Analysis of Residual Stress in Electrical Penetration Assembly Based on a Fiber Bragg Grating Sensor †

Abstract

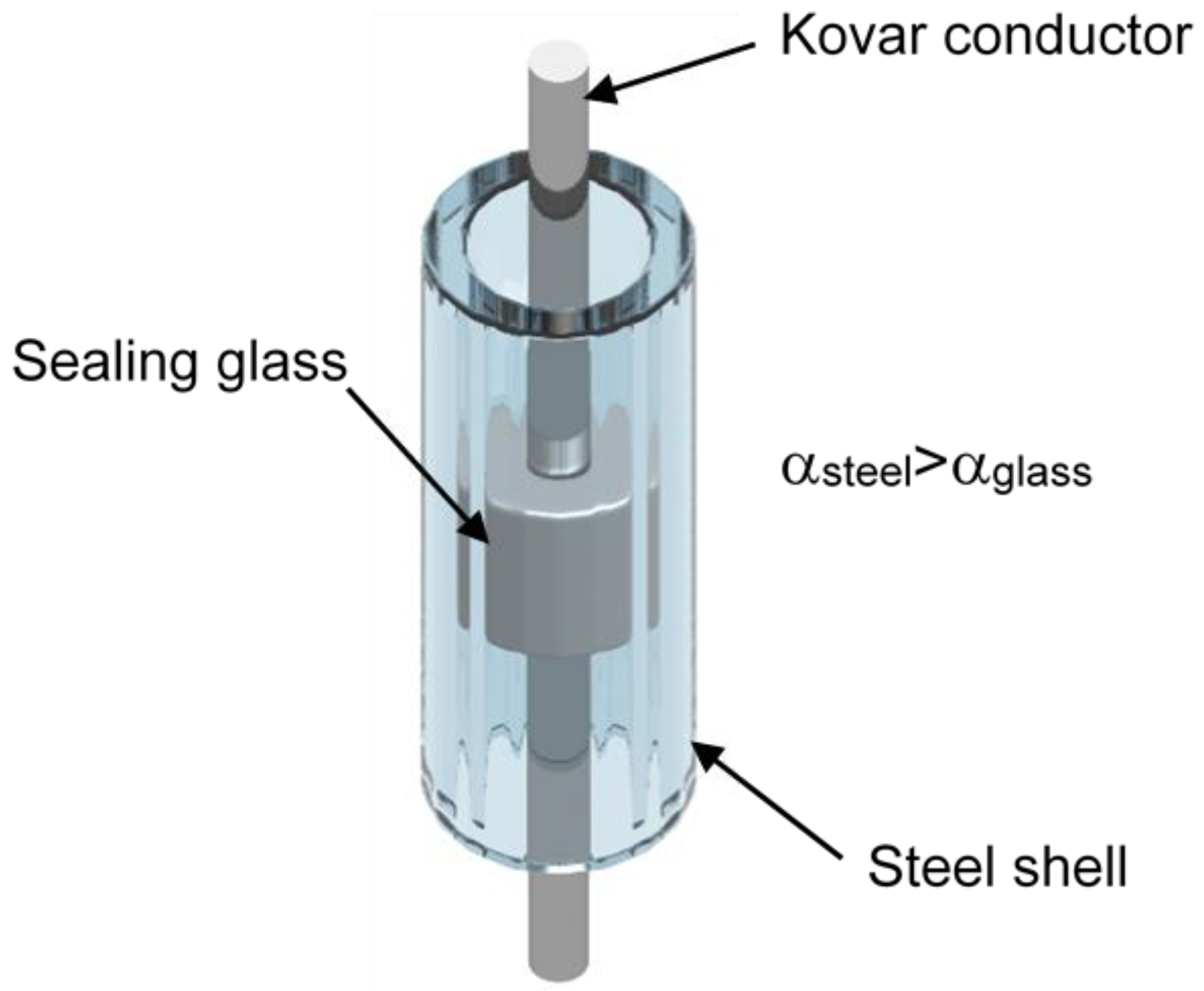

1. Introduction

2. Experimental Setup

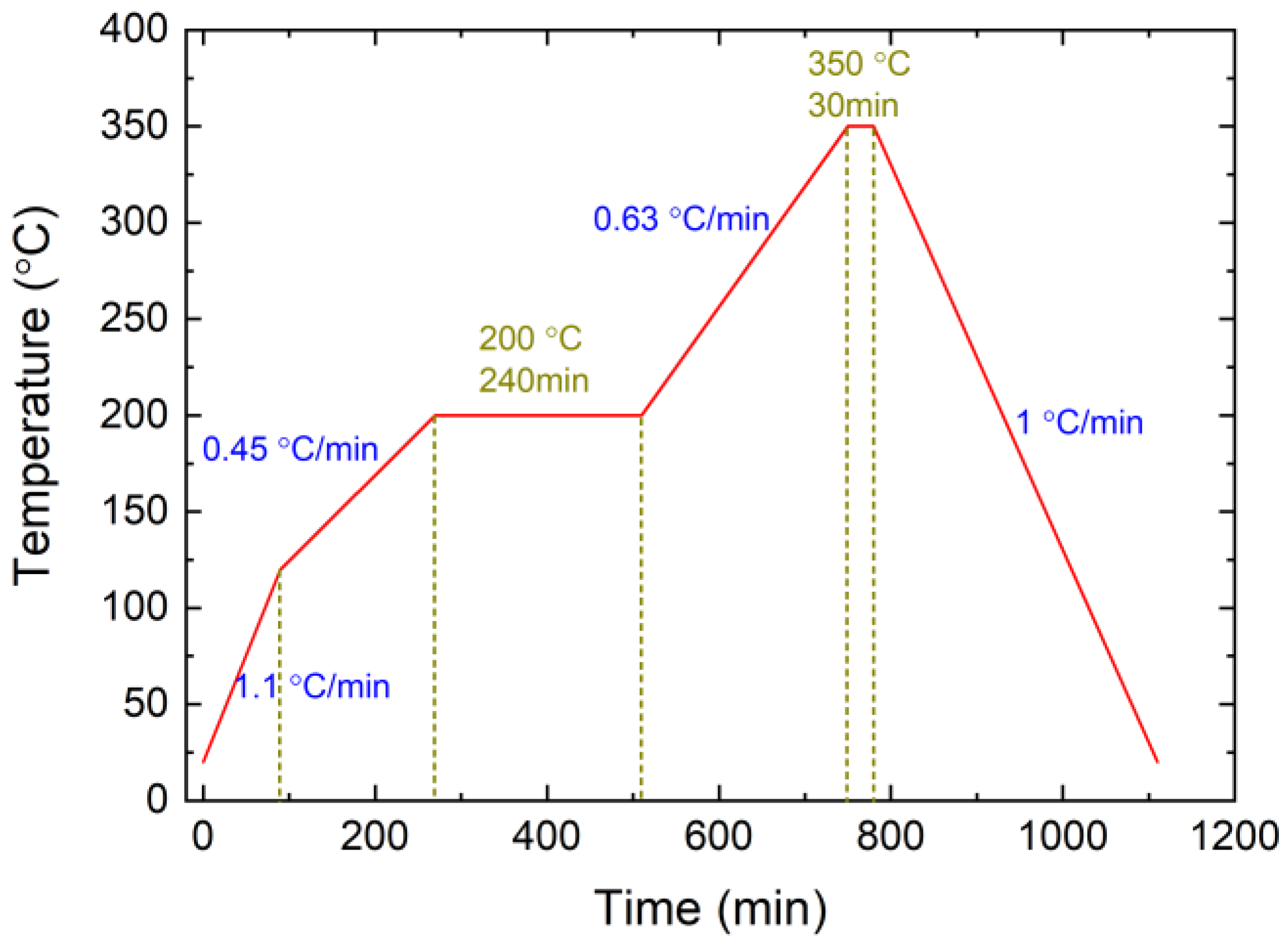

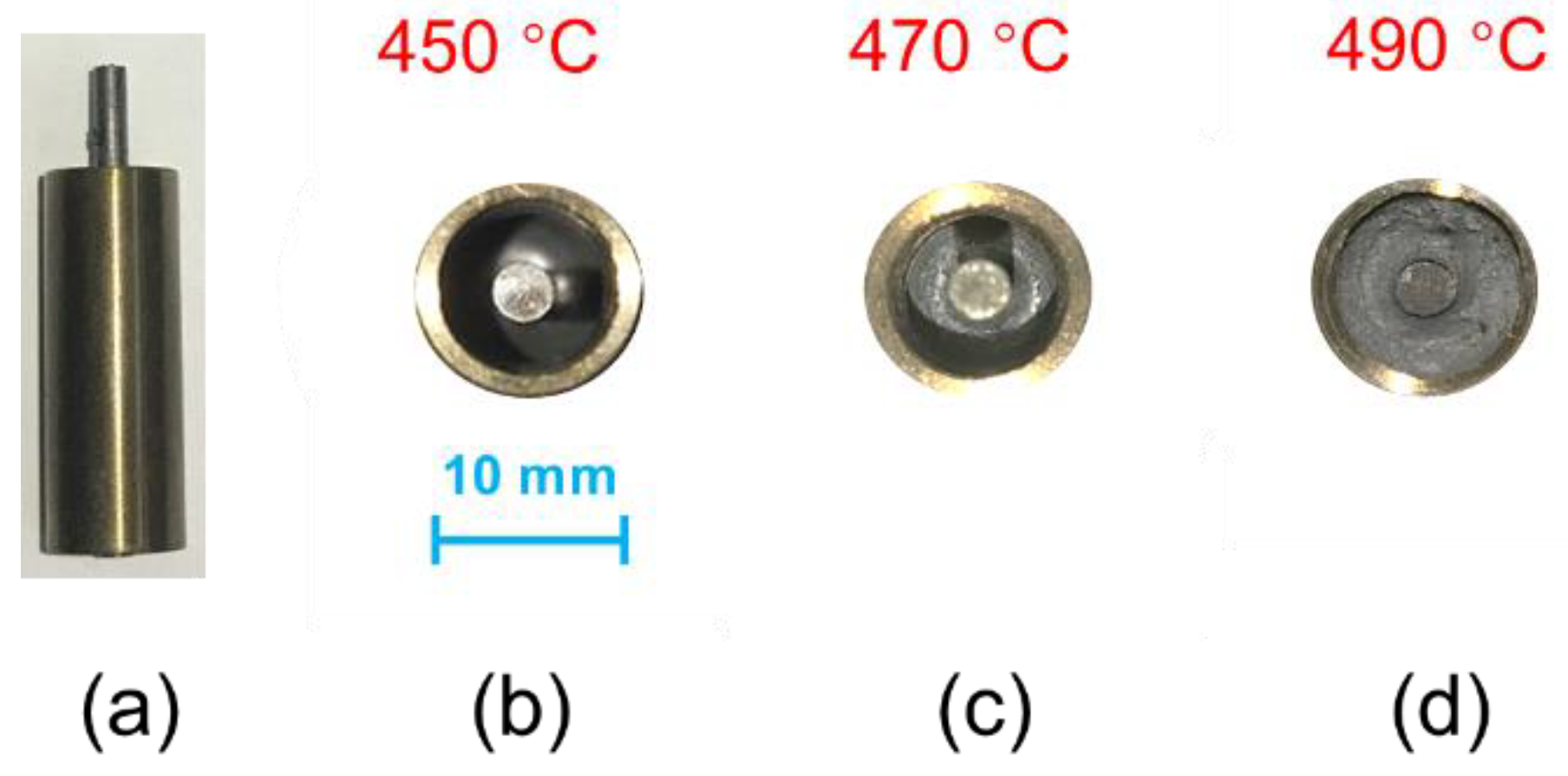

2.1. Investigations into the EPA Sealing Process

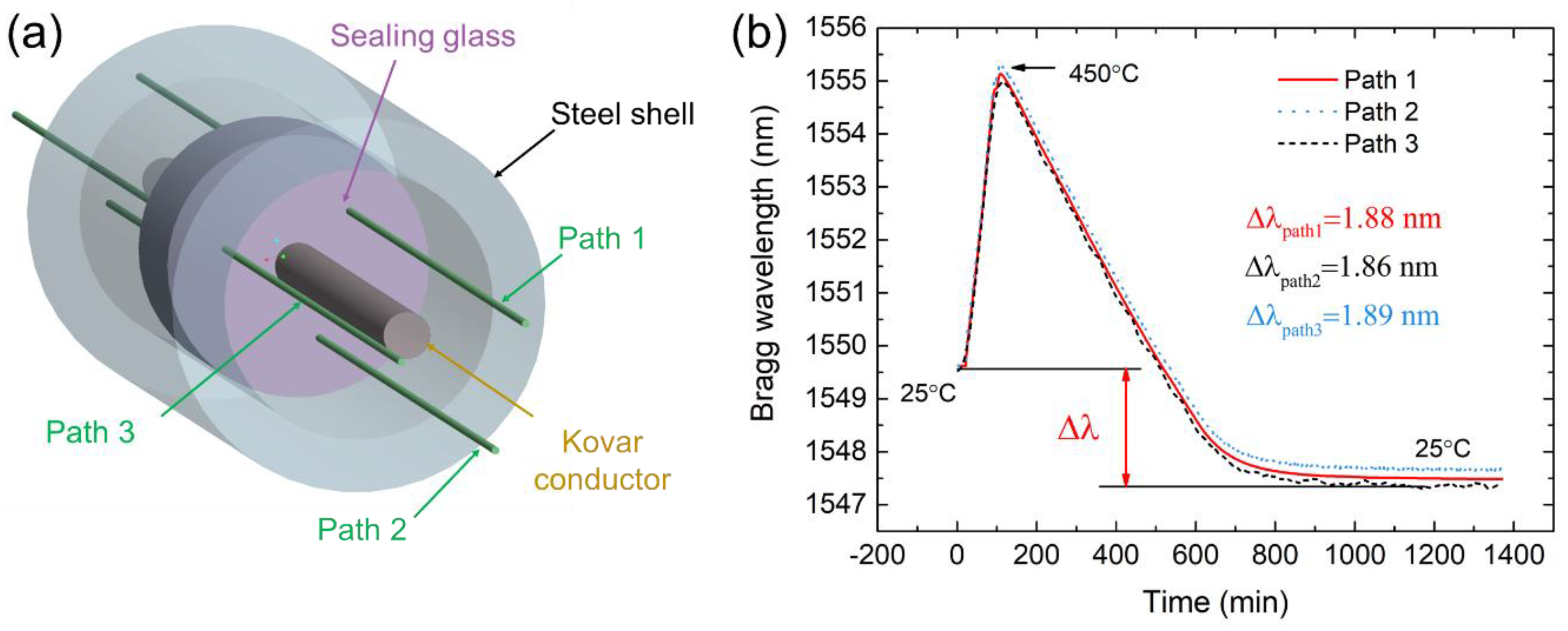

2.2. Temperature Measurement During the Sealing Process

2.3. Measurement of the Residual Stress of the Sealing Glass

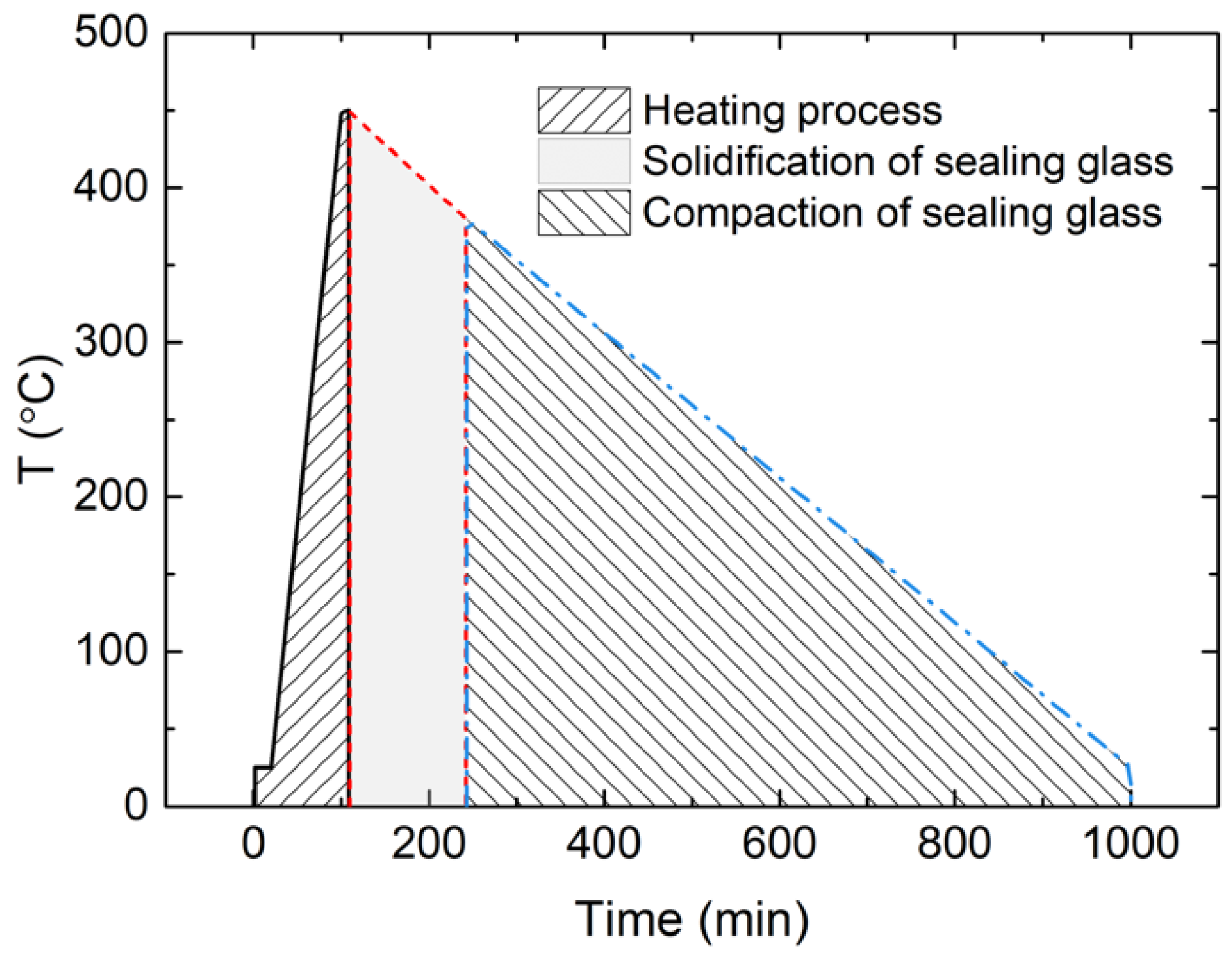

2.4. Measurement of the Cure Temperature of the Sealing Glass

3. Numerical Simulation

3.1. Finite Element Model

3.2. Boundary Conditions and Mesh

4. Results and Discussion

4.1. Results of Investigation into the EPA Sealing Process

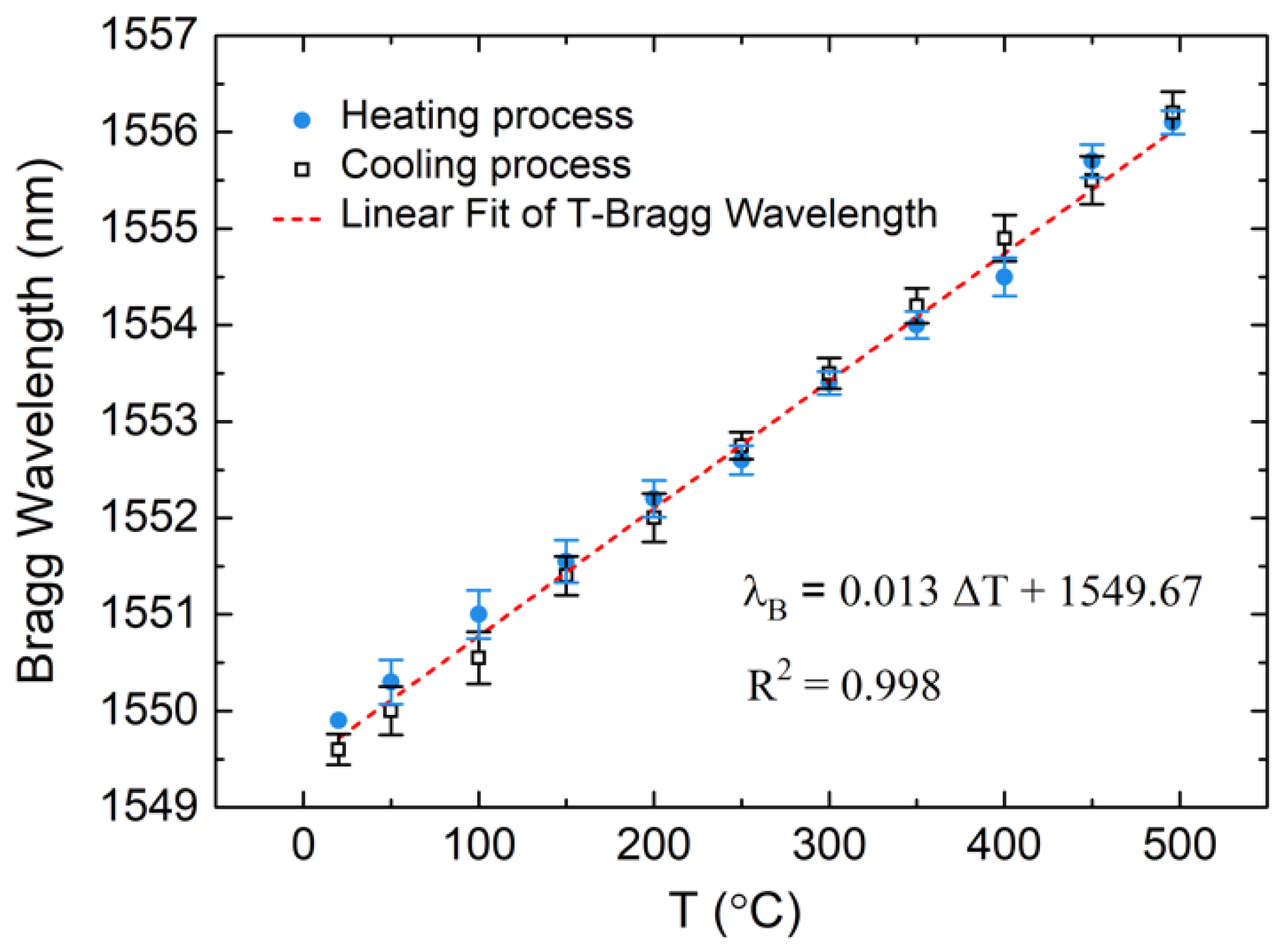

4.2. Results of Temperature Measurement

4.3. Results of Residual Stress Measurement

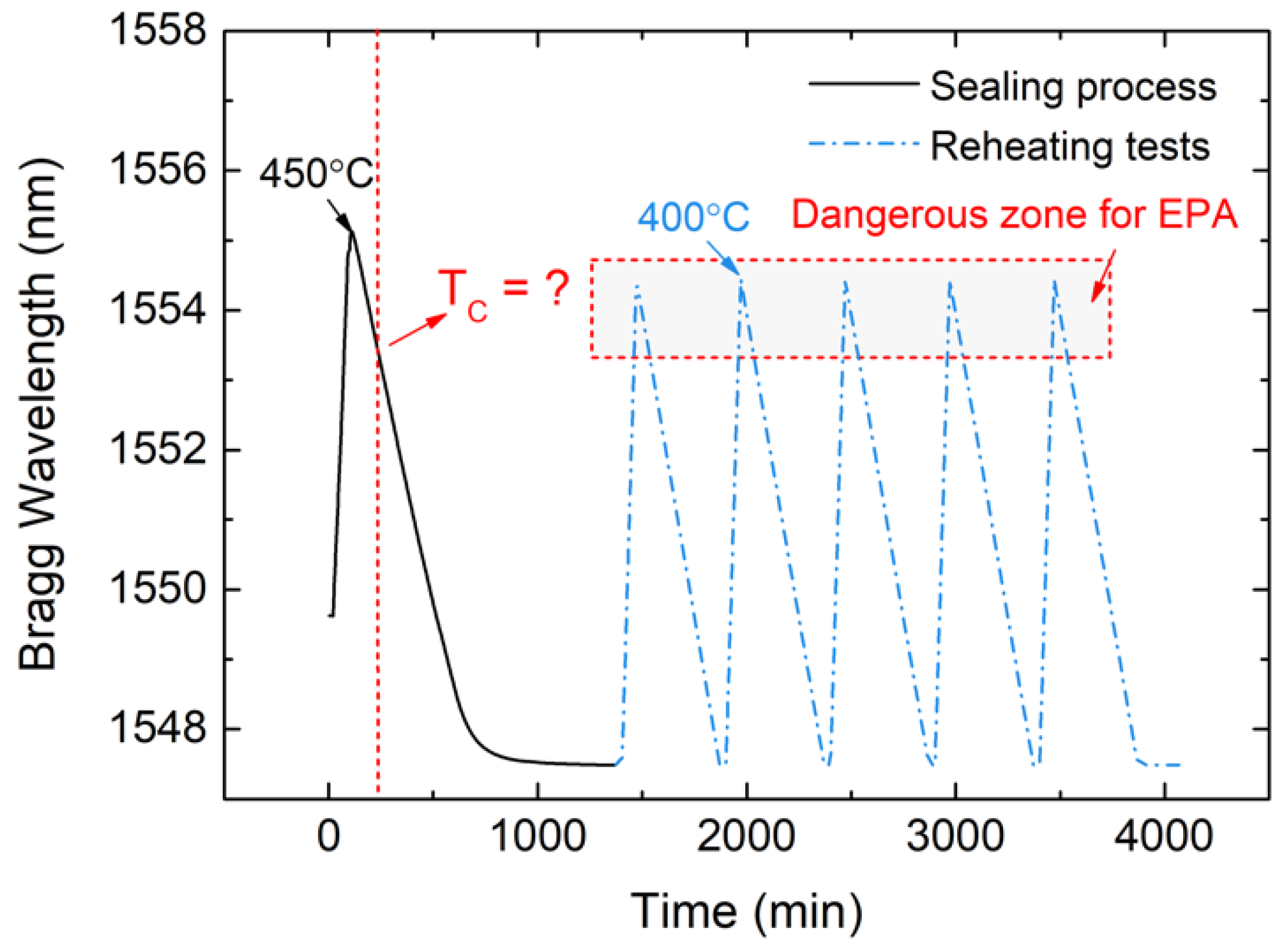

4.4. Results of Cure Temperature Estimation

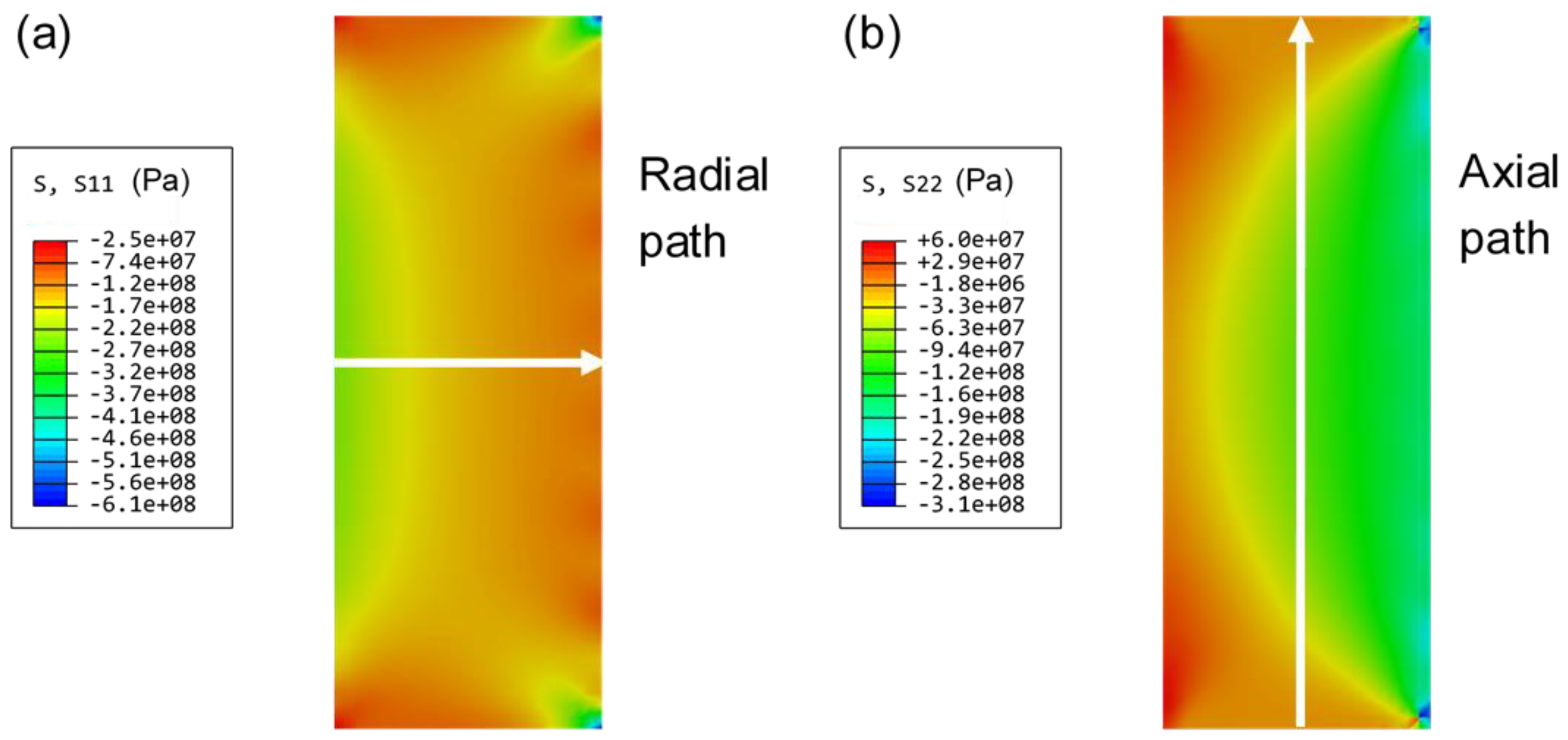

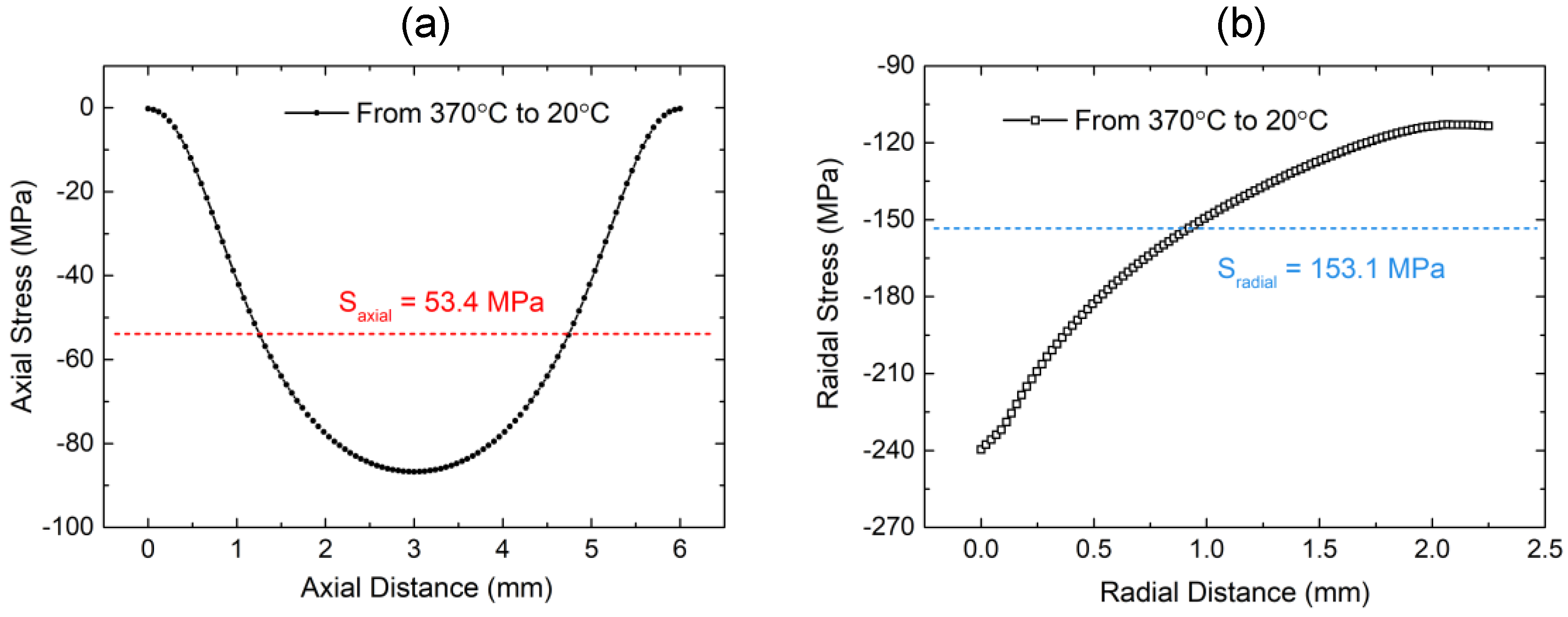

4.5. Results of Numerical Simulation

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lei, D.; Wang, Z.; Li, J. The analysis of residual stress in glass-to-metal seals for solar receiver tube. Mater. Des. 2010, 31, 1813–1820. [Google Scholar] [CrossRef]

- Shekoofa, O.; Wang, J.; Qi, J.; Zhang, J.; Yin, Z. Analysis of residual stress for mismatch metal–glass seals in solar evacuated tubes. Sol. Energy Mater. Sol. Cells 2014, 128, 421–426. [Google Scholar] [CrossRef]

- Shim, D.J.; Sun, H.W.; Vengallatore, S.T.; Spearing, S.M. Damage and Failure in Silicon-Glass-Metal Microfluidic Joints for High-Pressure MEMS Devices. J. Microelectromech. Syst. 2006, 15, 246–258. [Google Scholar] [CrossRef]

- Donald, I.W.; Mallinson, P.M.; Metcalfe, B.L.; Gerrard, L.A.; Fernie, J.A. Recent developments in the preparation, characterization and applications of glass- and glass-ceramic-to-metal seals and coatings. J. Mater. Sci. 2011, 46, 1975–2000. [Google Scholar] [CrossRef]

- Lammens, N.; Kinet, D.; Chah, K.; Luyckx, G.; Caucheteur, C.; Degrieck, J.; Mégret, P. Residual strain monitoring of out-of-autoclave cured parts by use of polarization dependent loss measurements in embedded optical fiber Bragg gratings. Compos. Part A Appl. Sci. Manuf. 2013, 52, 38–44. [Google Scholar] [CrossRef]

- Chiuchiolo, A.; Palmieri, L.; Consales, M.; Giordano, M.; Borriello, A.; Bajas, H.; Galtarossa, A.; Bajko, M.; Cusano, A. Cryogenic-temperature profiling of high-power superconducting lines using local and distributed optical-fiber sensors. Opt. Lett. 2015, 40, 4424–4427. [Google Scholar] [CrossRef] [PubMed]

- De Pauw, B.; Vanlanduit, S.; van Tichelen, K.; Geernaert, T.; Chah, K.; Berghmans, F. Benchmarking of deformation and vibration measurement techniques for nuclear fuel pins. Measurement 2013, 46, 3647–3653. [Google Scholar] [CrossRef]

- Berruti, G.; Consales, M.; Giordano, M.; Sansone, L.; Petagna, P.; Buontempo, S.; Breglio, G.; Cusano, A. Radiation hard humidity sensors for high energy physics applications using polyimide-coated fiber Bragg gratings sensors. Sens. Actuators B Chem. 2013, 177, 94–102. [Google Scholar] [CrossRef]

- Yan, A.; Huang, S.; Li, S.; Chen, R.; Ohodnicki, P.; Buric, M.; Lee, S.; Li, M.J.; Chen, K.P. Distributed Optical Fiber Sensors with Ultrafast Laser Enhanced Rayleigh Backscattering Profiles for Real-Time Monitoring of Solid Oxide Fuel Cell Operations. Sci. Rep. 2017, 7, 9360. [Google Scholar] [CrossRef] [PubMed]

- Cangialosi, C.; Ouerdane, Y.; Girard, S.; Boukenter, A.; Delepine-Lesoille, S.; Bertrand, J.; Marcandella, C.; Paillet, P.; Cannas, M. Development of a Temperature Distributed Monitoring System Based On Raman Scattering in Harsh Environment. IEEE Trans. Nucl. Sci. 2014, 61, 3315–3322. [Google Scholar] [CrossRef]

- Wada, D.; Igawa, H.; Murayama, H. Simultaneous distributed measurement of the strain and temperature for a four-point bending test using polarization-maintaining fiber Bragg grating interrogated by optical frequency domain reflectometry. Measurement 2016, 94, 745–752. [Google Scholar] [CrossRef]

- Díaz, C.A.R.; Leal-Junior, A.G.; André, P.S.B.; Antunes, P.F.C.; Pontes, M.J.; Neto, A.F.; Ribeiro, M.R.N. Liquid Level Measurement based on FBG-embedded Diaphragms with Temperature Compensation. IEEE Sens. J. 2018, 18, 193–200. [Google Scholar] [CrossRef]

- Bhatia, V.; Campbell, D.; Claus, R.O.; Vengsarkar, A.M. Simultaneous strain and temperature measurement with long-period gratings. Opt. Lett. 1997, 22, 648–650. [Google Scholar] [CrossRef] [PubMed]

- Kisala, P.; Harasim, D.; Mroczka, J. Temperature-insensitive simultaneous rotation and displacement (bending) sensor based on tilted fiber Bragg grating. Opt. Express 2016, 24, 29922–29929. [Google Scholar] [CrossRef] [PubMed]

- Bevenot, X.; Trouillet, A.; Veillas, C.; Gagnaire, H.; Clement, M. Hydrogen leak detection using an optical fibre sensor for aerospace applications. Sens. Actuators B Chem. 2000, 67, 57–67. [Google Scholar] [CrossRef]

- Mihailov, S.J.; Grobnic, D.; Hnatovsky, C.; Walker, R.B.; Lu, P.; Coulas, D.; Ding, H. Extreme Environment Sensing Using Femtosecond Laser-Inscribed Fiber Bragg Gratings. Sensors 2017, 17, 2909. [Google Scholar] [CrossRef] [PubMed]

- Dreyer, U.J.; Mezzadri, F.; Dutra, G.; da Silva, T.; Bavastri, C.A.; da Silva, E.V.; Martelli, C.; da Silva, J.C.C. Quasi-Distributed Optical Fiber Transducer for Simultaneous Temperature and Vibration Sensing in High-Power Generators. IEEE Sens. J. 2018, 18, 1547–1554. [Google Scholar] [CrossRef]

- Mohammed, A.; Djurovic, S. FBG Thermal Sensing Features for Hot Spot Monitoring in Random Wound Electric Machine Coils. IEEE Sens. J. 2017, 17, 3058–3067. [Google Scholar] [CrossRef]

- Luo, J.; Hao, Y.; Ye, Q.; Hao, Y.; Li, L. Development of Optical Fiber Sensors Based on Brillouin Scattering and FBG for On-Line Monitoring in Overhead Transmission Lines. J. Lightwave Technol. 2013, 31, 1559–1565. [Google Scholar] [CrossRef]

- Li, M.; Yan, H.; Diao, X.; Zhang, Y. Prestress measurement during glass-metal sealing based on a fiber sensor. J. Tsinghua Univ. (Sci. Technol.) 2018, 58, 664–670. [Google Scholar]

- Dai, S.; Rodriguez, M.A.; Griego, J.J.M. Sealing Glass-Ceramics with Near Linear Thermal Strain, Part I: Process Development and Phase Identification. J. Am. Ceram. Soc. 2016, 99, 3719–3725. [Google Scholar] [CrossRef]

- Rodriguez, M.A.; Griego, J.J.M.; Dai, S. Sealing Glass-Ceramics with Near-Linear Thermal Strain, Part II: Sequence of Crystallization and Phase Stability. J. Am. Ceram. Soc. 2016, 99, 3726–3733. [Google Scholar] [CrossRef]

- Dai, S.; Elisberg, B.; Calderone, J.; Lyon, N. Sealing glass-ceramics with near-linear thermal strain, part III: Stress modeling of strain and strain rate matched glass-ceramic to metal seals. J. Am. Ceram. Soc. 2017, 100, 3652–3661. [Google Scholar] [CrossRef]

- Fan, Z.; Li, M.; Chen, F.; Huang, Z.; Yan, H. Stress Monitoring of Sealing Materials in Electrical Penetration Assemblies. In Proceedings of the International Conference on Nuclear Engineering, London, UK, 22–26 July 2018. [Google Scholar]

- Hill, K.O.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

| Property | 316 Steel | Kovar Alloy | Glass |

|---|---|---|---|

| Density (g/cm3) | 7.98 | 8.30 | 2.75 |

| Young’ modulus (GPa) | 183 | 157 | 56.5 |

| Poisson ratio | 0.3 | 0.3 | 0.25 |

| Coefficient of thermal expansion (1/°C) | 1.6 × 10−5 | 4.9 × 10−6 | 8.9 × 10−6 |

| Heating Temperature (°C) | Surface Morphology of Sealing Glass | Hermeticity (8 MPa for 24 h) |

|---|---|---|

| 420 | Sealing glass had melted, but not fused with steel shell and Kovar conductor | Failed |

| 430 | Smooth and glossy | Failed |

| 440 | Smooth and glossy | Succeeded |

| 450 | Smooth and glossy | Succeeded |

| 460 | Small bubbles on the glass surface | Succeeded |

| 470 | Small bubbles on the glass surface | Succeeded |

| 480 | Small bubbles on the glass surface | Succeeded |

| 490 | Glass surface was uneven and not flat | Failed |

| 500 | Glass surface was uneven and not flat | Failed |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Diao, X.; Zhang, Y.; Liu, M.; Chen, F.; Huang, Z.; Yan, H. Analysis of Residual Stress in Electrical Penetration Assembly Based on a Fiber Bragg Grating Sensor. Sensors 2019, 19, 18. https://doi.org/10.3390/s19010018

Fan Z, Diao X, Zhang Y, Liu M, Chen F, Huang Z, Yan H. Analysis of Residual Stress in Electrical Penetration Assembly Based on a Fiber Bragg Grating Sensor. Sensors. 2019; 19(1):18. https://doi.org/10.3390/s19010018

Chicago/Turabian StyleFan, Zhichun, Xingzhong Diao, Yong Zhang, Malin Liu, Feng Chen, Zhiyong Huang, and He Yan. 2019. "Analysis of Residual Stress in Electrical Penetration Assembly Based on a Fiber Bragg Grating Sensor" Sensors 19, no. 1: 18. https://doi.org/10.3390/s19010018

APA StyleFan, Z., Diao, X., Zhang, Y., Liu, M., Chen, F., Huang, Z., & Yan, H. (2019). Analysis of Residual Stress in Electrical Penetration Assembly Based on a Fiber Bragg Grating Sensor. Sensors, 19(1), 18. https://doi.org/10.3390/s19010018