Valorization of Agricultural Wastes into Environmentally Sustainable Asphalt Binders

Abstract

1. Introduction

2. Results

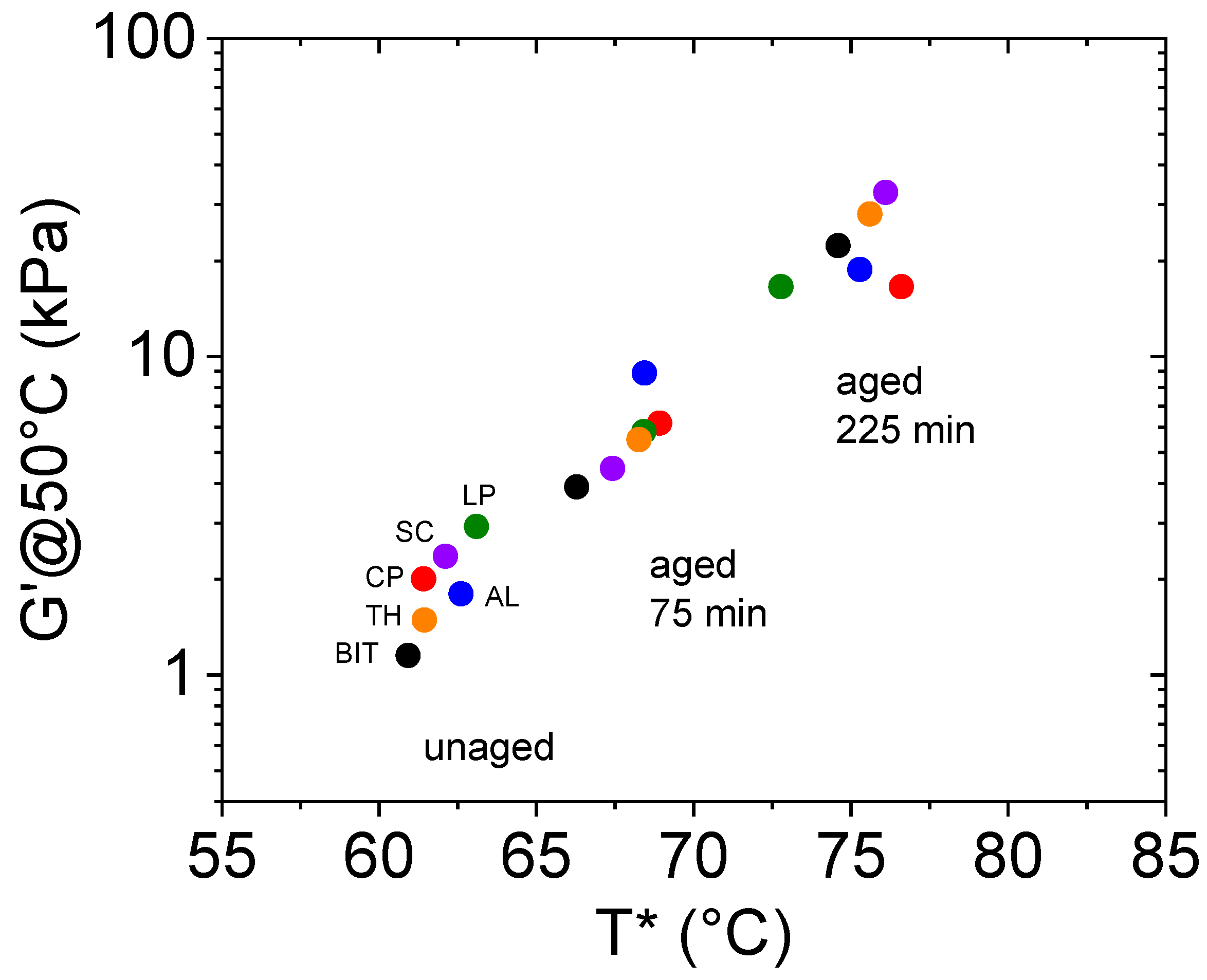

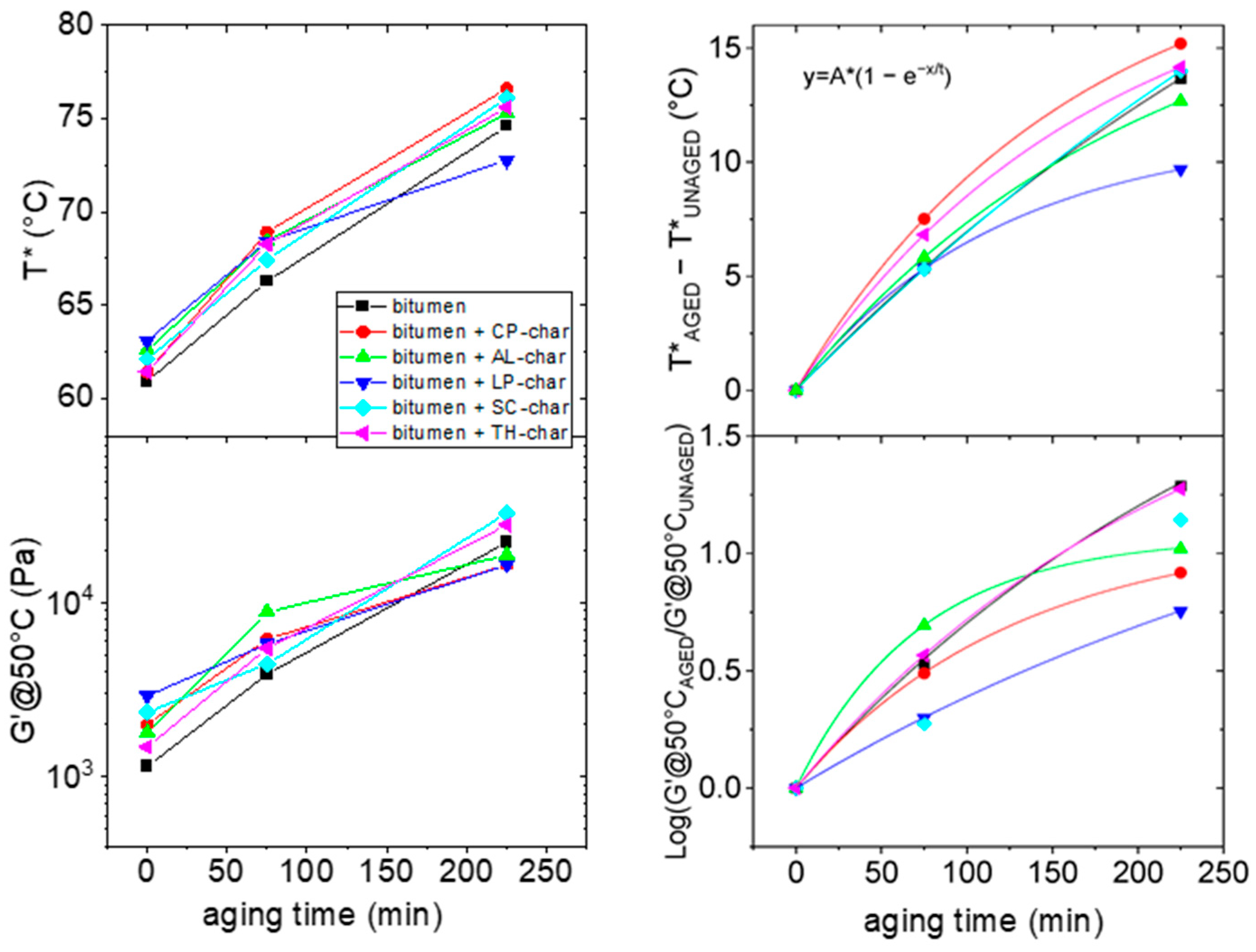

2.1. Rheological Properties

- (1)

- The increase in transition temperature (ΔT = T*AGED − T*UNAGED) after a given aging tune, i.e., the values obtained from differences between the T* recorded after and before the aging process RTFOT under short (75 min) and long (225 min) times.

- (2)

- The increase in the G′@50°C value, calculated as the logarithm of the quantity (G′@50°CAGED/G′@50°CUNAGED) i.e., the ratio of G′@50°C recorded after and before the aging process RTFOT under short (75 min) and long (225 min) times.

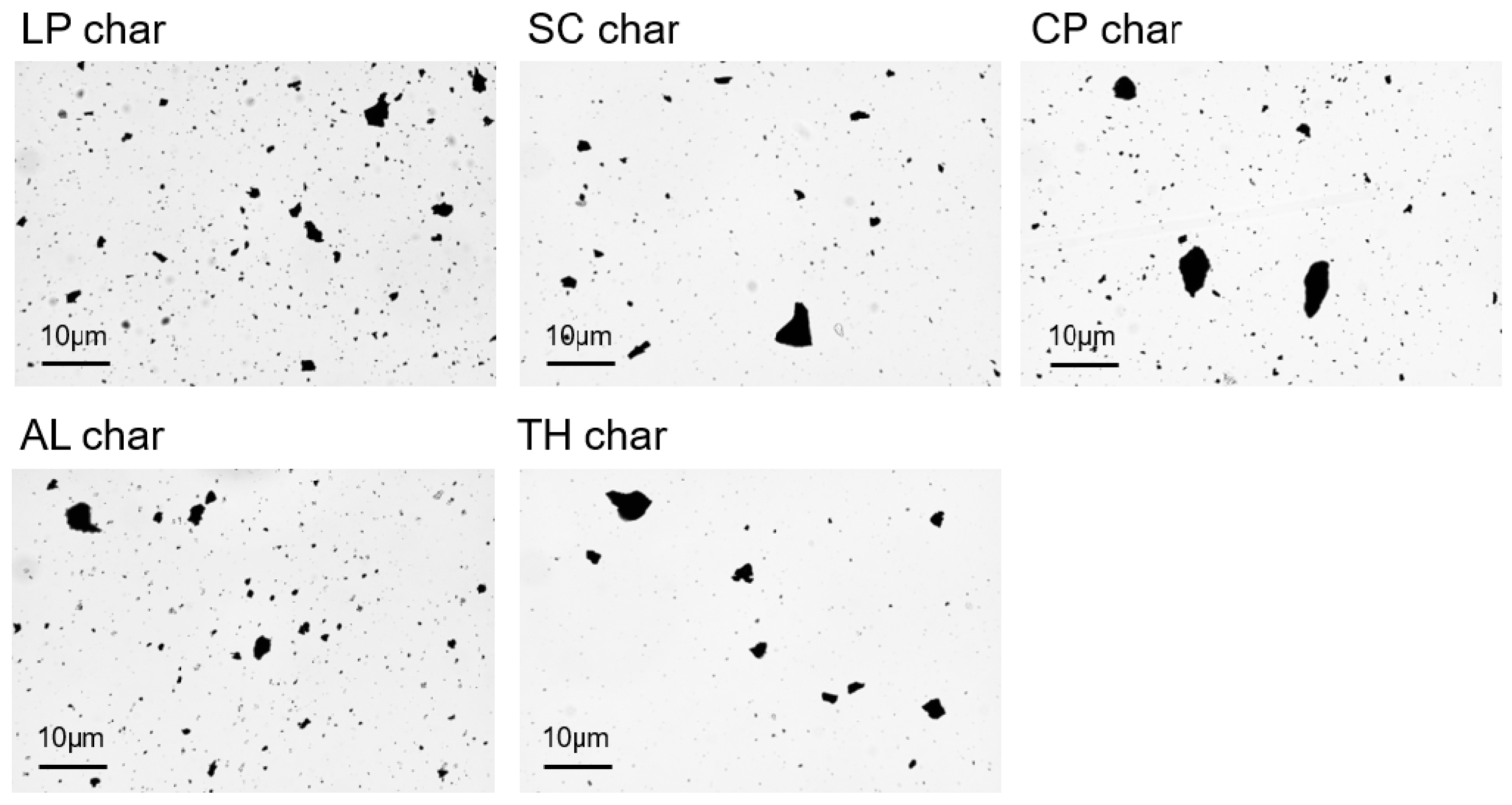

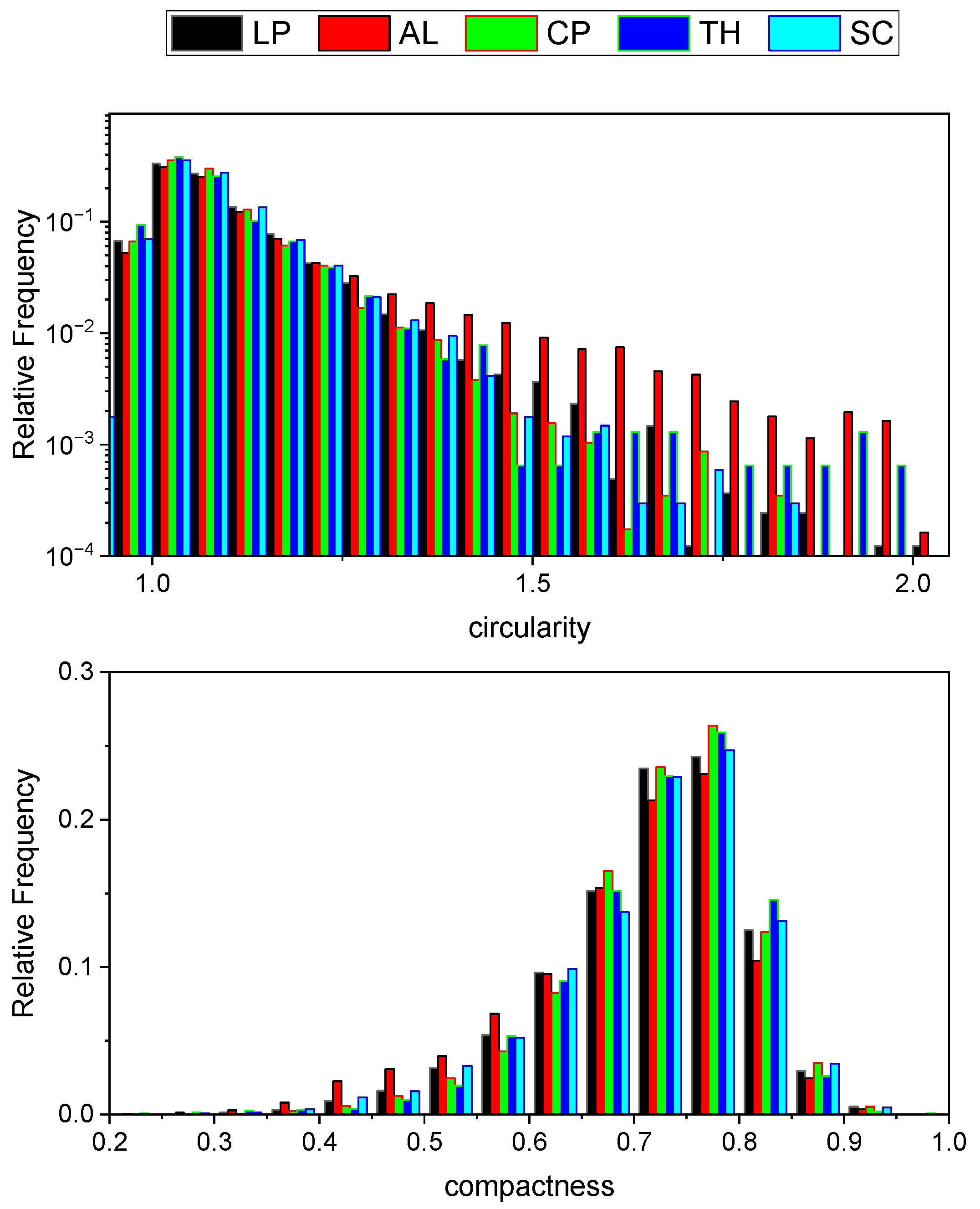

2.2. Char Characterization (Morphology)

- The CP-char sample shows the presence of a bump in the range 20–50 µm suggesting the tendency towards a bimodal distribution. Even if the relative abundance of the bigger particles is limited, being less than one order of magnitude lower than the smaller ones in number, it must be noted that in terms of mass, such bigger particles constitute the majority of the sample. The volume indeed scales with the third power of the diameter, so the bigger particles are ~10 times larger and consequently have a volume ~1000 times higher than the smaller ones, a difference that outweighs their lower abundance.

- The TH-char sample shows a slightly broader size distribution. The presence of bigger particles whose diameter can extend up to 100 µm is notable, as well as the consequently slightly lower frequency of occurrence of particles in the range 3–10 µm in the size distribution. Quantitatively, the polydispersity, measured as the standard deviation of the diameter values, is around 8 when compared to the values for the other samples ranging in the 4–6.5 interval.

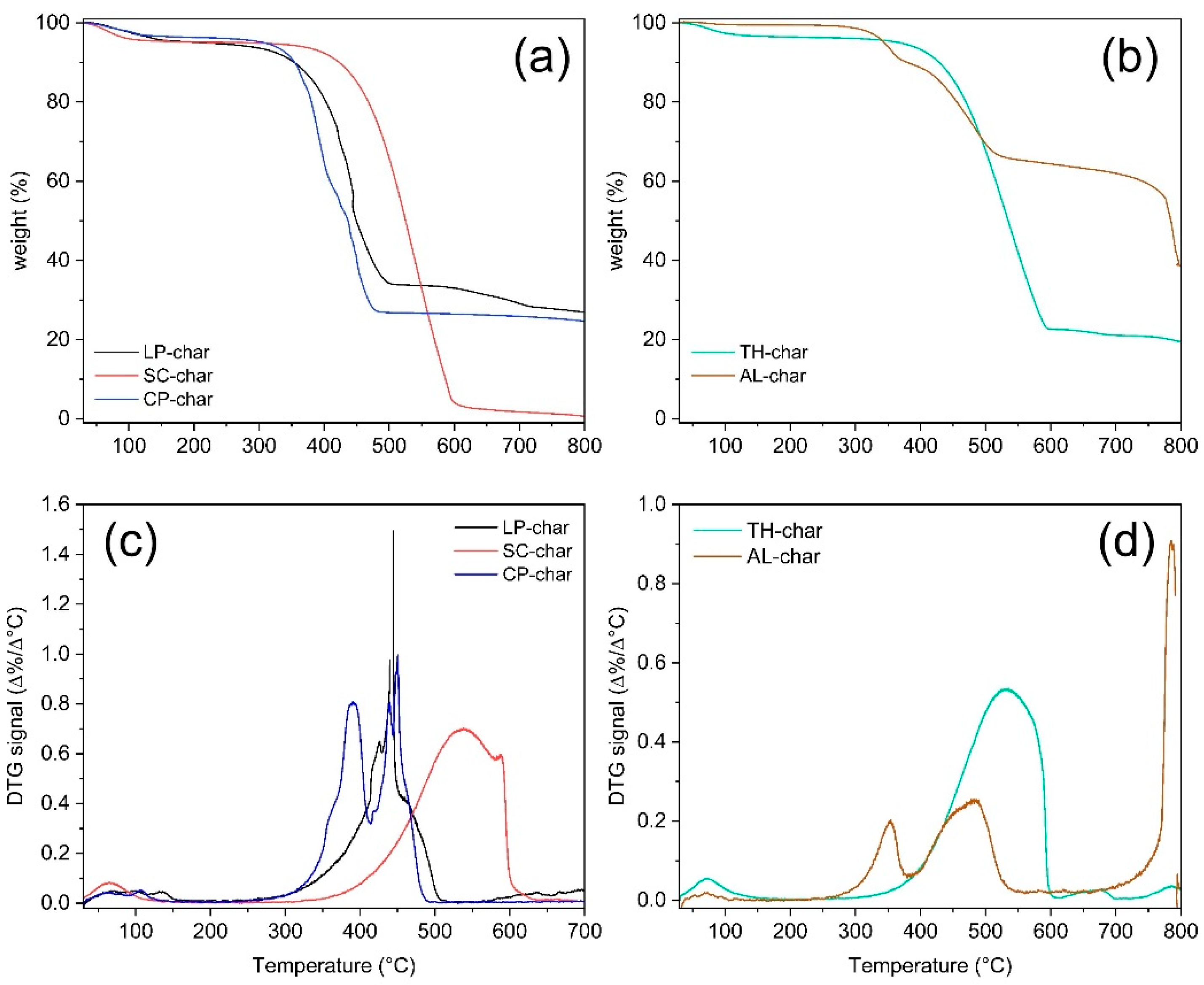

2.3. Char Characterization (Thermal Behavior, Chemical Composition, and Contact Angle)

3. Materials and Methods

3.1. Materials

3.2. Biochar Production

3.3. Preparation of Bitumen–Char Composites

3.4. Aging Tests

3.5. Structural Characterization Methods

4. Conclusions

- Biochars derived from selected biomass sources through pyrolysis have been structurally characterized, resulting in the identification of key properties for each char: alkali lignin yielded high-aromatic char, shrimp chitosan and thistle (Cirsium vulgare) produced nitrogen-rich chars, and lemon peel and citrus pectin produced oxygen-rich chars;

- All the produced chars have been tested as bitumen modifiers and antioxidant agents;

- All the tested chars were found to have limited modifying properties towards the gel-to-sol transition temperature, resulting in an increase of only 0.5 to 2.5 °C, significantly lower than the ~4 °C increase observed with CaCO3 addition.

- Among the samples, lemon peel-derived char (LP-char) showed superior antioxidant properties against bitumen oxidative aging: after a long aging time (225 min), the T* of the bitumen loaded with LP-char is ~10 °C higher than that of the unaged sample, conversely, that of the other char-loaded bitumen samples is above 13 °C;

- The antioxidant effect of LP-char was found to not be primarily related to particle morphology (size and shape), but instead associated with chemical attributes, including lowest hydrogen content, high carbon and inorganic elemental contents, and lowest hydrophobicity, which enhanced the interactions with the bituminous molecular matrix;

- A key insight of this study is that specific chemical characteristics may serve as predictive indicators of antioxidant activity in biochars derived from biomass pyrolysis.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bao, D.-X.; Yu, Y.-Y.; Zhao, Q.-M. Evaluation of the chemical composition and rheological properties of bio-asphalt from different biomass sources. Road Mater. Pavement Des. 2020, 21, 1829–1843. [Google Scholar] [CrossRef]

- Malinowski, S.; Woszuk, A.; Wróbel, M.; Makowska, M.; Franus, W.; Zofka, A. Bitumen binders modified with chemically-crosslinked chitosan. Road Mater. Pavement Des. 2023, 24, 3–18. [Google Scholar] [CrossRef]

- Woszuk, A.; Wróbel, M.; Bandura, L.; Franus, W. Brick Debris Dust as an Ecological Filler and Its Effect on the Durability of Asphalt Mix. Materials 2020, 13, 5023. [Google Scholar] [CrossRef]

- Holleran, I.; Wilson, D.J.; Masad, E.; Holleran, G.; Alrashydah, E. Effect of bio-rejuvenator on recycled porous asphalt mixes. Road Mater. Pavement Des. 2023, 24, 340–366. [Google Scholar] [CrossRef]

- Wróbel, M.; Woszuk, A.; Ratajczak, M.; Franus, W. Properties of reclaimed asphalt pavement mixture with organic rejuvenator. Constr. Build. Mater. 2021, 271, 121514. [Google Scholar] [CrossRef]

- Vinet-Cantot, J.; Gaudefroy, V.; Delfosse, F.; Chailleux, E.; Crews, E. Stripping at the Bitumen–Aggregate Interface: A Laboratory Method To Assess the Loss of Chemical Adhesion. Energy Fuels 2019, 33, 2641–2650. [Google Scholar] [CrossRef]

- Alessandro, B.; del Barco Carrión, A.J.; Davide, L.P.; Filippo, G. Effects of Laboratory Aging on Properties of Biorejuvenated Asphalt Binders. J. Mater. Civ. Eng. 2017, 29, 4017149. [Google Scholar] [CrossRef]

- Robertson, G.; Adiningtyas, K.V.; Ebrahim, S.A.; Scoles, L.; Baranova, E.A.; Singh, D. Understanding the nature of bio-asphaltenes produced during hydrothermal liquefaction. Renew. Energy 2021, 173, 128–140. [Google Scholar] [CrossRef]

- Nagtode, V.S.; Cardoza, C.; Yasin, H.K.A.; Mali, S.N.; Tambe, S.M.; Roy, P.; Singh, K.; Goel, A.; Amin, P.D.; Thorat, B.R.; et al. Green Surfactants (Biosurfactants): A Petroleum-Free Substitute for Sustainability─Comparison, Applications, Market, and Future Prospects. ACS Omega 2023, 8, 11674–11699. [Google Scholar] [CrossRef]

- Pérez, I.P.; Rodríguez Pasandín, A.M.; Pais, J.C.; Alves Pereira, P.A. Use of lignin biopolymer from industrial waste as bitumen extender for asphalt mixtures. J. Clean. Prod. 2019, 220, 87–98. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Chaves-Pabón, S.B.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Use of Biochar in Asphalts: Review. Sustainability 2022, 14, 4745. [Google Scholar] [CrossRef]

- Gan, X.; Zhang, W. Application of biochar from crop straw in asphalt modification. PLoS ONE 2021, 16, e0247390. [Google Scholar] [CrossRef]

- Rajib, A.; Saadeh, S.; Katawal, P.; Mobasher, B.; Fini, E.H. Enhancing Biomass Value Chain by Utilizing Biochar as A Free Radical Scavenger to Delay Ultraviolet Aging of Bituminous Composites Used in Outdoor Construction. Resour. Conserv. Recycl. 2021, 168, 105302. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Ji, J.; Wang, H. Viscoelastic Properties, Rutting Resistance, and Fatigue Resistance of Waste Wood-Based Biochar-Modified Asphalt. Coatings 2022, 12, 89. [Google Scholar] [CrossRef]

- Celauro, C.; Teresi, R.; Dintcheva, N.T. Evaluation of Anti-Aging Effect in Biochar-Modified Bitumen. Sustainability 2023, 15, 10583. [Google Scholar] [CrossRef]

- Nair, R.; Bandyopadhyay, A.; Sunitha, V. Rheological and Mechanical Behaviour of Biochar-Modified Bitumen Under High-Temperature Conditions. Int. J. Pavement Res. Technol. 2025. [Google Scholar] [CrossRef]

- Yegane, M.; Katanalp, B.Y.; Ahmedzade, P. Effects of using biochar materials obtained from cherry and sour cherry wastes on bitumen modification. Constr. Build. Mater. 2025, 470, 140609. [Google Scholar] [CrossRef]

- Zhou, J.; Dong, Z.; Yu, Y.; Sun, Z.; Zhou, T.; Chen, Z. Utilization of biochar derived from rice straw in petroleum bitumen: Agricultural waste recycling and pavement sustainability. J. Clean. Prod. 2025, 490, 144808. [Google Scholar] [CrossRef]

- Wani, I.; Garg, A. Critical review on use of biochar as a modifier in asphaltic binders for pavement construction. Environ. Dev. Sustain. 2024, e0247390. [Google Scholar] [CrossRef]

- Musco, A.; Tarsi, G.; Tataranni, P.; Salzano, E.; Sangiorgi, C. Use of bio-based products towards more sustainable road paving binders: A state-of-the-art review. J. Road Eng. 2024, 4, 151–162. [Google Scholar] [CrossRef]

- Afraz, M.; Muhammad, F.; Nisar, J.; Shah, A.; Munir, S.; Ali, G.; Ahmad, A. Production of value added products from biomass waste by pyrolysis: An updated review. Waste Manag. Bull. 2024, 1, 30–40. [Google Scholar] [CrossRef]

- Liu, W.-J.; Jiang, H.; Yu, H.-Q. Development of Biochar-Based Functional Materials: Toward a Sustainable Platform Carbon Material. Chem. Rev. 2015, 115, 12251–12285. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Ye, X.P.; Shu, X.; Jia, X. Utilizing bio-char as a bio-modifier for asphalt cement: A sustainable application of bio-fuel by-product. Fuel 2014, 133, 52–62. [Google Scholar] [CrossRef]

- Penki, R.; Rout, S. Next-generation bitumen: A review on challenges and recent developments in bio-bitumen preparation and usage. Biomass Convers. Biorefinery 2021, 13, 9583–9600. [Google Scholar] [CrossRef]

- Caputo, P.; Calandra, P.; Loise, V.; Le Pera, A.; Putz, A.-M.; Abe, A.A.; Madeo, L.; Teltayev, B.; Luprano, M.L.; Alfè, M.; et al. When Physical Chemistry Meets Circular Economy to Solve Environmental Issues: How the ReScA Project Aims at Using Waste Pyrolysis Products to Improve and Rejuvenate Bitumens. Sustainability 2022, 14, 5790. [Google Scholar] [CrossRef]

- Somé, C. Rheological behavior of vegetable oil-modified asphaltite binders and mixes. In Proceedings of the 6th Eurasphalt & Eurobitume, Prague, Czech Republic, 1–3 June 2016. [Google Scholar]

- Oliviero Rossi, C.; Caputo, P.; Loise, V.; Miriello, D.; Teltayev, B.; Angelico, R. Role of a food grade additive in the high temperature performance of modified bitumens. Colloids Surfaces A Physicochem. Eng. Asp. 2017, 532, 618–624. [Google Scholar] [CrossRef]

- Caputo, P.; Calandra, P.; Policicchio, A.; Conte, G.; Agostino, R.G.; Pochylski, M.; Abe, A.; Oliviero Rossi, C. Char from Pyrolysis of Waste Tires to Increase Bitumen Performances. Appl. Sci. 2024, 14, 30. [Google Scholar] [CrossRef]

- Verma, M.; Saboo, N. Use of antioxidants to retard aging of bitumen: A review. Environ. Sci. Pollut. Res. 2024, 31, 48839–48863. [Google Scholar] [CrossRef]

- Maziarka, P.; Kienzl, N.; Dieguez-Alonso, A.; Prins, W.; Arauzo, P.J.; Skreiberg, Ø.; Anca-Couce, A.; Manyà, J.J.; Ronsse, F. Part 2—Tailoring of Pyrolytic Char Properties with a Single Particle CFD Model with a Focus on the Impact of Shrinking, Vapor Cracking, and Char Permeability. Energy Fuels 2024, 38, 9772–9793. [Google Scholar] [CrossRef]

- Lushinga, N.; Cao, L.; Dong, Z. Effect of Silicone Oil on Dispersion and Low-Temperature Fracture Performance of Crumb Rubber Asphalt. Adv. Mater. Sci. Eng. 2019, 2019, 8602562. [Google Scholar] [CrossRef]

- Venczel, M.; Bognár, G.; Veress, Á. Temperature-Dependent Viscosity Model for Silicone Oil and Its Application in Viscous Dampers. Processes 2021, 9, 331. [Google Scholar] [CrossRef]

- Rennhofer, H.; Zanghellini, B. Dispersion State and Damage of Carbon Nanotubes and Carbon Nanofibers by Ultrasonic Dispersion: A Review. Nanomaterials 2021, 11, 1469. [Google Scholar] [CrossRef] [PubMed]

- Champion-Lapalu, L.; Wilson, A.; Fuchs, G.; Martin, D.; Planche, J.-P. Cryo-Scanning Electron Microscopy: A New Tool for Interpretation of Fracture Studies in Bitumen/Polymer Blends. Energy Fuels 2002, 16, 143–147. [Google Scholar] [CrossRef]

- Stewart, P.L. Cryo-electron microscopy and cryo-electron tomography of nanoparticles. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2017, 9, e1417. [Google Scholar] [CrossRef]

- Murphy, D.B.; Davidson, M.W. Fundamentals of Light Microscopy and Electronic Imaging; Fundamentals of Light Microscopy and Electronic Imaging; John Wiley & Sons, Incorporated: New York, NY, USA, 2012; ISBN 9780471692140. [Google Scholar]

- Arnal, C.; Alfe, M.; Gargiulo, V.; Ciajolo, A.; Alzueta, M.U.; Millera, A.; Bilbao, R. Characterization of soot. In Developing Detailed Chemical Kinetic Models Series: Green Energy and Technology; Battin-Leclerc, F., Simmie, J.M., Blurock, E., Eds.; Springer: London, UK, 2013; pp. 333–362. [Google Scholar]

- Calandra, P.; Caputo, P.; De Santo, M.; Todaro, L.; Liveri, V.; Oliviero, C. Effect of additives on the structural organization of asphaltene aggregates in bitumen. Constr. Build. Mater. 2018, 199, 288–297. [Google Scholar] [CrossRef]

- Gargiulo, V.; Alfe, M.; Ruoppolo, G.; Cammarota, F.; Rossi, C.O.; Loise, V.; Porto, M.; Calandra, P.; Pochylski, M.; Gapinski, J.; et al. How char from waste pyrolysis can improve bitumen characteristics and induce anti-aging effects. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132199. [Google Scholar] [CrossRef]

- Hofko, B.; Hospodka, M. Rolling Thin Film Oven Test and Pressure Aging Vessel Conditioning Parameters: Effect on Viscoelastic Behavior and Binder Performance Grade. Transp. Res. Rec. 2016, 2574, 111–116. [Google Scholar] [CrossRef]

- Lu, G.; Zhang, S.; Xu, S.; Dong, N.; Yu, H. Rheological Behavior of Warm Mix Asphalt Modified with Foaming Process and Surfactant Additive. Crystals 2021, 11, 410. [Google Scholar] [CrossRef]

- Macosko, C.W.; Larson, R.G.; (Firm), K. Rheology: Principles, Measurements, and Applications; Advances in interfacial engineering series; VCH: Hoboken, NJ, USA, 1994; ISBN 9781560815792. [Google Scholar]

- Shillaber, C.P. Photomicrography in Theory and Practice; John Wiley & Sons, Incorporated: New York, NY, USA, 1944. [Google Scholar]

- Rickman, D.; Lohn-Wiley, B.; Knicely, J.; Hannan, B. Probabilistic solid form determined from 2D shape measurement. Powder Technol. 2016, 291, 466–472. [Google Scholar] [CrossRef]

- Giudicianni, P.; Gargiulo, V.; Grottola, C.M.; Alfè, M.; Ferreiro, A.I.; Mendes, M.A.A.; Fagnano, M.; Ragucci, R. Inherent Metal Elements in Biomass Pyrolysis: A Review. Energy Fuels 2021, 35, 5407–5478. [Google Scholar] [CrossRef]

| C (wt.%) | H (wt.%) | N (wt.%) | Other Elements (wt.%) * | |

|---|---|---|---|---|

| LP-char | 55.9 | 0.65 | 0.35 | 43.1 |

| AL-char | 57.7 | 0.70 | - | 41.6 |

| CP-char | 62.8 | 0.2 | - | 37.0 |

| SC-char | 70.8 | 1.50 | 8.50 | 19.2 |

| TH-char | 56.4 | 0.80 | 1.60 | 41.2 |

| Lipophilicity/ Lipophobicity (CA, °) | Hydrophilicity/ Hydrophobicity (CA, °) | Average Roughness (Ra, µm) | |

|---|---|---|---|

| LP-char | 51.96 | 28.90 | 0.44 |

| AL-char | 29.19 | 42.79 | 0.57 |

| CP-char | 45.35 | 35.04 | 0.23 |

| SC-char | 57.73 | 101.21 | 3.3 |

| TH-char | 25.89 | 132.83 | 1.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caputo, P.; Gargiulo, V.; Calandra, P.; Loise, V.; Cimino, L.; Clemente, C.; Kenzhegaliyeva, A.; Ongarbayev, Y.; Oliviero Rossi, C.; Pochilskj, M.; et al. Valorization of Agricultural Wastes into Environmentally Sustainable Asphalt Binders. Molecules 2025, 30, 3473. https://doi.org/10.3390/molecules30173473

Caputo P, Gargiulo V, Calandra P, Loise V, Cimino L, Clemente C, Kenzhegaliyeva A, Ongarbayev Y, Oliviero Rossi C, Pochilskj M, et al. Valorization of Agricultural Wastes into Environmentally Sustainable Asphalt Binders. Molecules. 2025; 30(17):3473. https://doi.org/10.3390/molecules30173473

Chicago/Turabian StyleCaputo, Paolino, Valentina Gargiulo, Pietro Calandra, Valeria Loise, Luciana Cimino, Claudio Clemente, Aliya Kenzhegaliyeva, Yerdos Ongarbayev, Cesare Oliviero Rossi, Mikołaj Pochilskj, and et al. 2025. "Valorization of Agricultural Wastes into Environmentally Sustainable Asphalt Binders" Molecules 30, no. 17: 3473. https://doi.org/10.3390/molecules30173473

APA StyleCaputo, P., Gargiulo, V., Calandra, P., Loise, V., Cimino, L., Clemente, C., Kenzhegaliyeva, A., Ongarbayev, Y., Oliviero Rossi, C., Pochilskj, M., Gapinski, J., & Alfè, M. (2025). Valorization of Agricultural Wastes into Environmentally Sustainable Asphalt Binders. Molecules, 30(17), 3473. https://doi.org/10.3390/molecules30173473