Effect of the Addition of Lemongrass (Cymbopogon citratus) on the Quality and Microbiological Stability of Craft Wheat Beers

Abstract

1. Introduction

2. Results and Discussion

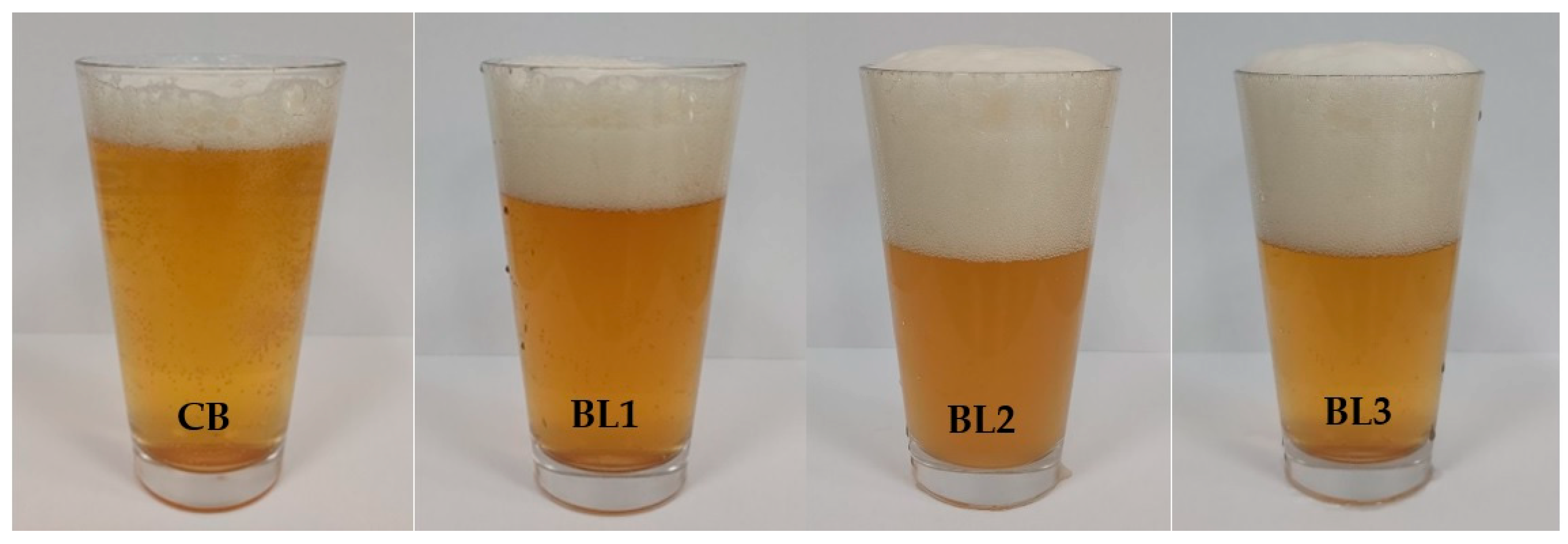

2.1. Physicochemical Characteristics of Wheat Beers

2.2. Content of Bioactive Compounds in Wheat Beers Enriched with Lemongrass

2.3. Microbiological Stability of Wheat Beers

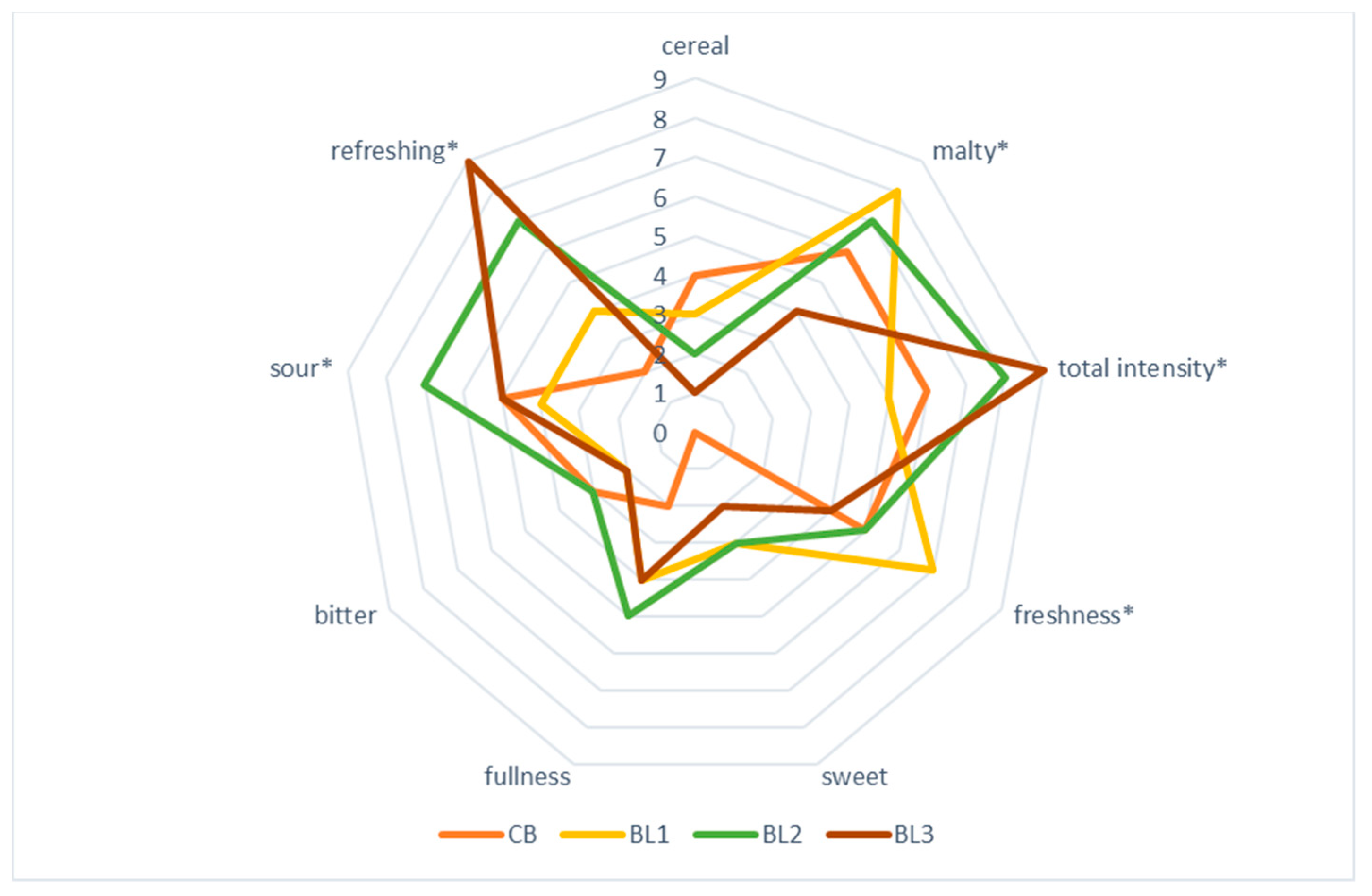

2.4. Sensory Analysis of Wheat Beers

3. Materials and Methods

3.1. Material

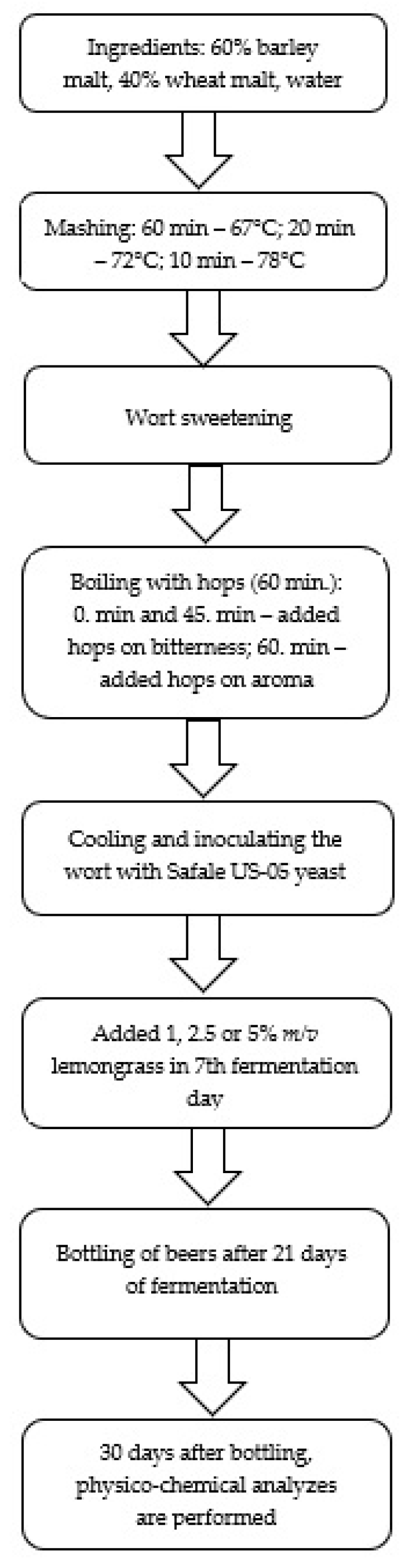

3.2. Production of Beers

3.3. Analysis of Quality Indicators for Beers

3.4. Total Polyphenol Content and Antioxidant Activity of Wheat Beers

3.5. Microbiological Stability of Wheat Beers

3.6. Sensory Analysis

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Hayward, L.; Wedel, A.; McSweeney, M.B. Acceptability of beer produced with dandelion, nettle and sage. Int. J. Gastron. Food Sci. 2019, 18, 100180. [Google Scholar] [CrossRef]

- Belcar, J.; Buczek, J.; Kapusta, I.; Gorzelany, J. Quality and Pro-Healthy Properties of Belgian Witbier-Style Beers Relative to the Cultivar of Winter Wheat and Raw Materials Used. Foods 2022, 11, 1150. [Google Scholar] [CrossRef] [PubMed]

- Kunze, W. Technology Brewing and Malting, 4th ed.; VLB Berlin: Berlin, Germany, 2010; pp. 108, 843. [Google Scholar]

- Byeon, Y.S.; Lim, S.-T.; Kim, H.-J.; Kwak, H.S.; Kim, S.S. Quality Characteristcs of Wheat Malts with Different Country of Origin and Their Effect on Beer Brewing. J. Food Qual. 2021, 2021, 2146620. [Google Scholar] [CrossRef]

- Hu, X.; Jin, Y.; Du, J. Differences in protein content and foaming properties of cloudy beers based on wheat malt content. J. Inst. Brew. 2019, 125, 235–241. [Google Scholar] [CrossRef]

- Wu, X.; Du, J.; Zhang, K.; Ju, Y.; Jin, Y. Changes in protein molecular weight during cloudy wheat beer brewing. J. Inst. Brew. 2015, 121, 137–144. [Google Scholar] [CrossRef]

- Rošul, M.D.; Mandić, A.I.; Mišan, A.Č.; Derić, N.R.; Pejin, J.D. Review of trends in formulation of functional beer. Food Feed Res. 2019, 46, 23–35. [Google Scholar] [CrossRef]

- Leitao, C.; Marchioni, E.; Bergaentzlé, M.; Zhao, M.; Didierjean, L.; Miesch, L.; Holder, E.; Miesch, M.; Ennahar, S. Fate of polyphenols and antioxidant activity of barley throughout malting and brewing. J. Cereal Sci. 2012, 55, 318–322. [Google Scholar] [CrossRef]

- He, G.; Du, J.; Zhang, K.; Wei, G.; Wang, W. Antioxidant capability and potableness of fresh cloudy wheat beer stored at different temperatures. J. Inst. Brew. 2012, 118, 386–392. [Google Scholar] [CrossRef]

- Brien, S.E.; Ronksley, P.E.; Turner, B.J.; Mukamal, K.J.; Ghali, W.A. Effect of alcohol consumption on biological markers associated with risk of coronary heart disease: Systematic review and meta-analysis of interventional studies. BMJ 2011, 342, 636. [Google Scholar] [CrossRef]

- Fogarasi, A.-L.; Kun, S.; Tankó, G.; Stefanovits-Bányai, É.; Hegyesné-Vecseri, B. A comparative assessment of antioxidant properites, total phenolic content of einkorn, wheat, barley and their malts. Food Chem. 2015, 167, 1–6. [Google Scholar] [CrossRef]

- Stachowiak, B.; Bukowski, K. New trends in the brewing industry. Functional beers—Raw materials and technological aspects of their production. FOOD Sci. Technol. Qual. 2021, 28, 5–27. (In Polish) [Google Scholar] [CrossRef]

- Majewska, E.; Kozłowska, M.; Gruczyńska—Sękowska, E.; Kowalska, D.; Tarnowska, K. Lemongrass (Cymbopogon citratus) Essential Oil: Extraction, Composition, Bioactivity and Uses for Food Preservation—A Review. Pol. J. Food Nutr. Sci. 2019, 69, 327–341. [Google Scholar] [CrossRef]

- Haque, A.N.M.A.; Remadevi, R.; Naebe, M. Lemongrass (Cymbopogon): A review on its structure, properties, applications and recent developments. Cellulose 2018, 25, 5455–5477. [Google Scholar] [CrossRef]

- Olorunnisola, S.K.; Asiyanbi, H.T.; Hammed, A.M.; Simsek, S. Biological properties of lemongrass: An overview. Intern. Food Res. J. 2014, 21, 455–462. [Google Scholar]

- Kamaruddin, Z.H.; Jumaidin, R.; Selamat, M.Z.; Ilyas, R.A. Characteristics and Properties of Lemongrass (Cymbopogan Citratus): A Comprehensive Review. J. Nat. Fibers 2021, 19, 1–18. [Google Scholar] [CrossRef]

- Mascia, I.; Fadda, C.; Dostálek, P.; Olšovská, J.; Del Caro, A. Preliminary characterization of an Italian craft durum wheat beer. J. Inst. Brew. 2014, 120, 495–499. [Google Scholar] [CrossRef]

- Tomova, T.; Petelkov, I.; Shopska, V.; Denkova-Kostova, R.; Kstov, G.; Denkova, Z. Production of probiotic wort-based beverages with grapefruit (Citrus paradisi L.) or tangerine (Citrus reticulata L.) zest essential oil addition. Acta Sci. Pol. Technol. Aliment. 2021, 20, 237–245. [Google Scholar] [CrossRef]

- Nardini, M.; Garaguso, I. Characterization of bioactive compounds and antioxidant activity of fruit beers. Food Chem. 2020, 305, 125437. [Google Scholar] [CrossRef] [PubMed]

- Baigts-Allende, D.K.; Pérez-Alva, A.; Ramírez-Rodrigues, M.A.; Palacios, A.; Ramírez-Rodrigues, M.M. A comparative study of polyphenolic and amino acids profiles of commercial fruit beers. J. Food Comp. Anal. 2021, 100, 103921. [Google Scholar] [CrossRef]

- Patraşcu, L.; Banu, I.; Bejan, M.; Aprodu, I. Quality parameters of fruit beers available on Romanian market. Sci. Study Res. Chem. Chem. Eng. Biotechnol. Food Ind. 2018, 19, 323–335. [Google Scholar]

- Gasiński, A.; Kawa-Rygielska, J.; Szumny, A.; Czubaszek, A.; Gąsior, J.; Pietrzak, W. Volatile Compounds Content Physicochemical Parametrers and Antioxidant Activity of Beers with Addition of Mango Fruit (Mangifera Indica). Molecules 2020, 25, 3033. [Google Scholar] [CrossRef] [PubMed]

- Habschied, K.; Košir, I.J.; Krstanović, V.; Kumrić, G.; Mastanjević, K. Beer Polyphenols—Bitterness, Astrigency, and Off-Flavors. Beverages 2021, 7, 38. [Google Scholar] [CrossRef]

- Martínez, A.; Vegara, S.; Martí, N.; Valero, M.; Saura, D. Physicochemical characterization of special persimmon fruit beers using bohemian pilsner malt as a base. J. Inst. Brew. 2017, 123, 319–327. [Google Scholar] [CrossRef]

- Mikyška, A.; Dušek, M.; Slabý, M. How does fermentation, filtration and stabilization of beer affect polyphenols with health benefits. Kvas. Prum. 2019, 65, 120–126. [Google Scholar] [CrossRef]

- Gouvintas, I.; Breda, C.; Barros, A.I. Characterization and Discrimination of Commercial Portuguese Beers Based on Phenolic Composition and Antioxidant Capacity. Foods 2021, 10, 1144. [Google Scholar] [CrossRef]

- Dordević, S.; Popović, D.; Despotović, S.; Veljović, M.; Atanacković, M.; Cvejić, J.; Nedović, V.; Leskošek-Čukalović, I. Extracts of medicinal plants as functional beer additives. Chem. Ind. Chem. Eng. Q. 2016, 22, 301–308. [Google Scholar] [CrossRef]

- Ulloa, P.A.; Vidal, J.; Ávila, M.I.; Labbe, M.; Cohen, S.; Salazar, F.N. Effect of the Addition of Propolis Extract on Bioactive Compounds and Antioxidant Activity of Craft Beer. J. Chem. 2017, 2017, 6716053. [Google Scholar] [CrossRef]

- Bustos, L.; Soto, E.; Parra, F.; Echiburú, C.; Parra, C. Brewing of a Porter Craft Beer Enriched with the Plant Parastrephia lucida: A Promising Source of Antioxidant Compounds. J. Am. Soc. Brew. Chem. 2019, 77, 261–266. [Google Scholar] [CrossRef]

- Belščak-Cvitanović, A.; Nedović, V.; Salević, A.; Despotović, S.; Komes, D.; Nikšić, M.; Bugarski, B.; Leskošek-Ćukalović, I. Modification of functional quality of beer by using microencapsulated green tea (Camellia sinensis L.) and Ganoderma mushroom (Ganoderma lucidum L.) bioactive compounds. Chem. Ind. Chem. Eng. Q. 2017, 23, 457–471. [Google Scholar] [CrossRef]

- Bogdan, P.; Kordialik-Bogacka, E. Antioxidant activity of beers produced with the addition of unmalted quinoa and amaranth. FOOD Sci. Technol. Qual. 2016, 3, 118–126. (In Polish) [Google Scholar] [CrossRef]

- Ditrych, M.; Kordialik-Bogacka, E.; Czyżowska, A. Antiradical and Reducting Potential of Commercial Beer. Czech. J. Food Sci. 2015, 33, 261–266. [Google Scholar] [CrossRef]

- Bokulich, N.A.; Bamforth, Ch.W. The Microbiology of Malting and Brewing. Microbiol. Mol. Biol. Rev. 2013, 77, 157–172. [Google Scholar] [CrossRef] [PubMed]

- Silvetti, T.; Brasca, M.; Lodi, R.; Vanoni, L.; Chiolerio, F.; de Groot, M.; Bravi, A. Effect of Lysozyme on the Microbiological Stability and Organoleptic Properties of Unpasteurized Beer. J. Inst. Brew. 2010, 116, 33–40. [Google Scholar] [CrossRef]

- Jakuos, L.; Óré-Sütő, B.V. Initial microbiological experience in small-scale fruit beer product development. J. Food Investig. 2022, 68, 3877–3887. [Google Scholar] [CrossRef]

- Jagodziński, J.; Dziągow, S.; Krzywonos, M. Microbiological stability of home unpasteurized beers. Acta Sci. Pol. Biotechnol. 2016, 15, 15–24. (In Polish) [Google Scholar]

- Habschied, K.; Živković, A.; Krtanović, V.; Mastanjević, K. Functional Beer—A Review on Possibilities. Beverages 2020, 6, 51. [Google Scholar] [CrossRef]

- Belcar, J.; Sekutowski, T.R.; Zardzewiały, M.; Gorzelany, J. Effect of malting process duration on malting losses and quality of wheat malts. Acta Univ. Cinbinesis Ser. E: Food Technol. 2021, 25, 221–232. [Google Scholar] [CrossRef]

- Gorzelany, J.; Patyna, M.; Pluta, S.; Kapusta, I.; Balawejder, M.; Belcar, J. The Effect of the Addition of Ozonated and Non-Ozonated Fruits of the Saskatoon Berry (Amelanchier alnifolia Nutt.) on the Quality and Pro-Healthy Profile of Craft Wheat Beers. Molecules 2022, 27, 4544. [Google Scholar] [CrossRef]

- PB-77/LM, *!!! REPLACE !!!* (Ed.) 5; The Number of Mesophilic Aerobic Bacteria. Factory standards of Laboratory GBA POLSKA Sp. z o.o: Legionowo, Poland, 2022. [Google Scholar]

- PN-ISO 15214:2002; Food and Feed Microbiology—Horizontal Method for the Enumeration of Mesophilic Lactic Acid Bacteria—Plate Method at 30 Degrees C. Polish Committee for Standardization: Warsaw, Poland, 2002.

- PN-ISO 21527:2009; Food and Feed Microbiology—Horizontal Method for the Enumeration of Yeasts and Molds—Part 1: Colony Counting Method in Products with a Water Activity Greater than 0.95. Polish Committee for Standardization: Warsaw, Poland, 2009.

- Analytica EBC; 13.13—Sensory Analysis: Routine Descriptive Test Guideline; European Brewery Convention, Hans Carl Getrӓnke-Fachverlag: Nürnberg, Germany, 2004.

- Belcar, J.; Gorzelany, J. Feasibility of Defatted Juice from Sea-Buckthorn Berries (Hippophae rhamnoides L.) as a Wheat Beer Enhancer. Molecules 2022, 27, 3916. [Google Scholar] [CrossRef]

| CB | BL1 | BL2 | BL3 | |

|---|---|---|---|---|

| Apparent extract [%; m/m] | 3.52 c ± 0.06 | 2.58 b ± 0.08 | 2.06 a ± 0.06 | 2.22 a ± 0.22 |

| Real extract [%; m/m] | 3.27 c ± 0.07 | 1.85 a ± 0.05 | 2.31 b ± 0.01 | 4.08 d ± 0.08 |

| Original extract [%; m/m] | 14.62 d ± 0.08 | 11.60 b ± 0.10 | 10.67 a ± 0.06 | 12.03 c ± 0.03 |

| Degree of final apparent attenuation [%] | 75.92 a ± 0.10 | 77.76 b ± 0.06 | 80.69 c ± 0.09 | 81.55 d ± 0.05 |

| Degree of final real attenuation [%] | 77.63 b ± 0.04 | 84.05 d ± 0.05 | 78.35 c ± 0.04 | 66.08 a ± 0.08 |

| Content of alcohol [%; m/m] | 5.94 d ± 0.05 | 5.02 c ± 0.05 | 4.28 b ± 0.08 | 4.12 a ± 0.08 |

| Content of alcohol [%; v/v] | 4.73 c ± 0.05 | 4.00 b ± 0.10 | 3.40 a ± 0.05 | 3.28 a ± 0.07 |

| Colour [EBC units] | 22.7 d ± 0.6 | 21.5 c ± 0.5 | 19.3 b ± 0.2 | 16.9 a ± 0.7 |

| Titratable acidity [0.1 M NaOH/100 mL] | 3.82 a ± 0.05 | 4.36 b ± 0.06 | 4.82 c ± 0.02 | 5.38 d ± 0.08 |

| pH | 4.79 c ± 0.04 | 4.68 b ± 0.03 | 4.63 b ± 0.03 | 4.52 a ± 0.02 |

| Bitter substances [IBU] | 14.4 a ± 0.3 | 16.1 b ± 0.1 | 17.7 c ± 0.4 | 18.5 d ± 0.5 |

| Content of carbon dioxide [%] | 0.43 a ± 0.02 | 0.47 a ± 0.07 | 0.49 a ± 0.04 | 0.47 a ± 0.03 |

| Energy value [kcal/100 mL] | 54.83 d ± 0.07 | 42.59 b ± 0.07 | 39.28 a ± 0.04 | 45.42 c ± 0.10 |

| CB | BL1 | BL2 | BL3 | |

|---|---|---|---|---|

| Total polyphenol content [mg GAE/L] | 248.2 c ± 0.5 | 230.8 b ± 0.8 | 264.7 d ± 0.06 | 182.0 a ± 0.5 |

| DPPH. [mM TE/L] | 2.38 c ± 0.08 | 2.46 c ± 0.06 | 1.70 b ± 0.05 | 1.08 a ± 0.08 |

| FRAP [mM Fe2+/L] | 2.42 c ± 0.08 | 1.56 b ± 0.10 | 0.92 a ± 0.08 | 1.62 b ± 0.07 |

| ABTS+· [mM TE/L] | 0.92 b ± 0.10 | 1.46 d ± 0.06 | 0.79 c ± 0.01 | 0.46 a ± 0.06 |

| Fermentation Day after Bottling of Wheat Beer | Number of Yeasts and Moulds [cfu mL−1] | Number of Mesophilic Aerobic Bacteria [cfu mL−1] | Number of Mesophilic Bacteria of Lactic Fermentation [cfu mL−1] | |

|---|---|---|---|---|

| CB | 15 | 9.3 cB. × 10⁴ | 5.7 bA × 10⁴ | <1.0 aB × 10¹ |

| 45 | <1.0 aA × 10⁰ | 1.9 aA × 10³ | <1.0 aA × 10⁰ | |

| BL1 | 15 | 8.4 cdB × 10⁵ | 1.1 dB × 10⁶ | <1.0 aB × 10¹ |

| 45 | 6.3 bA × 10² | 4.7 bA × 10⁴ | <1.0 aA × 10⁰ | |

| BL2 | 15 | 1.8 dB × 10⁶ | 6.8 cB × 10⁵ | <1.0 aB × 10¹ |

| 45 | 3.3 bA × 10² | 8.5 bA × 10⁴ | <1.0 aA × 10⁰ | |

| BL3 | 15 | 1.3 cB × 10⁵ | 6.4 bA × 10⁴ | <1.0 aB × 10¹ |

| 45 | <1.0 aA × 10⁰ | 4.2 bA × 10⁴ | <1.0 aA × 10⁰ |

| CB | BL1 | BL2 | BL3 | |

|---|---|---|---|---|

| Aroma | 4.11 a ± 0.74 | 4.73 a ± 0.79 | 4.45 a ± 0.69 | 4.54 a ± 0.69 |

| Taste | 3.34 a ± 0.82 | 3.73 a ± 1.10 | 4.27 c ± 0.65 | 4.09 b ± 0.83 |

| Foam stability | 3.52 a ± 0.53 | 3.64 ab ± 0.51 | 4.09 bc ± 0.85 | 4.18 c ± 0.87 |

| Bitterness | 3.47 a ± 0.52 | 3.04 a ± 0.89 | 3.64 a ± 1.03 | 3.18 a ± 0.75 |

| Saturation | 3.76 a ± 0.48 | 4.09 ab ± 0.83 | 4.45 b ± 0.69 | 4.09 ab ± 0.83 |

| Overall impression | 3.52 a ± 0.46 | 3.77 a ± 0.71 | 4.25 b ± 0.54 | 4.08 b ± 0.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belcar, J.; Gorzelany, J. Effect of the Addition of Lemongrass (Cymbopogon citratus) on the Quality and Microbiological Stability of Craft Wheat Beers. Molecules 2022, 27, 9040. https://doi.org/10.3390/molecules27249040

Belcar J, Gorzelany J. Effect of the Addition of Lemongrass (Cymbopogon citratus) on the Quality and Microbiological Stability of Craft Wheat Beers. Molecules. 2022; 27(24):9040. https://doi.org/10.3390/molecules27249040

Chicago/Turabian StyleBelcar, Justyna, and Józef Gorzelany. 2022. "Effect of the Addition of Lemongrass (Cymbopogon citratus) on the Quality and Microbiological Stability of Craft Wheat Beers" Molecules 27, no. 24: 9040. https://doi.org/10.3390/molecules27249040

APA StyleBelcar, J., & Gorzelany, J. (2022). Effect of the Addition of Lemongrass (Cymbopogon citratus) on the Quality and Microbiological Stability of Craft Wheat Beers. Molecules, 27(24), 9040. https://doi.org/10.3390/molecules27249040