1. Introduction

The importance of bacterial culture has been emphasized by many case studies in various fields. The low cost and simple procedure of bacterial culture enables various applications and experiments in the field, especially on-site experiments or laboratories in developing countries [

1]. The key barrier in utilizing bacterial culture experiments is growth detection, as it requires measuring of the optical density (OD) [

2], which is difficult to automate. OD requires careful tuning and setup as the distance and angle between the photo emitter and receiver is important. Many commercial OD machines use mostly cuvettes or fixed-size vessels for measurement, and therefore, it is impossible or very cumbersome to control a small volume of liquid during the culture experiment. Some automated culture and OD measurement devices are commercially available; however, these machines are generally expensive, not portable, and too sensitive for field operations.

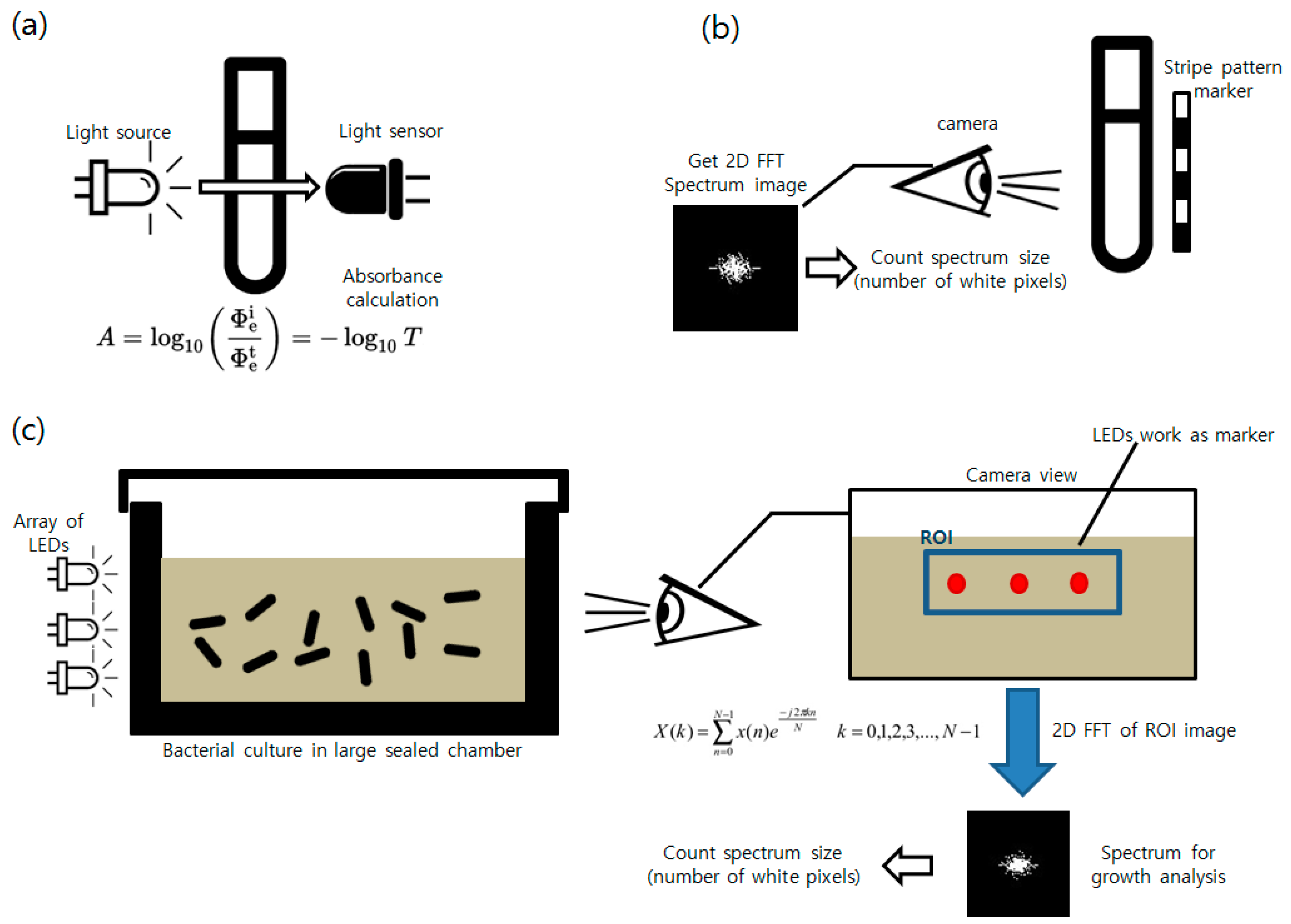

To replace existing OD measurement methods, Kim et al. [

3] proposed a visual marker-based solution to conduct bacterial growth measurement. This method uses a stripe patterned marker placed in the culture vessel and takes the image of the marker. As the bacteria grow and blur the liquid culture media, the fast Fourier transformation (FFT) spectrum decreases as the high frequency region of the image caused by the marker pattern disappears [

4]. The resolution of this method was lower than that of the OD measurement, but was still able to clearly distinguish between the fully-grown state (near the end of the log phase of the growth curve: about 0.8~1.5 of OD

600 value) and no-growth state (before the growth curve enters the log phase: OD

600 value < 0.3). Since many bacterial detection methods just require Presence/Absence (P/A) results [

2,

5,

6], this method can replace OD used in P/A tests and help automate the biological experiment procedures.

The key feature of the FFT based measurement is this method only requires appropriate image of the marker between the culture vessel regardless of the factors such as size of the reactor or distance of the marker and image sensor. Exact tuning of angle and distance of the photodiodes and the light emission power based on the turbidity and thickness of the vessel and contained liquid is not required in this case. Easy automation allows processing multiple remote samples at the given time; treating large number of samples at local public health authority in case of outbreak of contagious diseases or handling water samples at a large food processing facility [

2]. Visual inspection by the technician can replace the checkup procedure; however, it becomes very labor intensive and error prone as the human inspector can easily make mistakes due to fatigue.

However, the application of the marker and FFT spectrum calculation has a few limitations. Since it is an image processing based technique, proper lighting is required. The bacterial culture processes are generally performed in the culture room or inside the incubator for 4~24 h and it is unrealistic to expect proper lighting conditions in the incubator or during an overnight culture. The second problem is the error caused by the color of the liquid broth. The frequently used liquid broths such as nutrient broth (NB) or Luria-Bertani broth (LB) have clear, weakly yellow colors. However some broths like tryptic soy broth (TSB) have dark brown colors. When culturing bacteria in a large volume of this dark medium, even before the bacteria has had time to grow, the dark color of the broth blocks the marker and hides the striped patterns, thus disrupting proper FFT calculation of the image.

In this research, the authors propose a light emitting marker-based method to overcome the addressed problems of the existing marker system. We aim to build a system that can distinguish the growth state of the bacteria in the 7 cm thick rectangular vessel (distinguishing the OD

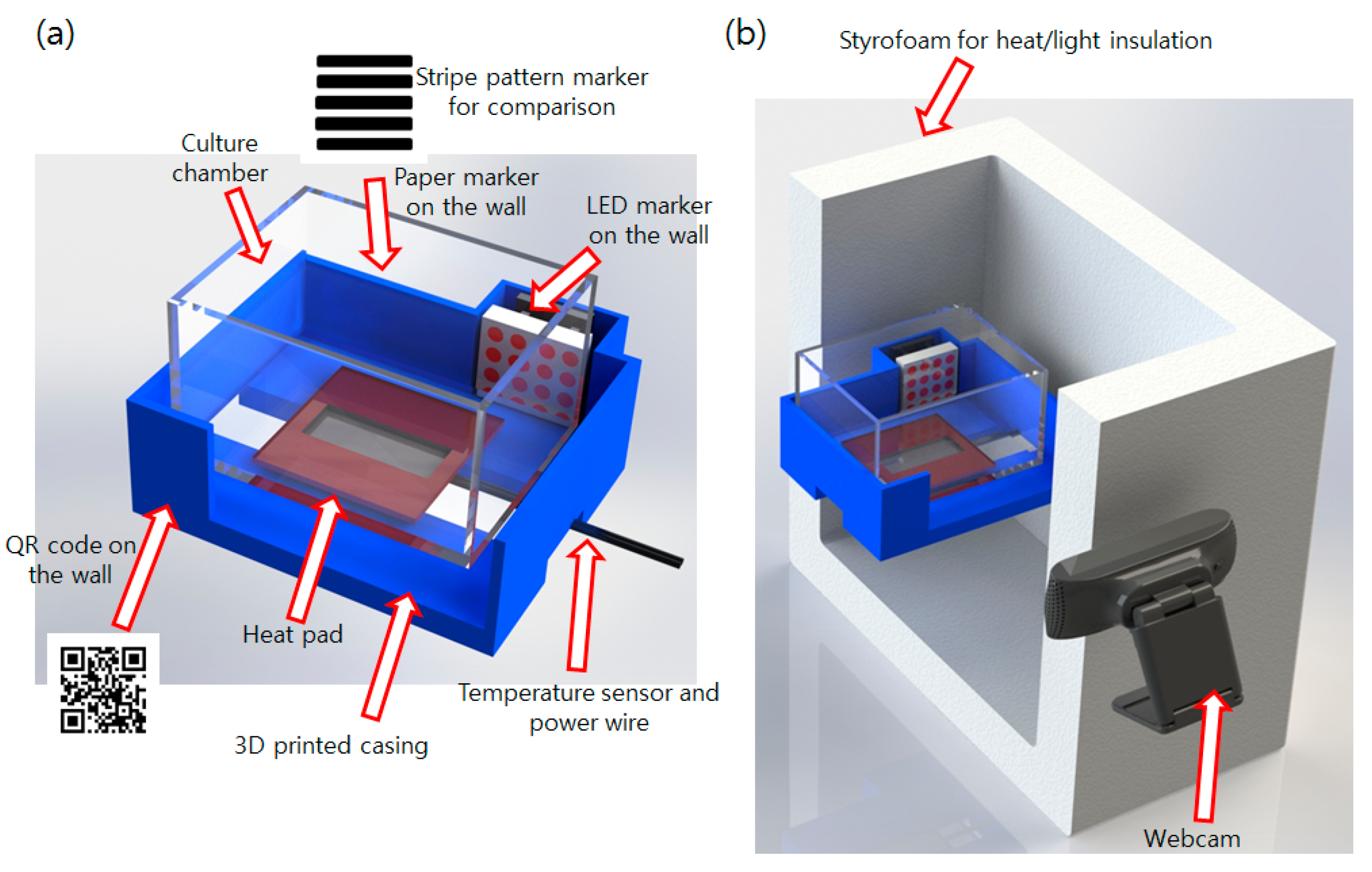

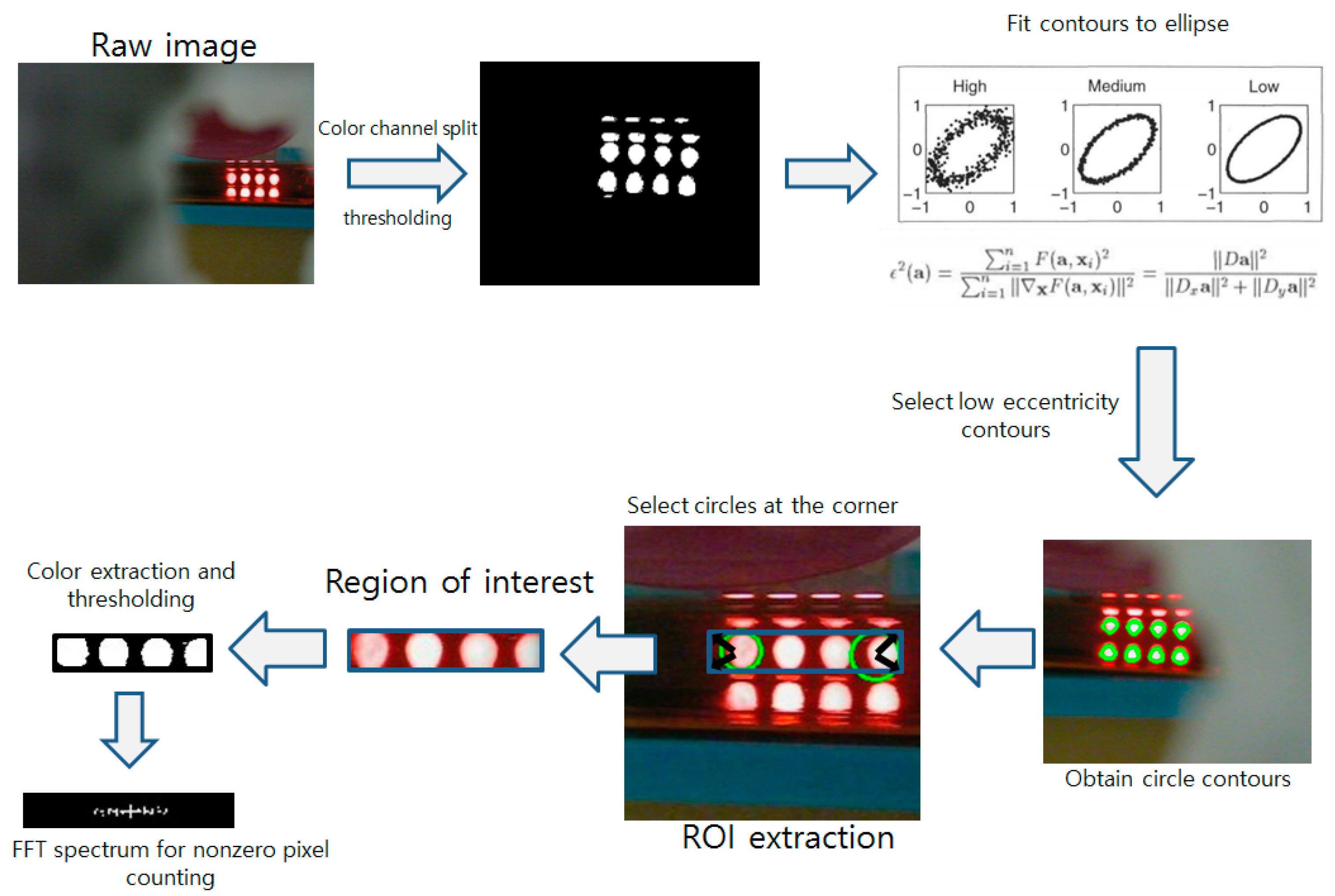

600 value under 0.2 and over 0.7) regardless of the presence of the external lightings when culturing with the LB and TSB broth. Furthermore, we aim the final prototyping cost of the entire incubating system and image processing units to be less than 150 U.S. dollars to facilitate spread of similar systems to the users. Unlike in the striped pattern marker-based system, in the proposed system, the LED placed along the culture vessel emits the light used for the measurement. Instead of measuring the strength of the transmitted light as is done in the OD method, an image of the glowing LED itself is taken. Multiple LEDs are placed in series to create an array that has a similar configuration as the striped pattern marker. The repeating LEDs serve as both the region of interest (ROI) indicator and FFT pattern generator. Growth detection in an environment without LEDs or bacteria cultured in dark-colored broth was performed to show that, by comparison, the proposed LED array markers have higher robustness than the striped pattern marker. Moreover, a new incubator system with a simpler design and improved portability compared to existing systems [

2] was developed. A schematic describing the process of the ODs, striped pattern marker, and the proposed LED array marker is shown in

Figure 1.

3. Results and Discussion

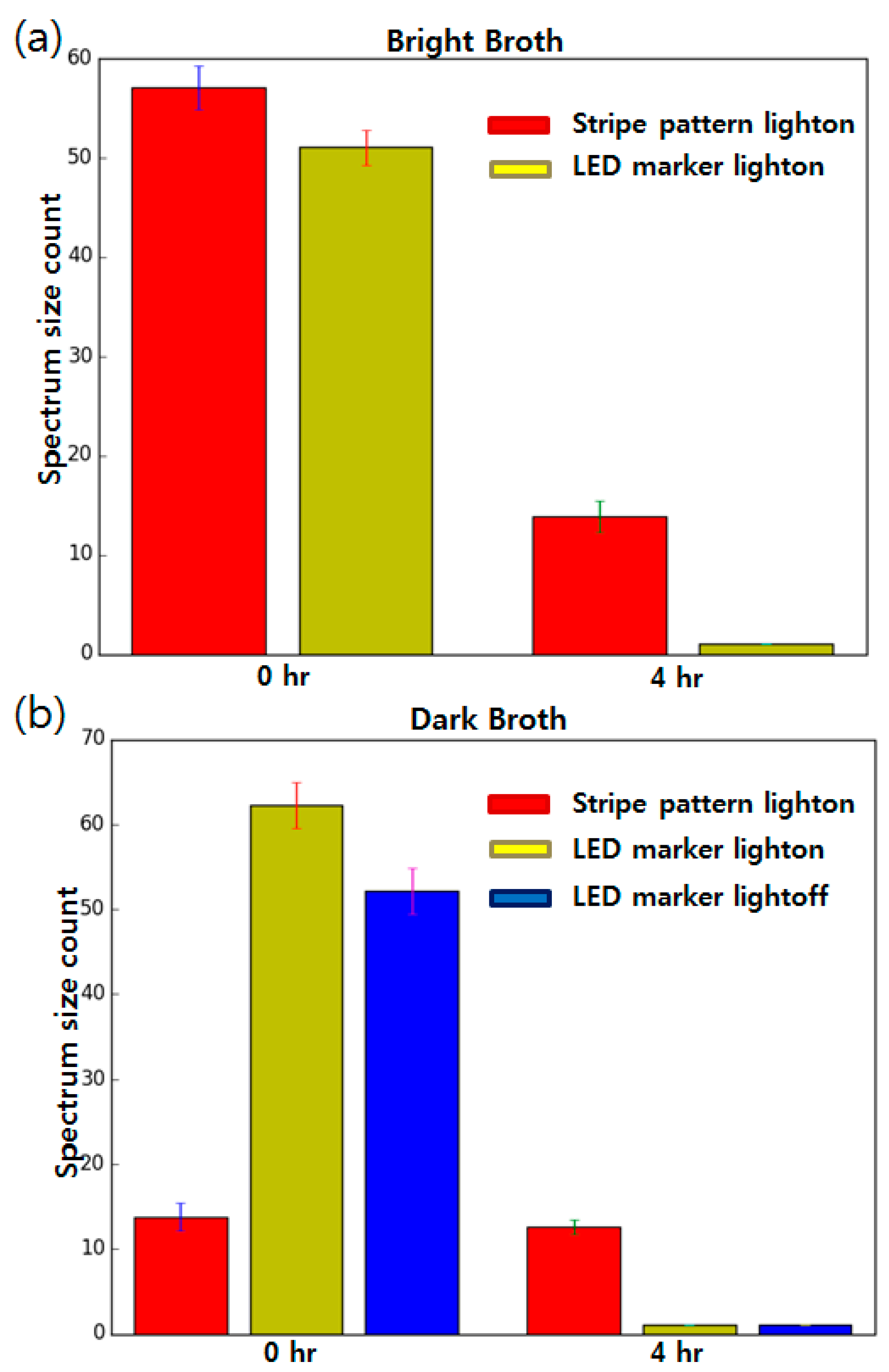

Growth measurement tests were performed when the color of the culture broth was dark to evaluate the functionality of the proposed method. For comparison, the striped pattern marker method was also introduced under the same conditions. Images of each marker were taken at the point of inoculation and after 4 h of incubation. LB broth was used as the brightly colored broth and TSB broth was used as the dark-colored medium. The experimental results are shown in

Figure 4.

As shown in

Figure 4, the striped pattern marker was highly distinguishable in the brightly colored medium (

Figure 4a). Previous research [

3] reported a decrease in the FFT spectrum area after the bacteria had grown, and same results were replicated in this study. The FFT spectrum size (number of nonzero pixels) of the clear LB showed a count of 51, and dropped to 17 after being cultured. However, this difference in the FFT spectrum size did not show when the dark colored medium was used (

Figure 4b). Even though the bacteria had not yet grown, the FFT spectrum size showed a value of only 11, much smaller than the value measured from the brightly colored broth. The culture vessel used in the previous research study used approximately 3 to 5 mL of broth in either a thin culture tube (radius of 20 mm) or in a millifluidic scale PDMS device [

3]. Though dark broth was used, it did not significantly affect the measurements since the thickness of the liquid layer was too thin. However, environmental bacterial detection methods such as coliform detection [

2] require a larger volume to process, which can be problematic in data acquisition as shown in

Figure 4.

Compared to the striped pattern marker, the proposed LED marker showed similar visibility when the bright broth was used (

Figure 4c), but showed better visibility when the dark broth was used (

Figure 4d). Though the thickness of the dark liquid layer increased, the bright red circles were clearly observable. After 4 h of incubation, the blurred media concealed the glowing LEDs and only scattered red lights were seen. The FFT calculation showed 51 counts before the incubation and 0 counts after the culture was completed.

Moreover, the consistency of the LED array marker FFT calculation results was maintained, even when the lighting was changed. The culture box was placed in a completely dark room and the incubation was performed. The results of the zeroth hour and fourth hour (

Figure 4e) showed no significant difference from the results measured with light (

Figure 4d). The FFT spectrum at the zeroth hour yielded counts of 51 (53 in the bright room) and 0 (0 in the bright room) after the fourth hour. Obviously, the striped pattern paper marker was not observable when no light was provided. Multiple FFT spectrum size values were collected from each condition and compared. The results are summarized in

Figure 5.

In the brightly colored broth, both the striped pattern marker and LED marker showed similar results; high FFT counts at the zeroth hour and low FFT counts at the fourth hour were observed. However, previous research studies could not distinguish the zeroth hour from the fourth hour when using dark broth. The average FFT count value showed only a 0.8 point difference while more than 20 count differences could be observed when the brightly colored broth was used. However, the proposed LED marker still showed good detection ability, even when the dark colored broth was used with about 60 FFT count differences. In the dark environment without lighting, the striped marker imaging was not possible, whereas the LED marker still functioned with similar FFT count differences to experiments with other conditions. The results show that it is expected that the proposed method can be effectively used in P/A tests such as antibiotics susceptibility tests (AST) or toxicity measurements [

10,

11,

12], where comparison of only the growth/no growth state is required.

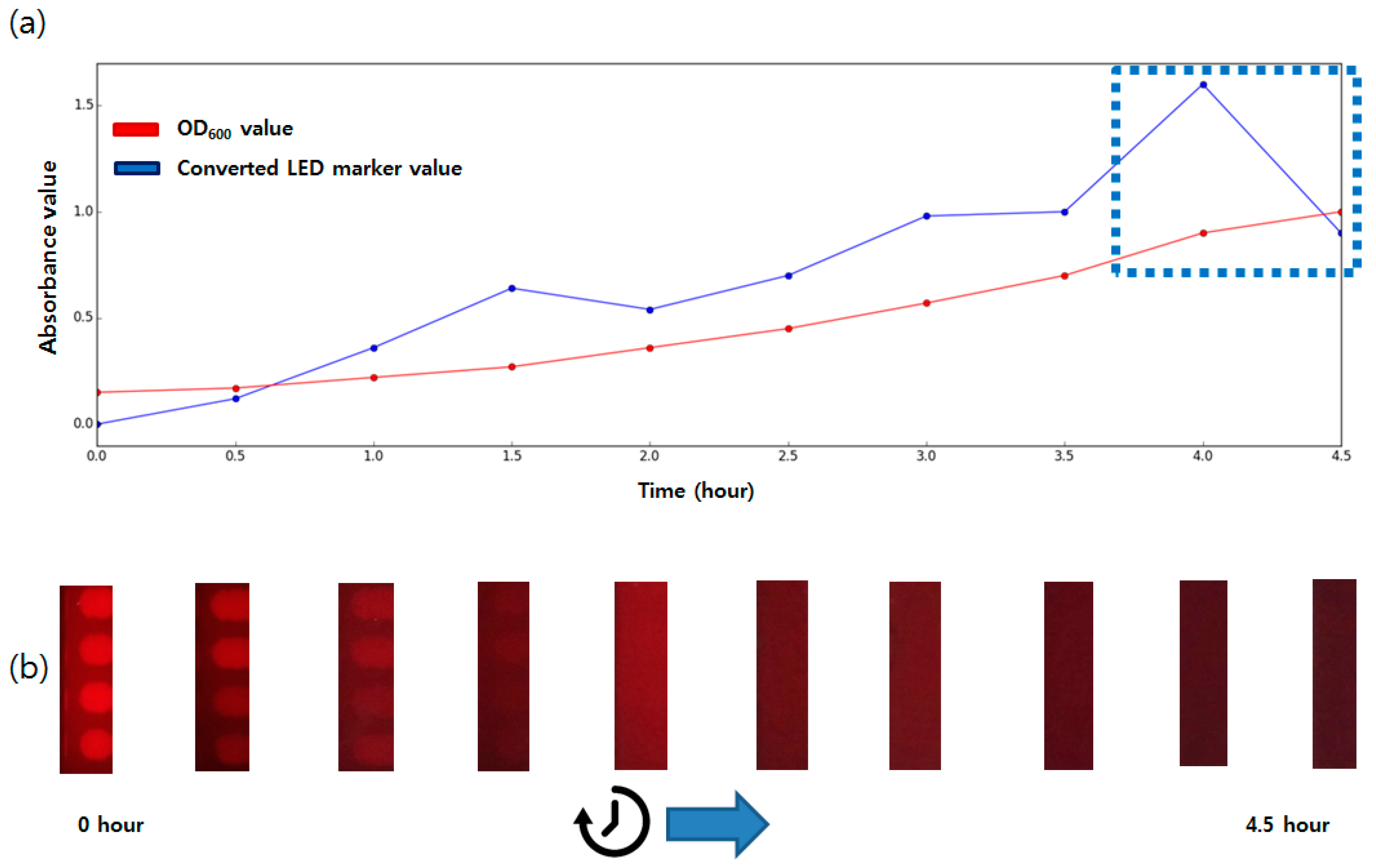

For the comparison with the traditional technique, OD

600 (OD at the 600 nm wavelength) values were also measured with the commercial spectrometer. (Ultrospec 7000, GE, Boston, MA, USA). From the inoculation, OD values and sensor outputs from the proposed method were measured every 30 min until the OD value reached 1.0. Light was turned on during the measurement as the proposed LED marker system does not affect by the presence of the lighting as shown at the

Figure 5. For easier comparison, the FFT values were log transformed using the following absorbance calculation formula,

where measured spectrum area count of the sample was used as

Ti value and the maximum area value was used as

Tt value [

3]. The data are shown at the

Figure 6.

The both measurement values increased as time passed; the OD value changed from 0.15 to 1.0 and the FFT spectrum size changed from 0 to 1.0. Two data showed good correlation (

r2 value of 0.97 with

p-value < 0.01 from the Pearson correlation analysis) which indicates that the LED marker based measurement can be used for the bacterial growth measurement in the liquid medium. Compared to the optical density, the proposed method showed rather rapid increase at the early stage of the incubation (0 to 1.5 h). Towards the end of the culture period, the output of the sensor became noisy due to saturation at the near OD 0.9 (dotted box at the

Figure 6). At the high cell density, the FFT spectrum size drops to near 0, which gradually increases the absorbance which is the negative of log transformed value. The cuvette used for the OD measurement contains only 1 mL of the broth between thin container walls while the main culture vessel of the proposed system is 70 mm thick. Although there is small increase of the bacterial cells in each unit of volume of the culture broth, the containers with thick walls are more affected by these changes as the total number of the integrated bacterial cells between the LED marker and camera are larger than the small containers such as cuvette. We expect that the changing the size of the culture vessel can help in adjusting the measurement resolutions or measurement range of the proposed system. For the target application of this article, the P/A test, where early detection of the meaningful bacterial cell increase is important, a thick container which allows faster turbidity increase of the culture vessel could be an appropriate selection. If a user wishes to obtain higher resolution data at high concentrations (e.g., culture until OD 1.0 for competent cell preparation), it would be desirable to use a small container such as a 50 mL tube.

The overall results showed that the LED array marker functions under conditions in which obtaining a clear image of the striped pattern marker is difficult or impossible. Consistent lighting is very important for the image processing, but it is often challenging to establish the proper settings. On-the-spot tasks, requiring the handling of environmental samples in an outdoor environment, must conceal sunlight while installing the appropriate light settings in the incubator for proper illumination. Laboratories can rather easily set the light conditions, but operating the lights during the entire culture time (4 h to overnight) is a waste of electricity, especially in places where the electrical infrastructure is not well established. Even when light sources are installed in the incubator box, reflections of the light to the nearby surfaces can disturb proper image processing. The proposed method uses a light emitting marker to solve this issue. Since red LEDs generate higher intensity compared to other objects, they are easily detectable in the noisy environment or behind the larger culture chamber. Even when the external lights are turned off, they can still function since the marker itself is a light source. Additionally, the camera used in this research is a low cost webcam, which is much cheaper and easier to connect to various devices such as a laptop compared to the smartphone camera used in the previous research. Bright and easy detectability of the LED marker can help decrease the total cost of the system and improve the interfacing between devices.

The incubator system used to obtain automatic measurements was also improved compared to previous research investigations. Previous studies used a small culture tube attached to a shaking incubator, which required a 220 V hot wire to warm up the entire incubator box. The newly developed incubator uses a low powered heating pad directly attached to the culture chamber; it decreases the amount of energy required to warm up the culture chamber. Also, removing the actuating component helps to decrease the weight and power consumption. The proposed system improves image processing, lowers energy consumption, and enables the use of a larger culture volume, allowing for portable bacterial culture. These features can facilitate starting the culture right after the sample is collected or during its transport to the laboratories. Pathogens such as

Vibrio cholera,

Vibrio vulnificus, or

Vibrio pharahaemolyticus [

13,

14,

15], which are found in warm seawater, require enrichment processes before the separation or identification is performed [

1]. Multiple culture steps take a long time and make detecting these pathogens labor intensive. Being able to start the culture and growth check of these pathogens during transportation can help decrease the total time required to conduct the bacterial experiments.