Production of α-Tocopherol–Chitosan Nanoparticles by Membrane Emulsification

Abstract

:1. Introduction

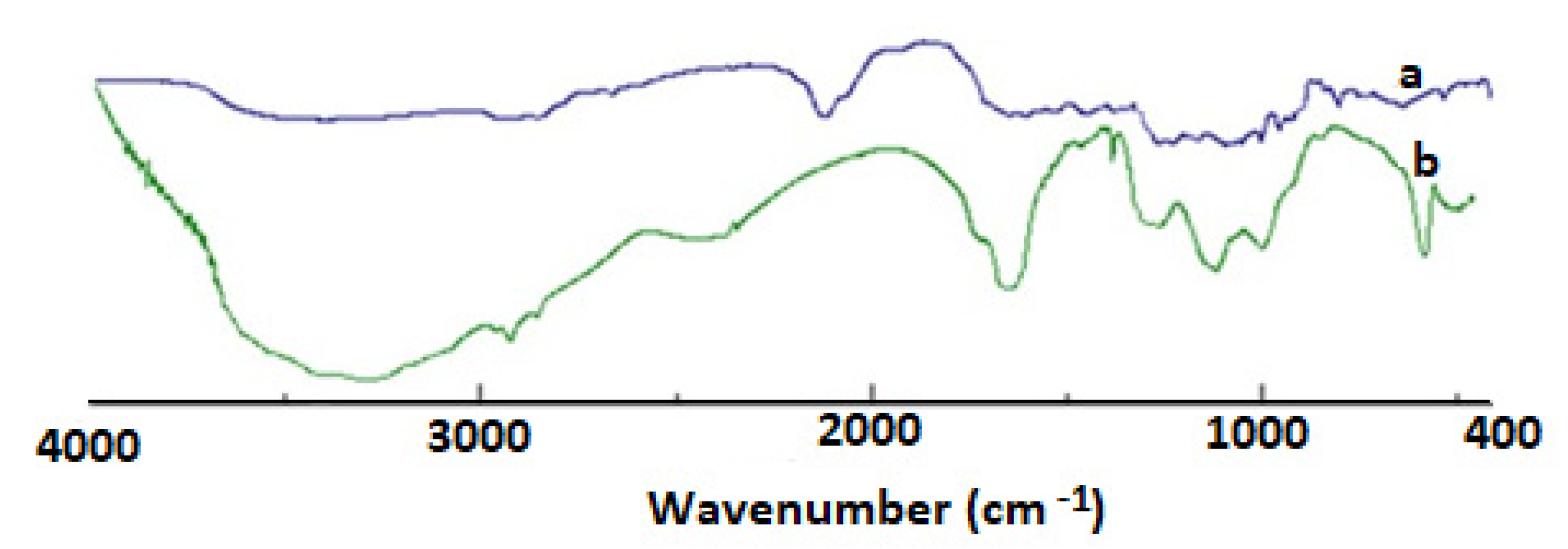

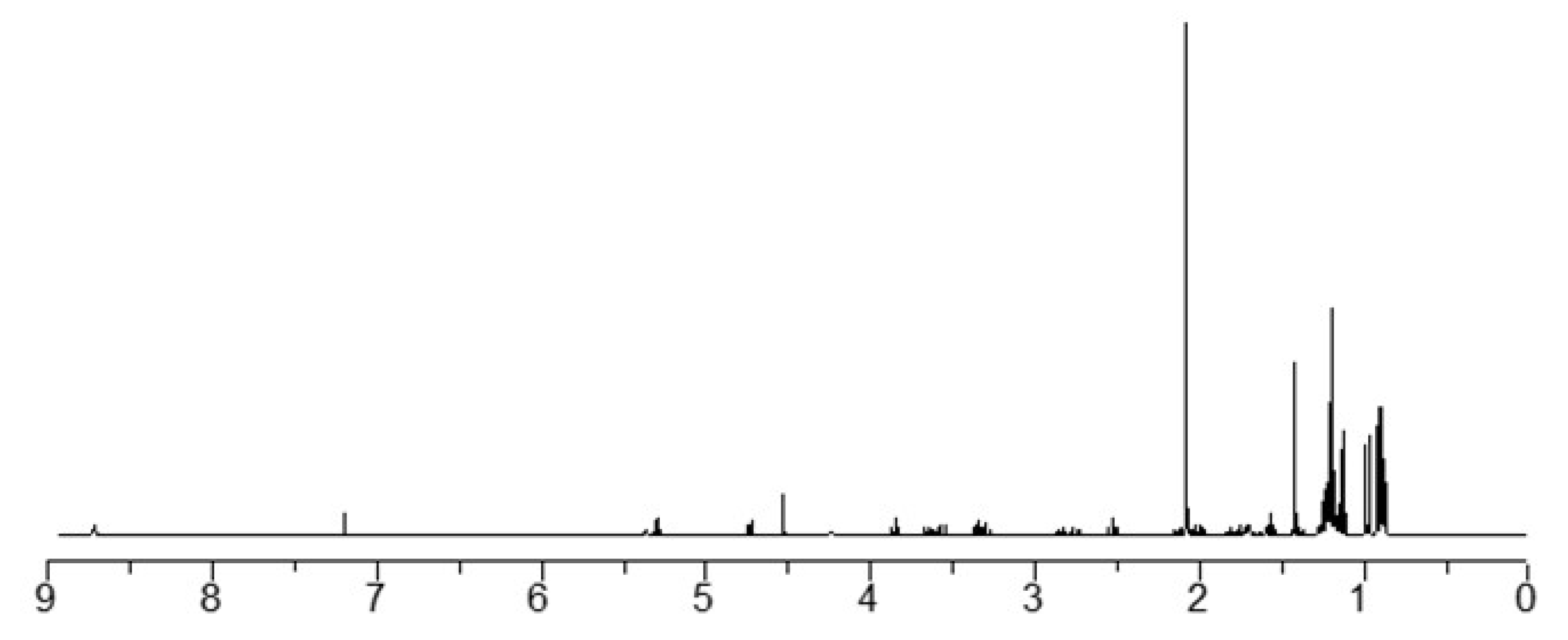

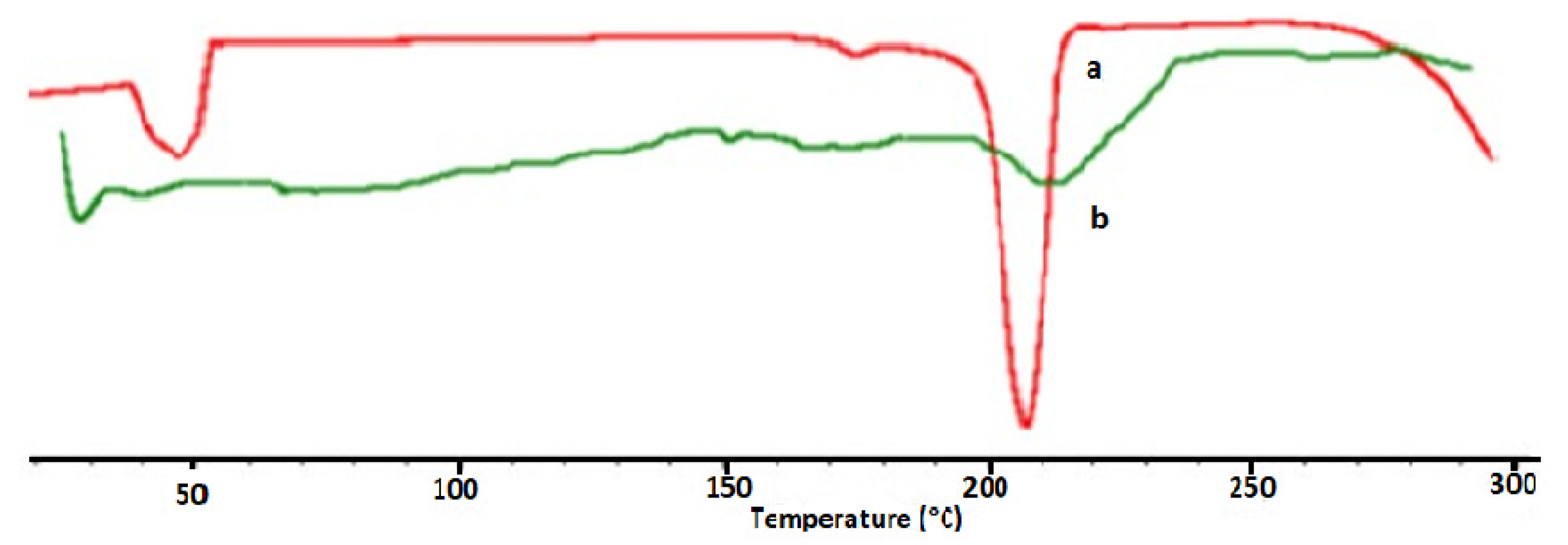

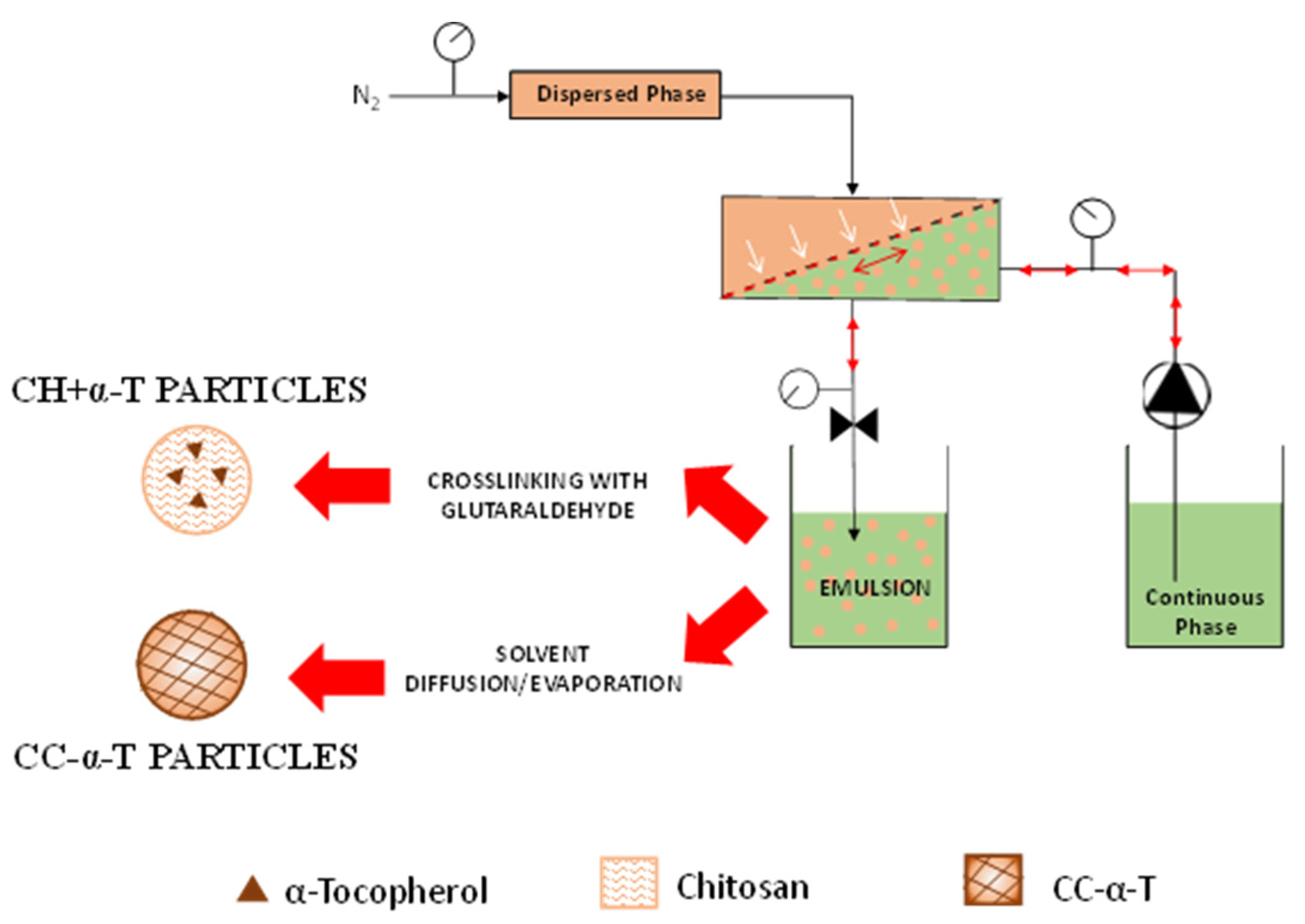

2. Results and Discussion

3. Materials and Methods

3.1. Materials

3.2. Instruments

3.3. Carboxy-Chitosan Synthesis (CC)

3.4. Reaction between α-Tocopherol and CC

3.5. Production of α-Tocopherol-Loaded Nanoparticles Based on Chitosan by Membrane Emulsification

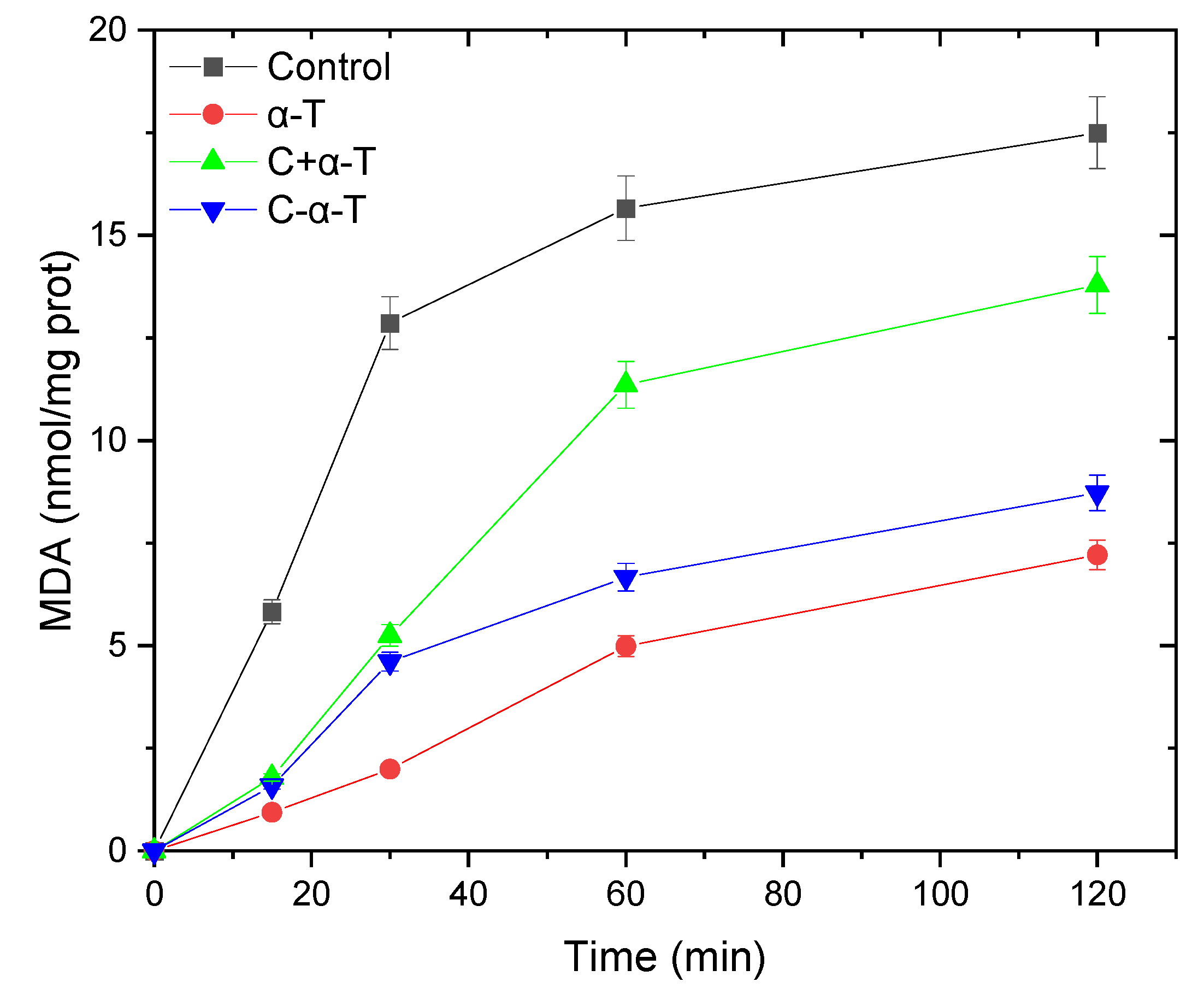

3.6. Evaluation of Antioxidant Capacity

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Jiang, Q.; Im, S.; Wagner, J.G.; Hernandez, M.L.; Peden, D.B. Gamma-tocopherol, a major form of vitamin E in diets: Insights into antioxidant and anti-inflammatory effects, mechanisms, and roles in disease management. Free Radic. Biol. Med. 2022, 178, 347–359. [Google Scholar] [CrossRef] [PubMed]

- Flory, S.; Birringer, M.; Frank, J. Bioavailability and Metabolism of Vitamin E. In Vitamin E in Human Health; Weber, P., Birringer, M., Blumberg, J., Eggersdorfer, M., Frank, J., Eds.; Nutrition and Health; Springer: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Souto, E.B.; Baldim, I.; Oliveira, W.P.; Rao, R.; Yadav, N.; Gama, F.M.; Mahant, S. SLN and NLC for topical, dermal, and transdermal drug delivery. Exp. Op. Drug. Deliv. 2020, 17, 357–377. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.A.; Yeda, J.T.M.; Wasan, K.M.; Wasan, E.K. An Overview of Chitosan Nanoparticles and Its Application in Non-Parentera. Drug Delivery. Pharm. 2017, 9, 53. [Google Scholar]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef] [PubMed]

- Trombino, S.; Curcio, F.; Di Gioia, M.L.; Armentano, B.; Poerio, T.; Cassano, R. Multifunctional Membranes Based on β-Glucans and Chitosan Are Useful in Wound Treatment. Membranes 2022, 12, 121. [Google Scholar] [CrossRef] [PubMed]

- Trombino, S.; Curcio, F.; Poerio, T.; Pellegrino, M.; Russo, R.; Cassano, R. Chitosan Membranes Filled with Cyclosporine A as Possible Devices for Local Administration of Drugs in the Treatment of Breast Cancer. Molecules 2021, 26, 1889. [Google Scholar] [CrossRef] [PubMed]

- Matalqah, S.M.; Aiedeh, K.; Mhaidat, N.M.; Alzoubi, K.H.; Bustanji, Y.; Hamad, I. Chitosan Nanoparticles as a Novel Drug Delivery System: A Review. Curr. Drug. Targets 2020, 21, 1613–1624. [Google Scholar] [CrossRef]

- Aboudzadeh, M.A.; Mehravar, E.; Fernandez, M.; Lezama, L.; Tomovska, R. Low-Energy Encapsulation of α-Tocopherol Using Fully Food Grade Oil-in-Water Microemulsions. ACS Omega 2018, 3, 10999–11008. [Google Scholar] [CrossRef]

- Giri, T.K. Chitosan basednanoparticulate system for controlled delivery of biological macromolecules. Nanomat. Drug Deliv. Therap. 2019, 15, 435–459. [Google Scholar]

- Essaghraoui, A.; Belfkira, A.; Hamdaoui, B.; Nunes, C.; Costa Lima, S.A.; Reis, S. Improved Dermal Delivery of Cyclosporine A Loaded in Solid Lipid Nanoparticles. Nanomaterials 2019, 9, 1204. [Google Scholar] [CrossRef] [Green Version]

- Kohn, J. Formulation Strategy for the Delivery of Cyclosporine A: Comparison of Two Polymeric Nanospheres. Sci. Rep. 2015, 5, 13065. [Google Scholar]

- Nasiri, F.; Faghfouri, L.; Hamidi, M. Preparation, optimization, and in-vitro characterization of α-tocopherol-loaded solid lipid nanoparticles (SLNs). Drug. Dev. Ind. Pharm. 2020, 46, 159–171. [Google Scholar] [CrossRef] [PubMed]

- Zigoneanu, I.G.; Astete, C.E.; Sabliov, C.M. Nanoparticles with entrapped α-tocopherol: Synthesis, characterization, and controlled release. Nanotechnology 2008, 19, 105606. [Google Scholar] [CrossRef] [PubMed]

- Piacentini, E.; Dragosavac, M.; Giorno, L. Pharmaceutical particles design by membrane emulsification: Preparation methods and applications in drug delivery. Curr. Pharm. Design. 2017, 23, 302–318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vladisavljević, G.T. Structured microparticles with tailored properties produced by membrane emulsification. Adv. Colloid Interface Sci. 2015, 225, 53–87. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, W.; Yang, X.L.; Winston Ho, W.S. Preparation of uniform-sized multiple emulsions and micro/nano particulates for drug delivery by membrane emulsification. J. Pharm. Sci. 2011, 100, 75–93. [Google Scholar] [CrossRef]

- Imbrogno, A.; Piacentini, E.; Drioli, E.; Giorno, L. Preparation of uniformpoly-caprolactoneMicroparticles by membrane emulsification/solventdiffusionprocess. J. Membr. Sci. 2014, 467, 262–268. [Google Scholar] [CrossRef]

- Piacentini, E.; Drioli, E.; Giorno, L. Pulsed back-and-forward cross-flow batch membrane emulsification with high productivity to obtain highly uniform and concentrate emulsions. J. Membr. Sci. 2014, 453, 119–125. [Google Scholar] [CrossRef]

- Mazzei, R.; Piacentini, E.; Nardi, M.; Giorno, L.; Pellegrino, M. Production of Plant-Derived Oleuropein Aglycone by a Combined Membrane Process and Evaluation of Its Breast Anticancer Properties. Front. Bioeng. Biotechnol. 2020, 8, 908. [Google Scholar] [CrossRef]

- Piacentini, E.; Bazzarelli, F.; Poerio, T.; Sebastian, V.; Giorno, L. Encapsulation of water-soluble drugs in Poly (vinyl alcohol) (PVA)- microparticles via membrane emulsification: Influence of process and formulation parameters on structural and functional properties. Mater. Today Commun. 2020, 24, 100967. [Google Scholar] [CrossRef]

- Imbrogno, A.; Dragosavac, M.M.; Piacentini, E.; Holdich, R.G.; Giorno, L. Polycaprolactone multicore-matrix particle for the simultaneous encapsulation of hydrophilic and hydrophobic compounds produced by membrane emulsification and solvent diffusion processes. Colloids Surf. B Biointerfaces 2015, 135, 116–125. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Piacentini, E.; Poerio, T.; Bazzarelli, F.; Giorno, L. Continuous production of PVA-basedhydrogelnanoparticles by membrane nanoprecipitation. J. Membr. Sci. 2021, 637, 119649. [Google Scholar] [CrossRef]

- De Jesus, M.; Zuhorn, I.S. Solid lipid nanoparticles as nucleic acid delivery system: Properties and molecular mechanism. J. Control. Release 2015, 201, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Imbrogno, A.; Piacentini, E.; Drioli, E.; Giorno, L. Micro and nano polycaprolactone particles preparation by pulsed back-and-forward crossflow batch membrane emulsification for parenteral administration. Int. J. Pharm. 2014, 477, 344–350. [Google Scholar] [CrossRef]

- Mitsunobu, O.; Yamada, Y. Preparation of Esters of Carboxylic and Phosphoric Acid via Quaternary Phosphonium Salts. Bull. Chem. Soc. Jpn. 1967, 40, 2380–2382. [Google Scholar] [CrossRef] [Green Version]

- Trombino, S.; Cassano, R.; Bloise, E.; Muzzalupo, R.; Leta, S.; Puoci, F.; Picci, N. Design and synthesis of cellulose derivates with antioxidant activity. Macromol. Biosci. 2007, 8, 85–96. [Google Scholar]

- Trombino, S.; Servidio, C.; Laganà, A.S.; Conforti, F.; Marrelli, M.; Cassano, R. Viscosified solid lipidic nanoparticles based on naringenin and linolenic acid for the release of cyclosporine a on the skin. Molecules 2020, 25, 3535. [Google Scholar] [CrossRef]

- Cassano, R.; Mellace, S.; Marrelli, M.; Conforti, F.; Trombino, S. α-Tocopheryl linolenate solid lipid nanoparticles for the encapsulation, protection, and release of the omega-3 polyunsaturated fatty acid: In vitro anti-melanoma activity evaluation. Colloids Surf. B Biointerfaces 2017, 151, 128–133. [Google Scholar] [CrossRef]

- Trombino, S.; Poerio, T.; Ferrarelli, T.; Mauro, M.V.; Giorno, L.; Cassano, R. Multifunctional membranes based on natural polymers: Preparation, characterization and in vitro performance evaluation. Polym. Int. 2015, 64, 344–351. [Google Scholar] [CrossRef]

| Reagents | Washing Solvent | |||||

|---|---|---|---|---|---|---|

| CC (g) | α-tocopherol (g) | DMAc (mL) | LiCl (g) | ADDP (mL) | Bu3P (mL) | Metanol (mL) |

| 1 | 2.54 | 370 | 3.73 | 2.91 | 3.92 | 358 |

| Reagents | |||

|---|---|---|---|

| CC-α-T (g) | NaOH (etanol.) (mL) | HCl 1 p. eq. (mL | HCl 2 p. eq. (mL) |

| 0.05 | 5 | 0.6 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trombino, S.; Poerio, T.; Curcio, F.; Piacentini, E.; Cassano, R. Production of α-Tocopherol–Chitosan Nanoparticles by Membrane Emulsification. Molecules 2022, 27, 2319. https://doi.org/10.3390/molecules27072319

Trombino S, Poerio T, Curcio F, Piacentini E, Cassano R. Production of α-Tocopherol–Chitosan Nanoparticles by Membrane Emulsification. Molecules. 2022; 27(7):2319. https://doi.org/10.3390/molecules27072319

Chicago/Turabian StyleTrombino, Sonia, Teresa Poerio, Federica Curcio, Emma Piacentini, and Roberta Cassano. 2022. "Production of α-Tocopherol–Chitosan Nanoparticles by Membrane Emulsification" Molecules 27, no. 7: 2319. https://doi.org/10.3390/molecules27072319

APA StyleTrombino, S., Poerio, T., Curcio, F., Piacentini, E., & Cassano, R. (2022). Production of α-Tocopherol–Chitosan Nanoparticles by Membrane Emulsification. Molecules, 27(7), 2319. https://doi.org/10.3390/molecules27072319