Study on the Incorporation of Oat and Yeast β-Glucan into Shortbread Biscuits as a Basis for Designing Healthier and High Quality Food Products

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characteristic of Raw Lipids

2.2. Nutritional Value of Lipids in Shortbread Biscuits and Their Density and Geometry

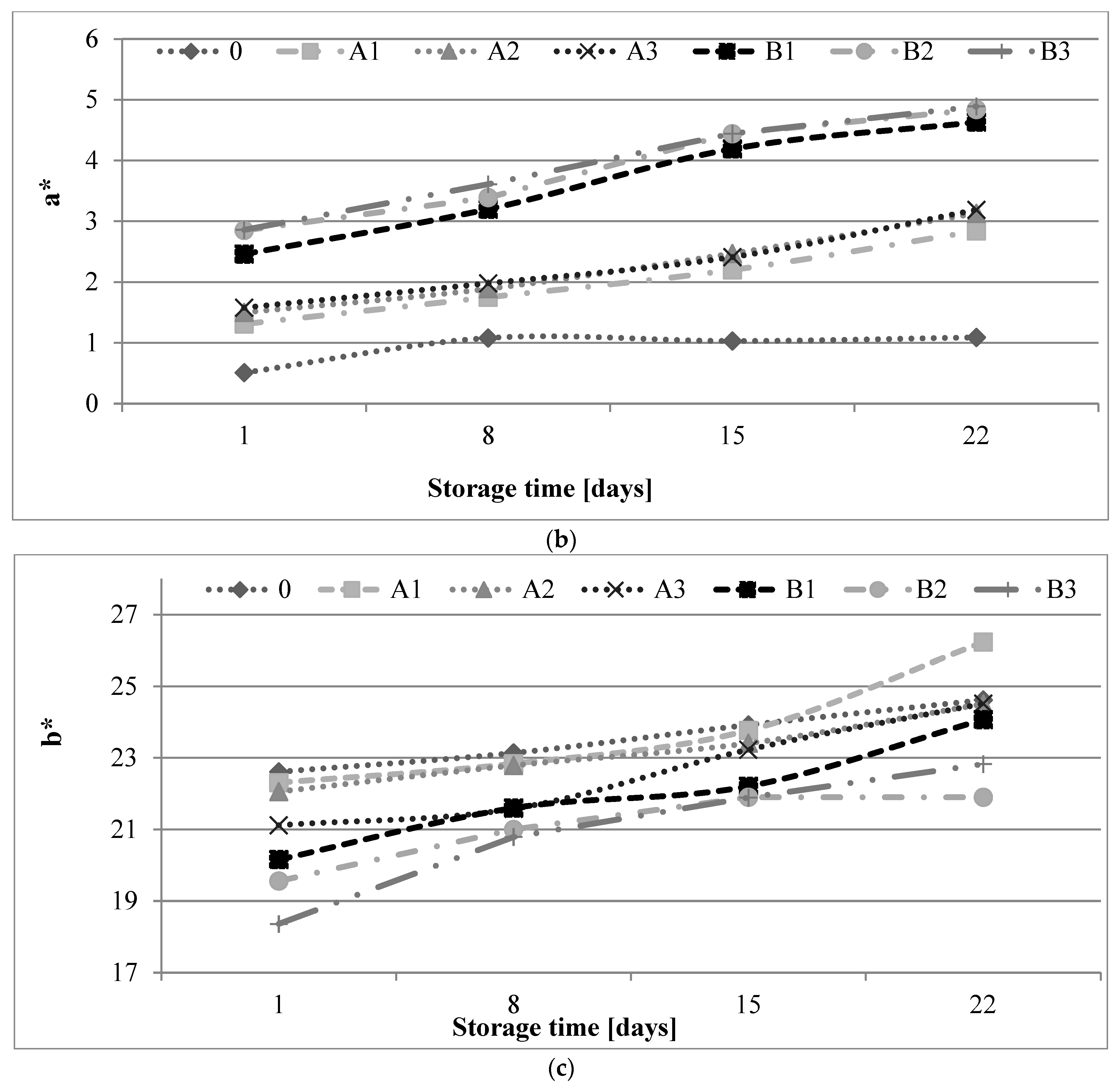

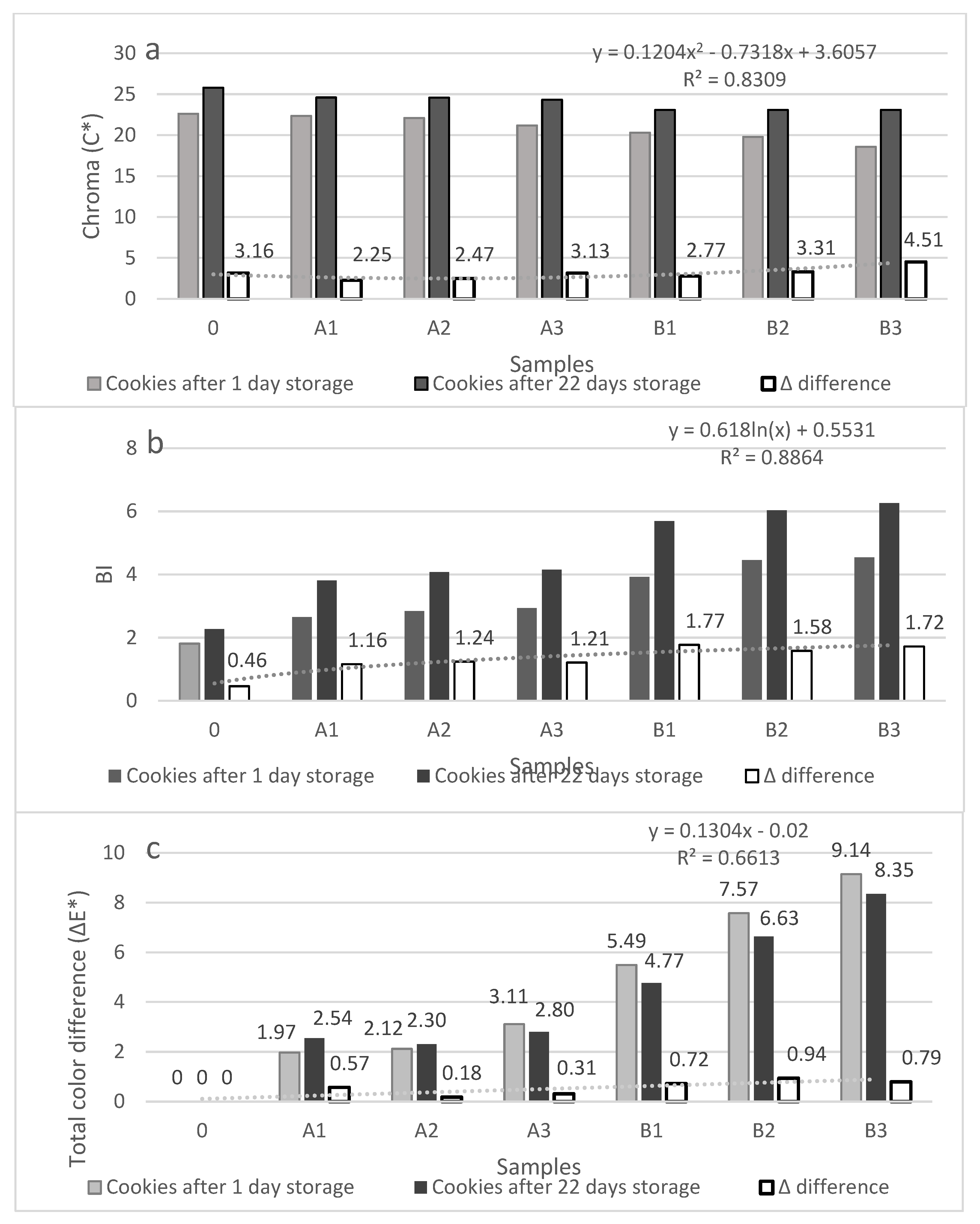

2.3. Color Parameters Assessment

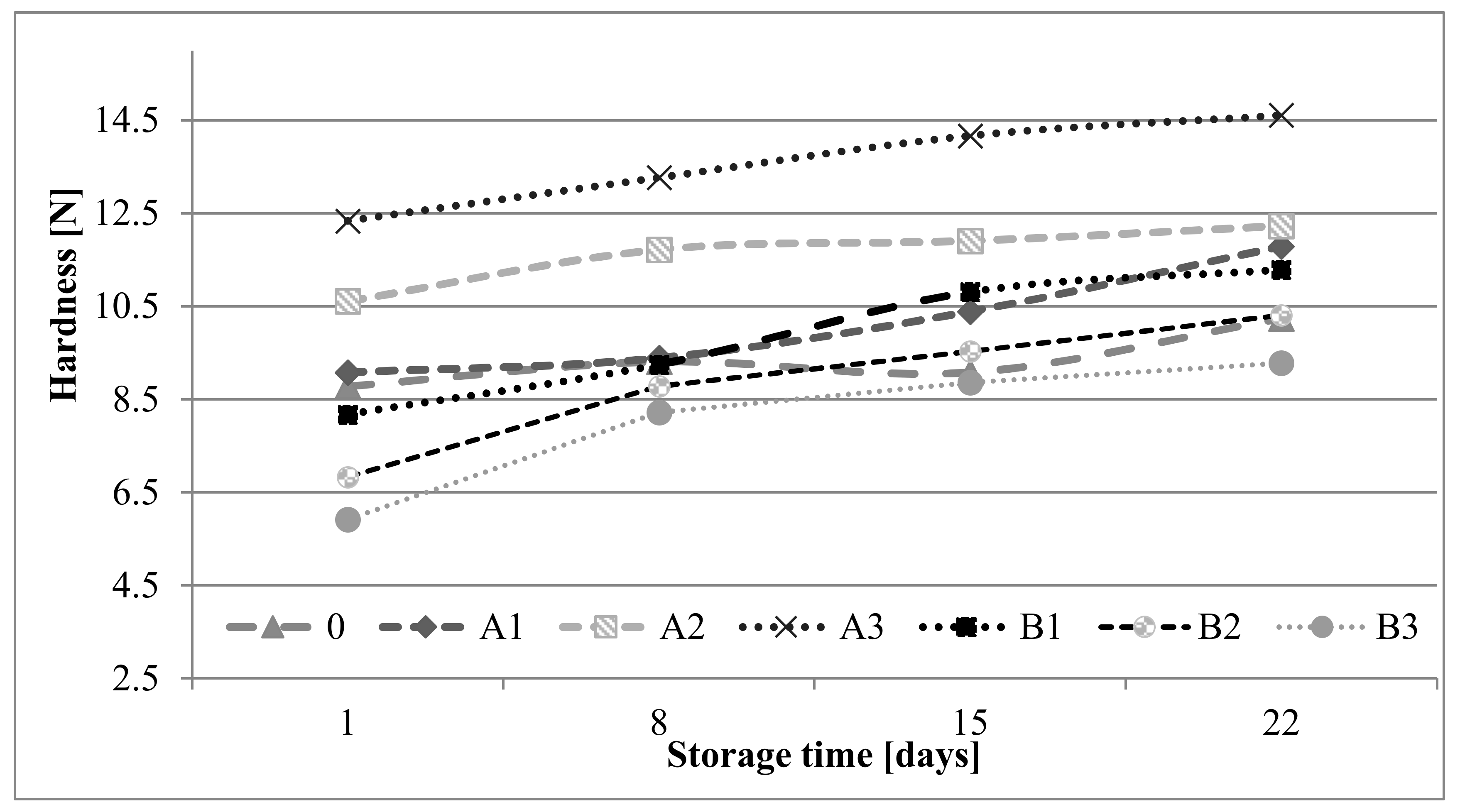

2.4. Texture Parameters Assessment

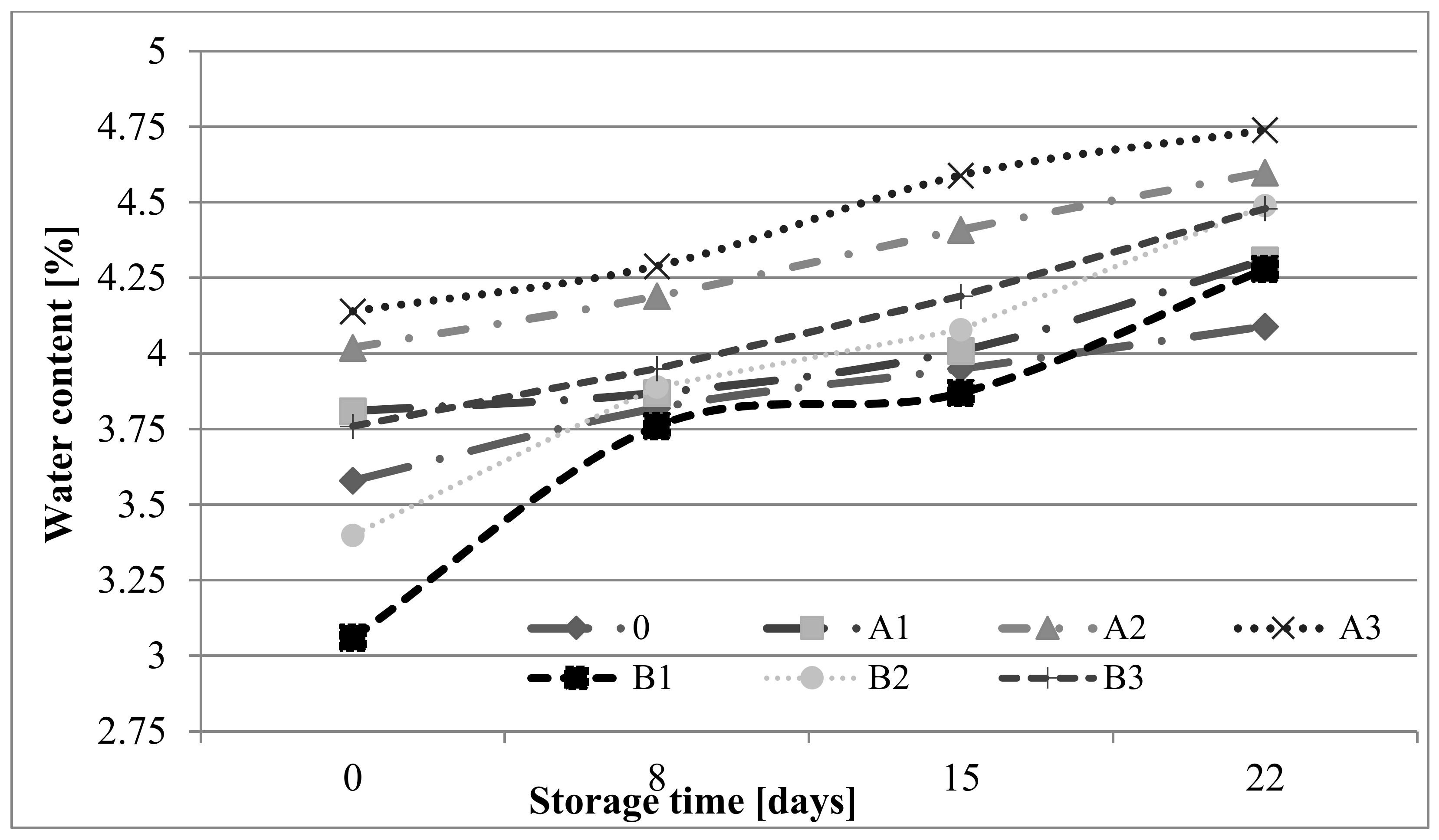

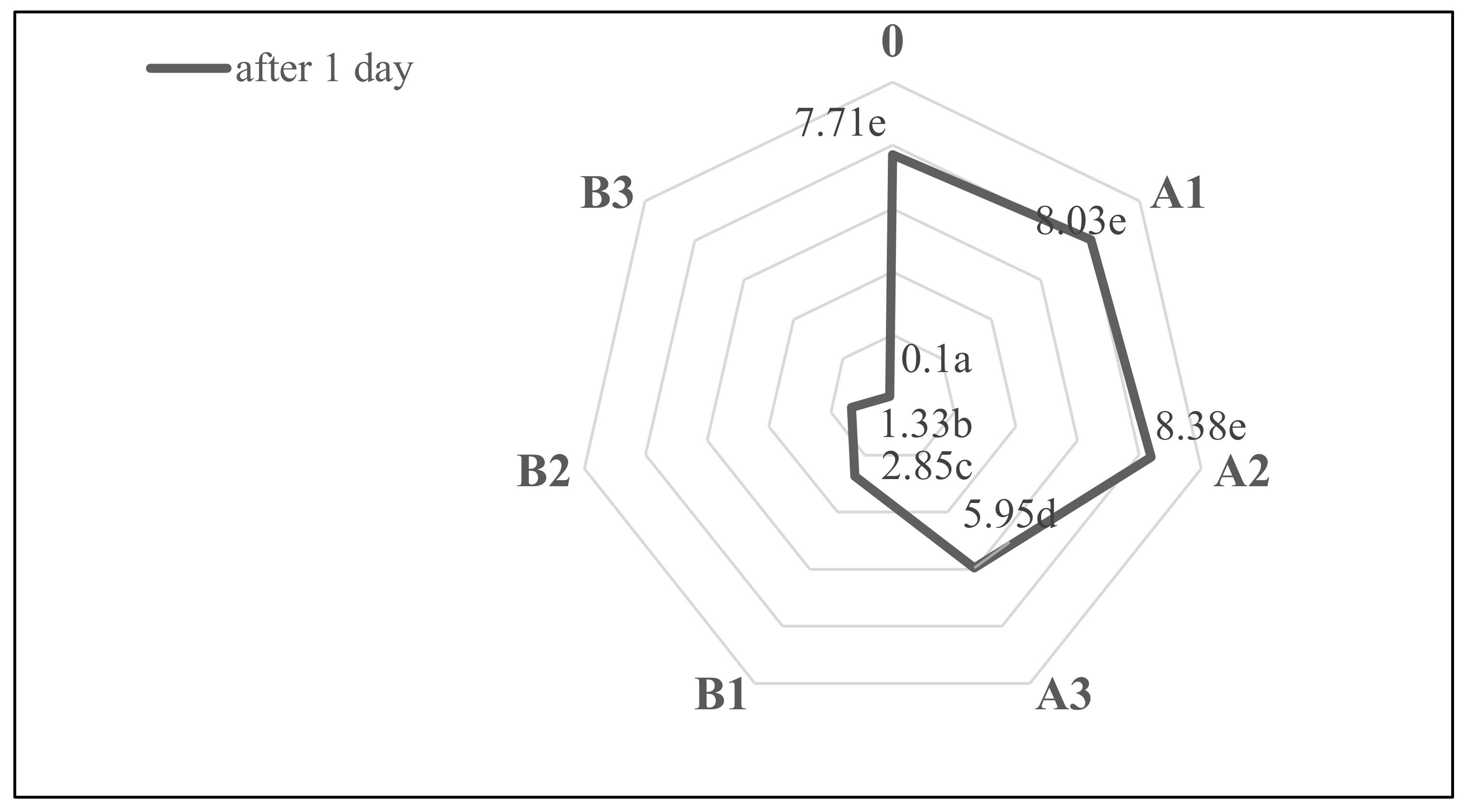

2.5. Analysis of Water Content in Stored Shortbread Biscuits

2.6. Sensory Properties of Shortbread Biscuits

2.7. Correlation Analysis between the Properties of Shortbread Biscuits and the Type of β-Glucan

3. Materials and Methods

3.1. Material

3.2. Preparation of Shortbread Biscuits

3.3. Analysis

3.3.1. Analysis of Raw Fat

3.3.2. Methods for Shortbread Biscuits Analysis

Biscuits Density

Geometry of Biscuits and Spread Ratio

Color Assessment

Texture Analysis of Shortbread Biscuits

Moisture Content

Sensory Evaluation of Shortbread Biscuits

3.4. Storage Test

3.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Castro-Gomez, P.; Garcia-Serrano, A.; Visioli, F.; Fontecha, J. Relevance of dietary glycerophospholipids and sphingolipids to human health. Prostaglandins Leukot. Essent. Fat. Acids. 2015, 101, 41–51. [Google Scholar] [CrossRef]

- Visioli, F.; Poli, A. Fatty acids and cardiovascular risk. Evidence, lack of evidence, and diligence. Nutrients 2020, 12, 3782. [Google Scholar] [CrossRef] [PubMed]

- Zbikowska, A.; Onacik-Gür, S.; Kowalska, M.; Rutkowska, J. Trans fatty acids in polish pastry. J. Food Prot. 2019, 82, 1028–1033. [Google Scholar] [CrossRef]

- Gouveia, L.; Coutinho, C.; Mendonca, E.; Batista, A.P.; Sousa, I.; Bandarra, N.M.; Raymundo, A. Function biscuits with PUFA—ω3 from Isochrysis galbana. J. Sci. Food Agric. 2008, 88, 891–896. [Google Scholar] [CrossRef] [Green Version]

- Lim, J.; Jeong, S.; Lee, J.H.; Park, S.; Lee, J.; Lee, S. Effect of shortening replacement with oleogels on the rheological and tomographic characteristics of aerated baked goods. J. Sci. Food Agric. 2017, 97, 3727–3732. [Google Scholar] [CrossRef]

- Zbikowska, A.; Rutkowska, J.; Kowalska, M. Consumption safety of pastries, confectioneries, and potato products as related to fat content. J. Am. Coll. Nutr. 2015, 34, 507–514. [Google Scholar] [CrossRef] [PubMed]

- EFSA-European Food Safety Authority. Opinion of the Scientific Panel on Dietetic Products, Nutrition and Allergies on a request from the Commission related to nutrition claims concerning omega-3 fatty acids, monounsaturated fat, polyunsaturated fat and unsaturated fat. EFSA J. 2005, 253, 32. [Google Scholar] [CrossRef]

- Fu, J.; Liu, Y.; Zhang, L.; Zhou, L.; Li, D.; Quan, H.; Zhu, L.; Hu, F.; Li, X.; Meng, S.; et al. Nonpharmacologic interventions for reducing blood pressure in adults with prehypertension to established hypertension. J. Am. Heart Assoc. 2020, 9, e016804. [Google Scholar] [CrossRef] [PubMed]

- Di Daniele, N.; Marrone, G.; Di Lauro, M.; Di Daniele, F.; Palazzetti, D.; Guerriero, C.; Noce, A. Effects of caloric restriction diet on arterial hypertension and endothelial dysfunction. Nutrients 2021, 13, 274. [Google Scholar] [CrossRef]

- Kupiec, M.; Zbikowska, A.; Marciniak-Lukasiak, K.; Zbikowska, K.; Kowalska, M.; Kowalska, H.; Rutkowska, J. Study on the introduction of solid fat with a high content of unsaturated fatty acids to gluten-free muffins as a basis for designing food with higher health value. Int. J. Mol. Sci. 2021, 22, 9220. [Google Scholar] [CrossRef]

- Brayner, B.; Kaur, G.; Keske, M.A.; Perez-Cornago, A.; Piernas, C.; Livingstone, K.M. Dietary Patterns Characterized by Fat Type in Association with Obesity and Type 2 Diabetes: A Longitudinal Study of UK Biobank Participants. J. Nutr. 2021, 151, 3570–3578. [Google Scholar] [CrossRef]

- WHO. World and Health Organization; Global Health Observatory (GHO). Overweight and Obesity. Available online: https://www.who.int/gho/ncd/risk_factors/overweight/en (accessed on 2 September 2021).

- EU REGULATION: Commission Regulation (EU) 2019/649 of 24 April 2019 Amending Annex III to Regulation (EC) No 1925/2006 of the European Parliament and of the Council as Regards Trans Fat, Other than Trans Fat Naturally Occurring in Fat of Animal. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX:32019R0649 (accessed on 2 September 2021).

- Zbikowska, A.; Kowalska, M.; Pieniowska, J. Assessment of shortcrust biscuits with reduced fat content of microcrystalline cellulose and psyllium as fat replacements. J. Food Proc. Preserv. 2018, 42, e13675. [Google Scholar] [CrossRef]

- Zahn, S.; Pepke, F.; Rohm, H. Effect of inulin as a fat replacer on texture and sensory properties of muffins. Int. J. Food Sci. Technol. 2010, 45, 2531–2537. [Google Scholar] [CrossRef]

- Żbikowska, A.; Kupiec, M.; Szymanska, I.; Osytek, K.; Kowalska, M.; Marciniak-Lukasiak, K.; Rutkowska, J. Microbial β-glucan incorporated into muffins: Impact on quality of the batter and baked products. Agriculture 2020, 10, 126. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Ye, F.; Li, S.; Wei, F.; Chen, J.; Zhao, G. Wheat flour enriched with oat b-glucan: A study of hydration, rheological and fermentation properties of dough. J. Cereal Sci. 2017, 75, 143–150. [Google Scholar] [CrossRef]

- Dadkah, A.; Hashemiravan, M.; Seyedain-Ardebili, M. Effect of shortening replacement with nutrim oat bran on chemical and physical properties of shortened cakes. Ann. Biol. Res. 2012, 3, 2682–2687. [Google Scholar]

- Colla, K.; Costanzo, A.; Gamlath, S. Fat replacers in baked food products. Foods 2018, 7, 192. [Google Scholar] [CrossRef] [Green Version]

- Onacik-Gur, S.; Żbikowska, A.; Kapler, E.; Kowalska, H. Effect of barley glucan addition as a fat replacer on muffin quality. Acta Sci. Pol. Technol. Aliment. 2016, 15, 247–256. [Google Scholar] [CrossRef] [Green Version]

- Vetvicka, V.; Vetvickova, J. Physiological effects of different types of beta-glucan. Biomed. Pap. Med. Fac. Palacky Univ. Olomouc 2007, 151, 225–231. [Google Scholar] [CrossRef] [Green Version]

- Commission Regulation 432/2012 of 16 May 2012 Establishing a List of Permitted Health Claims Made on Foods, Other Than Those Referring to the Reduction of Disease Risk and to Children’s Development and Health. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32012R0432 (accessed on 2 September 2021).

- Krupińska, P.; Zegan, M. β-glucan—Selected sanitary advantages with particular reference to lipid metabolism. Bromat. Chem. Toksykol. 2013, 46, 162–170. [Google Scholar]

- Du, B.; Bian, Z.; Xu, B. Skin Health Promotion E_ects of Natural Beta-Glucan Derived from Cereals and Microorganisms: A Review. Phytotherm. Res. 2014, 28, 159–166. [Google Scholar] [CrossRef] [PubMed]

- Vannucci, L.; Krizan, J.; Sima, P.; Stakheev, D.; Caja, F.; Rajsiglova, L.; Horak, V.; Saieh, M. Immunostimulatory properties and antitumor activities of glucans (Review). Int. J. Oncol. 2013, 43, 357–364. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Onacik-Gür, S.; Zbikowsk, A. Effect of high-oleic rapeseed oil oleogels on the quality of short-dough biscuits and fat migration. J Food Sci. Technol. 2020, 57, 1609–1618. [Google Scholar] [CrossRef] [PubMed]

- Dassanayake, L.S.K.; Kodali, D.R.; Ueno, S. Formation of oleogels based on edible lipid materials. Curr. Opin. Colloid Interface Sci. 2011, 16, 432–439. [Google Scholar] [CrossRef]

- Briggs, M.A.; Petersen, K.S.; Kris-Etherton, P.M. Saturated fatty acids and cardiovascular disease: Replacements for saturated fat to reduce cardiovascular risk. Healthcare 2017, 5, 29. [Google Scholar] [CrossRef] [Green Version]

- Ramírez, M.; Amate, L.; Gil, A. Absorption and distribution of dietary fatty acids from different sources. Early Hum. Dev. 2001, 65, 95–101. [Google Scholar] [CrossRef]

- De Onis, M.; Blossner, M.; Borghi, E. Global prevalence and trends of overweight and obesity among preschool children. Am. J. Clin. Nutr. 2010, 92, 1257–1264. [Google Scholar] [CrossRef] [Green Version]

- Biro, F.M.; Wien, M. Childhood obesity and adult morbidities. Am. J. Clin. Nutr. 2010, 91, 1499S–1505S. [Google Scholar] [CrossRef] [Green Version]

- Worrasinchai, S.; Suphantharika, M.; Pinjai, S.; Jamnong, P. β-Glucan prepared from spent brewer’s yeast as a fat replacer in mayonnaise. Food Hydrocoll. 2006, 20, 68–78. [Google Scholar] [CrossRef]

- EFSA. Scientific Opinion on Dietary Reference Values for fats, including saturated fatty acids, polyunsaturated fatty acids, monounsaturated fatty acids, trans fatty acids, and cholesterol. EFSA J. 2010, 1461, 1–107. [Google Scholar] [CrossRef] [Green Version]

- Żbikowska, A.; Kowalska, M. The use of apple fiber as a fat substitute in the manufacture of bakery products. J. Food Proc. Preserv. 2017, 41, 1–6. [Google Scholar] [CrossRef]

- Kalinga, D.; Mishra, V.K. Rheological and physical properties of low fat cakes produced by addition of cereal β-glucan concentrates. J. Food Proc. Preserv. 2009, 33, 384–400. [Google Scholar] [CrossRef]

- Neff, W.E.; Byrdwell, W.M.C.; List, G.R. Triacylglycerol structures of food fats high in saturated acids by HPLC and mass spectrometry. J. Liquid Chromatogr. Related Technol. 2001, 24, 837–854. [Google Scholar] [CrossRef]

- Abozeid, M.; Wafaa, M.M.; Salama, M.; Manal, F.; Moawad, R.K. Utilization of fat replacer in the production of reduced cakes and cookies by. Aust. J. Basic Appl. Sci. 2011, 5, 2833–2840. [Google Scholar]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.-J. Colour measurement and analysis in fresh and processed foods: A Review. Food Bioprocess Technol. 2013, 6, 36–60. [Google Scholar] [CrossRef]

- Onacik-Gür, S.; Żbikowska, A.; Majewska, B. Effect of spirulina (Spirulina Platensis) addition on textural and quality properties of cookies. Ital. J. Food Sci. 2018, 30, 1–12. [Google Scholar]

- Bal, L.M.; Kar, A.; Satya, S.; Naik, S.N. Kinetics of colour change of bamboo shoot slices during microwave drying. Int. J. Food Sci. Technol. 2011, 46, 827–833. [Google Scholar] [CrossRef]

- Patras, A.; Brunton, N.P.; Tiwari, B.K.; Butler, F. Stability and degradation kinetics of bioactive compounds and colour in strawberry jam during storage. Food Bioprocess Technol. 2011, 4, 1245–1252. [Google Scholar] [CrossRef]

- Devi, A.; Khatkar, B.S. Physicochemical, rheological and functional properties of fats and oils in relation to cookie quality: A review. J. Food Sci. Technol. 2016, 53, 3633–3641. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Inglett, G.E. Rheological and physical evaluation of jet-cooked oat bran in low calorie cookies. Int. J. Food Sci. Technol. 2006, 41, 553–559. [Google Scholar] [CrossRef]

- Aydogdu, A.; Sumnu, G.; Serpil Sahin, S. Effects of addition of different fibers on rheological characteristics of cake batter and quality of cakes. J. Food Sci. Technol. 2018, 55, 667–677. [Google Scholar] [CrossRef]

- Shyu, Y.S.; Sung, W.C. Improving the emulsion stability of sponge cakes by the addition of γ-polyglutamic acid. J. Mar. Sci. Technol. Taiw. 2010, 18, 895–900. [Google Scholar] [CrossRef]

- Serin, S.; Sayar, S. The effect of the replacement of fat with carbohydrate-based fat replacers on the dough properties and quality of the baked pogaca: A traditional high-fat bakery product. Food Sci. Technol. 2017, 37, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Mohebbi, Z.; Homayouni, A.; Azizi, M.H.; Hosseini, S.J. Effects of beta-glucan and resistant starch on wheat dough and prebiotic bread properties. J. Food Sci. Technol. 2018, 55, 101–110. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Effect of flour particle size and damaged starch on the quality of cookies. J. Food Sci. Technol. 2014, 51, 1342–1348. [Google Scholar] [CrossRef] [Green Version]

- Laguna, L.; Primo-Martín, C.; Varela, P.; Salvador, A.; Sanz, T. HPMC and inulin as fat replacers in biscuits: Sensory and instrumental evaluation. LWT Food Sci. Technol. 2013, 30, 1–8. [Google Scholar] [CrossRef]

- ISO 5508. Animal and Vegetable Fats and Oils—Analysis by Gas Chromatography of Methyl Esters of Fatty Acids; International Organization for Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- ISO 5509. Animal and Vegetable Fats and Oils—Preparation of Methyl Esters of Fatty Acids; International Organization for Standardization: Geneva, Switzerland, 2000. [Google Scholar]

- Omri, B.; Chalghoumi, R.; Izzo, L.; Ritieni, A.; Lucarini, M.; Durazzo, A.; Abdouli, H.; Santini, A. Effect of dietary incorporation of linseed alone or together with tomato-red pepper mix on laying hens egg yolk fatty acids profile and health lipid indexes. Nutrients 2019, 11, 813. [Google Scholar] [CrossRef] [Green Version]

- ISO 660. Animal and Vegetable Fats and Oils—Determination of Acid Value and Acidity; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- ISO 3960. Animal and Vegetable Fats and Oils—Determination of Peroxide Value—Iodometric Visual Endpoiunt Determination; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Rahmati, N.F.; Tehrani, M.M. Influence of different emulsifiers on characteristics of eggless cake containing soy milk: Modeling of physical and sensory properties by mixture experimental design. J. Food Sci. Technol. 2014, 51, 1697–1710. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kupiec, M.; Zbikowska, A.; Marciniak-Lukasiak, K.; Kowalska, M. Rapeseed oil in new application: Assessment of structure of oleogels based on their physicochemical properties and microscopic observations. Agriculture 2020, 10, 211. [Google Scholar] [CrossRef]

| AV (mg KOH/g of Fat) | PV (meqO/kg of Fat) | Main Groups of Fatty Acids (FA) [%] | OFA | DFA | IA | |||

|---|---|---|---|---|---|---|---|---|

| SFA | TFA | MUFA | Essential FA | |||||

| 0.19 ± 0.01 | 0.74 ± 0.02 | 51.60 ± 0.21 (4.82%—stearic acid) | 0.52 ± 0.05 | 39.94 ± 0.73 (39.02%—oleic acid) | 7.94 ± 0.24 | 52.12 | 47.88 | 1.13 |

| Samples | Fat Reduction (%) | Density (g/cm3) | Diameter (mm) | Hight (mm) | SI |

|---|---|---|---|---|---|

| 0 (control) | 0 | 0.72 a ± 0.02 | 56.18 d ± 0.87 | 6.14 cd ± 0.28 | 9.15 |

| A1 | 5 | 0.72 a ± 0.01 | 55.96 d ± 0.58 | 6.30 de ± 0.20 | 8.88 |

| A2 | 10 | 0.78 c ± 0.02 | 55.33 c ± 0.17 | 6.41 ef ± 0.23 | 8.63 |

| A3 | 15 | 0.82 d ± 0.00 | 54.85 b ± 0.47 | 6.52 f ± 0.32 | 8.41 |

| B1 | 5 | 0.75 b ± 0.02 | 55.09 bc ± 0.44 | 6.02 c ± 0.27 | 9.15 |

| B2 | 10 | 0.77 c ± 0.01 | 54.31 a ± 0.24 | 5.80 b ± 0.26 | 9.36 |

| B3 | 15 | 0.94 d ± 0.02 | 54.11 a ± 0.38 | 5.61 a ± 0.25 | 9.65 |

| Sample | L* | a* | b* | ΔE | IB | Chrome |

|---|---|---|---|---|---|---|

| 0 | 74.64 e ± 1.02 | 0.51 a ± 0.24 | 22.61 d ± 1.31 | - | 1.81 | 22.62 |

| A1 | 72.86 d ± 1.81 | 1.31 b ± 0.52 | 22.31 d ± 1.09 | 1.97 | 2.65 | 22.35 |

| A2 | 72.76 d ± 1.87 | 1.50 b ± 0.53 | 22.06 d ± 1.01 | 2.12 | 2.84 | 22.11 |

| A3 | 72.13 d ± 1.93 | 1.58 b ± 0.47 | 21.12 c ± 1.50 | 3.11 | 2.94 | 21.18 |

| B1 | 70.13 c ± 1.33 | 2.46 c ± 1.10 | 20.16 b ± 0.93 | 5.49 | 3.92 | 20.31 |

| B2 | 68.12 b ± 1.26 | 2.85 c ± 0.86 | 19.56 b ± 0.97 | 7.57 | 4.45 | 19.77 |

| B3 | 66.90 a ± 1.42 | 2.86 c ± 0.95 | 18.36 a ± 0.74 | 9.14 | 4.54 | 18.58 |

| Samples | 0 | A1 | A2 | A3 | B1 | B2 | B3 | |

|---|---|---|---|---|---|---|---|---|

| Parameter | Appearance | |||||||

| color uniformity | 6.26 ± 1.41 | 6.33 ± 1.42 | 6.58 ± 1.71 | 6.74 ± 1.07 | 6.95 ± 1.33 | 7.45 ± 1.33 | 8.38 ± 1.14 | |

| cracking | 0.88 ± 0.45 | 0.81 ± 0.56 | 2.08 ± 0.98 | 3.91 ± 1.02 | 2.91 ± 0.88 | 4.45 ± 1.23 | 4.75 ± 1.34 | |

| Texture | ||||||||

| hardness | 6.35 ± 1.51 | 5.64 ± 1.04 | 5.31 ± 1.24 | 3.13 ± 1.03 | 3.15 ± 1.00 | 2.05 ± 1.02 | 1.58 ± 0.67 | |

| crispness | 8.34 ± 1.16 | 8.48 ± 1.01 | 8.39 ± 1.17 | 6.88 ± 1.03 | 7.10 ± 1.08 | 6.89 ± 0.98 | 4.9 ± 0.92 | |

| Odor | ||||||||

| typical | 7.58 ± 1.46 | 7.95 ± 1.27 | 8.1 ± 0.98 | 7.91 ± 2.06 | 5.93 ± 0.98 | 5.2 ± 1.02 | 2.44 ± 0.65 | |

| oily | 6.7 ± 0.97 | 4.79 ± 1.02 | 3.03 ± 0.65 | 2.25 ± 1.21 | 5.05 ± 1.23 | 5.91 ± 1.72 | 7.25 ± 2.17 | |

| floury | 1.69 ± 0.67 | 0.83 ± 0.24 | 1.51 ± 0.45 | 2.3 ± 1.02 | 1.08 ± 0.21 | 0.96 ± 0.22 | 0.75 ± 0.21 | |

| others | 0 ± 0.00 | 0 ± 0.00 | 0.46 ± 0.23 | 0.08 ± 0.02 | 1.66 ± 0.54 | 4.8 ± 0.76 | 6.58 ± 1.54 | |

| Taste | ||||||||

| typical | 7.28 ± 1.21 | 7.86 ± 1.09 | 8.2 ± 0.82 | 6.76 ± 0.88 | 3.15 ± 1.02 | 2.18 ± 0.88 | 0.19 ± 0.08 | |

| oily | 5.89 ± 0.72 | 4.64 ± 1.48 | 3.79 ± 1.05 | 2.19 ± 1.00 | 4.2 ± 1.13 | 2.26 ± 0.99 | 1.85 ± 1.01 | |

| sweet | 5.94 ± 1.27 | 5.91 ± 0.77 | 5.01 ± 1.06 | 4.89 ± 1.18 | 3.48 ± 1.04 | 1.46 ± 1.05 | 0.85 ± 0.22 | |

| bitter | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 0.00 ± 0.00 | 4.08 ± 1.02 | 7.28 ± 1.22 | 8.64 ± 2.89 | |

| others | 0.00 ± 0.00 | 0.06 ± 0.02 | 0.56 ± 0.32 | 0.88 ± 0.12 | 4.74 ± 1.01 | 7.61 ± 1.32 | 9.4 ± 0.69 | |

| Parameter | Oat β-Glucan | Yeast β-Glucan | ||

|---|---|---|---|---|

| R | p-Value | r | p-Value | |

| Weight | 0.37 | 0.006 | 0.26 | 0.021 |

| Width | −0.78 | 0 | −0.88 | 0 |

| Thickness | 0.48 | 0 | −0.62 | 0 |

| Volume | −0.89 | 0 | −0.91 | 0 |

| Texture | −0.30 | 0.026 | - | >0.5 |

| Water content | 0.96 | 0 | 0.35 | 0.091 |

| Color | ||||

| L* | - | >0.05 | −0.88 | 0 |

| a* | - | >0.05 | - | >0.05 |

| b* | −0.39 | 0.003 | −0.82 | 0 |

| Sensory analysis | ||||

| Overall quality | −0.39 | 0.0274 | −0.89 | 0 |

| Shortbread Biscuits | 0 | A1/B1 | A2/B2 | A3/B3 |

|---|---|---|---|---|

| Fat (%) | 27.0% | 25.7 | 24.3 | 23.0 |

| SFA (%) | 13.9 | 13.2 | 12.5 | 11.8 |

| MUFA+PUFA (%) | 12.9 | 12.3 | 11.6 | 11.0 |

| Caloric value decrease (kcal) | - | 11.7 | 24.3 | 36.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zbikowska, A.; Kowalska, M.; Zbikowska, K.; Onacik-Gür, S.; Łempicka, U.; Turek, P. Study on the Incorporation of Oat and Yeast β-Glucan into Shortbread Biscuits as a Basis for Designing Healthier and High Quality Food Products. Molecules 2022, 27, 1393. https://doi.org/10.3390/molecules27041393

Zbikowska A, Kowalska M, Zbikowska K, Onacik-Gür S, Łempicka U, Turek P. Study on the Incorporation of Oat and Yeast β-Glucan into Shortbread Biscuits as a Basis for Designing Healthier and High Quality Food Products. Molecules. 2022; 27(4):1393. https://doi.org/10.3390/molecules27041393

Chicago/Turabian StyleZbikowska, Anna, Malgorzata Kowalska, Katarzyna Zbikowska, Sylwia Onacik-Gür, Urszula Łempicka, and Paweł Turek. 2022. "Study on the Incorporation of Oat and Yeast β-Glucan into Shortbread Biscuits as a Basis for Designing Healthier and High Quality Food Products" Molecules 27, no. 4: 1393. https://doi.org/10.3390/molecules27041393

APA StyleZbikowska, A., Kowalska, M., Zbikowska, K., Onacik-Gür, S., Łempicka, U., & Turek, P. (2022). Study on the Incorporation of Oat and Yeast β-Glucan into Shortbread Biscuits as a Basis for Designing Healthier and High Quality Food Products. Molecules, 27(4), 1393. https://doi.org/10.3390/molecules27041393