Hybrid Passivated Red Organic LEDs with Prolonged Operation and Storage Lifetime

Abstract

1. Introduction

2. Experimental Section

2.1. Optimization of Encapsulation Layers

2.2. Device Fabrication

2.3. Testing of Encapsulation Layers and Devices

3. Results and Discussions

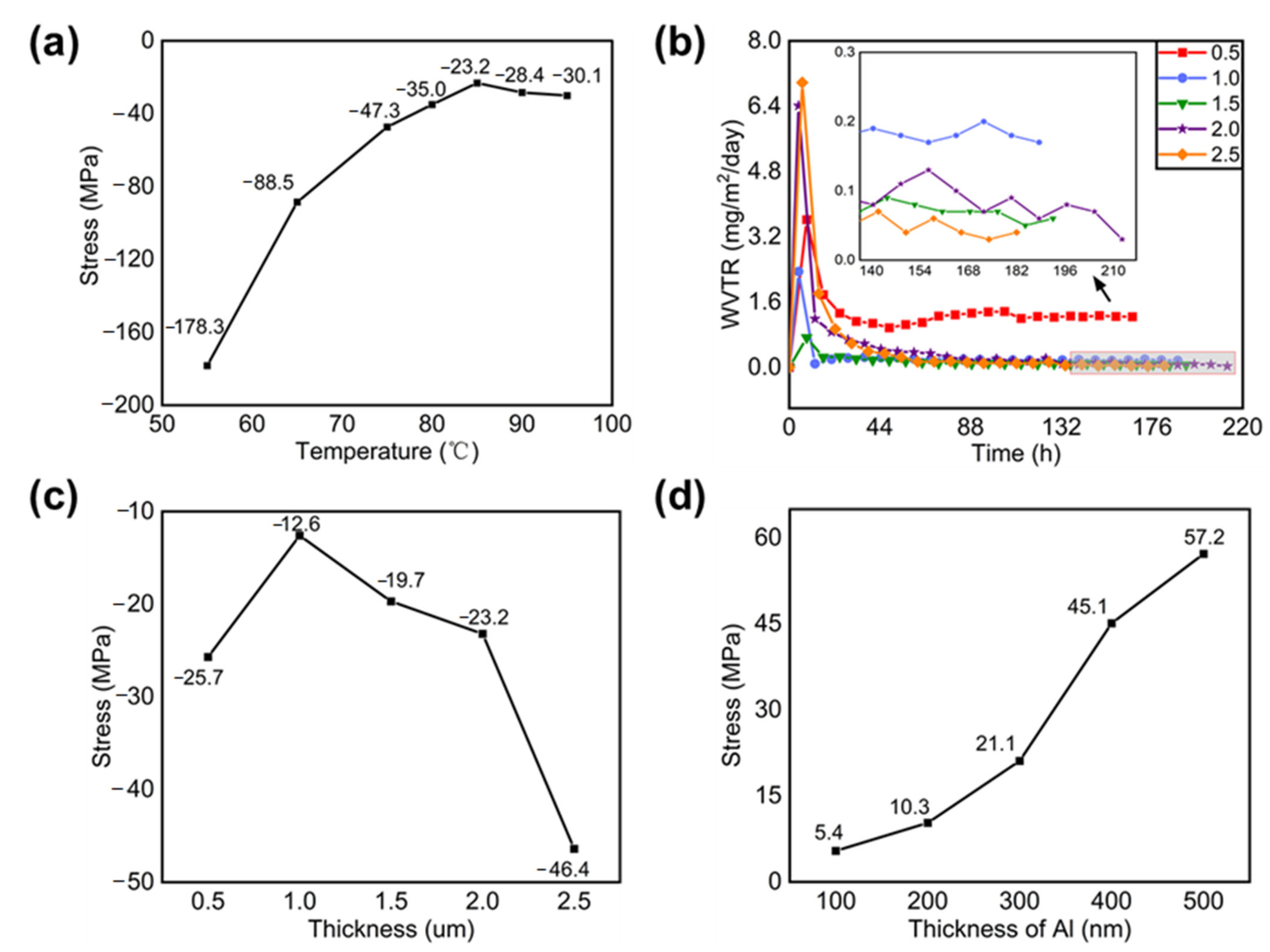

3.1. Characteristics of SixNy Thin Films Deposited by PECVD

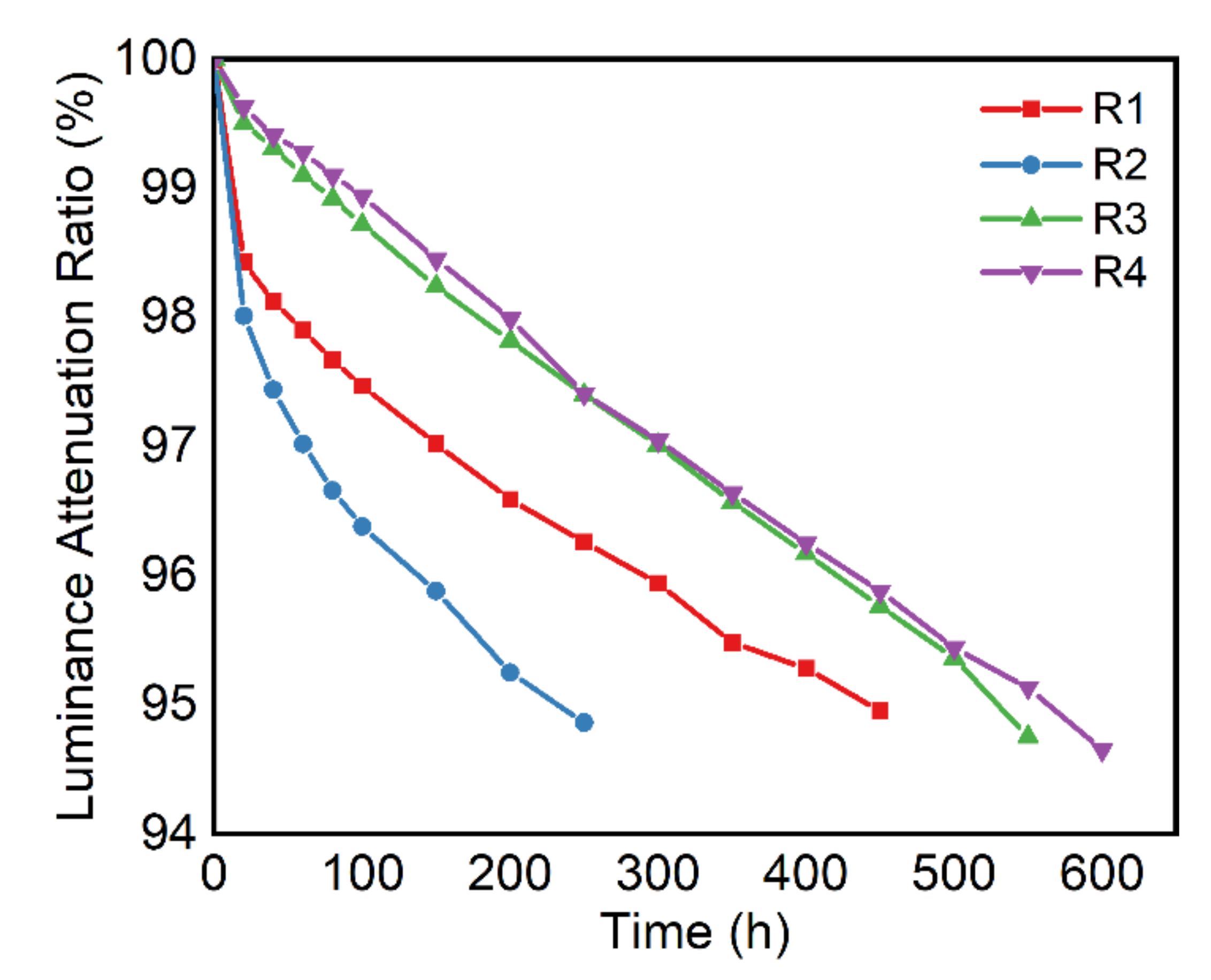

3.2. Encapsulation Performance of Red OLEDs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Du, J.; Zhang, D.; Sun, H.; Yin, L.; Ma, L.; Chen, J.; Ma, D.; Cheng, H.M.; Ren, W. Rosin-enabled ultraclean and damage-free transfer of graphene for large-area flexible organic light-emitting diodes. Nat. Commun. 2017, 8, 14560. [Google Scholar] [CrossRef]

- Hong, G.; Gan, X.; Leonhardt, C.; Zhang, Z.; Seibert, J.; Busch, J.M.; Brase, S. A Brief History of OLEDs-Emitter Development and Industry Milestones. Adv. Mater. 2021, 33, 2005630. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Zhang, Y.; Zhou, J.; Sun, S.; Luo, W.; He, W.; Wang, J.; Shi, X.; Fung, M.K. Hybrid Tandem White OLED with Long Lifetime and 150 Lm W−1 in Luminous Efficacy Based on TADF Blue Emitter Stabilized with Phosphorescent Red Emitter. Adv. Opt. Mater. 2020, 8, 2000727. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.L.; Luo, D.; Xiao, P.; Xiao, W.; Song, Y.; Ang, Q.; Liu, B. Strategies to Achieve High-Performance White Organic Light-Emitting Diodes. Materials 2017, 10, 1378. [Google Scholar] [CrossRef] [PubMed]

- Koo, J.H.; Jeong, S.; Shim, H.J.; Son, D.; Kim, J.; Kim, D.C.; Choi, S.; Hong, J.I.; Kim, D.H. Wearable Electrocardiogram Monitor Using Carbon Nanotube Electronics and Color-Tunable Organic Light-Emitting Diodes. ACS Nano 2017, 11, 10032. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.; Kwon, J.; Kim, C.; Kim, T.S.; Choi, K.C.; Yoo, S. Design of ultrathin OLEDs having oxide-based transparent electrodes and encapsulation with sub-mm bending radius. Org. Electron. 2020, 82, 105704. [Google Scholar] [CrossRef]

- Kim, H.; Choi, H.R.; Park, Y.; Jeon, Y.; Lee, H.S.; Jeong, E.G.; Park, K.C.; Choi, K.C. A Flexible and Wavelength-Designable Polymer Light-Emitting Diode Employing Sandwich-Encapsulation for Wearable Skin Rejuvenation Photomedicine. Adv. Mater. Interfaces 2021, 8, 2100856. [Google Scholar] [CrossRef]

- Jeon, Y.; Choi, H.R.; Kwon, J.H.; Choi, S.; Nam, K.M.; Park, K.C.; Choi, K.C. Sandwich-structure transferable free-form OLEDs for wearable and disposable skin wound photomedicine. Light Sci. Appl. 2019, 8, 114. [Google Scholar] [CrossRef]

- Chen, H.; Tan, G.; Wu, S.T. Ambient contrast ratio of LCDs and OLED displays. Opt. Express 2017, 25, 33643. [Google Scholar] [CrossRef]

- Yeom, J.-M.; Jung, H.-J.; Choi, S.-Y.; Lee, D.S.; Lim, S.-R. Environmental Effects of the Technology Transition from Liquid–Crystal Display (LCD) to Organic Light-Emitting Diode (OLED) Display from an E-Waste Management Perspective. Int. J. Environ. Res. 2018, 12, 479. [Google Scholar] [CrossRef]

- Huang, Y.; Hsiang, E.L.; Deng, M.Y.; Wu, S.T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef] [PubMed]

- Burroughes, J.H.; Bradley, D.; Brown, A.R.; Marks, R.N.; Mackay, K.; Friend, R.H.; Burns, P.L.; Holmes, A. Light-emitting diodes baed on conjugated polymers. Nature 1990, 347, 539. [Google Scholar] [CrossRef]

- Choi, Y.; Ha, R.; Cha, H. Fully automated OLED display power modeling for mobile devices. Pervasive Mob. Comput. 2018, 50, 41–55. [Google Scholar] [CrossRef]

- Salehi, A.; Fu, X.; Shin, D.H.; So, F. Recent Advances in OLED Optical Design. Adv. Funct. Mater. 2019, 29, 1808803. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Kim, S.-W.; Lee, J.-R.; Um, S.H.; Joung, Y.K.; Bhang, S.H. Comparing the cytotoxic effect of light-emitting and organic light-emitting diodes based light therapy on human adipose-derived stem cells. J. Ind. Eng. Chem. 2021, 103, 239–246. [Google Scholar] [CrossRef]

- Yang, X.; Guo, H.; Xu, X.; Sun, Y.; Zhou, G.; Ma, W.; Wu, Z. Enhancing Molecular Aggregations by Intermolecular Hydrogen Bonds to Develop Phosphorescent Emitters for High-Performance Near-Infrared OLEDs. Adv. Sci. 2019, 6, 1801930. [Google Scholar] [CrossRef] [PubMed]

- Lian, C.; Piksa, M.; Yoshida, K.; Persheyev, S.; Pawlik, K.J.; Matczyszyn, K.; Samuel, I.D.W. Flexible organic light-emitting diodes for antimicrobial photodynamic therapy. NPJ Flex. Electron. 2019, 3, 18. [Google Scholar] [CrossRef]

- Guo, H.W.; Lin, L.T.; Chen, P.H.; Ho, M.H.; Huang, W.T.; Lee, Y.J.; Chiou, S.H.; Hsieh, Y.S.; Dong, C.Y.; Wang, H.W. Low-fluence rate, long duration photodynamic therapy in glioma mouse model using organic light emitting diode (OLED). Photodiagn. Photodyn. Ther. 2015, 12, 504. [Google Scholar] [CrossRef]

- Melendez-Celis, U.; Spezzia-Mazzocco, T.; Persheyev, S.; Lian, C.; Samuel, I.; Ramirez-San-Juan, J.C.; Ramos-Garcia, R. Organic light emitting diode for in vitro antimicrobial photodynamic therapy of Candida strains. Photodyn Ther. 2021, 36, 102567. [Google Scholar] [CrossRef]

- Attili, S.K.; Lesar, A.; McNeill, A.; Camacho-Lopez, M.; Moseley, H.; Ibbotson, S.; Samuel, I.D.; Ferguson, J. An open pilot study of ambulatory photodynamic therapy using a wearable low-irradiance organic light-emitting diode light source in the treatment of nonmelanoma skin cancer. Br. J. Dermatol. 2009, 161, 170–173. [Google Scholar] [CrossRef]

- Güney, A.; Yelten, M.B.; Ferhanoğlu, O.; Kahraman, N. Experimental and modeling studies of automotive-qualified OLEDs under electrical stress. Microelectron. Reliab. 2020, 111, 113704. [Google Scholar] [CrossRef]

- Melpignano, P.; Sinesi, S.; Rotaris, G.; Antonipieri, M.; Cicoira, F.; Loi, M.A.; Muccini, M.; Zamboni, R.; Gale, M.T.; Westenhöfer, S. Optical coupling of flexible microstructured organic light sources for automotive applications. Synth. Met. 2003, 139, 913–916. [Google Scholar] [CrossRef][Green Version]

- Mügge, M.; Hohmann, C. Signal lights–designed light for rear lamps and new upcoming technologies: Innovations in automotive lighting. Adv. Opt. Techn. 2016, 5, 117. [Google Scholar] [CrossRef]

- Kim, L.H.; Kim, K.; Park, S.; Jeong, Y.J.; Kim, H.; Chung, D.S.; Kim, S.H.; Park, C.E. Al2O3/TiO2 nanolaminate thin film encapsulation for organic thin film transistors via plasma-enhanced atomic layer deposition. ACS Appl. Mater. Interfaces 2014, 6, 6731–6738. [Google Scholar] [CrossRef]

- Jen, S.H.; George, S.M.; McLean, R.S.; Carcia, P.F. Alucone interlayers to minimize stress caused by thermal expansion mismatch between Al2O3 films and Teflon substrates. ACS Appl. Mater. Interfaces 2013, 5, 1165–1173. [Google Scholar] [CrossRef] [PubMed]

- Carcia, P.F.; McLean, R.S.; Reilly, M.H.; Groner, M.D.; George, S.M. Ca test of Al2O3 gas diffusion barriers grown by atomic layer deposition on polymers. Appl. Phys. Lett. 2006, 89, 031915. [Google Scholar] [CrossRef]

- Rückerl, A.; Zeisel, R.; Mandl, M.; Costina, I.; Schroeder, T.; Zoellner, M.H. Characterization and prevention of humidity related degradation of atomic layer deposited Al2O3. J. Appl. Phys. 2017, 121, 025306. [Google Scholar] [CrossRef]

- Han, Y.C.; Kim, E.; Kim, W.; Im, H.-G.; Bae, B.-S.; Choi, K.C. A flexible moisture barrier comprised of a SiO2-embedded organic–inorganic hybrid nanocomposite and Al2O3 for thin-film encapsulation of OLEDs. Org. Electron. 2013, 14, 1435–1440. [Google Scholar] [CrossRef]

- Chen, N.; Kovacik, P.; Howden, R.M.; Wang, X.; Lee, S.; Gleason, K.K. Low Substrate Temperature Encapsulation for Flexible Electrodes and Organic Photovoltaics. Adv. Energy Mater. 2015, 5, 1401442. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Kang, K.S.; Jeong, E.G.; Jeon, Y.; Choi, K.C. A Bilayer Encapsulation with High Chemical Stability in Harsh Environments for Environmentally Robust OLEDs. SID Symp. Dig. Tech. Pap. 2021, 52, 66. [Google Scholar] [CrossRef]

- Park, K.W.; Lee, S.; Lee, H.; Cho, Y.-H.; Park, Y.C.; Im, S.G.; Ko Park, S.-H. High-performance thin H:SiON OLED encapsulation layer deposited by PECVD at low temperature. RSC Adv. 2019, 9, 58–64. [Google Scholar] [CrossRef]

- Féry, C.; Racine, B.; Vaufrey, D.; Doyeux, H.; Cinà, S. Physical mechanism responsible for the stretched exponential decay behavior of aging organic light-emitting diodes. Appl. Phys. Lett. 2005, 87, 213502. [Google Scholar] [CrossRef]

- Haillant, O.; Dumbleton, D.; Zielnik, S. An Arrhenius approach to estimating organic photovoltaic module weathering acceleration factors. Sol. Energy Mater. Sol. Cells 2011, 95, 1889. [Google Scholar] [CrossRef]

| Type | Fresh | 5 h | 20 h | 50 h | 200 h | 400 h | 600 h | 800 h |

|---|---|---|---|---|---|---|---|---|

| R1 |  |  |  |  |  | 400 h | ||

| R2 |  |  |  | 45 h | ||||

| R3 |  |  |  |  |  |  |  | 760 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, D.-D.; Sun, S.-Q.; He, W.; Wang, J.; Shi, X.-B.; Fung, M.-K. Hybrid Passivated Red Organic LEDs with Prolonged Operation and Storage Lifetime. Molecules 2022, 27, 2607. https://doi.org/10.3390/molecules27092607

Feng D-D, Sun S-Q, He W, Wang J, Shi X-B, Fung M-K. Hybrid Passivated Red Organic LEDs with Prolonged Operation and Storage Lifetime. Molecules. 2022; 27(9):2607. https://doi.org/10.3390/molecules27092607

Chicago/Turabian StyleFeng, Dan-Dan, Shuang-Qiao Sun, Wei He, Jun Wang, Xiao-Bo Shi, and Man-Keung Fung. 2022. "Hybrid Passivated Red Organic LEDs with Prolonged Operation and Storage Lifetime" Molecules 27, no. 9: 2607. https://doi.org/10.3390/molecules27092607

APA StyleFeng, D.-D., Sun, S.-Q., He, W., Wang, J., Shi, X.-B., & Fung, M.-K. (2022). Hybrid Passivated Red Organic LEDs with Prolonged Operation and Storage Lifetime. Molecules, 27(9), 2607. https://doi.org/10.3390/molecules27092607