Recycling of Sewage Sludge: Synthesis and Application of Sludge-Based Activated Carbon in the Efficient Removal of Cadmium (II) and Lead (II) from Wastewater

Abstract

1. Introduction

2. Results and Discussion

2.1. The Ultimate Analysis of Activated Carbon

2.2. X-ray Fluorescence (XRF) Analysis

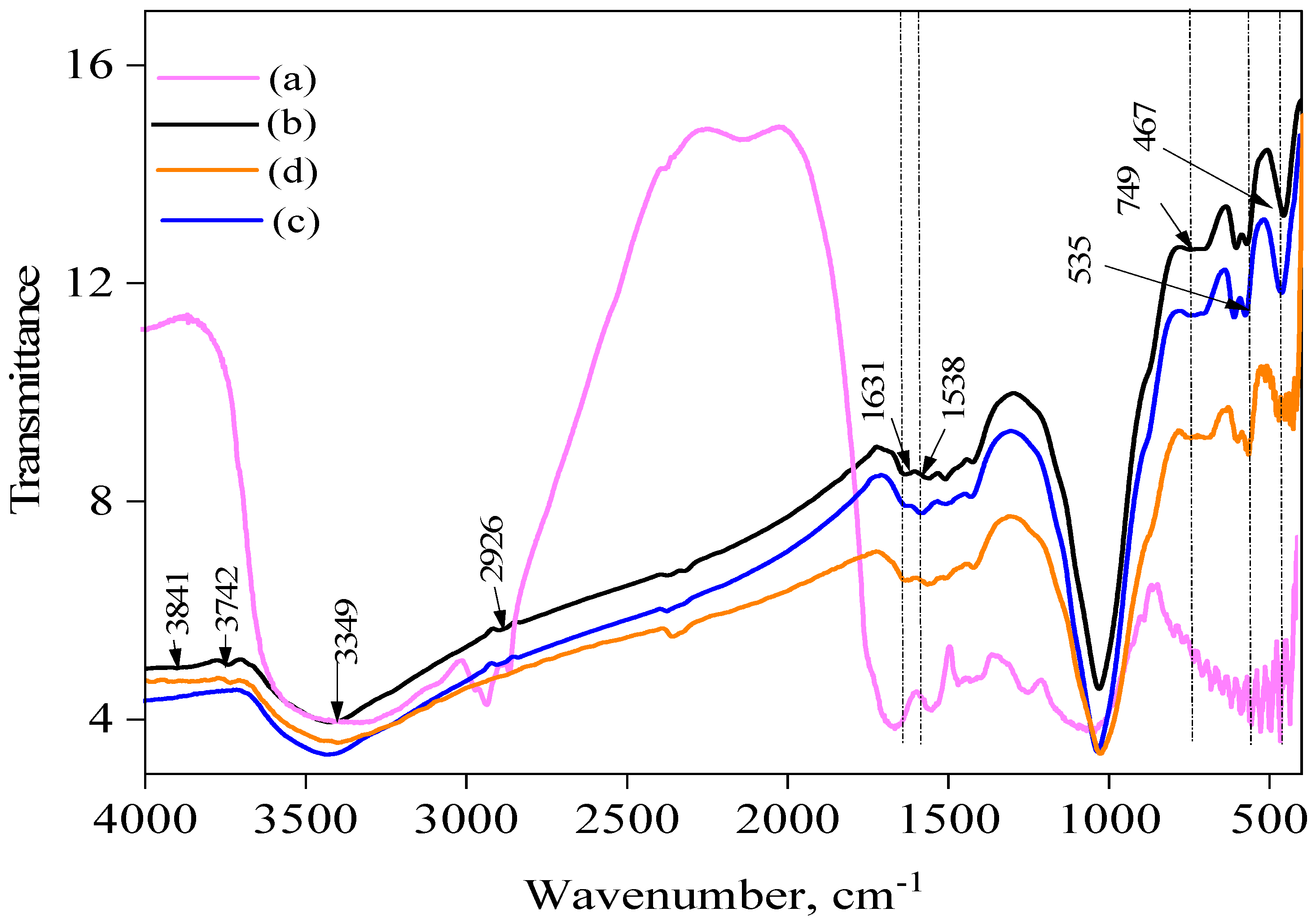

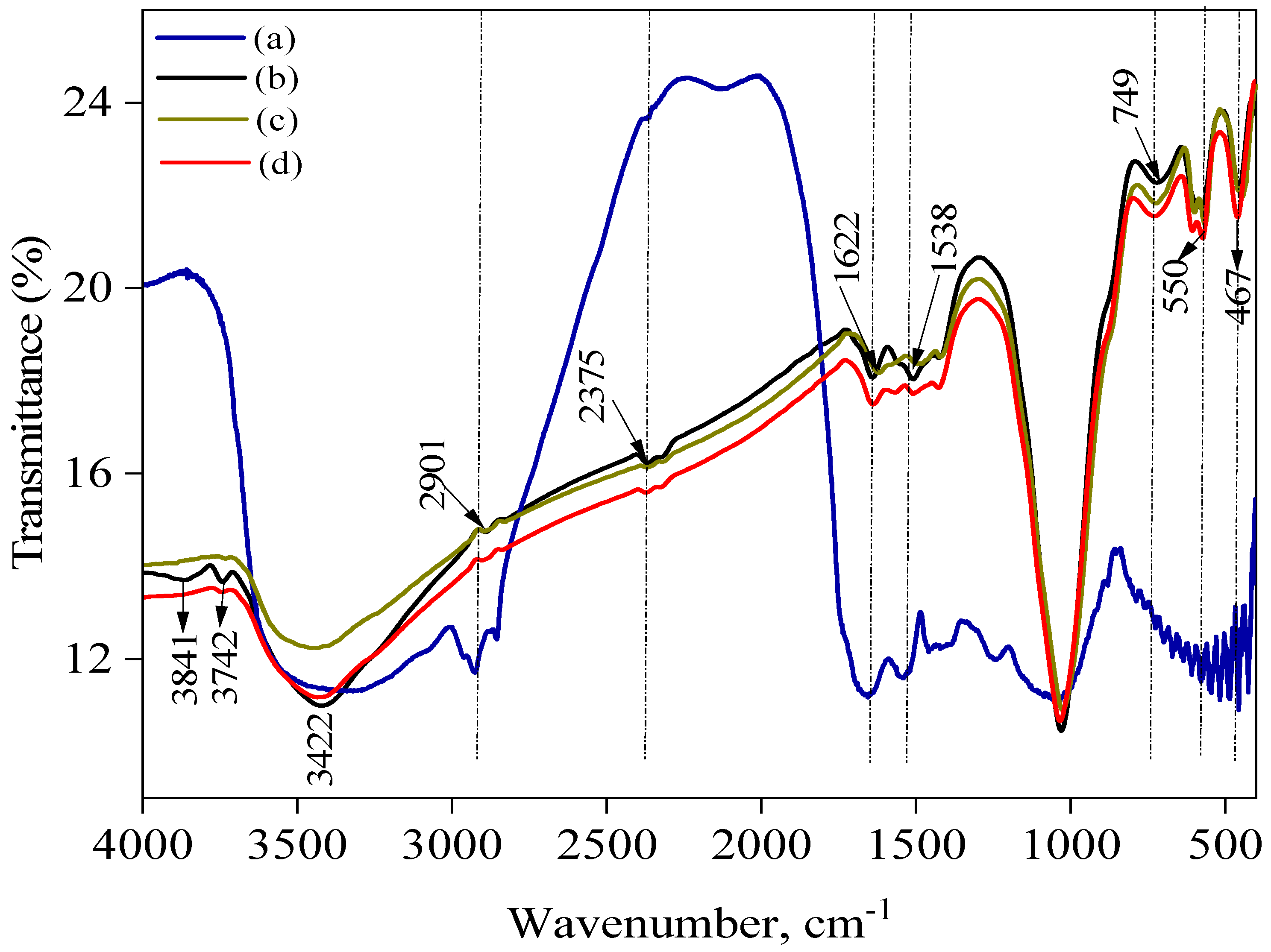

2.3. FT-IR Analysis

2.4. Characteristics of the Porous Structure

2.5. Zeta Potential Results

2.6. X-ray Diffraction

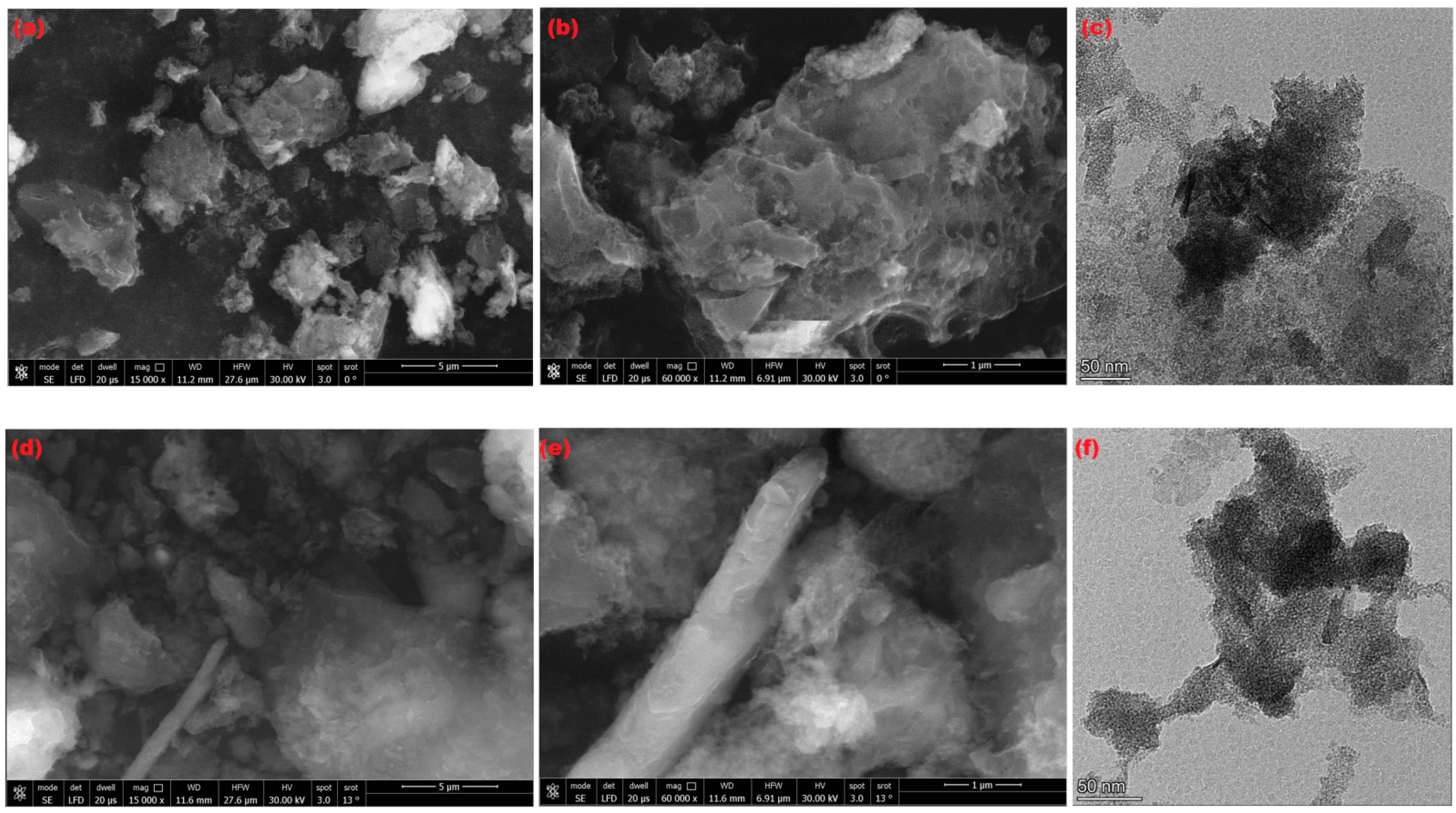

2.7. Microstructure of Activated Carbon

2.8. Adsorption Study

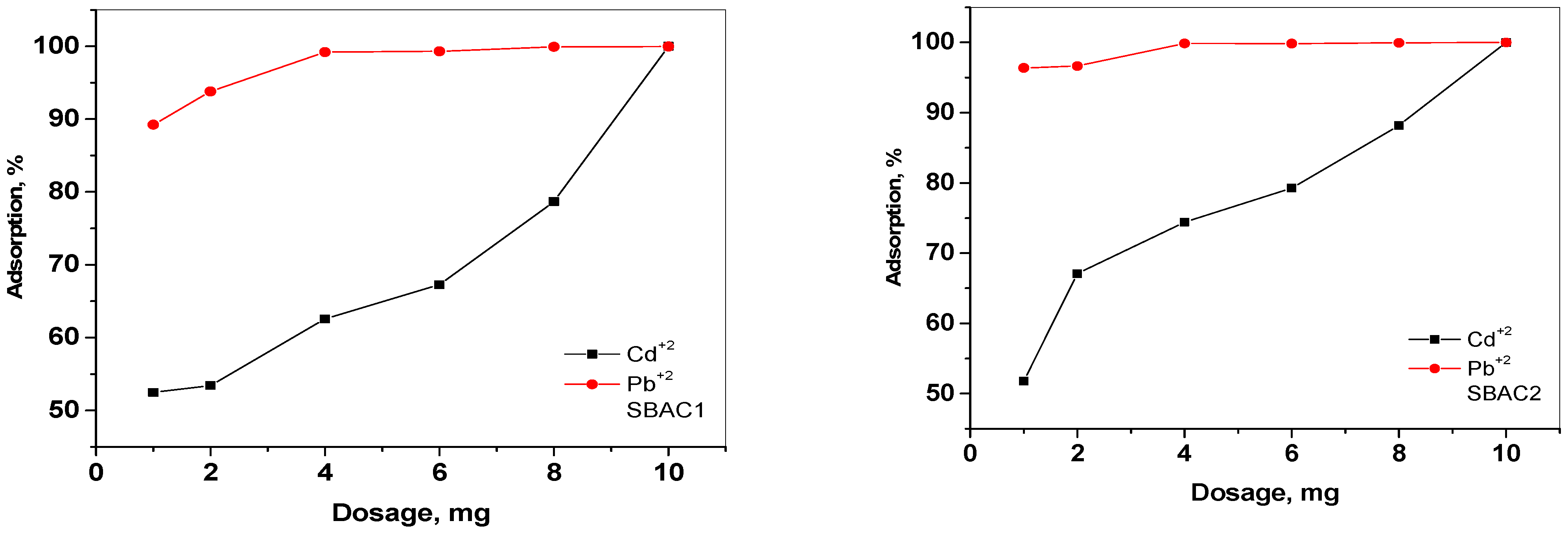

2.8.1. Influence of the SBAC1 and SBAC2 Dosage

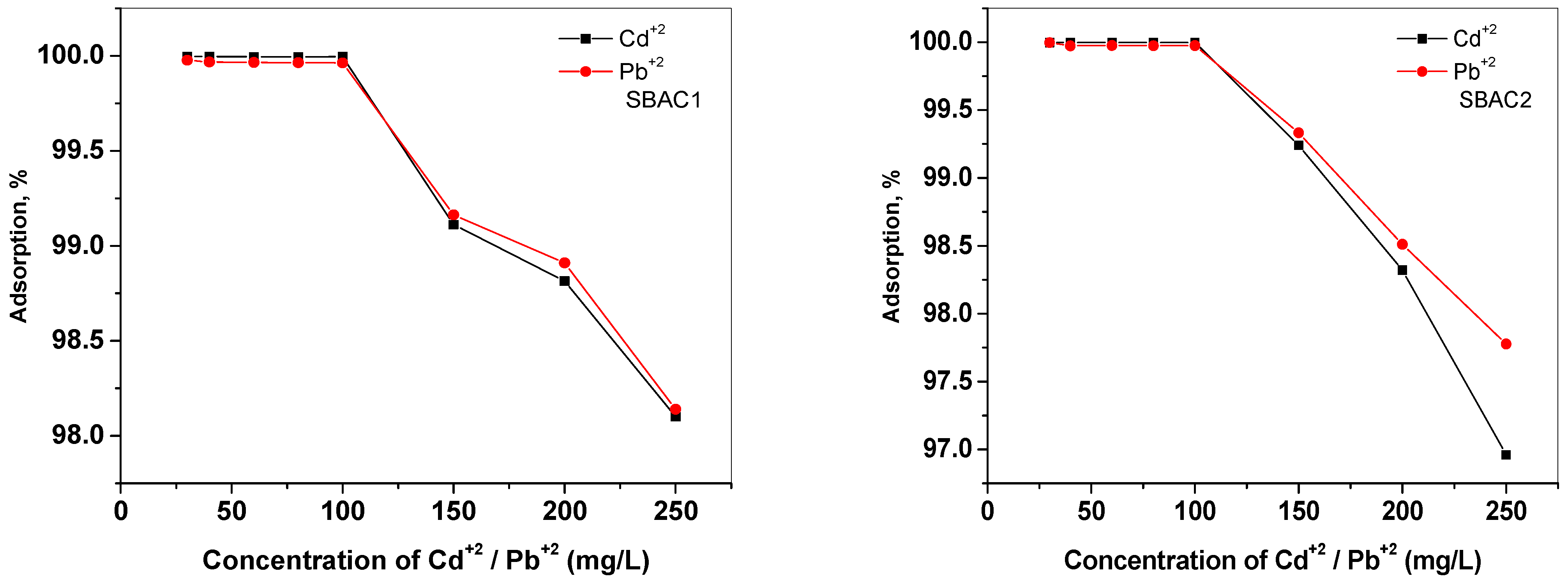

2.8.2. Influence of the of Metal Ion Concentration

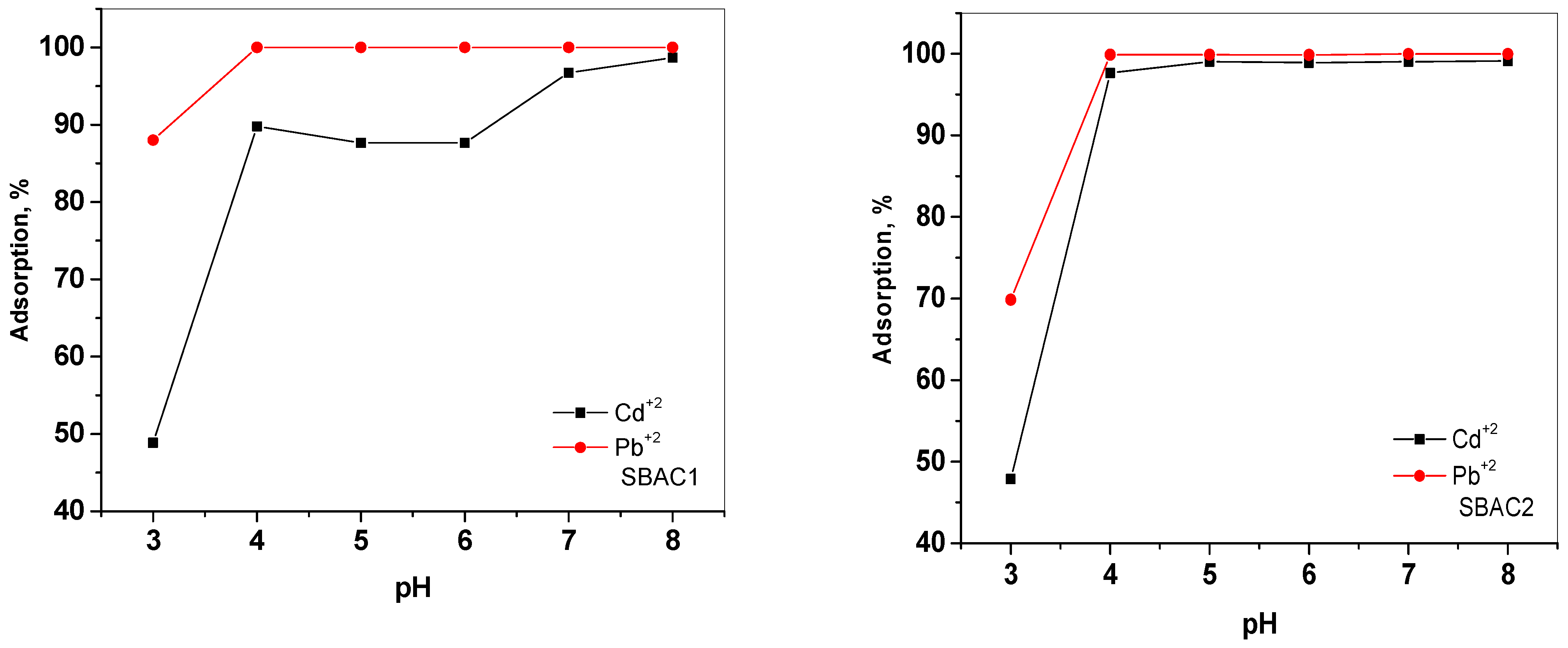

2.8.3. Influence of pH

2.8.4. Influence of Time

2.8.5. Influence of Temperature

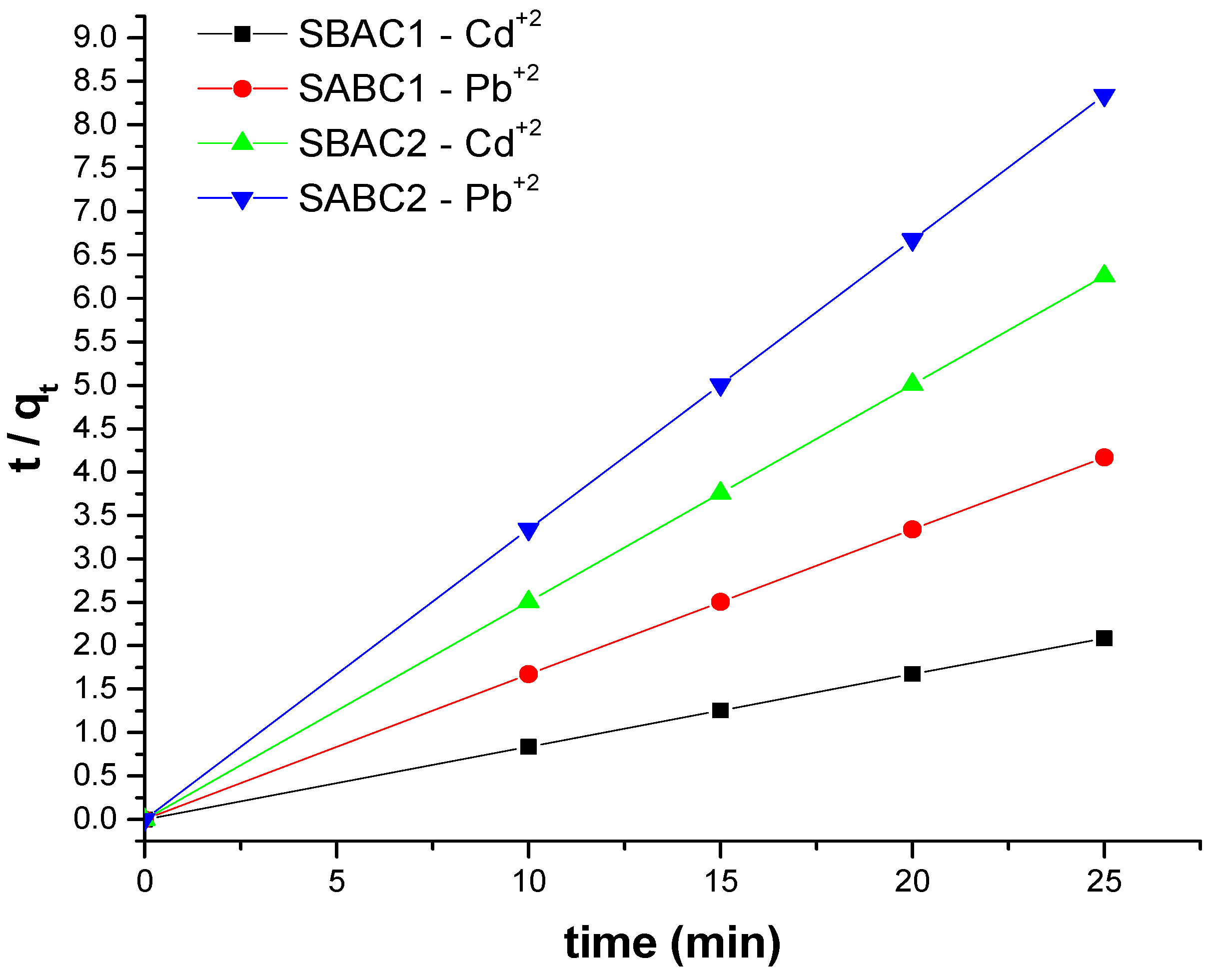

2.9. Adsorption Kinetics

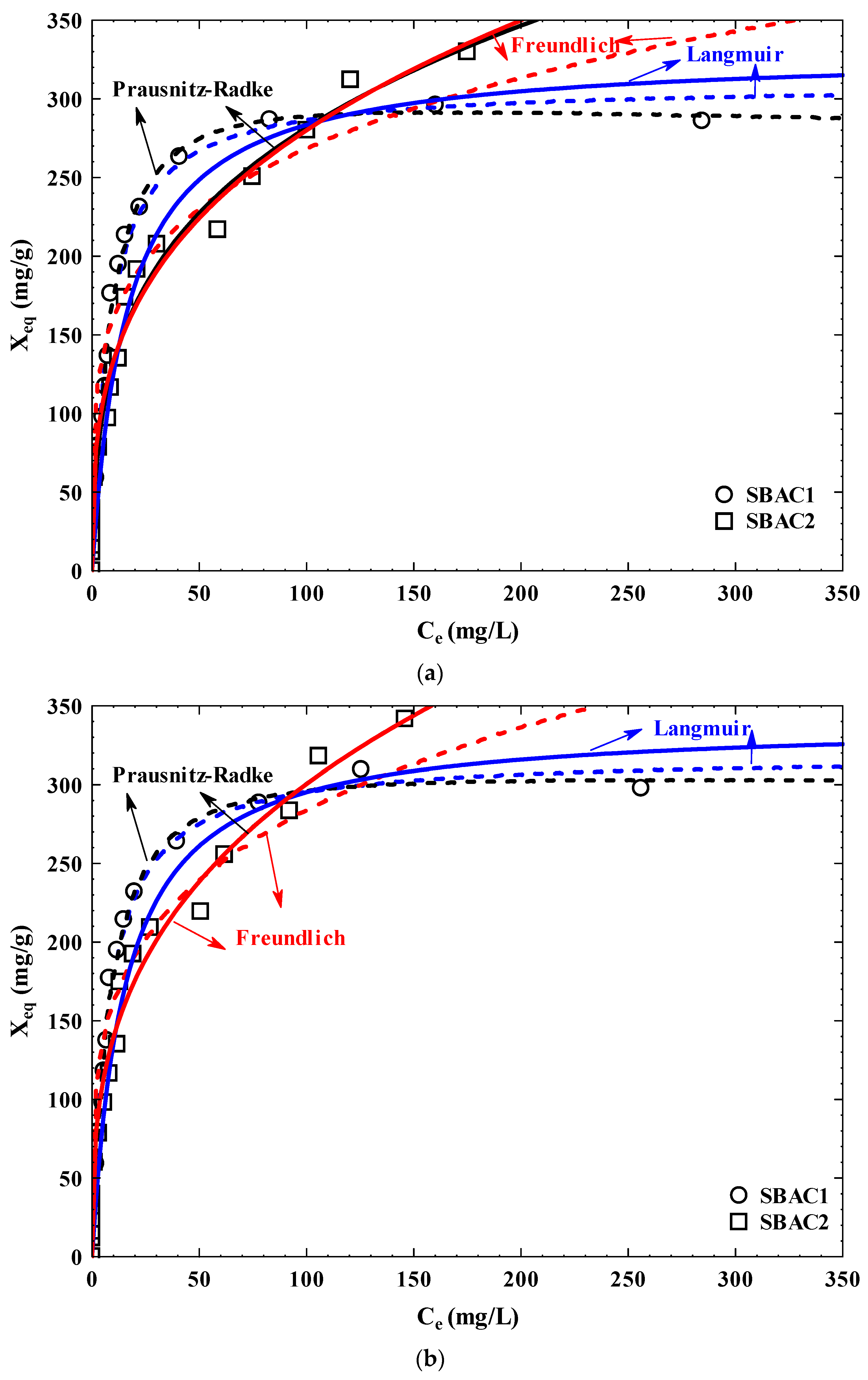

2.10. Adsorption Isotherm

2.11. Analysis of Real Wastewater

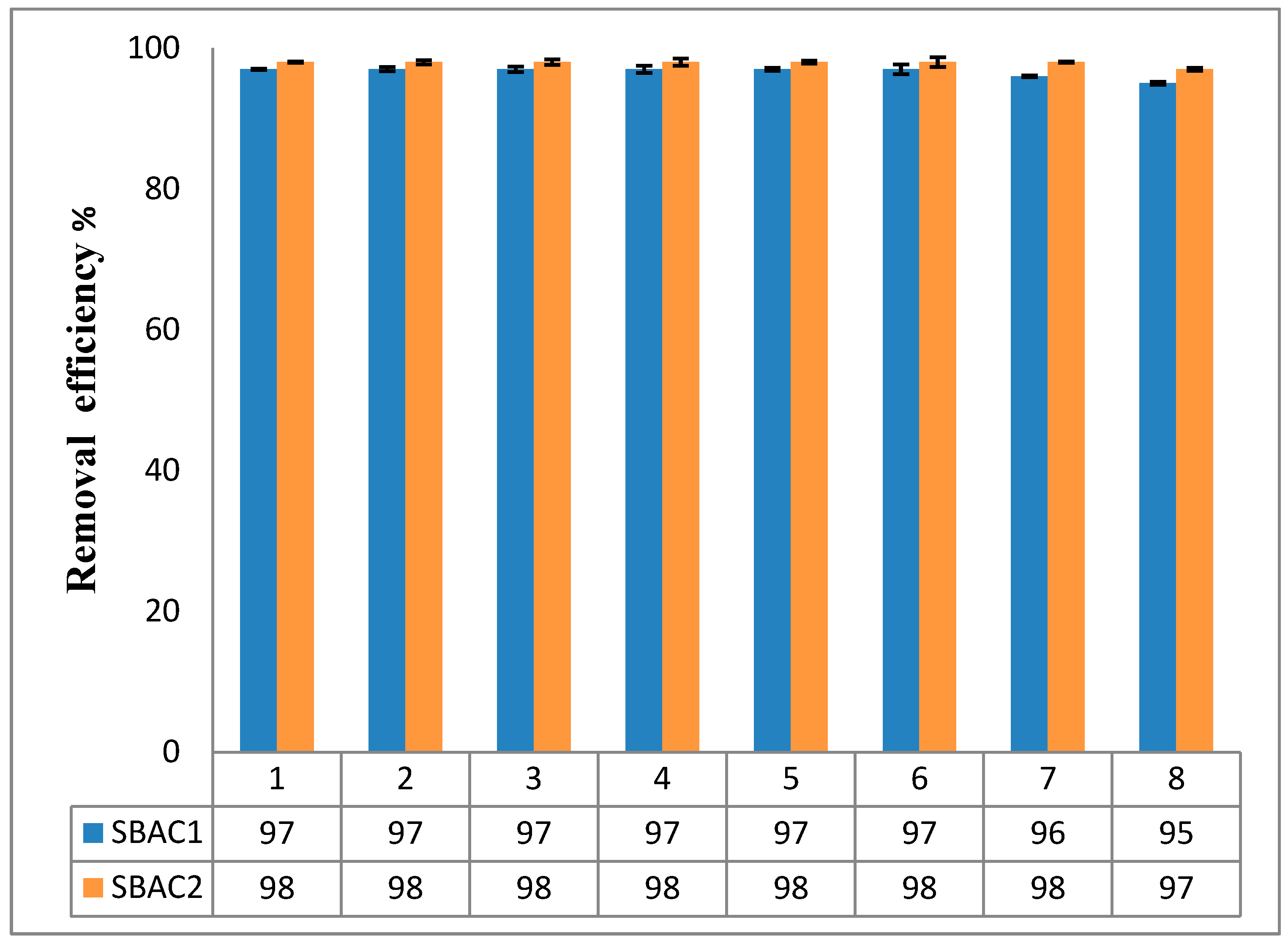

2.12. Recovery and Recyclability SBAC1 and SBAC2

2.13. Comparison with Another Method

3. Materials and Methods

3.1. Chemicals

3.2. Instruments

3.3. Fabrication of Activated Carbon

3.4. Adsorption Studies

3.4.1. Adsorption Procedures of Cd+2 and Pb+2

3.4.2. Adsorption Isotherms

3.4.3. Adsorption Kinetics

3.5. Environmental and Industrial Wastewater Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Almahbashi, N.M.Y.; Kutty, S.R.M.; Ayoub, M.; Noor, A.; Salihi, I.U.; Al-Nini, A.; Jagaba, A.H.; Aldhawi, B.N.S.; Ghaleb, A.A.S. Optimization of Preparation Conditions of Sewage sludge based Activated Carbon. Ain Shams Eng. J. 2021, 12, 1175–1182. [Google Scholar] [CrossRef]

- Spinosa, L.; Ayol, A.; Baudez, J.-C.; Canziani, R.; Jenicek, P.; Leonard, A.; Rulkens, W.; Xu, G.; Van Dijk, L. Sustainable and Innovative Solutions for Sewage Sludge Management. Water 2011, 3, 702–717. [Google Scholar] [CrossRef]

- Bibby, K.; Peccia, J. Identification of Viral Pathogen Diversity in Sewage Sludge by Metagenome Analysis. Environ. Sci. Technol. 2013, 47, 1945–1951. [Google Scholar] [CrossRef]

- Nnorom, M.-A.; Saroj, D.; Avery, L.; Hough, R.; Guo, B. A review of the impact of conductive materials on antibiotic resistance genes during the anaerobic digestion of sewage sludge and animal manure. J. Hazard. Mater. 2023, 446, 130628. [Google Scholar] [CrossRef]

- Samolada, M.C.; Zabaniotou, A.A. Comparative assessment of municipal sewage sludge incineration, gasification and pyrolysis for a sustainable sludge-to-energy management in Greece. Waste Manag. 2014, 34, 411–420. [Google Scholar] [CrossRef]

- del Rosario Moreno, V.M.; Omar Francisco González, V.; Virginia Hernández, M.; Rigoberto Tovar, G. Removal of Heavy Metals Using Adsorption Processes Subject to an External Magnetic Field. In Heavy Metals; Hosam El-Din, M.S., Refaat, F.A., Eds.; IntechOpen: Rijeka, Croatia, 2018; p. Ch. 15. [Google Scholar]

- Senthilkumar, T.S.; Chattopadhyay, S.K.; Miranda, L.R. Optimization of Activated Carbon Preparation from Pomegranate Peel (Punica granatum Peel) Using RSM. Chem. Eng. Commun. 2017, 204, 238–248. [Google Scholar] [CrossRef]

- Wen, Q.; Li, C.; Cai, Z.; Zhang, W.; Gao, H.; Chen, L.; Zeng, G.; Shu, X.; Zhao, Y. Study on activated carbon derived from sewage sludge for adsorption of gaseous formaldehyde. Bioresour. Technol. 2011, 102, 942–947. [Google Scholar] [CrossRef]

- Im, U.-S.; Kim, J.; Lee, S.H.; Lee, S.m.; Lee, B.-R.; Peck, D.-H.; Jung, D.-H. Preparation of activated carbon from needle coke via two-stage steam activation process. Mater. Lett. 2019, 237, 22–25. [Google Scholar] [CrossRef]

- Sulaiman, N.S.; Hashim, R.; Mohamad Amini, M.H.; Danish, M.; Sulaiman, O. Optimization of activated carbon preparation from cassava stem using response surface methodology on surface area and yield. J. Clean. Prod. 2018, 198, 1422–1430. [Google Scholar] [CrossRef]

- Chen, X.; Jeyaseelan, S.; Graham, N. Physical and chemical properties study of the activated carbon made from sewage sludge. Waste Manag. 2002, 22, 755–760. [Google Scholar] [CrossRef] [PubMed]

- Devi, P.; Saroha, A.K. Utilization of sludge based adsorbents for the removal of various pollutants: A review. Sci. Total Environ. 2017, 578, 16–33. [Google Scholar] [CrossRef]

- Björklund, K.; Li, L.Y. Adsorption of organic stormwater pollutants onto activated carbon from sewage sludge. J. Environ. Manag. 2017, 197, 490–497. [Google Scholar] [CrossRef] [PubMed]

- N’goran, K.P.D.A.; Diabaté, D.; Yao, K.M.; Kouassi, N.G.L.B.; Gnonsoro, U.P.; Kinimo, K.C.; Trokourey, A. Lead and cadmium removal from natural freshwater using mixed activated carbons from cashew and shea nut shells. Arab. J. Geosci. 2018, 11, 498. [Google Scholar] [CrossRef]

- Kavand, M.; Eslami, P.; Razeh, L. The adsorption of cadmium and lead ions from the synthesis wastewater with the activated carbon: Optimization of the single and binary systems. J. Water Process Eng. 2020, 34, 101151. [Google Scholar] [CrossRef]

- Gerçel, Ö.; Gerçel, H.F. Adsorption of lead(II) ions from aqueous solutions by activated carbon prepared from biomass plant material of Euphorbia rigida. Chem. Eng. J. 2007, 132, 289–297. [Google Scholar] [CrossRef]

- Thornton, I.; Butler, D.; Docx, P.; Hession, M.; Makropoulos, C.; McMullen, M.; Nieuwenhuijsen, M.; Pitman, A.; Rautiu, R.; Sawyer, R. Pollutants in urban waste water and sewage sludge. In Final Report Prepared for European Commission Directorate-General Environment; European Commission: Brussels, Belgium, 2001. [Google Scholar]

- Asuquo, E.; Martin, A.; Nzerem, P.; Siperstein, F.; Fan, X. Adsorption of Cd(II) and Pb(II) ions from aqueous solutions using mesoporous activated carbon adsorbent: Equilibrium, kinetics and characterisation studies. J. Environ. Chem. Eng. 2017, 5, 679–698. [Google Scholar] [CrossRef]

- Dzul Erosa, M.S.; Saucedo Medina, T.I.; Navarro Mendoza, R.; Avila Rodriguez, M.; Guibal, E. Cadmium sorption on chitosan sorbents: Kinetic and equilibrium studies. Hydrometallurgy 2001, 61, 157–167. [Google Scholar] [CrossRef]

- Gascó, G.; Lobo, M.C. Composition of a Spanish sewage sludge and effects on treated soil and olive trees. Waste Manag. 2007, 27, 1494–1500. [Google Scholar] [CrossRef]

- Gascó, G.; Blanco, C.G.; Guerrero, F.; Méndez Lázaro, A.M. The influence of organic matter on sewage sludge pyrolysis. J. Anal. Appl. Pyrolysis 2005, 74, 413–420. [Google Scholar] [CrossRef]

- Cao, J.P.; Xiao, X.B.; Zhang, S.Y.; Zhao, X.Y.; Sato, K.; Ogawa, Y.; Wei, X.Y.; Takarada, T. Preparation and characterization of bio-oils from internally circulating fluidized-bed pyrolyses of municipal, livestock, and wood waste. Bioresour. Technol. 2011, 102, 2009–2015. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Hu, M.; Cui, B.; Liu, S.; Guo, D.; Xiao, B. The effect of bioleaching on sewage sludge pyrolysis. Waste Manag. 2016, 48, 383–388. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-H.; Kim, S.; Yoom, H.; Son, H. Evaluation of organics reduction performance of the GAC filtration with regenerated carbons using the long-term operational data of drinking water treatment facilities. AQUA—Water Infrastruct. Ecosyst. Soc. 2022, 71, 1219–1228. [Google Scholar] [CrossRef]

- Park, J.E.; Lee, G.B.; Hong, B.U.; Hwang, S.Y. Regeneration of Activated Carbons Spent by Waste Water Treatment Using KOH Chemical Activation. Appl. Sci. 2019, 9, 5132. [Google Scholar] [CrossRef]

- Reig, F.B.; Adelantado, J.G.; Moreno, M.M. FTIR quantitative analysis of calcium carbonate (calcite) and silica (quartz) mixtures using the constant ratio method. Application to geological samples. Talanta 2002, 58, 811–821. [Google Scholar] [CrossRef]

- Kenne Diffo, B.; Elimbi, A.; Cyr, M.; Dika Manga, J.; Tchakoute Kouamo, H. Effect of the rate of calcination of kaolin on the properties of metakaolin-based geopolymers. J. Asian Ceram. Soc. 2015, 3, 130–138. [Google Scholar] [CrossRef]

- Yang, B.; Liu, Y.; Liang, Q.; Chen, M.; Ma, L.; Li, L.; Liu, Q.; Tu, W.; Lan, D.; Chen, Y. Evaluation of activated carbon synthesized by one-stage and two-stage co-pyrolysis from sludge and coconut shell. Ecotoxicol. Environ. Saf. 2019, 170, 722–731. [Google Scholar] [CrossRef]

- Herselman, J.; Snyman, H. Guidelines for the utilisation and disposal of wastewater sludge. In Water Research Commission; Water Research Commission: Pretoria, South Africa, 2009. [Google Scholar]

- Al-Malack, M.H.; Dauda, M. Competitive adsorption of cadmium and phenol on activated carbon produced from municipal sludge. J. Environ. Chem. Eng. 2017, 5, 2718–2729. [Google Scholar] [CrossRef]

- Ahmad, A.; Idris, A. Preparation and characterization of activated carbons derived from bio-solid: A review. Desalination Water Treat. 2014, 52, 4848–4862. [Google Scholar] [CrossRef]

- Jindarom, C.; Meeyoo, V.; Kitiyanan, B.; Rirksomboon, T.; Rangsunvigit, P. Surface characterization and dye adsorptive capacities of char obtained from pyrolysis/gasification of sewage sludge. Chem. Eng. J. 2007, 133, 239–246. [Google Scholar] [CrossRef]

- Boehm, H.P. Surface oxides on carbon and their analysis: A critical assessment. Carbon 2002, 40, 145–149. [Google Scholar] [CrossRef]

- Keppetipola, N.M.; Dissanayake, M.; Dissanayake, P.; Karunarathne, B.; Dourges, M.A.; Talaga, D.; Servant, L.; Olivier, C.; Toupance, T.; Uchida, S. Graphite-type activated carbon from coconut shell: A natural source for eco-friendly non-volatile storage devices. RSC Adv. 2021, 11, 2854–2865. [Google Scholar] [CrossRef] [PubMed]

- Everett, D.H.; Stone, F.S. The Structure and Properties of Porous Materials; Academic Press: Cambridge, MA, USA, 1958; Volume 10. [Google Scholar]

- Rengaraj, S.; Moon, S.-H. Kinetics of adsorption of Co (II) removal from water and wastewater by ion exchange resins. Water Res. 2002, 36, 1783–1793. [Google Scholar] [CrossRef] [PubMed]

- Elsehly, E.; Chechenin, N.; Makunin, A.; Vorobyeva, E.; Motaweh, H. Oxidized carbon nanotubes filters for iron removal from aqueous solutions. Int. J. New Technol. Sci. Eng. 2015, 2, 14–18. [Google Scholar]

- Salam, E.A.; Abou El-Nour, K.M.; Awad, A.A.; Orabi, A.S. Carbon nanotubes modified with 5,7-dinitro-8-quinolinol as potentially applicable tool for efficient removal of industrial wastewater pollutants. Arab. J. Chem. 2020, 13, 109–119. [Google Scholar] [CrossRef]

- Kosa, S.A.; Al-Zhrani, G.; Salam, M.A. Removal of heavy metals from aqueous solutions by multi-walled carbon nanotubes modified with 8-hydroxyquinoline. Chem. Eng. J. 2012, 181, 159–168. [Google Scholar] [CrossRef]

- Dzombak, D.A.; Morel, F.M. Surface Complexation Modeling: Hydrous Ferric Oxide; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Mushtaq, S.; Jamil, F.; Hussain, M.; Inayat, A.; Majeed, K.; Akhter, P.; Khurram, M.S.; Shanableh, A.; Kim, Y.M.; Park, Y.-K. Utilizing sludge-based activated carbon for targeted leachate mitigation in wastewater treatment. Environ. Res. 2024, 249, 118326. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, Z.; Cheng, B.; Yu, J. Glycine-assisted hydrothermal synthesis and adsorption properties of crosslinked porous α-Fe2O3 nanomaterials for p-nitrophenol. Chem. Eng. J. 2012, 211, 153–160. [Google Scholar] [CrossRef]

- Luo, C.; Tian, Z.; Yang, B.; Zhang, L.; Yan, S. Manganese dioxide/iron oxide/acid oxidized multi-walled carbon nanotube magnetic nanocomposite for enhanced hexavalent chromium removal. Chem. Eng. J. 2013, 234, 256–265. [Google Scholar] [CrossRef]

- Nassar, M.Y.; Ahmed, I.S.; Mohamed, T.Y.; Khatab, M. A controlled, template-free, and hydrothermal synthesis route to sphere-like α-Fe2O3 nanostructures for textile dye removal. RSC Adv. 2016, 6, 20001–20013. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Massas, I.; Ehaliotis, C. Composting improves biosorption of Pb2+ and Ni2+ by renewable lignocellulosic materials. Characteristics and mechanisms involved. Chem. Eng. J. 2013, 231, 245–254. [Google Scholar] [CrossRef]

- Liu, Q.-S.; Zheng, T.; Wang, P.; Jiang, J.-P.; Li, N. Adsorption isotherm, kinetic and mechanism studies of some substituted phenols on activated carbon fibers. Chem. Eng. J. 2010, 157, 348–356. [Google Scholar] [CrossRef]

- Li, Q.; Yang, F.; Zhang, J.; Zhou, C. Magnetic Fe3O4/MnO2 core–shell nano-composite for removal of heavy metals from wastewater. SN Appl. Sci. 2020, 2, 1375. [Google Scholar] [CrossRef]

- Giles, C.H.; Smith, D.; Huitson, A. A general treatment and classification of the solute adsorption isotherm. I. Theoretical. J. Colloid Interface Sci. 1974, 47, 755–765. [Google Scholar] [CrossRef]

- Alrowais, R.; Said, N.; Bashir, M.T.; Ghazy, A.; Alwushayh, B.; Daiem, M.M.A. Adsorption of Diphenolic Acid from Contaminated Water onto Commercial and Prepared Activated Carbons from Wheat Straw. Water 2023, 15, 555. [Google Scholar] [CrossRef]

- Alrowais, R.; Bashir, M.T.; Khan, A.A.; Bashir, M.; Abbas, I.; Abdel Daiem, M.M. Adsorption and Kinetics Modelling for Chromium (Cr6+) Uptake from Contaminated Water by Quaternized Date Palm Waste. Water 2024, 16, 294. [Google Scholar] [CrossRef]

- Alrowais, R.; Abdel Daiem, M.M.; Nasef, B.M.; Said, N. Activated Carbon Fabricated from Biomass for Adsorption/Bio-Adsorption of 2,4-D and MCPA: Kinetics, Isotherms, and Artificial Neural Network Modeling. Sustainability 2023, 16, 299. [Google Scholar] [CrossRef]

- Sulaymon, A.H.; Mohammed, A.A.; Al-Musawi, T.J. Competitive biosorption of lead, cadmium, copper, and arsenic ions using algae. Environ. Sci. Pollut. Res. 2013, 20, 3011–3023. [Google Scholar] [CrossRef]

- Samadi, S.; Shalmani, M.M.; Zakaria, S.A. Removal of heavy metals from Tehran south agricultural water by Zeolite N.P./PEG/GO nano-composite. J. Water Environ. Nanotechnol. 2019, 4, 157–166. [Google Scholar]

- Obayomi, K.; Bello, J.; Yahya, M.D.; Chukwunedum, E.; Adeoye, J. Statistical analyses on effective removal of cadmium and hexavalent chromium ions by multiwall carbon nanotubes (MWCNTs). Heliyon 2020, 6, e04174. [Google Scholar] [CrossRef]

- Karnib, M.; Kabbani, A.; Holail, H.; Olama, Z. Heavy metals removal using activated carbon, silica and silica activated carbon composite. Energy Procedia 2014, 50, 113–120. [Google Scholar] [CrossRef]

- Méndez-Díaz, J.D.; Rivera-Utrilla, J.; Sánchez-Polo, M.; Bautista-Toledo, I. Adsorption/bioadsorption of phthalic acid, an organic micropollutant present in landfill leachates, on activated carbons. J. Colloid Interface Sci. 2012, 369, 358–365. [Google Scholar] [CrossRef] [PubMed]

- Ullah, M.; Nazir, R.; Khan, M.; Khan, W.; Shah, M.; Afridi, S.G.; Zada, A. The effective removal of heavy metals from water by activated carbon adsorbents of Albizia lebbeck and Melia azedarach seed shells. Soil Water Res. 2019, 15, 30–37. [Google Scholar] [CrossRef]

- Wilson, N. Soil water monitoring devices. In Soil Water and Ground Water Sampling; CRC Press: Boca Raton, FL, USA, 2020; pp. 15–30. [Google Scholar]

- Adam, A.M.; Saad, H.A.; Atta, A.A.; Alsawat, M.; Hegab, M.S.; Altalhi, T.A.; Refat, M.S. An Environmentally Friendly Method for Removing Hg(II), Pb(II), Cd(II) and Sn(II) Heavy Metals from Wastewater Using Novel Metal–Carbon-Based Composites. Crystals 2021, 11, 882. [Google Scholar] [CrossRef]

- El-Shwiniy, W.H.; El-Desoky, S.I.; Alrabie, A.; Abd El-wahaab, B. Spectrophotometric determination of Zr(IV), Hg(II) and U(VI) in solution with their analytical applications: Structural characterization and molecular docking of the solid complexes. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 279, 121400. [Google Scholar] [CrossRef]

| Samples | Yield % | C (wt. %) a | H (wt. %) a | O (wt. %) b | N (wt. %) | H/C | O/C | N/C | Ash % |

|---|---|---|---|---|---|---|---|---|---|

| RSS | 67.7 | 9.2 | 14.3 | 9.3 | 0.14 | 0.21 | 0.14 | 13.9 | |

| SBAC1 | 83 | 90.8 | 4.2 | 5.1 | 1.6 | 0.05 | 0.06 | 0.02 | 7.4 |

| SBAC1 | 85 | 93.1 | 5.5 | 4.9 | 2.1 | 0.06 | 0.05 | 0.02 | 2.7 |

| Component | Elements (wt %) | ||

|---|---|---|---|

| RSS | SBAC1 | SBAC2 | |

| Al | 3.00 | 3.65 | 5.08 |

| Ca | 11.21 | 19.01 | 20.67 |

| Cu | 0.01 | 0.04 | 0.03 |

| Fe | 8.02 | 9.44 | 9.52 |

| K | 1.03 | 3.69 | 1.56 |

| Mn | 0.14 | 0.24 | 0.22 |

| Nb | 0.01 | 0.04 | 0.02 |

| Ni | 0.01 | 0.03 | 0.02 |

| P | 4.08 | 4.93 | 5.56 |

| Si | 13.20 | 15.20 | 15.05 |

| Ti | 1.34 | 1.76 | 1.68 |

| Sr | 0.12 | 0.15 | 0.22 |

| Zn | 0.35 | 0.59 | 0.45 |

| Zr | 0.10 | 0.03 | 0.02 |

| Co | 0.04 | 0.06 | — |

| Cl | 1.01 | 1.73 | — |

| Mo | 0.02 | 0.04 | — |

| Samples | SBET (m2 g−1) | VT (cm3 g−1) | VBJH (cm3 g−1) | ζ (mV) |

|---|---|---|---|---|

| SBAC1 | 336.339 | 0.268858 | 1.59873 | −11.50 |

| SBAC2 | 498.386 | 0.374884 | 1.5026 | −8.85 |

| Samples | 2θd100 (°) | FWHM (β°) | hkl | d100 (nm) | |

|---|---|---|---|---|---|

| SBACI | 26.45 | 0.4942 | 100 | 14.7195 | 16.2498 |

| 31.80 | 0.4544 | 002 | 17.7801 | ||

| SBAC2 | 28.31 | 0.5428 | 100 | 15.0883 | 16.5584 |

| 31.80 | 0.4580 | 002 | 18.0286 |

| Sample | T/K | ΔG0 (kJ mol−1) | ΔH0 (kJ mol−1) | ΔS0 (J K−1·mol−1) | |||

|---|---|---|---|---|---|---|---|

| Cd+2 | Pb+2 | Cd+2 | Pb+2 | Cd+2 | Pb+2 | ||

| 313 | −15.06 | −24.55 | |||||

| SBAC1 | 323 | −12.92 | −25.82 | −61.24 | 217.04 | −0.1475 | 0. 7718 |

| 333 | −11.58 | −26.00 | |||||

| 313 | −15.50 | −25.44 | |||||

| SBAC2 | 323 | −14.61 | −26.00 | −47.64 | 141.39 | −0.1027 | 0.5330 |

| 333 | −13.45 | −27.04 | |||||

| Kinetics Models | Variables | SBAC1 | SBAC2 | ||

|---|---|---|---|---|---|

| Pb+2 | Cd+2 | Pb+2 | Cd+2 | ||

| Pseudo-first-order | k1 (min−1) | 0.00032 | 0.00085 | 0.0009 | 0.0009 |

| qe(cal) (mg g−1) | 12.00 | 11.937 | 12.00 | 11.9848 | |

| R12 | 0.500 | 0.1529 | 0.6621 | 0.6619 | |

| qe(exp) (mg g−1) | 1.7716 | 1.249 | 1.471 | 1.4720 | |

| Pseudo-second-order | k2 [g mg−1 min−1] | 6.94 | 4.3556 | −110.1 | 13.527 |

| qe(cal) (mg g−1) | 11.999 | 11.936 | 11.998 | 11.9848 | |

| R22 | 1.00 | 1.00 | 1.00 | 1.00 | |

| qe(exp) (mg g−1) | 11.999 | 11.978 | 11.998 | 11.9817 | |

| AC | Pollutant | Langmuir | Freundlich | Prausnitz–Radke | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Xm (a) (mg/g) | B (b) (L/mg) | BXm (c) (L/g) | X′m × 10−4 (mg/m2/g) | %D | KF (d) (L/g) | 1/nF (e) | %D | a (f) (L/g) | b (g) (Lβ/mgβ) | β (h) | %D | ||

| SBAC 1 | Cd+2 | 309.24 | 0.13 | 40.20 | 0.92 | 5.94 | 96.07 | 0.22 | 23.51 | 33.37 | 0.08 | 1.06 | 5.80 |

| SBAC 2 | 329.62 | 0.06 | 19.78 | 0.66 | 12.84 | 63.79 | 0.32 | 9.41 | 109.99 | 1.42 | 0.71 | 8.41 | |

| SBAC 1 | Pb+2 | 318.46 | 0.13 | 41.40 | 0.95 | 6.67 | 91.66 | 0.25 | 21.70 | 37.06 | 0.10 | 1.03 | 6.66 |

| SBAC 2 | 339.61 | 0.07 | 23.77 | 0.68 | 13.19 | 64.79 | 0.33 | 8.49 | 1.52 × 107 | 2.34 × 105 | 0.67 | 8.50 | |

| Sample | pH | Metal Ions | % Adsorption | |

|---|---|---|---|---|

| SBAC1 | SBAC2 | |||

| TW | 7.50 | Cd+2 | 99.00 ± 0.01 | 99.44 ± 0.02 |

| Pb+2 | 99.03 ± 0.01 | 99.80 ± 0.003 | ||

| GW | 8.00 | Cd+2 | 98.02 ± 0.04 | 99.60 ± 0.005 |

| Pb+2 | 98.53 ± 0.05 | 98.73 ± 0.006 | ||

| RSW | 7.95 | Cd+2 | 98.33 ± 0.03 | 98.58 ± 0.004 |

| Pb+2 | 98.58 ± 0.01 | 98.88 ± 0.02 | ||

| BTW | 7.27 | Cd+2 | 97.00 ± 0.02 | 98.00 ± 0.001 |

| Pb+2 | 97.19 ± 0.03 | 98.50 ± 0.001 | ||

| WW1 | 6.91 | Cd+2 | 97.33 ± 0.01 | 98.44 ± 0.03 |

| Pb+2 | 97.96 ± 0.06 | 98.77 ± 0.01 | ||

| WW2 | 7.45 | Cd+2 | 97.60 ± 0.02 | 97.74 ± 0.001 |

| Pb+2 | 97.54 ± 0.01 | 97.88 ± 0.003 | ||

| Adsorbent | Adsorbent Dosage (g) | Metal Ions | Lower/Upper Concentration (mg/L) | pH | Time | qm (mg/g) | Reference |

|---|---|---|---|---|---|---|---|

| Zeolite | 0.3 0.005 | Pb+2 Cd+2 | 5–20 | 6 4 | 24 h 20 min | 56.82 50.2 | [39] [54] |

| MWCNTs | 0.03 0.05 | Pb+2 Cd+2 | 3–250 50–150 | 4 8 | 1.5 h 1 h | 200 200 | [39] [55] |

| Activated carbon | 0.02 0.02 | Pb+2 Cd+2 | 30–200 30–200 | 2 2 | 24 h 24 h | 294.11 178.5 | [56] |

| SBAC1 | 0.02 | Pb+2 Cd+2 | 30–250 30–250 | 7 7 | 30 min 30 min | 318.46 309.24 | This work |

| SBAC2 | 0.02 | Pb+2 Cd+2 | 30–250 30–250 | 7 7 | 30 min 30 min | 339.61 329.62 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aljubiri, S.M.; Younes, A.A.O.; Alosaimi, E.H.; Abdel Daiem, M.M.; Abdel-Salam, E.T.; El-Shwiniy, W.H. Recycling of Sewage Sludge: Synthesis and Application of Sludge-Based Activated Carbon in the Efficient Removal of Cadmium (II) and Lead (II) from Wastewater. Int. J. Mol. Sci. 2024, 25, 9866. https://doi.org/10.3390/ijms25189866

Aljubiri SM, Younes AAO, Alosaimi EH, Abdel Daiem MM, Abdel-Salam ET, El-Shwiniy WH. Recycling of Sewage Sludge: Synthesis and Application of Sludge-Based Activated Carbon in the Efficient Removal of Cadmium (II) and Lead (II) from Wastewater. International Journal of Molecular Sciences. 2024; 25(18):9866. https://doi.org/10.3390/ijms25189866

Chicago/Turabian StyleAljubiri, Salha M., Ayman A. O. Younes, Eid H. Alosaimi, Mahmoud M. Abdel Daiem, Enas T. Abdel-Salam, and Walaa H. El-Shwiniy. 2024. "Recycling of Sewage Sludge: Synthesis and Application of Sludge-Based Activated Carbon in the Efficient Removal of Cadmium (II) and Lead (II) from Wastewater" International Journal of Molecular Sciences 25, no. 18: 9866. https://doi.org/10.3390/ijms25189866

APA StyleAljubiri, S. M., Younes, A. A. O., Alosaimi, E. H., Abdel Daiem, M. M., Abdel-Salam, E. T., & El-Shwiniy, W. H. (2024). Recycling of Sewage Sludge: Synthesis and Application of Sludge-Based Activated Carbon in the Efficient Removal of Cadmium (II) and Lead (II) from Wastewater. International Journal of Molecular Sciences, 25(18), 9866. https://doi.org/10.3390/ijms25189866