Fusion of Laser-Induced Breakdown Spectroscopy and Raman Spectroscopy for Mineral Identification Based on Machine Learning

Abstract

1. Introduction

2. Results and Discussion

2.1. LIBS and RS Spectra

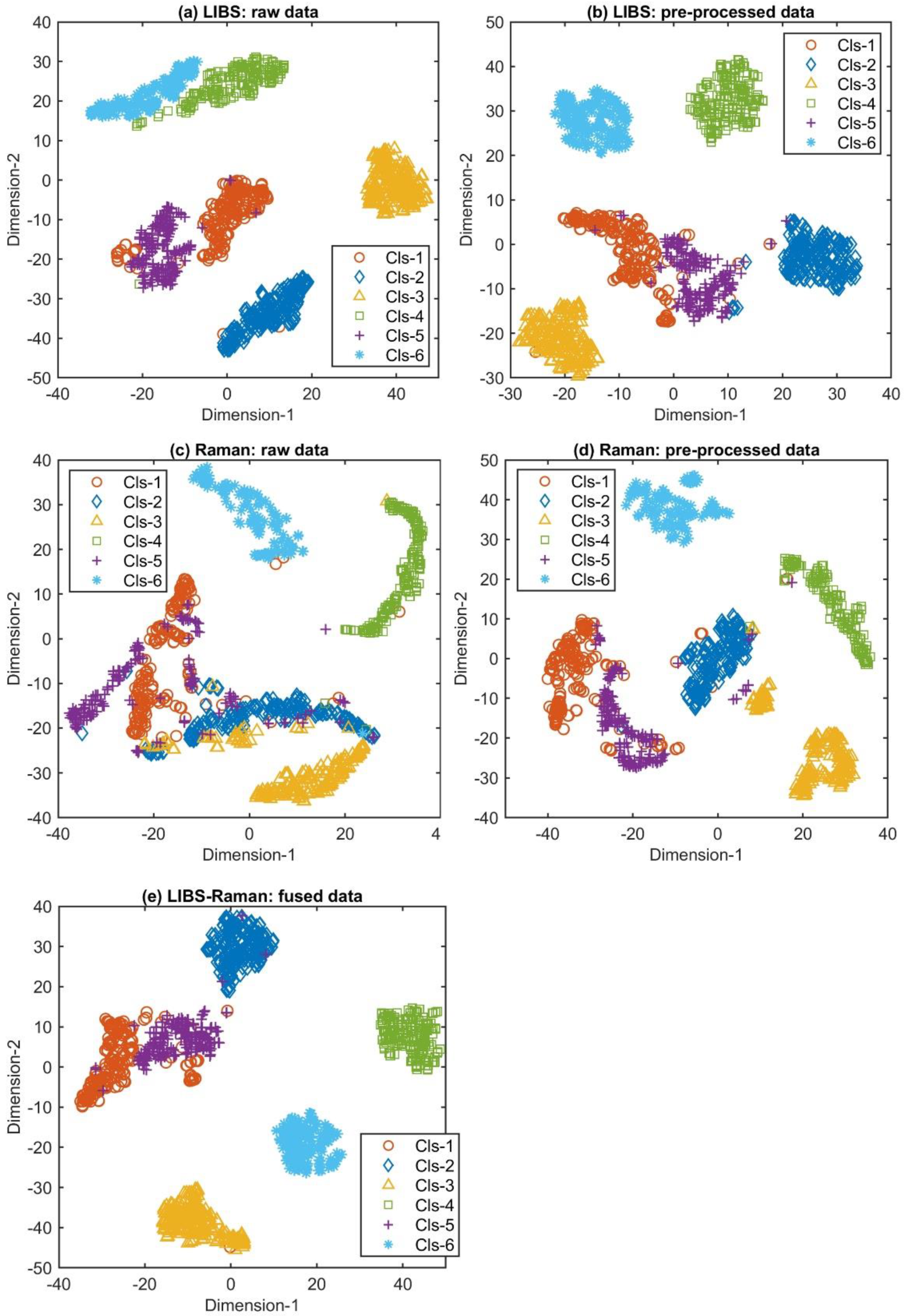

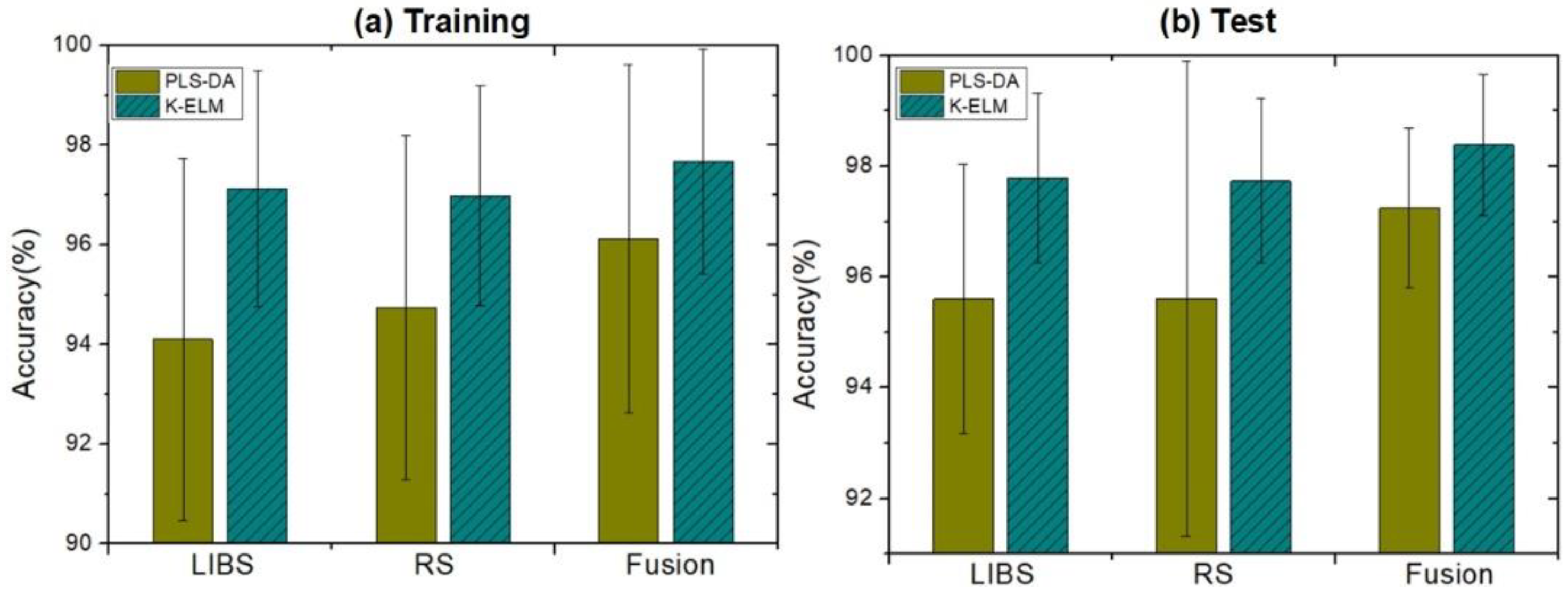

2.2. Mineral Classification

2.3. Mineral Identification

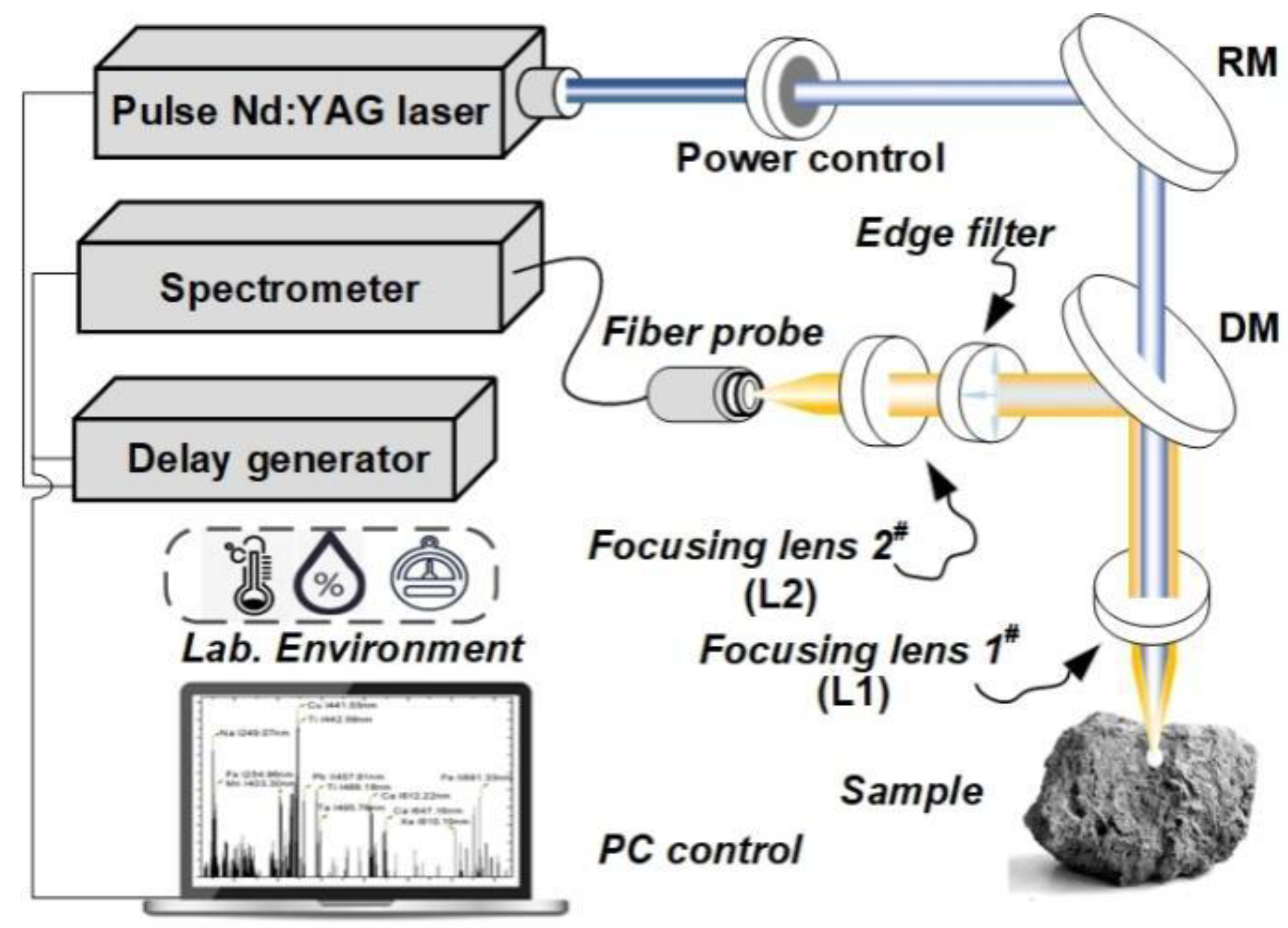

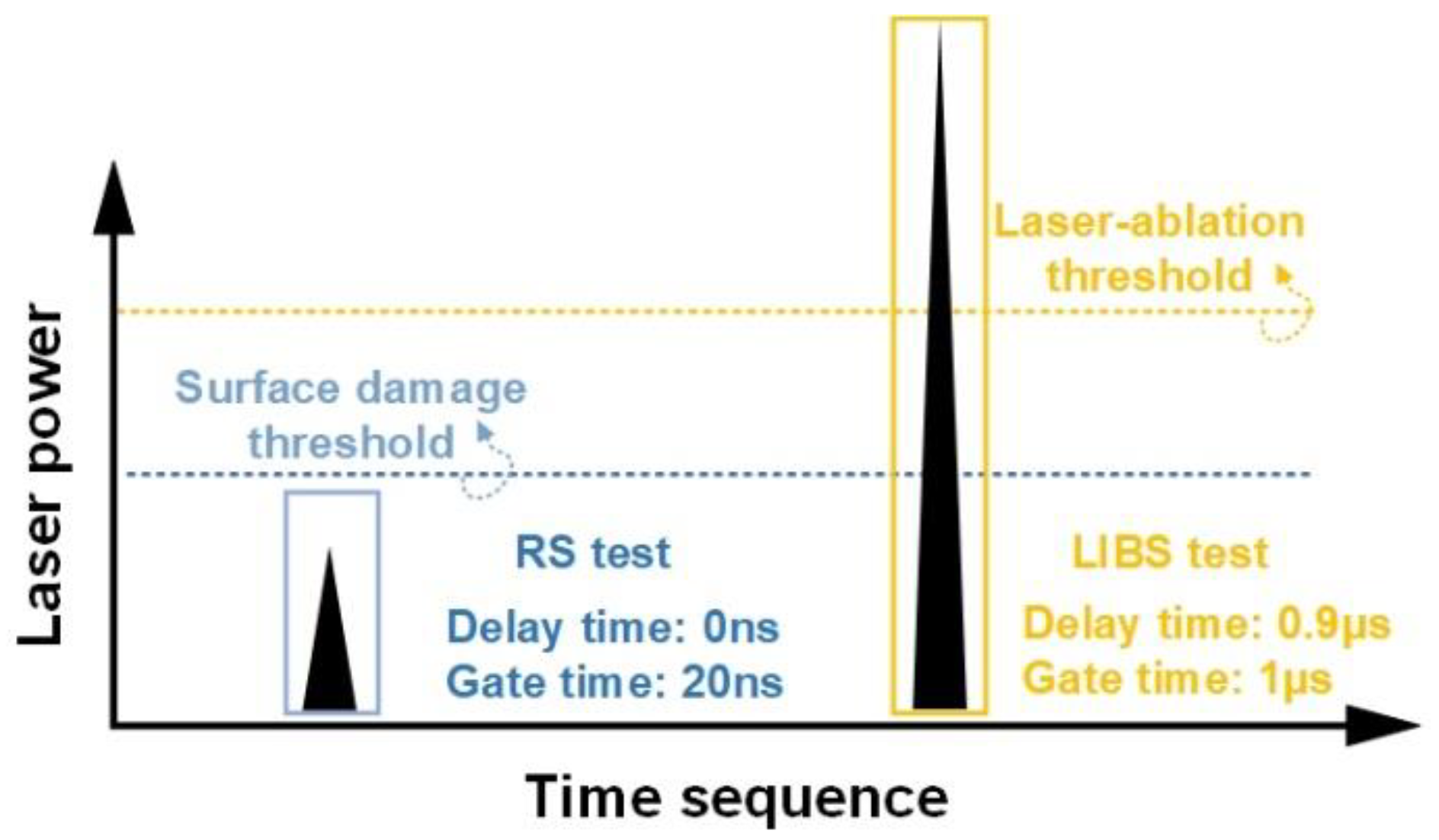

3. Experiment Methods

3.1. Mineral Samples

3.2. Integrated LIBS-RS System

3.3. Spectral Data Processing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mahrous, E.; Chen, R.; Zhao, C.; Farag, M.A. Lipidomics in food quality and authentication: A comprehensive review of novel trends and applications using chromatographic and spectroscopic techniques. Crit. Rev. Food Sci. Nutr. 2023, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, J.; Velasquez, M.; Myakalwar, A.K.; Sandoval, C.; Fuentes, R.; Castillo, R.; Sbarbaro, D. Determination of copper-based mineral species by laser induced breakdown spectroscopy and chemometric methods. J. Anal. At. Spectrom. 2019, 34, 2459–2468. [Google Scholar] [CrossRef]

- Chukanov, N.V.; Chervonnyi, A.D. Infrared Spectroscopy of Minerals and Related Compounds; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Schmidt, F.; Legendre, M.; Mouëlic, S.L. Minerals detection for hyperspectral images using adapted linear unmixing: LinMin. Icarus 2014, 237, 61–74. [Google Scholar] [CrossRef]

- Krohn, M.D.; Altaner, S.P. Near infrared detection of ammonium minerals. Geophysics 1987, 52, 924–930. [Google Scholar] [CrossRef]

- Zhao, S.; Song, W.; Zhao, Y.; Hou, Z.; Wang, Z. In-situ measurement method of material ratio and chemical uniformity in sintering–pelleting operation using laser-induced breakdown spectroscopy and partial least squares regression. Microchem. J. 2022, 183, 107986. [Google Scholar] [CrossRef]

- Harmon, R.S.; Lawley, C.J.M.; Watts, J.; Harraden, C.L.; Somers, A.M.; Hark, R.R. Laser-Induced Breakdown Spectroscopy—An Emerging Analytical Tool for Mineral Exploration. Minerals 2019, 9, 718. [Google Scholar] [CrossRef]

- Sharma, S.K.; Lucey, P.G.; Ghosh, M.; Hubble, H.W.; Horton, K.A. Stand-off Raman spectroscopic detection of minerals on planetary surfaces. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2003, 59, 2391–2407. [Google Scholar] [CrossRef] [PubMed]

- Winefordner, J.D.; Gornushkin, I.B.; Correll, T.; Gibb, E.; Smith, B.W.; Omenetto, N. Comparing several atomic spectrometric methods to the super stars: Special emphasis on laser induced breakdown spectrometry, LIBS, a future super star. J. Anal. At. Spectrom. 2004, 19, 1061–1083. [Google Scholar] [CrossRef]

- Wang, W.; Kong, W.; Shen, T.; Man, Z.; Zhu, W.; He, Y.; Liu, F.; Liu, Y. Application of laser-induced breakdown spectroscopy in detection of cadmium content in rice stems. Front. Plant Sci. 2020, 11, 599616. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Shen, T.; Kong, W.; Peng, J.; Zhang, C.; Song, K.; Wang, W.; Zhang, C.; He, Y. Quantitative analysis of cadmium in tobacco roots using laser-induced breakdown spectroscopy with variable index and chemometrics. Front. Plant Sci. 2018, 9, 1316. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Liu, F.; Zhang, C.; Wang, W.; Yang, R.; Zhao, Y.; Peng, J.; Kong, W.; Huang, J. Trends in digital detection for the quality and safety of herbs using infrared and Raman spectroscopy. Front. Plant Sci. 2023, 14, 1128300. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Vo-Dinh, K.C.; Yan, F.; Wabuyele, M.B.; Vo-Dinh, T. Direct identification of alizarin and lac dye on painting fragments using surface-enhanced RS scattering. Anal. Chim. Acta 2006, 569, 234–237. [Google Scholar] [CrossRef]

- Ishikawa, S.T.; Gulick, V.C. An automated mineral classifier using Raman spectra. Comput. Geosci. 2013, 54, 259–268. [Google Scholar] [CrossRef]

- Downs, R.T. The RRUFF project: An integrated study of the chemistry, crystallography, RS and infrared spectroscopy of minerals. In Proceedings of the 19th General Meeting of the International Mineralogical Association, Kobe, Japan, 23–28 July 2006; pp. 3–13. [Google Scholar]

- Liu, J.; Osadchy, M.; Ashton, L.; Solomon, C.J.; Gibson, S.J.; Foster, M. Deep convolutional neural networks for Raman spectra recognition: A unified solution. Analyst 2017, 142, 4067–4074. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Liu, Z.; Zhang, T.; Zhao, S.; Gao, X.; Sun, T.; Dai, Y. Multielement simultaneous quantitative analysis of trace elements in stainless steel via full spectrum laser-induced breakdown spectroscopy. Talanta 2024, 272, 125745. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Hou, Z.; Sheta, S.; Dong, J.; Han, W.; Lu, T.; Wang, Z. Provenance classification of nephrite jades using multivariate LIBS: A comparative study. Anal. Methods 2018, 10, 281–289. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, Z.; Zhang, T.; Sun, T.; Gao, X.; Dai, Y. Small-sample stacking model for qualitative analysis of aluminum alloys based on femtosecond laser-induced breakdown spectroscopy. Opt. Express 2023, 31, 27633–27653. [Google Scholar] [CrossRef] [PubMed]

- Allen, A.; Williams, M.R.; Sigman, M.E. Application of likelihood ratios and optimal decision thresholds in fire debris analysis based on a partial least squares discriminant analysis (PLS-DA) model. Forensic Chem. 2019, 16, 100188. [Google Scholar] [CrossRef]

- Chen, J.; Pisonero, J.; Chen, S.; Wang, X.; Fan, Q.; Duan, Y. Convolutional neural network as a novel classi fi cation approach for laser- induced breakdown spectroscopy applications in lithological recognition. Spectrochim. Acta Part B 2020, 166, 105801. [Google Scholar] [CrossRef]

- Khajehzadeh, N.; Haavisto, O.; Koresaar, L. On-stream mineral identification of tailing slurries of an iron ore concentrator using data fusion of LIBS, reflectance spectroscopy and XRF measurement techniques. Miner. Eng. 2017, 113, 83–94. [Google Scholar] [CrossRef]

- Jahoda, P.; Drozdovskiy, I.; Payler, S.J.; Turchi, L. Machine learning for recognizing minerals from multispectral data. Analyst 2020, 146, 184–195. [Google Scholar] [CrossRef] [PubMed]

- Bi, Y.; Zhang, Y.; Yan, J.; Wu, Z.; Li, Y. Classification and discrimination of minerals using laser induced breakdown spectroscopy and RS spectroscopy. Plasma Sci. Technol. 2015, 17, 923–927. [Google Scholar] [CrossRef]

- Gibbons, E.; Léveillé, R.; Berlo, K. Data fusion of laser-induced breakdown and RS spectroscopies: Enhancing clay mineral identification. Spectrochim. Acta Part B 2020, 170, 105905. [Google Scholar] [CrossRef]

- Kristin, R.; Susanne, S.; Simon, K.; Sven, F.; Peder, B.H.; Ute, B.; Franziska, H.; Heinz-Wilhelm, H. Low-level LIBS and Raman data fusion in the context of in situ Mars exploration. J. Raman Spectrosc. 2019, 51, 1682–1701. [Google Scholar]

- Sun, H.; Song, C.; Lin, X.; Gao, X. Identification of meat species by combined laser-induced breakdown and Raman spectroscopies. Spectrochim. Acta Part B At. Spectrosc. 2022, 194, 106456. [Google Scholar] [CrossRef]

- Choi, S.J.; Choi, J.J.; Yoh, J.J. Advancing the experimental design for simultaneous acquisition of laser induced plasma and RS signals using a single pulse. Spectrochim. Acta Part B At. Spectrosc. 2016, 123, 1–5. [Google Scholar] [CrossRef]

- Shameem, K.M.M.; Dhanada, V.S.; Harikrishnan, S.; George, S.D.; Kartha, V.B.; Santhosh, C.; Unnikrishnan, V.K. Echelle LIBS-RS system: A versatile tool for mineralogical and archaeological applications. Talanta 2020, 208, 120482. [Google Scholar] [CrossRef] [PubMed]

- Buzgar, N.; Andrei, I.A. The Raman study of certain carbonates. Geol. Tomul L 2009, 2, 97–112. [Google Scholar]

- Barker, M.; Rayens, W. Partial least squares for discrimination. J. Chemom. A J. Chemom. Soc. 2003, 17, 166–173. [Google Scholar] [CrossRef]

- Huang, G.B.; Siew, C.K. Extreme learning machine with randomly assigned RBF kernels. Int. J. Inf. Technol. 2005, 11, 16–24. [Google Scholar]

- Zheng, W.; Shu, H.; Tang, H.; Zhang, H. Spectra data classification with kernel extreme learning machine. Chemom. Intell. Lab. Syst. 2019, 192, 103815. [Google Scholar] [CrossRef]

- Song, W.; Hou, Z.; Gu, W.; Wang, H.; Cui, J.; Zhou, Z.; Yan, G.; Ye, Q.; Li, Z.; Wang, Z. Industrial at-line analysis of coal properties using laser-induced breakdown spectroscopy combined with machine learning. Fuel 2021, 306, 121667. [Google Scholar] [CrossRef]

- Devassy, B.M.; George, S. Dimensionality reduction and visualisation of hyperspectral ink data using t-SNE. Forensic Sci. Int. 2020, 311, 110194. [Google Scholar] [CrossRef] [PubMed]

| Data Sets | Raw Data | Pre-Processed Data | |

|---|---|---|---|

| LIBS | Training | 92.63% ± 3.78% ±3.78 | 94.10% ± 3.66% ±3.66 |

| Test | 94.42% ± 4.70% ±4.70 | 95.61% ± 2.45% ±2.45 | |

| RS | Training | 90.36% ± 4.39% ±4.39 | 93.34% ± 3.49% ±3.49 |

| Test | 94.74% ± 5.47% ±5.47 | 95.61% ± 4.33% ±4.33 |

| Method | LIBS | Raman | Fusion | |

|---|---|---|---|---|

| Training | PLS-DA | 94.10 ±3.66 | 93.34 ± 3.49 | 96.12 ± 3.49 |

| K-ELM | 97.12 ± 3.37 | 96.98 ± 3.19 | 97.67 ± 3.25 | |

| Test | PLS-DA | 95.61 ± 2.45 | 95.61 ± 4.33 | 97.24 ± 1.44 |

| K-ELM | 97.78 ± 1.53 | 97.73 ± 1.48 | 98.39 ± 1.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Liu, Z.; Zhao, S. Fusion of Laser-Induced Breakdown Spectroscopy and Raman Spectroscopy for Mineral Identification Based on Machine Learning. Molecules 2024, 29, 3317. https://doi.org/10.3390/molecules29143317

Dai Y, Liu Z, Zhao S. Fusion of Laser-Induced Breakdown Spectroscopy and Raman Spectroscopy for Mineral Identification Based on Machine Learning. Molecules. 2024; 29(14):3317. https://doi.org/10.3390/molecules29143317

Chicago/Turabian StyleDai, Yujia, Ziyuan Liu, and Shangyong Zhao. 2024. "Fusion of Laser-Induced Breakdown Spectroscopy and Raman Spectroscopy for Mineral Identification Based on Machine Learning" Molecules 29, no. 14: 3317. https://doi.org/10.3390/molecules29143317

APA StyleDai, Y., Liu, Z., & Zhao, S. (2024). Fusion of Laser-Induced Breakdown Spectroscopy and Raman Spectroscopy for Mineral Identification Based on Machine Learning. Molecules, 29(14), 3317. https://doi.org/10.3390/molecules29143317