Differential Microfluidic Sensors Based on Dumbbell-Shaped Defect Ground Structures in Microstrip Technology: Analysis, Optimization, and Applications

Abstract

1. Introduction

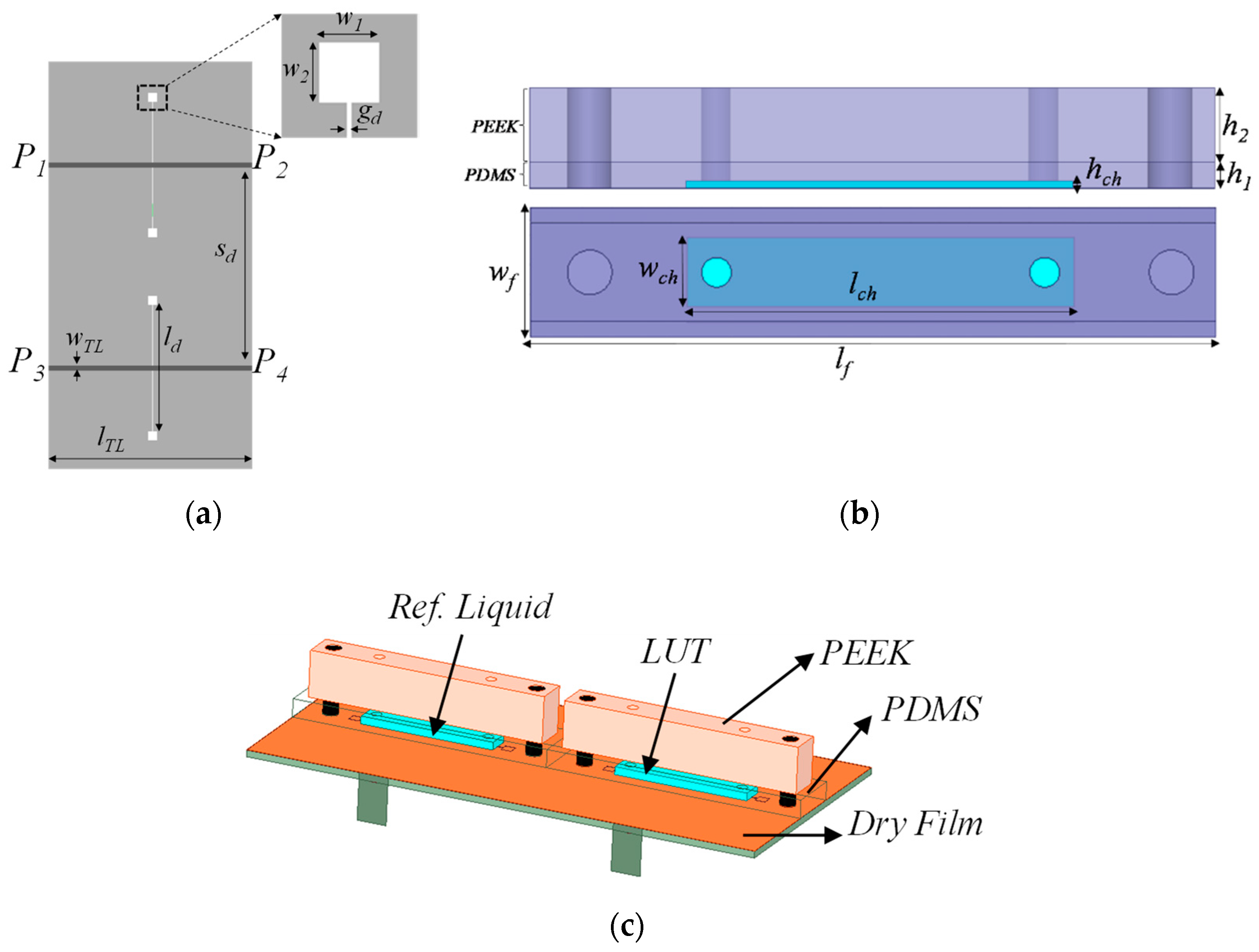

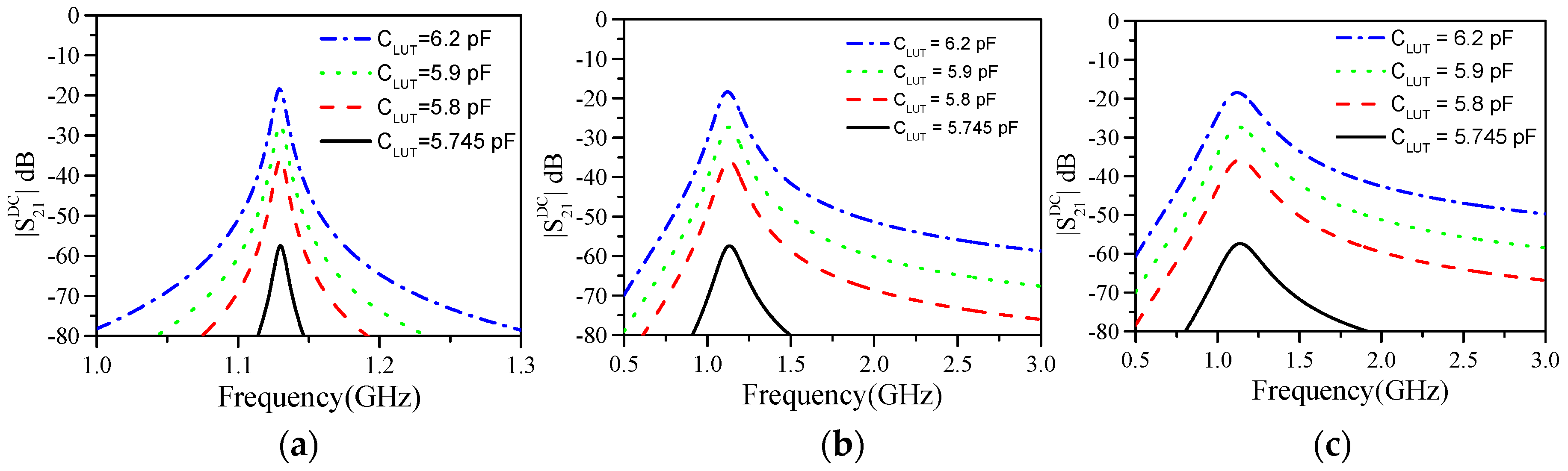

2. The Proposed Sensor, Functionality, Circuit Model, and Analysis

3. Results

3.1. Electrolyte (NaCl) Concentration Measurements in DI Water

3.2. Dielectric Characteritzation of Isopropanol in DI Water

4. Comparison with Other Microwave Sensor Approaches and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ahn, D.; Park, J.S.; Kim, C.S.; Qian, Y.; Itoh, T. A Design of the Lowpass Filter Using the Novel Microstrip Defected Ground Structure. IEEE Trans. Microw. Theory Tech. 2001, 49, 86–93. [Google Scholar] [CrossRef]

- Kumar, A.; Kartikeyan, A. Design and realization of microstrip filters with new defected ground structure (DGS). Eng. Sci. Technol. Int. J. 2017, 20, 679–686. [Google Scholar] [CrossRef]

- Kumar-Khandelwal, M.; Kumar-Kanaujia, B.; Kumar, S. Defected Ground Structure: Fundamentals, Analysis, and Applications in Modern Wireless Trends. Int. J. Antennas Propag. 2017, 2017, 22. [Google Scholar]

- Arya, A.K.; Kartikeyan, M.V.; Patnaik, A. Defected Ground Structure in the perspective of Microstrip Antennas: A Review. Frequenz 2010, 64, 79–84. [Google Scholar] [CrossRef]

- Zainud-Deen, H.; Badr, M.E.; El-Deen, E.; Awadallaand, K.H.; Sharshar, H.A. Microstrip antenna with defected ground plane structure as a sensor for landmines detection. Prog. Electromagn. Res. B 2008, 4, 27–39. [Google Scholar] [CrossRef]

- Rezaee, M.; Joodaki, M. Two-Dimensional Displacement Sensor Based on CPW Line Loaded by Defected Ground Structure with Two Separated Transmission Zeroes. IEEE Sens. J. 2017, 17, 994–999. [Google Scholar] [CrossRef]

- Naqui, J.; Durán-Sindreu, M.; Martín, F. Novel sensors based on the symmetry properties of split ring resonators (SRRs). Sensors 2011, 11, 7545–7553. [Google Scholar] [CrossRef] [PubMed]

- Naqui, J. Symmetry Properties in Transmission Lines Loaded with Electrically Small Resonators: Circuit Modeling and Applications; Springer: Heidelberg, Germany, 2016. [Google Scholar]

- Naqui, J.; Durán-Sindreu, M.; Martín, F. Alignment and position sensors based on split ring resonators. Sensors 2012, 12, 11790–11797. [Google Scholar] [CrossRef]

- Horestani, A.K.; Fumeaux, C.; Al-Sarawi, S.F.; Abbott, D. Displacement sensor based on diamond-shaped tapered split ring resonator. IEEE Sens. J. 2013, 13, 1153–1160. [Google Scholar] [CrossRef]

- Horestani, A.K.; Abbott, D.; Fumeaux, C. Rotation sensor based on horn-shaped split ring resonator. IEEE Sens. J. 2013, 13, 3014–3015. [Google Scholar] [CrossRef]

- Naqui, J.; Martín, F. Transmission lines loaded with bisymmetric resonators and their application to angular displacement and velocity sensors. IEEE Trans. Microw. Theory Tech. 2013, 61, 4700–4713. [Google Scholar] [CrossRef]

- Naqui, J.; Martín, F. Angular displacement and velocity sensors based on electric-LC (ELC) loaded microstrip lines. IEEE Sens. J. 2014, 14, 939–940. [Google Scholar] [CrossRef]

- Horestani, A.K.; Naqui, J.; Abbott, D.; Fumeaux, C.; Martín, F. Two-dimensional displacement and alignment sensor based on reflection coefficients of open microstrip lines loaded with split ring resonators. Electron. Lett. 2014, 50, 620–622. [Google Scholar] [CrossRef]

- Naqui, J.; Martín, F. Microwave sensors based on symmetry properties of resonator-loaded transmission lines: A review. Sensors 2015, 2015, 10. [Google Scholar] [CrossRef]

- Naqui, J.; Coromina, J.; Karami-Horestani, A.; Fumeaux, C.; Martín, F. Angular displacement and velocity sensors based on coplanar waveguides (CPWs) loaded with S-shaped split ring resonator (S-SRR). Sensors 2015, 15, 9628–9650. [Google Scholar] [CrossRef] [PubMed]

- Horestani, A.K.; Naqui, J.; Shaterian, Z.; Abbott, D.; Fumeaux, C.; Martín, F. Two-dimensional alignment and displacement sensor based on movable broadside-coupled split ring resonators. Sens. Actuators A 2014, 210, 18–24. [Google Scholar] [CrossRef]

- Su, L.; Naqui, J.; Mata-Contreras, J.; Martín, F. Modeling metamaterial transmission lines loaded with pairs of coupled split ring resonators. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 68–71. [Google Scholar] [CrossRef]

- Su, L.; Naqui, J.; Mata-Contreras, J.; Martín, F. Modeling and applications of metamaterial transmission lines loaded with pairs of coupled complementary split ring resonators (CSRRs). IEEE Antennas Wirel. Propag. Lett. 2016, 15, 154–157. [Google Scholar] [CrossRef]

- Naqui, J.; Damm, C.; Wiens, A.; Jakoby, R.; Su, L.; Mata-Contreras, J.; Martín, F. Transmission Lines Loaded with Pairs of Stepped Impedance Resonators: Modeling and Application to Differential Permittivity Measurements. IEEE Trans. Microw. Theory Tech. 2016, 64, 3864–3877. [Google Scholar] [CrossRef]

- Su, L.; Mata-Contreras, J.; Naqui, J.; Martín, F. Splitter/combiner microstrip sections loaded with pairs of complementary split ring resonators (CSRRs): Modeling and optimization for differential sensing applications. IEEE Trans. Microw. Theory Tech. 2016, 64, 4362–4370. [Google Scholar] [CrossRef]

- Vélez, P.; Su, L.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martín, F. Microwave microfluidic sensor based on a microstrip splitter/combiner configuration and split ring resonators (SRR) for dielectric characterization of liquids. IEEE Sens. J. 2017, 17, 6589–6598. [Google Scholar] [CrossRef]

- Vélez, P.; Mata-Contreras, J.; Dubuc, D.; Grenier, K.; Martín, F. Solute Concentration Measurements in Diluted Solutions by means of Split Ring Resonators. In Proceedings of the 48th European Microwave Conference, Madrid, Spain, 25–27 September 2018. [Google Scholar]

- Vélez, P.; Mata-Contreras, J.; Su, L.; Dubuc, D.; Grenier, K.; Martín, F. Modeling and Analysis of Pairs of Open Complementary Split Ring Resonators (OCSRRs) for Differential Permittivity Sensing. In Proceedings of the 2017 IEEE MTT-S International Microwave Workshop Series Advanced Materials and Processes for RF and THz Applications (IMWS-AMP 2017), Pavia, Italy, 20–22 September 2017. [Google Scholar]

- Vélez, P.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martín, F. Highly-sensitive microwave sensors based on open complementary split ring resonators (OCSRRs) for dielectric characterization and solute concentration measurements in liquids. IEEE Access 2018, 6, 48324–48338. [Google Scholar] [CrossRef]

- Vélez, P.; Muñoz-Enano, J.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martín, F. Split ring resonator (SRR) based microwave fluidic sensor for electrolyte concentration measurements. IEEE Sens. J. 2019, 19, 2562–2569. [Google Scholar] [CrossRef]

- Puentes, M. Planar Metamaterial Based Microwave Sensor Arrays for Biomedical Analysis and Treatment; Springer: Heidelberg, Germany, 2014. [Google Scholar]

- Ebrahimi, A.; Withayachumnankul, W.; Al-Sarawi, S.; Abbott, D. High-sensitivity metamaterial-inspired sensor for microfluidic dielectric characterization. IEEE Sens. J. 2014, 14, 1345–1351. [Google Scholar] [CrossRef]

- Schueler, M.; Mandel, C.; Puentes, M.; Jakoby, R. Metamaterial inspired microwave sensors. IEEE Microw. Mag. 2012, 13, 57–68. [Google Scholar] [CrossRef]

- Boybay, M.S.; Ramahi, O.M. Material characterization using complementary split-ring resonators. IEEE Trans. Instrum. Meas. 2012, 61, 3039–3046. [Google Scholar] [CrossRef]

- Lee, C.S.; Yang, C.L. Complementary split-ring resonators for measuring dielectric constants and loss tangents. IEEE Microw. Wirel. Compon. Lett. 2014, 24, 563–565. [Google Scholar] [CrossRef]

- Yang, C.L.; Lee, C.S.; Chen, K.W.; Chen, K.Z. Noncontact measurement of complex permittivity and thickness by using planar resonators. IEEE Trans. Microw. Theory Tech. 2016, 64, 247–257. [Google Scholar] [CrossRef]

- Withayachumnankul, W.; Jaruwongrungsee, K.; Tuantranont, A.; Fumeaux, C.; Abbott, D. Metamaterial-based microfluidic sensor for dielectric characterization. Sens. Actuators A Phys. 2013, 189, 233–237. [Google Scholar] [CrossRef]

- Salim, A.; Lim, S. Complementary split-ring resonator-loaded microfluidic ethanol chemical sensor. Sensors 2016, 16, 1802. [Google Scholar] [CrossRef]

- Su, L.; Mata-Contreras, J.; Vélez, P.; Fernández-Prieto, A.; Martín, F. Analytical method to estimate the complex permittivity of oil samples. Sensors 2018, 18, 984. [Google Scholar] [CrossRef] [PubMed]

- Muñoz-Enano, J.; Vélez, P.; Mata-Contreras, J.; Gil, M.; Dubuc, D.; Grenier, K.; Martín, F. Microwave sensors/comparators with optimized sensitivity based on microstrip lines loaded with open split ring resonators (OSRRs). In Proceedings of the 49th European Microwave Conference, Paris, France, 1–3 October 2019. [Google Scholar]

- Vélez, P.; Muñoz-Enano, J.; Martín, F. Electrolyte concentration measurements in DI water with 0. In 125g/L resolution by means of CSRR-based structures. In Proceedings of the 49th European Microwave Conference, Paris, France, 1–3 October 2019. [Google Scholar]

- Martín, F.; Zhu, L.; Hong, J.; Medina, F. Balanced Microwave Filters; Wiley/IEEE-Press: Hoboken, NJ, USA, 2018. [Google Scholar]

- Weiner, O. Die theorie des Mischkorpers für das Feld des statonare Stromung i. die mittelwertsatze für kraft polarisation und energie. Der Abhandlungen der Mathematisch-Physischen Klasse der Konigl. Sachs. Ges. Wiss. 1912, 32, 509–604. (In German) [Google Scholar]

- Babajanyan, A.; Kim, J.; Kim, S.; Lee, K.; Friedman, B. Sodium chloride sensing by using a near-field microwave microprobe. Appl. Phys. Lett. 2006, 89, 183504. [Google Scholar] [CrossRef]

- Soffiatti, A.; Max, Y.; Silva, S.G.; de Mendonça, L.M. Microwave metamaterial-based sensor for dielectric characterization of liquids. Sensors 2018, 18, 1513. [Google Scholar] [CrossRef] [PubMed]

- Frau, I.; Wylie, S.; Byrne, P.A.; Cullen, J.; Korostynska, O.; Mason, A. New sensing system based on electromagnetic waves and functionalised EM sensors for continuous monitoring of Zn in freshwater. In Proceedings of the 11th ICARD-IMWA-MWD Conference—Risk to Opportunity, Pretoria, South Africa, 10–14 September 2018. [Google Scholar]

- Ilaria, F.; Korostynska, O.; Byrne, P.; Mason, A. Feasibility of in-situ quality assessment of zinc contamination in water. In Proceedings of the 2017 IEEE First Ukraine Conference on Electrical and Computer Engineering (UKRCON), Kiev, Ukraine, 29 May–2 June 2017. [Google Scholar]

- Babajanyan, A.; Melikyan, H.; Kim, S.; Kim, J.; Lee, K.; Friedman, B. Real-time noninvasive measurement of glucose concentration using microwave biosensors. J. Sens. 2010, 2010. [Google Scholar] [CrossRef]

- Kim, S.; Melikyan, H.; Kim, J.; Babajanyan, A.; Lee, J.H.; Enkhtur, L.; Friedman, B.; Lee, K. Noninvasive in vitro measurement of pig blood D-glucose by using a microwave cavity sensor. Diabetes Res. Clin. Pract. 2012, 96, 379–384. [Google Scholar] [CrossRef] [PubMed]

- Sharafadinzadeh, N.; Abdolrazzaghi1, M.; Daneshmand, M. Highly sensitive microwave split ring resonator sensor using gap extension for glucose sensing. In Proceedings of the 2017 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes (IMWSAMP 2017), Pavia, Italy, 20–22 September 2017. [Google Scholar]

- Kim, J.; Babajanyan, A.; Hovsepyan, A.; Lee, K.; Friedman, B. Microwave dielectric resonator biosensor for aqueous glucose solution. Rev. Sci. Instrum. 2008, 79. [Google Scholar] [CrossRef] [PubMed]

- Chretiennot, T.; Dubuc, D.; Grenier, K. A microwave and microfluidic planar resonator for efficient and accurate complex permittivity characterization of aqueous solution. IEEE Trans. Microw. Theory Tech. 2013, 61, 972–978. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Daneshmand, M.; Iyer, A.K. Strongly enhanced sensitivity in planar microwave sensors based on metamaterial coupling. IEEE Trans. Microw. Theory Tech. 2018, 66, 1843–1855. [Google Scholar] [CrossRef]

- Wiltshire, B.D.; Zarifi, M.H. 3-D Printing Microfluidic Channels with Embedded Planar Microwave Resonators for RFID and Liquid Detection. IEEE Microw. Wirel. Compon. Lett. 2019, 29, 65–67. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Zarifi, M.H.; Daneshmand, M. Sensitivity enhancement of split ring resonator based liquid sensors. In Proceedings of the 2016 IEEE Sensors, Orlando, FL, USA, 30 October–3 November 2016; pp. 1–3. [Google Scholar]

- Zhang, X.; Ruan, C.; Chen, K. High-Sensitivity Microwave Sensor for Liquid Characterization Using a Complementary Circular Spiral Resonator. Sensors 2019, 19, 787. [Google Scholar] [CrossRef] [PubMed]

- Ruan, C.; Zhang, X.; Ullah, S. Complementary Metamaterial Sensor for Nondestructive Evaluation of Dielectric Substrates. Sensors 2019, 19, 2100. [Google Scholar]

- Liang, Y.; Ma, M.; Zhang, F.; Liu, F.; Liu, Z.; Wang, D.; Li, Y. An LC Wireless Microfluidic Sensor Based on Low Temperature Co-Fired Ceramic (LTCC) Technology. Sensors 2019, 19, 1189. [Google Scholar] [CrossRef] [PubMed]

- Kilpijärvi, J.; Halonen, N.; Juuti, J.; Hannu, J. Microfluidic Microwave Sensor for Detecting Saline in Biological Range. Sensors 2019, 19, 819. [Google Scholar]

| Reference | Max. Sensitivity (dB·L/g) | Resolution (g/L) | Dynamic Range (g/L) |

|---|---|---|---|

| [25] | 4.3 | 0.25 | 80 |

| [26] | 12.27 | 0.25 | 60 |

| [23] | 1.609 | 0.5 | 100 |

| [40] | 0.005 | 2 | 10 |

| [44] | 0.003 | 1 | 300 |

| [45] | 1.75 | 1.5 | 5.5 |

| [46] | 0.017 | 10 | 150 |

| [47] | 0.003 | 5 | 300 |

| [37] | 6.54 | 0.125 | 60 |

| [41] | 0.822 | 0.5 | 40 |

| [42] | 7 | 0.0001 | 0.01 |

| [43] | 65 | 0.001 | 0.1 |

| [This work] | 10.08 | 0.25 | 60 |

| Reference | f0 (GHz) | Fv (%) | |

|---|---|---|---|

| [48] | 20 | -/2.98 | 5 |

| [28] | 2 | -/2.38 | 10 |

| [33] | 1.9 | -/0.81 | 10 |

| [34] | 3.5 | -/2.61 | 10 |

| [22] | 0.87 | -/0.91 | 10 |

| [49] | 2.5 | -/3.2 | 0.005 |

| [25] | 0.9 | 1.86/2.28 | 5 |

| [50] | 5.5 | -/0.53 | 0.1 |

| [51] | 5.28 | -/0.193 | - |

| [52] | 2.3 | -/4.08 | 10 |

| [53] | 2.29 | -/3.26 | |

| [54] | 0.077 | -/1.08 | 0.5 |

| [55] | 5.2 | -/1.12 | 20 |

| This work | 1.05 | 1.02/5.98 | 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vélez, P.; Muñoz-Enano, J.; Gil, M.; Mata-Contreras, J.; Martín, F. Differential Microfluidic Sensors Based on Dumbbell-Shaped Defect Ground Structures in Microstrip Technology: Analysis, Optimization, and Applications. Sensors 2019, 19, 3189. https://doi.org/10.3390/s19143189

Vélez P, Muñoz-Enano J, Gil M, Mata-Contreras J, Martín F. Differential Microfluidic Sensors Based on Dumbbell-Shaped Defect Ground Structures in Microstrip Technology: Analysis, Optimization, and Applications. Sensors. 2019; 19(14):3189. https://doi.org/10.3390/s19143189

Chicago/Turabian StyleVélez, Paris, Jonathan Muñoz-Enano, Marta Gil, Javier Mata-Contreras, and Ferran Martín. 2019. "Differential Microfluidic Sensors Based on Dumbbell-Shaped Defect Ground Structures in Microstrip Technology: Analysis, Optimization, and Applications" Sensors 19, no. 14: 3189. https://doi.org/10.3390/s19143189

APA StyleVélez, P., Muñoz-Enano, J., Gil, M., Mata-Contreras, J., & Martín, F. (2019). Differential Microfluidic Sensors Based on Dumbbell-Shaped Defect Ground Structures in Microstrip Technology: Analysis, Optimization, and Applications. Sensors, 19(14), 3189. https://doi.org/10.3390/s19143189