Template-Assisted Electrodeposited Copper Nanostructres for Selective Detection of Hydrogen Peroxide

Abstract

1. Introduction

2. Results and Discussion

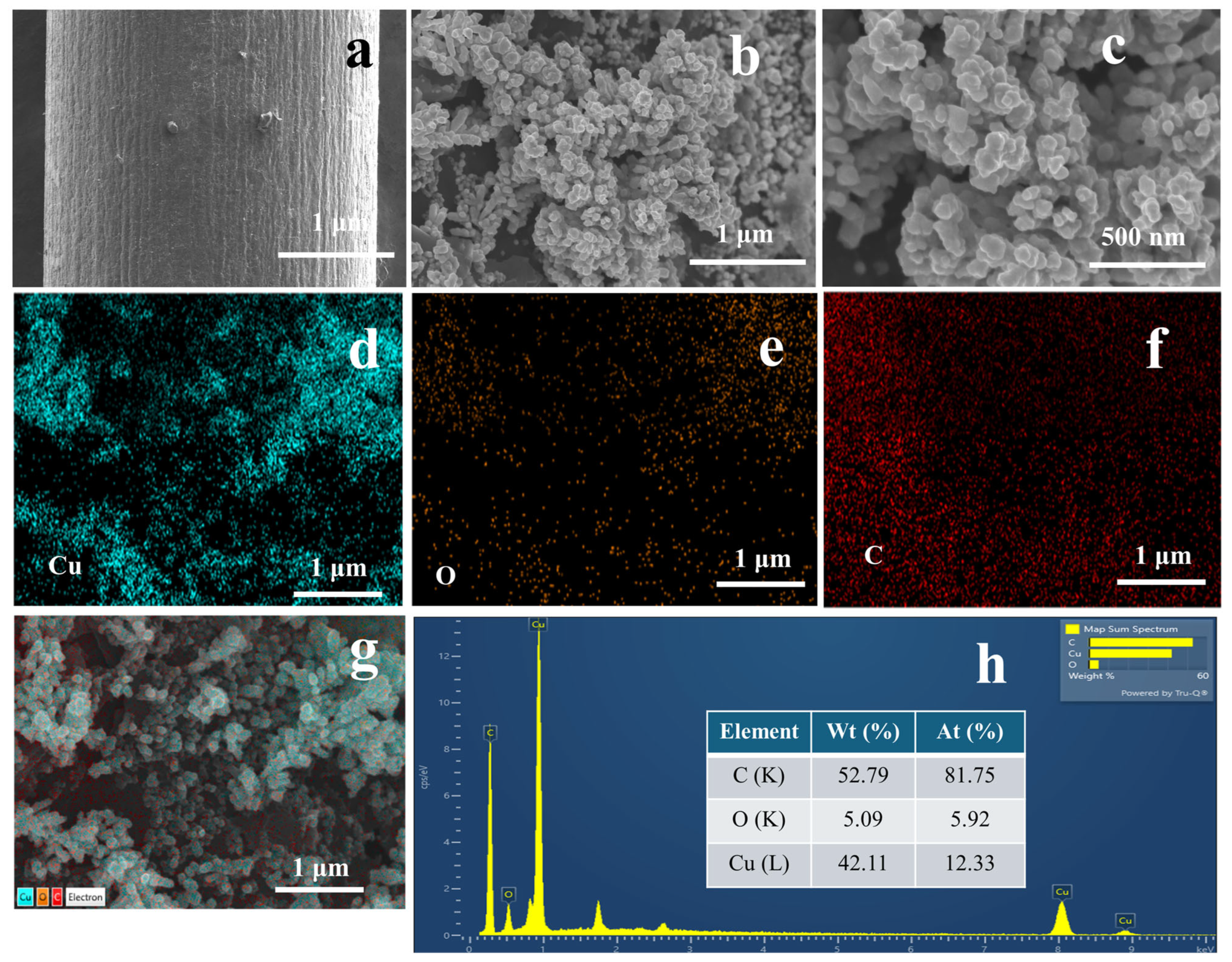

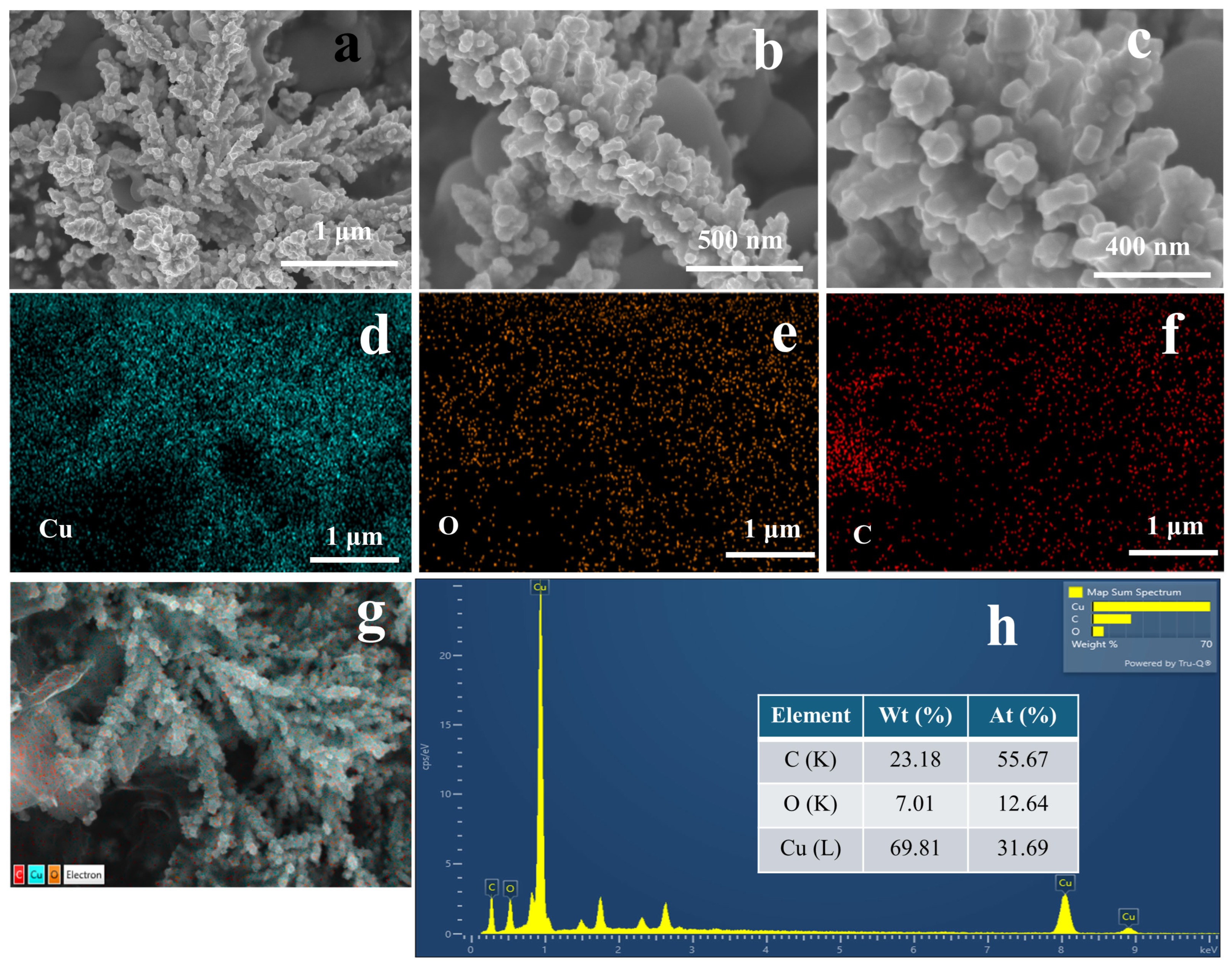

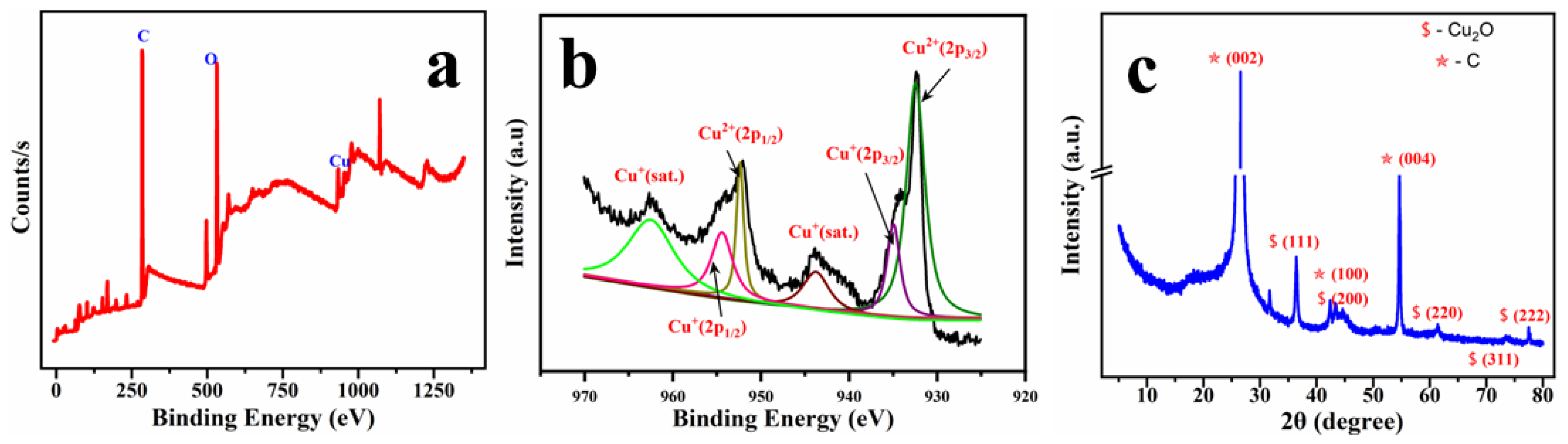

2.1. Physical Characterization

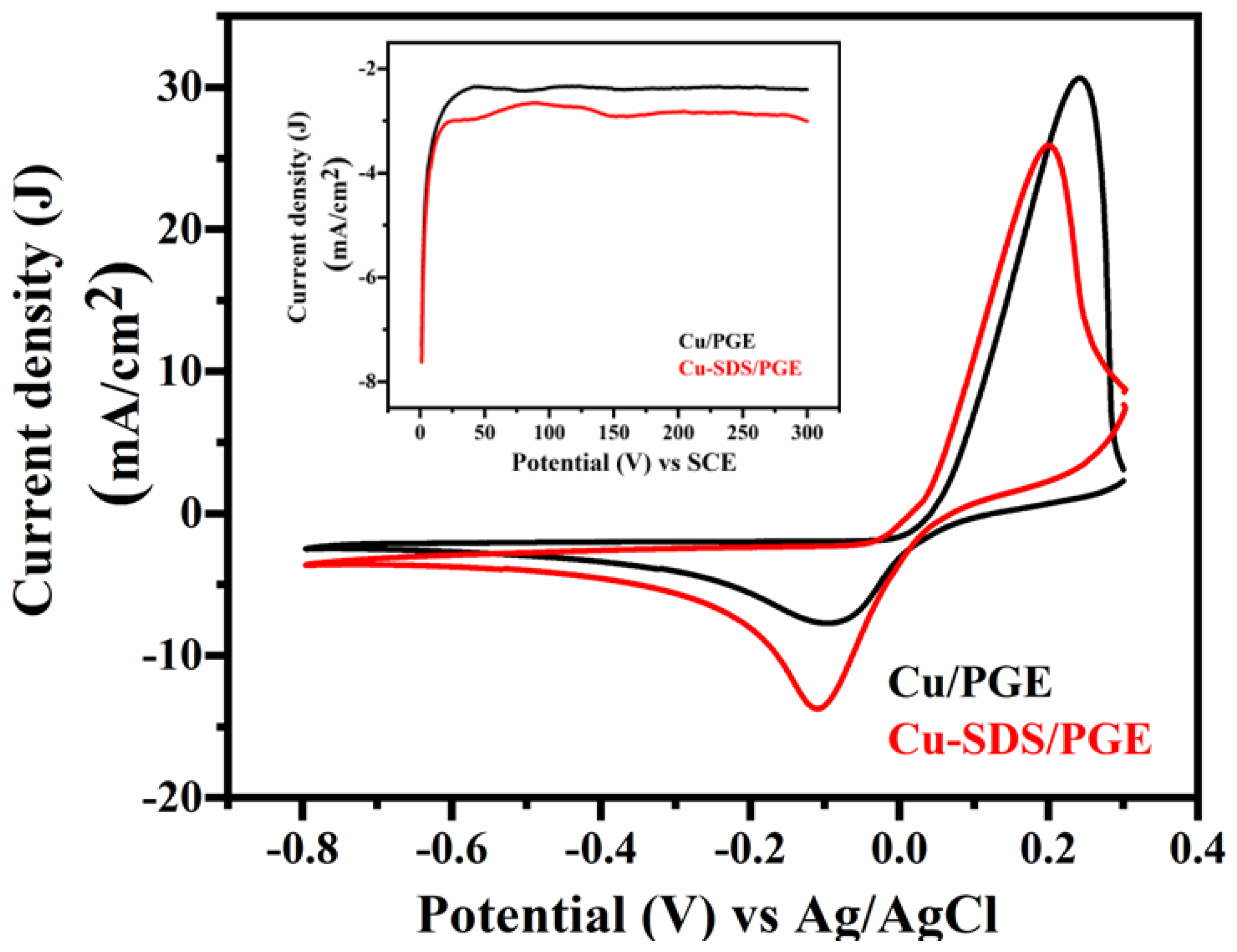

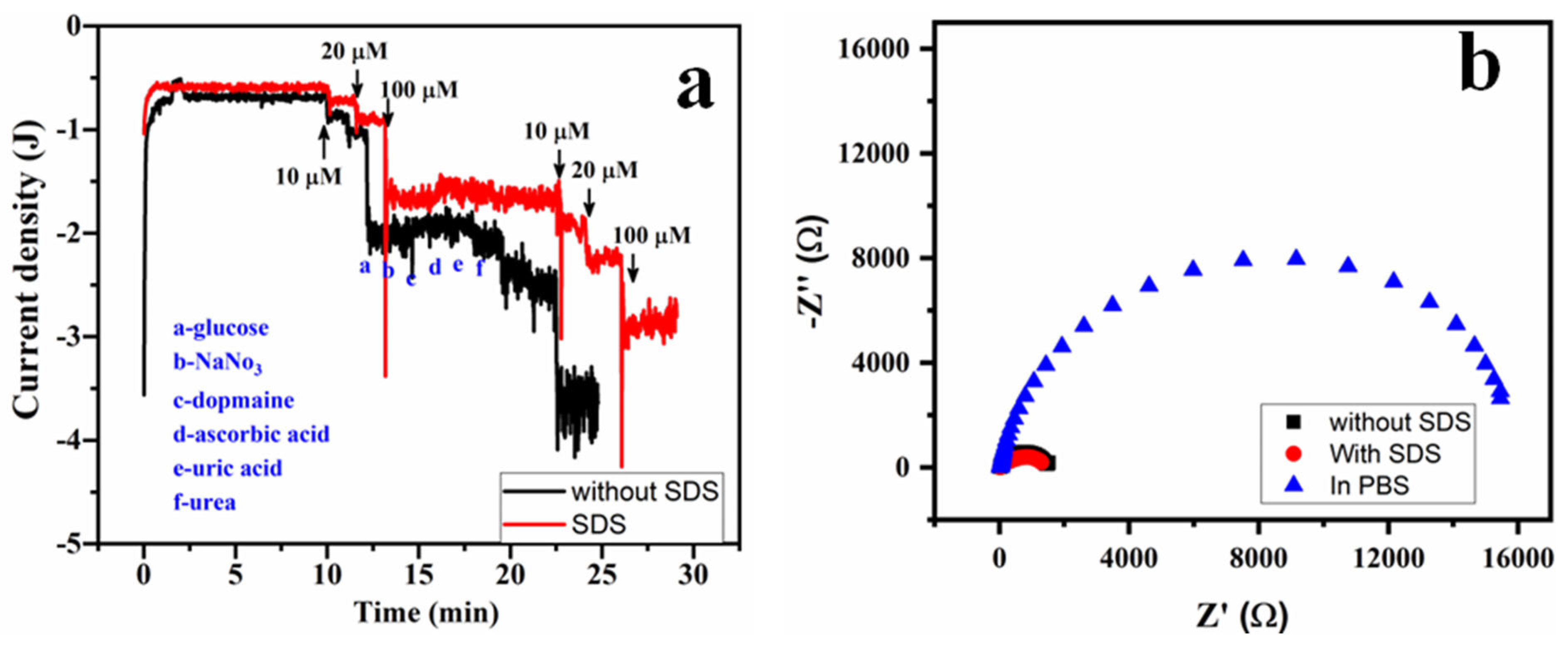

2.2. Electrochemical Studies

3. Materials and Methods

3.1. Chemicals

3.2. Experimental Methods

3.3. Material Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Li, M.; Liu, W.; Hao, Z.; Zhang, F.; Pang, H.; Zhang, R.; Zhang, L. Advances in Non-Enzymatic Electrochemical Materials for H2O2 Sensing. J. Electroanal. Chem. 2024, 954, 118060. [Google Scholar] [CrossRef]

- Ullah, N.; Khan, S.; Barton, B.; Guziejewski, D.; Smarzewska, S.; Koszelska, K.; Mirceski, V. A Mini Review on Topographical and Structural Insight of Metal Carbides for Electrocatalytic Hydrogen Peroxide Detection. Microchem. J. 2024, 200, 109961. [Google Scholar] [CrossRef]

- Yu, Y.; Pan, M.; Peng, J.; Hu, D.; Hao, Y.; Qian, Z. A Review on Recent Advances in Hydrogen Peroxide Electrochemical Sensors for Applications in Cell Detection. Chin. Chem. Lett. 2022, 33, 4133–4145. [Google Scholar] [CrossRef]

- Kailasa, S.K.; Vajubhai, G.N.; Koduru, J.R.; Park, T.J. Recent Progress of Nanomaterials for Colorimetric and Fluorescence Sensing of Reactive Oxygen Species in Biological and Environmental Samples. Trends Environ. Anal. Chem. 2023, 37, e00196. [Google Scholar] [CrossRef]

- Tjell, A.O.; Jud, B.; Schaller-Ammann, R.; Mayr, T. Optical Hydrogen Peroxide Sensor for Measurements in Flow. Sens. Actuators B Chem. 2024, 400, 134904. [Google Scholar] [CrossRef]

- Ahmad, T.; Khan, A.; El Deeb, S.; Al-Harrasi, A. Recent Advances in Electrochemical Sensing of Hydrogen Peroxide (H2O2) Released from Cancer Cells. Nanomaterials 2022, 12, 1475. [Google Scholar] [CrossRef]

- Giaretta, J.E.; Duan, H.; Oveissi, F.; Farajikhah, S.; Dehghani, F.; Naficy, S. Flexible Enzymatic Sensors for Detection of Hydrogen Peroxide. In Proceedings of the 2021 IEEE Sensors, Sydney, Australia, 31 October–3 November 2021; pp. 1–4. [Google Scholar]

- Nasir, A.; Khalid, S.; Mazare, A.; Yasin, T. Non-Enzymatic Hydrogen Peroxide Detection on a Novel Nanohybrid Composite of Chitosan and Grafted Graphene Oxide. Mater. Res. Bull. 2023, 167, 112427. [Google Scholar] [CrossRef]

- Miao, B.; Arsalan, M.; BaQais, A.; Murugadoss, V.; Saddique, I.; Amin, M.A.; Ren, J.; Awais, A.; Zhu, Q.; Xu, B.; et al. Highly Efficient Tetrametallic PtNiCuCo Alloy Nanoparticles for Sensitive Detection of Hydrogen Peroxide. Adv. Compos. Mater. 2023, 6, 110. [Google Scholar] [CrossRef]

- Giaretta, J.E.; Duan, H.; Oveissi, F.; Farajikhah, S.; Dehghani, F.; Naficy, S. Flexible Sensors for Hydrogen Peroxide Detection: A Critical Review. ACS Appl. Mater. Interfaces 2022, 14, 20491–20505. [Google Scholar] [CrossRef]

- Naveen, B.; Reddy, B.P.; Palathedath, S.K. Dual Performing Copper–Platinum Core–Shell Nanozyme for Environmental Electrochemistry–Electrocatalytic Oxidation and Electroanalysis of Ammonia. Environ. Sci. Nano 2021, 8, 3603–3612. [Google Scholar] [CrossRef]

- Gajjala, R.K.R.; Naveen, B.; Suresh Kumar, P. Cu@Pd Core–Shell Nanostructures on Pencil Graphite Substrates as Disposable Electrochemical Sensors for the Detection of Biological Amines. ACS Appl. Mater. Interfaces. 2021, 4, 5047–5057. [Google Scholar] [CrossRef]

- Zhao, J.; Xue, S.; Barber, J.; Zhou, Y.; Meng, J.; Ke, X. An Overview of Cu-Based Heterogeneous Electrocatalysts for CO2 Reduction. J. Mater. Chem. A 2020, 8, 4700–4734. [Google Scholar] [CrossRef]

- Rajput, A.; Kundu, A.; Chakraborty, B. Recent Progress on Copper-Based Electrode Materials for Overall Water-Splitting. ChemElectroChem 2021, 8, 1698–1722. [Google Scholar] [CrossRef]

- Li, G.R.; Xu, H.; Lu, X.-F.; Feng, J.-X.; Tong, Y.-X.; Su, C.Y. Electrochemical Synthesis of Nanostructured Materials for Electrochemical Energy Conversion and Storage. Nanoscale 2013, 5, 4056. [Google Scholar] [CrossRef]

- Holmberg, K. Surfactant-Templated Nanomaterials Synthesis. J. Colloid Interface Sci. 2004, 274, 355–364. [Google Scholar] [CrossRef]

- Perez-Page, M.; Yu, E.; Li, J.; Rahman, M.; Dryden, D.M.; Vidu, R.; Stroeve, P. Template-Based Syntheses for Shape Controlled Nanostructures. Adv. Colloid Interface Sci. 2016, 234, 51–79. [Google Scholar] [CrossRef]

- Spataru, T.; Preda, L.; Osiceanu, P.; Munteanu, C.; Anastasescu, M.; Marcu, M.; Spataru, N. Role of Surfactant-Mediated Electrodeposited Titanium Oxide Substrate in Improving Electrocatalytic Features of Supported Platinum Particles. Appl. Surf. Sci. 2014, 288, 660–665. [Google Scholar] [CrossRef]

- Bommireddy, N.; Palathedath, S.K. Surfactant Mediated Electrodeposition of Copper Nanostructures for Environmental Electrochemistry: Influence of Morphology on Electrochemical Nitrate Reduction Reaction. J. Solid State Electrochem. 2022, 26, 2733–2742. [Google Scholar] [CrossRef]

- Bommireddy, N.; Palathedath, S.K. Templated Bimetallic Copper-Silver Nanostructures on Pencil Graphite for Amperometric Detection of Nitrate for Aquatic Monitoring. J. Electroanal. Chem. 2020, 856, 113660. [Google Scholar] [CrossRef]

- Ning, D.; Wu, H. Effect of Surfactants on the Electrodeposition of Cu-TiO2 Composite Coatings Prepared by Jet Electrodeposition. J. Alloys Compd. 2019, 777, 1245–1250. [Google Scholar] [CrossRef]

- Hara, A.; Swiątek, Z.; Ozga, P. The Role of Surfactants in Induced Electrodeposition of Zn–Mo Layer from Citrate Solutions. J. Alloys Compd. 2020, 827, 154195. [Google Scholar] [CrossRef]

- Madhusha, C.; Jayasundara, T.; Robles Hernandez, F.C.; Ajayan, P.M.; Kottegoda, N. Synthesis and Structural Characterization of Copper Nanoparticles Doped Activated Carbon Derived from Coconut Coir for Drinking Water Purification. Mater. Today Chem. 2023, 27, 101312. [Google Scholar] [CrossRef]

- Ghodselahi, T.; Vesaghi, M.A.; Shafiekhani, A.; Baghizadeh, A.; Lameii, M. XPS Study of the Cu@Cu2O Core-Shell Nanoparticles. Appl. Surf. Sci. 2008, 255, 2730–2734. [Google Scholar] [CrossRef]

- Keerthana, S.P.; Rani, B.J.; Yuvakkumar, R.; Alharbi, S.A.; Velauthapillai, D. Copper Molybdate Nanoparticles for Electrochemical Water Splitting Application. Int. J. Hydrogen Energy 2021, 46, 7701–7711. [Google Scholar] [CrossRef]

- Lo Po, C.; Ruffino, F.; Terrasi, A.; Bruno, E.; Reitano, R.; Grimaldi, M.G.; Boscarino, S. Cu-Based Nanocatalyst by Pulsed Laser Ablation in Liquid for Water Splitting: Effect of the Solvent. J. Phys. Chem. Solids 2024, 193, 112162. [Google Scholar] [CrossRef]

- Li, C.W.; Kanan, M.W. CO2 Reduction at Low Overpotential on Cu Electrodes Resulting from the Reduction of Thick Cu2O Films. J. Am. Chem. Soc. 2012, 134, 7231–7234. [Google Scholar] [CrossRef]

- Allen, J.; Bard, L.R.F. Electrochemical Methods: Fundamentals and Applications; John Wiley and Sons: Noida, India, 2004. [Google Scholar]

- Forster, R.J. Kinetic Separation of Amperometric Sensor Responses. Analyst 1996, 121, 733. [Google Scholar] [CrossRef]

- Nebiyal, A.; Swaminathan, R.; Karpagavalli, S.G. Reaction Kinetics of Amperometric Enzyme Electrode in Various Geometries Using the Akbari-Ganji Method. Int. J. Electrochem. Sci. 2023, 18, 100240. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, F.; Zeng, B. One-Step Synthesis of a Copper-Based Metal–Organic Framework–Graphene Nanocomposite with Enhanced Electrocatalytic Activity. RSC Adv. 2015, 5, 22060–22065. [Google Scholar] [CrossRef]

- Zhang, Y.; Bo, X.; Luhana, C.; Wang, H.; Li, M.; Guo, L. Facile Synthesis of a Cu-Based MOF Confined in Macroporous Carbon Hybrid Material with Enhanced Electrocatalytic Ability. Chem. Commun. 2013, 49, 6885. [Google Scholar] [CrossRef]

- Ramezani, H.; Azizi, S.N.; Hosseini, S.R. NaY Zeolite as a Platform for Preparation of Ag Nanoparticles Arrays in Order to Construction of H2O2 Sensor. Sens. Actuators B Chem. 2017, 248, 571–579. [Google Scholar] [CrossRef]

- Gholami, M.; Koivisto, B. A Flexible and Highly Selective Non-Enzymatic H2O2 Sensor Based on Silver Nanoparticles Embedded into Nafion. Appl. Surf. Sci. 2019, 467–468, 112–118. [Google Scholar] [CrossRef]

- Lorestani, F.; Nia, P.M.; Alias, Y.; Manan, N.S.A. One-Step Synthesis of Different Silver-Polyaniline Composite Morphologies for Enzymless Hydrogen Peroxide Detection. J. Electrochem. Soc. 2015, 162, B193–B200. [Google Scholar] [CrossRef]

- Lopa, N.S.; Chandra Sutradhar, S.; Ryu, T.; Kim, W. A Base-Stable Metal-Organic Framework for Sensitive and Non-Enzymatic Electrochemical Detection of Hydrogen Peroxide. Electrochim. Acta 2018, 274, 49–56. [Google Scholar] [CrossRef]

- Tao, Y.; Chang, Q.; Liu, Q.; Dong, C. Highly Sensitive Nonenzymatic H2O2 Sensor Based on NiFe-Layered Double Hydroxides Nanosheets Grown on Ni Foam. Surf. Interfaces 2018, 12, 102–107. [Google Scholar] [CrossRef]

- Qiao, X.; Arsalan, M.; Ma, X.; Wang, Y.; Yang, S.; Wang, Y.; Sheng, Q.; Yue, T. A Hybrid of Ultrathin Metal-Organic Framework Sheet and Ultrasmall Copper Nanoparticles for Detection of Hydrogen Peroxide with Enhanced Activity. Anal. Bioanal. Chem. 2021, 413, 839–851. [Google Scholar] [CrossRef]

| Electrode | Linear Range (µM) | Sensitivity (µA/mM/cm2) | LOD (µM) |

|---|---|---|---|

| Cu/PGE | 1–10 | 14.82 | 0.92 ± 0.07 |

| 20–100 | 6.8 | ||

| Cu-SDS/PGE | 1–10 | 21.42 | 0.35 ± 0.04 |

| 20–100 | 5.27 |

| Electrode | Potential (V) | Linear Range (µM) | LOD (µM) | Sensitivity (µA/mM/cm2) | Ref. |

|---|---|---|---|---|---|

| Cu-BTC/GN/GCE | −0.35 | 10–11,180 | 2 | 57.73 | [31] |

| Cu-BTC/MPC/GCE | −0.23 | 10–11,600 | 3.2 | 2.97 | [32] |

| Ag Y/CPE | −0.65 | 10–5000 | 1.4 | 650.7 | [33] |

| Ag Nps/Nafion | −0.35 | 100–8000 | 0.48 | - | [34] |

| Ag Nps-PANINRs | −0.35 | 100–1000 | 0.13 | - | [35] |

| MIL-53-CrIIIAs/GCE | DPV | 25–500 | 3.52 | 11.9 | [36] |

| NiFe-LDH/Ni foam | 0.4 | 0.5–0.84 | 0.5 | 1704 | [37] |

| Cu-TCPP MOF | −0.7 | 0.1–600 | 0.13 | - | [38] |

| Cu/PGE | −0.6 | 1–1000 | 0.92 | 14.82 | This work |

| Cu-SDS/PGE | −0.6 | 1–1000 | 0.35 | 21.42 | This work |

| Quantity Spiked (µM) | Detected (µM) | Recovery (%) | RSD (%) |

|---|---|---|---|

| 5 | 5.36 | 109.6 | 2.52 |

| 10 | 10.62 | 106.2 | 1.55 |

| 15 | 15.33 | 102.2 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naveen, B.; Lee, S.-W. Template-Assisted Electrodeposited Copper Nanostructres for Selective Detection of Hydrogen Peroxide. Molecules 2024, 29, 4571. https://doi.org/10.3390/molecules29194571

Naveen B, Lee S-W. Template-Assisted Electrodeposited Copper Nanostructres for Selective Detection of Hydrogen Peroxide. Molecules. 2024; 29(19):4571. https://doi.org/10.3390/molecules29194571

Chicago/Turabian StyleNaveen, Bommireddy, and Sang-Wha Lee. 2024. "Template-Assisted Electrodeposited Copper Nanostructres for Selective Detection of Hydrogen Peroxide" Molecules 29, no. 19: 4571. https://doi.org/10.3390/molecules29194571

APA StyleNaveen, B., & Lee, S.-W. (2024). Template-Assisted Electrodeposited Copper Nanostructres for Selective Detection of Hydrogen Peroxide. Molecules, 29(19), 4571. https://doi.org/10.3390/molecules29194571