1. Introduction

Data fusion has been widely used in military and civilian applications. Biological oxidation pretreatment is a novel but difficult strategy of industrial gold production [

1]. The process of biological oxidation pretreatment uses bacteria that oxidize the mineral wrapped with gold, and expose the gold outside. The control process has several important factors, such as temperature, oxygen quantity, pH value, and ORP (oxidation-reduction potential). To ensure the activity of bacteria, the temperature accuracy of the measurement and control processes becomes important.

Figure 1 shows the biological oxidation pretreatment:

As an effect method, data fusion was first applied to the military field, which attracted the attention of researchers. Then, data fusion became widely used in many other fields. For example, Skladnev built a probabilistic model to simulate 90 to 100 patients’ measurements, and used data fusion to assess the patients’ conditions. The simulated addition of Hypo Mon data produced an improvement in the CGMS (continuous glucose monitoring system) hypoglycemia alarm performance of 10% at equal specificity [

2]. Seal used three types of data fusion ranking algorithms on the PknB dataset, namely: sum rank, sum score, and reciprocal rank to select compounds in a virtual screening process and determine the best approach [

3]. Rigatos proposed extended and unscented information filters for the condition monitoring of electric power transmission and distribution systems [

4]. Maschi proposed a method for collecting and processing local data through a data fusion technology. The method effectively reduced the volume of data generated and decreased the volume of messages generated by the Internet of Things environment [

5]. Moussavi Khalkhali introduced Dempster–Shafer evidential theory and proportional conflict redistribution rule number five into intelligent housing systems to solve the problem of room security [

6]. Tsinganos compared three newly proposed data fusion schemes that have been applied in human activity recognition and fall detection for old people. The author proposed a machine learning strategy that provided a useful inspiration for the study of drop detection [

7]. Pan proposed a gray Kalman filter and a novel open-circuit voltage model for the estimation of the state of charge of lithium-ion batteries to improve the accuracy of charge estimation [

8]. As an important branch of data fusion, multi-sensor data fusion has also been used in industrial processes [

9,

10,

11,

12].

The present work aims to solve the problems related to the detection and estimation of temperature. In previous studies on temperature treatment, Zhao designed an ultra-low temperature online monitoring system and introduced the correlation function of a careless error elimination method on the basis of fuzzy theory. This method improves the accuracy of sensor data [

13] and obtains a good effect. Regarding the problems of temperature and humidity detection in an industrial environment, Lv used a fuzzy set-based approach for multi-sensor data related to temperature and humidity fusion. The approach solves the problem of inaccurate data caused by a large industrial range [

14]. The author also implemented the idea in hardware. Sung used adaptive fuzzy logic algorithms to compute the monitoring area temperature in a 30 m (L) × 40 m (W) × 15 m (H) room [

15]. The authors in [

16,

17] used the Bayesian estimation combined with an improved array of sensors to solve the problem of high-precision measurement by non-contact sensors and performance by boiler heat treatment. In a plant factory, Cui eliminated the gross error by using the Dixon criterion, and then used adaptive weighting data fusion to obtain an accurate temperature value [

18]. The results have greatly inspired and helped the current study. Such results also provide guidance for temperature processing that uses data fusion. However, the aforementioned studies mainly focused on an ideal external environment situation, for example, in a room, or a thermostatic chamber, or a high-temperature environment [

17], which is not easily disturbed by the outside world. In [

14], the author conducted research in an indoor environment to solve the problem of multi-field fusion in different industrial sites. The research object of biological oxidation pretreatment in the present study is different from those of previous studies for the following reasons. First, due to the characteristics of minerals that contain sulfur, arsenic, and other substances, the location of the factory is consistently in remote areas. Second, the reactor of biological oxidation pretreatment is set on an outdoor field. Third [

19] analyzed the problem of the “sensor actuator effect” in greenhouses. The sensor near the temperature regulator was considerably affected due to the placement of the temperature regulator; however, the sensor that was far from the temperature regulator could not evidently change. Therefore, temperature detection was inaccurate, and the current study obtains the same result. Last but not least is that at present, the common schemes in actual industrial sites are using single sensor measurement. In order to save the cost of building a reactor, most schemes place the single sensor on the edge of the reactor. However, the environment of the object in this paper is very harsh. In the former research, we have analyzed the temperature distribution of the reactor in detail. In [

20],

Figure 2 shows the cloud distribution of the temperature of an oxidation tank in a wind field in different positions. As we can see, when a sensor is placed in an ideal position, we can obtain a measurement with high accuracy. However, the temperature field is very uneven. Some regions can’t reach the setting value, thereby reducing the industrial yield.

To improve the global accuracy of temperature detection, this study presents a distributed sensor fusion algorithm for severe environments.

(1) The mechanism of heat transfer in biological oxidation pretreatment is analyzed, and a suitable state model is also established to facilitate prediction and measurement.

(2) We define a structure of data fusion on the basis of a multi-connected fusion structure. The sensors in the network are divided into three levels, in which each sensor can measure the temperature and process data. The level of sensors is determined by their location in the reactor. Low-level sensors play an important role in global estimation and accuracy improvement.

(3) Regarding data processing, we improve the traditional extended Kalman filtering (EKF). First, we introduce the idea of iterative operation for the state prediction. Then, multi-fading factors are improved by using a weighted fading memory index.

(4) In comparison with the traditional single-sensor measurement method, we propose a small-range sensor fusion method. The proposed method can fully consider the influence of external factors on the reactor temperature.

The remainder of this paper is organized as follows.

Section 2 elaborates the algorithm, including the model of heat transfer in an oxidation tank, the improvement of the traditional EKF, and the criterion of the distributed sensor fusion.

Section 3 presents the simulation and experiment to demonstrate the performance of the proposed algorithm.

Section 4 draws the conclusions, and discusses future work with corresponding solutions in this study.

3. Simulation and Experiment

3.1. Simulation Results and Discussion

A simulation implemented in MATLAB is performed on a PC with a 2.5-GHz Intel Core CPU and 4 GB of memory to verify the effect of the improved distributed multi-sensor data fusion algorithm for the temperature measurement of the biological oxidation pretreatment process. In this simulation, the sensor nodes are located on the top of a 10-m diameter reactor and follow the array described in

Section 2.2. The simulation model is set following the heat transfer model of the oxidation reactor. The object is the same for each sensor; thus, the PDF (probability density function) setting of object is coincident. However, given the different positions and levels of the sensors, the interference of the simulation is different. Therefore, the noise covariance settings for each sensor are different during the simulation. The simulation data of each sensor are recorded, for the reason that each sensor has different accuracies because of the influence of external factors and its own characteristics. Each sensor’s performance will be evaluated by using the mean absolute error (MAE), mean relative error (MRE), and root mean square error (RMSE). The calculation of these performances can be expressed as follows:

where

represents the predicted value of each sensor, and

represents the true value.

The value of the single-sensor simulation is used as a contrast method of the algorithm. The location of the single sensor is the same as the position of level-one sensor nine. In each simulation, the proposed and contrast methods perform under the same conditions to ensure the consistency of the simulation.

The simulation result in

Figure 9 shows the value of the reactor temperature in the model simulation, the measurement of the contrast method, and the fusion value for each level of the sensors.

Figure 10 shows the absolute value error of each simulation result, including the model simulation value of the temperature, the fusion value for each level of the sensors, and the simulation of the contrast method.

Figure 11 presents the recorded simulation of each sensor. In

Figure 9 and

Figure 10, each level of the sensors shows the average value of all of the sensors.

The simulation results show that the contrast method has a strong fluctuation (

Figure 9 and

Figure 10). When the simulation time reaches 140, the contrast method loses accuracy and deviates from the model simulation. Conversely, as the level of the sensor fusion increases, the simulation error becomes increasingly small. On the basis of the given formula,

Table 1 shows the average performance index of each level of the sensors.

From the table, the MAE of the contrast method and level-three, level-two, and level-one sensor fusion values are 10.6973, 3.5261, 3.4948, and 2.4361, respectively. The MRE of the contrast method and level-three, level-two, and level-one sensor fusion values are 1.79, 0.59, 0.58, and 0.41, respectively. The RMSE of the contrast method and level-three, level-two, and level-one sensor fusion values are 16.2528, 4.1562, 4.1297, and 3.5869, respectively. Each performance index indicates that the proposed method has a considerable improvement in measurement accuracy compared with the contrast method. In addition, the error of the simulation result may become small as the fusion level increases. Therefore, the given simulations and analysis demonstrate that the proposed algorithm can provide globally optimal fusion results. Moreover, as the level of data fusion increases, the accuracy of the proposed algorithm can be improved accordingly. This algorithm can also enhance the adaptability and robustness against linear errors to overcome the limitation of the traditional EKF.

As described in

Section 2.2, the fusion structure contains sensor information sharing. When a sensor is damaged, other sensors will correct the error covariance of local fusion. Dynamic weights also reduce the influence of damaged sensors, thereby reducing the effect of gross error. Consider that a level-three sensor, namely, sensor one, is damaged, and transports error data.

Figure 12 shows the simulation value of temperature.

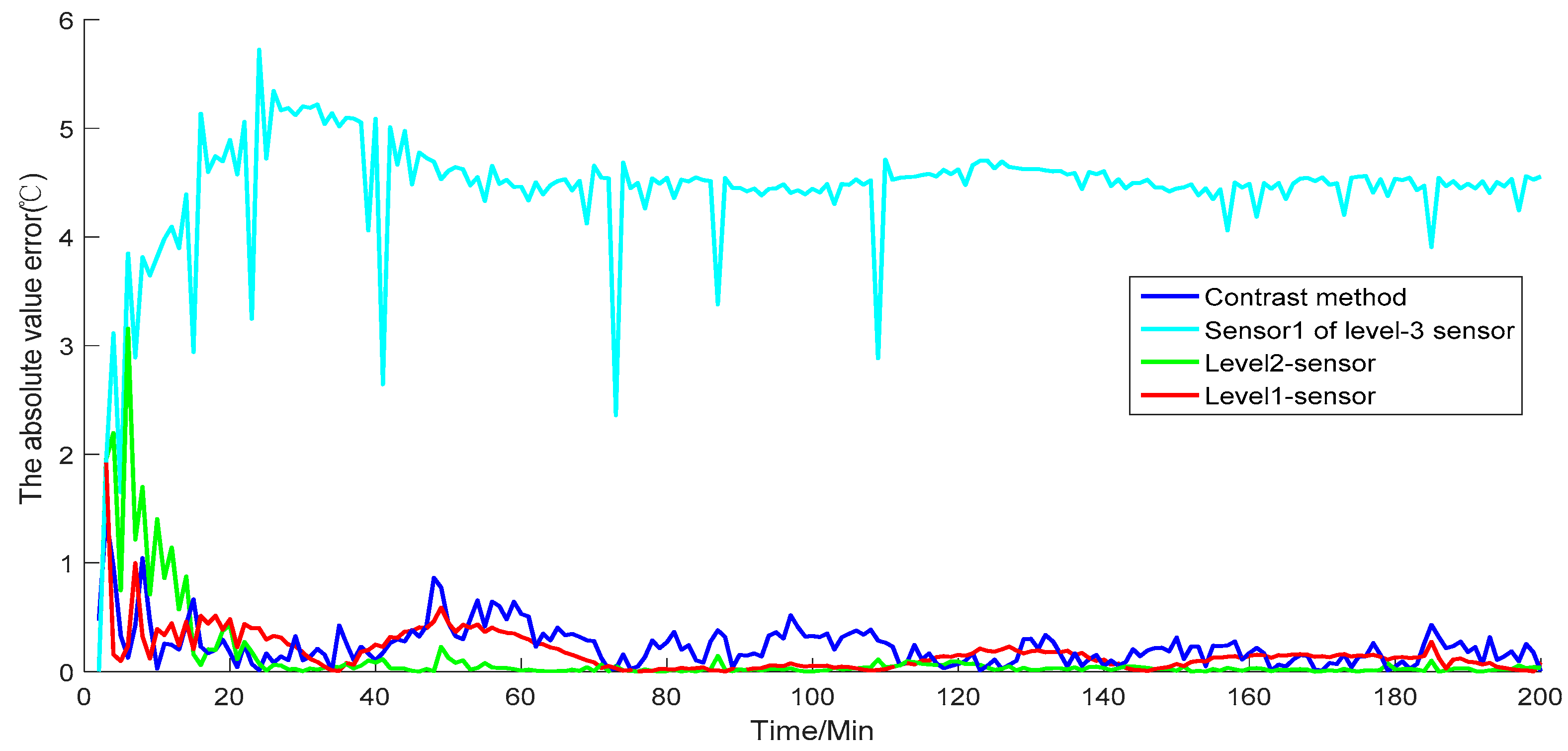

Figure 13 presents the absolute value error of temperature with the damaged sensor, and

Figure 14 shows each sensor value. The results in

Figure 12 and

Figure 13 show the simulation results and absolute value error of the damaged sensor one in level-three sensors. These values are then compared with those of the level-two and level-one sensors.

Although sensor one is damaged, the weighting principle corrects the error covariance of local fusion. The principle reduces the weight of the local fusion values, which contain damaged sensor one. Thus, high-level fusion values are affected as little as possible by the damaged sensor. As shown in

Figure 12, the simulation results of the level-two local fusion in the initial stage of the simulation are not well tracked to the model simulation result due to the influence of the damaged sensor one in level three. Nevertheless, the final fusion result of level one shows that the simulation results have been well tracked to the simulated model value. The trend of the absolute value error in

Figure 13 reveals that as the error of the damaged sensor increases, the results of the level-two local fusion sensors are affected at the beginning of the simulation but with the correction of the weighting criterion. The absolute value error of the final fusion value can be kept in an extremely low range. Moreover, the simulation experiment continues to achieve better results in comparison with the contrast method.

Table 2 displays the average performance index of each level of the sensors. For level-three sensors, we show the performance index of sensor one.

The simulations in the two given situations show that when the temperature is stable, the proposed algorithm can fit the value smoothly when a damaged sensor exists. Level-two sensors may be affected to a certain extent in the initial stage of the simulation. Nevertheless, the results gradually improve as the simulation continues. In addition, the proposed algorithm cannot produce a large error when the temperature is stable. In comparison with the contrast method, the proposed algorithm has higher accuracy and is closer to the actual simulation value of the model; moreover, the proposed fusion algorithm has higher stability in the simulation experiment and does not produce tracking divergence. The comparison of the performance index shows that the distributed sensor fusion has higher data-filtering accuracy, smaller errors, and more accurate simulation than the contrast method based on a single sensor. The comparison of the MRE of the proposed and contrast methods indicates that the accuracy of the former is 55.39% higher than the latter.

3.2. Experimental Setup

To achieve the effectiveness of distributed sensor data fusion, an experiment is set up for the biological oxidation pretreatment in the laboratory.

Figure 15 shows the installation of the experiment:

As shown in

Figure 15, similar to the temperature control in the actual industrial site, the installation of the experiment contains a main tank and two sub-tanks in the device. The diameter of the main tank is approximately one m, and a mixing system is installed at the top of the main tank. A snake-shaped casing is installed to regulate the temperature inside the tank. A magnetic flip-plate liquid-level meter is installed on the side, and a sensor support frame is installed inside the main box to install the temperature detection sensor. The two sub-boxes are equipped with cold and hot water, which will be used for heat exchange. The snake-shaped casing outlet is equipped with a flow sensor to detect the cold and hot water flow. Two pumps are installed at the lower end of the device to regulate the circulating water flow. These pumps also play a role in controlling the temperature. The temperature is set at 40 °C.

In the actual industrial field, the brand of sensors that we used was HACH (USA), and the type of sensor was a P53 pH/ORP sensor. This type of sensor measures the pH value, ORP value, and temperature. The temperature compensator element was a PT-1000.

In the calibration process of each sensor, a high-precision mercury thermometer was detected into the ore pulp by the workers on the spot. The temperature of the sensor position was measured and compared with the data transmitted by the sensor to check whether the sensor was inaccurate.

The high-precision mercury thermometer that was used in the industrial field was about 20–30 cm long in total and had an immersion length of 10 cm. The workers on the spot fixed the thermometer to a plastic insulation rod and only exposed the thermometer probe. In the actual industrial sites, our workers calibrated each sensor in three periods: in the morning, at noon, and in the evening. In each period, for each sensor, a group of data was measured in a short time. If it was consistent with the data transmitted by the data acquisition box, the sensor did not need to be calibrated; if there was a minor difference, the workers would calibrate each sensor using the standard electrolyte; if there was a big difference, first, the workers would check the high-precision mercury thermometer, or replace another thermometer to measure it again. If there was still a big difference, it may have been caused by the sensor. After the sensor problem was identified, we might have repaired or replaced the sensor until the sensor was consistent with the high-precision mercury thermometer. In the industrial sites, the workers would calibrate the sensors for few days, over three periods, and if they were all consistent, the sensors would be put into use.

Table 3 shows the parameters of this type of sensor.

If we take into account the circumstances that were not affected by the external environment, the accuracy and precision of each sensor is the same.

Table 4 shows the physical property parameters of the materials.

In the actual industrial site, the measurements of each sensor could be obtained in a control box.

Figure 16 shows the data acquisition box of each variable (including temperature, oxygen quantity, pH value, and potential value), and a far-away view of the reactor in the actual industrial site.

The data acquisition of the experimental equipment was recorded on the computer by using multi-sensors to transport real-time data of the experimental temperature. When the temperature was stable in the setting value, data were recorded, and raw data were obtained. The proposed method was then used to process the raw data, and the fusion value was obtained using the original data. By comparing the deviation of the fusion value with the setting value and that of the original measurement with the setting value, we could obtain the measuring effect of the original measuring method and that of the proposed method.

Figure 17 illustrates the processing flow of the experimental data.

The measurement data in

Section 3.2 are from the actual industrial area in Xinjiang, China during winter. We adopted 200 temperature values after stabilizing the temperature. These 200 acquisition points are discrete data, and the sample period of each point was 15 minutes. Given the different positions of the installed sensors, the measurement of each sensor may be different due to internal and external factors.

Figure 18 shows the measured temperature of each sensor obtained from the experiment. The transverse coordinates represent 200 data points.

After obtaining the data of each sensor, the proposed algorithm was used to obtain the final experimental result.

Figure 19 shows the distributed data fusion result of sensor nine.

After obtaining all the data of each sensor and the fusion value, we could obtain the MRE of the low-level sensor and the fusion result, as shown in

Figure 20.

After processing the algorithm, the accuracy of the fusion result was higher than when the algorithm was not used. The accuracy of industrial measurement improved by 36.84% when the proposed method was used in the equipment experiment.