Thermal Properties and Crystallite Morphology of Nylon 66 Modified with a Novel Biphenyl Aromatic Liquid Crystalline Epoxy Resin

Abstract

:1. Introduction

2. Results and Discussion

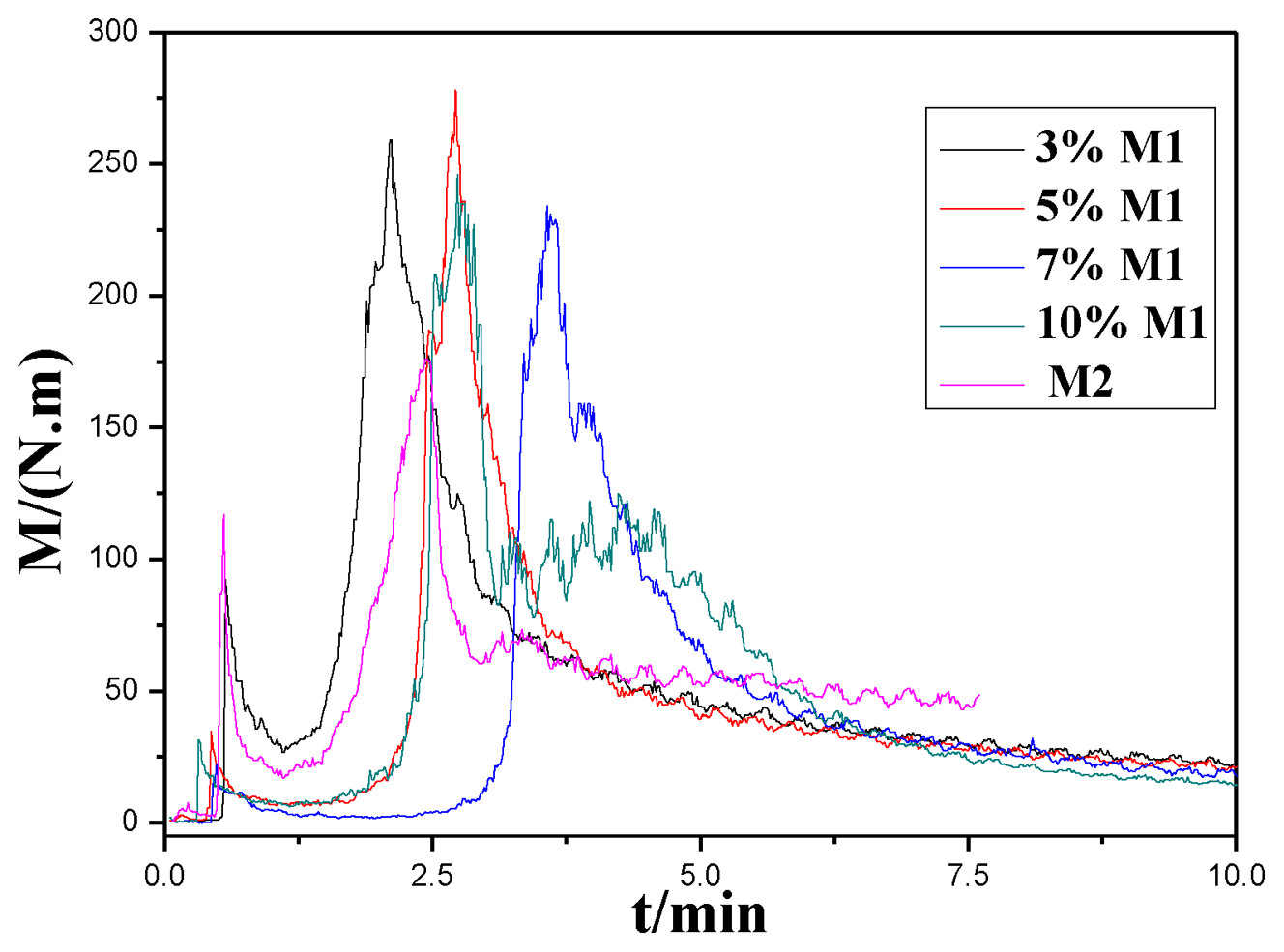

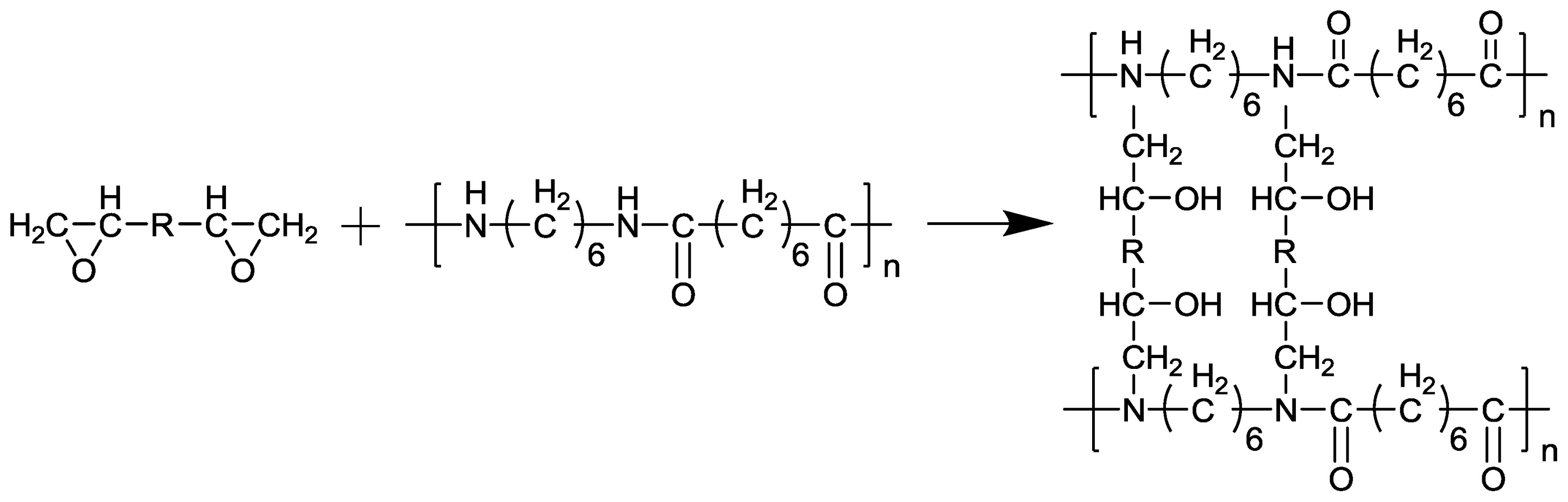

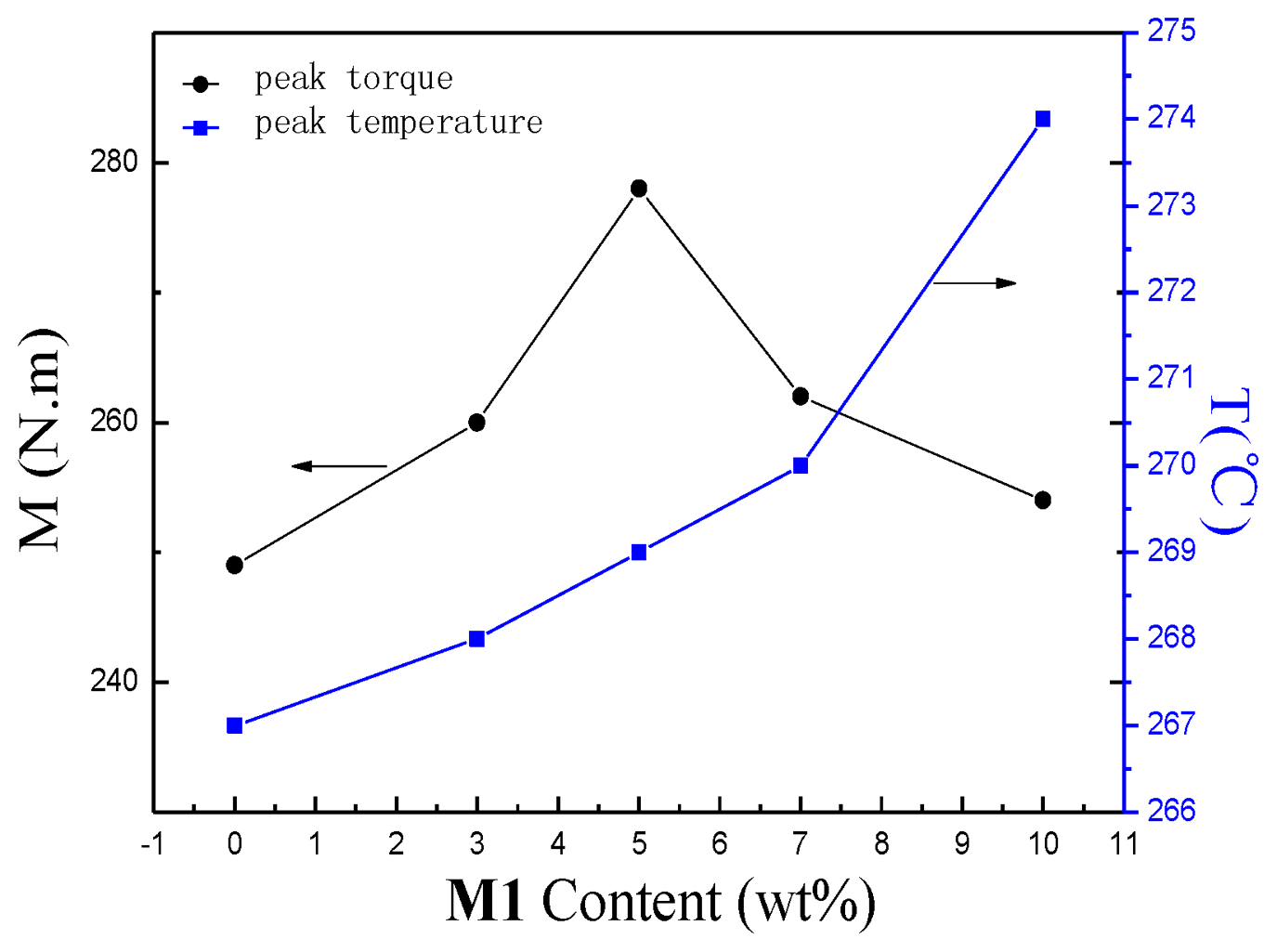

2.1. Mixing Analysis

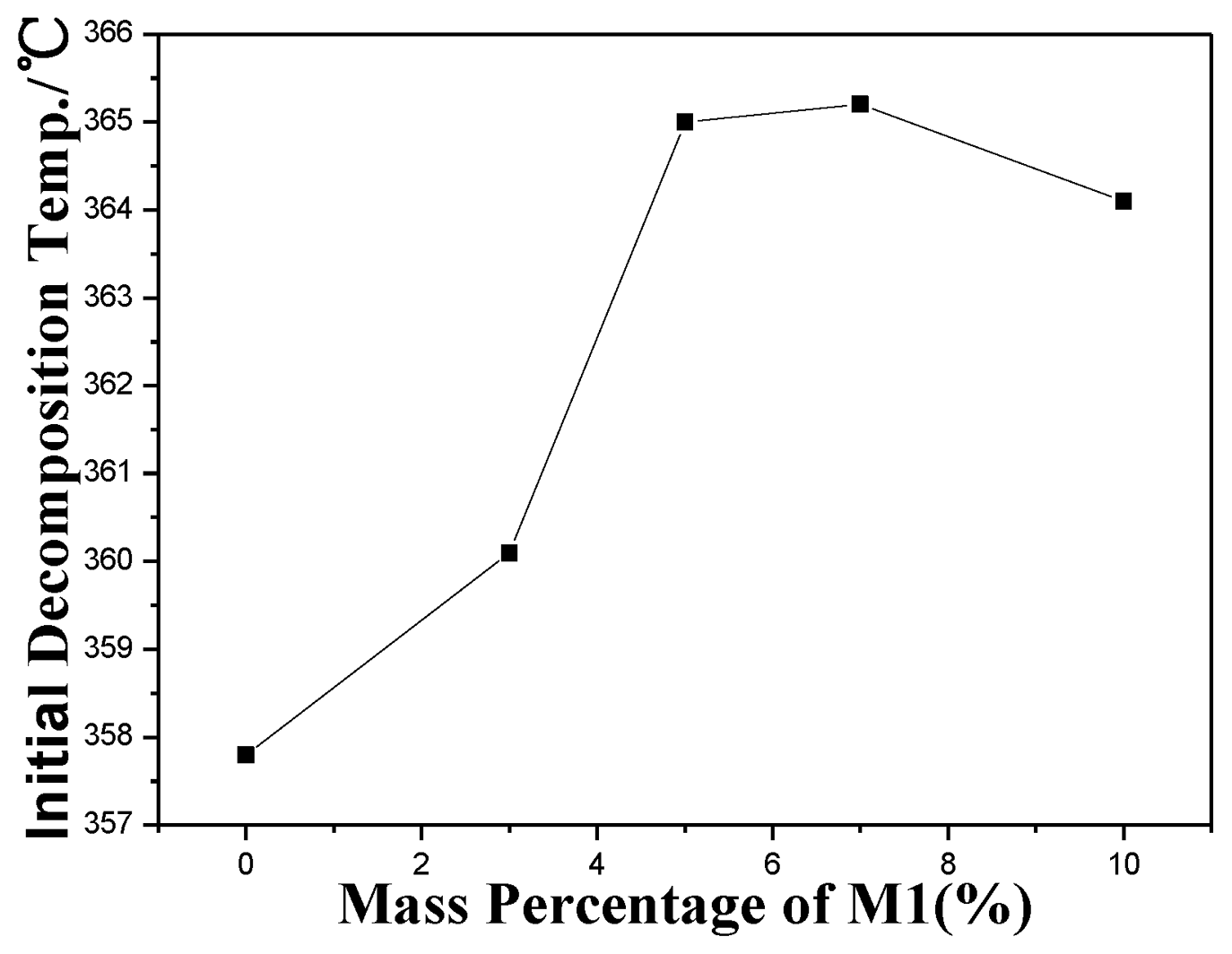

2.2. Thermogravimetric Analysis

2.3. Differential Scanning Calorimetry Analysis

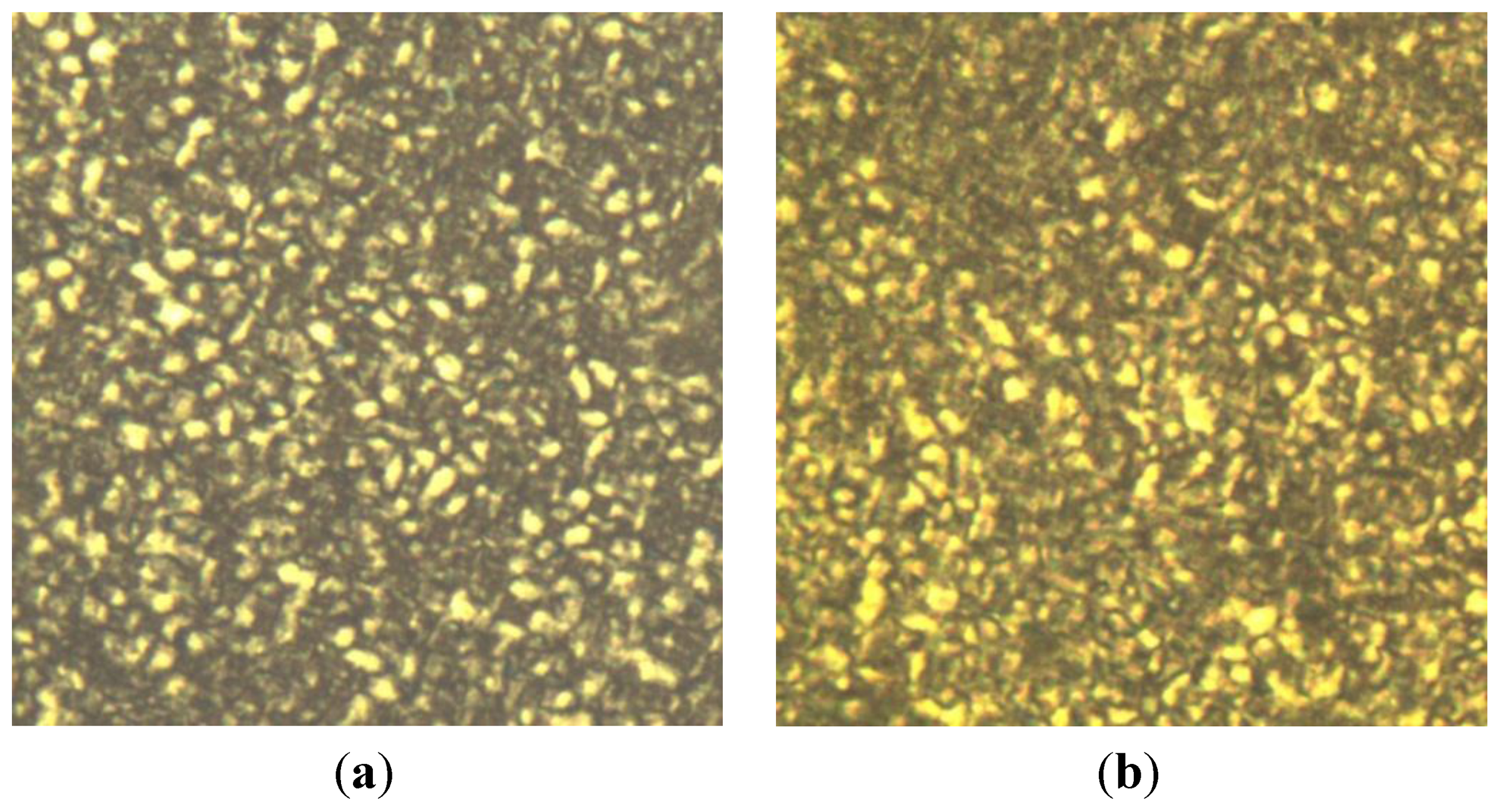

2.4. Crystallite Morphology

3. Experimental Section

4. Conclusions

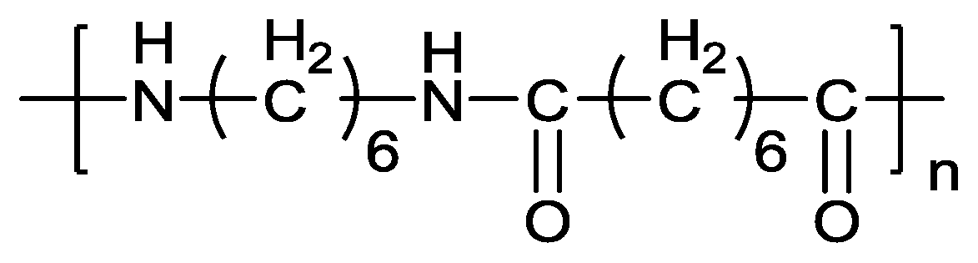

| Monomer | Constitutions Formula |

|---|---|

| M1 |  |

| M2 |  |

| ø | 0 | 3 | 5 | 7 | 10 |

|---|---|---|---|---|---|

| Tdi (°C) | 358 | 360 | 365 | 365 | 364 |

| Td (°C) | 381 | 382 | 386 | 389 | 388 |

| Tdt (°C) | 402 | 402 | 398 | 407 | 406 |

| ø | 0 | 3 | 5 | 7 | 10 |

|---|---|---|---|---|---|

| Tm/°C | 251.2 | 247.2 | 241.5 | 239.1 | 231.1 |

| Tmo/°C | 238.1 | 229.5 | 221.1 | 218.9 | 211.4 |

| Tmf/°C | 260.0 | 254.0 | 248.8 | 247.6 | 240.6 |

| ΔTm/°C | 21.9 | 24.5 | 27.7 | 28.7 | 29.2 |

| ΔHm/(J.g−1) | 16.5 | 15.9 | 11.8 | 10 | 12.3 |

Acknowledgments

Conflicts of Interest

References

- Flood, P.W.; Mason, C.D.; Schulze, S.R. High Impact Molding Compositions. E.P. 002796(A1), 2 June 1982. [Google Scholar]

- Baer, M. Multiphase Core/Shell Polymers. U.S. Patent 4375532, 1 March 1983. [Google Scholar]

- Anbarasan, R.; Muthumani, N.; Vasudevan, T.; Gopalan, A.; Wen, T.C. Chemical grafting of polyaniline onto nylon 66 fiber in different media. J. Appl. Polym. Sci 2001, 79, 1283–1296. [Google Scholar]

- Huang, Y.; Li, W.H.; Yan, D.Y. Preparation and characterization of a series of polyamides with long alkylene segments: Nylons 12 20, 10 20,s 20, 6 20, 4 20 and 2 20. Polym. Bull 2002, 49, 111–118. [Google Scholar]

- Krumova, M.; Flores, A.; Calleja, F.B.; Fakirov, S. Elastic properties of oriented polymers, blends and reinforced composites using the microindentation technique. Colloid Polym. Sci 2002, 280, 591–598. [Google Scholar]

- Singh, D.; Malhotra, V.P.; Vats, J.L. The dynamic mechanical analysis, impact, and morphological studies of EPDM-PVC and MMA-g-EPDM-PVC blends. J. Appl. Polym. Sci 1999, 71, 1959–1968. [Google Scholar]

- Tomova, D.; Radusch, H.J. Morphology and properties of ternary polyamide 6/polyamide 66/elastomer blends. Polym. Adv. Technol 2003, 14, 19–26. [Google Scholar]

- Ebeling, T.; Norek, S.; Hasan, A.; Hiltner, A.; Baer, E. Effect of a tie layer on the delamination toughness of polypropylene and polyamide-66 microlayers. J. Appl. Polym. Sci 2007, 71, 1461–1468. [Google Scholar]

- Gellert, E.P.; Pattie, S.D.; Woodward, R.L. Energy transfer in ballistic perforation of fiber reinforced composites. J. Mater. Sci 1998, 33, 1845–1850. [Google Scholar]

- Javangula, S.; Ghorashi, B.; Draucker, C.C. Mixing of glass fibers with nylon 6,6. J. Mater. Sci 1999, 34, 5143–5151. [Google Scholar]

- Zhang, Q.X.; Yu, Z.Z.; Yang, M.S.; Ma, J.; Mai, Y.W. Multiple melting and crystallization of nylon-66/montmorillonite nanocomposites. J. Polym. Sci. B 2003, 41, 2861–2869. [Google Scholar]

- Yu, Z.Z.; Yang, M.S.; Zhang, Q.X.; Zhao, C.G.; Mai, Y.W. Dispersion and distribution of organically modified montmorillonite in nylon-66 matrix. J. Polym. Sci. B 2003, 41, 1234–1243. [Google Scholar]

- La Mantia, F.P.; Valenza, A.; Paci, M.; Magagnini, P.L. Liquid crystal polymers (LCP) as processing aids and reinforcing agents: A study of nylon 6/LCP blends. J. Appl. Polym. Sci 1989, 38, 583–589. [Google Scholar]

- Bose, S.; Mukherjee, M.; Rath, T.; Das, C.K. Effect of Polyphosphazene on the properties of blend of nylon 66/thermotropic liquid crystalline polymer. J. Reinforce. Plast. Compos 2009, 28, 157–166. [Google Scholar]

- Liu, Y.L.; Cai, Z.Q.; Wen, X.; Pi, P.; Zheng, D.; Cheng, J.; Yang, Z. A new and efficient synthetic method of a liquid crystalline epoxy resin with biphenol and aromatic ester group. Polym. Bull 2010, 67, 57–66. [Google Scholar]

- Liu, Y.L.; Cai, Z.Q.; Wang, W.C.; Wen, X.; Pi, P.; Zheng, D.; Cheng, J.; Yang, Z. Mechanical properties and morphology studies of thermosets from a liquid-crystalline epoxy resin with biphenol and aromatic ester groups. Macromol. Mater. Eng 2011, 296, 83–91. [Google Scholar]

- Wang, W.; He, J.; Pi, P.; Cai, Z.; Ye, H.; Xu, S.; Wen, X.; Cheng, J. Thermal properties of liquid crystalline epoxy resin/glass fiber-reinforced nylon 66. Proceedings of Annual Technical Conference-Society of Plastics Engineers, Orlando, FL, USA, 2012; pp. 655–659.

- He, M.J.; Chen, W.X.; Dong, X.X. Physics of High Polymers; Revised ed.; Fudan University Press: Shanghai, China, 1990; pp. 34–96. [Google Scholar]

- Feng, Y.X.; Ling, L.Q.; Ping, C.Z.; Feng, Y.Y.; Lei, Z. Study on crystallization behaviour of co-polyamide 66 containing triarylphosphine oxide. Bull. Mater. Sci 2012, 35, 233–242. [Google Scholar]

- Muellerleile, J.T.; Freeman, J.J. Effect of solvent precipitation on the crystallization behavior and morphology of nylon 6,6. J. Appl. Polym. Sci 1994, 54, 135–152. [Google Scholar]

- Huang, Y.W.; Liu, W.T.; He, S.Q.; Li, Z.Y.; Xu, S.Z.; Wu, L.S.; Zhu, C.S. Preparation and characterization of pa66/amine-based carbon nanotube composites. China Plast. Ind 2010, 38, 61–64. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Cai, Z.; Mei, S.; Lu, Y.; He, Y.; Pi, P.; Cheng, J.; Qian, Y.; Wen, X. Thermal Properties and Crystallite Morphology of Nylon 66 Modified with a Novel Biphenyl Aromatic Liquid Crystalline Epoxy Resin. Int. J. Mol. Sci. 2013, 14, 20682-20691. https://doi.org/10.3390/ijms141020682

Cai Z, Mei S, Lu Y, He Y, Pi P, Cheng J, Qian Y, Wen X. Thermal Properties and Crystallite Morphology of Nylon 66 Modified with a Novel Biphenyl Aromatic Liquid Crystalline Epoxy Resin. International Journal of Molecular Sciences. 2013; 14(10):20682-20691. https://doi.org/10.3390/ijms141020682

Chicago/Turabian StyleCai, Zhiqi, Shuang Mei, Yuan Lu, Yuanqi He, Pihui Pi, Jiang Cheng, Yu Qian, and Xiufang Wen. 2013. "Thermal Properties and Crystallite Morphology of Nylon 66 Modified with a Novel Biphenyl Aromatic Liquid Crystalline Epoxy Resin" International Journal of Molecular Sciences 14, no. 10: 20682-20691. https://doi.org/10.3390/ijms141020682

APA StyleCai, Z., Mei, S., Lu, Y., He, Y., Pi, P., Cheng, J., Qian, Y., & Wen, X. (2013). Thermal Properties and Crystallite Morphology of Nylon 66 Modified with a Novel Biphenyl Aromatic Liquid Crystalline Epoxy Resin. International Journal of Molecular Sciences, 14(10), 20682-20691. https://doi.org/10.3390/ijms141020682