Localized Photoactuation of Polymer Pens for Nanolithography

Abstract

1. Introduction

2. Results and Discussion

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Li, M.; Pal, A.; Aghakhani, A.; PenaFrancesch, A.; Sitti, M. Soft actuators for real-world applications. Nat. Rev. Mater. 2022, 7, 235–249. [Google Scholar] [CrossRef] [PubMed]

- Miriyev, A.; Stack, K.; Lipson, H. Soft material for soft actuators. Nat. Commun. 2017, 8, 596. [Google Scholar] [CrossRef] [PubMed]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- McEvoy, M.A.; Correll, N. Materials that couple sensing, actuation, computation, and communication. Science 2015, 347, 1261689. [Google Scholar] [CrossRef] [PubMed]

- Mather, P.T. Soft answers for hard problems. Nat. Mater. 2007, 6, 93–94. [Google Scholar] [CrossRef] [PubMed]

- Lendlein, A.; Gould, O.E.C. Reprogrammable recovery and actuation behaviour of shape-memory polymers. Nat. Rev. Mater. 2019, 4, 116–133. [Google Scholar] [CrossRef]

- Ge, F.; Lu, X.; Xiang, J.; Tong, X.; Zhao, Y. An optical actuator based on gold-nanoparticle-containing temperature-memory semicrystalline polymers. Angew. Chem. Int. Ed. 2017, 56, 6126–6130. [Google Scholar] [CrossRef] [PubMed]

- Mahato, M.; Tabassian, R.; Nguyen, V.H.; Oh, S.; Nam, S.; Kim, K.J.; Oh, I.-K. Sulfur- and nitrogen-rich porous π-conjugated COFs as stable electrode materials for electro-ionic soft actuators. Adv. Funct. Mater. 2020, 30, 2003863. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, S.; Mackie, D.M.; Kwon, J.; Kim, S.H.; Choi, C.; Moon, Y.H.; Lee, H.B.; Ko, S.H. Shape morphing smart 3D actuator materials for micro soft robot. Mater. Today 2020, 41, 243–269. [Google Scholar] [CrossRef]

- Mura, S.; Nicolas, J.; Couvreur, P. Stimuli-responsive nanocarriers for drug delivery. Nat. Mater. 2013, 12, 991–1003. [Google Scholar] [CrossRef]

- Ohm, C.; Brehmer, M.; Zentel, R. Liquid crystalline elastomers as actuators and sensors. Adv. Mater. 2010, 22, 3366–3387. [Google Scholar] [CrossRef] [PubMed]

- Ding, T.; Valev, V.K.; Salmon, A.R.; Forman, C.J.; Smoukov, S.K.; Scherman, O.A.; Frenkel, D.; Baumberg, J.J. Light-induced actuating nanotransducers. Proc. Natl. Acad. Sci. USA 2016, 113, 5503–5507. [Google Scholar] [CrossRef] [PubMed]

- Matsubara, K.; Tachibana, D.; Matsuda, R.; Onoe, H.; Fuchiwaki, O.; Ota, H. Hydrogel actuator with a built-in stimulator using liquid metal for local control. Adv. Intell. Syst. 2020, 2, 2000008. [Google Scholar] [CrossRef]

- Lauback, S.; Mattioli, K.R.; Marras, A.E.; Armstrong, M.; Rudibaugh, T.P.; Sooryakumar, R.; Castro, C.E. Real-time magnetic actuation of DNA nanodevices via modular integration with stiff micro-levers. Nat. Commun. 2018, 9, 1446. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zhang, J.; Hu, W.; Khan, M.T.A.; Sitti, M. Shape-programmable liquid crystal elastomer structures with arbitrary three-dimensional director fields and geometries. Nat. Commun. 2021, 12, 5936. [Google Scholar] [CrossRef] [PubMed]

- Kanygin, M.; Joy, A.P.; Bahreyni, B. Localized mechanical actuation using pn junctions. Sci. Rep. 2019, 9, 14885. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, H.J.; Mun, S.; Yun, S.; Kang, T.J. A light-driven vibrotactile actuator with a polymer bimorph film for localized haptic rendering. ACS Appl. Mater. Interfaces 2021, 13, 6597–6605. [Google Scholar] [CrossRef] [PubMed]

- Koleoso, M.; Feng, X.; Xue, Y.; Li, Q.; Munshi, T.; Chen, X. Micro/nanoscale magnetic robots for biomedical applications. Mater. Today Bio 2020, 8, 100085. [Google Scholar] [CrossRef] [PubMed]

- Hedayati, R.; Mirzaali, M.J.; Vergani, L.; Zadpoor, A.A. Action-at-a-distance metamaterials: Distributed local actuation through far-field global forces. APL Mater. 2018, 6, 036101. [Google Scholar] [CrossRef]

- Soto, F.; Wang, J.; Ahmed, R.; Demirci, U. Medical micro/nanorobots in precision medicine. Adv. Sci. 2020, 7, 2002203. [Google Scholar] [CrossRef] [PubMed]

- Bao, B.; Rivkin, B.; Akbar, F.; Karnaushenko, D.D.; Bandari, V.K.; Teuerle, L.; Becker, C.; Baunack, S.; Karnaushenko, D.; Schmidt, O.G. Digital electrochemistry for on-chip heterogeneous material integration. Adv. Mater. 2021, 33, 2101272. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.; Johnson, B.V.; Jing, W.; Cappelleri, D.J. Designing local magnetic fields and path planning for independent actuation of multiple mobile microrobots. J. Micro-Bio Robot. 2017, 12, 21–31. [Google Scholar] [CrossRef]

- Leroy, E.; Hinchet, R.; Shea, H. Multimode hydraulically amplified electrostatic actuators for wearable haptics. Adv. Mater. 2020, 32, 2002564. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, Y.; Karnaushenko, D.; Chen, L.; Hao, J.; Ding, F.; Schmidt, O.G. Addressable and color-tunable piezophotonic light-emitting stripes. Adv. Mater. 2017, 29, 1605165. [Google Scholar] [CrossRef]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Schneider, F.; Draheim, J.; Kamberger, R.; Wallrabe, U. Process and material properties of polydimethylsiloxane (PDMS) for optical MEMS. Sens. Actuator A Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- McDonald, J.C.; Whitesides, G.M. Poly(dimethylsiloxane) as a material for fabricating microfluidic devices. Acc. Chem. Res 2002, 35, 491–499. [Google Scholar] [CrossRef] [PubMed]

- Eduok, U.; Faye, O.; Szpunar, J. Recent developments and applications of protective silicone coatings: A review of PDMS functional materials. Prog. Org. Coat 2017, 111, 124–163. [Google Scholar] [CrossRef]

- Zhou, L.; Song, H.; Liang, J.; Singer, M.; Zhou, M.; Stegenburgs, E.; Zhang, N.; Xu, C.; Ng, T.; Yu, Z.; et al. A polydimethylsiloxane-coated metal structure for all-day radiative cooling. Nat. Sustain. 2019, 2, 718–724. [Google Scholar] [CrossRef]

- Huh, D.; Kim, H.J.; Fraser, J.P.; Shea, D.E.; Khan, M.; Bahinski, A.; Hamilton, G.A.; Ingber, D.E. Microfabrication of human organs-on-chips. Nat. Protoc. 2013, 8, 2135–2157. [Google Scholar] [CrossRef]

- Cacucciolo, V.; Shintake, J.; Kuwajima, Y.; Maeda, S.; Floreano, D.; Shea, H. Stretchable pumps for soft machines. Nature 2019, 572, 516–519. [Google Scholar] [CrossRef] [PubMed]

- Qin, D.; Xia, Y.; Whitesides, G.M. Soft lithography for micro- and nanoscale patterning. Nat. Protoc. 2010, 5, 491–502. [Google Scholar] [CrossRef] [PubMed]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Noimark, S.; Colchester, R.J.; Poduval, R.K.; Maneas, E.; Alles, E.J.; Zhao, T.; Zhang, E.Z.; Ashworth, M.; Tsolaki, E.; Chester, A.H.; et al. Polydimethylsiloxane composites for optical ultrasound generation and multimodality imaging. Adv. Funct. Mater. 2018, 28, 1704919. [Google Scholar] [CrossRef]

- Ajayan, P.; Tour, J. Materials science—Nanotube composites. Nature 2007, 447, 1066–1068. [Google Scholar] [CrossRef]

- Eichelsdoerfer, D.J.; Liao, X.; Cabezas, M.D.; Morris, W.; Radha, B.; Brown, K.A.; Giam, L.R.; Braunschweig, A.B.; Mirkin, C.A. Large-area molecular patterning with polymer pen lithography. Nat. Protoc. 2013, 8, 2548–2560. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Li, L.; Zhang, X.A.; Alsharif, N.; Wu, X.; Peng, Z.; Cheng, X.; Wang, P.; Brown, K.A.; Wang, Y. Photoactuated pens for molecular printing. Adv. Mater. 2018, 30, 1705303. [Google Scholar] [CrossRef] [PubMed]

- Horiuchi, N. Photoactuated printing. Nat. Photonics 2018, 12, 123. [Google Scholar] [CrossRef]

- Li, L.; Huang, Z.; Wang, Y.; Brown, K.A. Design of elastomer-CNT film photoactuators for nanolithography. Polymers 2019, 11, 314. [Google Scholar] [CrossRef]

- Choi, K.M.; Rogers, J.A. A photocurable poly(dimethylsiloxane) chemistry designed for soft lithographic molding and printing in the nanometer regime. J. Am. Chem. Soc. 2003, 125, 4060–4061. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Parra-Cabrera, C.; Kim, Y.T.; Kuo, A.P.; Folch, A. Desktop-stereolithography 3D-printing of a poly(dimethylsiloxane)-based material with sylgard-184 properties. Adv. Mater. 2018, 30, 1800001. [Google Scholar] [CrossRef] [PubMed]

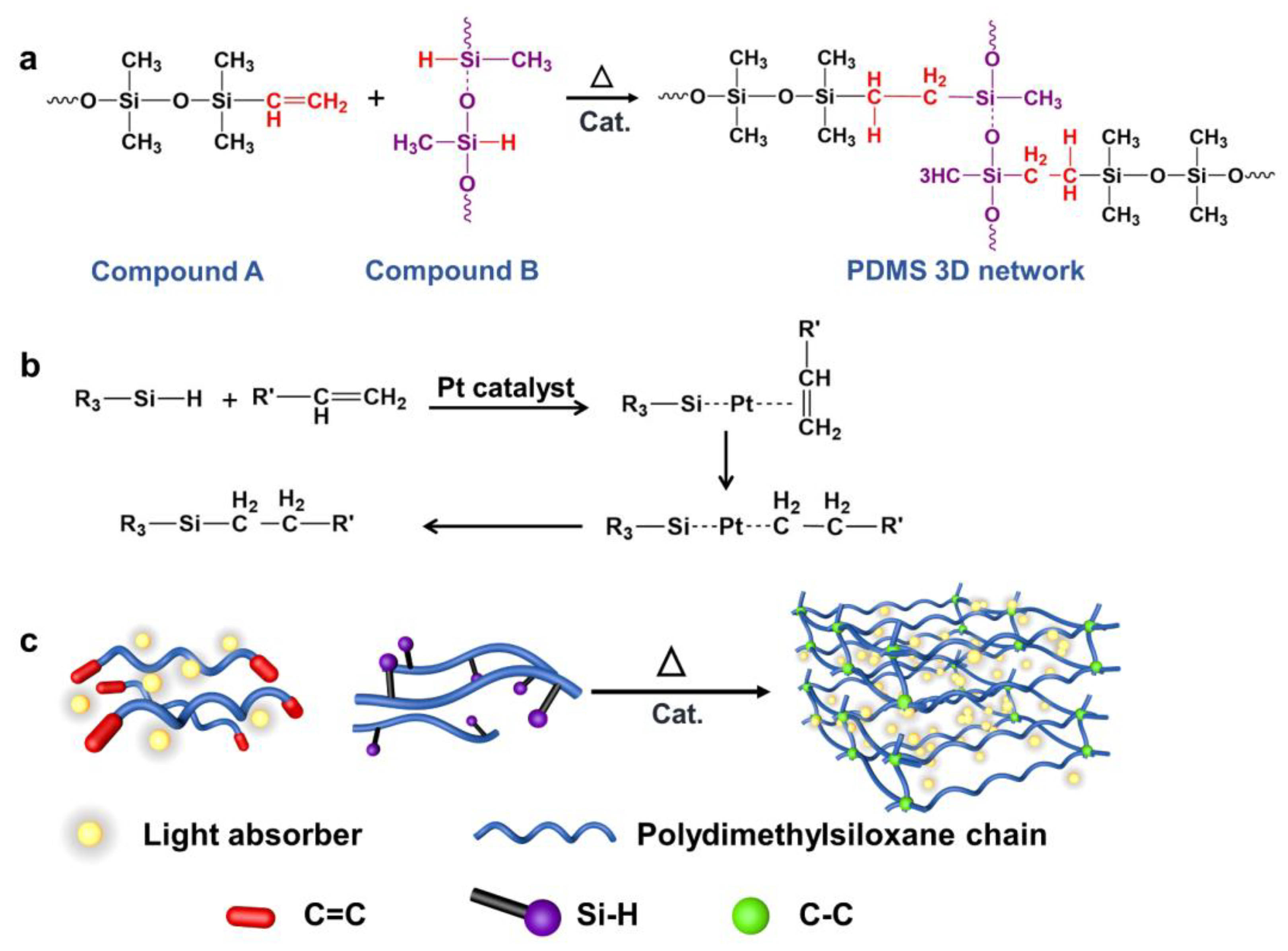

- Troegel, D.; Stohrer, J. Recent advances and actual challenges in late transition metal catalyzed hydrosilylation of olefins from an industrial point of view. Coordin. Chem. Rev. 2011, 255, 1440–1459. [Google Scholar] [CrossRef]

- Meister, T.K.; Riener, K.; Gigler, P.; Stohrer, J.; Herrmann, W.A.; Kühn, F.E. Platinum catalysis revisited-unraveling -principles of catalytic olefin hydrosilylation. ACS Catal. 2016, 6, 1274–1284. [Google Scholar] [CrossRef]

- Chalk, A.J.; Harrod, J.F. Homogeneous catalysis. II. the mechanism of the hydrosilation of olefins catalyzed by group VIII metal complexes1. J. Am. Chem. Soc. 1965, 87, 16–21. [Google Scholar] [CrossRef]

- Marciniec, B. Comprehensive Handbook on Hydrosilylation, 1st ed.; Pergamon: New York, NY, USA, 1992. [Google Scholar]

- Marciniec, B.; Maciejewski, H.; Pietraszuk, C.; Pawluc, P. Hydrosilylation: A Comprehensive Review on Recent Advances, 1st ed.; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Product Information about Dow Corning Brand Silicone Encapsulants. Available online: http://bdml.stanford.edu/twiki/pub/Rise/PDMSProceSS/PDMSdatasheet.pdf (accessed on 1 January 2023).

- Parbhoo, B.; O’Hare, L.A.; Leadley, S.R. Chapter 14—Fundamental aspects of adhesion technology in silicones. In Adhesion Science and Engineering; Dillard, D.A., Pocius, A.V., Chaudhury, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; pp. 677–709. [Google Scholar]

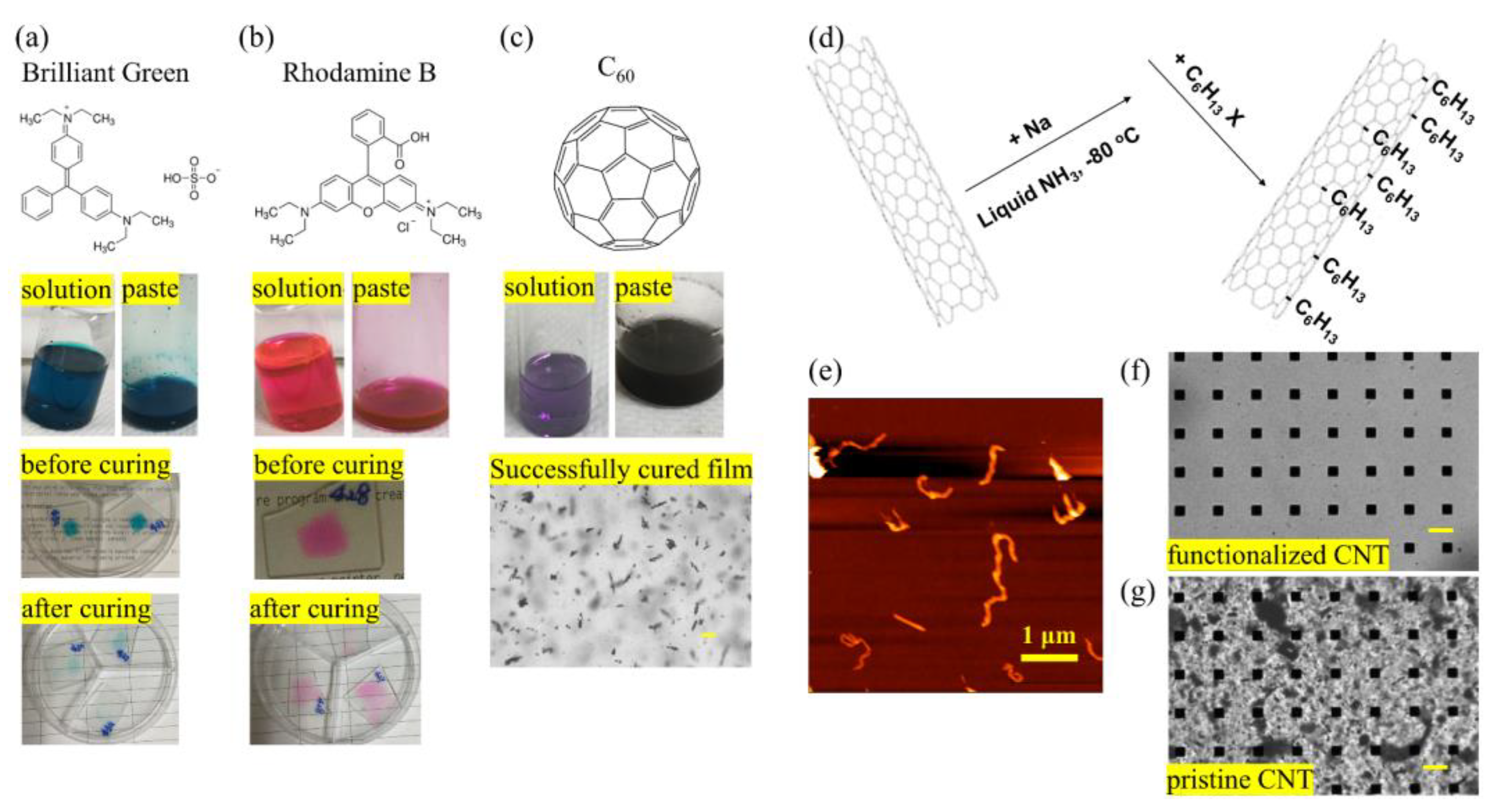

- Astefanei, A.; Núñez, O.; Galceran, M.T. Characterisation and determination of fullerenes: A critical review. Anal. Chim. Acta 2015, 882, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Bogdanov, A.A. Processes of aggregation of fullerene C60 in polymer–fullerene composites. Phys. Solid State 2020, 62, 354–358. [Google Scholar] [CrossRef]

- Liao, X.; Brown, K.A.; Schmucker, A.L.; Liu, G.; He, S.; Shim, W.; Mirkin, C.A. Desktop nanofabrication with massively multiplexed beam pen lithography. Nat. Commun. 2013, 4, 2103. [Google Scholar] [CrossRef]

- Carbonell, C.; Valles, D.J.; Wong, A.M.; Tsui, M.W.; Niang, M.; Braunschweig, A.B. Massively multiplexed tip-based photochemical lithography under continuous capillary flow. Chem 2018, 4, 857–867. [Google Scholar] [CrossRef]

- Brown, K.A.; Eichelsdoerfer, D.J.; Shim, W.; Rasin, B.; Radha, B.; Liao, X.; Schmucker, A.L.; Liu, G.; Mirkin, C.A. A cantilever-free approach to dot-matrix nanoprinting. Proc. Natl. Acad. Sci. USA 2013, 110, 12921–12924. [Google Scholar] [CrossRef] [PubMed]

- Salaita, K.; Wang, Y.; Fragala, J.; Vega, R.A.; Liu, C.; Mirkin, C.A. Massively parallel dip–pen nanolithography with 55 000-pen two-dimensional arrays. Angew. Chem. Int. Ed. 2006, 45, 7220–7223. [Google Scholar] [CrossRef]

- Salaita, K.; Wang, Y.; Mirkin, C.A. Applications of dip-pen nanolithography. Nat. Nanotech. 2007, 2, 145–155. [Google Scholar] [CrossRef] [PubMed]

- Gallastegui, A.; Dominguez-Alfaro, A.; Lezama, L.; Alegret, N.; Prato, M.; Gómez, M.L.; Mecerreyes, D. Fast visible-light photopolymerization in the presence of multiwalled carbon nanotubes: Toward 3D printing conducting nanocomposites. ACS Macro Lett. 2022, 11, 303–309. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Ramadani, E.; Egap, E. Thiol ligand capped quantum dot as an efficient and oxygen tolerance photoinitiator for aqueous phase radical polymerization and 3D printing under visible light. Polym. Chem. 2021, 12, 5106–5116. [Google Scholar] [CrossRef]

- Wang, P.; Barnes, B.; Huang, Z.; Wang, Z.; Zheng, M.; Wang, Y. Beyond color: The new carbon ink. Adv. Mater. 2021, 33, 2005890. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Powell, L.R.; Wu, X.; Kim, M.; Qu, H.; Wang, P.; Fortner, J.L.; Xu, B.; Ng, A.L.; Wang, Y. Photolithographic patterning of organic color-centers. Adv. Mater. 2020, 32, 1906517. [Google Scholar] [CrossRef] [PubMed]

- Deng, S.; Zhang, Y.; Brozena, A.H.; Mayes, M.L.; Banerjee, P.; Chiou, W.-A.; Rubloff, G.W.; Schatz, G.C.; Wang, Y. Confined propagation of covalent chemical reactions on single-walled carbon nanotubes. Nat. Commun. 2011, 2, 382. [Google Scholar] [CrossRef]

- Huo, F.; Zheng, Z.; Zheng, G.; Giam, L.R.; Zhang, H.; Mirkin, C.A. Polymer Pen Lithography. Science 2008, 321, 1658–1660. [Google Scholar] [CrossRef]

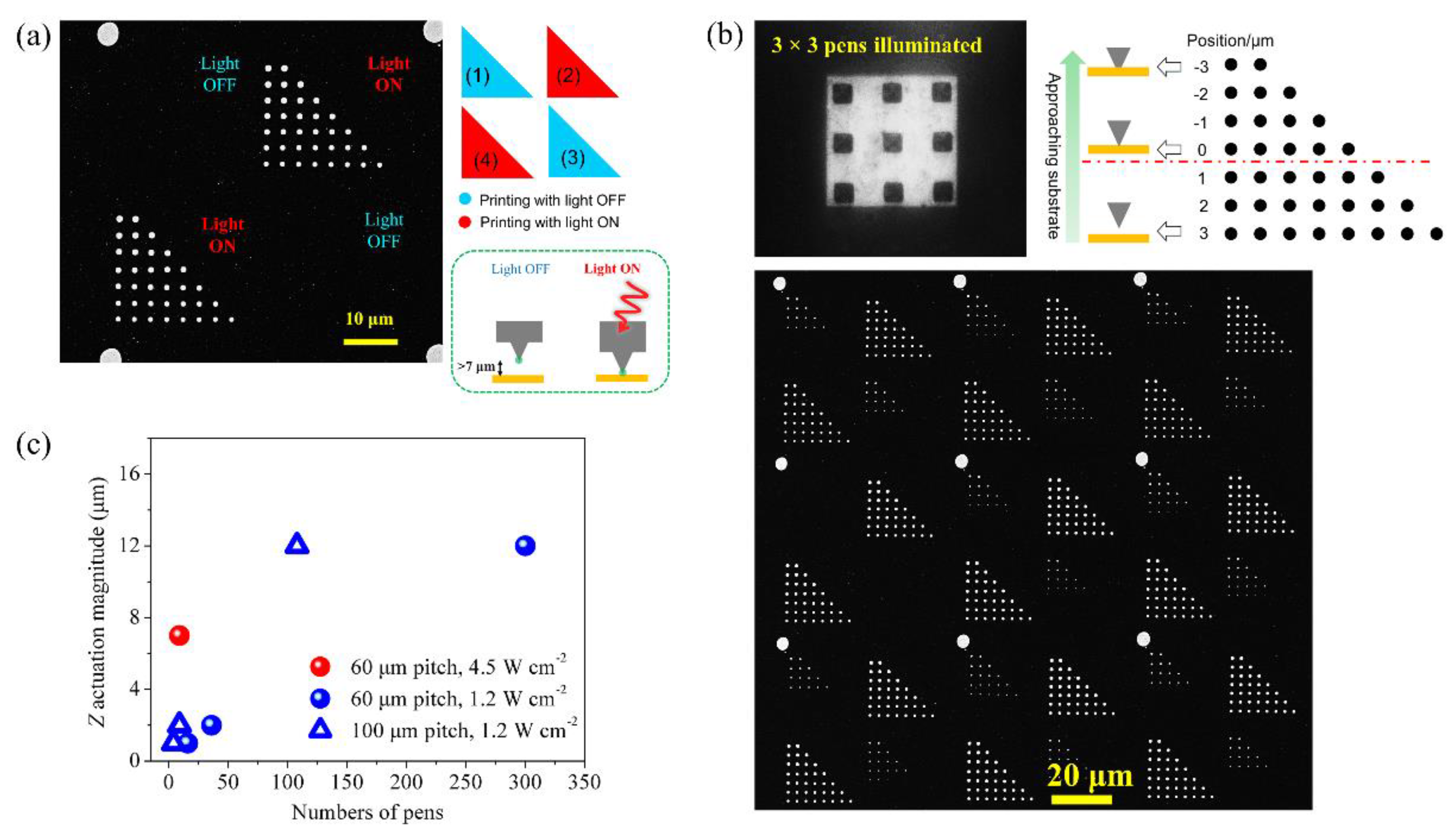

| Actuation Approach | Typical Actuation Resolution | Actuation Magnitude (μm) | Potential for Scaling up | Year/Ref |

|---|---|---|---|---|

| resistive heating | 4 × 4 | 2–4 | challenge in fabricating complex system | 2013 [53] |

| photoactuation through microscopic light | ~3000 | 3 | inability to address small groups of or individual pens | 2018 [37] |

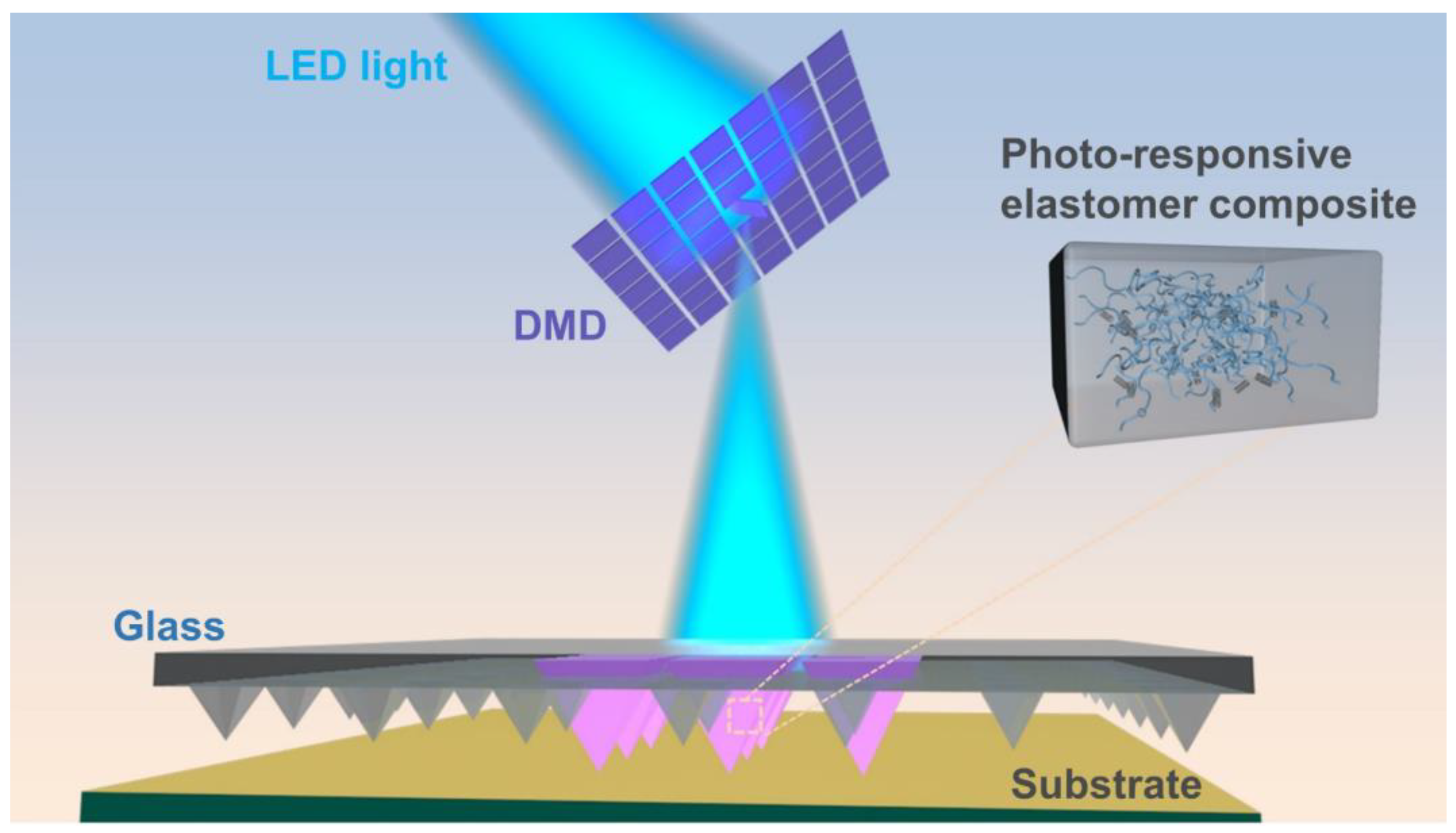

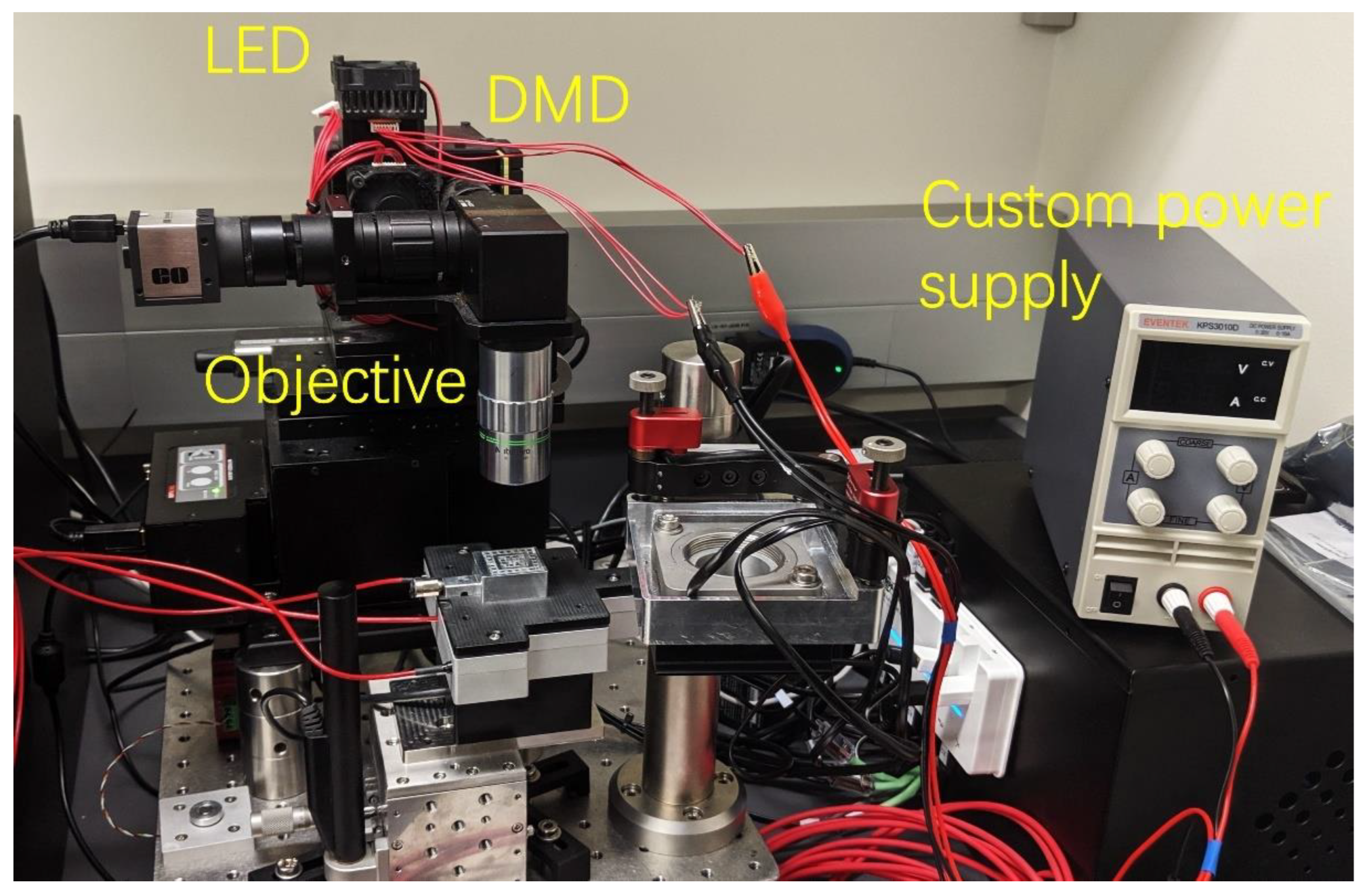

| photoactuation through DMD | 3 × 3 | >7 | promising for scaling up | this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Li, S.; Zhang, J.; Pang, H.; Ivankin, A.; Wang, Y. Localized Photoactuation of Polymer Pens for Nanolithography. Molecules 2023, 28, 1171. https://doi.org/10.3390/molecules28031171

Huang Z, Li S, Zhang J, Pang H, Ivankin A, Wang Y. Localized Photoactuation of Polymer Pens for Nanolithography. Molecules. 2023; 28(3):1171. https://doi.org/10.3390/molecules28031171

Chicago/Turabian StyleHuang, Zhongjie, Shaopeng Li, Jiaqi Zhang, Huan Pang, Andrey Ivankin, and Yuhuang Wang. 2023. "Localized Photoactuation of Polymer Pens for Nanolithography" Molecules 28, no. 3: 1171. https://doi.org/10.3390/molecules28031171

APA StyleHuang, Z., Li, S., Zhang, J., Pang, H., Ivankin, A., & Wang, Y. (2023). Localized Photoactuation of Polymer Pens for Nanolithography. Molecules, 28(3), 1171. https://doi.org/10.3390/molecules28031171