Production of Long-Fiber Pulp from Enset Plant Residues by Soda Pulping

Abstract

1. Introduction

2. Results and Discussion

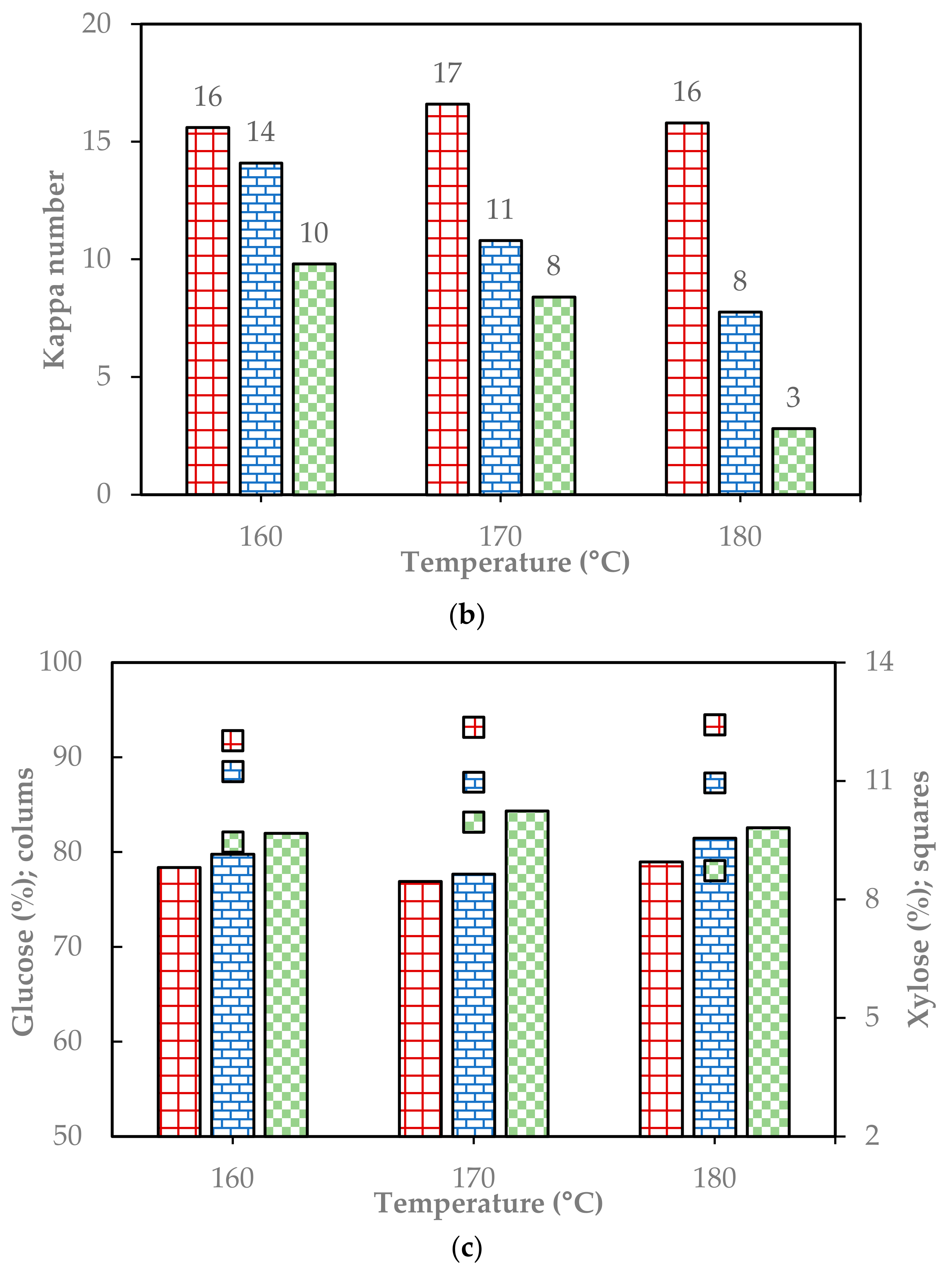

2.1. Laboratory-Scale Soda Pulping and Jokro Mill Beating

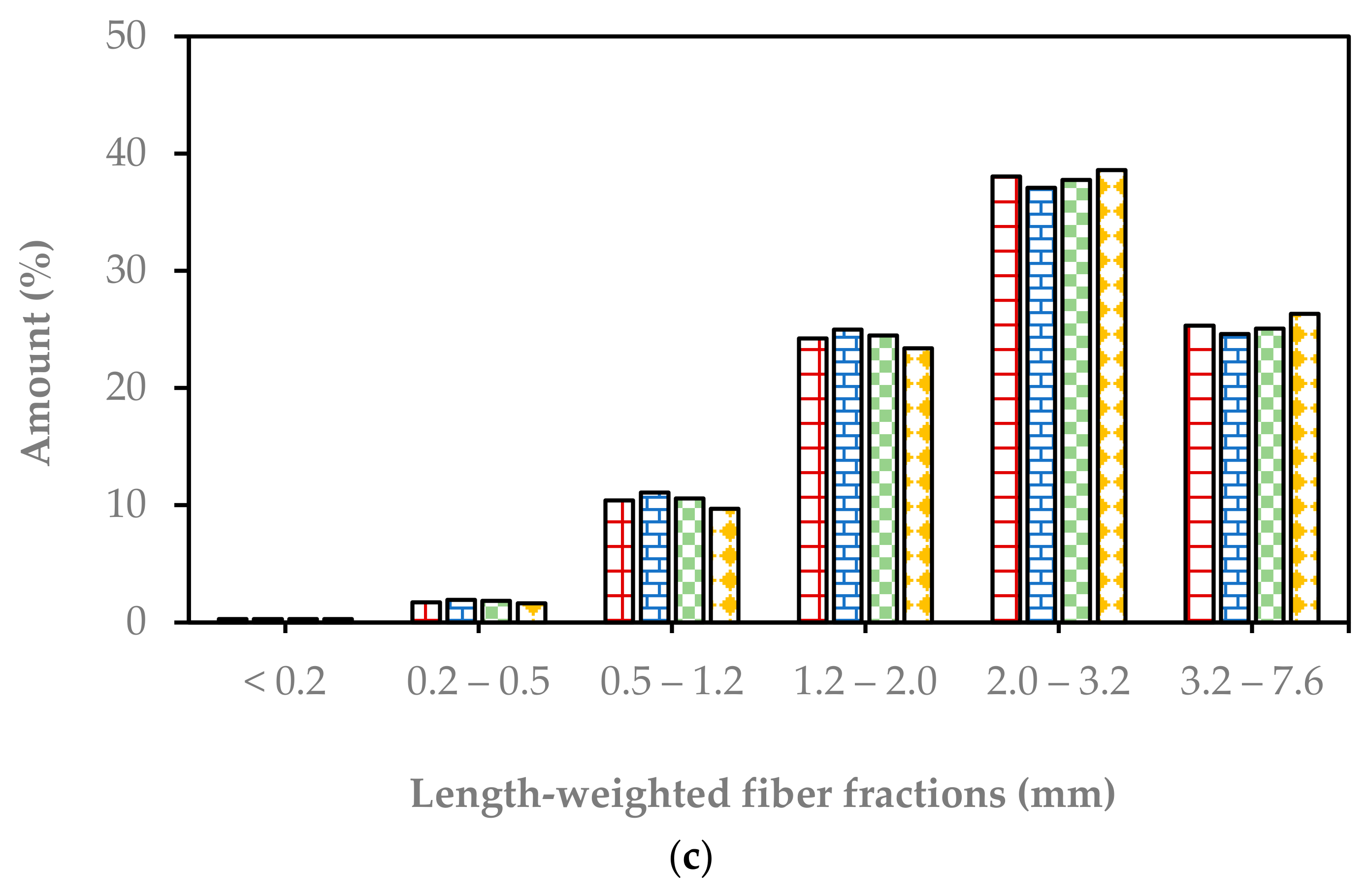

2.2. Pilot-Scale Soda Pulping

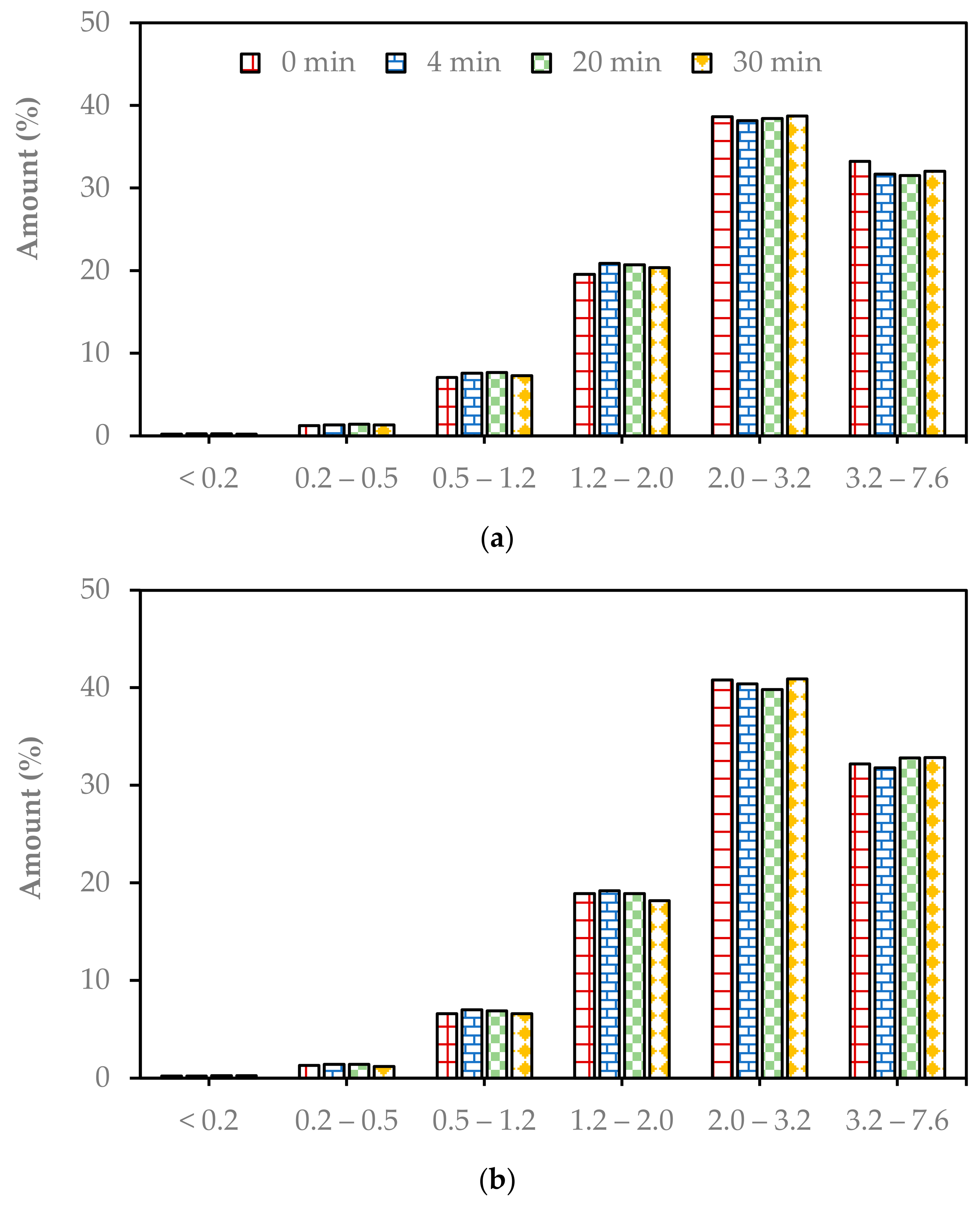

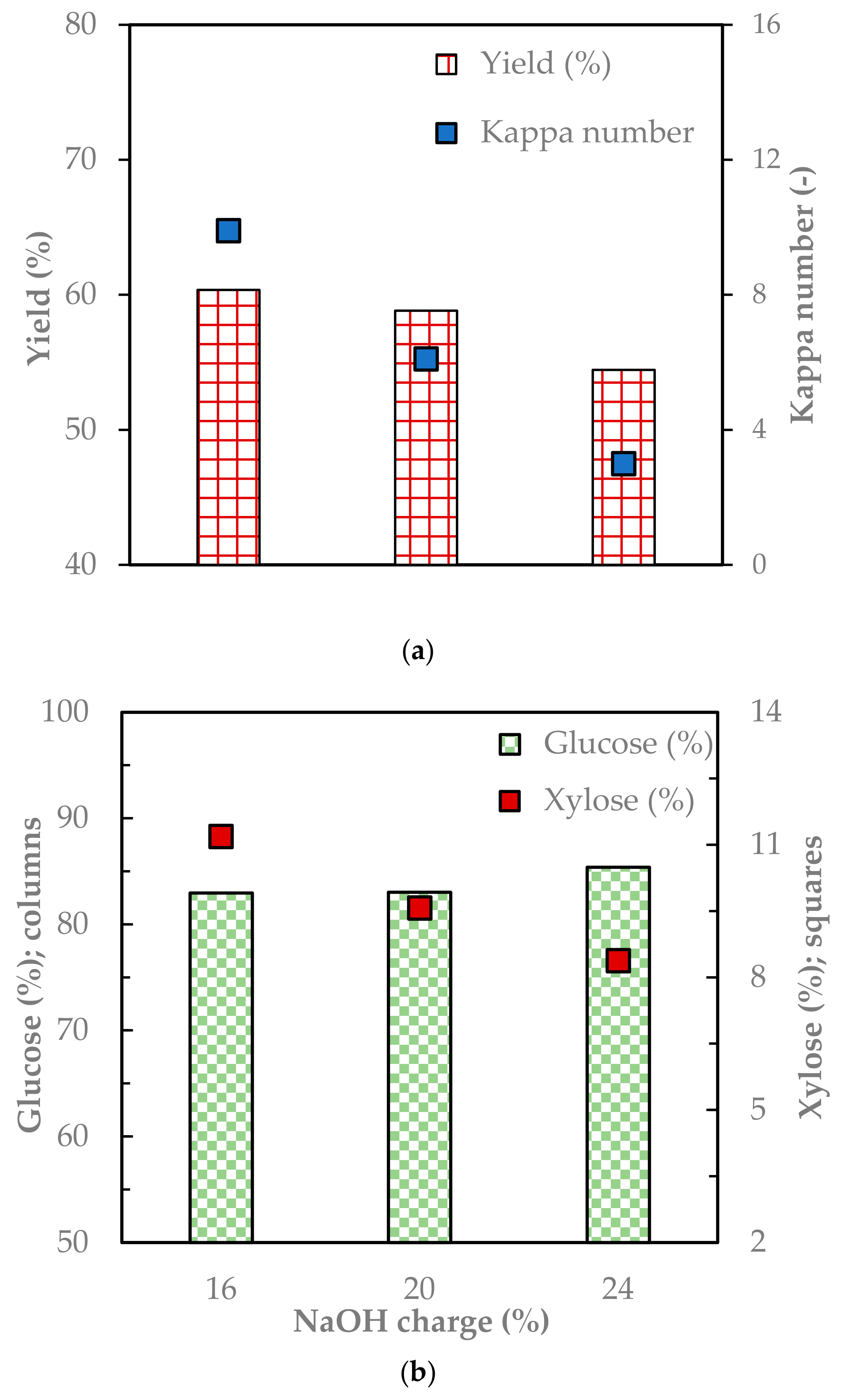

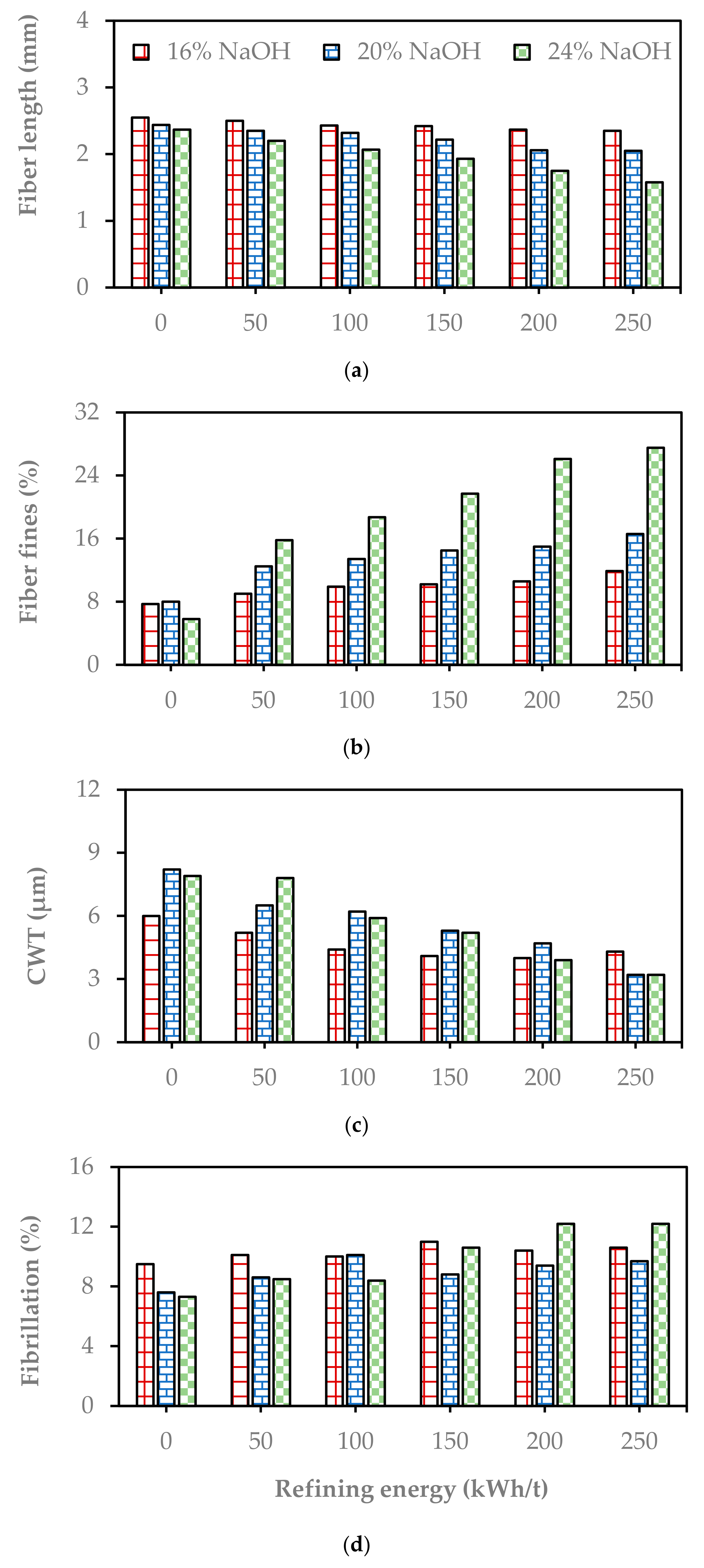

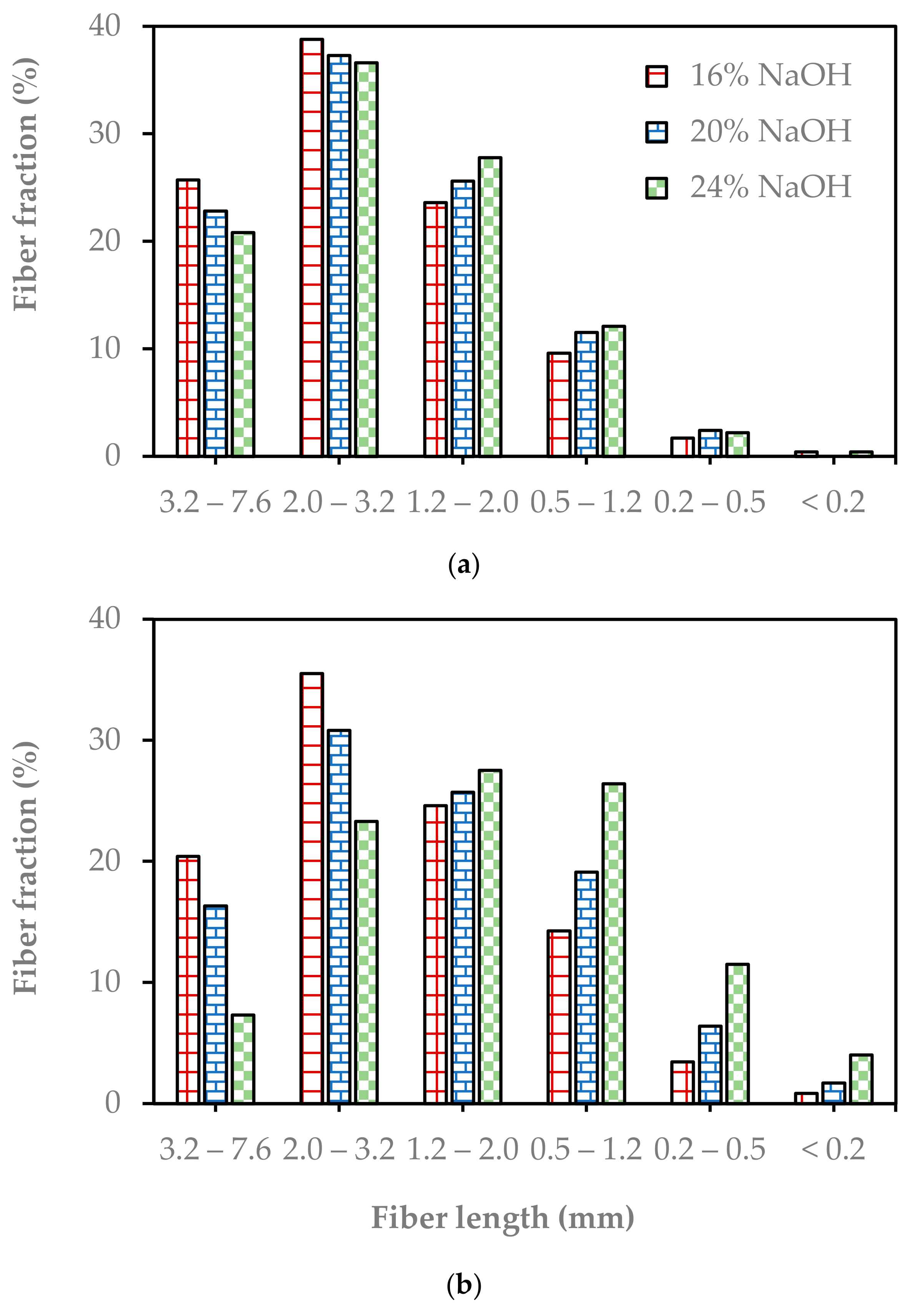

2.3. Refining and Fiber Morphology

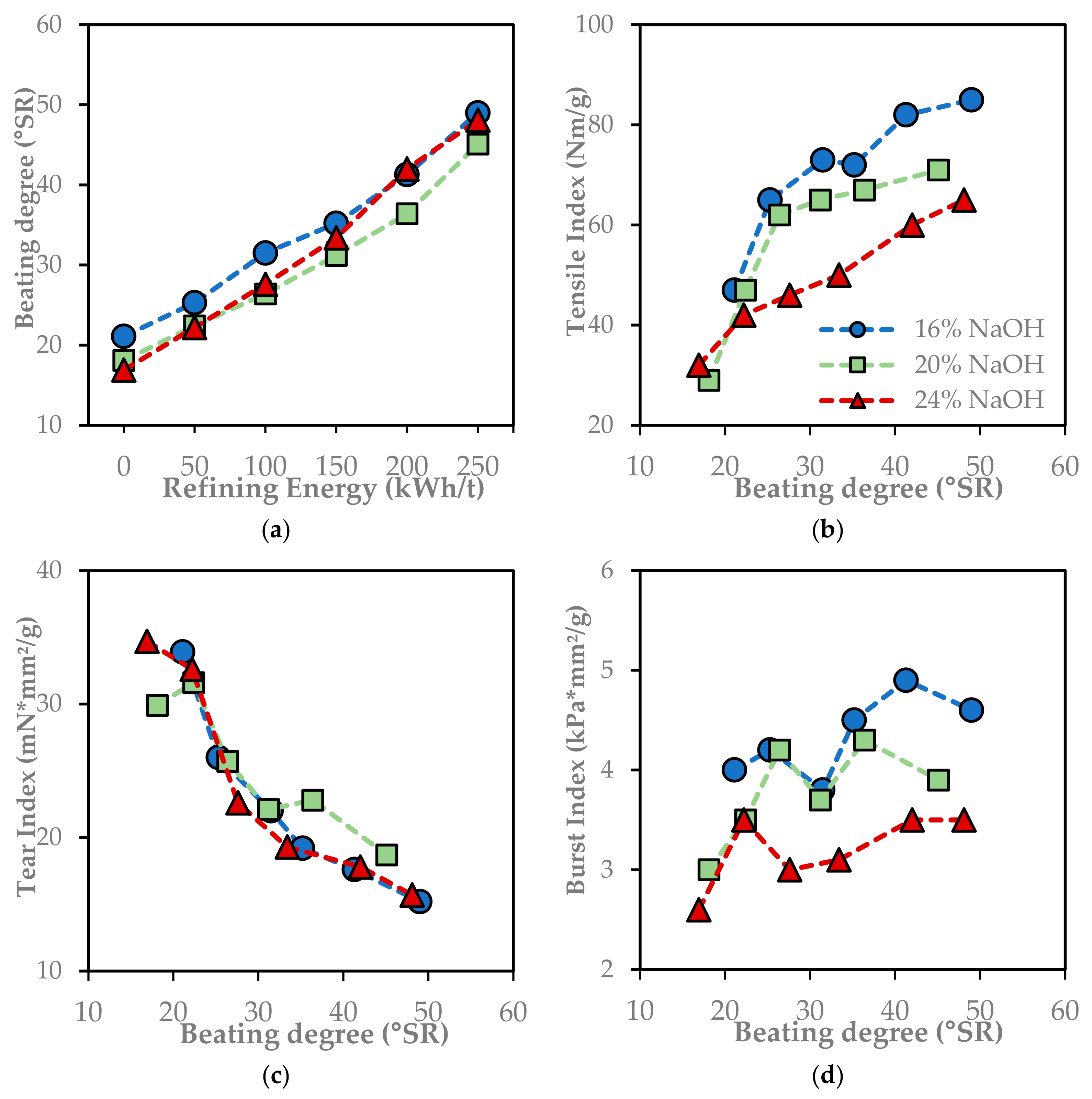

2.4. Refining and Paper Strength Property

3. Materials and Methods

3.1. Raw Material Characterization

3.2. Soda Pulping of the Enset Fiber

3.3. Chemical Composition of the Enset Fiber Soda Pulp

3.4. Pulp Beating and Refining

3.5. Analysis of the Paper Strength

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Berhanu, H.; Kiflie, Z.; Neiva, D.; Gominho, J.; Feleke, S.; Yimam, A.; Pereira, H. Optimization of ethanol-alkali delignification of false banana (Ensete ventricosum) fibers for pulp production using response surface methodology. Ind. Crops Prod. 2018, 126, 426–433. [Google Scholar] [CrossRef]

- Berhanu, H.; Kiflie, Z.; Miranda, I.; Lourenço, A.; Ferreira, J.; Feleke, S.; Yimam, A.; Pereira, H. Characterization of crop residues from false banana/Ensete ventricosum/in Ethiopia in view of a full-resource valorization. PLoS ONE 2018, 13, e0199422. [Google Scholar] [CrossRef] [PubMed]

- Ek, M.; Gellerstedt, G.; Henriksson, G. Pulping Chemistry and Technology; De Gruyter: Berlin, Germany, 2009; Volume 2. [Google Scholar] [CrossRef]

- Heitner, C.; Dimmel, D.; Schmidt, J. Lignin and Lignans: Advances in Chemistry; Taylor and Francis: Boca Raton, FL, USA, 2010. [Google Scholar] [CrossRef]

- Olejnik, K. Impact of pulp consistency on refining process conducted under constant intensity determined by SEL and SEC factors. BioResources 2013, 8, 3212–3230. [Google Scholar] [CrossRef]

- Bajpai, P. Chapter 14—Production of Dissolving Grade Pulp. In Biermann’s Handbook of Pulp and Paper, 3rd ed.; Bajpai, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Bajpai, P. Chapter 16—Pulp Cleaning, Screening, and Fractionation. In Biermann’s Handbook of Pulp and Paper, Volume 1, Raw Material and Pulp Making; Bajpai, P., Ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Miscanthus × giganteus stalks as a potential non-wood raw material for the pulp and paper industry. Influence of pulping and beating conditions on the fiber and paper properties. Ind. Crops Prod. 2019, 141, 111744. [Google Scholar] [CrossRef]

- Danielewicz, D.; Kmiotek, M.; Surma-Ślusarska, B. Comparison of Some Properties of Selected Non-Wood Plants and Wood Species and Unbleached Kraft Pulps from These Materials. J. Nat. Fibers 2021, 18, 1296–1306. [Google Scholar] [CrossRef]

- Chen, T.; Xie, Y.; Wei, Q.; Wang, X.; Hagman, O.; Karlsson, O.; Liu, J. Effect of refining on physical properties and paper strength of Pinus massoniana and China fir cellulose fibers. BioResources 2016, 11, 7839–7848. [Google Scholar] [CrossRef]

- Motamedian, H.R.; Halilovic, A.E.; Kulachenko, A. Mechanisms of strength and stiffness improvement of paper after PFI refining with a focus on the effect of fines. Cellulose 2019, 26, 4099–4124. [Google Scholar] [CrossRef]

- Karlsson, H. Fiber Guide—Fiber Analysis and Process Applications in the Pulp and Paper Industry; AB Lorentzen & Wettre: Kista, Sweden, 2006. [Google Scholar]

- Gharehkhani, S.; Sadeghinezhad, E.; Kazi, S.N.; Yarmand, H.; Badarudin, A.; Safaei, M.R.; Mohd Zubir, M.N. Basic effects of pulp refining on fiber properties—A review. Carb. Pol. 2015, 115, 785–803. [Google Scholar] [CrossRef] [PubMed]

- Hintz, H.L. Paper: Pulping and Bleaching. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Flemings, M.C., Kramer, E.J., Veyssière, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Salehi, K.; Kordsachia, O.; Patt, R. Comparison of MEA/AQ, soda and soda/AQ pulping of wheat and rye straw. Ind. Crops Prod. 2014, 52, 603–610. [Google Scholar] [CrossRef]

- Lemma, H.B.; Kiflie, Z.; Feleke, S.; Yimam, A. Chemical and Morphological Analysis of Enset (Ensete ventricosum) Fiber, Leaf, and Pseudo stem. Lignocellulose 2016, 5, 139–151. [Google Scholar]

- Salehi, K.; Latibari, A.J.; Kordsachia, O.; Saake, B. The potential of bagasse soda pulp as a strength enhancer for old corrugated pulp. Appita J. 2017, 70, 371–377. [Google Scholar]

- Salehi, K.; Kordsachia, O.; Saake, B. The potential of wheat straw high yield MEA pulp for enhancing strength properties of recycled paper. BioResources 2017, 12, 8255–8271. [Google Scholar] [CrossRef]

- Iwamoto, S.; Abe, K.; Yano, H. The Effect of Hemicelluloses on Wood Pulp Nanofibrillation and Nanofiber Network Characteristics. Biomacromolecules 2008, 9, 1022–1026. [Google Scholar] [CrossRef] [PubMed]

- McKean, W.T.; Jacobs, R.S. Wheat Straw as a Paper Fiber Source. Available online: https://www.paperonweb.com/Documents/WheatStrawAsPaperFiber.pdf (accessed on 26 February 2024).

- Seth, R.S. Fiber Quality Factors in Paper Making—I The Importance of Fiber Length and Strength; Materials Research Society Symposium Proceedings; Cambridge University Press: Cambridge, UK, 1990; Volume 197, pp. 125–141. [Google Scholar]

- Gonzalo, A.; Bimbela, F.; Sánchez, J.L.; Labidi, J.; Marín, F.; Arauzo, J. Evaluation of different agricultural residues as raw materials for pulp and paper production using a semichemical process. J. Clean. Prod. 2017, 156, 184–193. [Google Scholar] [CrossRef]

- Omer, S.H.; Khider, T.O.; Elzaki, O.T.; Mohieldin, S.D.; Shomeina, S.K. Application of soda-AQ pulping to agricultural waste (okra stalks) from Sudan. BMC Chem. Eng. 2019, 1, 6. [Google Scholar] [CrossRef]

- Fadavi, F. Effect of fiber fractionation on refineability and strength properties of wheat straw soda-AQ pulp. Lignocellul. J. 2012, 1, 153–163. [Google Scholar]

- Chibudike, H.O.; Mgbachiuzo, E.; Ndukwe, N.A.; Obi, N.I.; Adeyoju, O.A.; Chibudike, E.C. A study on mea-pulping of ten (10) nigerian cultivated agro-based fiber for the production of pulp stock paper. IEEE-SEM 2020, 8, 112–121. [Google Scholar]

- Lemma, H.B.; Freund, C.; Yimam, A.; Steffen, F.; Saake, B. Prehydrolysis soda pulping of Enset fiber for production of dissolving grade pulp and biogas. RSC Adv. 2023, 13, 4314–4323. [Google Scholar] [CrossRef] [PubMed]

- Lorenz, D.; Erasmy, N.; Akil, Y.; Saake, B. A new method for the quantification of monosaccharides, uronic acids and oligosaccharides in partially hydrolyzed xylans by HPAEC-UV/VIS. Carbohydr. Polym. 2016, 140, 181–187. [Google Scholar] [CrossRef] [PubMed]

- Maekawa, E.; Ichizawa, T.; Koshijima, T. An evaluation of the acid-soluble lignin determination in analyses of lignin by the sulfuric acid method. J. Wood Chem. Technol. 2006, 9, 549–567. [Google Scholar] [CrossRef]

- TAPPI/ANSI T 236 om-13; Kappa Number of Pulp TAPPI/ANSI T 236 om-13. TAPPI: Peachtree Corners, GA, USA, 1999.

- Zellcheming. Zellcheming Standard V/5/60; Zellcheming: Frankfurt, Germany, 1960. [Google Scholar]

- ISO 5263-2:2004; Pulps—Laboratory Wet Disintegration Part 2: Disintegration of Mechanical Pulps at 20 Degrees. ISO: Geneva, Switzerland, 2004.

- DIN 54518:2004; Testing of Paper and Board—Compression Strength, Short Span Test. DIN: Berlin, Germany, 2004.

- ISO 2759:2014; Board—Determination of Bursting Strength. ISO: Geneva, Switzerland, 2014.

- NEN-EN-ISO 1924-2:2009 en; Paper and Board—Determination of Tensile Properties—Part 2: Constant Rate of Elongation Method (20 mm/min). ISO: Geneva, Switzerland, 2009.

- DIN EN ISO 1974:2012-09; Paper—Determination of Tearing Resistance—Elmendorf Method. DIN: Berlin, Germany, 2012.

| Beating Time (min) | Fiber Length (mm) | Fiber Width (µm) | CWT | Fines Fraction (%) | Fibrillation (%) |

|---|---|---|---|---|---|

| 0 | 2.8 | 17.5 | 7.0 | 5.0 | 9.7 |

| 4 | 2.8 | 17.7 | 6.4 | 5.0 | 9.6 |

| 20 | 2.8 | 17.7 | 6.1 | 5.7 | 9.7 |

| 30 | 2.8 | 17.7 | 6.6 | 5.4 | 9.6 |

| Extractives (%) | Petrol ether | 0.1 |

| Acetone | 0.9 | |

| Water | 3.4 | |

| ∑ | 4.4 | |

| Lignin (%) | Klason lignin | 10.8 |

| Acid-soluble | 2.5 | |

| ∑ | 13.3 | |

| Monosaccharides (%) | Rhamnose, mannose, arabinose, galactose | 2.4 |

| Xylose | 10.7 | |

| Glucose | 58.9 | |

| ∑ | 72.1 | |

| Ash (%) | Silica | 2.6 |

| ∑ | 5.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berhanu Lemma, H.; Steffen, F.; Yimam Ali, A.; Saake, B. Production of Long-Fiber Pulp from Enset Plant Residues by Soda Pulping. Molecules 2024, 29, 4874. https://doi.org/10.3390/molecules29204874

Berhanu Lemma H, Steffen F, Yimam Ali A, Saake B. Production of Long-Fiber Pulp from Enset Plant Residues by Soda Pulping. Molecules. 2024; 29(20):4874. https://doi.org/10.3390/molecules29204874

Chicago/Turabian StyleBerhanu Lemma, Hanna, Friedrich Steffen, Abubeker Yimam Ali, and Bodo Saake. 2024. "Production of Long-Fiber Pulp from Enset Plant Residues by Soda Pulping" Molecules 29, no. 20: 4874. https://doi.org/10.3390/molecules29204874

APA StyleBerhanu Lemma, H., Steffen, F., Yimam Ali, A., & Saake, B. (2024). Production of Long-Fiber Pulp from Enset Plant Residues by Soda Pulping. Molecules, 29(20), 4874. https://doi.org/10.3390/molecules29204874