably acquired regardless of the reflectivity, we measured two target objects with different reflectivities. As shown in

Figure 10a, Δ

Qπ had a nonlinear response without the application of the two-step comparison scheme. This measured curve is similar to the curve illustrated in

Figure 3a. Therefore, the accurate depth frame difference could not be detected, because even a small depth difference provided an abrupt change of Δ

Qπ at a short distance, whereas a large depth difference was needed to provide a sufficient change of Δ

Qπ at a long distance. Moreover, differences in reflectivity induced the variation of Δ

Qπ.

Figure 10b shows the Δ

Qπ measured using the two-step comparison scheme. With this scheme, the output PF·Δ

Qπ exhibited a linear response regardless of the reflectivity. The maximum relative error between the ideal PF·Δ

Qπ and the measured PF·Δ

Qπ was 1.5% at a distance of 2.5 m.

Figure 10c shows the RMS noise of the Δ

Qπ. Considering that the RMS error of Δ

Qπ can be increased by up to 5.25 cm at a 2.5-m distance, the RMS error of the depth frame difference Δ

Qπ(1) −

ΔQπ(2) was <10 cm (=

). Thus, the targeted resolution of the depth frame difference was 7.4 cm. In the experiment, the location of the object was adjusted in increments of 10 cm from a distance of 1 m to 2.5 m. It is noteworthy that the RMS error of Δ

Qπ is quite constant over the whole range of distances, whereas the RMS error of the depth measured using the conventional four-phase modulation increases along with the distance. This is because the charge is integrated up to the

QREF in the two-step comparison scheme, where

QREF cannot be set as a high value considering the maximum range of the distance. Therefore, the two-step comparison scheme provides more error in the short range, whereas it provides a similar error in the long range compared with the four-phase modulation scheme. Even though the two-step comparison scheme using the single reference

QREF provides constant error under 7.4 cm in the prototype sensor, we expect that the error can be further suppressed by using dual references, i.e., using high

QREF1 for short range and low

QREF2 for long range such that a small error can be achieved in the short range. This dual reference can be implemented spatially (implemented in dual pixels) or temporally (implemented in dual frames).

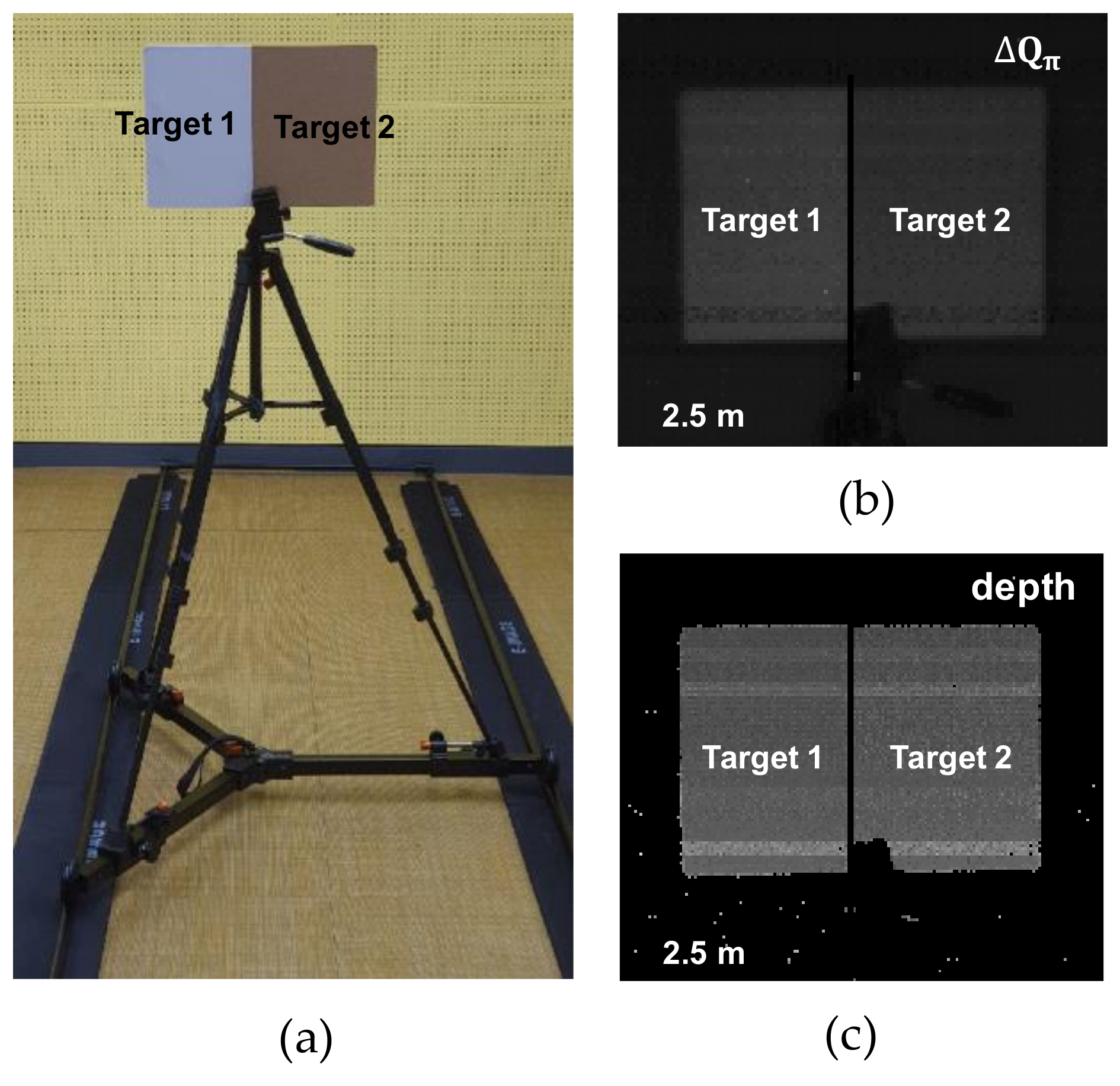

Figure 11 shows the testing environment and captured images from the fabricated sensor. As shown in

Figure 11a, we used the hardboard with different reflectivities as a target object.

Figure 11b shows the IR image of Δ

Qπ without the two-step comparison scheme. As illustrated in

Figure 10a, output values are different owing to the reflectivity. The depth image using conventional four-phase modulation scheme is also shown in

Figure 11c. No differences between reflectivities were measured, as expected. Note that the images have row patterns because the pixel split with slightly different layout was performed in a row-by-row manner for characterization purposes.

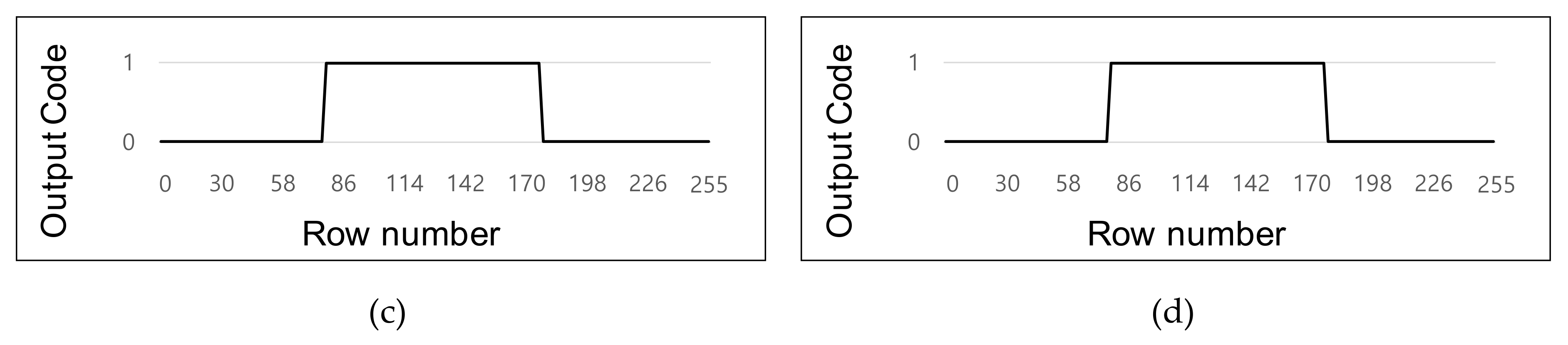

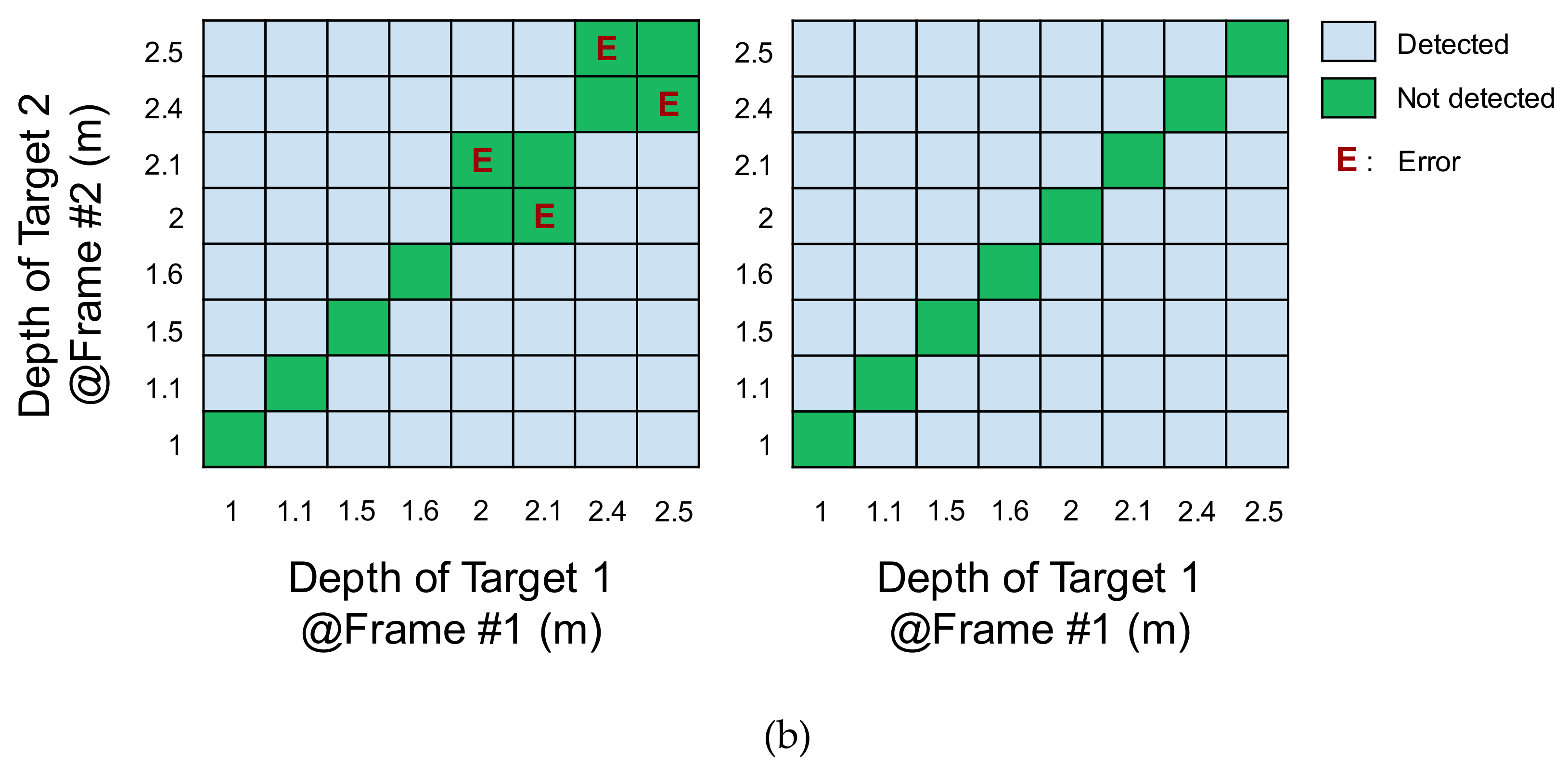

Figure 12a,b show the line images of the depth frame difference that were generated from the test column with application of the four-phase modulation scheme and the proposed two-step comparison scheme, respectively.

Figure 12c,d show the result of binary quantization. The threshold of the binary detection was set as 10 cm. In both results, no detection error was found regardless of the reflectivity.

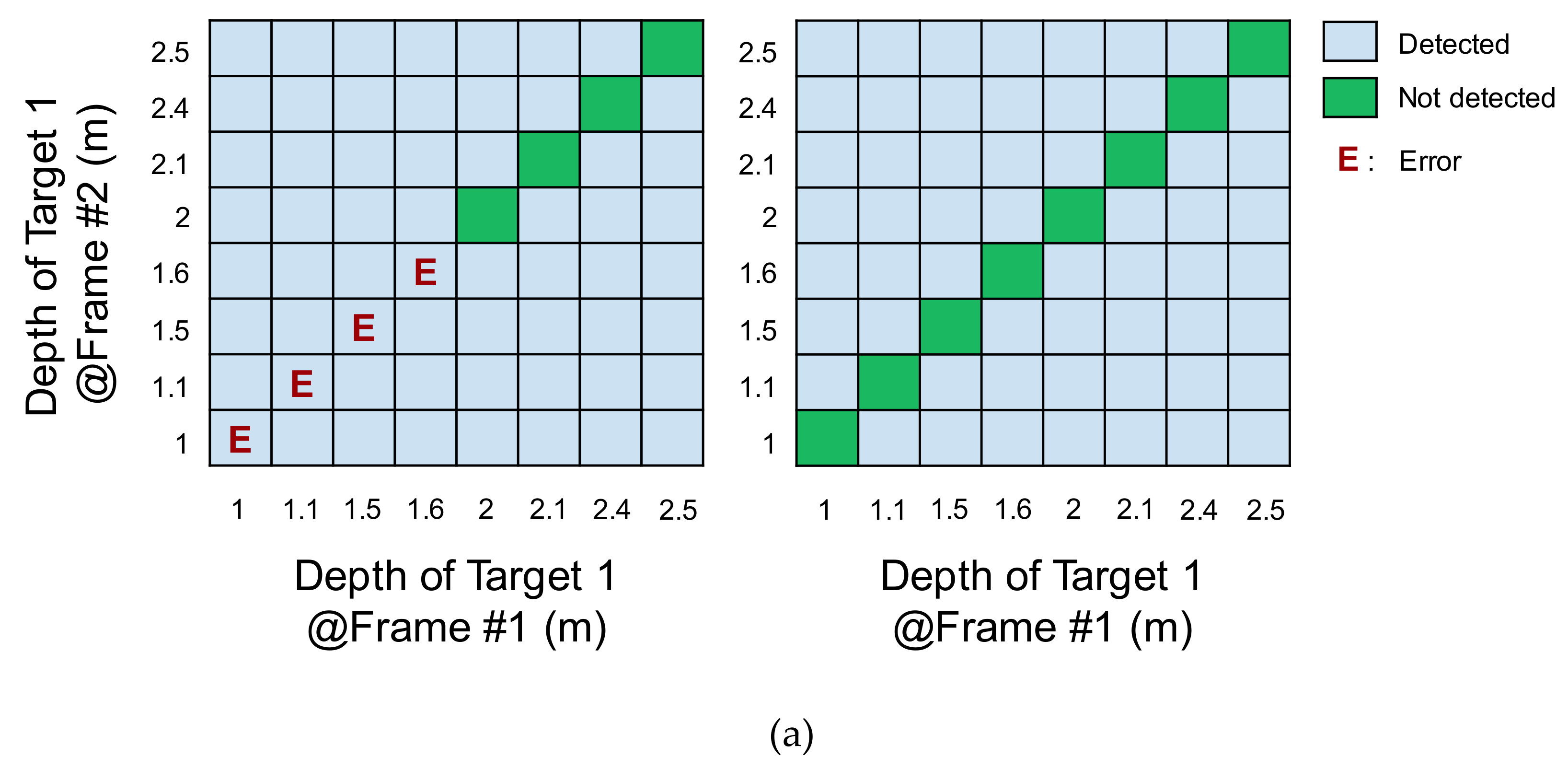

Figure 13 summarizes the result for the depth frame difference. Without the two-step comparison scheme, the frame difference was not detected in a significant portion of the range. Moreover, the detection results exhibited differences due to the different reflectivities. With the two-step comparison scheme, the frame difference was successfully detected in the entire range for both target objects with different reflectivities.

Table 2 shows a comparison of conventional depth sensors with a four-phase modulation scheme. Regarding the performance of the depth sensor itself, our prototype sensor includes non-optimized pixels in terms of the demodulation contrast, modulation frequency, and so on. However, with a given pixel, the proposed two-step comparison scheme offers three advantages to generate on-chip depth frame difference compared with the conventional four-phase modulation scheme. Firstly, the frame rate can be doubled. In order to calculate the depth (D) using a four-phase modulation scheme, we have to acquire four signals

Q0,

Qπ,

Qπ/2, and

Q3π/2 in two frames. For calculating the depth frame difference, four frames of images are required. Therefore, the frame rate is reduced by half compared with the proposed two-step comparison scheme. This is disadvantageous because of motion blur for detecting moving objects. Secondly, memory requirement is reduced by half. In each frame of the depth acquisition with the four-phase modulation, two delta charges (Δ

Qπ and Δ

Qπ/2) should be stored in the frame memory in order to calculate the depth. Therefore, we need two 10-bit frame memories per pixel to store Δ

Q0 and Δ

Qπ/2. The two-step comparison scheme reduces the requirement into a single 10-bit frame memory that stores only Δ

Qπ. Moreover, we used the over-pixel MIM capacitor as a frame memory without any area overhead. Thirdly, power consumption can be significantly saved. For the four-phase modulation, both the light source (LD) and pixels should be modulated with high frequency over 10 MHz in two frames. This modulation power that occurs in the two-frame modulation can be saved by the single-frame modulation of the two-step comparison scheme. In summary, the proposed depth sensor can provide both power and area efficiency while providing sufficient resolution of the depth frame difference; thus, the sensor is applicable to gesture sensors, object trackers, motion-triggered surveillance, vacuum robot navigators, etc.