Abstract

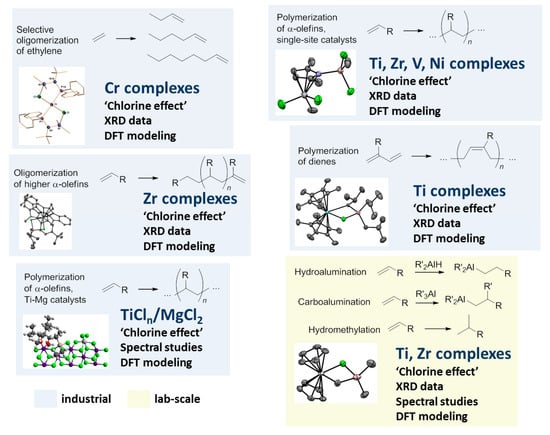

Olefin and diene transformations, catalyzed by organoaluminum-activated metal complexes, are widely used in synthetic organic chemistry and form the basis of major petrochemical processes. However, the role of M–(μ-Cl)–Al bonding, being proven for certain >C=C< functionalization reactions, remains unclear and debated for essentially more important industrial processes such as oligomerization and polymerization of α-olefins and conjugated dienes. Numerous publications indirectly point at the significance of M–(μ-Cl)–Al bonding in Ziegler–Natta and related transformations, but only a few studies contain experimental or at least theoretical evidence of the involvement of M–(μ-Cl)–Al species into catalytic cycles. In the present review, we have compiled data on the formation of M–(μ-Cl)–Al complexes (M = Ti, Zr, V, Cr, Ni), their molecular structure, and reactivity towards olefins and dienes. The possible role of similar complexes in the functionalization, oligomerization and polymerization of α-olefins and dienes is discussed in the present review through the prism of the further development of Ziegler–Natta processes and beyond.

1. Introduction

In the past few decades, catalytic transformations of olefins and conjugated dienes have become mainstream processes of the petrochemical industry: polyolefins are major multi-tonnage plastics [1,2]; polydienes are still indispensable in rubber manufacturing [3,4]. Advanced technologies of polyolefins and diene rubbers are based on the coordination polymerization of α-olefins, buta-1,3-diene, and isoprene [1,2,4,5,6,7,8,9,10,11]. Selective coordination di-, tri- and tetramerization of ethylene [12,13,14,15] are also industrially important processes. Coordination oligomerization [16,17], as well as the hydro- and carboalumination [18] of higher α-olefins, are currently lab-based processes, even though they show strong industrial prospects.

Supported metal salts (primarily chlorides) or metal complexes as pre-catalysts, and organoaluminum compounds as co-catalysts, are used in the majority of these processes. After activation, the reaction mixtures contain metal alkyls and alkylaluminum chlorides. In coordination polymerization, mechanistic understanding of the reaction mechanism as a coordination/insertion of α-olefin or diene molecule at the metal–alkyl (or metal–hydride) center in stable ligand environments is generally accepted [13,16,19,20,21]. For group 4 metal polymerization catalysts, the conventional Cossee–Arlman mechanism has been expanded by including interactions between the metal center and bulky counterions (XMAO−, B(C6F5)4−, anionic supports, etc.) [22,23,24,25,26,27,28,29,30,31,32,33,34,35], and binuclear Zr2 complexes [34,36]; however, the direct participation of R2AlCl in the formation of catalytic species remains hypothetic, even with the results of numerous experimental and theoretical studies [37,38,39,40,41,42,43]. It is also an open question whether M–(μ-Cl)–Al species participate in the coordination polymerization of 1,3-dienes.

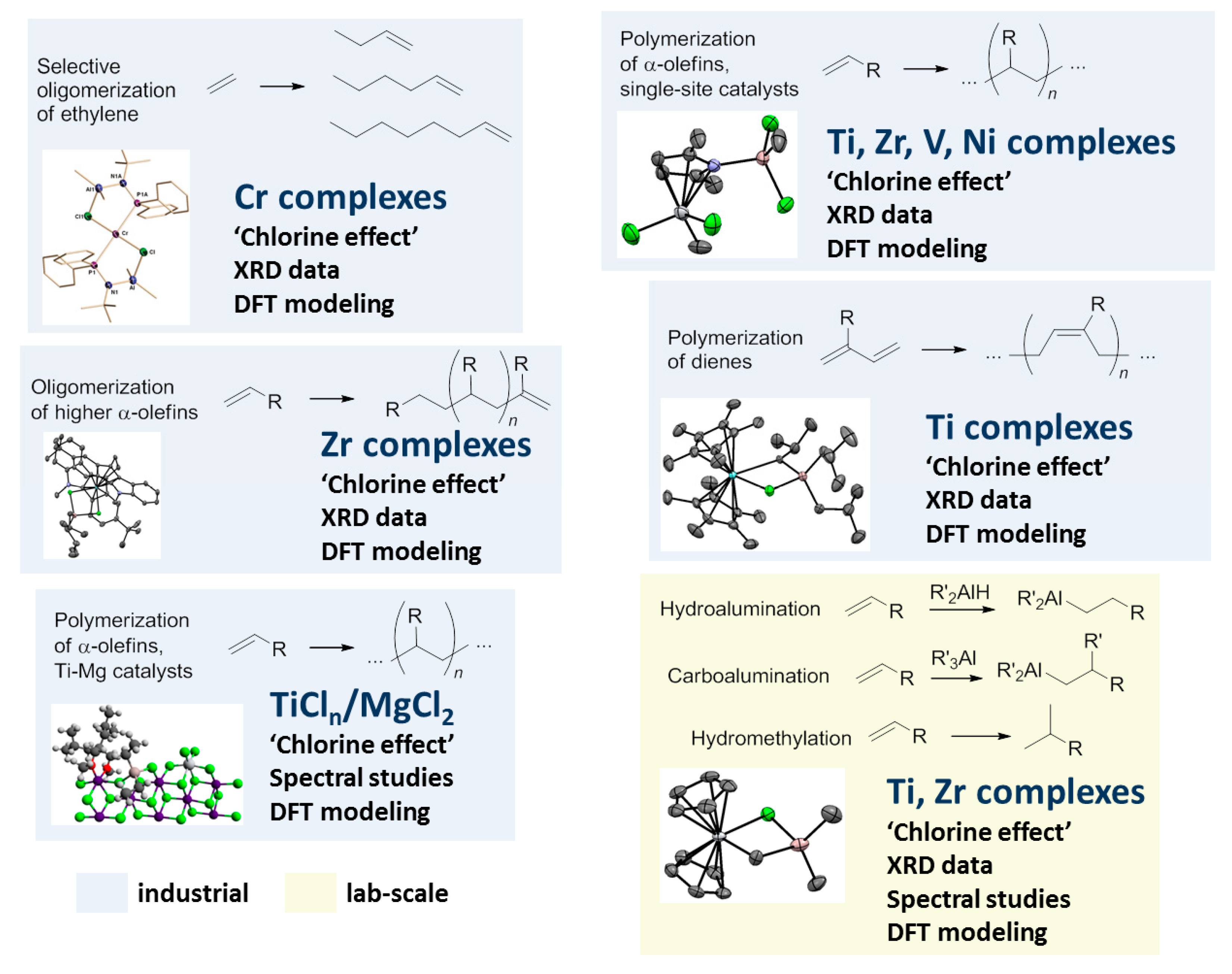

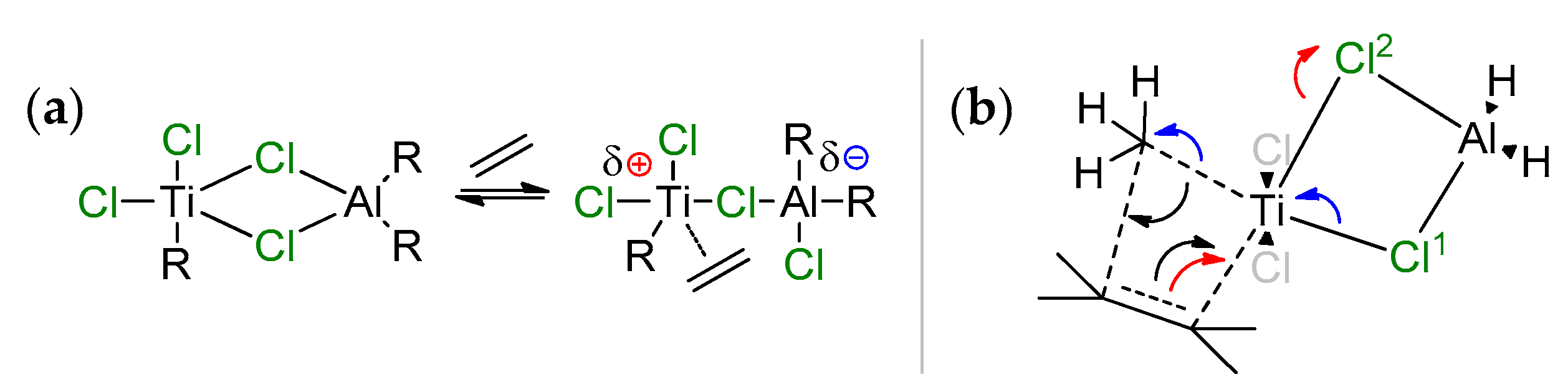

The current view of the problem is presented in Figure 1. Despite the many reviews on α-olefin and 1,3-diene functionalization, polymerization, and oligomerization, factual information about the possible role of M–(μ-Cl)–Al bonding is either absent or presented only fragmentary. In particular, M–(μ-Cl)–Al bonding was mentioned in reviews devoted to V-catalyzed olefin polymerization [44] and the Ni-catalyzed oligomerization of olefins [45,46]. In our recent review [17], we touched upon the possible role of Zr–(μ-Cl)–Al complexes in the selective dimerization of higher α-olefins, catalyzed by (η5-C5H5)2ZrCl2 (Cp2ZrCl2) and ansa-zirconocene dichlorides in the presence of 1–10 eq. methylalumoxane (MAO). The formation of Zr–(μ-Cl)–Al species during zirconocene-catalyzed hydro- and carboalumination of α-olefins is also not in doubt; however, the specific role of M–(μ-Cl)–Al in other catalytic process remains unclear [18]. To date, the comprehensive mechanistic concept, which takes into consideration M–(μ-Cl)–Al bonding in reaction intermediates and transition states of the catalytic process, has only been developed for the Cr-catalyzed trimerization of ethylene with the use of pyrrole/Cr/Et2AlX (X = Cl, Et) systems [13,47,48].

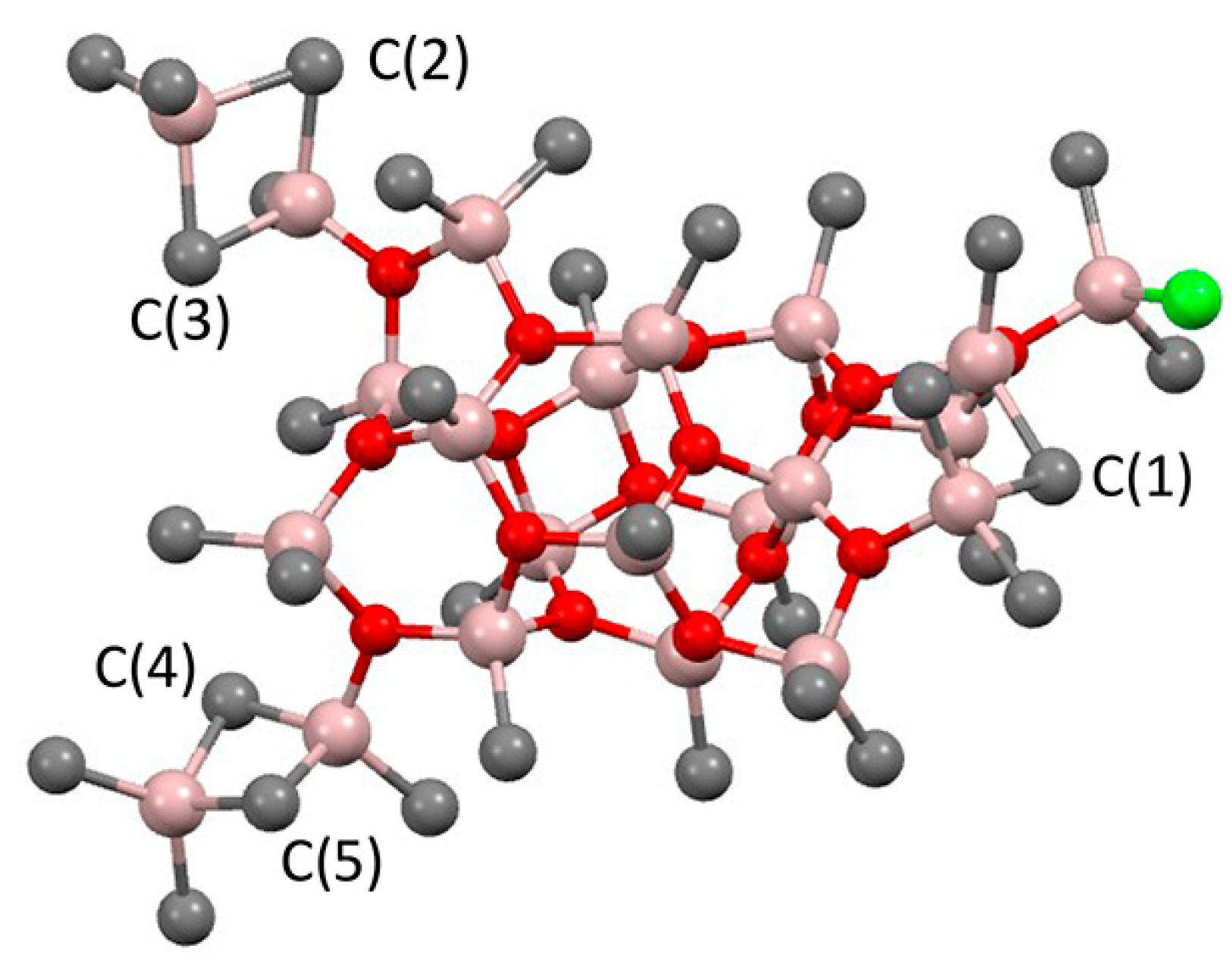

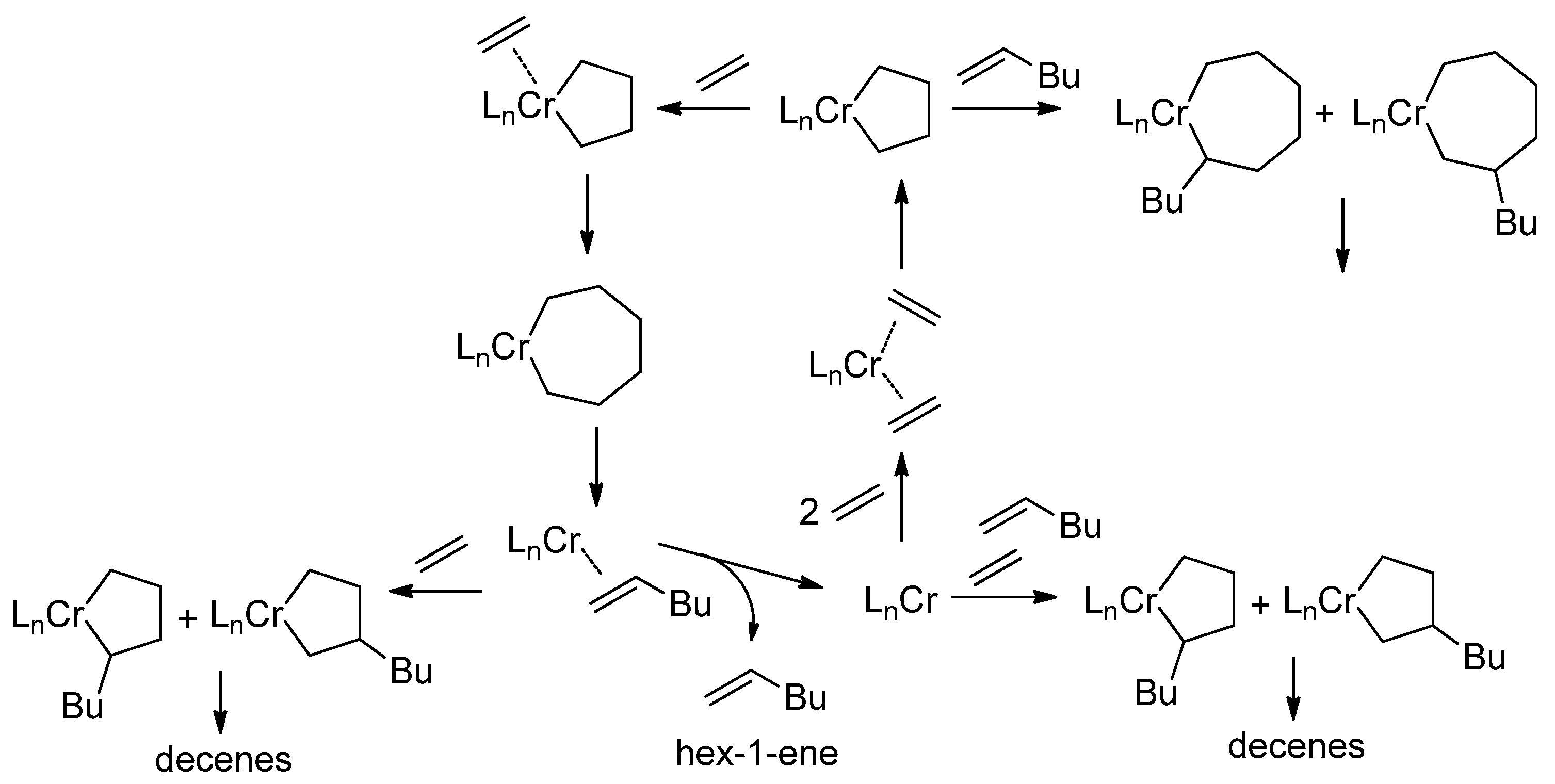

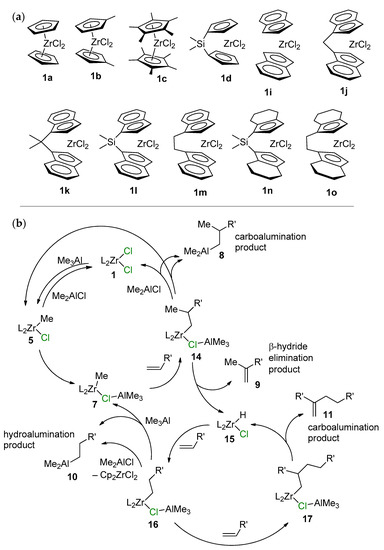

Figure 1.

The reactions of α-olefins and dienes with the possible participation of M–(μ-Cl)–Al species.

In this study, we summarized disparate facts, presented in scientific periodicals, with the aim of demonstrating the fact that metal complexes, containing M–(μ-Cl)–Al fragments, are or may be directly involved in olefin and diene transformations as reagents or catalytic species. The review is divided into sections by the type of metal in the complex core.

2. Complexes of Ti

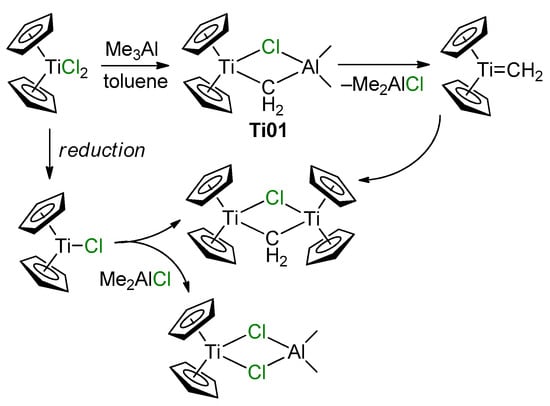

2.1. The Tebbe Reagent and Similar Ti Complexes

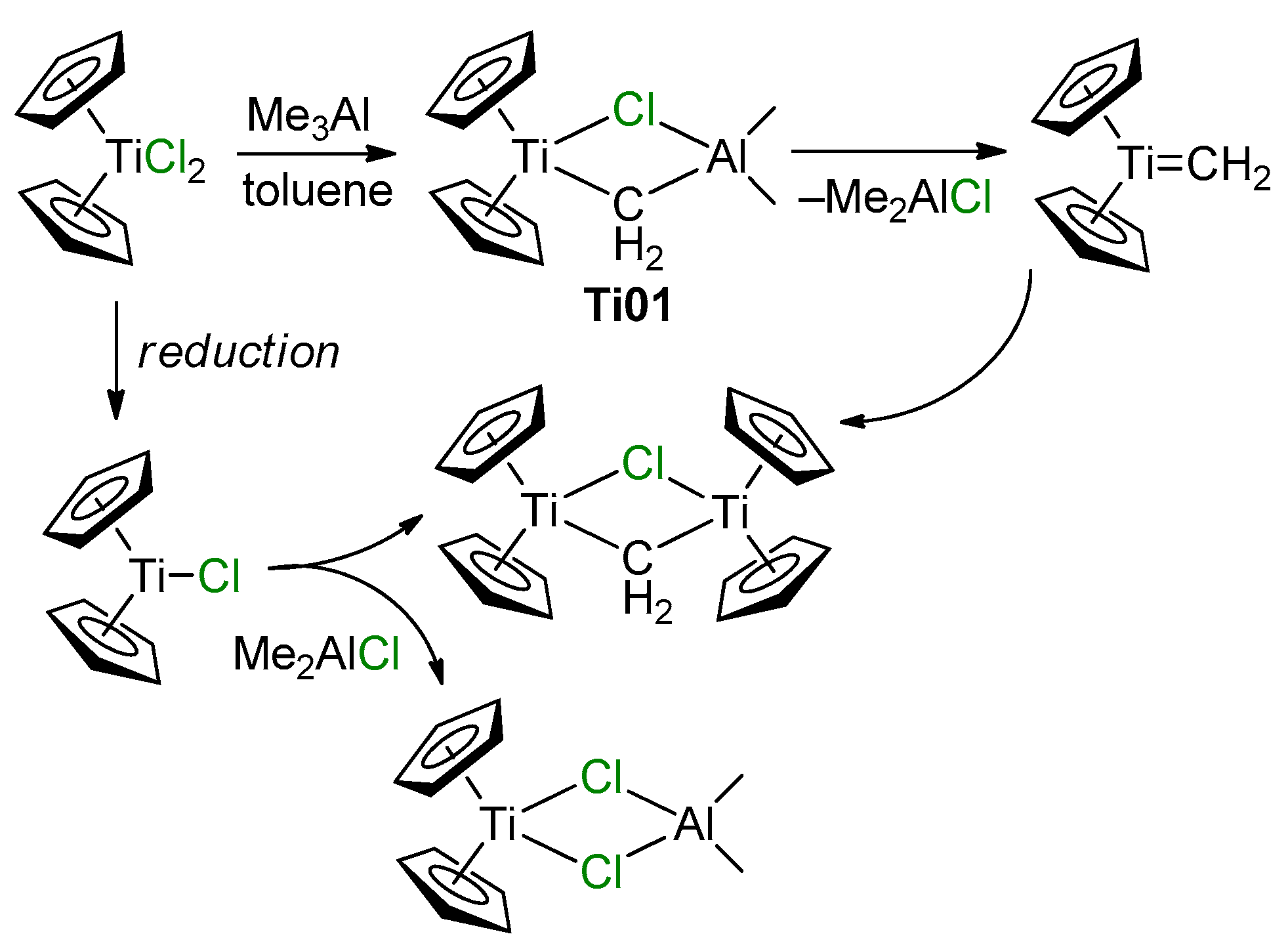

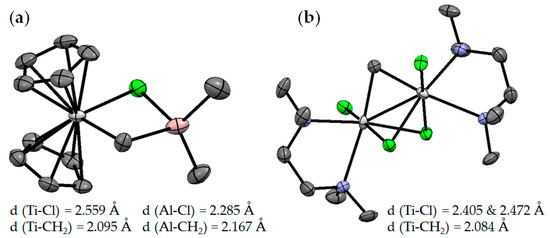

The Ti–Al heterobimetallic complex of the formula Cp2Ti(μ-Cl)(μ-CH2)AlMe2 (Ti01) was first synthesized by Tebbe et al. in 1978; the reaction of Cp2TiCl2 with AlMe3 resulted in the formation of Ti01 with 80–90% yields [49]. The synthesis of Ti01 was complicated by side reactions (Scheme 1), making it difficult to isolate the samples suitable for X-ray diffraction (XRD) analysis, and as a result, the molecular structure of Ti01 was only determined in 2014 [50] (Figure 2a). The difference between interatomic distances (d(Ti–CH2) < d(Al–CH2), d(Ti–Cl) > d(Al–Cl)) considers Ti01 as a complex of Cp2Ti=CH2 and Me2AlCl. In this way, in Ti01, Me2AlCl serves as a stabilizing agent for the Ti(IV) carbene complex, that can be removed by Lewis base.

Scheme 1.

Synthesis of Tebbe reagent Ti01 and possible side reactions and products [50].

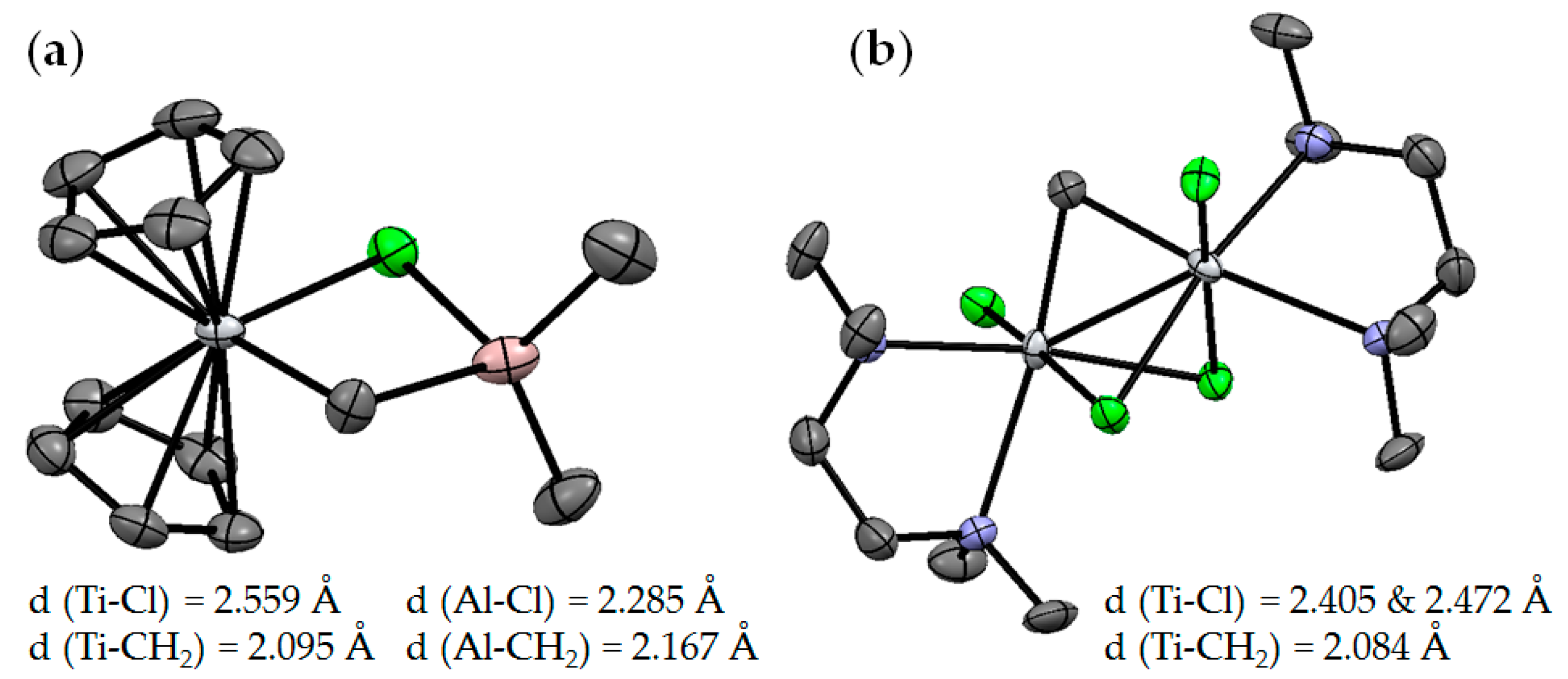

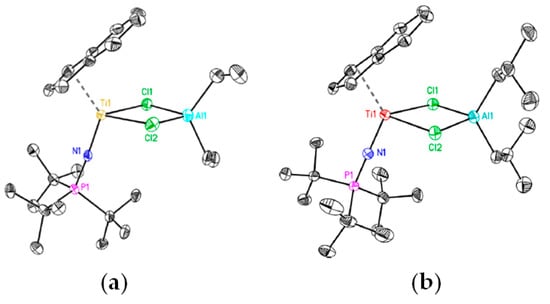

Figure 2.

Molecular structures of (a) Ti01 [50] and (b) Ti02 [51]. The hydrogen atoms are omitted for clarity.

A structural analog of the Tebbe reagent, Ti02, was synthesized by the reaction of the N1,N1,N2,N2-tetramethylethane-1,2-diamine (TMEDA) complex (TMEDA)TiCl3(THF) with [(TMEDA)ZnI]2CH2 [51]. Analysis of the molecular structure of Ti02 (Figure 2b) showed that the value of d(Ti–CH2) does not differ from that in Ti01. Notably, a series of chlorine-free analogs of Tebbe reagent was described in [52].

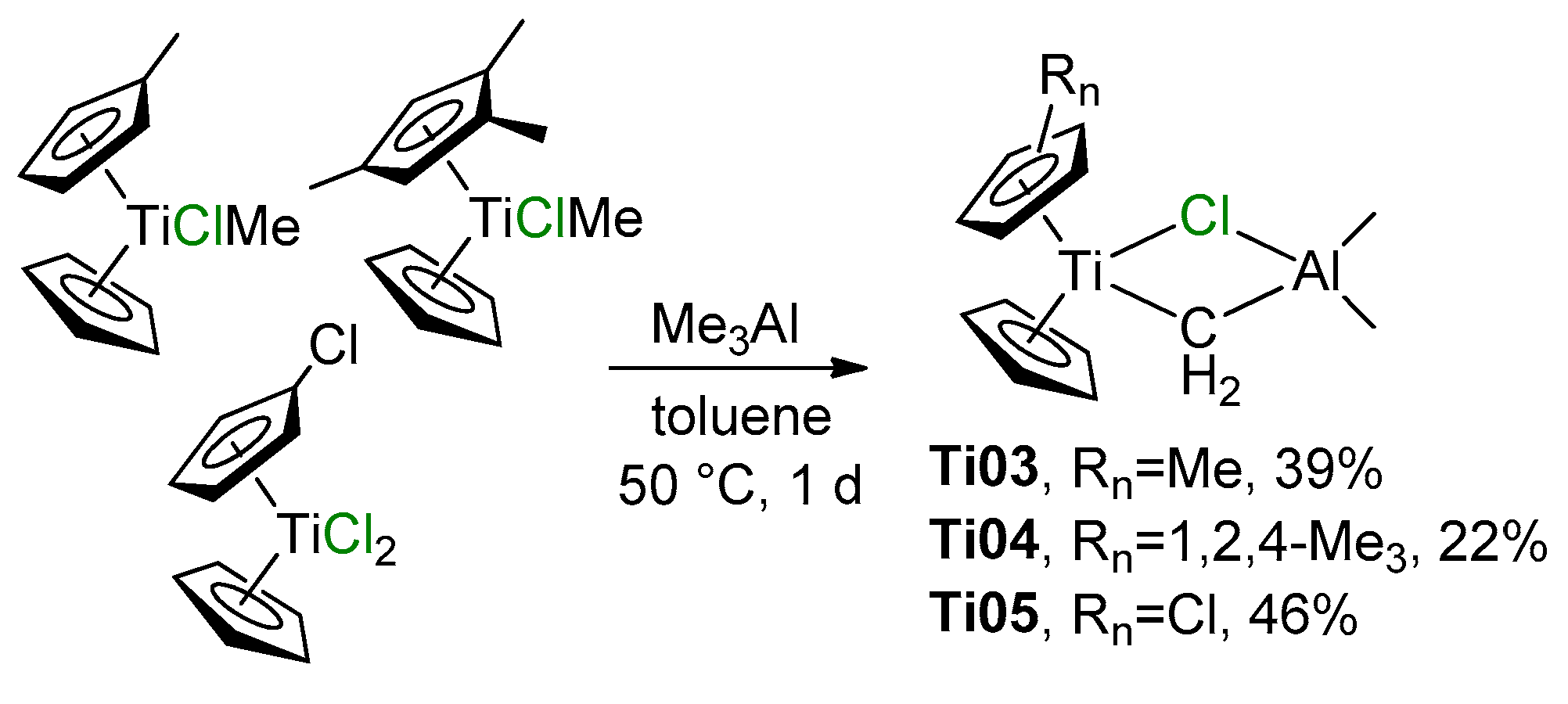

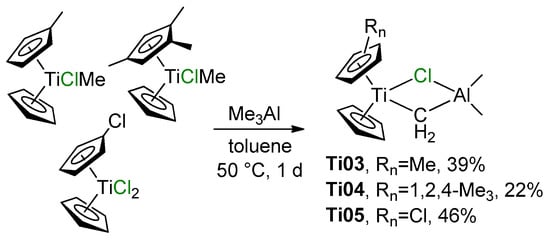

Close structural analogs of Ti01 were synthesized by the reactions of (η5-C5H4Me)CpTiClMe and (η5-1,2,4-C5H2Me3)CpTiClMe with Me3Al (Scheme 2, complexes Ti03 and Ti04, respectively) or by the interaction of (η5-C5H4Cl)CpTiCl2 with Me3Al (Scheme 2, complex Ti05) [53]. Treatment of Cp2TiCl(CH=CHMe) with iBu2AlH resulted in the formation of complex Cp2Ti(μ-Cl)(μ-CHEt)AliBu2 [54]; the product was not isolated, but has been identified by NMR spectroscopy. The attempt of Halterman and Ramsey to synthesize the chiral Tebbe reagent from 1,1’-binaphthyl-bridged bis(η5-tetrahydroinden-2-yl) Ti(IV) dichloride failed [55].

Scheme 2.

Synthesis of ring-substituted analogs of the Tebbe reagent [53].

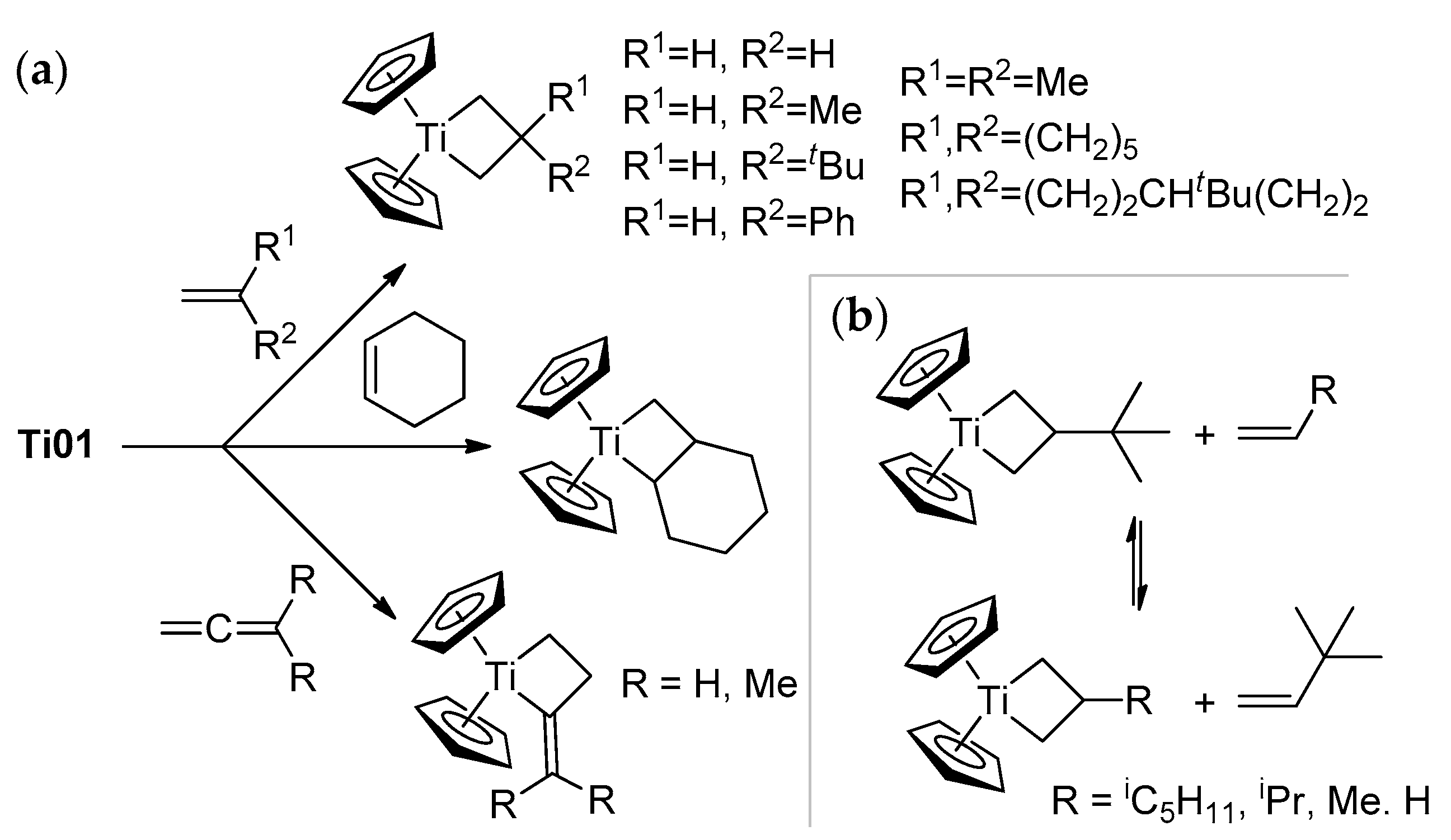

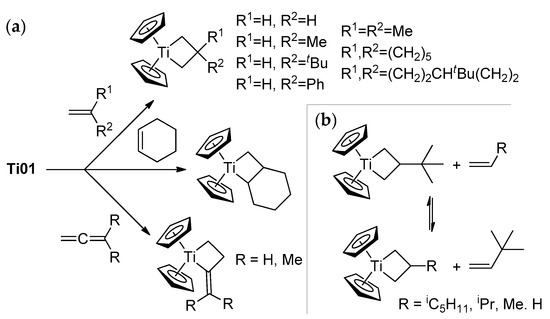

Ti01 has found its main applications for carbonyl methylenation similarly to phosphonium ylides in the Wittig reaction [52]. The reactions of Ti01 with carbonyl compounds are rapid and selective, even in the presence of other reactive groups (for example, –COOR [56], –C=NOR [57]), but this subject is beyond the scope of our review. However, α-olefins can react with Ti01: as shown by Grubbs et al., this reaction resulted in the formation of titanacyclobutanes, and allenes formed titanacyclobutanes with exocyclic C=C bonds (Scheme 3a) [58,59,60]. Titanacyclobutanes are reactive towards α-olefins, as demonstrated by Grubbs et al.; this reversible process proceeds through the formation of Cp2Ti=CH2 [61] (Scheme 3b). Ti–Al complexes Ti03–Ti05 reacted with tBuCH=CH2 similarly, with a formation of the mixtures of isomeric titanacyclobutanes [53].

Scheme 3.

(a) Formation of titanacyclobutanes [59,60]; (b) reactivity of tert-butyl-substituted titanacyclobutane towards α-olefins [61].

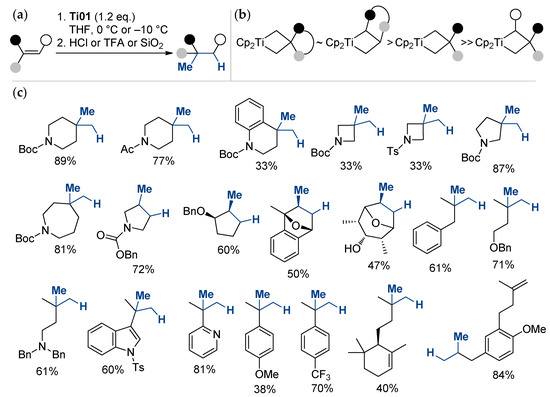

A degenerate metathesis reaction between titanium methylidene unveiled from Ti01 and unactivated alkenes, followed by acid hydrolysis, was recently proposed by Frederich et al. [62] as a direct method for the Markovnikov hydromethylation of alkenes (Scheme 4). The reaction is site-specific; the reactivity of olefins decreases in the order α-olefins > methylenealkanes > trisubstituted alkenes.

Scheme 4.

(a) General reaction scheme; (b) relative stability of titanacyclobutane intermediates; (c) scope and limitations of the titanium-mediated hydromethylation of alkenes [62].

2.2. Single-Site Ti Catalysts of the Polymerization and Oligomerization of α-Olefins

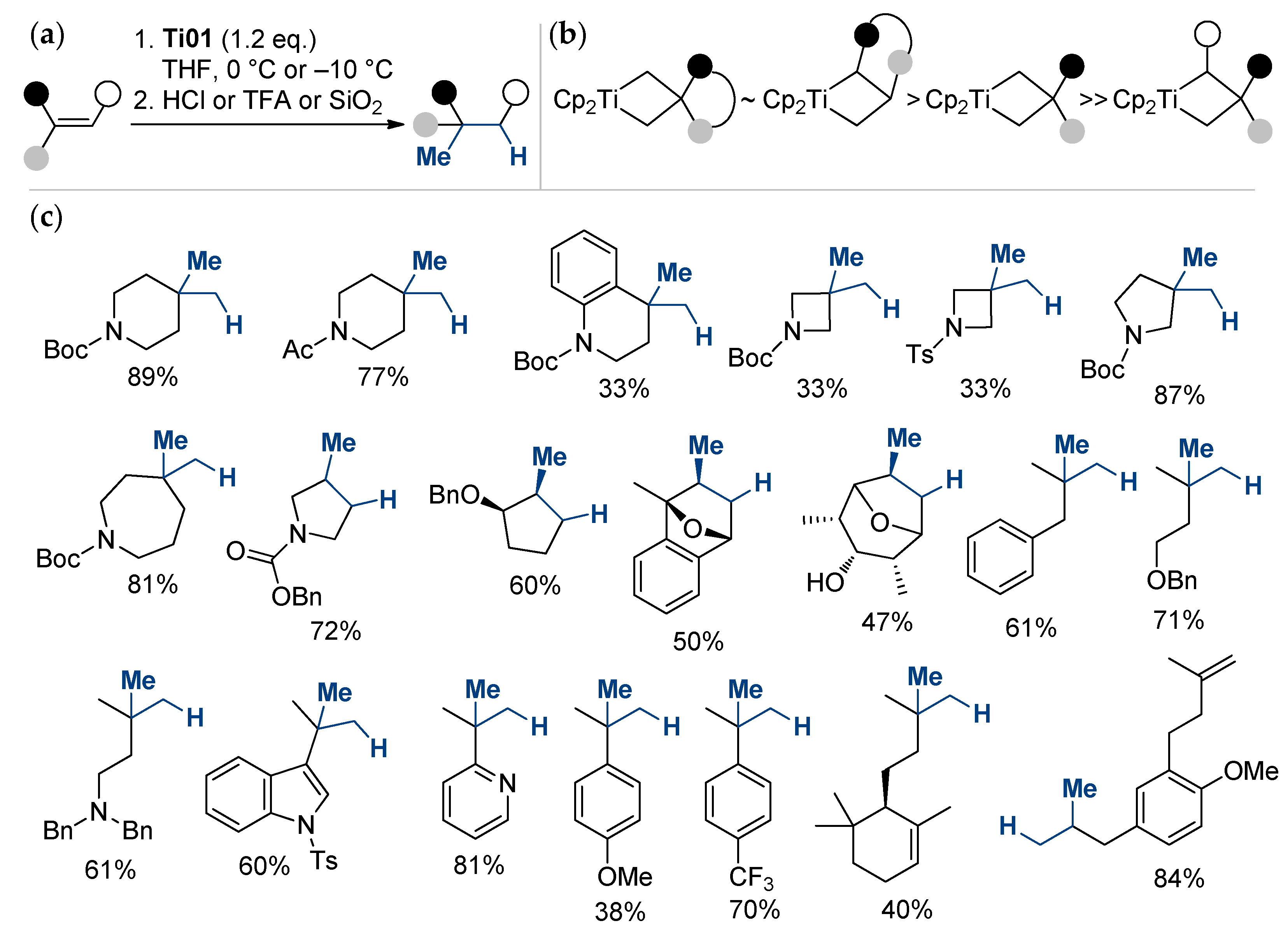

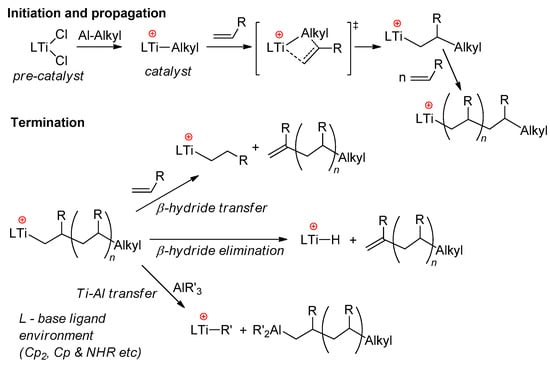

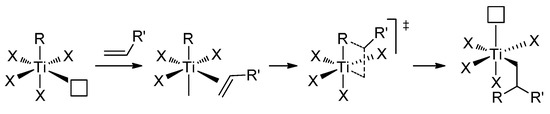

In early experiments on the single-site polymerization of ethylene, conducted by Shilov’s group, the occurrence of cationic species during the reaction of Cp2TiCl2 with Et2AlCl was regarded as an experimental criterion of the rapid catalytic process [63,64]. In the opinion of Shilov, after the intermediate formation of complex Cp2TiClEt·EtAlCl2, partial dissociation of the complex occurs, and Cp2TiEt+ is active in polymerization. For the most part, this view has not fundamentally changed in terms of the reaction mechanism, and for sandwich and half-sandwich complexes of Ti(IV), the polymerization of α-olefins includes stages of π-coordination of alkene at the Ti–Alkyl cation and insertion of the alkene via the four-membered Cossee–Arlman transition state. Possible termination events for the growing polyolefin chain are β-hydride transfer to monomer, β-hydride elimination, and Ti → Al alkyl transfer (Scheme 5) [65,66]. The main problems arising during the use of Ti(IV) sandwich complexes derive from side reactions that deactivate the active titanocene catalyst via reduction of the Ti(IV) cationic center [65]. Stabilization of the active Ti(IV) species was achieved via ligand design, with the development of half-sandwich constrained-geometry complexes (CGCs) [67,68,69,70] and different Ti(IV)-based post-metallocene catalysts [5,71].

Scheme 5.

Conventional mechanism of α-olefin polymerization, catalyzed by sandwich and half-sandwich Ti(IV) complexes [65].

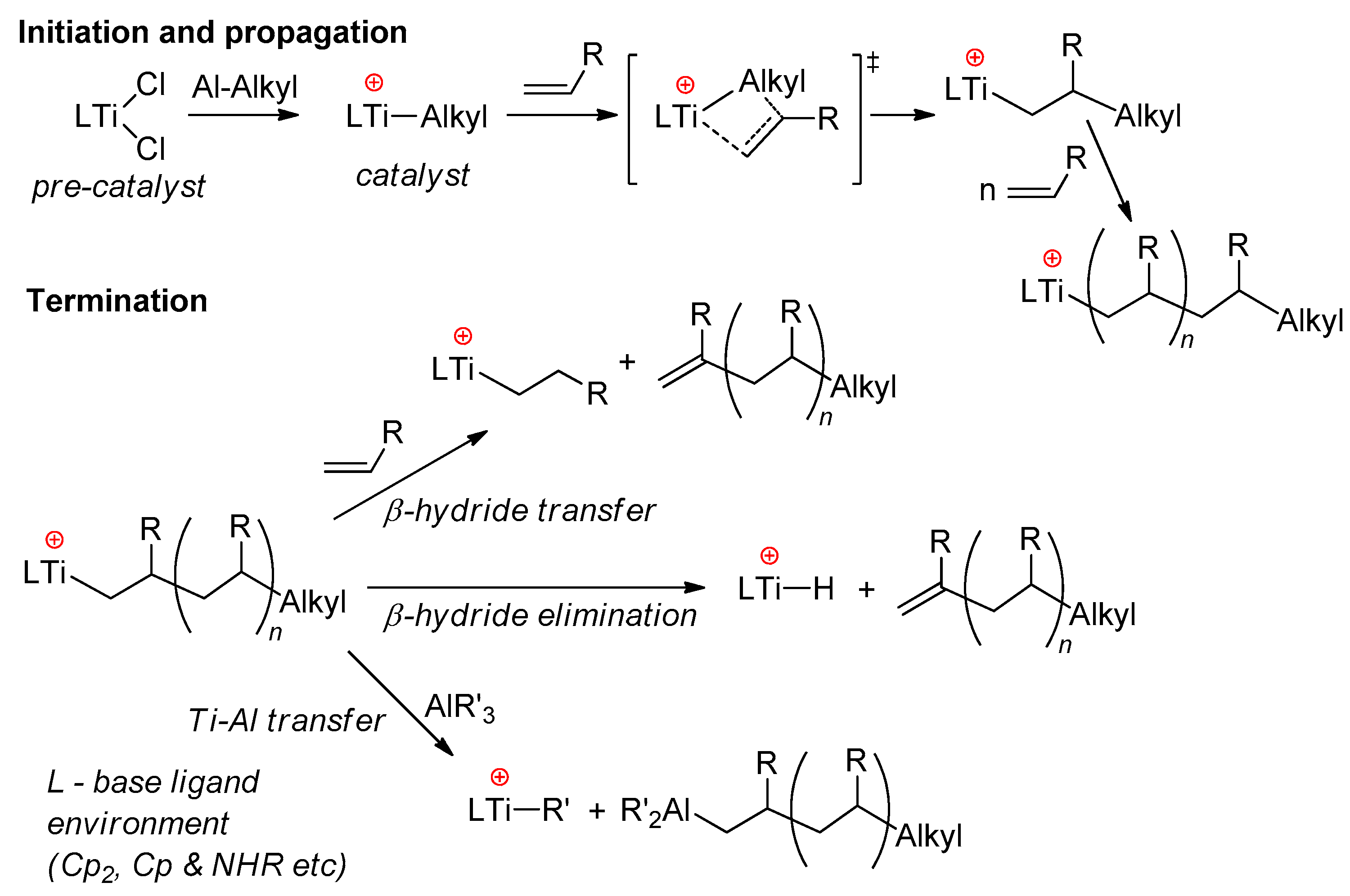

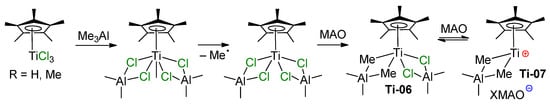

In the following model experiments on activation of Ti(IV) chloro complexes by aluminum alkyls, Ti–(μ-Cl)–Al-containing products were detected by ESR and electronic absorption spectroscopy. Thus, in the 1980s, Mach’s group studied the formation and relative stability of Ti–Al half-sandwich complexes with the formula CpTiAl2Cl8–xEtx and (η6-C6H6)TiAl2Cl8–xEtx, and demonstrated their reduced stability by increasing the number of Et fragments, x [72,73]. In 2004, Bonoldi et al. studied the activation of CpTiCl3 and (η5-C5Me5)TiCl3 (Cp*TiCl3) by different aluminum alkyls, MAO and AlMe3/[CPh3][B(C6F5)4] [74]. ESR spectral studies have shown that during the reaction of LTiCl3 with Me3Al at an Al/Ti ratio of 10:1, after 3 h, Ti(III) complexes are formed with 12% and 8% yields, respectively. This was explained by the more electron-rich nature of Cp* in comparison with Cp, which hindered an increase in the electron density by reduction (Ti(IV) + e− → Ti(III)). In the presence of MAO, complex Ti06 was formed (Scheme 6). This complex demonstrated moderate catalytic activity in the polymerization of styrene, although it is the cationic complex Ti07 that was considered as an active polymerization catalyst.

Scheme 6.

Formation of catalytically active half-sandwich Ti–Al complexes [74].

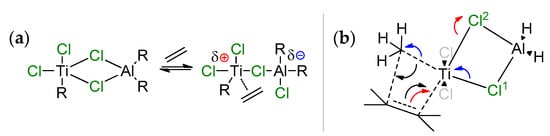

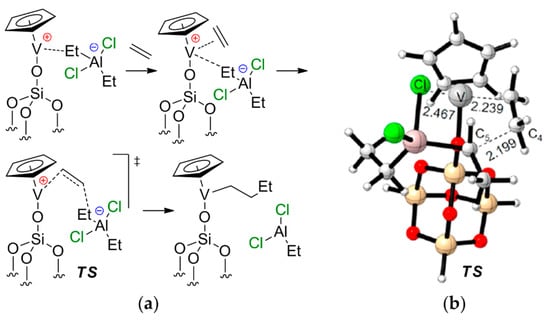

The hypothesis of the coordination of R2AlCl (Scheme 7a) with the possibility of the partial ionization of the active center, followed by the coordination/insertion of ethylene, was put forward by Jensen et al. in 1994 [75]. This hypothesis was based on the assumption that single-site Ziegler–Natta catalysts, obtained by the reaction of TiCl4 with AlR3, contain active Ti(IV) species. Quantum chemical optimization of the model complex MeCl2Ti(μ-Cl)2AlH2·CH2=CH2 at the DFTG level showed weak coordination of the ethylene molecule (d(Ti–C) > 3 Å) [76]; no stationary point due to the π-coordination of ethylene was found for this system. Similar results were obtained by the same research group during more thorough theoretical studies [77]; however, the authors have not abandoned the idea of the direct participation of Ti–(μ-Cl)–Al species in the catalytic process. Notably, one year earlier, Sakai reported the results of ab initio studies of the formation and further transformations of exactly the same molecule, MeCl2Ti(μ-Cl)2AlH2·CH2=CH2, in comparison with the MeTiCl3/CH2=CH2 system [78]. First, Sakai was able to find the local minima corresponding to π-complex MeCl2Ti(μ-Cl)2AlH2·CH2=CH2 (Scheme 7b). Second, even more interestingly, no stationary point was found for π-complex MeTiCl3∙CH2=CH2, and the activation energy barrier of ethylene insertion for the MeTiCl3/CH2=CH2 system was 20.5 kcal·mol−1 higher than that for MeCl2Ti(μ-Cl)2AlH2·CH2=CH2. Sakai explained it in this way: in the rate-limiting transition state of the ethylene insertion, the π-electrons in ethylene move to the Ti–C(ethylene) region to form the new Ti–C bond. The electrons, belonging to the Ti–C(methyl) bond, move to the C–C (methyl–ethylene) region to form a new C–C bond (push-pull mechanism, black arrows). In the Ti–(μ-Cl)2–Al complex, the Ti–Cl2 bond, opposite to the ethylene coordination side for the Ti center, increases in length with electron transfer to the Cl2 atom along the reaction pathway (red arrow in Scheme 7b). The original π-electrons move to the new Ti–C bond region (opposite to the Ti–Cl2 bond) easily (red arrow), this process is similar to SN2 reaction. At the same viewpoints, the Ti–Cl1 bond, opposite to Ti–C(methyl), decreases in length, and the electrons move from Cl1 to Ti and from Ti–C(methyl) bond to C(methyl) (blue arrows). Therefore, the Al–Cl (or Ti–Cl) bonds switching mechanism facilitates the push–pull mechanism of the insertion.

Scheme 7.

(a) Suggested scheme for partial ionization of the active center through action of the aluminum cocatalyst [75]; the authors proposed that after the cleavage of one of the Ti–Cl–Al bonds, the vacated position due to partial ionization is occupied through the coordination of ethylene; (b) ab initio modeling [78] showed that Ti–(μ-Cl)2–Al bonding is retained in the rate-limited transition state, and facilitates the insertion.

It can be assumed that similar single-site catalytic species are formed when using TiCl4/AlCl3 on a SiO2 support, activated by Et2AlCl [79,80]. This catalyst was studied in the oligomerization of dec-1-ene, which resulted in the preferential formation of trimers (by wt.%). The authors did not discuss the nature of the catalytic species (including oxidation state of Ti), confining themselves to the analysis of oligomer’s microstructure. However, studies of the impact of AlCl3/Ti ratio on catalytic activity and oligomer distribution have shown the presence of an optimum, suggesting Ti–(μ-Cl)–Al contacts. Note that dec-1-ene oligomers, obtained with the use of this Ti/Al catalytic system, were regioirregular and contained nonnegligible proportion of tail-to-tail and head-to-head monomer units, differing from structurally homogeneous products of zirconocene-catalyzed oligomerization (see Section 3.2). This fact, and uniform molecular weight distribution (MWD) of the oligomer mixtures, suggest this Ti/Al catalyst to be qualitatively distinct from conventional heterogeneous Ziegler–Natta catalysts (see Section 2.4).

The results of Jensen et al. [75] were augmented with the studies of Ti ether complexes by Bulychev’s group [81]. Here, it has clearly been established that in the presence of ethers, R2AlCl reduces Ti(IV) to Ti(III). A conventional activator of single-site polymerization catalysts, MAO, was completely inactive towards Ti(III) etherates. In contrast, when using Et2AlCl or 3:1 Et2AlCl/Bu2Mg mixture as activators, the ionic complex of Ti(III) [(15-Crown-5)TiCl2]+[AlCl4]− (Ti08) demonstrated moderate activity in ethylene polymerization. The catalytic activity of Ti08 decreases with the increasing Al/Ti ratio; therefore, it can be assumed that only partial alkylation of the Ti–Cl bonds occurs. However, there was no experimental proof of Ti–(μ-Cl)–Al bonding in catalytic species discussed in [81].

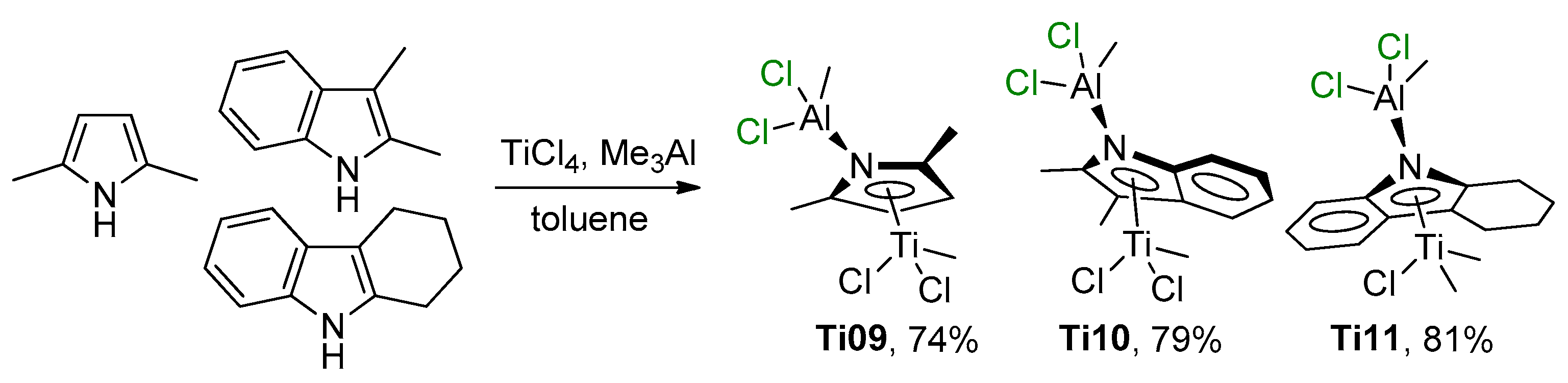

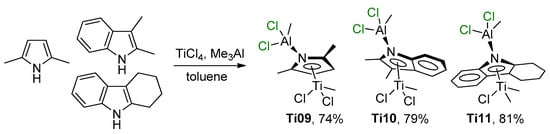

There are limited studies devoted to the participation of Ti–(μ-Cl)–Al complexes with proven structure in catalytic polymerization and oligomerization of α-olefins. In 2012, Duchateau et al. reported the synthesis, structural characterization, and ethylene polymerization performance of heterobimetallic Ti–Al–pyrrolyl complexes (η5-2,5-Me2C4H2NAlCl2Me)TiCl2Me (Ti09), (η5-2,3-Me2C8H4NAlCl2Me)TiCl2Me (Ti10), and (η5-3,4,5,6-C12H12NAlCl2Me)TiClMe2 (Ti11) [82]. These complexes were obtained by the treatment of TiCl4 with equimolar amounts of Me3Al and the corresponding pyrrole ligands (Scheme 8).

Scheme 8.

Synthesis of Ti(IV)–Al–pyrrolyl complexes Ti09–Ti11 [82].

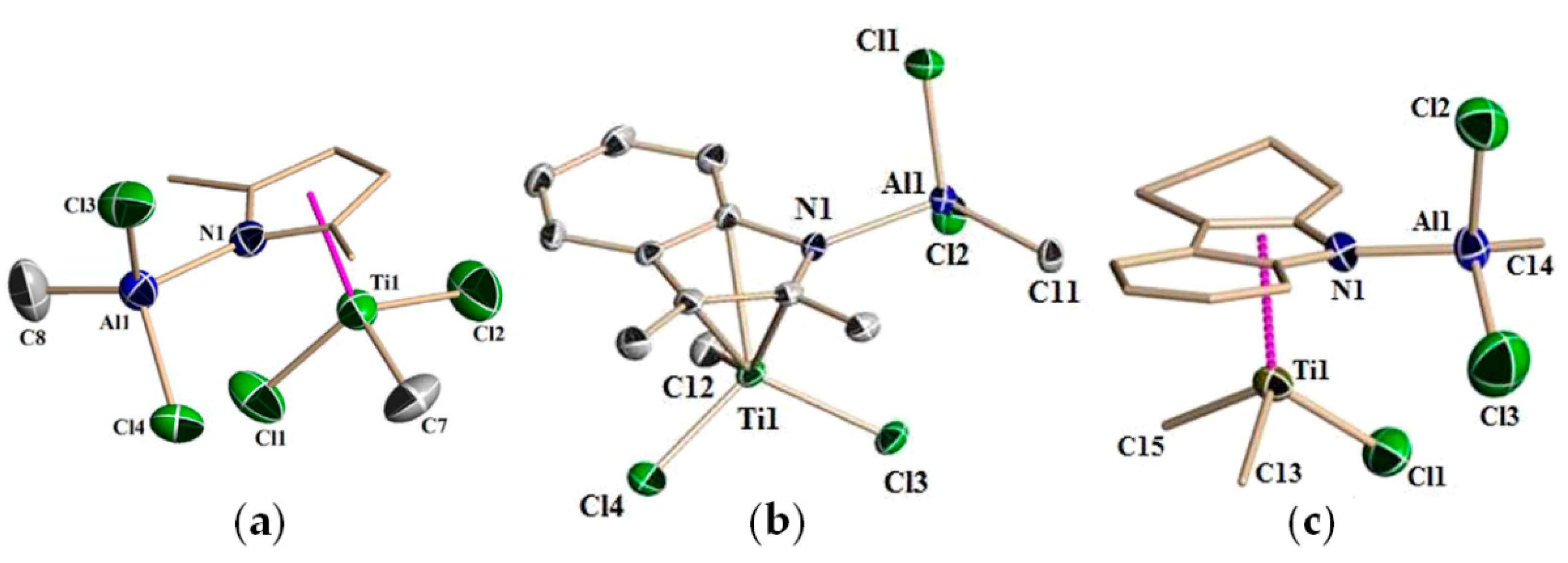

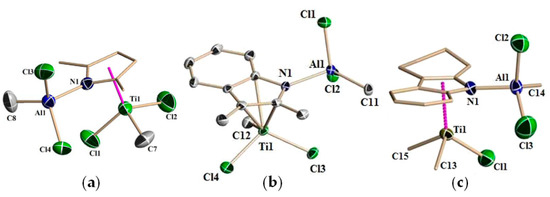

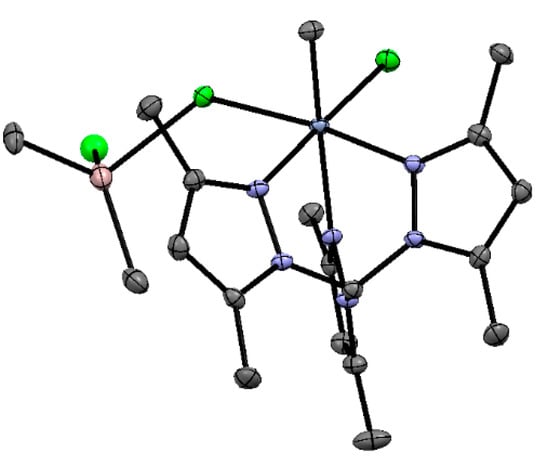

Molecular structures of Ti09–Ti11 were determined by XRD analysis (Figure 3). All molecules exhibited a distorted tetrahedral piano stool configuration. The Ti(1)–CENpyrrole bond distances (CENpyrrole is a centroid of the pyrrole ring) are identical in Ti09 and Ti10 (d(Ti(1)–CEN = 2.062 Å), but are slightly shorter than the Ti(1)–CENpyrrole bond distance in Ti11 (d(Ti(1)–CEN = 2.088 Å). Although formally Ti09–Ti11 were assigned to η5-type complexes, in Ti10 and Ti11, titanium has a stronger interaction with the N atom, resulting in an η4,κ-bonding mode for Al–indolyl and Al–carbazolyl ligands.

Figure 3.

Molecular structures of Ti(IV)–Al–pyrrolyl complexes: (a) Ti09; (b) Ti10; (c) Ti11. Reprinted with permission from [82]. Copyright (2012) American Chemical Society.

Upon activation with MAO at 30 °C, Ti09 produces a single-site catalyst affording ultra-high-molecular weight polyethylene (UHMWPE, Mw = 2300 kDa, ĐM= 2.5). When Ti09 was activated with [Ph3C]+[B(C6F5)4]− and TIBA (50 eq.) at 30 °C, bimodal distribution of the polymer was detected, indicating the formation of two distinct active species. A similar bimodal distribution and significant reduction in Mn were observed when MAO-activated polymerization was carried out at 60 °C. MAO-activated Ti–Al complexes Ti10 and Ti11 displayed higher catalytic activity compared with Ti09, and also produced UHMWPE. Complex Ti10 showed the same bimodal behavior when activated with [Ph3C]+[B(C6F5)4]− and TIBA.

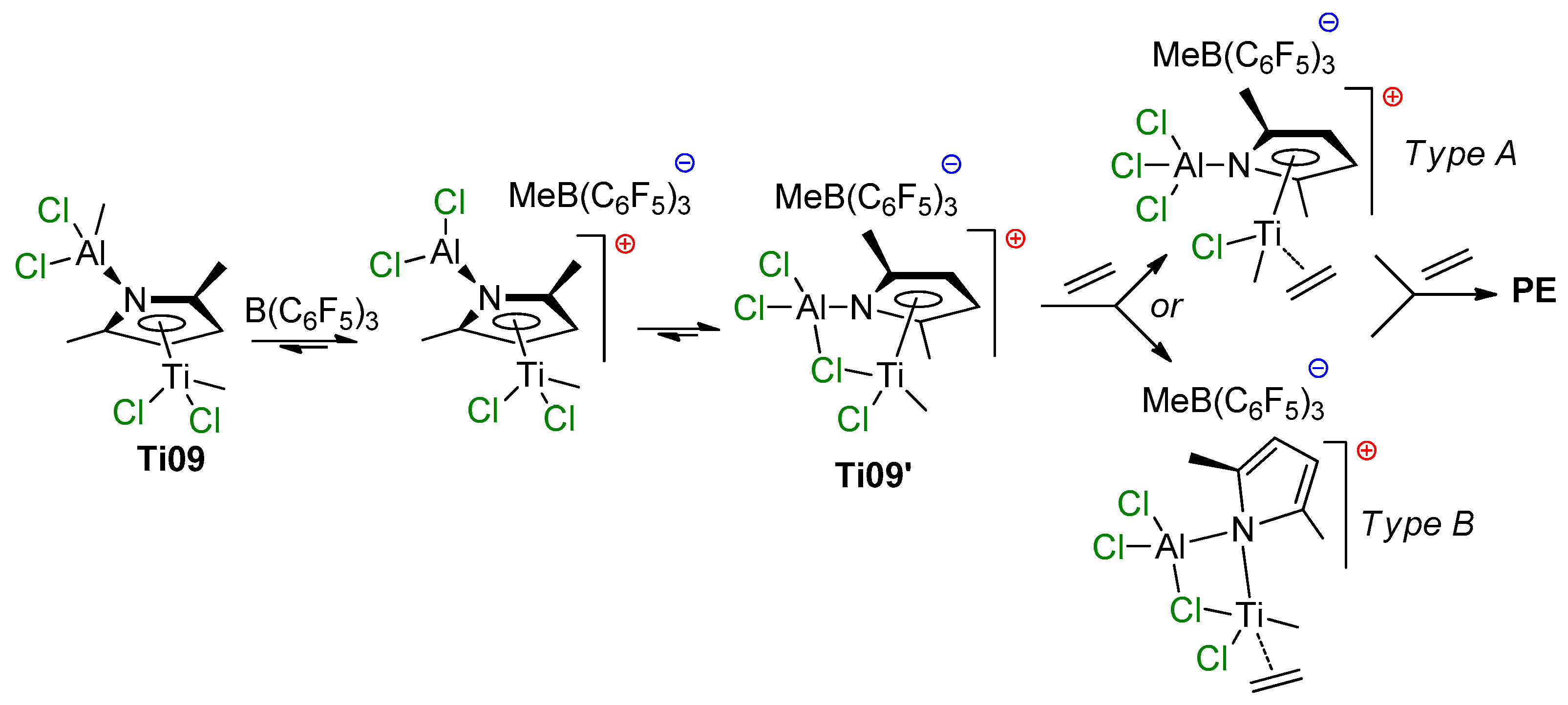

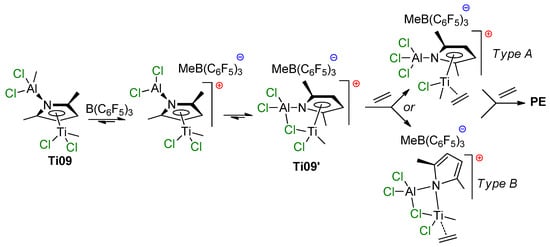

To clarify polymerization mechanism, the reaction of Ti09 with B(C6F5)3 was investigated to determine which of the methyl groups (Ti–Me or Al–Me) would be abstracted. The 1H NMR spectrum clearly showed that B(C6F5)3 selectively abstracts Al–Me group with the formation of a cationic complex Ti09′, containing a Ti–(μ-Cl)–Al fragment (Scheme 9). The ability of the supposed cationic species Ti09′ to polymerize ethylene was tested by treating Ti09 with B(C6F5)3 under ethylene pressure (20 bar) at room temperature, and the rapid formation of polyethylene was detected.

Scheme 9.

Proposed pathways of the activation of Ti09 by B(C6F5)3 [82].

DFT optimization of the putative structures of the cationic species and their ethylene adduct showed that a constrained type of geometry with the Ti–(μ-Cl)–Al fragment is the most stable configuration for Ti09′. This saturated complex Ti09′ should not be an active catalyst; either release of the bridged Cl (Type A structure in Scheme 9) or η5→μ ring slippage of the pyrrole moiety (Type B structure in Scheme 9) may result in a coordinatively unsaturated complex to coordinate and polymerize ethylene. The DFT calculations showed that the formation of a Type A complex requires 12.2 kcal·mol−1, and no local minima were found for the Type B product of η5→μ ring slippage.

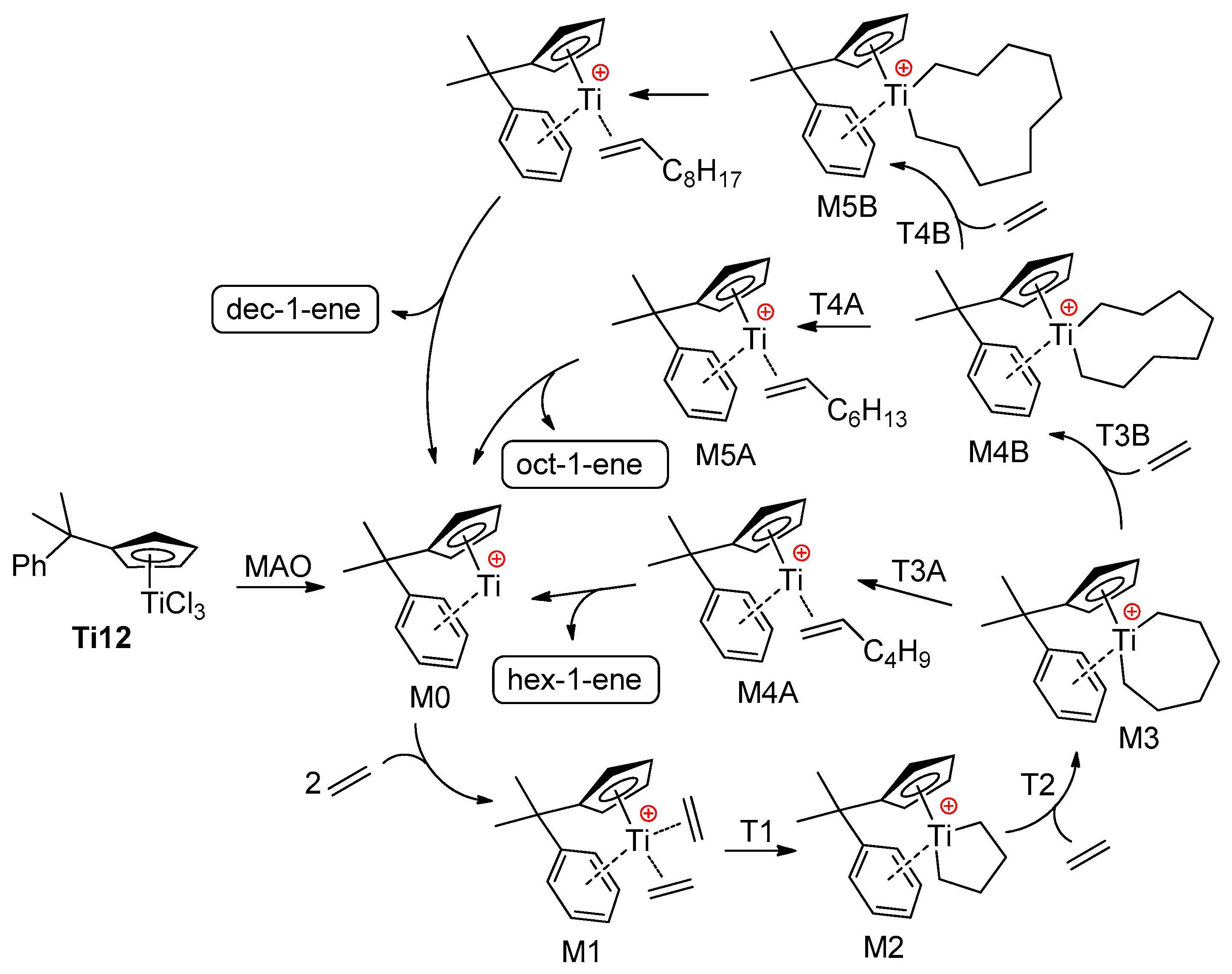

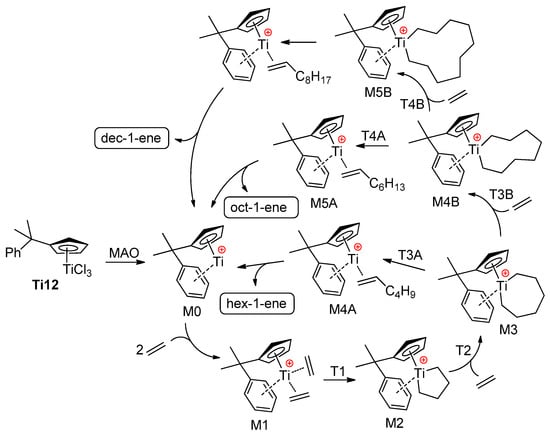

In this way, intramolecular Ti–(μ-Cl)–Al bonding has a strong impact on the catalytic behavior of Ti complex. The other extreme is weak Ti⋯Cl–Al coordination; de Bruin et al. [83] carried out a computational study of the influence of ‘chlorinated’ MAO anions on the catalytic behavior of complex Ti12 which represents an efficient pre-catalyst of the selective trimerization of ethylene with the formation of hex-1-ene [14,15,84]. The key intermediates of the reaction are presented in Scheme 10, although the energetically unfavorable process of but-1-ene elimination from intermediate M2 (see below) is not shown.

Scheme 10.

Reaction pathway for the oligomerization of ethylene, catalyzed by Ti12/MAO [83].

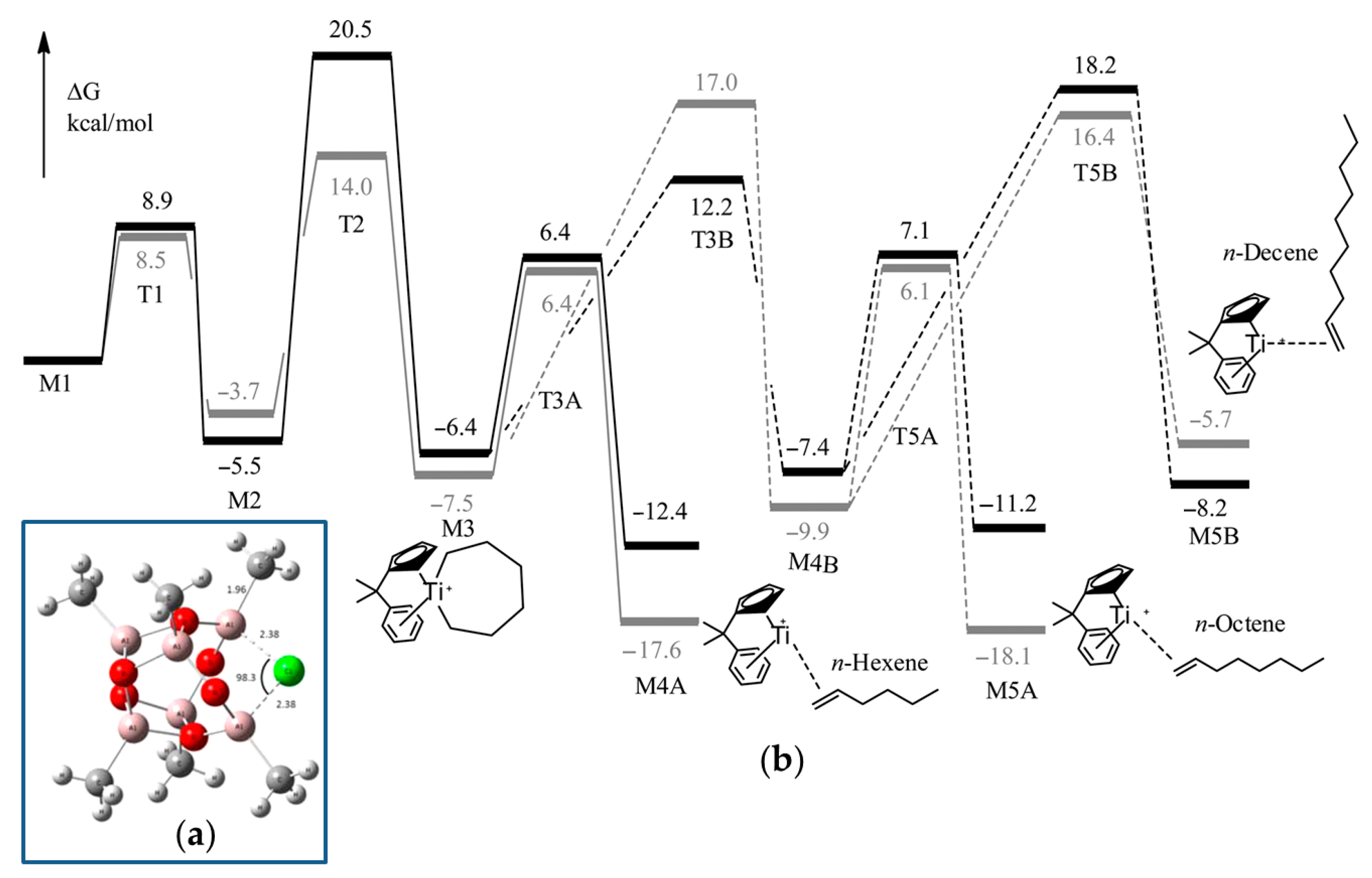

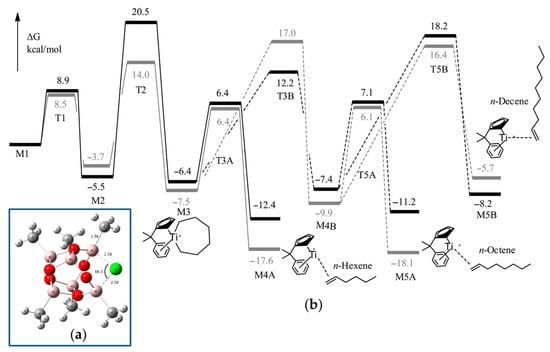

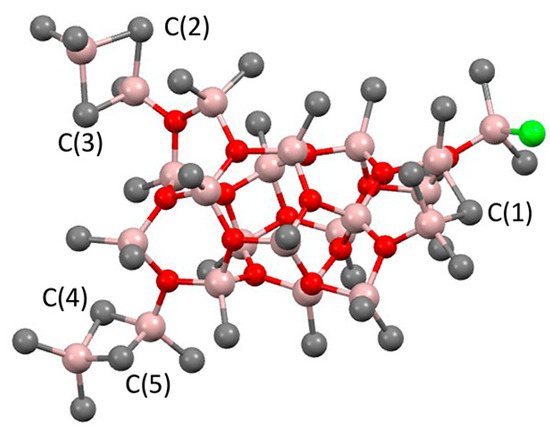

For DFT calculations, one of many possible MAO structures [85,86] was selected, namely, the cage (MeAlO)6Cl− model (Figure 4a), negatively charged due to the coordination of one Cl−, abstracted from Ti12 during activation. Two different potential free energy reaction profiles have been modeled (Figure 4b): the first only takes into account the cationic catalyst (cationic profile), whereas the second describes the energy changes in the presence of a chlorinated MAO (zwitterionic profile). The reaction starts with the activated catalyst M1 (two ethylene molecules coordinated to the cationic Ti(II) center). After oxidative coupling (M2), a third ethylene molecule coordinates and inserts with a formation of the seven-membered metallacycle (M3). This species can undergo a β-hydride transfer followed by reductive elimination (M4A), which, in turn, releases hex-1-ene. Alternatively, a fourth ethylene may coordinate to M3 and insert to yield a nine-membered metallacycle M4B. This latter species can then undergo a ring-opening reaction to yield 1-octene (M5A), or a fifth ethylene coordination and insertion can take place. The calculated barrier for β-hydride elimination in M2 (but-1-ene formation) was ~35 kcal·mol−1. Based on a comparison of cationic and zwitterionic profiles, it can be concluded that the presence of (MeAlO)6Cl− does not impact the selectivity of ethylene oligomerization. Based on the results of modeling, the authors concluded that the presence of MAO model does not necessarily need to be taken into account, and the cationic system alone is sufficiently representative.

Figure 4.

(a) B3LYP-optimized configuration of the [MAO-Cl]− anion; (b) comparative reaction profile over the potential energy surface for a cationic (gray) and zwitterionic (black) catalyst. The solid line indicates the main path; the dotted line indicates the less favorable alternative path. Reprinted with permission from [83]. Copyright (2015) American Chemical Society.

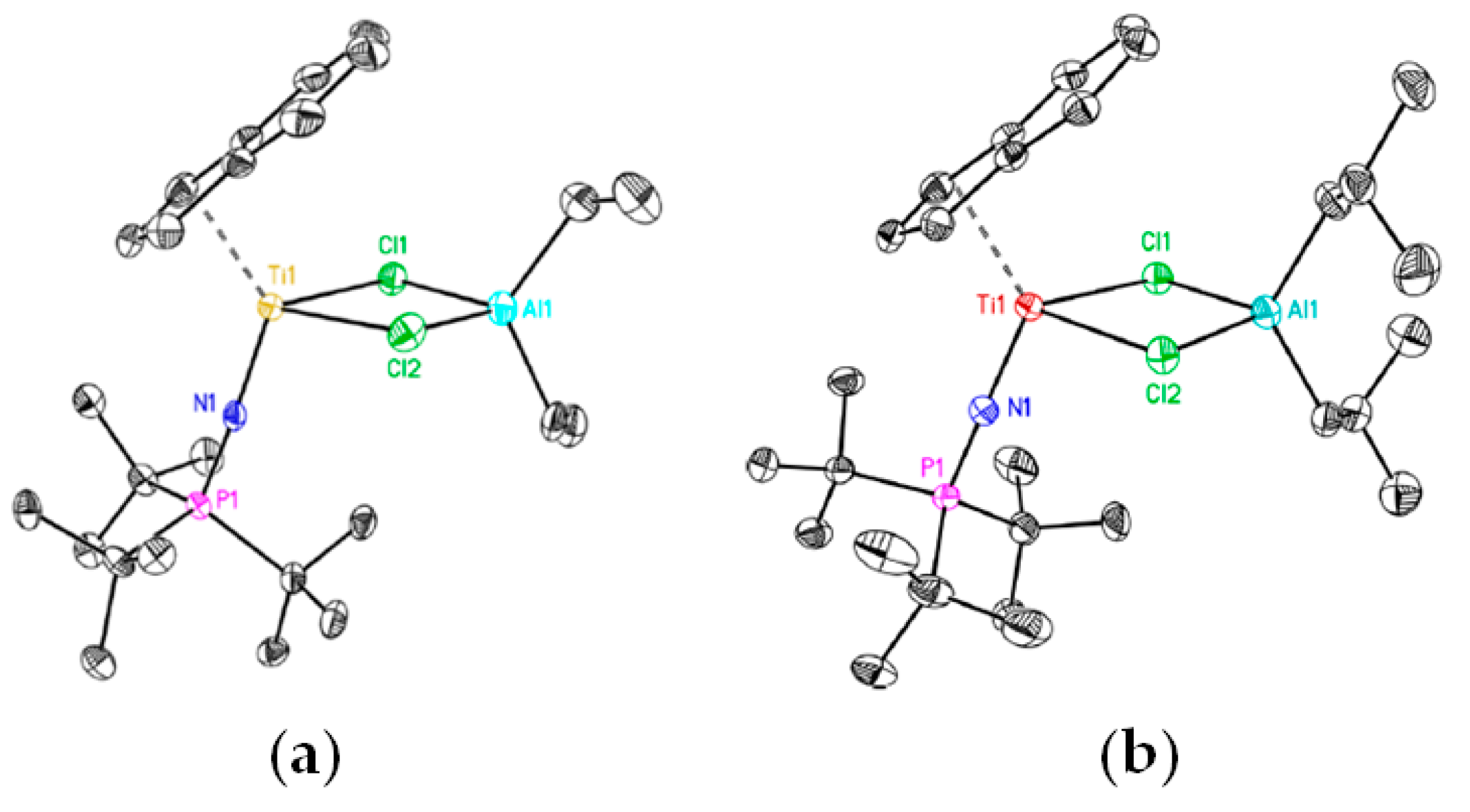

As reported by Blakemore et al., the reaction of the Ti(IV) complex (η6-C9H7)TiCl2(N=PtBu3) with Et3Al resulted in the formation of Ti(III)-Al complex Ti13 [87]. The molecular structure of Ti13 is presented in Figure 5a. Both complexes catalyzed the polymerization of ethylene being activated by Et3Al in the presence of a solid superacid. During subsequent research [88], the complexes Ti14 and Ti15 of the formula (η6-C9H7)Ti (N=PtBu3)(μ-Cl)2AlR2 (R = Me and iBu, respectively) were obtained, and the molecular structure of Ti15 (Figure 5b) was virtually identical to the molecular structure of Ti13. However, in experiments on the polymerization of ethylene, catalytic activities of the complexes decreased in the order Ti15 > Ti13 > Ti14. In this way, the nature of the substituents at Al atoms influenced the catalyst’s properties, thus indirectly confirming the presence of Ti–(μ-Cl)–Al bonding in catalytic species.

Figure 5.

Molecular structure of Ti–Al complexes (a) Ti13 and (b) Ti15. Reprinted with permission from [88]. Copyright (2021) American Chemical Society.

2.3. Single-Site Ti Catalysts of Polymerization of Dienes

Ti(IV) halogenides, activated by aluminum alkyls, represent the first-generation catalysts of coordination polymerization of 1,3-dienes [8,89]. However, despite half a century of research, molecular structure of the catalytic species, formed as a result of the reaction of LTiCln with RmAlCl3–m, is not entirely clear. In examining the reaction mechanisms of diene polymerization, the ‘pure’ cationic concept is still actual [90].

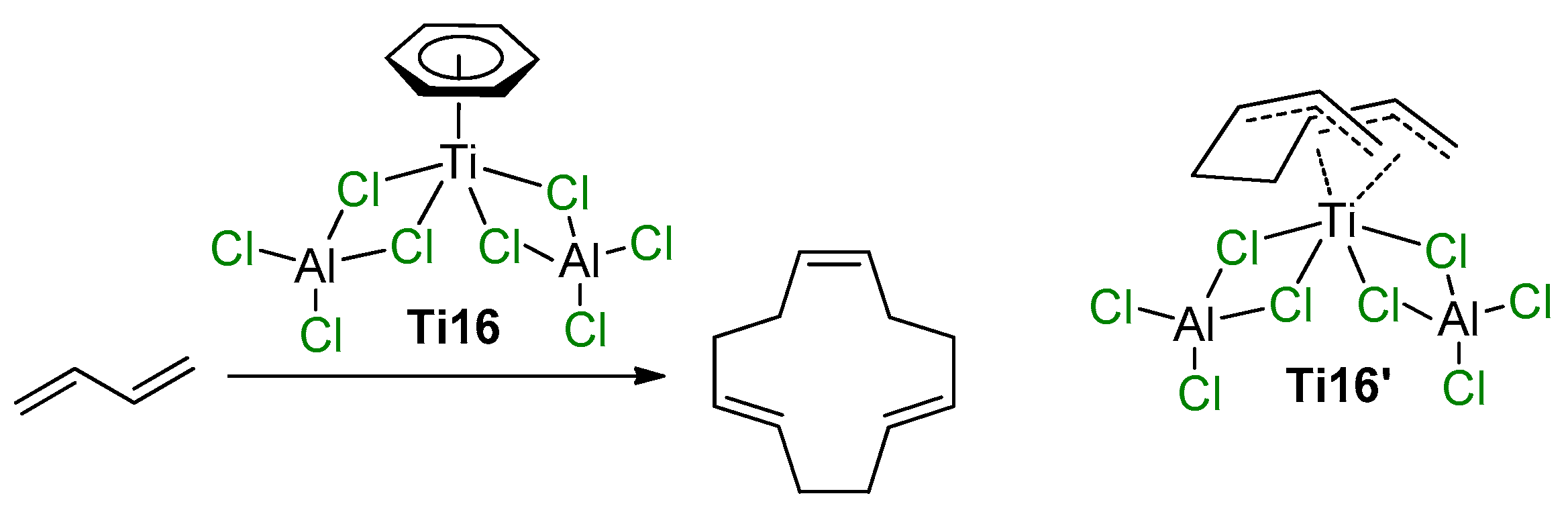

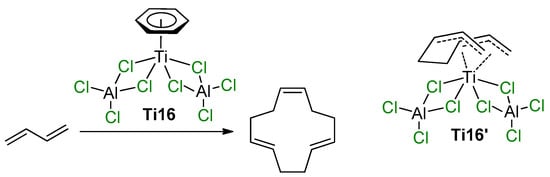

The participation of Ti–(μ-Cl)–Al species in the coordination polymerization of conjugated dienes was proposed by Mach et al., who studied the catalytic activity of η6-arene Ti complexes with AlCl3 and alkylaluminum chlorides [91,92,93]. Similar complexes of (η6-C6H6)Ti[(μ-Cl)2AlCl2]2 (Ti16) and (η6-C6Me6)Ti[(μ-Cl)2AlCl2]2 (Ti17) were obtained and structurally characterized in the late 1970s and early 1980s by Thewalt et al. [94,95]. The molecules of Ti16 and Ti17 exhibit square pyramidal geometry, with the titanium atom above the rectangle of the bridging Cl atoms and with the π-bonded arene at the apex. When Ti16 was used as a single-component catalyst of the oligomerization of buta-1,3-diene, (1Z,5E,9E)-cyclododeca-1,5,9-triene was formed with 92% selectivity (Scheme 11) [91]. The authors assumed that the high stereospecificity of the cyclotrimerization indicates that the reaction proceeds by a sterically controlled coordination mechanism. The experimental results, i.e., the approximate second-order dependence of the reaction rate on buta-1,3-diene concentration, the low concentrations of all the intermediates participating in the catalytic steps and no interaction between the catalyst and final product, suggest that cyclotrimerization may proceed via the replacement of C6H6 by two molecules of buta-1,3-diene, followed by the formation of the active species Ti16′ (Scheme 11). In the presence of EtAlCl2, Et2AlCl, and Et3Al, catalytic activity of complex Ti16 increased due to the substitution of non-bridged Cl atoms by Et groups [92]. In the presence of a large excess of Et3Al, complete deactivation of the catalyst was observed. Complex Ti17 demonstrated low activity due to higher stability of the (η6-C6Me6)–Ti bond in comparison with the (η6-C6H6)–Ti bond [93]. However, the substitution of non-bridged Cl atoms by Et groups proceeded stepwise with maximum preservation of the molecular symmetry—by an example of the complex (η6-C6Me6)Ti[(μ-Cl)2AlClEt]2 (Ti17′), for which XRD analysis was performed. This substitution resulted in a manyfold increase in the catalytic activity [93].

Scheme 11.

Selective cyclotrimerization of buta-1,3-diene, catalyzed by Ti16, and tentative structure of the intermediate Ti16′ [91].

In conclusion, we note that Ti complexes are not actually considered as prospective catalysts of the polymerization of conjugated dienes, and further comprehensive studies of the reaction mechanism seem unlikely.

2.4. Heterogeneous Ti Ziegler–Natta Catalysts

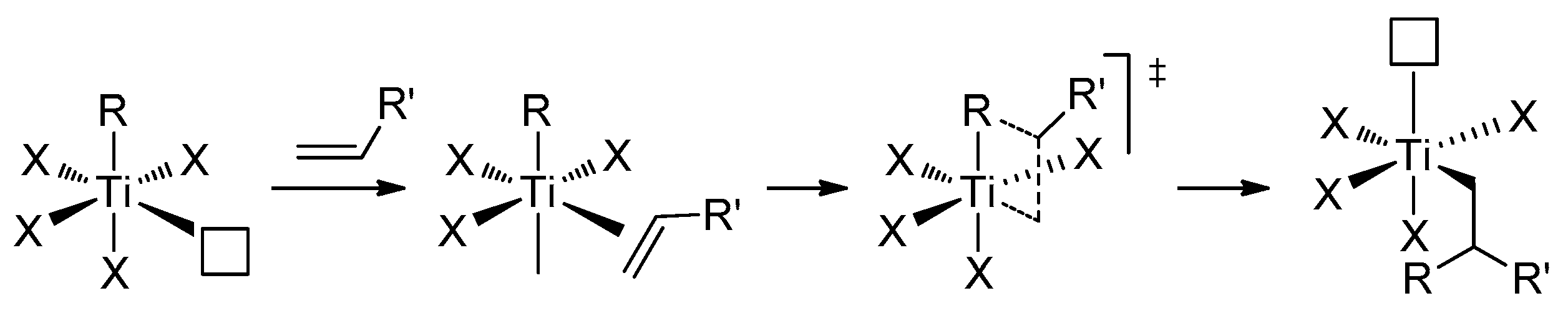

The TiCl3/R3Al system, called the ‘1st generation Ziegler–Natta catalyst’, was one of the early efficient catalysts of α-olefin polymerization [96]. It is for these catalysts that the common mechanism of the coordination polymerization of α-olefins was proposed by Cossee and Arlman [97,98]. This conventional mechanism (Scheme 12) involves the participation of Ti(III)–Alkyl species and is similar to the mechanism presented in Scheme 5, except that the Ti atom has zero charge and an oxidation state of +3.

Scheme 12.

Cossee–Arlman mechanism of α-olefin polymerization [97,98]; white square indicates the vacancy of the Ti(III) atom.

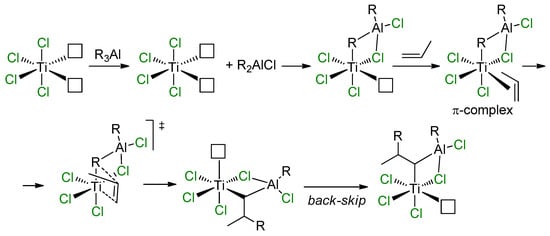

In approaching the topic of modern and efficient Ziegler–Natta (ZN) catalysts, tributes should be paid to the work of Rodriguez and van Looy, who formulated heterobimetallic concepts of the reaction mechanism to explain the impact of alkylating agents on stereospecificity of TiCl3 catalyst. This concept was based on an assumption of the presence of Ti centers with two potential vacancies on the Ti atom at the surface of TiCl3 (coordination number of the Ti atom CNTi is equal to 4) [99]. According to this concept (Scheme 13), after alkylation by R3Al, a Ti–(μ-Cl)–Al complex is formed (CNTi = 5). π-Coordination and subsequent insertion of the α-olefin molecule results in an alkyl complex, which further isomerizes with occupation of the position previously occupied by the R group, thus forming the isotactic polyolefin.

Scheme 13.

Mechanistic concept of Rodriguez and van Looy [99].

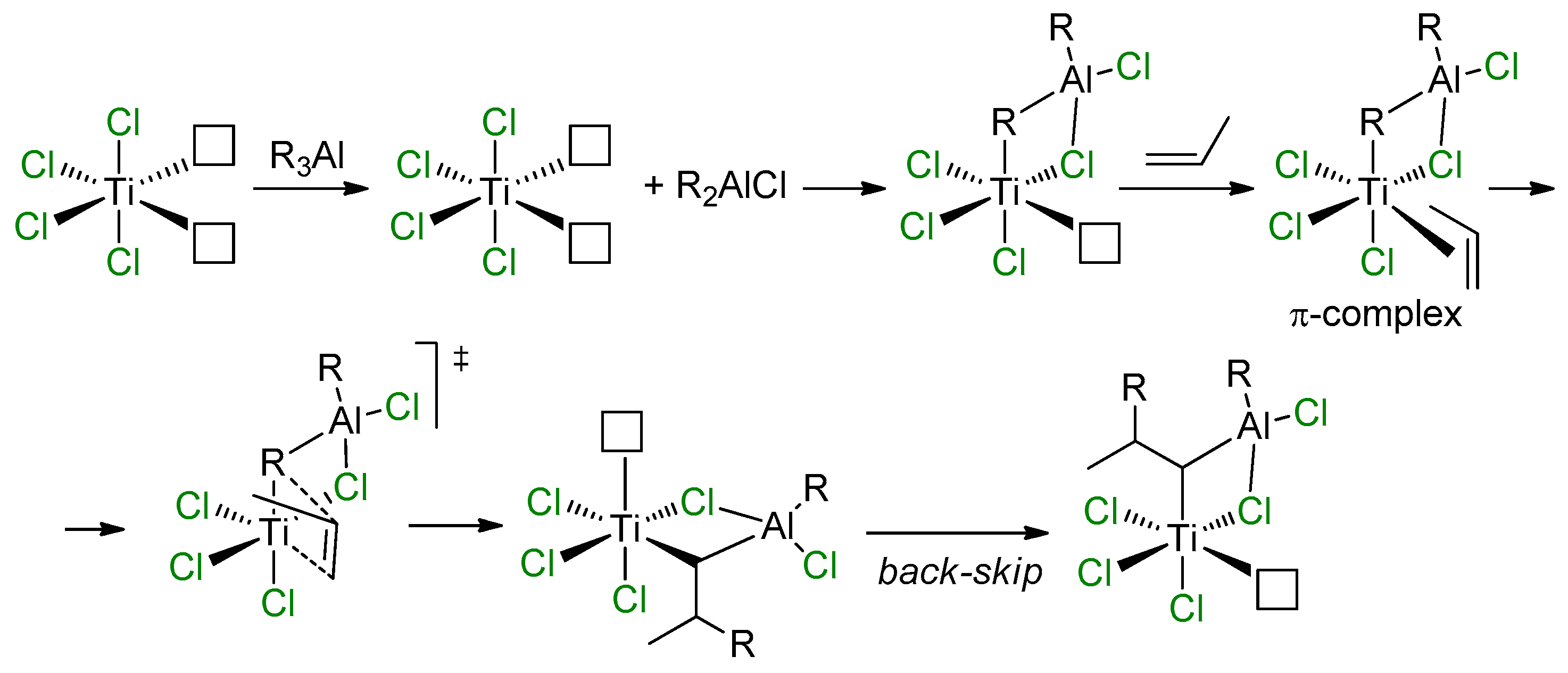

It has been nearly 70 years since the pioneering works of Ziegler and Natta [100,101], and there have been several generations of ZN catalysts. At present, the polymerization of α-olefins with the use of heterogeneous Ti-based MgCl2-supported Ziegler–Natta catalysts (TMCs) is the most important industrial chemical process in the polyolefin industry [102,103,104,105,106,107,108]. However, despite the importance and impact of TMCs, these catalyst systems have not yet been completely explored. TMCs comprise the MgCl2 support, the active Ti(III) [11,109,110], and Ti(II) [11,111] species; organoaluminum species formed from trialkylaluminum alkylating agent R3Al, and Lewis base donors. Due to the practical importance of TMCs, thus far, thousands of articles and dozens of reviews have been published; in this section, we restrict ourselves to listing several examples of the possible or proven (very rarely) participation of R2AlCl species in TMC-catalyzed polymerization.

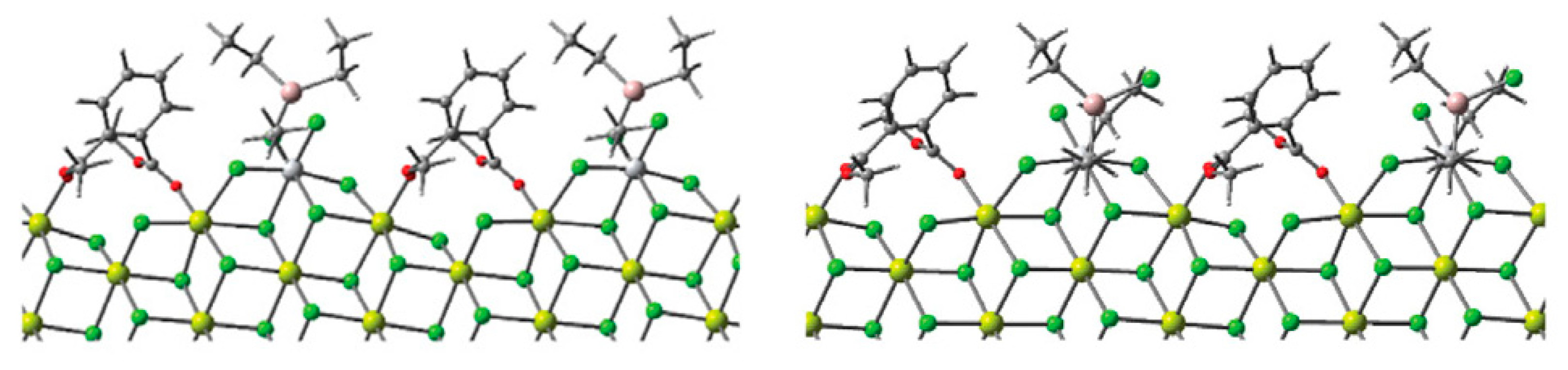

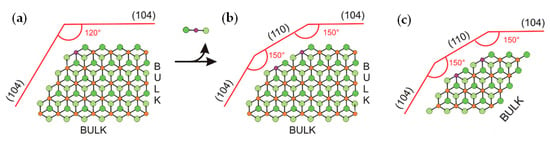

Catalytic processes occur on the TMC surface. Pre-catalysts represent TiCl4 adsorbed on MgCl2 crystallites, and the binding strength and coordination environment of the Ti atom depend on the crystal structure of the MgCl2 support. In their fundamental study [110], Cavallo et al. assumed the MgCl2 bulk to be in the α-crystalline phase with the surface comprising (104) lateral cuts (Figure 6a) that have five-coordinate magnesium centers. The removal of one MgCl2 unit results in a new (110) surface that can coordinate the titanium species (Figure 6b). Vanka et al. proposed the simpler model structure of the MgCl2 support, close in meaning to Cavallo’s model [102] (Figure 6c). In their subsequent publication, Cavallo et al. upgraded their MgCl2 model by (104)-facets presenting low-energy step-defects as potential sites for the strong coordination of TiCl4 [103].

Figure 6.

(a,b) The model for the MgCl2 layers developed by Cavallo et al. [110]; (c) the modified MgCl2 model with four layers instead of six employed in [102]. Reprinted with permission from [102]. Copyright (2014) Wiley-VCH Verlag GmbH & Co.

After the absorption of TiCl4, followed by the reaction with R3Al, Ti(III)–Cl and Ti(III)–R species are formed [102]. Recent experimental DR UV/vis and NEXAFS data coupled with DFT simulation indicated that the majority of Ti sites in MgCl2/TiCl4 and MgCl2/ethyl benzoate/TiCl4 pre-catalysts are reduced by Et3Al mostly to monomeric pentacoordinated Ti(III) Cl5 species and, to a minor extent, to alkylated Ti(III) Cl4Et species. For MgCl2/dibutyl phthalate/TiCl4 pre-catalyst, Et3Al additionally promoted the formation of small TiCl3 clusters with low catalytic activity [112].

The above-mentioned articles considered two-component systems MgCl2/TiCl3, but their results are relevant to the subject of our review, determining Ti-containing species capable of Ti–(μ-Cl)–Al bonding. However, real TMCs may contain absorbed organoaluminum species. During the study of the activation of the TiCl4/MgCl2 pre-catalyst by Et3Cl, Oct3Al, and Et2AlCl with the use of magic-angle spinning (MAS) 27Al NMR [113], Potapov et al. detected three types of alkylaluminum chloride species. The changes in 27Al NMR MAS spectra of the TMC before and after polymerization indicated that part of the Al compounds was removed from the catalyst surface or that the coordination environments of Al in these compounds became disordered. In the authors’ view, the existence of Al compounds unremovable from the catalysts surface indicates the presence of inactive Ti–(μ-Cl)–Al species; in other words, R2AlCl only acts as a catalyst inhibitor.

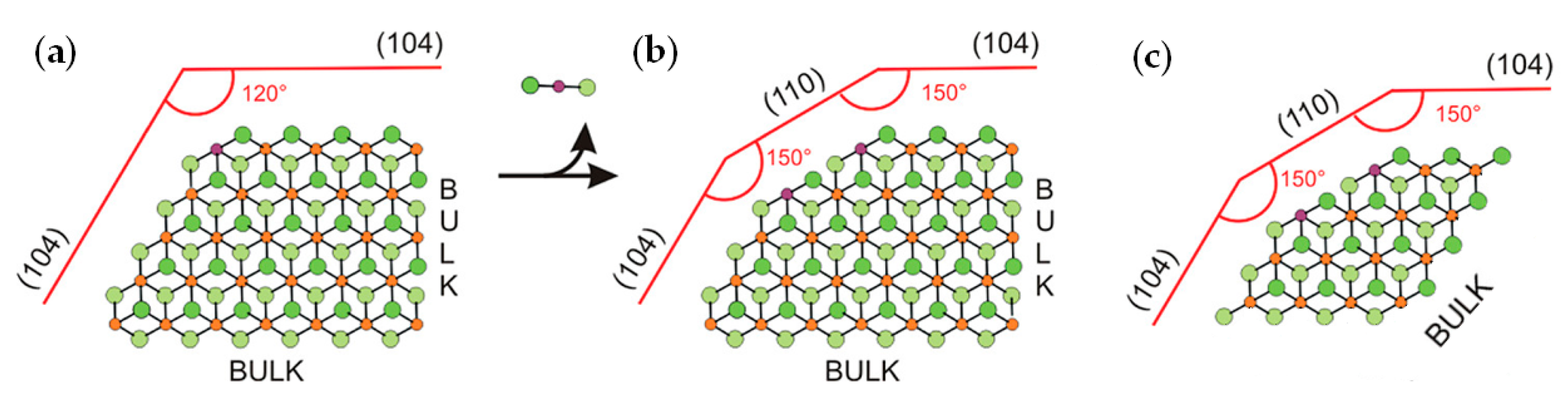

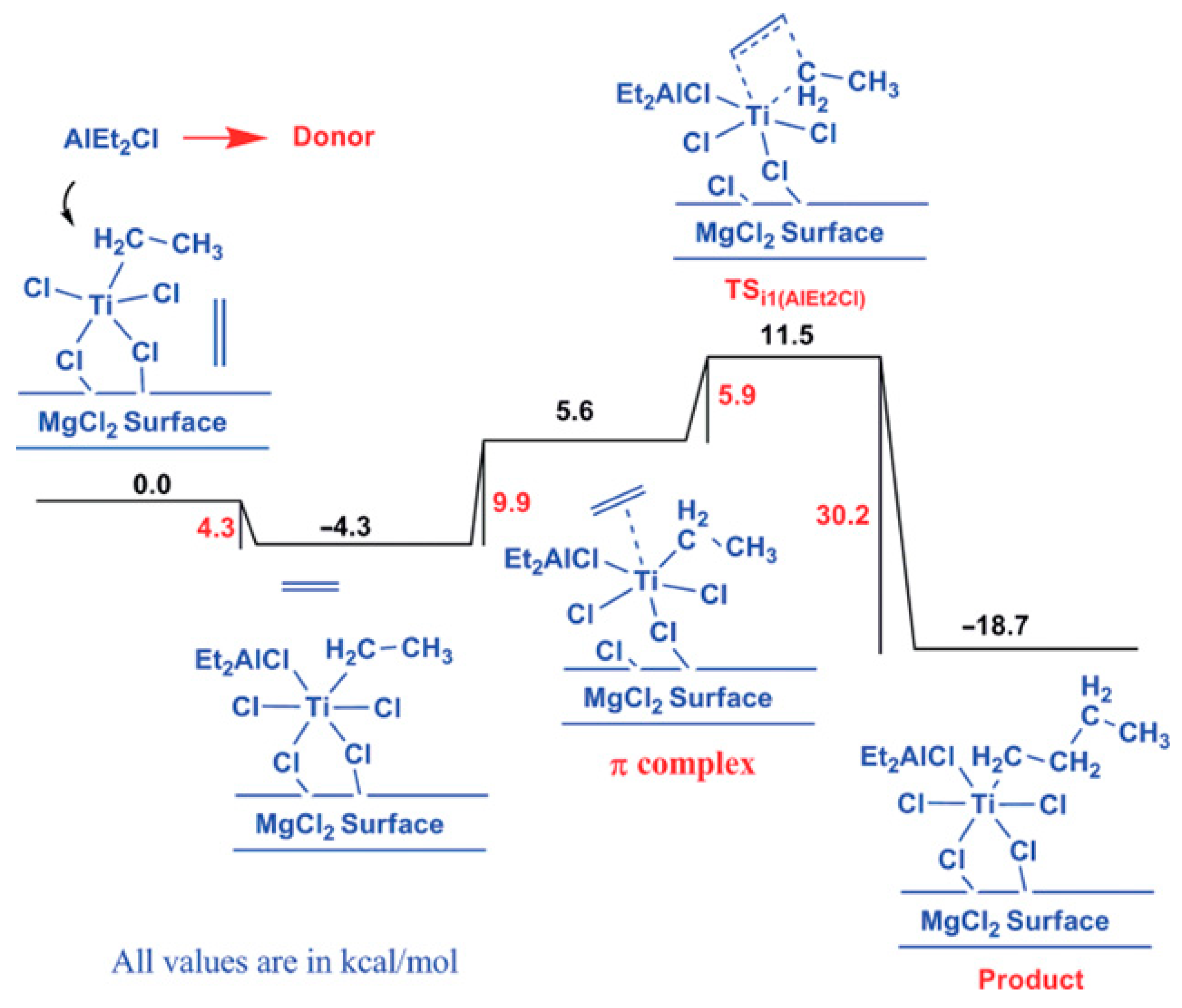

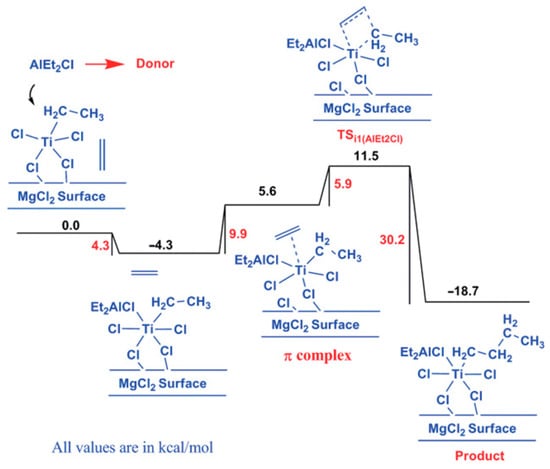

The same or a similar point of view received further development in a number of studies. In their theoretical study of the active sites in TMC [102], Vanka et al. used a simplified model of the MgCl2 surface (Figure 6c) and optimized the geometries of different TI(III)–Et catalytic species that are formed during the polymerization of ethylene, including the presence of the EtO− ligand, ester donors, or Et2AlCl. In the absence of additives, the calculated difference in free activation energies ΔG≠ for the propagation and termination stages was only 1.2 kcal·mol−1. In the presence of esters, the difference increased to 12–13 kcal·mol−1 and was only 3 kcal·mol−1 when Et2AlCl served as a donor. In the latter case, Ti–(μ-Cl)–Al coordination resulted in a substantial increase in the ΔG≠ of ethylene insertion (15.8 kcal·mol−1, see Figure 7). The results of this simulation explained how polymers can be successfully produced by TMCs without alkoxy groups and donor molecules [106]. In summary, the authors suggested that the possible role of organoaluminum activators is not limited by the reduction of Ti(IV); R2AlCl can act as a donor due to its relatively weak Ti–(μ-Cl)–Al binding.

Figure 7.

The free energy profile for the insertion of ethylene into the Ti–CH2CH3 chain with an AlClEt2 group coordinated to the Ti center. Reprinted with permission from [102]. Copyright (2014) American Chemical Society.

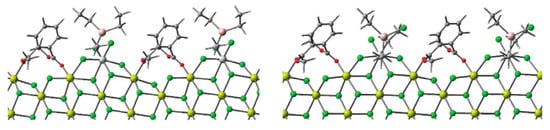

In 2017, Linnolahti et al. reported the first quantum chemical description of the initial steps of olefin polymerization on TMCs involving all the relevant catalyst components—absorbed Ti chlorides, electron donor, and R3Al [114]. They demonstrated that TiCl4 is coordinated on the (104) surface of MgCl2 as a binuclear Ti2Cl8 and on the (110) surface as a mononuclear TiCl4 (CNTi = 6 for both binding modes). Et3Al coordinates to the MgCl2 surface via an unsaturated Cl atom to initiate Ti alkylation. After alkylation via the Ti–(μ-Cl)–Al transition state on the (104) surface, Et2AlCl is released from the MgCl2 surface and dimerizes (exergonic process). However, in the presence of dimethyl phthalate as a model donor molecule at the (110) surface, the formation of Ti–(μ-Cl)2–Al and then Ti–(μ-Cl)(μ-Et)–Al species becomes energetically favorable (Figure 8). However, even in this case, the process is finished by Et2AlCl desorption. However, DFT modeling, presented in [114], closes by examining alkylation stage with a formation of Ti(IV)–Et species, the further reduction with a formation of active Ti(III) centers, as well as ability of these centers to conduct Ti–(μ-Cl)–Al bonding, remains open.

Figure 8.

Optimized geometries of Ti–(μ-Cl)2–Al and Ti–(μ-Cl)(μ-Et)–Al species formed during the alkylation of Ti chloride at the (110) surface of MgCl2. Reprinted with permission from [114]. Copyright (2017) Elsevier B.V.

A recent study by Boisson [115] provided answers to certain questions about the role of organoaluminum activators in TMC-catalyzed polymerization. Based on the results of the study of the microstructure and MWD of polyethylenes, the authors suggested that Ti–(μ-Cl)–Al bonding may need to be considered in addressing the issue of the nature of ZN catalysts.

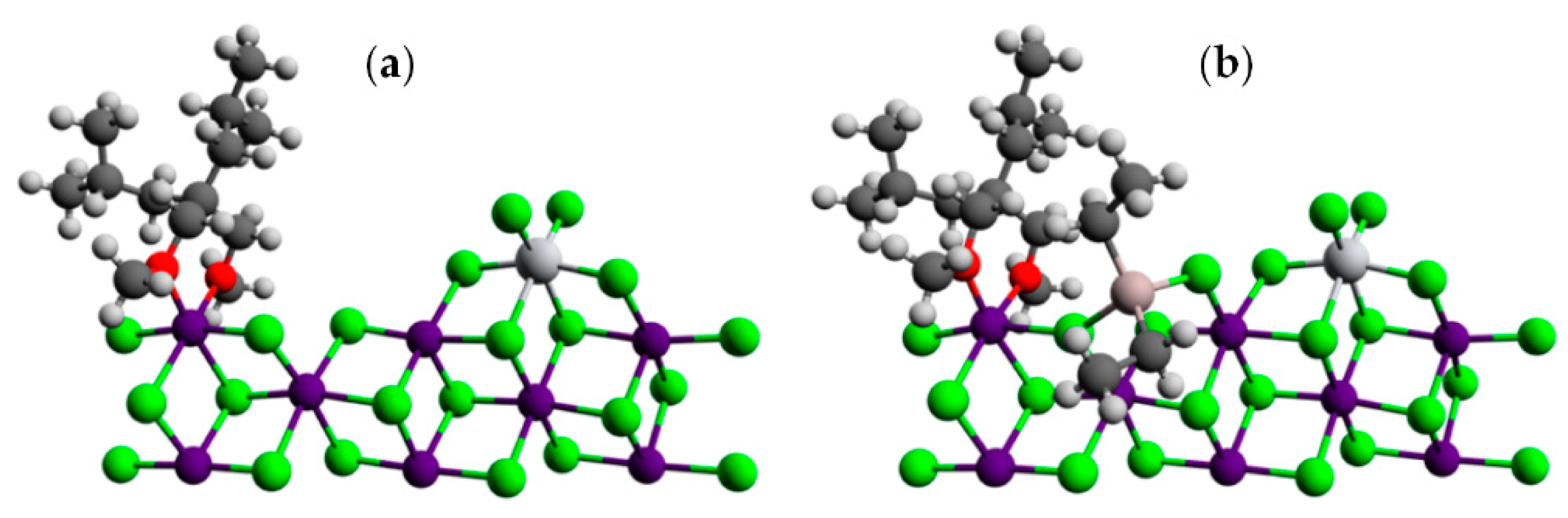

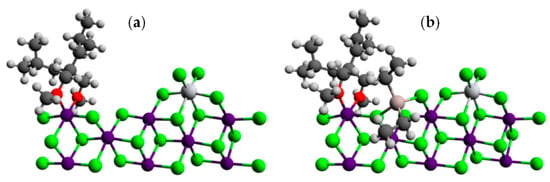

In [116], Busico’s group reported the results of an extensive experimental and theoretical investigation of the latest-generation commercial TMC. During this study, the researchers proposed a new function of R2AlCl species, namely, interactions with absorbed internal donors that provide a higher degree of stereocontrol: for the insertion of prop-1-ene at the catalytic species formed by alkylation and reduction of the TiCl4 precursors in panels (a) and (b) of Figure 9, the calculated ΔGre/si values were ≈0 and 1.5 kcal·mol−1, respectively; the latter was in good agreement with the experimental data.

Figure 9.

(a) DFT model of adjacent TiCl4 and 2,2-diisobutyl-1,3-dimethoxypropane co-adsorption on a MgCl2(110) edge; (b) same as panel a after the adsorption of an AlEt2Cl molecule. Reprinted with permission from [116]. Copyright (2017) American Chemical Society.

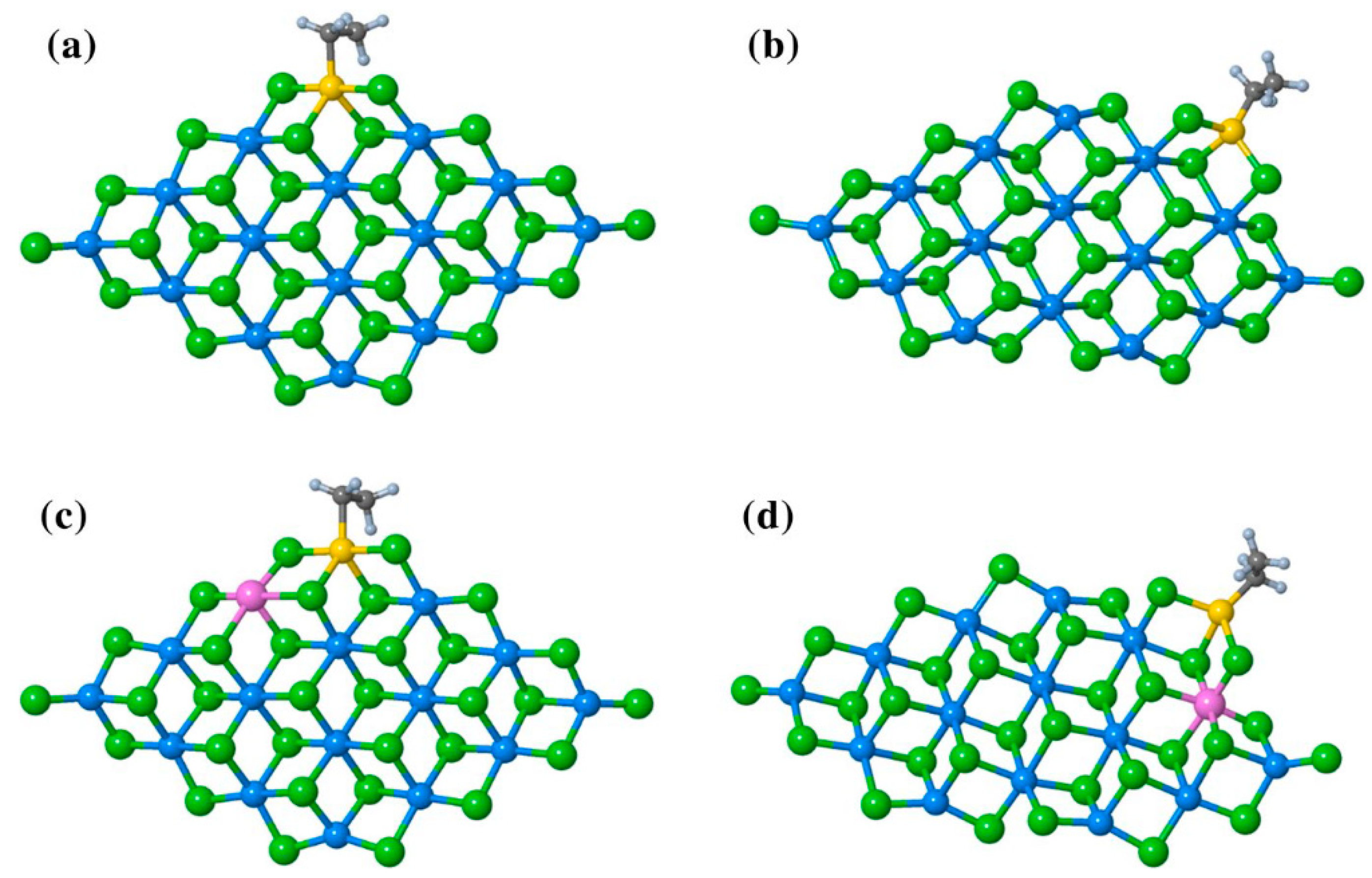

At the end of this section, it is appropriate to mention the most recent studies by Bahri-Laleh’s group [117,118]. In [117], ethylene coordination/insertion at different TiEt and TiEt–(μ-Cl)2–Al sites (Figure 10a–d) was modeled. Ethylene coordination at the Ti center on the (110) surface was thermodynamically more favored in comparison with it on the (104) surface due to the more acidic nature of 4-coordinated surface Mg atoms in (110). π-complexation of the ethylene molecule was more exergonic in Al-doped catalysts. The activation energy values for the insertion of ethylene molecule were 8.3 (a), 11.6 (b), 6.1 (c), and 9.5 (d) kcal·mol−1. In this way, Al-doping increased the energy barrier needed for olefin insertion. In addition, the authors proposed that absorption of the Ti chloride at the (104) surface should not be ignored when analyzing distribution of the active sites, which is in contrast to the established paradigm. However, because TMCs represent a very striking example of the ‘catalytic black box’, any substantial expansions of the existing worldview can only be welcomed.

Figure 10.

The structure of TiCl2Et adsorbed on (a) undoped (110); (b) undoped (104); (c) Al-doped (110); and (d) Al-doped (104) surfaces. Reprinted with permission from [117]. Copyright (2022) Springer Nature.

In [118], the catalytic activity of TMCs when using different organoaluminum activators (Et3Al, Et2AlCl, EtAlCl2, and iBu3Al) was studied experimentally, and the effect of Ti–(μ-Cl)–Al bonding on catalytic activity was evaluated theoretically for Ti centers at the (110) MgCl2 surface and these four organoaluminum compounds. From the results of the modeling, Et2AlCl was the best Al component among others.

Concluding this section of the review, we have to note that, with the sole exception of complexes Ti09–Ti11 [82], the question of the participation of Ti–(μ-Cl)–Al species in catalytic transformations of α-olefins still has no clear answer. Irrelevance of this question to Ti-based post-metallocenes (too high CNTi) and fundamental unknowability of the TMC (the most important Ti-based catalyst) leave room for speculations, not complete answers. However, in the field of Zr-based polymerization catalysts we are facing a slightly better situation.

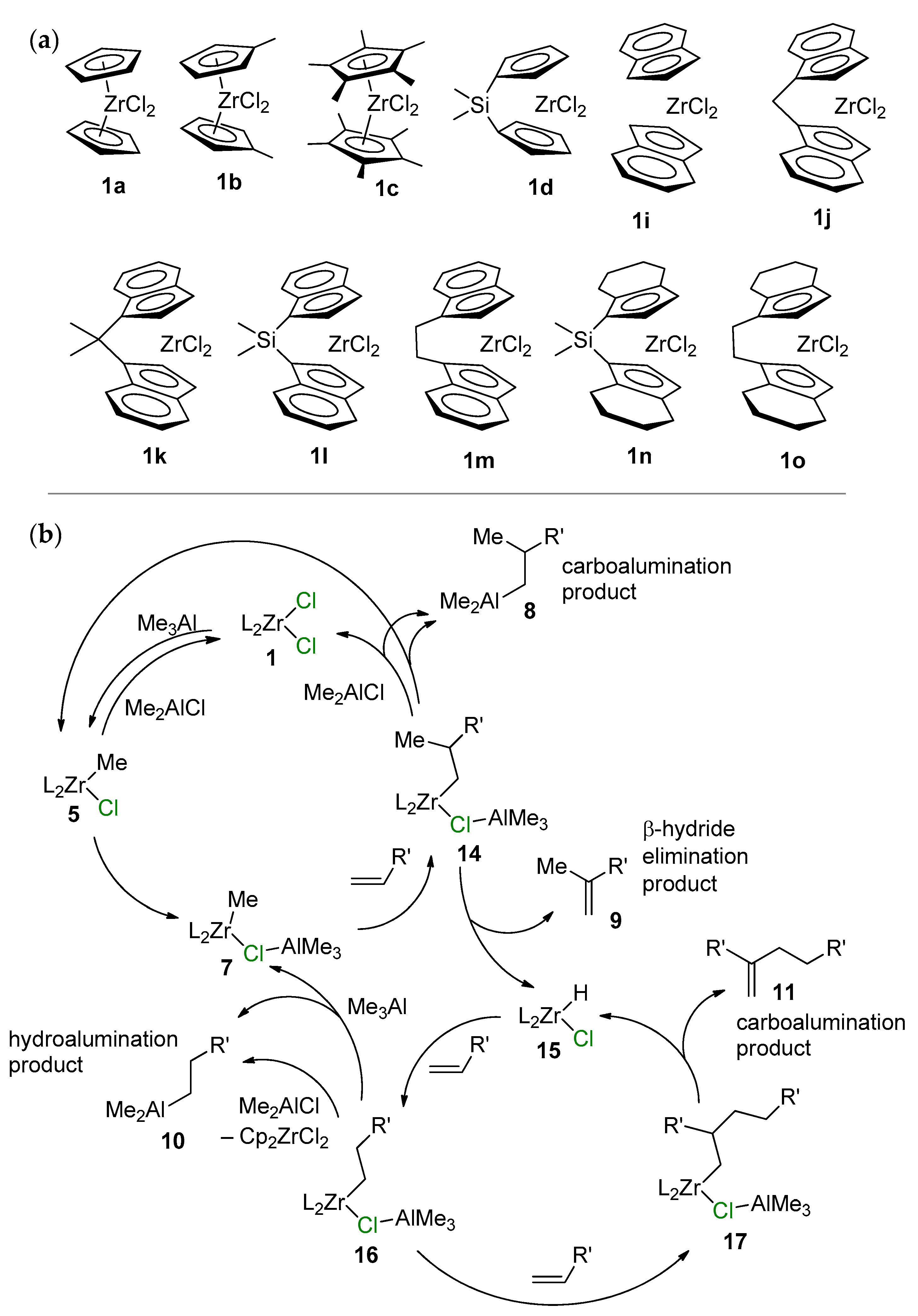

3. Complexes of Zr

Zirconocenes have a special place among Zr-based catalysts used in α-olefin chemistry. The hydro- and carboalumination of α-olefins [18], single-site polymerization with the use of MAO and perfluoroborate activators [119], selective dimerization [37,41,42] and oligomerization [16,17] of higher α-olefins—this is not a complete list of the processes with relevance for laboratory and industry. Historically, two groups of zirconocene-based catalytic species stand apart by the criterion of the charge of the catalytic Zr center. The first, zero-charged, group is traditionally considered as catalysts of hydroalumination, carboalumiation, and cyclocarboalumination of α-olefins and related reactions, limitedly used in the laboratory [18]. The second, ‘cationic’ species, represents highly efficient single-site α-olefin polymerization catalysts with a great potential of industrial applications [1,7,120,121]. Therefore, it is no surprise that the second group of the Zr catalysts attracted and continue to attract the most research attention; however, the participation of Zr–(μ-Cl)–Al species in catalytic process has only been proven experimentally for ‘neutral’ zirconocene species.

3.1. Zirconocene Chemistry: Non-Charged Complexes

The mechanisms of zirconocene-catalyzed hydroalumination and carboalumination of α-olefin were discussed ten years ago in the review by Parfenova et al. [18]. In this section, we consider only some key studies, published before 2010, and discuss the results of recent studies in more detail.

Before discussions of hydroalumination and carboalumination processes, it should be noted that the reaction of L2ZrCl2 with R3Al until recently was considered as the natural and only possible pathway of the activation of metallocene dichlorides. When studying this reaction, it was found that the nature of the η5-ligand significantly affects the completion of the process. As shown by Beck and Brintzinger [122] for alkyl exchange reactions (Equation (1)), the values of apparent equilibrium constants Kobs were 0.005 (L = η5-C5Me5), 0.016 (L = η5-C5H4tBu), 0.19 (L = η5-C5H4tSiMe3), 0.49 (L = Cp) and 1.2 (L2 = rac-Me2Si(Ind)2). Both steric and electronic factors affect this equilibrium, and in particular, decreased electron density at the Zr atom appears to favor uptake of the Me group.

2 Cp2ZrCl2 + Al2Me6 ⇆ 2 Cp2ZrMeCl⋯AlMe2Cl

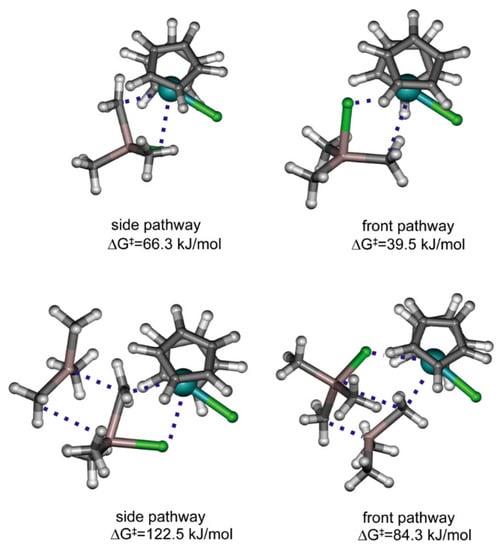

The difference in equilibria constants for this reaction can be explained based on the results of DFT modeling, as shown by Linnolahti et al., who showed that catalyst alkylation step by AlMe3 has two viable routes. AlMe3 coordinates to the metallocene either from the side or from the front, leading to corresponding alkylation reaction pathways. The kinetically favorable route is dependent on the ligand structure of the catalyst: the front pathway is preferred for Cp2ZrCl2 (Figure 11) but is sterically hindered for Me2C(Cp)(Flu)Zrl2, thereby preferring the side pathway [123]. Similar results have also been obtained in a more recent study by Kumawat and Gupta [124]. Zr01 was also detected by IR spectroscopy during studies of the activation of Cp2ZrCl2 by MAO [125].

Figure 11.

Illustration of transition states for the alkylation of Cp2ZrCl2 with Me3Al (top) and Al2Me6 (bottom). Reprinted with permission from [123]. Copyright (2012) Elsevier B.V.

Dimethyl derivatives of zirconocenes are formed during the second stage of the process. The intermediate complex of the formula Cp2ZrMeCl⋯AlMe3 (Zr01) was detected by 1H NMR at −85 °C; however, at −60 °C, the characteristic signal of Zr–Me group had already disappeared [126].

The presence of direct Zr–(μ-Cl)–Al bonding in Cp2ZrMeCl complexes with R3Al has clearly been proven by Barron et al. [127]. They showed that even Me2Al can coordinate with Cl (d(Al–Cl) = 2.46 Å, d(Zr–Cl) = 2.52 Å, Figure 12) with the formation of a relatively stable complex Cp2ZrMeCl⋯AlMe3 (Zr01′).

Figure 12.

Molecular structure of one of the crystallographic independent molecules of Cp2ZrMeCl⋯AlMe3 (Zr01′). Reprinted with permission from [127]. Copyright (1995) American Chemical Society.

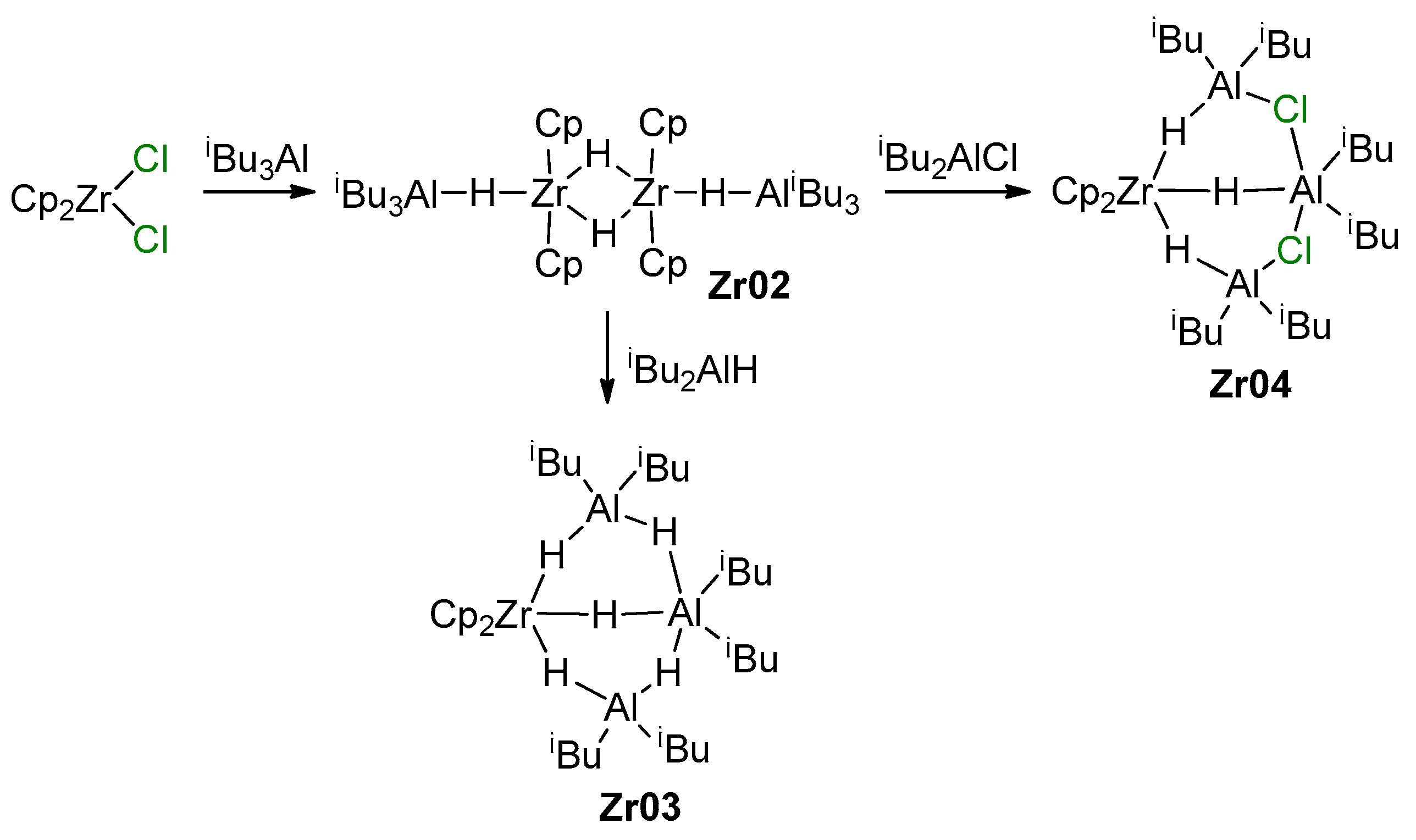

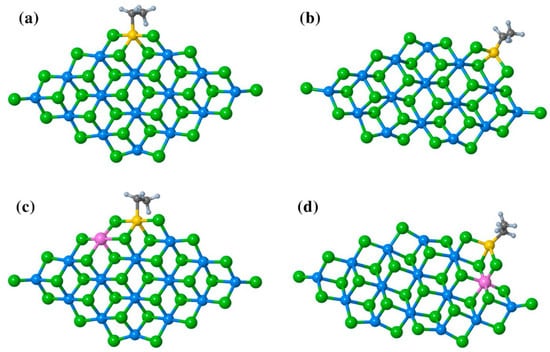

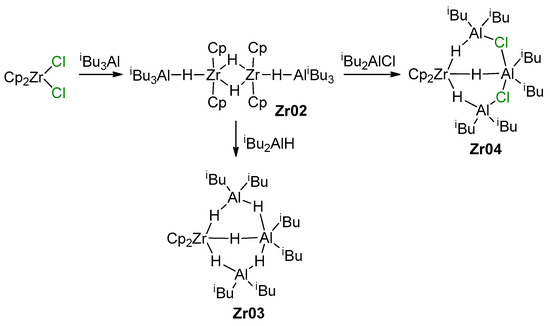

It is obvious that the reactions of L2ZrCl2 with iBu2AlH or iBu3Al may result in the formation of Zr–Al hydrides, which is accompanied by isobutylene elimination in the latter case [128]. The rate and equilibria of the reaction with iBu3Al also strongly depend on the nature of the η5-ligand fragment L2; for instance, Ph2C(Cp)(Flu) forms a mono-alkyl complex Ph2C(Cp)(Flu)Zr(iBu)Cl even with a 50-fold excess of iBu3Al, whereas Cp2ZrCl2 reacts with an excess of iBu3Al with the formation of [Cp2ZrH2·AliBu3]2 (Zr02) [128], and reaction with iBu2AlH results in Zr03 [129] (Scheme 14). In the presence of iBu2AlCl, Zr02 forms the Zr–Al3 complex Zr04; ring-substituted bis(cyclopentadienyl) L2ZrCl2 complexes demonstrate similar behavior [129]. For Zr ansa-complexes, the formation of L2ZrCl(μ-H)2AliBu2 species was detected.

Scheme 14.

Reaction of Cp2ZrCl2 with iBu3Al or iBu2AlH [128,129].

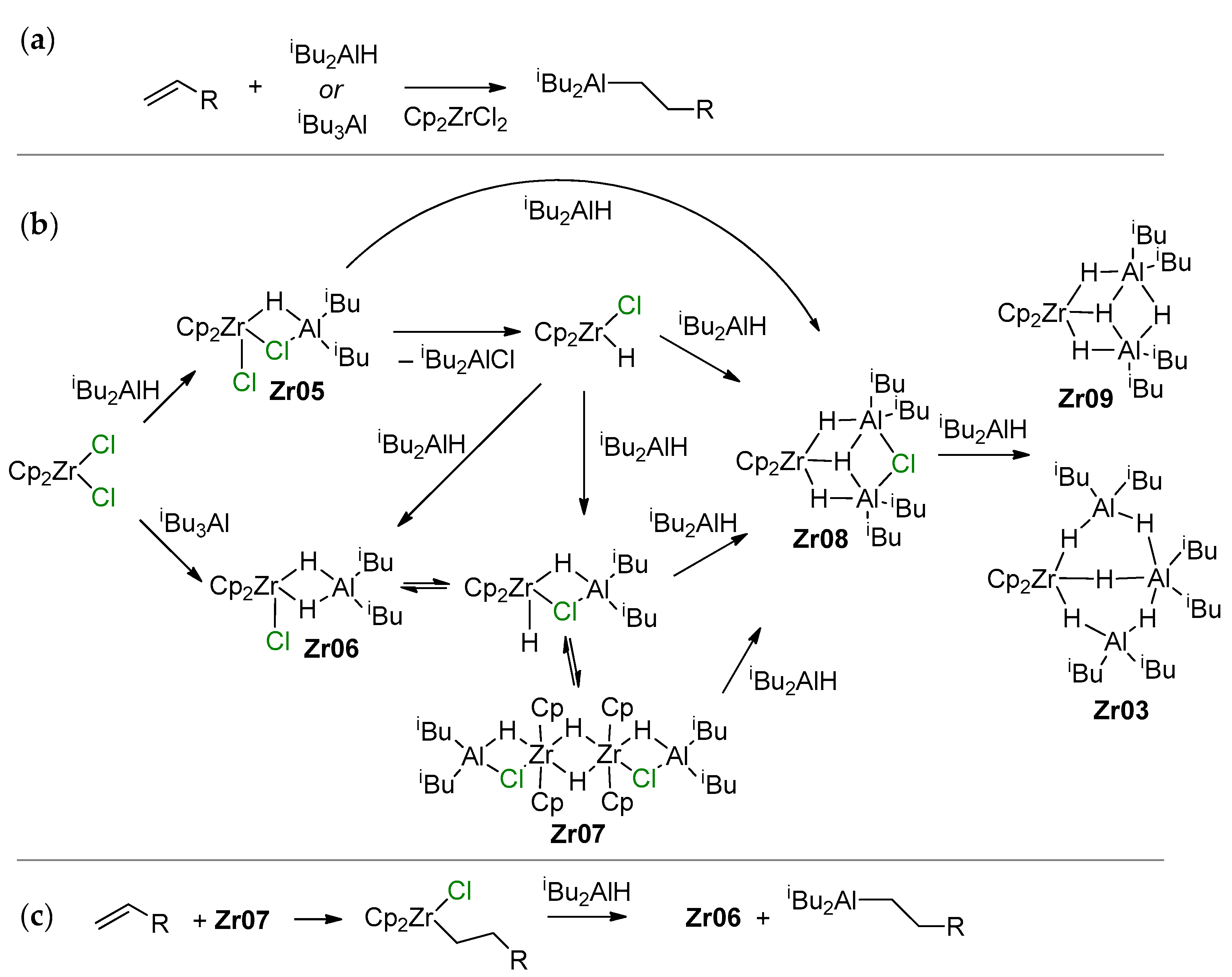

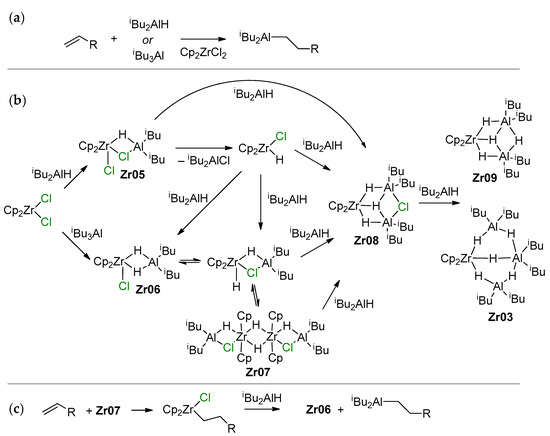

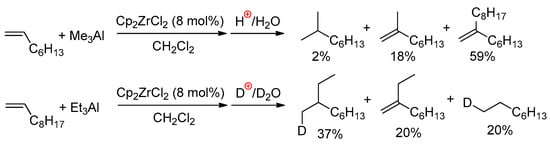

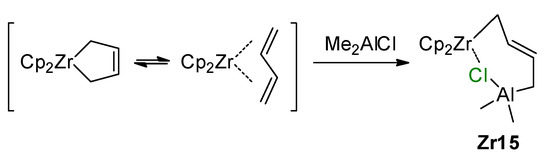

Efficient Cp2ZrCl2-catalyzed hydroalumination uses iBu2AlH or its equivalent iBu3Al as Al sources due to the ease of isobutylene elimination with the formation of Al–H bonds (Scheme 15a). A greatly simplified hypothetical mechanism of this reaction, proposed by Negishi [130], was substantially developed and supplemented by new experimental and theoretical results by Dzhemilev and Parfenova group. In [131], they proposed a hydroalumination mechanism involving the intermediate formation of Cp2Zr(μ-Cl)(μ-H)Al (Zr05) and Cp2Zr(μ-H)2Al (Zr06) species that are able to perform π-coordination and insertion of the α-olefin molecule. In the same study, a dimer of the Zr–Al complex (Zr07) was detected, and excess iBu3Al or iBu2AlH resulted in the formation of Zr–Al2 and Zr–Al3 complex hydrides (Zr03, Zr08, Zr09; the latter may contain μ-Cl fragments) (Scheme 15b). It was later discovered that in comparison with other Cp2Zr-based complexes (including the Schwartz’s reagent Cp2ZrHCl), Zr03 demonstrated the highest catalytic activity in hydroalumination (Scheme 15c) [132,133]. Probably, Cl-containing organoaluminum fragments in Zr–Al hydride complexes accelerate the intramolecular exchange between bridging and terminal H atoms and shift the equilibrium between the dimeric and active monomeric forms.

Scheme 15.

(a) Hydroalumination of α-olefins; (b) Zr–Al species formed during the reaction of Cp2ZrCl2 with iBu3Al or iBu2AlH; (c) the stages of Cp2ZrCl2-catalyzed hydroalumination [18,131,132,133].

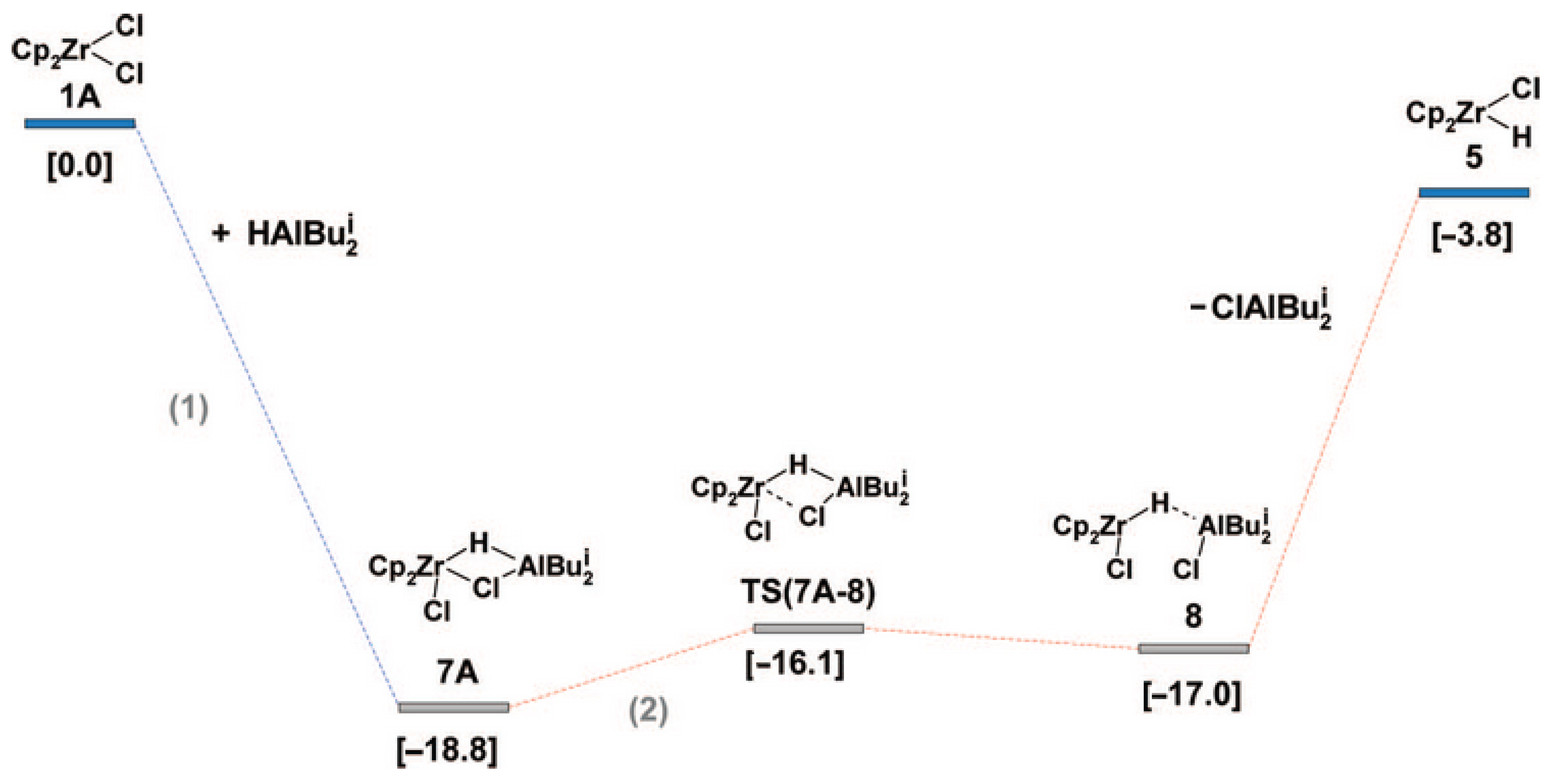

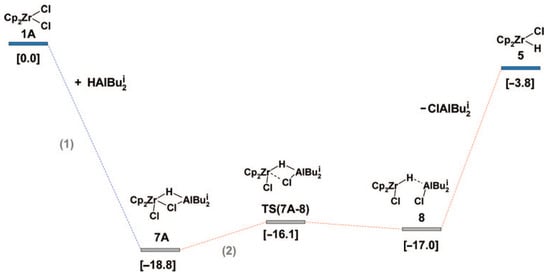

The validity of Scheme 15 was confirmed in follow-up studies of the reaction of different L2ZrCl2 complexes with iBu2AlH [134]; Zr08-type complexes were found to be active species of the hydroalumination process. Zr08 species are formed via Zr–(μ-Cl)–Al intermediate Zr06′; therefore, the presence of Cl in the catalytic system is important for the hydroalumination process. These experimental results were in line with the results of a number of theoretical studies on the mechanism of L2ZrCl2-catalyzed hydroalumination performed by Parfenova et al. In [135], the formation of Cp2ZrCl2-based catalytic species was analyzed in detail. The main results of the modeling matched Scheme 15; in particular, by the optimization of the molecular structure of Zr06 that was found to be relatively stable (Figure 13). In accordance with Scheme 15, the kinetic model for the reaction steps was developed [136,137].

Figure 13.

Energy profile of Cp2ZrHCl formation (reaction enthalpies in kcal·mol−1 are shown in square brackets). Reprinted with permission from [135]. Copyright (2009) American Chemical Society.

In [138], α-olefin interactions with catalytically active centers were studied by DFT and ab initio calculations. It was shown that Cp2ZrHCl, Zr06, Zr08, and Zr09 are able to perform coordination and insertion of the α-olefin molecule; the activity decreases in the order Cp2ZrHCl > Zr06 > Zr08 > Zr09. The results of the modeling correlate with experimental data on Cp2ZrCl2-catalyzed hydroalumination, considering the equilibria between Zr07 (isolated active catalyst) and Zr06 (highly reactive intermediate) and low solubility of Cp2ZrHCl that slows down the reaction. DFT modeling of the final stage of hydroalumination (Zr → Al alkyl transfer) was conducted for Cp2ZrCl(nPr)–iBu2AlX system (X = H, Cl, iBu) [139]. It was shown that the reaction of iBu2AlH needed no activation energy and proceeded through the coordination of iBu2AlH both outside and inside of the C–Zr–Cl angle, and led to the Cp2ZrHCl⋯Al iBu2Pr association, which further dissociated into the Al iBu2Pr and AliBu2nPr. Transmetallation in Cp2ZrCl(nPr)⋯ClAl iBu2 occurs via the coordination of iBu2AlCl to the inside of the C–Zr–Cl angle with the formation of a bridging complex Cp2ZrCl(μ-Cl)(μ-nPr)Al iBu2, followed by intramolecular ligand exchange that results in Cp2ZrCl2⋯AliBu2nPr association which further decomposes into AliBu2nPr and Cp2ZrCl2. It was also shown that the transmetallation of the propyl group in Cp2ZrCl(nPr)⋯AliBu3 is less probable due to the high activation barrier (ΔG≠ = 31.9 kcal·mol−1). In this way, the transmetallation rates of Cp2ZrCl(nPr) under the action of iBu2AlX decrease in the order iBu2AlCl > iBu2AlH > iBu3Al [139].

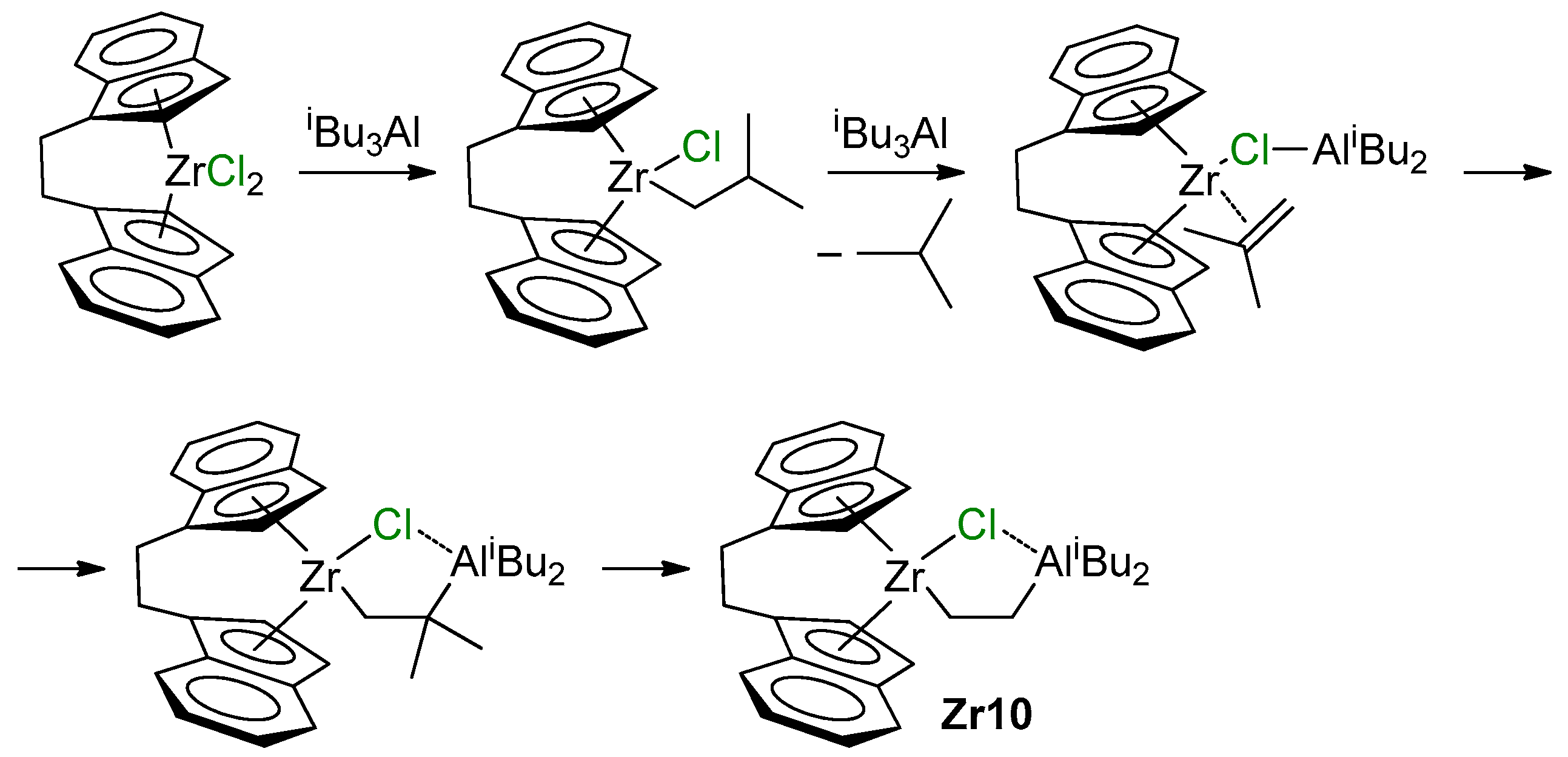

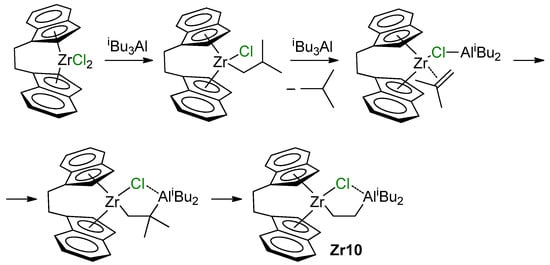

Current views on the mechanism of the reaction of L2ZrCl2 with iBu3Al were substantially expanded in the recent study by Conley et al. [140]. When studying reactions of [CH2CH2(η5-C9H6)2]ZrCl2 with 12 eq. of organoaluminum compound, they detected the formation of Zr–(μ-Cl)–Al complex Zr10, presumably through β-Me elimination/carboalumination stages (Scheme 16). Notably, the π-complex in this Scheme represents the Zr(II) complex.

Scheme 16.

The formation of Zr10 [140].

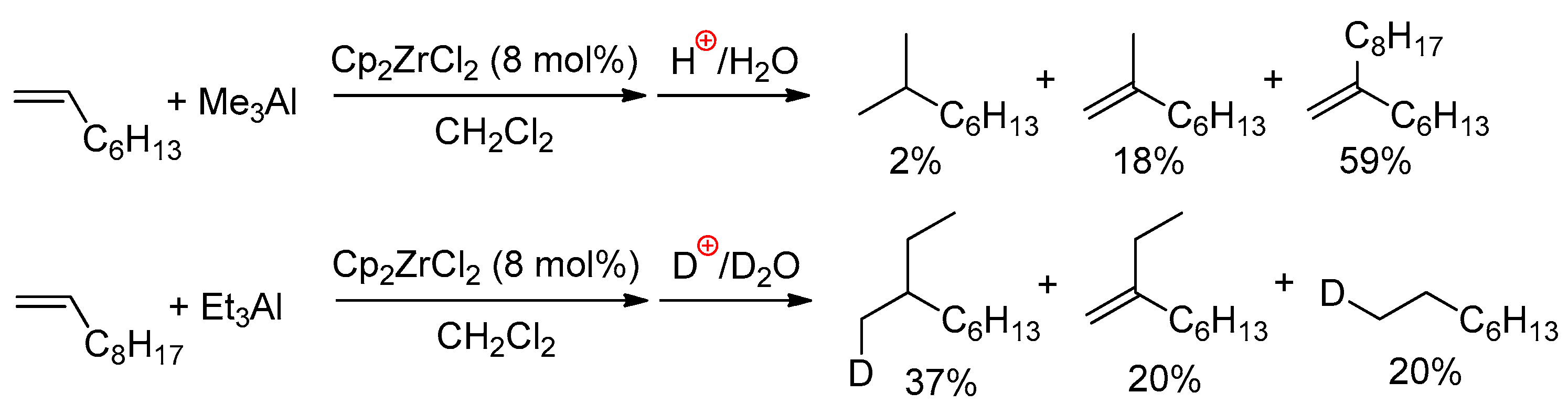

Cp2ZrCl2-catalyzed carboalumination was discovered by Van Horn and Negishi [141]. This reaction was also considered in the review by Parfenova [18] and in the more recent review of Negishi [142]. In most studies on catalytic carboalumination, Me3Al and (n-Alkyl)3Al have been used to avoid β-hydride elimination. Cp2ZrCl2 is not an efficient carboalumination catalyst (Scheme 17) [143,144]. As shown by Parfenova et al., the efficiency of carboalumination can be increased by the rational design of η5-ligands in the L2ZrCl2 pre-catalyst [145].

Scheme 17.

Cp2ZrCl2-catalyzed carboalumination [143,144].

When using Me3Al as an activator, both carboalumination and hydroalumination processes can take place in the presence of other L2ZrCl2 complexes. In 2018, Parfenova et al. [126] studied the ligand exchange in 15 different zirconocenes, and the oct-1-ene reactivity of 11 of them (Scheme 18a) for L2ZrCl2–Me3Al systems. Based on the results of NMR spectral studies and catalytic experiments, a mechanism of the L2ZrCl2-catalyzed reaction of alkenes with Me3Al was proposed (Scheme 18b). In the first step, complex 1 reacted with Me3Al to yield L2ZrClMe (5). The subsequent reaction of complex 5 with Me3Al yielded intermediate 7 (Zr01, see above), in which the Zr–Me bond is more polarized due to associations with electron-deficient Me3Al. As shown above, complex Zr01 exists in the associated state at temperatures below 230 K. At room temperature, it dissociates to Cp2ZrMeCl and Me3Al and its concentration becomes negligibly low; thus, the alkene does not react. Switching to the catalytic reaction shifts the equilibrium towards Zr01, and products 8–11 are formed in the system.

Scheme 18.

(a) Structural formula of the L2ZrCl2 complexes studied in the catalytic reaction of oct-1-ene with Me3Al; (b) probable mechanism of the L2ZrCl2-catalyzed reaction of alkenes with Me3Al [126].

Notably, Cp2ZrMe2 demonstrated low catalytic activity in the reaction with oct-1-ene and Me3Al. Complex 6 is not formed in the reaction of Cp2ZrCl2 with Me3Al; thus, a key role is played by Zr01-type intermediates. The degree of association of L2ZrMeCl with Me3Al also depends on the π-ligand environment of Zr and the nature of the solvent. In this way, realization of the process presented in Scheme 18b requires the presence of Cl in the reaction mixture. In other words, the presence of the Zr–(μ-Cl)–Al structural fragment in key catalytic species and the alkene insertion would, most likely, be accelerated in the L2ZrMe(μ-Cl)AlMe3 active complex.

Catalytic reactions were conducted in two different solvents (CH2Cl2 and toluene) using a L2ZrCl2/alkene/AlMe3 ratio of 1:50:60. The results of the experiments are presented in Table 1.

Table 1.

Conversion and product yields in the reaction of the oct-1-ene with Me3Al in the presence of 2 mol% L2ZrCl2 (L2ZrCl2/alkene/Me3Al = 1:50:60, 20 °C, 24 h) [126].

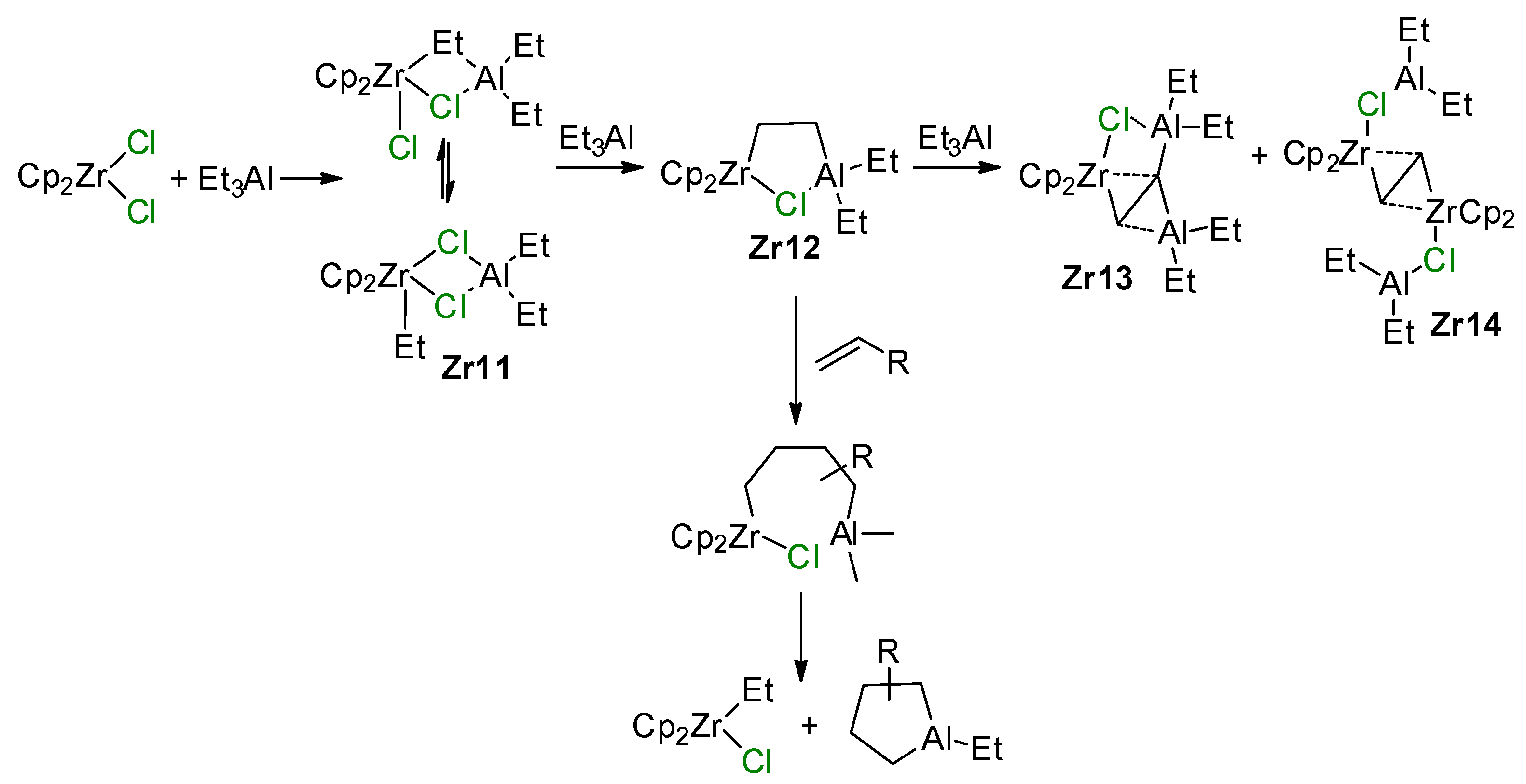

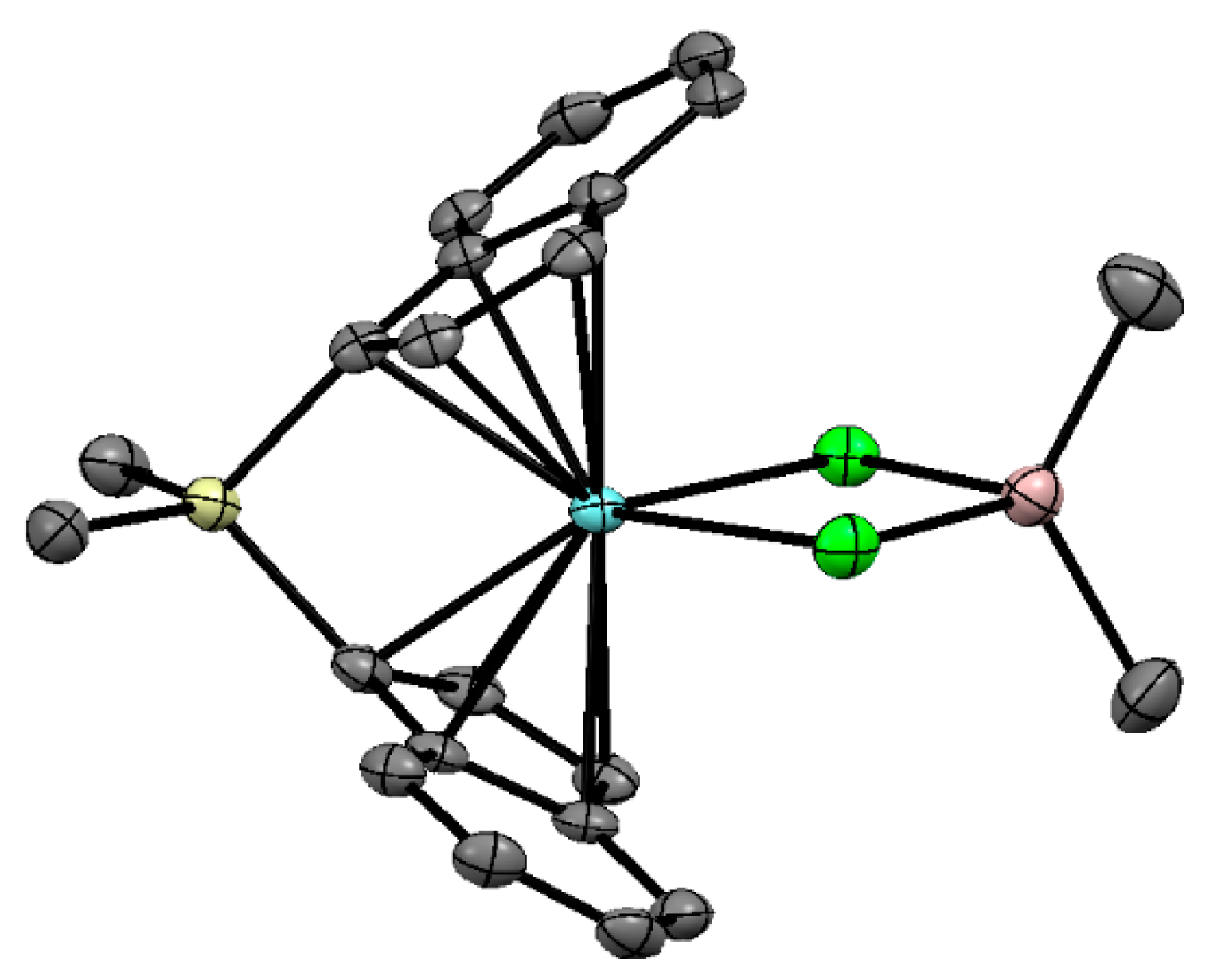

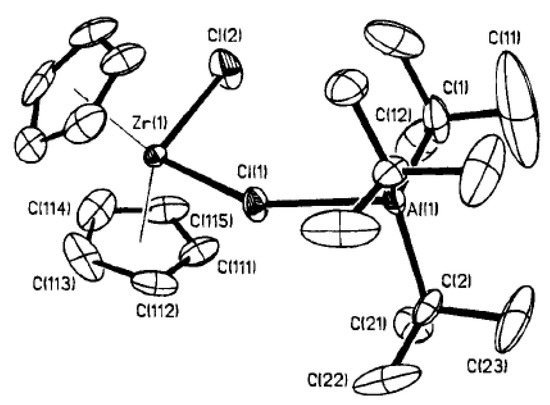

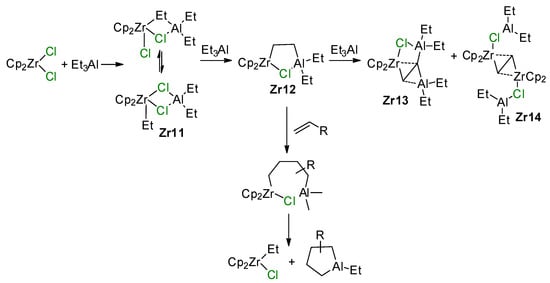

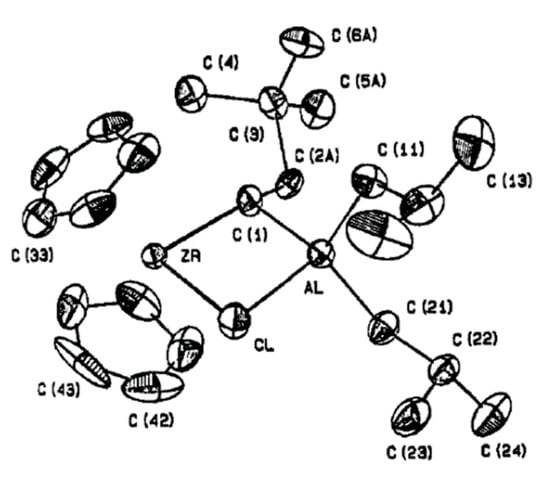

The reaction between Et3Al and Cp2ZrCl2 has a complex mechanism, which occurs in several elementary steps [146]. When using 1 eq. of Et3Al, the Zr–(μ-Cl)–Al complex Zr11 is formed. With an excess of Et3Al, C–H activation takes place to yield a relatively unstable species, Zr12, which is subsequently converted to a more stable Zr13 via the secondary C–H activation along with a smaller amount of Zr14 (Scheme 19). The molecular structure of Zr13 was determined by XRD [147] (Figure 14). In the presence of α-olefin, the highly reactive species Zr12 is further transformed into a cycloalumination product [148]. The mechanism of this reaction was studied by DFT modeling, which confirmed the importance of Zr–(μ-Cl)–Al bonding for all key reaction stages [149,150,151,152].

Scheme 19.

Reaction of Cp2ZrCl2 with Et3Al [146] and the cycloalumination process [148].

Figure 14.

Molecular structure of Zr13. Reprinted with permission from [147]. Copyright (1974) Wiley-VCH Verlag GmbH & Co.

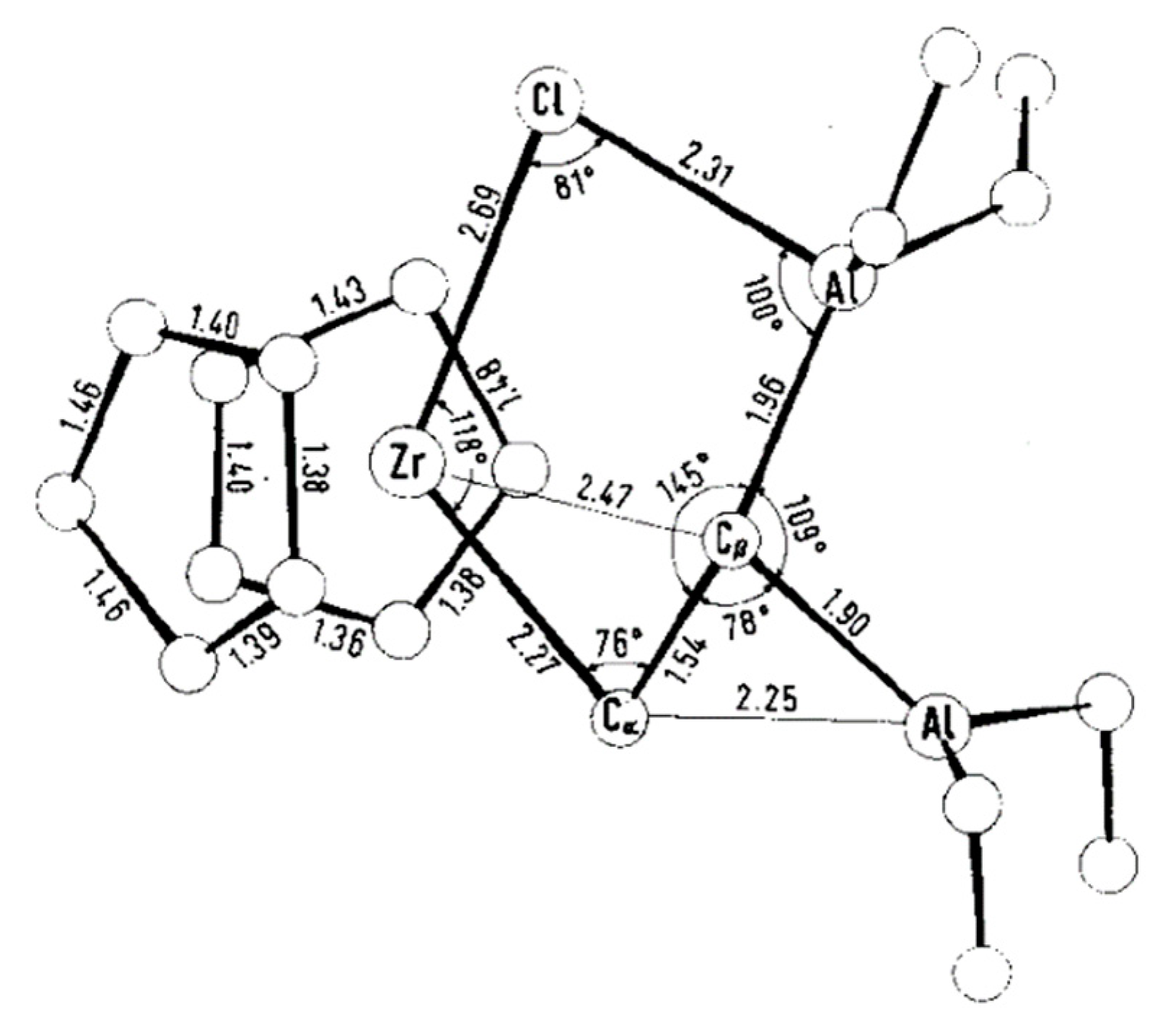

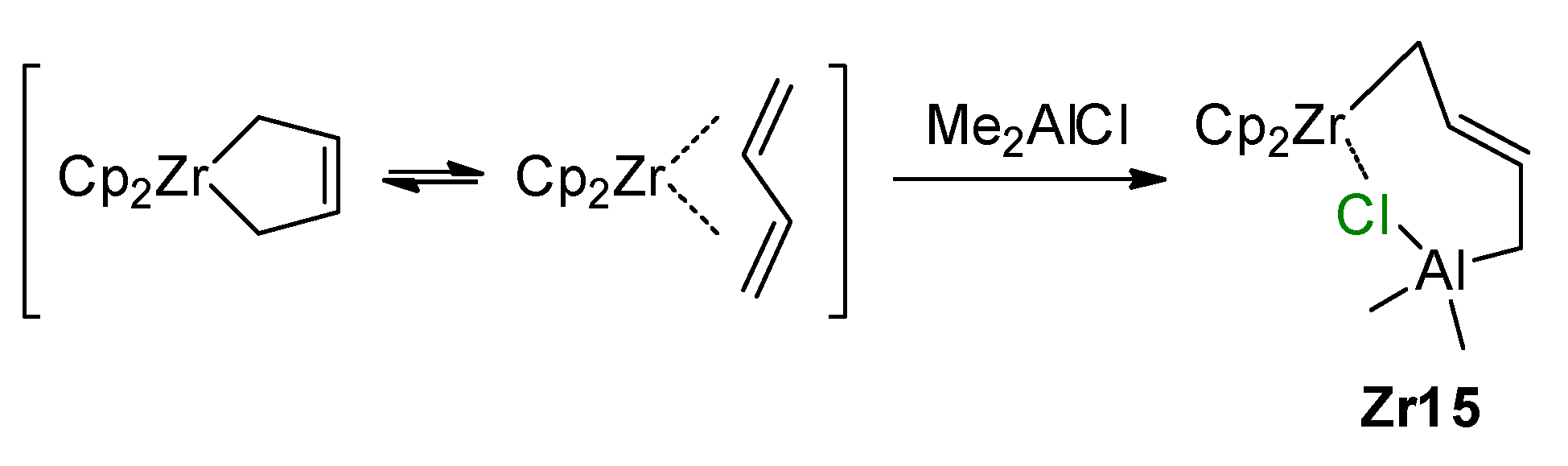

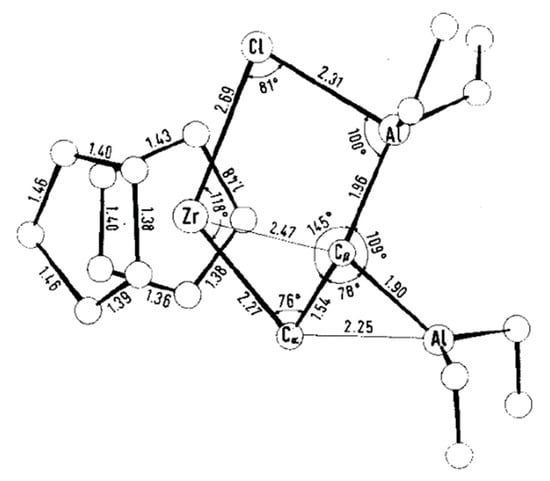

An interesting complex, Zr15 with a Zr–(μ-Cl)–Al fragment, was formed as a result of the reaction of the Cp2Zr buta-1,3-diene complex with Me2AlCl (Scheme 20) [153].

Scheme 20.

Reaction of the Zr(IV) buta-1,3-diene complex with Me2AlCl [153].

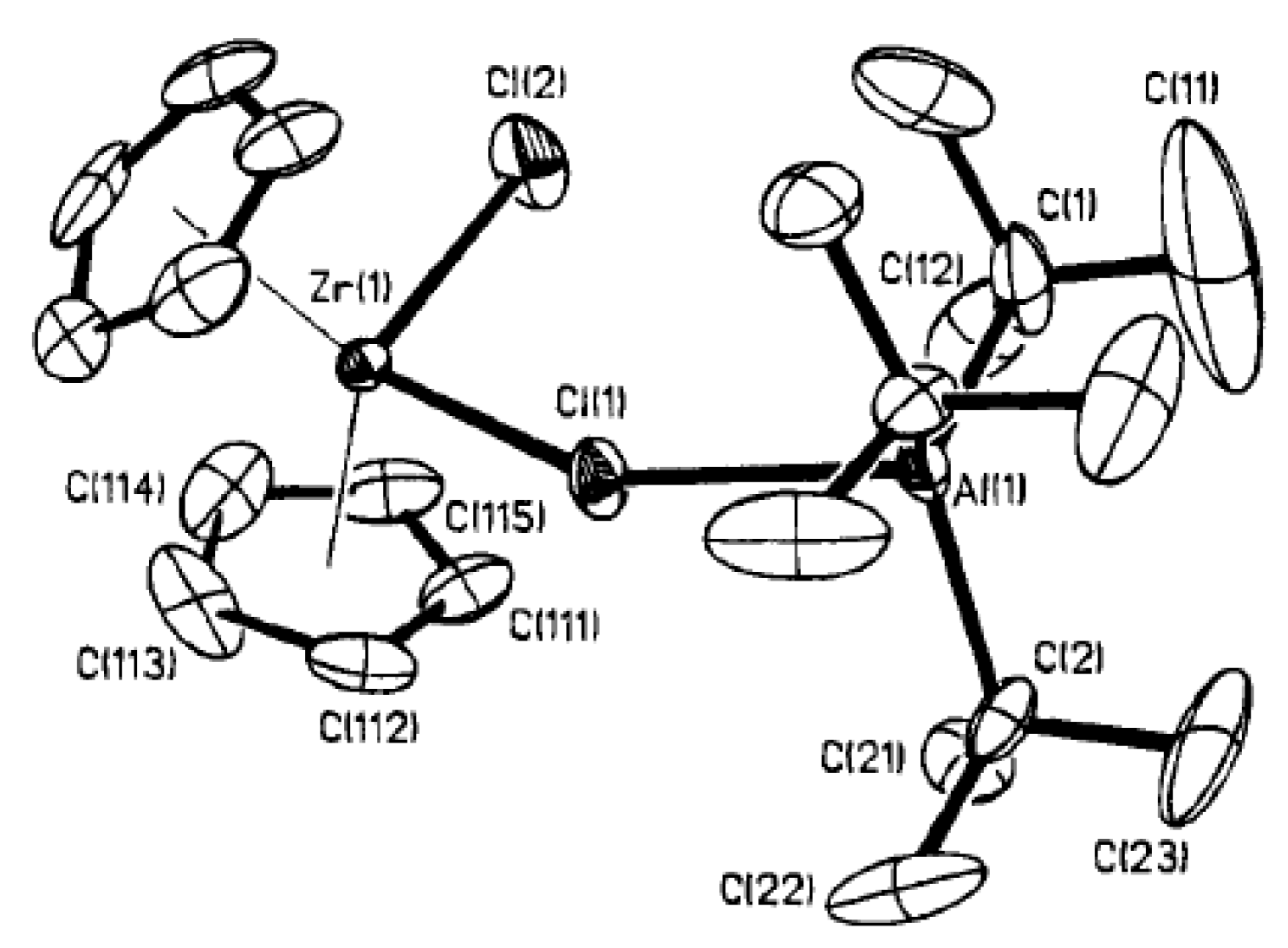

Zr analogs of the Tebbe reagent Cp2Zr(μ-CHR)(μ-Cl)AlR′2 were obtained (a) by the reaction of Cp2Zr(Cl)CH=CHR with R′2AlH or (b) by the reaction of Cp2ZrHCl with R′2AlCH=CHR [154,155]. The molecular structure of one of these complexes with R = CH2tBu and R′ = iBu (Zr16) was proven by XRD (Figure 15). Similar complexes have not demonstrated any synthetic or catalytic prospects.

Figure 15.

Molecular structure of complex Zr16. Reprinted with permission from [155]. Copyright (1987) American Chemical Society.

3.2. Zirconocene Cationic Complexes in Oligomerization and Polymerization of α-Olefins

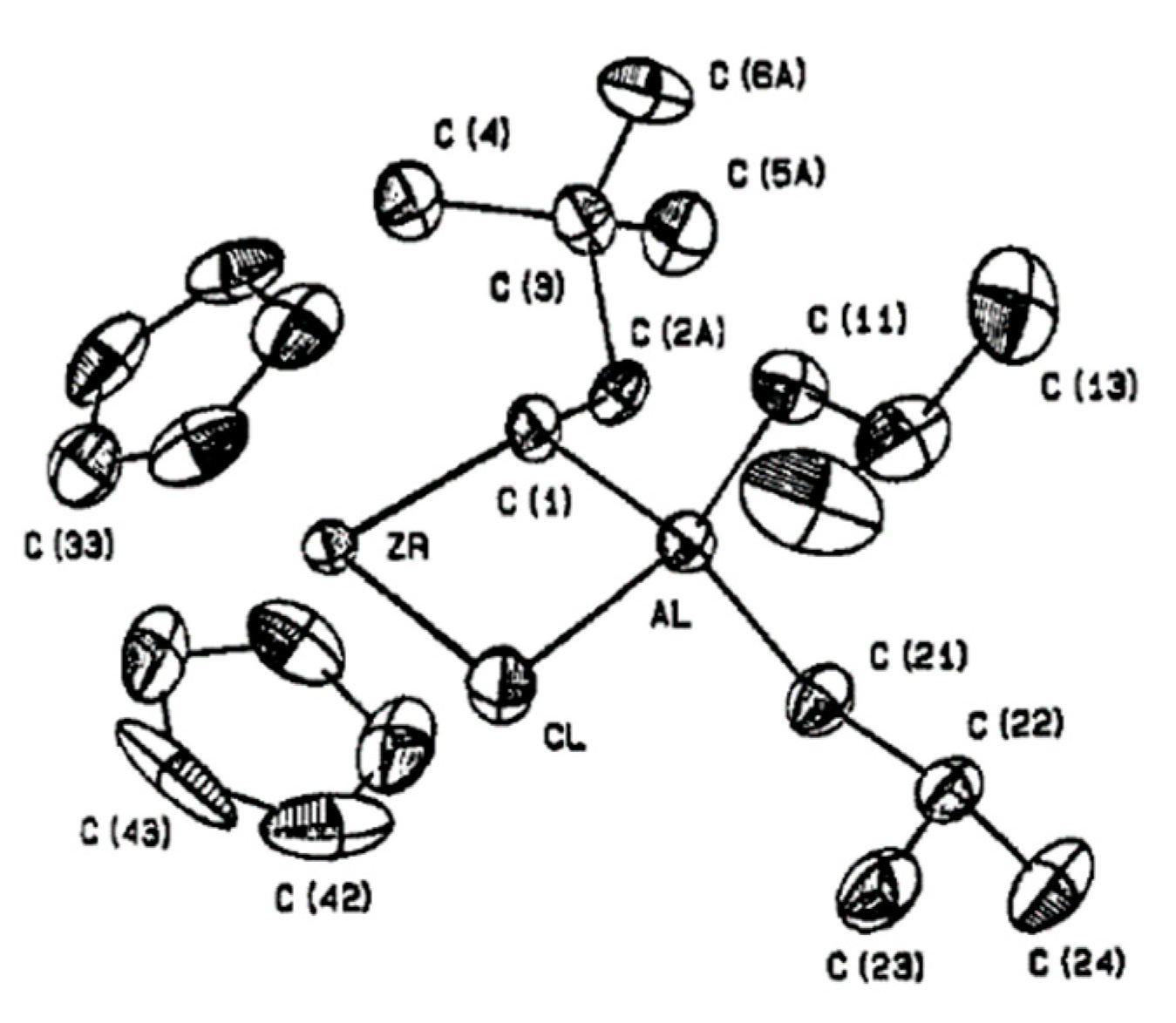

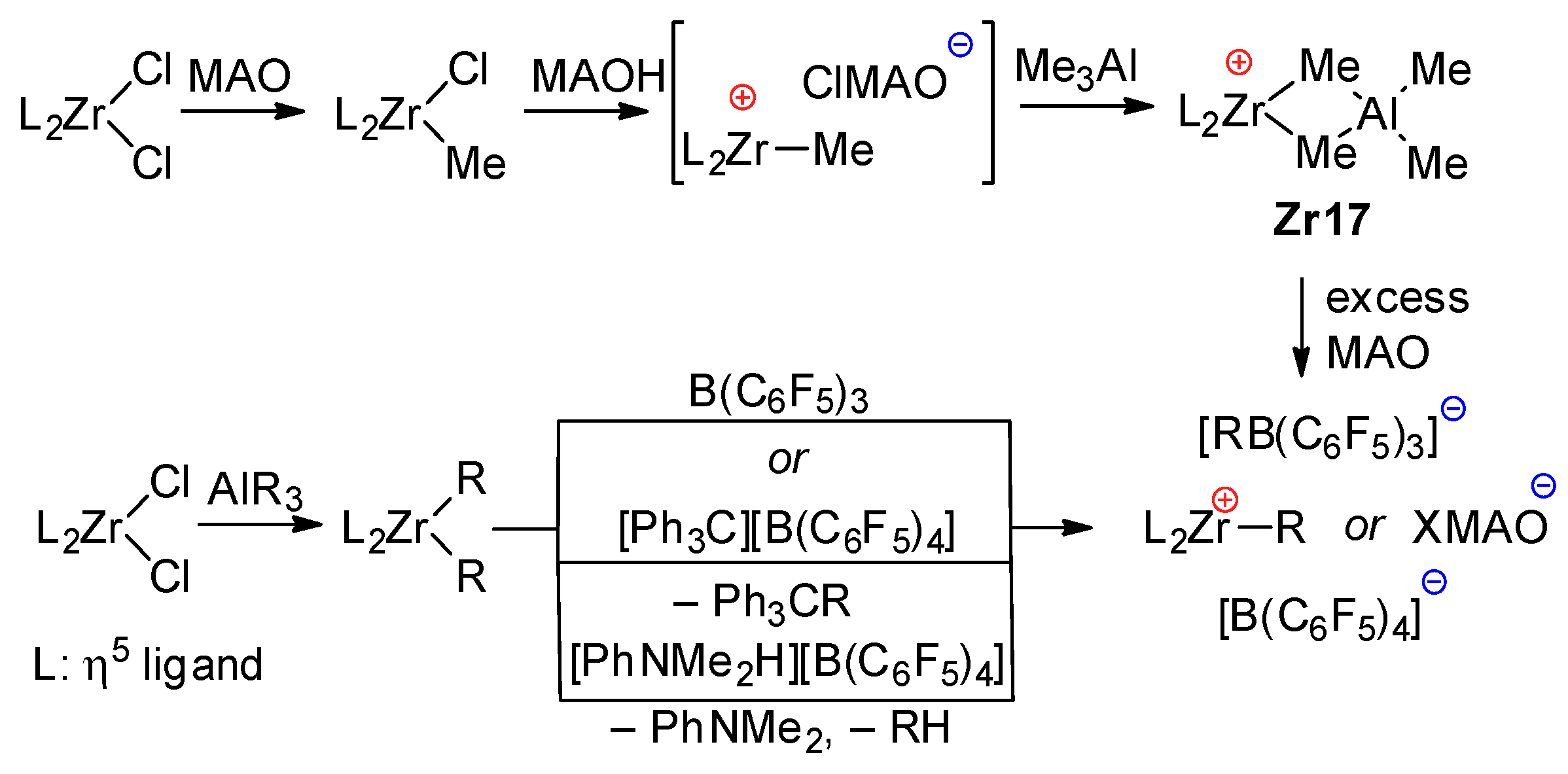

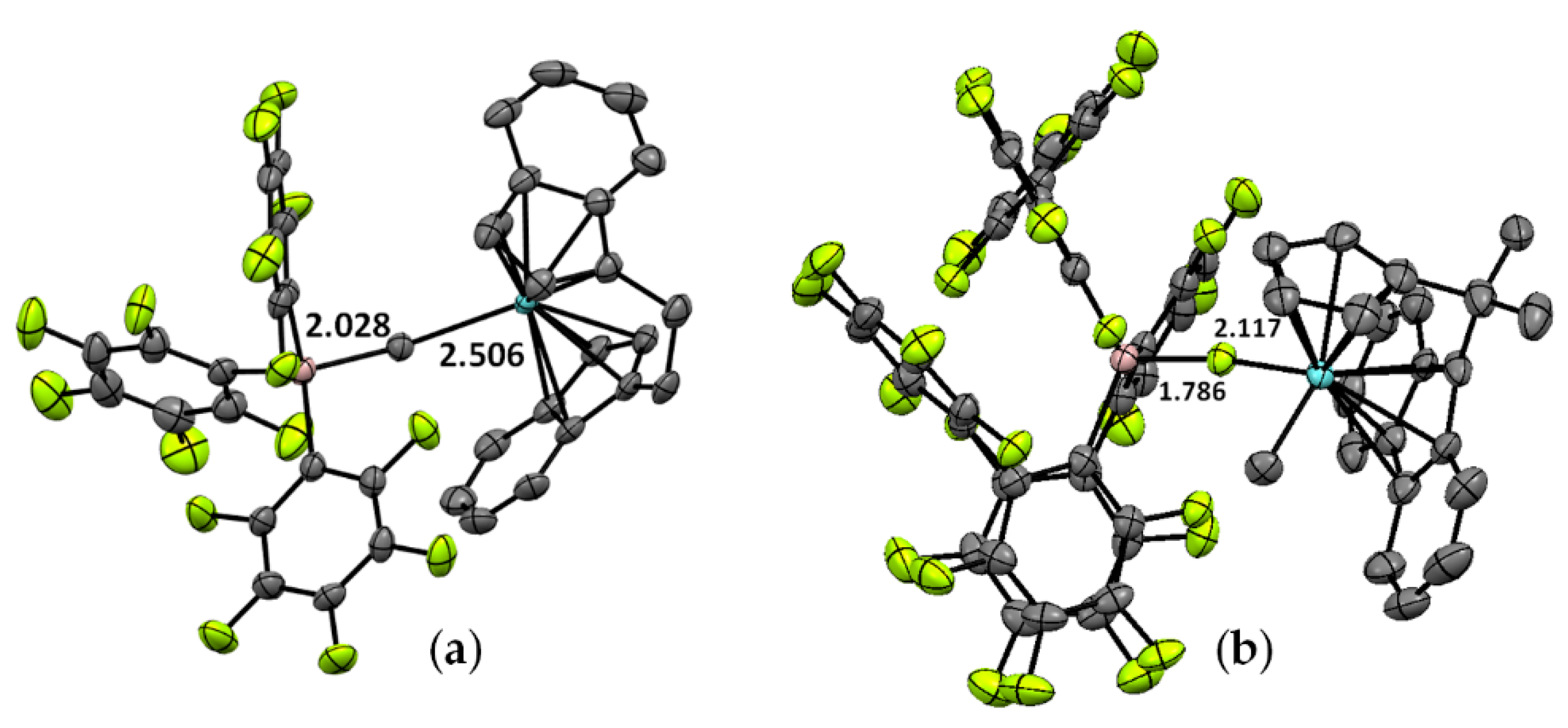

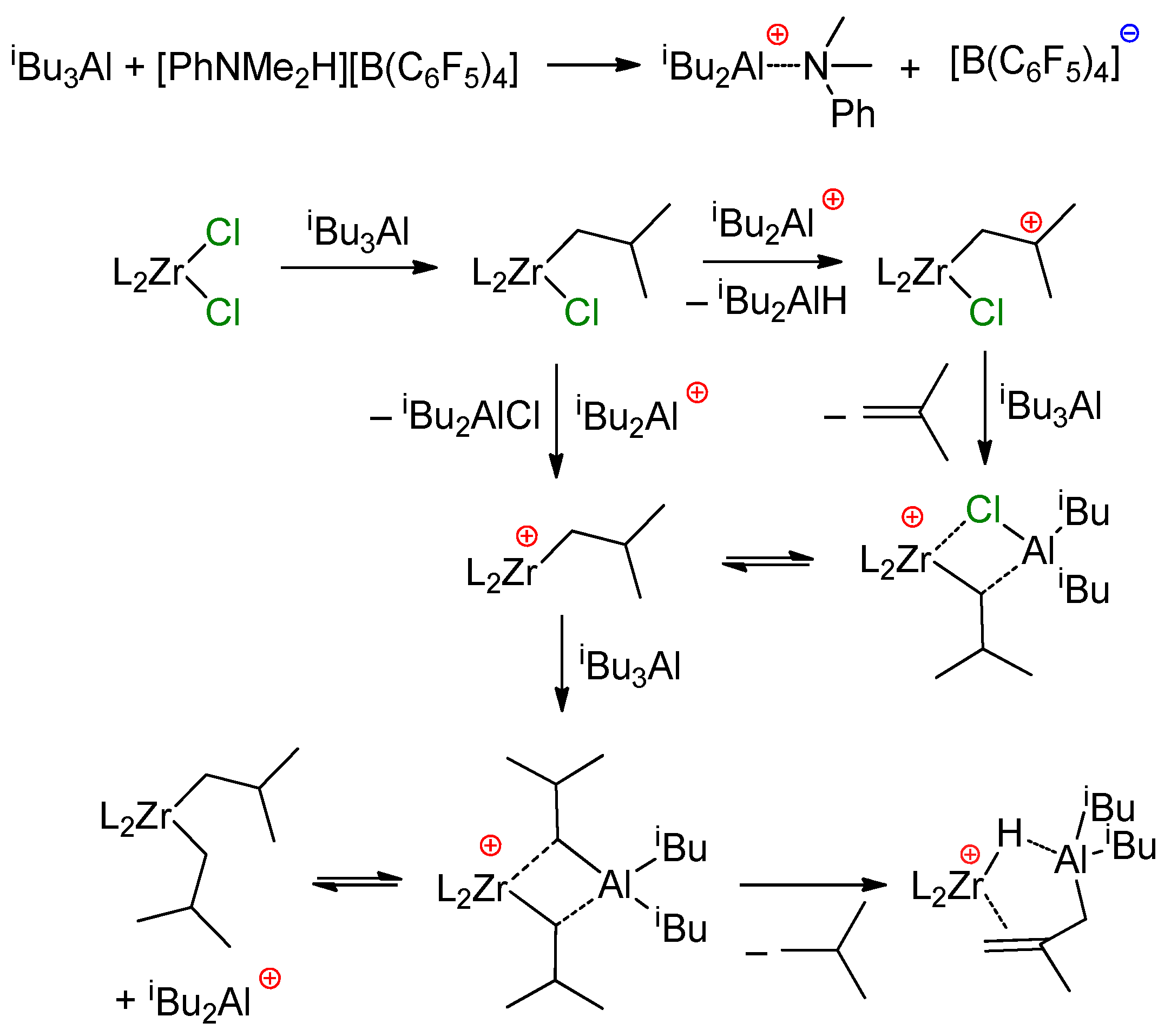

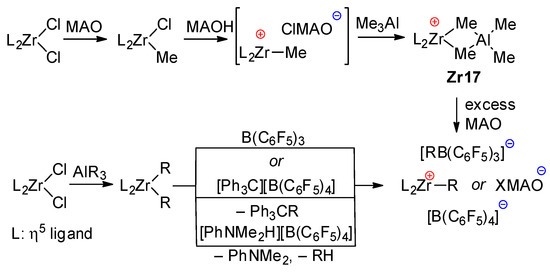

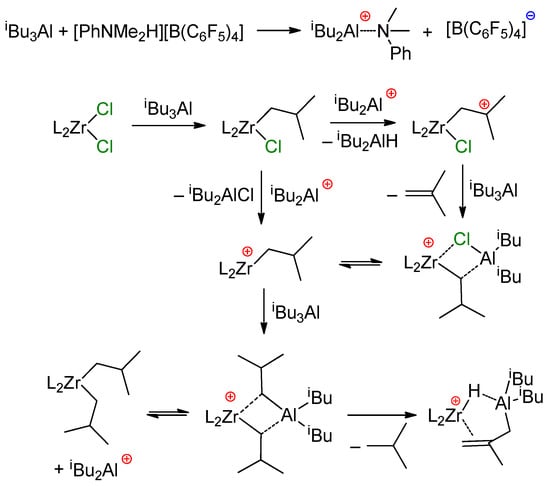

Generally accepted mechanisms of the activation of zirconocene pre-catalysts L2ZrCl2 depend on the type of activator. When using MAO, methylation results in a L2ZrMeCl complex, which eliminates Cl− under the action of MAO. However, when using a slight excess of MAO, Me3Al (inevitably present in MAO due to its dynamic nature), the intermediate active cation forms the inactive cationic complex Zr17, which can be reactivated when using a large excess of MAO. Notably, MAO has limited ability to activate L2ZrCl2; the nature of the primary η5-ligand environment (L2Zr fragment) affects the rate and equilibria of the formation of the catalytic species [122,156]. In the presence of trialkylaluminum and perfluoroaryl borates, an alkylzirconocene cation is formed through the alkylation of L2ZrCl2 with AlR3, followed by the elimination of one Zr–alkyl under the action of B(C6F5)3 or by the alkyl abstraction or protonation of Zr–alkyl by [Ph3C]+ or [PhNMe2H]+ counterions of [B(C6F5)4]−, respectively (Scheme 21).

Scheme 21.

Conventional mechanism of L2ZrCl2 activation by MAO and perfluoroaryl borates.

The negative role of Cl− in the zirconocene-catalyzed polymerization of α-olefins when using MAO as an activator was demonstrated by Cramail et al. in the framework of the simplified MAO model [157]; however, further studies have shown that not everything is so unambiguous, primarily because of the incompleteness of the early conceptions of the MAO structure. In recent years, this issue was clarified; essentially, the presence of Cl-containing MAO species as counter-ions was confirmed experimentally [28,125,158,159], In particular, the molecular ion with an m/z ratio of 1395 (Figure 16) was detected when analyzing the activation of Cp2ZrCl2 by MAO. Evidently, it is the Al–Cl fragment in this molecule that can coordinate at the Zr catalytic center. This model of ‘chlorinated’ MAO was developed on the basis of previous mass spectrometry studies [26].

Figure 16.

Model for anion with m/z 1395 featuring a terminal Me2AlCl. Reprinted with permission from [28]. Copyright (2017) American Chemical Society.

In [23], Linnolahti et al. proposed a simple and visual model of the structure of an MAO cluster, suitable for DFT modeling. They demonstrated that the chlorination of MAO leads to the overall facilitation of catalyst activation processes.

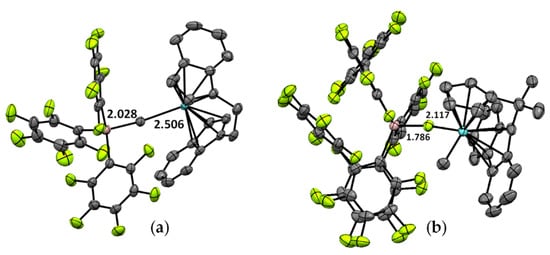

There are no examples of cationic catalytically active zirconocene species with Zr–(μ-Cl)–Al fragments whose molecular structures have been proven by XRD. It is worth pointing out here that cationic Zr complexes with [MeAl(2-C6F5C6F4)3]− (Zr18) [160] and [FAl(2-C6F5C6F4)3]− ions (Zr19) [22] have been separated and analyzed by XRD. As can be seen in Figure 17, the differences between Zr–(μ-X) and Al –(μ-X) are equal to 0.48 and 0.33 Å for X = C and X = F, respectively. Whether Al(C6F5)3 is capable of Cl abstraction from L2CpCl(Alkyl) complexes is now an open question.

Figure 17.

Molecular structures of the complexes (a) {[(CH2CH2)Ind2]ZrMe}+[MeAl(C6F5)3]− (Zr18) [160] and (b) [Me2C(Cp)(Flu)]ZrMe]+[FAl(2-C6F5C6F4)3]− (Zr19) [22].

In recent publications [161,162], the mechanism of the activation of L2ZrCl2 pre-catalysts by MAO was significantly revised with new experimental data that point to the intermediate formation of [L2Zr(μ-Cl)2AlR2]+ cationic species via the generation of R2Al+, followed by their reaction with L2ZrCl2. At the same time, an alternative activation pathway was proposed for the reaction of L2ZrCl2 with [iBu2Al][B(C6F5)4], namely, Cl− abstraction with a formation of L2ZrCl+ species [33].

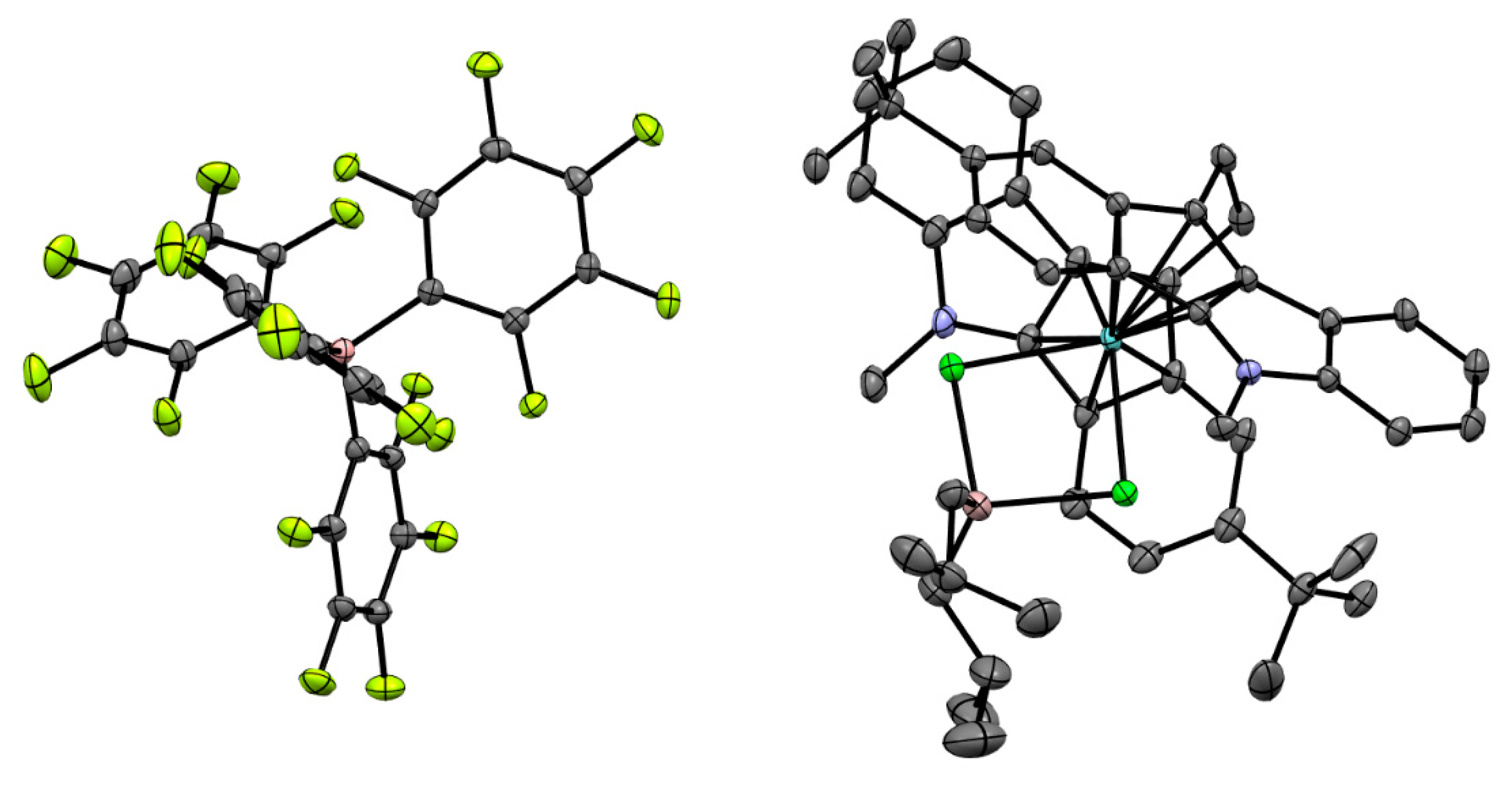

Notably, the cationic complex {rac-[Me2Si(η5-C9H6)2]Zr(μ-Cl)2AliBu2}+ (Zr20) was formed by the reaction of {rac-[Me2Si(η5-C9H6)2]Zr(μ-H)3(AliBu)2}+ and characterized by NMR spectroscopy [163]. The complex {rac-[Me2Si(η5-C9H6)2]Zr(μ-Cl)2AlMe2}+ (Zr21) was similarly obtained by the reaction of {rac-[Me2Si(η5-C9H6)2]Zr(μ-Cl)2AlMe2}+ with Me3AlCl [164]. XRD studies of type [L2Zr(μ-Cl)2AlR2]+ complexes are mentioned in [33], referring to conference papers [165,166]; however, the Cambridge Crystallographic Data Centre (CCDC) has no information about these compounds. The structure of {rac-[Me2Si(η5-C9H6)2]Zr(μ-Cl)2AlMe2}+ was proven by a combination of chemical modification and XRD analysis of the Zr(III) neutral complex rac-[Me2Si(η5-C9H6)2]Zr(μ-Cl)2AlMe2 (Zr22) obtained by the reduction of Zr21 (Figure 18). The complexes Zr20–Zr22 were inactive in α-olefin polymerization.

Figure 18.

Molecular structure of rac-[Me2Si(η5-C9H6)2]Zr(μ-Cl)2AlMe2 (Zr22). Reprinted with permission from [164]. Copyright (2013) American Chemical Society.

In the presence of [Ph3C][B(C6F5)4], the activation of L2ZrCl2 by iBu2AlH results in the formation of complex cationic hydrides L2Zr(μ-H)3(AliBu2)2+ via a L2ZrCl(μ-H)2AliBu2 intermediate [163]. However, the reaction of L2ZrCl2 (L2 = Ph2C(Cp)(Flu)) with TIBA and a [PhNMe2H][B(C6F5)4] activator proceeds in a complex pathway, allegedly involving Zr–(μ-Cl)–Al species (Scheme 22) [128].

Scheme 22.

Proposed formation of [Ph2C(Cp)(Flu)Zr(μ-H)(μ-C4H7)AliBu2]+ [128].

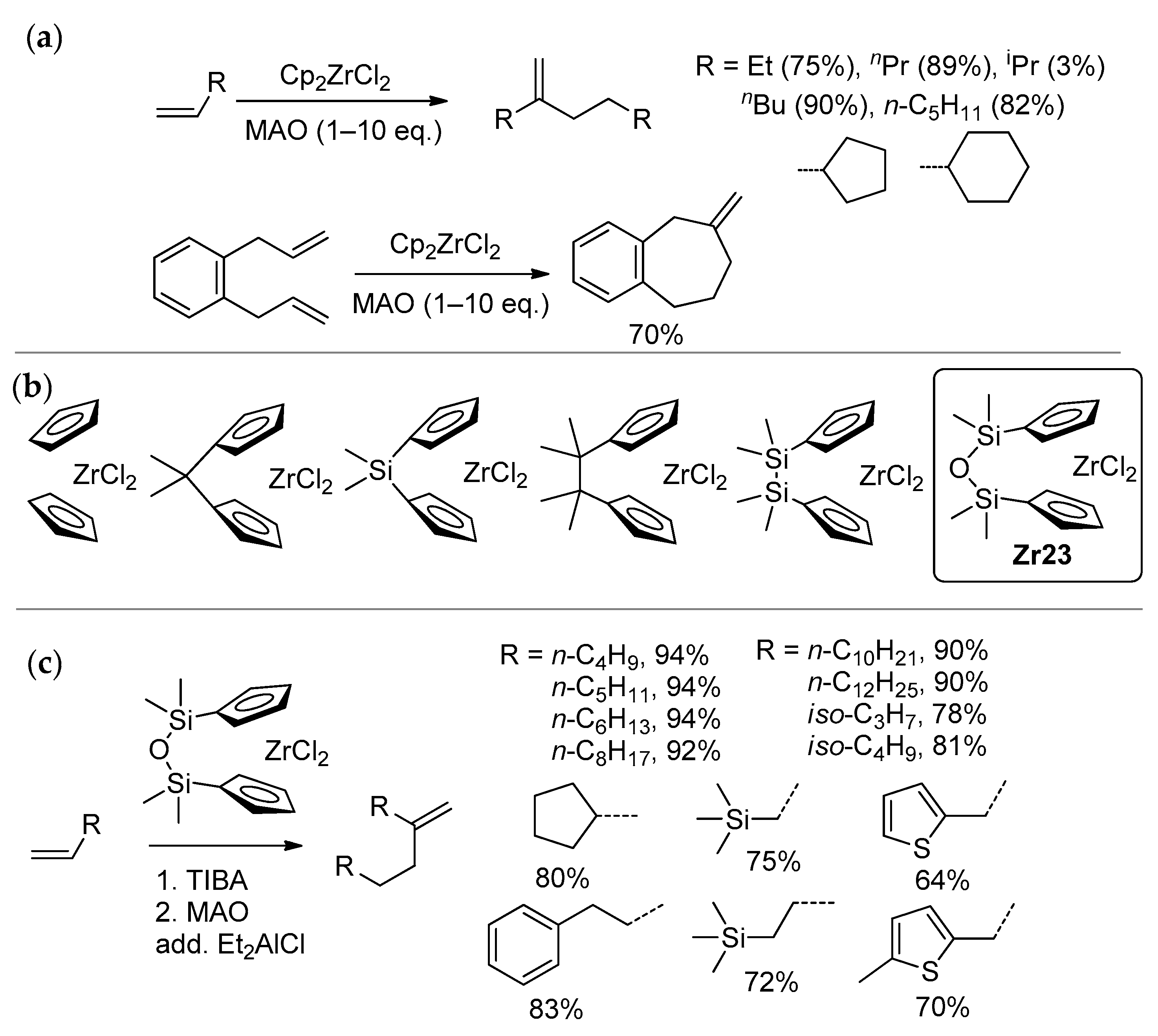

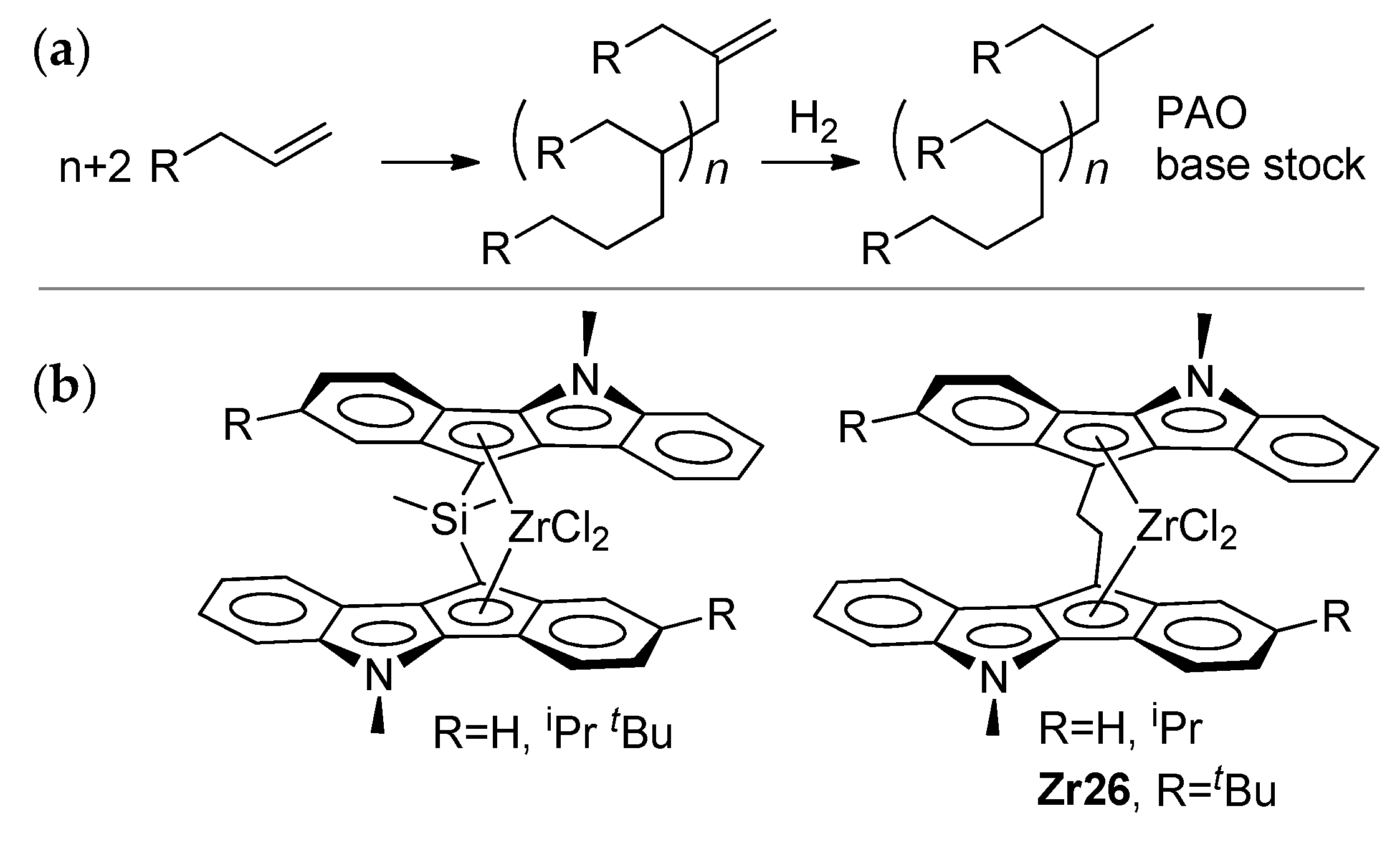

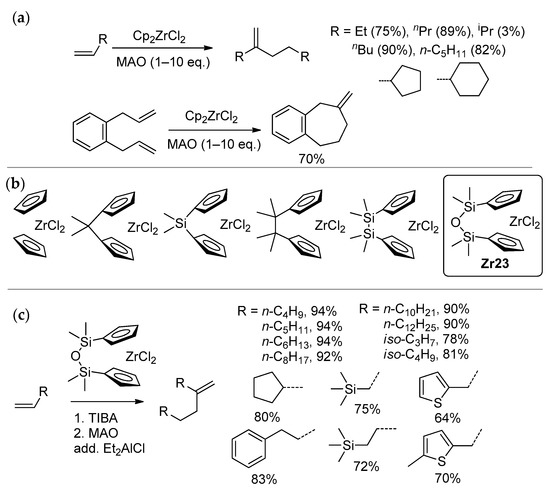

Zirconocene-catalyzed selective dimerization of α-olefins (Scheme 23) represents an interesting and practically important catalytic process, for which the participation of Zr–(μ-Cl)–Al is quite possible. Discovered in 1987 by Slaugh and Schoenthal [167], and first published in scientific periodicals by Christoffers and Bergman [37,38], this reaction was further studied by Erker [168], Janiak [169,170], Kissin [171,172], and Longo [173]. The main dimer of undec-1-ene was obtained by Samela et al. using MAO-activated Cp2ZrCl2 [174], but the reaction products were mistakenly recognized as undec-1-ene trimers. Methylenealkanes can be used in the synthesis of single-component poly-α-olefin oil basestocks [171,175,176] and other value-added chemicals [169,171,172,177,178,179,180].

Scheme 23.

(a) Zirconocene-catalyzed selective dimerization of α-olefins [38]; (b) L2ZrCl2 catalysts studied in the dimerization of hex-1-ene [39,181]; (c) high efficiency of complex Zr23 in dimerization [40].

By the mid-2010s, only Cp2ZrCl2 [37,38] and [Me2Si(η5-C5H4)2]ZrCl2 [173] were efficiently used as pre-catalysts in selective α-olefin dimerization. In comparative studies of a series of Zr complexes, activated sequentially by iBu3Al and MAO, in the dimerization of hex-1-ene (Scheme 23b) Nifant’ev et al. established the formula of complex Zr23 [39,181] that demonstrated high selectivity and activity in the dimerization of different α-olefins, including sterically hindered substrates [40]. Notably, the selectivity of dimerization increased with a decrease in the dihedral angle between cyclopentadienyl rings. During these experimental studies, increases in the selectivity of dimerization when adding R2AlCl were detected. A similar ‘chlorine effect’ was previously demonstrated by the chemists Idemitsu Kosan [182,183], and later by Parfenova et al. [184]. As was shown by Parfenova’s group, Zr2 bimetallic species are also active in selective dimerization [185]; however, the use of these in situ forming species is not of interest in practice.

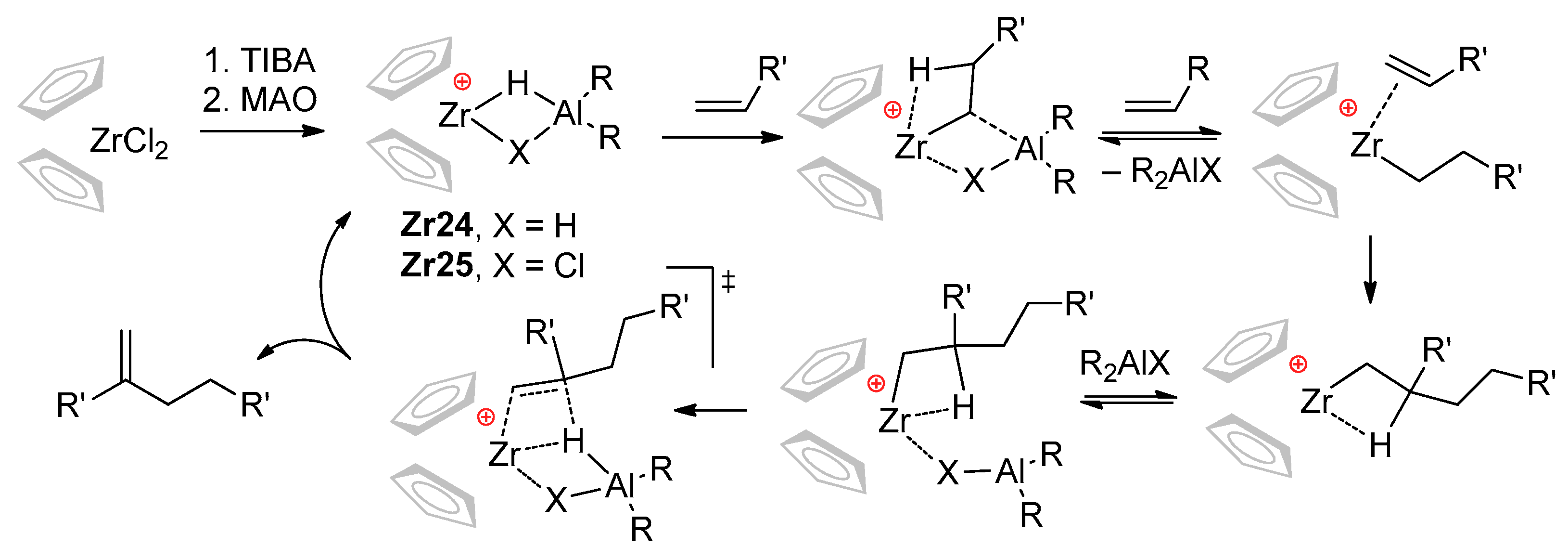

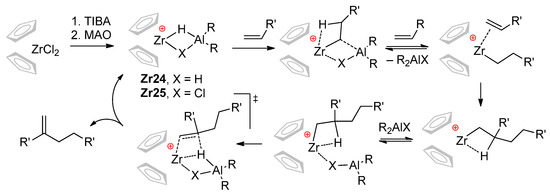

The ‘chlorine effect’ was also noted by Christoffers and Bergman [38]; they suggested the retention of Cl at the Zr catalytic center (Cp2ZrR+⋯ClMAO− species) on the one hand, but on the other, proposed Cp2ZrH+ as the actual catalyst. Based on experimental results, Nifant’ev and Ivchenko proposed a new mechanistic hypothesis, expanding the scope of the conventional cationic mechanism of the zirconocene-catalyzed oligomerization of α-olefins [39,40]. This hypothesis implies the participation of Zr–Al catalytic species Zr24 and Zr25 capable of reversible insertion of the α-olefin molecule. After the second α-olefin insertion, the reversible coordination of R2AlX fragment can facilitate irreversible β-hydride elimination with the formation of methylenealkanes that are inert towards Zr24 and Zr25 (Scheme 24). It was also supposed that R2AlCl should demonstrate the best efficiency as a selective ‘limiter’ of the degree of polymerization (DPn) to 2.

Scheme 24.

Mechanistic concept explaining the selective formation of α-olefin dimers by Zr–(μ-Cl)–Al bonding (X = H, Cl) [39,40,41,42].

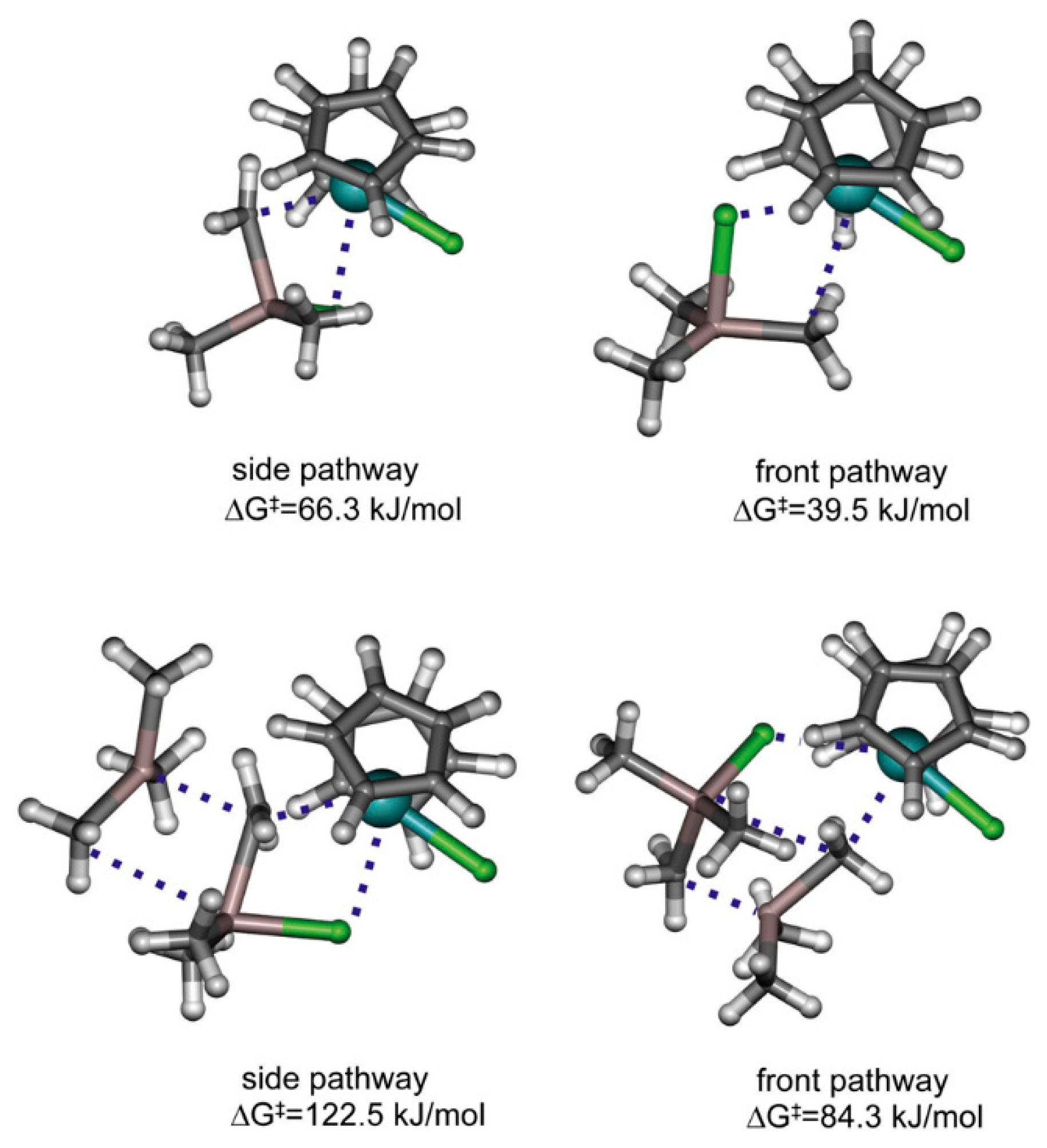

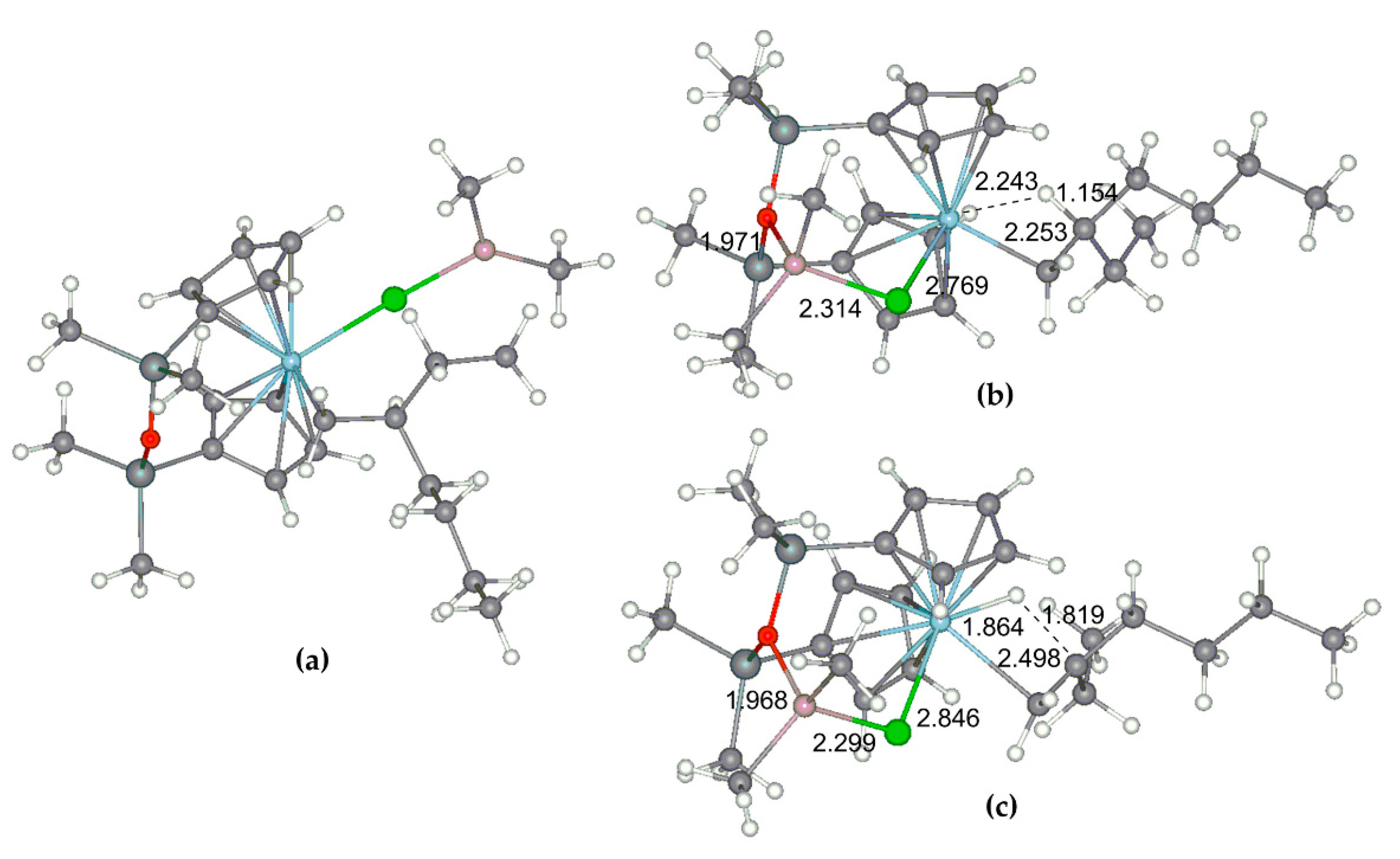

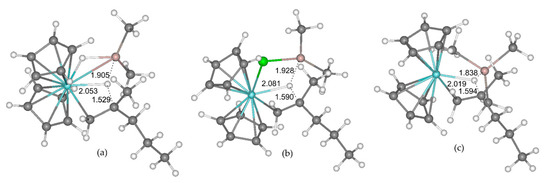

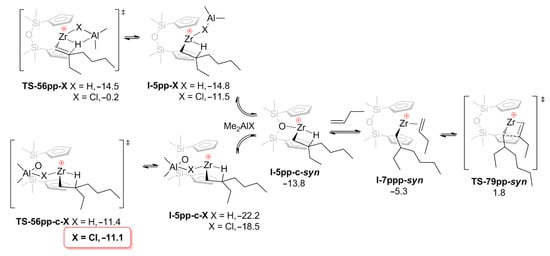

These hypotheses were supported by additional experiments and DFT calculations [41,42]. In [41], oligomerization of hex-1-ene with the use of Cp2ZrCl2 pre-catalyst was studied experimentally, and DFT optimizations for all possible reaction pathways of prop-1-ene oligomerization with and without the involvement of R2AlX (R = Me, iBu; X = H, Cl, Me) were performed. The key stage of the α-olefin formation was chain termination after insertion of the second α-olefin molecule. For the simple cationic model, this process is carried out on the mechanism of β-hydride transfer to monomer, whereas with the assistance of the R2AlX β-hydride, elimination occurs. In the latter case, Al atom demonstrates a cooperative effect (Figure 19). For R = Me, the values of the activation barriers ΔG≠ of β-hydride elimination stage were 17.7 (H), 13.6 (Cl), and 16.2 (Me) kcal/mol. Thus, β-hydride elimination is the most affected by Me2AlCl coordination at the Zr atom.

Figure 19.

Calculated geometries of the transition states of β-hydride elimination in Cp2Zr(µ-X)(CH2CHMePr)AlMe2 model complexes. (a) X = H; (b) X = Cl; (c) X = Me. The distances Zr–H, Al–H and βC–H are specified (Å). Reprinted with permission from [41]. Copyright (2019) MDPI.

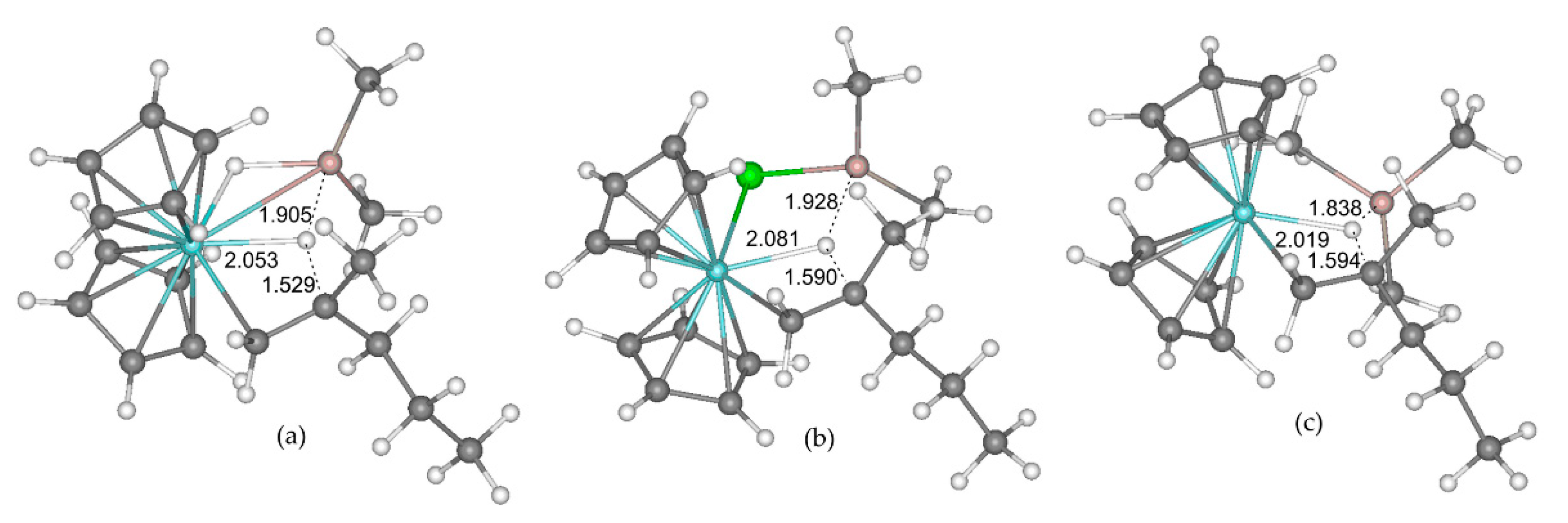

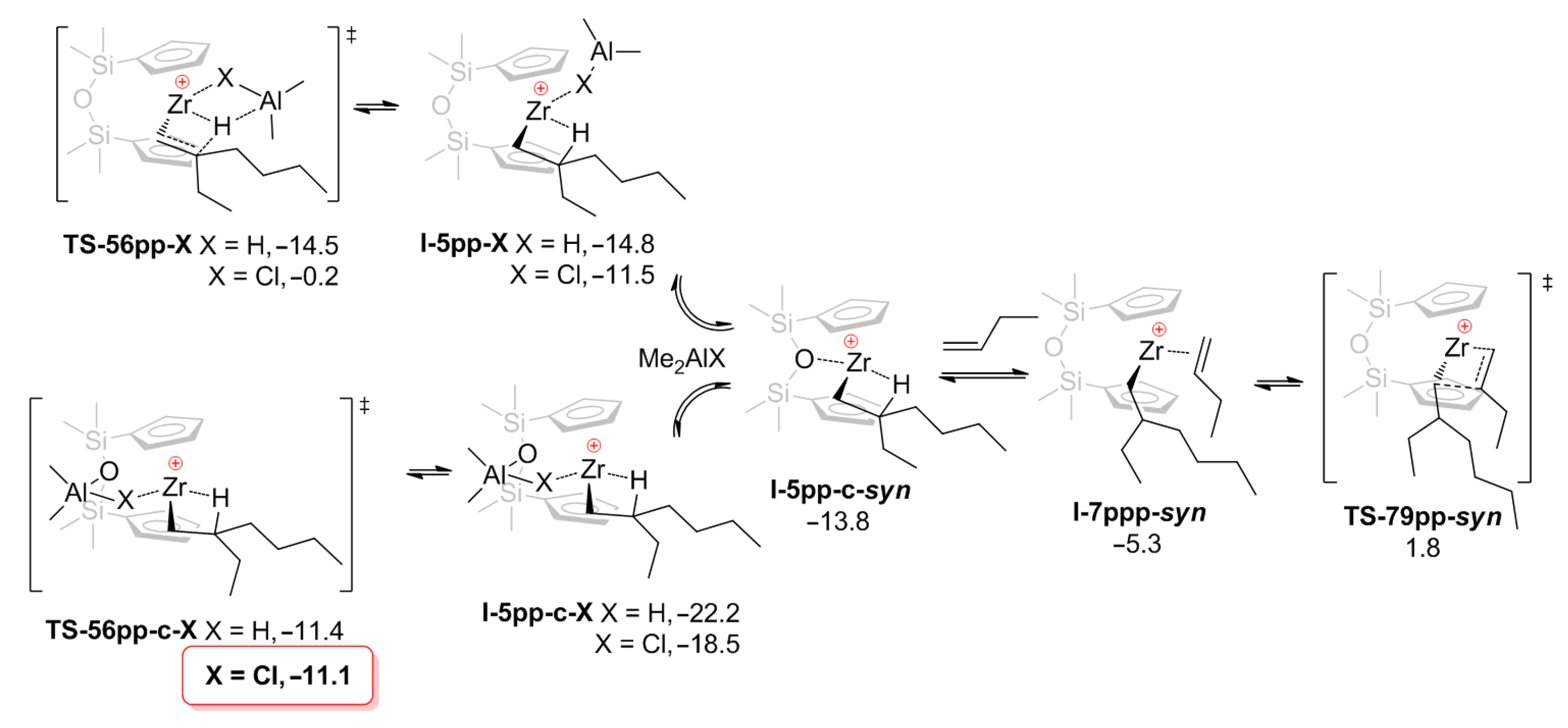

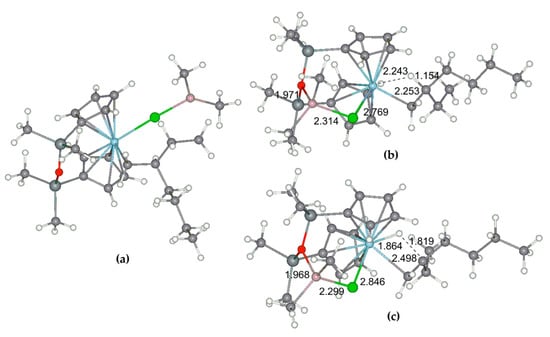

In the study by Nifant’ev et al. [42], oct-1-ene oligomerization with the use of pre-catalysts Cp2ZrCl2, Cp2ZrMe2, O[SiMe2(η5-C5H4)]2ZrCl2 (Zr23), and its dimethyl derivative Zr23′ was studied, DFT modeling was conducted for both zirconocenes using but-1-ene as a model α-olefin. The main theoretical results with regard to Cp2Zr-derived species were in line with the results of prior research [41], whereas in the case of Zr23-based catalytic species, additional Zr–O and Al–O interactions played a significant role in the catalytic process, stabilizing the reaction intermediates and lowering the activation barriers (Figure 20 and Figure 21).

Figure 20.

Transformations of O[SiMe2(η5-C5H4)]2Zr–derived β-agostic complex I-5pp with the participation of Me2AlX species. The values of calculated free energies (kcal/mol) relative to I-2pβ-c are given. Reprinted with permission from [42]. Copyright (2020) MDPI.

Figure 21.

Optimized geometries of O[SiMe2(η5-C5H4)]2Zr–derived stationary points I-5pp-Cl (a), I-5pp-c-Cl (b), and transition state TS-56pp-c-Cl (c). Reprinted with permission from [42]. Copyright (2020) MDPI.

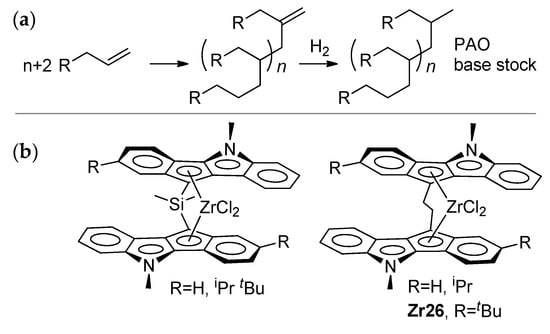

Thus, if zirconocene-catalyzed dimerization requires the a minimal excess of MAO (less than 10 eq.) and zirconocenes of the cyclopentadienyl type (Cp2ZrCl2, Zr23), the catalytic oligomerization of α-olefins (Scheme 25a) is usually conducted at higher AlMAO/Zr ratios. However, these ratios are hardly capable of the complete ‘fixation’ of R2AlCl (MAO as a ‘sponge’ for organoaluminum compounds in the reaction mixture). On the other hand, the greater diversity of zirconocenes used in this reaction still attracts researchers’ attention [17,186,187,188,189,190,191,192]. The activation of L2ZrCl2 by R3Al and perfluoroaryl borates was also found to be efficient in α-olefin oligomerization. This type of activation was used in the recent study by Nifant’ev et al., who reported that –CH2CH2– bridged indeno[1,2-b]indole ansa-complexes (Scheme 25b) demonstrate high efficiency in the synthesis of lightweight oligomers of dec-1-ene (DPn = 3–5) with uniquely homogeneous molecular structures [43].

Scheme 25.

(a) Coordination oligomerization of α-olefins; the idealized uniform molecular structure of the oligomers was achieved when using ‘heterocene’ catalysts (b) [43].

Such catalytic behavior differs from both the activity and selectivity of conventional zirconocenes; therefore, additional research was carried out. Surprisingly, the addition of iBu3Al to the solution of Zr26 did not result in Cl → iBu exchange at the Zr atom. One can assume that the dissolution of Zr26 occurs through the formation of the Zr26–iBu3Al complex with weak Cl–Al coordination. Notably, a similar complexation of L2ZrCl2 with metal alkyls was recently discussed by Kumawat and Gupta in their study on the DFT modeling of zirconocene activation and chain transfer [124].

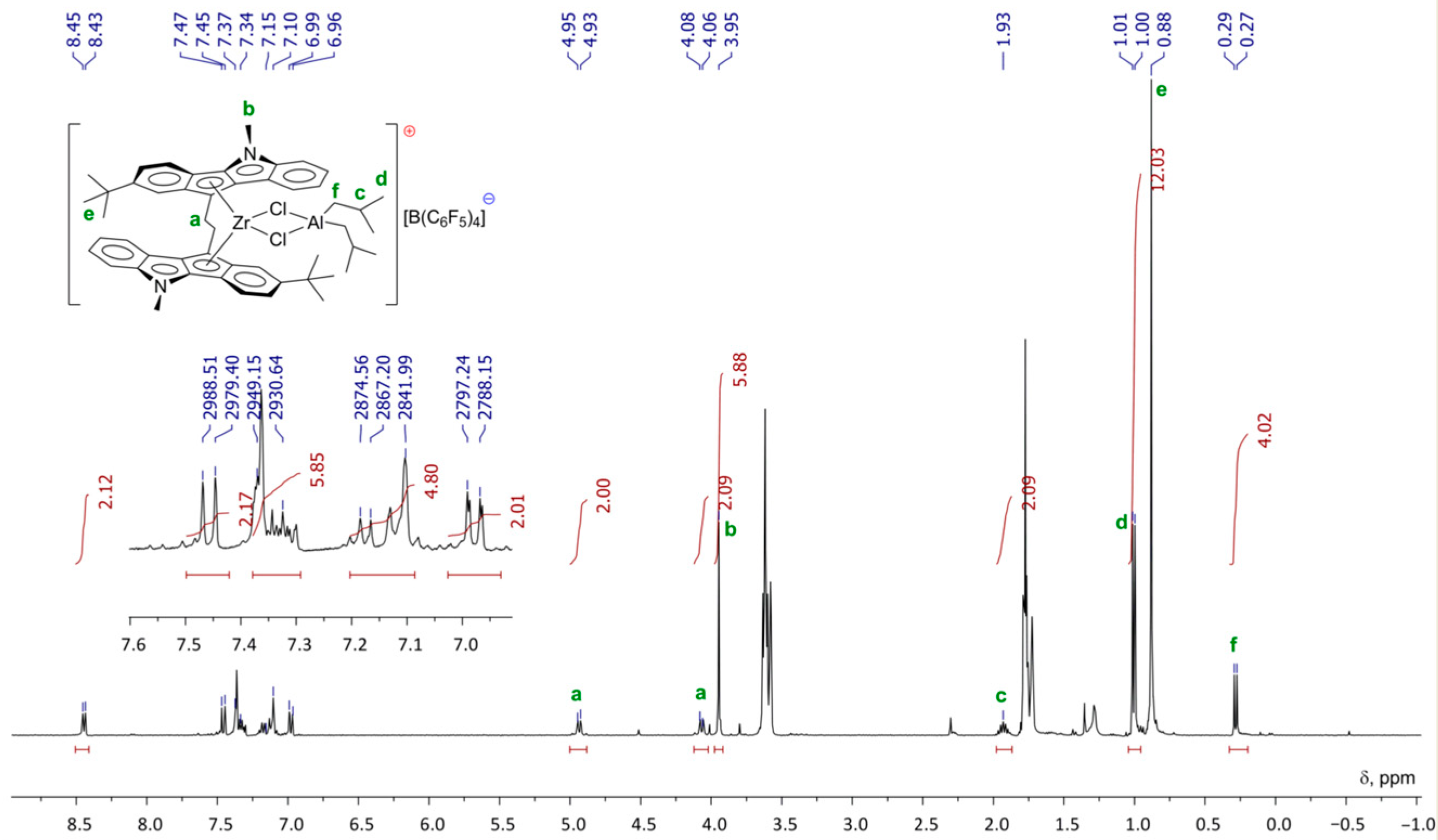

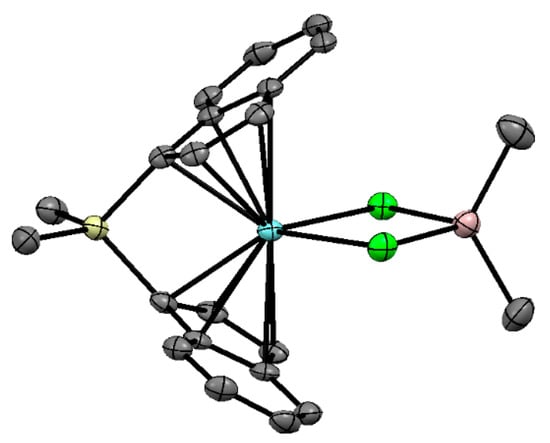

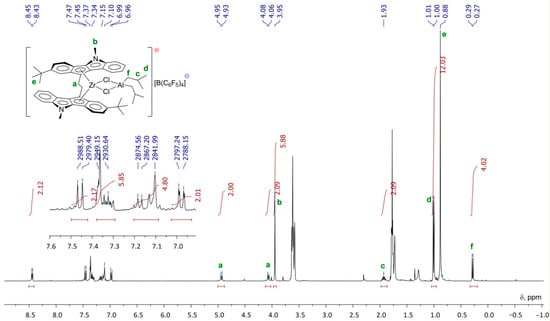

At the first stage of the activation, Zr26 does not exhibit substantial conversion to Zr–Al hydrides under the action of TIBA. However, after the addition of [PhNHMe2][B(C6F5)4], a rapid reaction proceeded with the sedimentation of oily low-soluble product. After the addition of dec-1-ene, no oligomerization was observed. Rapid oligomerization was detected when the activation of Zr26 by TIBA and borate were conducted in the presence of molecular hydrogen, and light-brown crystals of Zr27 were formed at the end of the reaction. After the addition of dec-1-ene to the reaction mixture, oligomerization started again. It turned out that Zr27 alone was inactive in dec-1-ene oligomerization in the presence of H2; however, when TIBA was added to the Zr27 suspension in toluene, the rapid oligomerization of dec-1-ene occurred. The final product of the catalyst transformation of Zr27 was separated and characterized by NMR (Figure 22) and XRD analysis (Figure 23). The spectral view of Zr27 remained unchanged after 7 days, which indicates high stability of the cationic complex in the solvating solvent (THF).

Figure 22.

1H NMR spectra (400 MHz, THF-d8, 20 °C) of Zr27. Reprinted with permission from [43]. Copyright (2022) Elsevier B.V.

Figure 23.

Schemes follow the same formatting. Reprinted with permission from [43]. Copyright (2022) Wiley-VCH Verlag GmbH & Co. Copyright (2016) Royal Society of Chemistry. Copyright (2012) American Chemical Society. Copyright (2015) Springer Nature. Copyright (2019) Elsevier B.V.

The experimental fact of the ‘recovery’ of Zr–(μ-Cl)2–Al complex Zr27 clearly indicates that the mechanism of heterocene-catalyzed oligomerization went beyond the conventional cationic mechanism of the zirconocene-catalyzed polymerization of α-olefins. There is a very realistic chance that it is the retention of Zr–Cl–Al coordination that provides structural homogeneity of dec-1-ene oligomers when using heterocene catalysis.

Comparison of the hydrogen response during ethylene polymerization, demonstrated by dichloro- and dimethyl ansa–complexes [(η5-C9Me6)SiMe2(η5-C5H4)]ZrX2 (X = Cl, Zr28; X = Me, Zr29), immobilized on solid MAO, may also be seen as indirect evidence of Zr–(μ-Cl)–Al bonding in catalytic species: Zr28-based catalysts turned out to be inert to molecular hydrogen [193]. The relative stability of Zr–(μ-Cl)–Al bonding in catalyst precursor, L2Zr(R)-(μ-Cl)-AlR’3 complexes, essentially depends on the electrophilicity of the Al atom. With the introduction of the electron acceptor fragments, e.g., when using iBu2Al(OC6F5) [194], an ion pair is easily formed, as evidenced by polymerization experiments.

On the basis of the latest investigations [33,43,161,162], it can be concluded that the difference in the mechanisms of the L2ZrCl2 + AlR3 reactions in the absence and presence of MAO (or perfluoroaryl borates) consists of various degrees of ‘chlorination’ for the first-stage products. In the absence of MAO or borate, alkyl transfer from Al to Zr occurs with the formation of LZrR2⋯ClAlR2 complexes with weak Zr⋯Cl bonds (if R = iBu, the transformation to Zr–Al hydrides results in heterometallic complexes with stronger Zr–(μ-H)–Al bonds). When using MAO or perfluoroaryl borates, resulting R2Al+ species rapidly react with LZrCl2 to form cationic [LZr(μ-Cl)2AlR2]+, thus creating certain preconditions for the involvement of R2AlCl in further reactions with α-olefins.

4. Complexes of V

Vanadium-catalyzed α-olefin polymerization was previously reviewed by van Koten et al. in 2002 [195]; by Gambarotta in 2003 [196]; by Redshaw in 2010 [197]; by Wu and Li in 2011 [198]; by Nomura and Zhang in the same year [199]; and by Phillips et al. in 2020 [44]. In these reviews, the focus was on different types of the coordination compounds of V, pre-catalysts of α-olefin polymerization. The mechanisms of polymerization in these reviews were fragmented; however, in contrast to reviews on group 4 metal Ziegler–Natta and single-site catalysts, the importance of V–(μ-Cl)–Al bonding in pre-catalysts and in catalytic species was not ignored (Scheme 26). Here, in strong contrast to Ti- and Zr-based pre-catalysts, a large number of V-based catalysts are effectively activated by R2AlCl of RAlCl2, as opposed to ineffective R3Al and MAO. In this section, we discuss several examples of V–(μ-Cl)–Al complexes that have been missed in previous reviews, or that had been served poorly, as well as new examples of these complexes.

Scheme 26.

Examples of V–(μ-Cl)–Al active species mentioned in previous reviews [44,195,199].

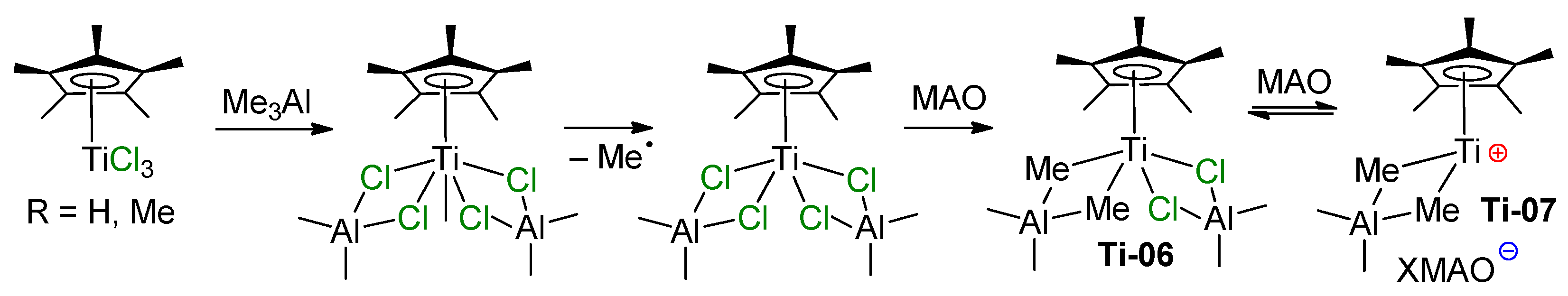

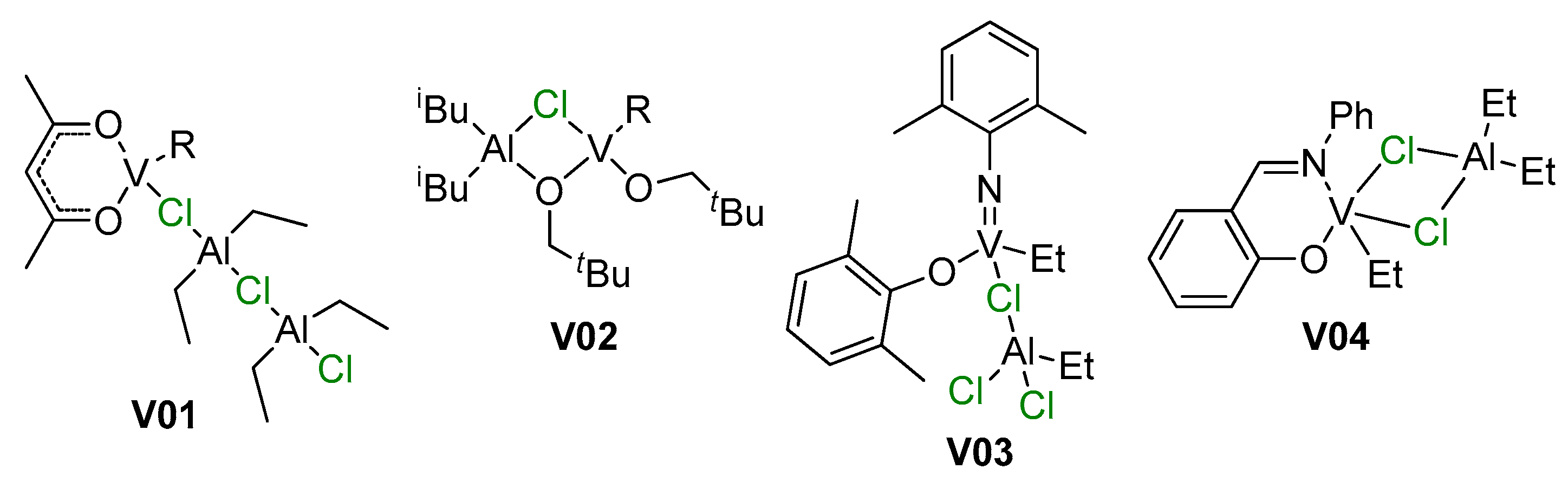

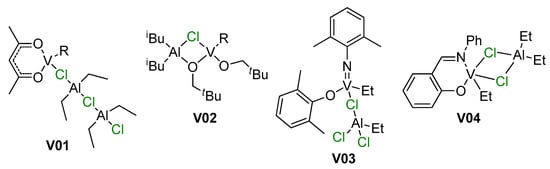

Among older publications on the subject of V-catalyzed polymerizations of α-olefins, the feature article of Zambelli et al. [200] merits special attention. The authors reinvestigated three models of catalytic complexes V05–V07 proposed in the literature for VCl3/R2AlCl catalyst systems (Scheme 27). DFT modeling of the insertion of ethylene molecule was conducted for P = Me according to the conventional Cossee–Arlman scheme. Thermodynamic data for ethylene insertion were close for all three complexes, but significant differences were observed for values of the activation barrier of insertion that were 16, 16, and only 1.7 kcal·mol−1 for V05, V06, and V07, respectively. DFT modeling of prop-1-ene insertion explained the observed syndiotacticity of prop-1-ene polymerization.

Scheme 27.

The hypothetical active species for V catalysts (P = polymer chain) [200].

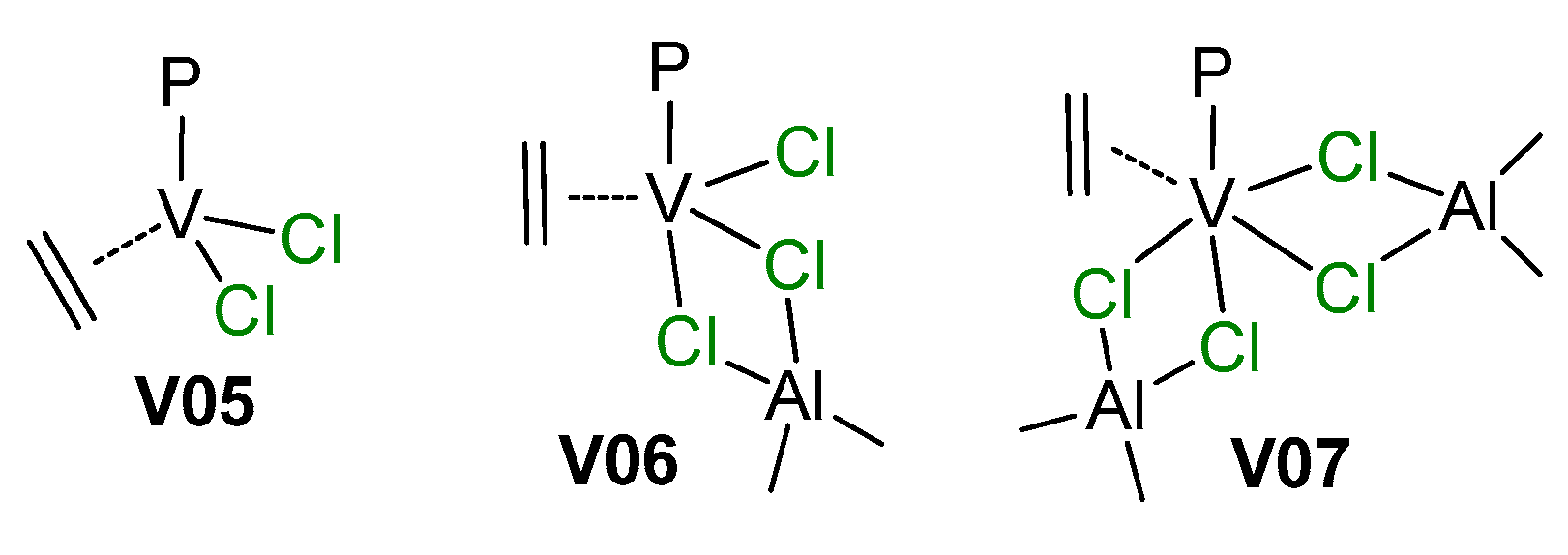

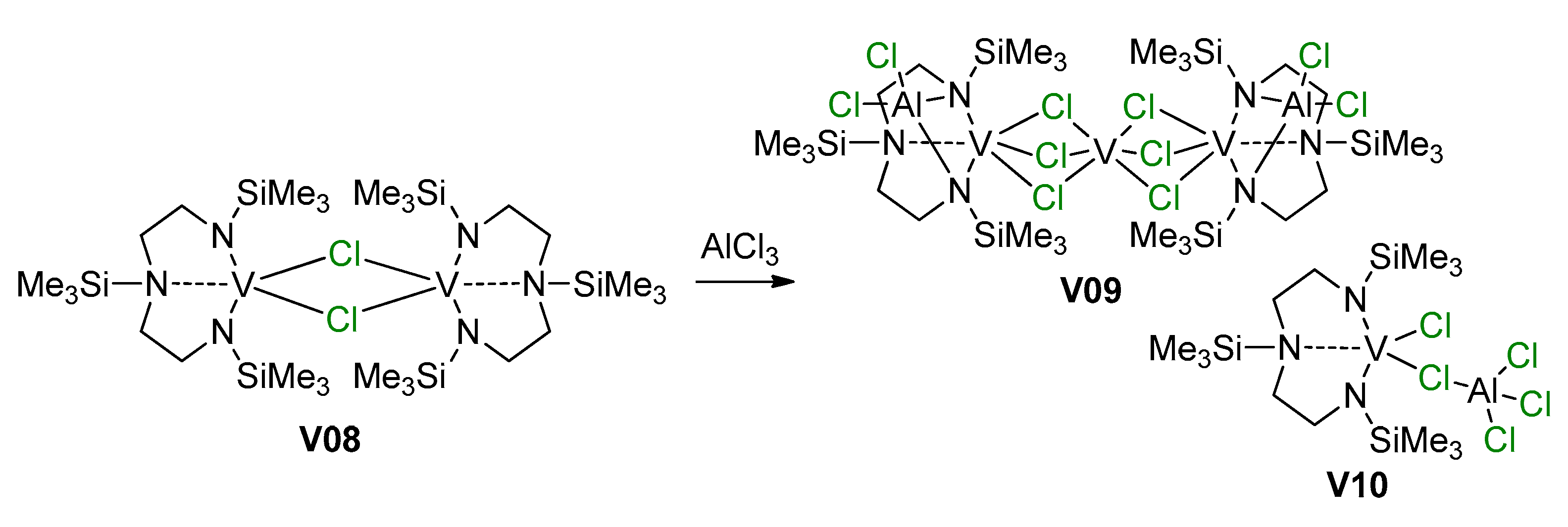

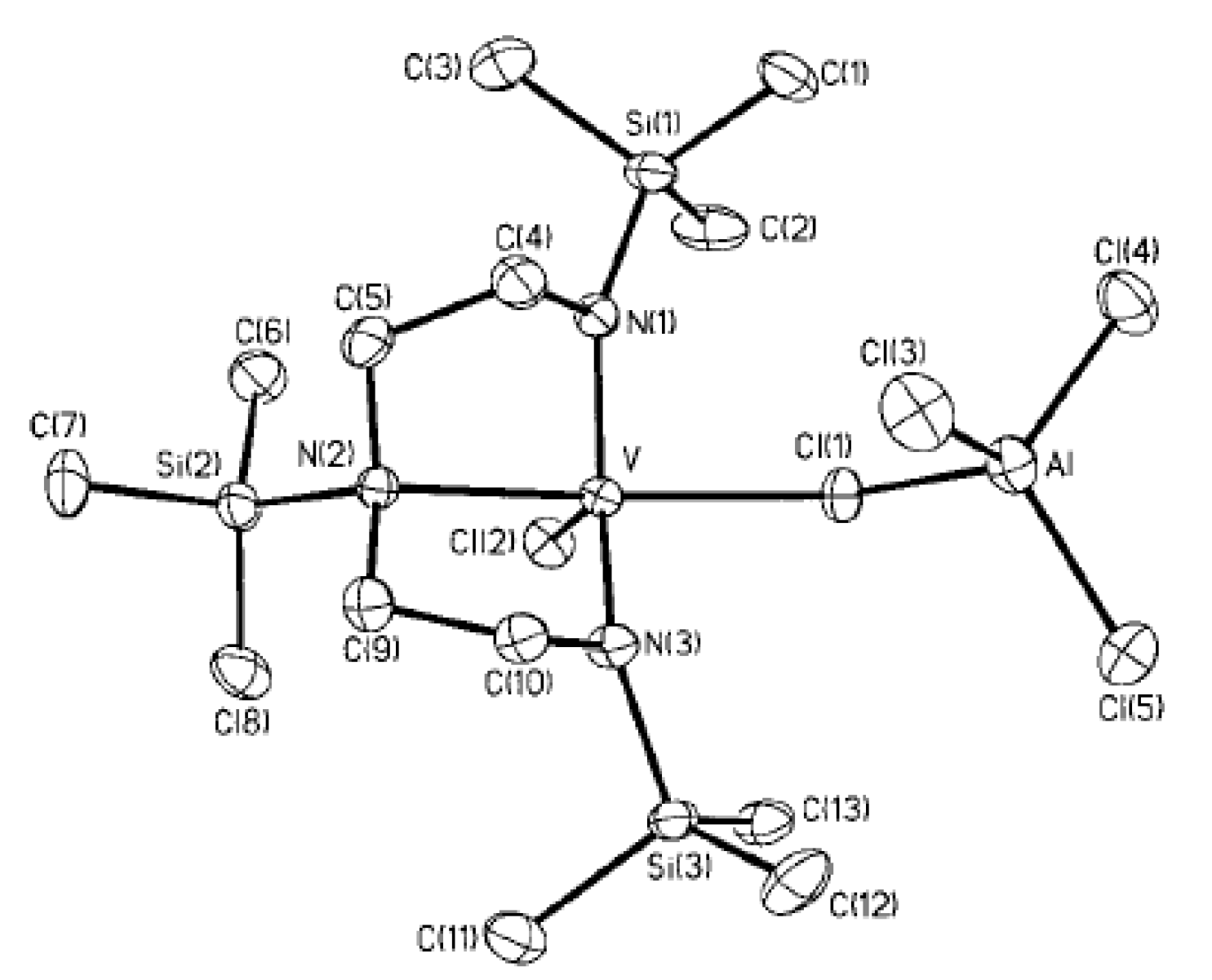

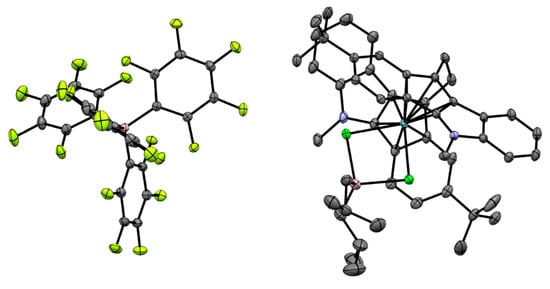

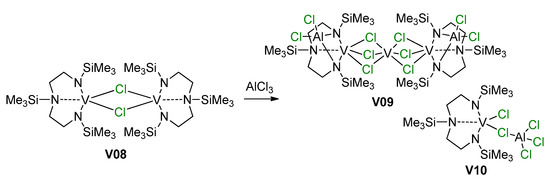

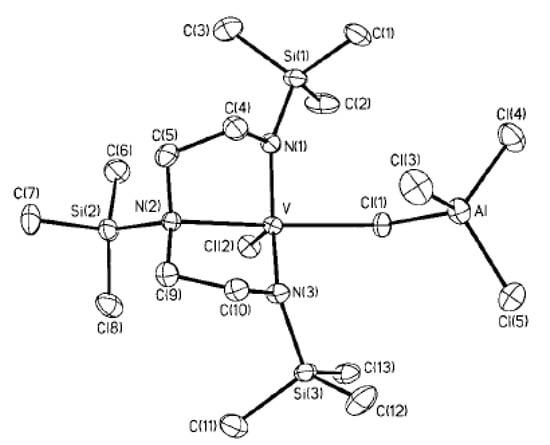

As can be seen in Scheme 26 and Scheme 27, V(III) species are active in polymerization. Obviously, the mechanisms of the deactivation of V centers are important for the development of efficient catalysts. It is thought that the most likely route for deactivation would be reactions with the organoaluminum compound. However, in 2002, Gambarotta et al. demonstrated an alternative pathway of such deactivation via disproportionation of the V(III) complex V08 with the formation of V(II)/V(III) (V09) and V(IV) (V10) species [201] (Scheme 28, Figure 24); AlCl3 in this process acts as Lewis acid and it cannot be ruled out that organoaluminum co-catalysts can promote catalyst deactivation in a similar way.

Scheme 28.

Disproportionation of V(III) complex V08 [201].

Figure 24.

ORTEP plot of V10. Thermal ellipsoids are drawn at the 30% probability level. Reprinted with permission from [201]. Copyright (2002) American Chemical Society.

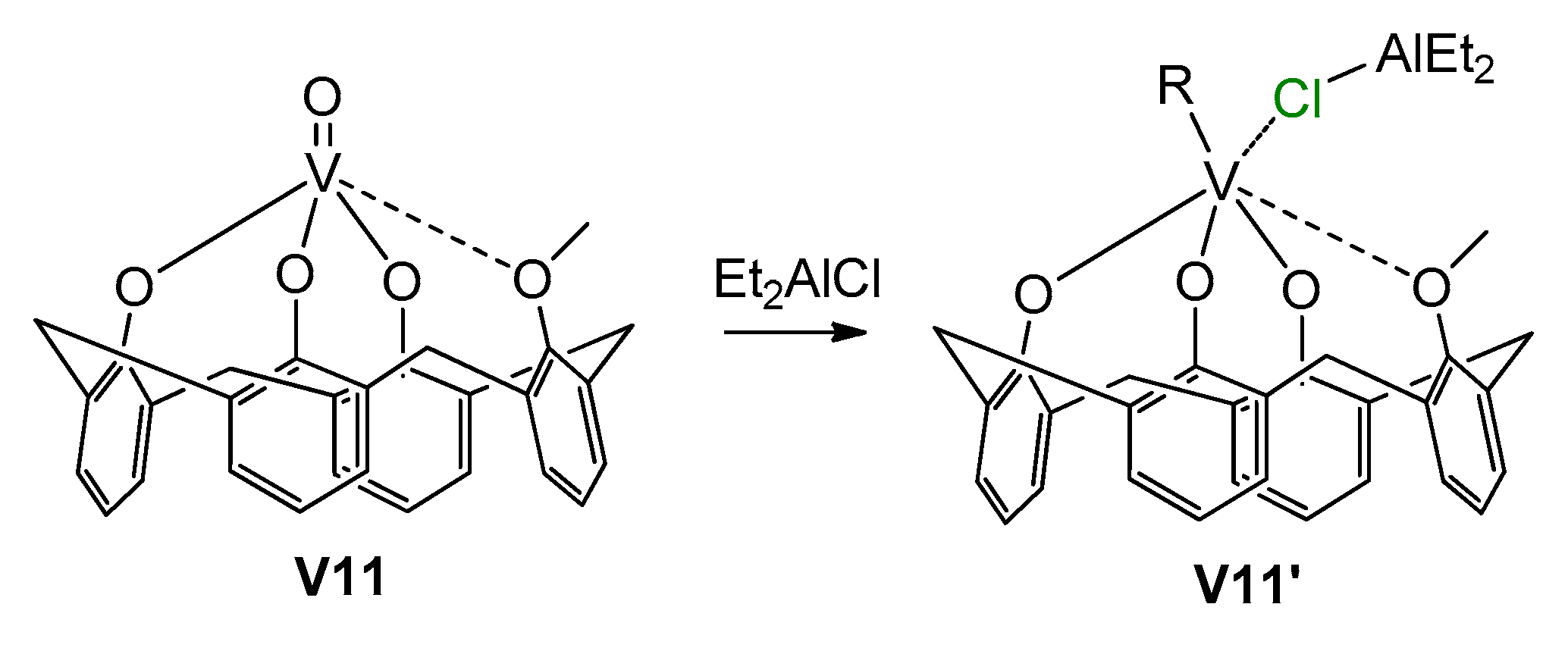

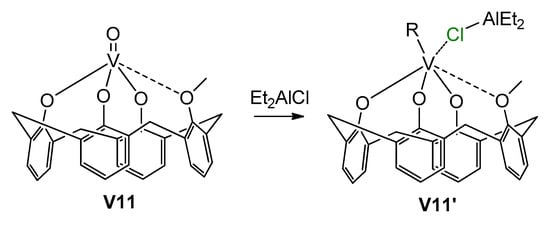

Another important aspect of V catalysis in α-olefin and diene polymerization was demonstrated by Centore et al. [202], who studied the catalytic activity of the pre-catalyst [(κ1-iPrN=C(Ph)NiPr)V(O)Cl(μ-Cl)]2 using different organoaluminum activators. They showed that the amidinate ligand can easily be removed from the vanadium in the reaction with organometallic cocatalysts, and the active species are closely related to those obtained from other vanadium precatalysts such as VCl4 (for example, V07). This result imposes certain restrictions on the ligand-oriented design of V-based polymerization catalysts. Stronger V–ligand bonding, such as in V03 [203], provides a retention of the base ligand environment. Polyphenolate ligands can also provide stability of the catalytic species [204]; in particular, activation of the pre-catalyst V11 (Scheme 29) resulted in the formation of V(IV) complex V11′, which is active in ethylene polymerization. V(III) complexes with bidentate N,N-chelating iminopyrrolyl ligands also demonstrated stability in the base ligand environment and relatively high catalytic activity in the polymerization of ethylene when using Et2AlCl as an activator; in the presence of Et3Al or MAO, PE was formed in trace amounts [205]. The complexes with tridentate iminopyrrolyl and tetradentate bis(iminopyrrolyl) ligands [206], well as with bidentate phenoxy-phosphine ligands [207] and with tridentate 2,6-bis(diphenylhydroxymethyl)pyridyl ligand [208], have demonstrated similar behavior. However, in the last case, when comparing V(III) and V(V) derivatives in Et2AlCl-activated polymerization, the V(V) complex demonstrated higher activity. Apparently, even when using the same Cl-containing activator, the nature of the active site essentially depends on the nature of the polydentate ligand.

Scheme 29.

Formation of active V(IV) phenolate complex V11′ [204].

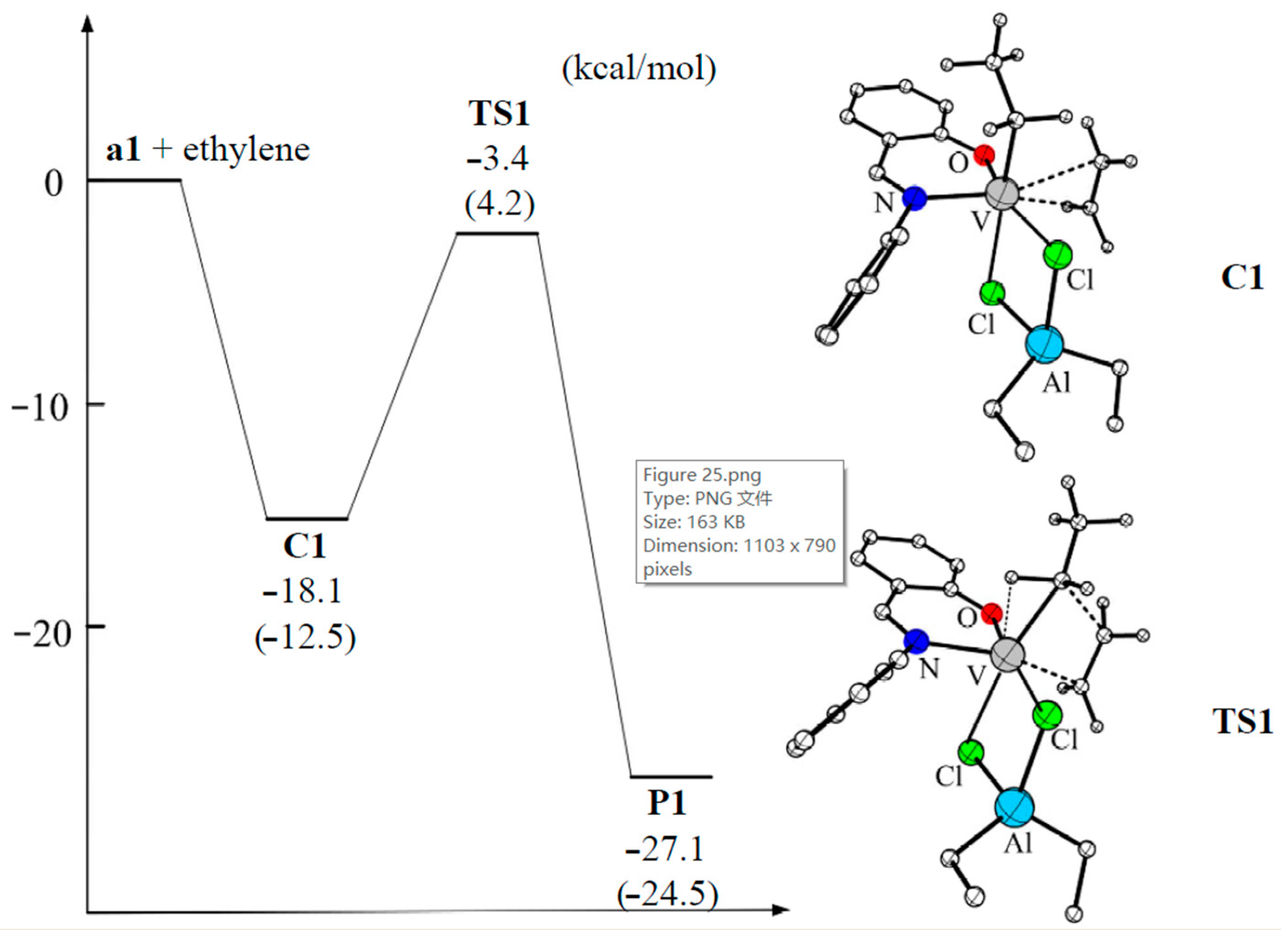

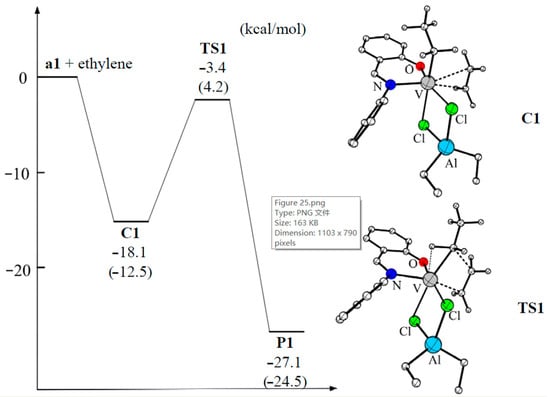

V(III) complexes bearing salicylaldiminato ligands (similar to V04), synthesized by Lee et al. [209,210], also showed high activity when using Et2AlCl as an activator. In their later work [211], these same authors reported the results of theoretical studies of the mechanism of ethylene polymerization with V04-type complexes. Actually, V04 was chosen for DFT calculations, together with the consideration of Et2AlCl-free species, in the modeling of ethylene insertion in the framework of the Cossee–Arlman mechanism (Figure 25). In the first step, the ethylene molecule coordinates to the vacant site in V04, forming a π-complex (–18.1 kcal·mol−1). Subsequently, ethylene inserts into the vanadium–carbon bond via the four-membered cyclic transition state which has an activation energy barrier of 14.7 kcal·mol−1 relative to the π-complex. The overall ethylene insertion was found to be highly exothermic (–27.1 kcal/mol), and insertion product resembled the starting structure of V04. For hypothetical cationic active species [(PhN=CHC6H4O)VEt(THF)]+, ethylene complexation was less exothermic and the insertion barrier was higher by 5.7 kcal/mol. An additional argument in favor of the V–(μ-Cl)2–Al model was a clear correlation between the results of modeling and polymerization experiments for V(III) complexes with substituted salicylaldiminato ligands.

Figure 25.

Potential energy surface and optimized geometries of the π-complex and transition state of the ethylene insertion catalyzed by the active species V04. The energy was calculated at the M06-L functional level, with energy changes calculated at the B3LYP-D3 functional level given in parentheses. Reprinted with permission from [211]. Copyright (2015) Elsevier B.V.

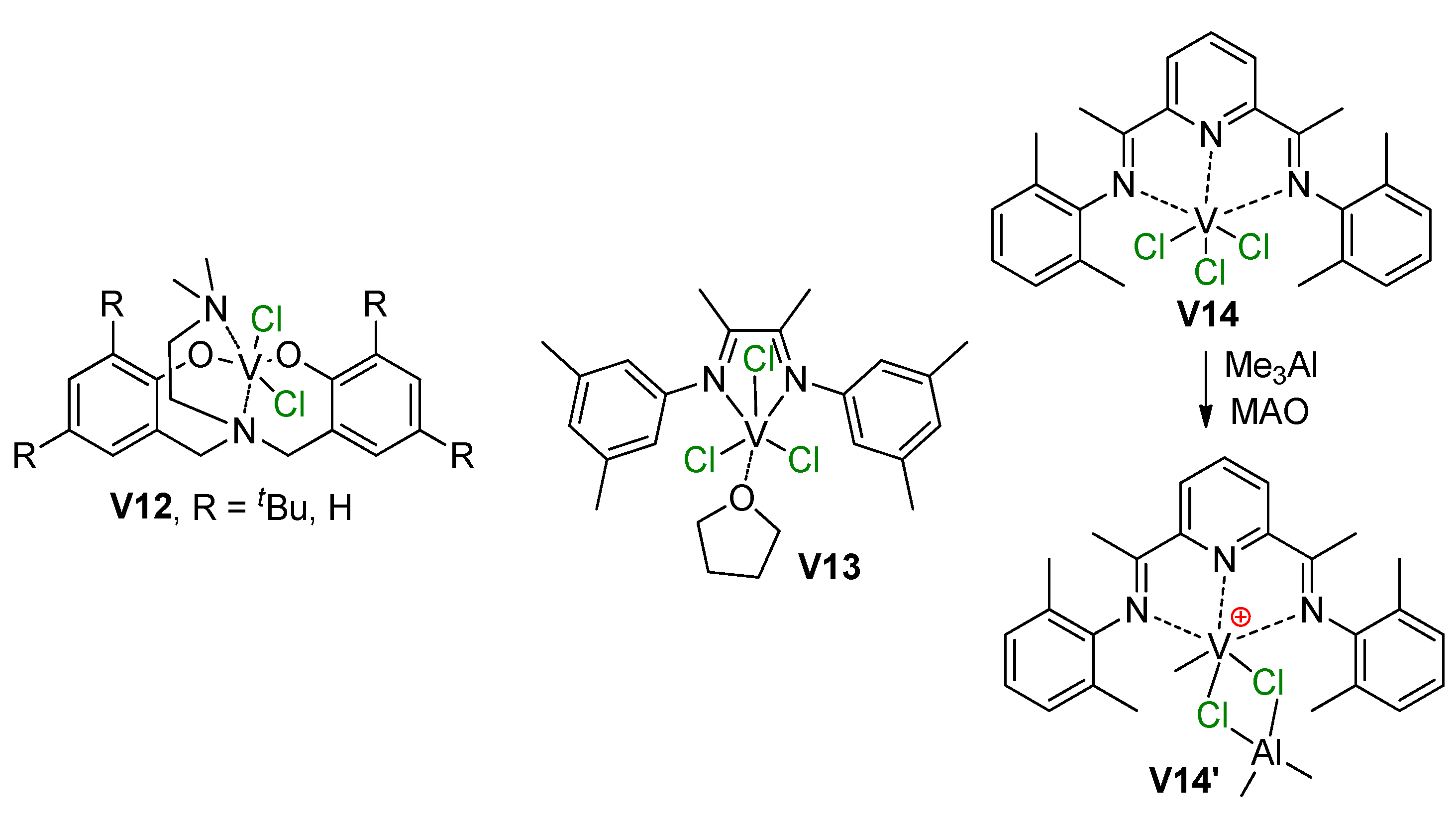

The results of relatively recent studies on V-catalyzed polymerization also confirm a distinct ‘chlorine effect’. In this regard, the study by Białek and Bisz [212] deserves a separate mention. In the polymerization of ethylene, ONNO-type bis(phenolates) V12 (Scheme 30) were manyfold more active in the presence of Et2AlCl in comparison with MAO and perfluoroaryl borates. In ethylene/oct-1-ene copolymerization, the difference in activities decreased when using Et2AlCl and 3Bu3Al/[Ph3C][B(C6F5)4], but higher comonomer incorporation was observed in the first case.

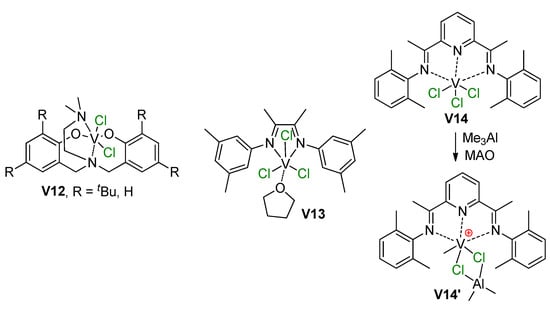

Scheme 30.

V(III) pre-catalysts V12–V14 studied recently [212,213] and the formation of V–(μ-Cl)–Al cationic active species, confirmed by NMR experiments [213].

In 2018 [213], Talsi et al. reported the results of the study of α-diimine (V13) and bis(imino)pyridine (V14) trichloro complexes of V(III) (Scheme 30) with the use of MAO, Me2AlCl, Me2AlCl/[Ph3C][B(C6F5)4], and Me3Al/[Ph3C][B(C6F5)4] activators. Through careful NMR experimentation, they demonstrated the formation of V13-based cationic complexes without V–(μ-Cl)–Al bonding, whereas V14 formed V(Me)–(μ-Cl)2–Al species V14′. Notably, when Me2AlCl alone was used, an inactive V(Cl)–(μ-Cl)2–Al complex was the main reaction product.

In a series of recent publications [214,215,216], Nomura et al. presented the results of the study of the activation of V complexes with the use of V K-edge X-ray absorption near-edge structure analysis (XANES) and extended X-ray absorption fine structure (EXAFS) analysis. Regarding V(V) pre-catalysts of (imido)VCl2(OAr), (imido)VCl3, and similar types, as well as VOCl3, these studies clearly indicated the presence of V(III) species in the reaction mixture after activation by the organoaluminum compounds Me2AlCl, Et2AlCl, and EtAlCl2. In this way, the attribution of V03 (Scheme 26) to active species should be corrected. However, no significant changes in either the oxidation state or the basic geometry were observed when (imido)vanadium(V) complexes were treated with MAO. In this way, the role of R2AlCl is in both the formation and stabilization of catalytic species.

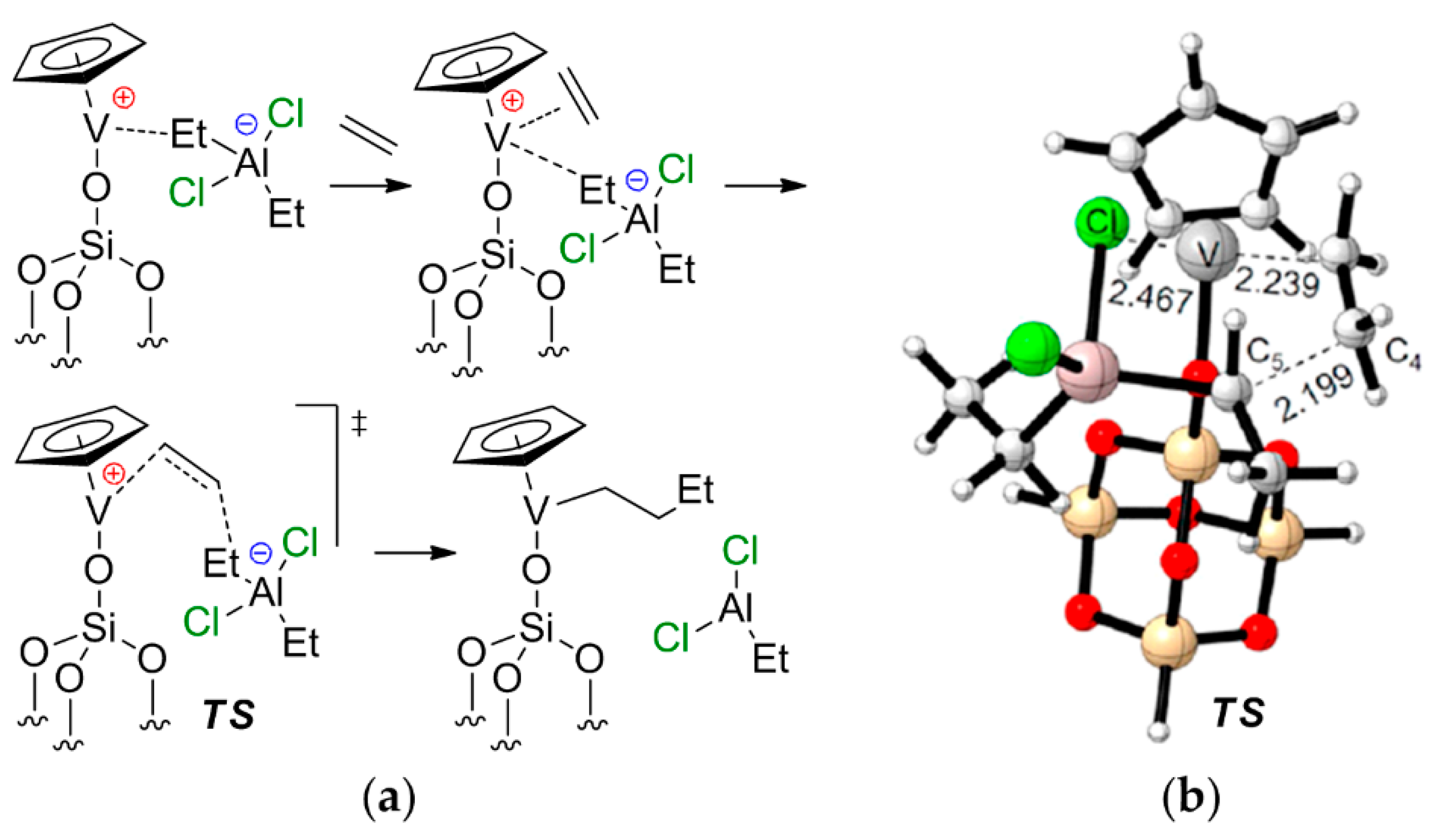

In conclusion, it should be noted that the chemistry of V-based single-site catalysts of α-olefin and diene polymerization primarily focuses on post-metallocene-type complexes. V-based catalysts exhibit some similarities to Ti(III) Ziegler–Natta catalysts (see V07 in Scheme 27); however, half-sandwich and sandwich complexes of V have not found wide application. What is more interesting is the possible role of V–(μ-Cl)–Al bonding in the catalytic behavior of Cp-ligated complexes of vanadium. Recent qualitative research of the catalytic activity of supported Cp2V, carried out by Liu et al. [217], sheds some light on the issue. The authors suggested the formation of cationic CpV–O–Si(μ-O)3(silica) species under the action of Et2AlCl, and proposed a non-trivial mechanism of ethylene coordination/insertion with a marked V–Al cooperative effect (Figure 26). The stages of chain initiation and release were also studied. The activation barrier of the chain propagation was found to be ~16 kcal·mol−1.

Figure 26.

(a) Proposed mechanism of ethylene coordination/insertion on the supported CpV–Et2AlCl complex; (b) optimized geometry of the key transition state. Reprinted with permission from [217]. Copyright (2020) Elsevier B.V.

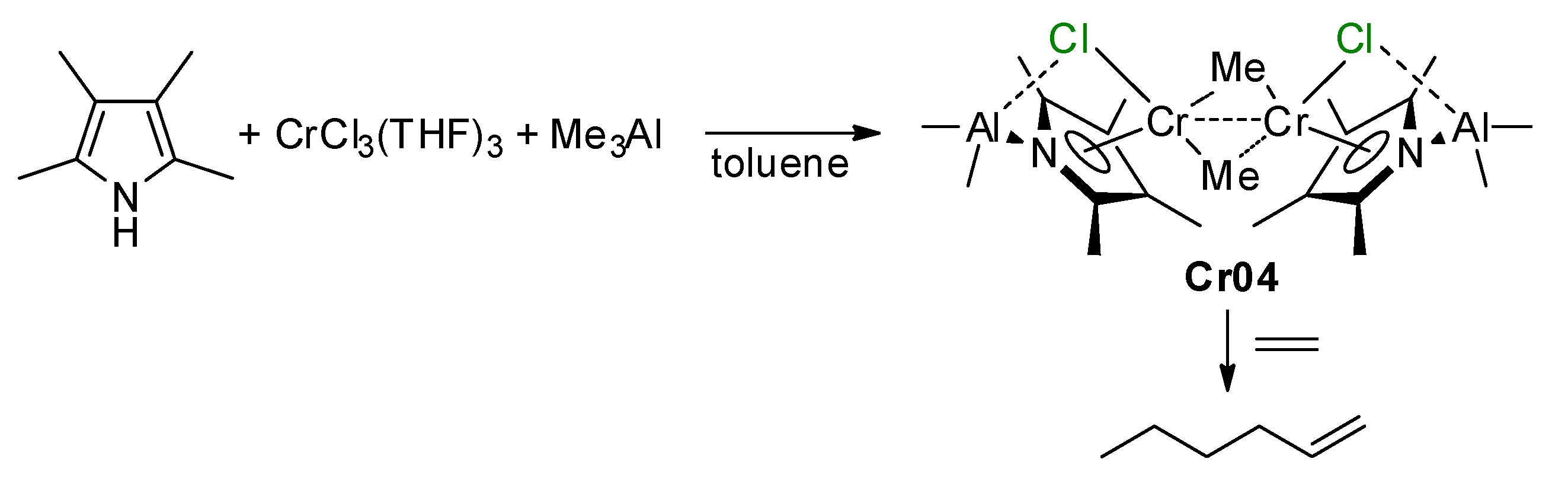

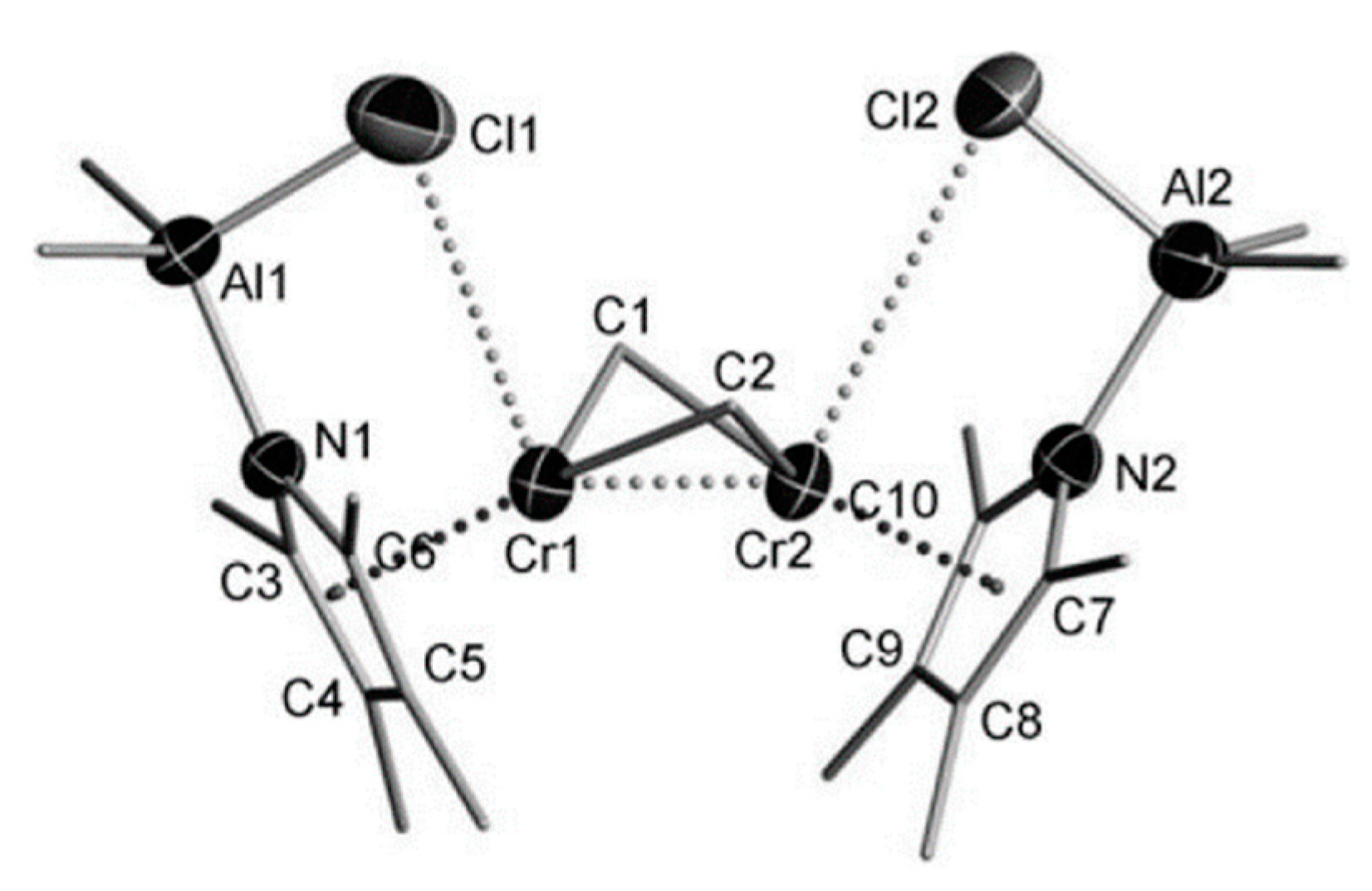

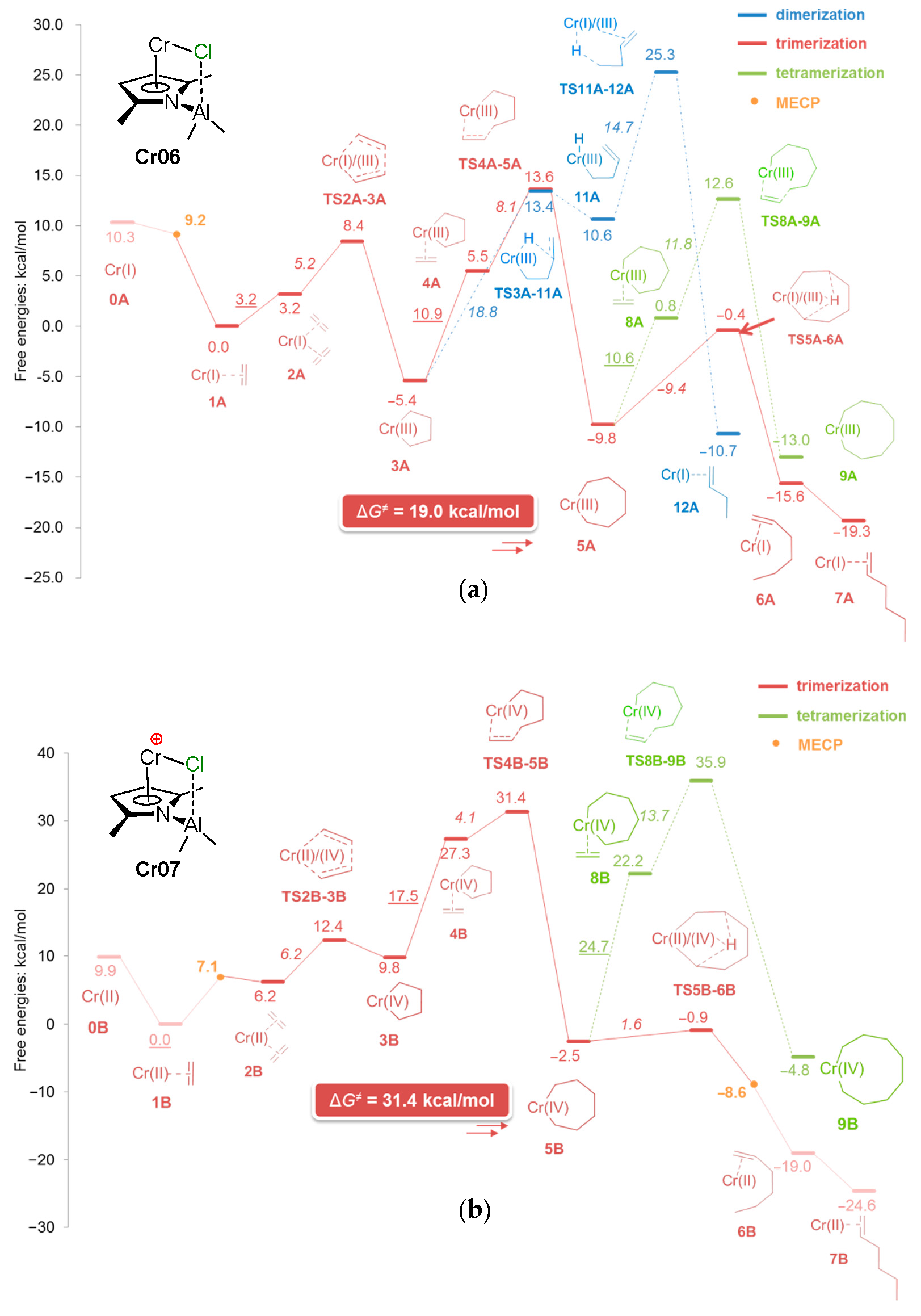

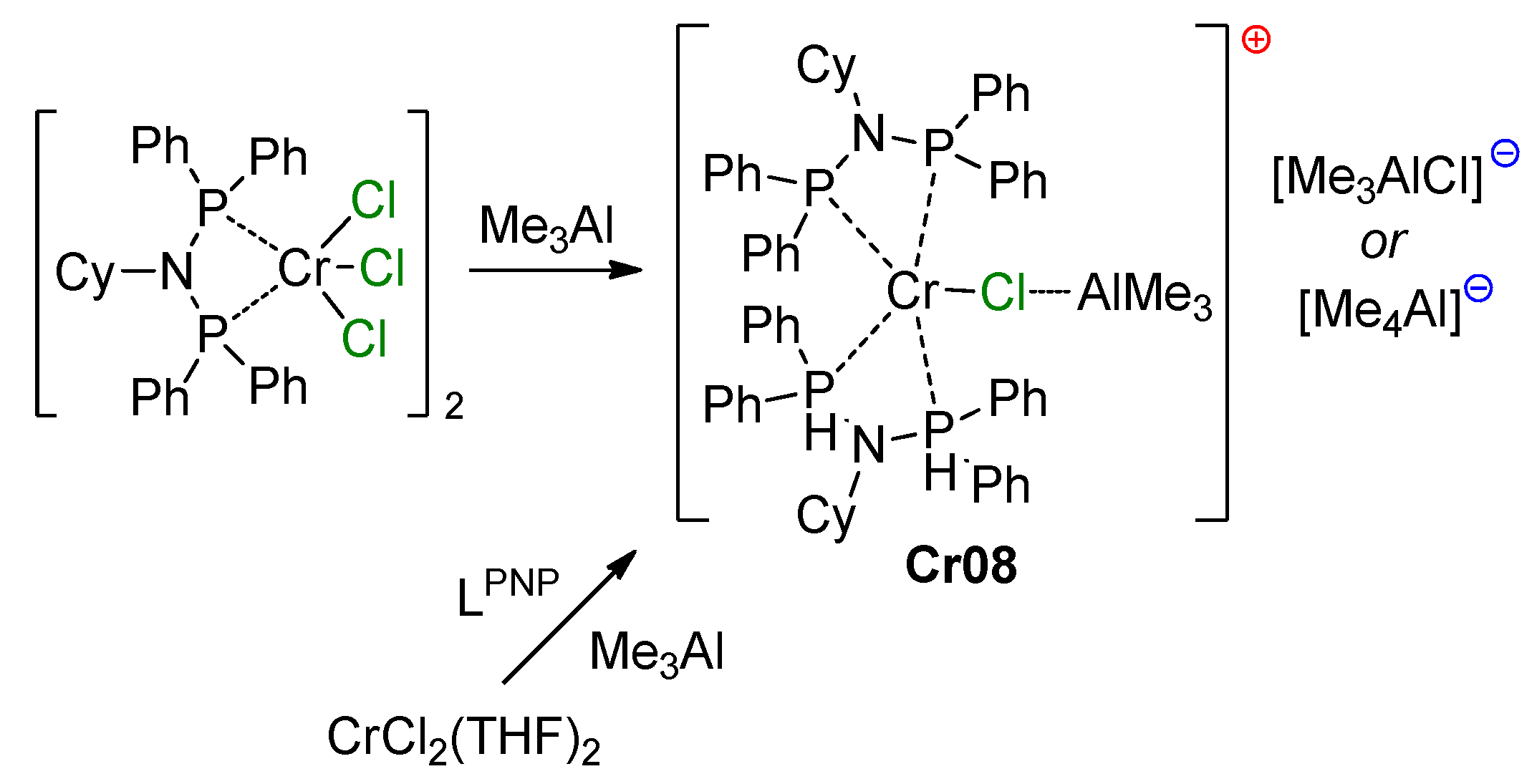

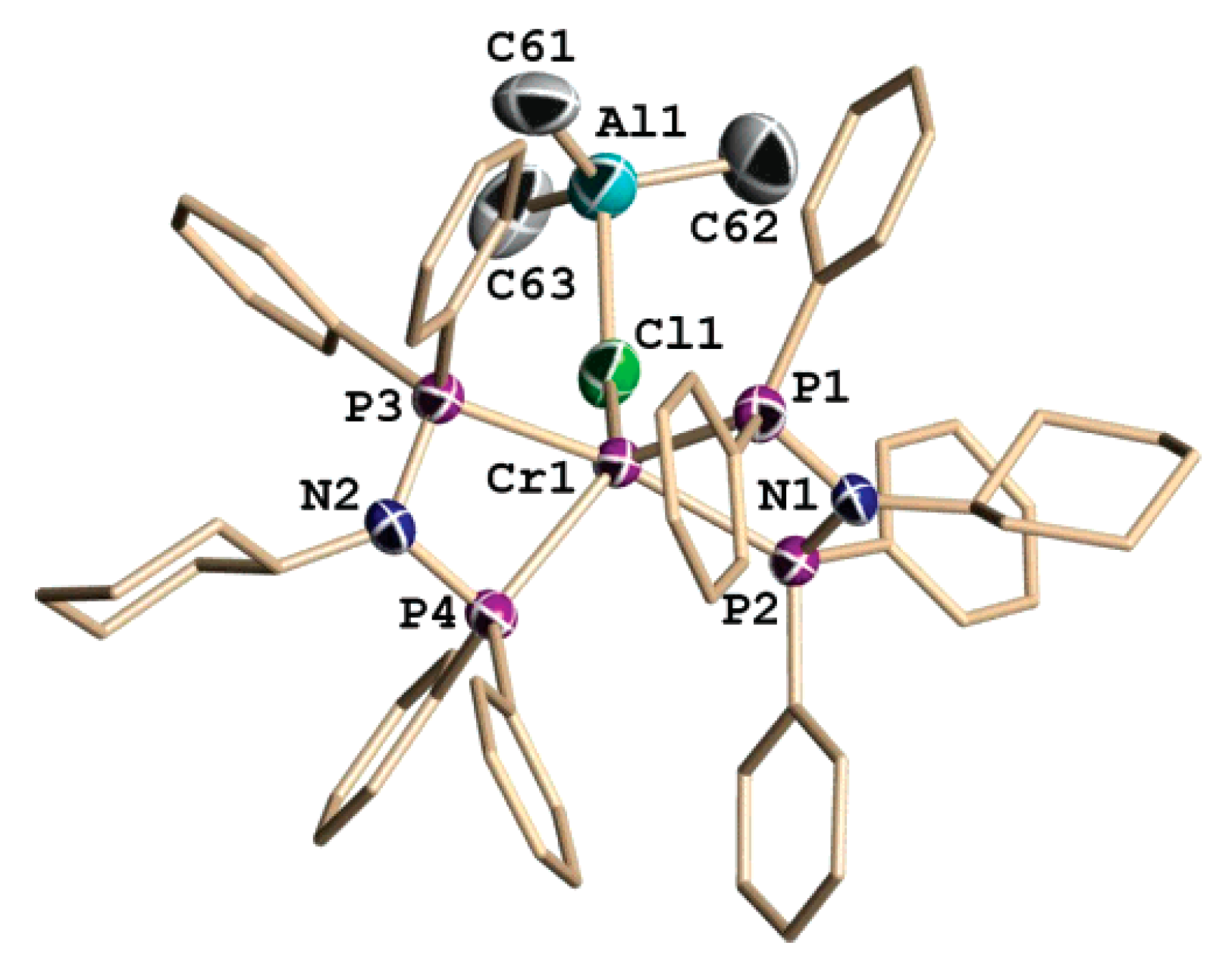

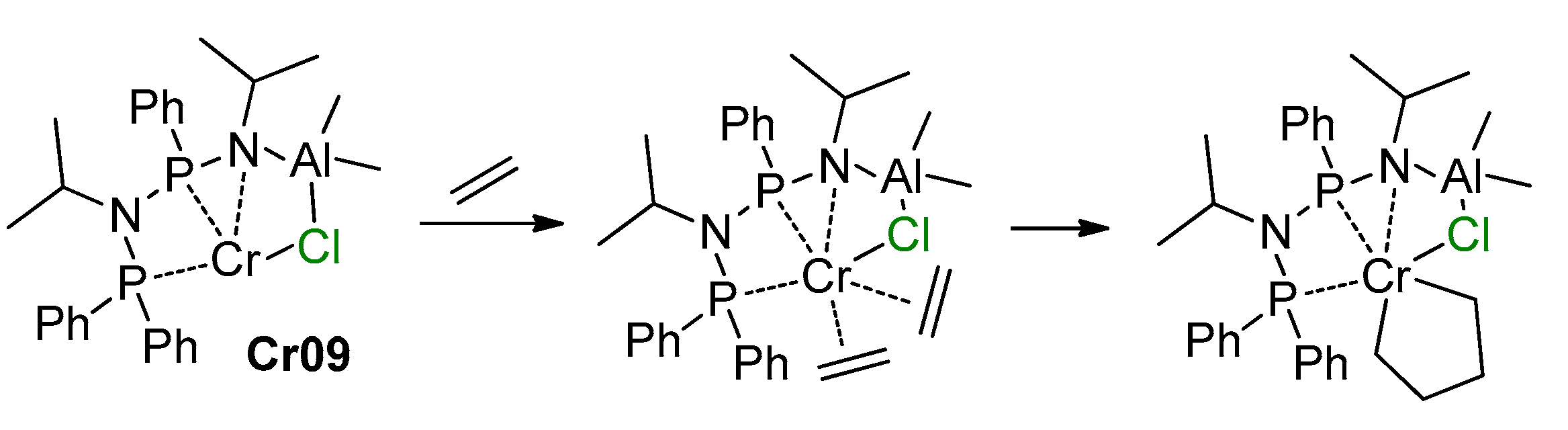

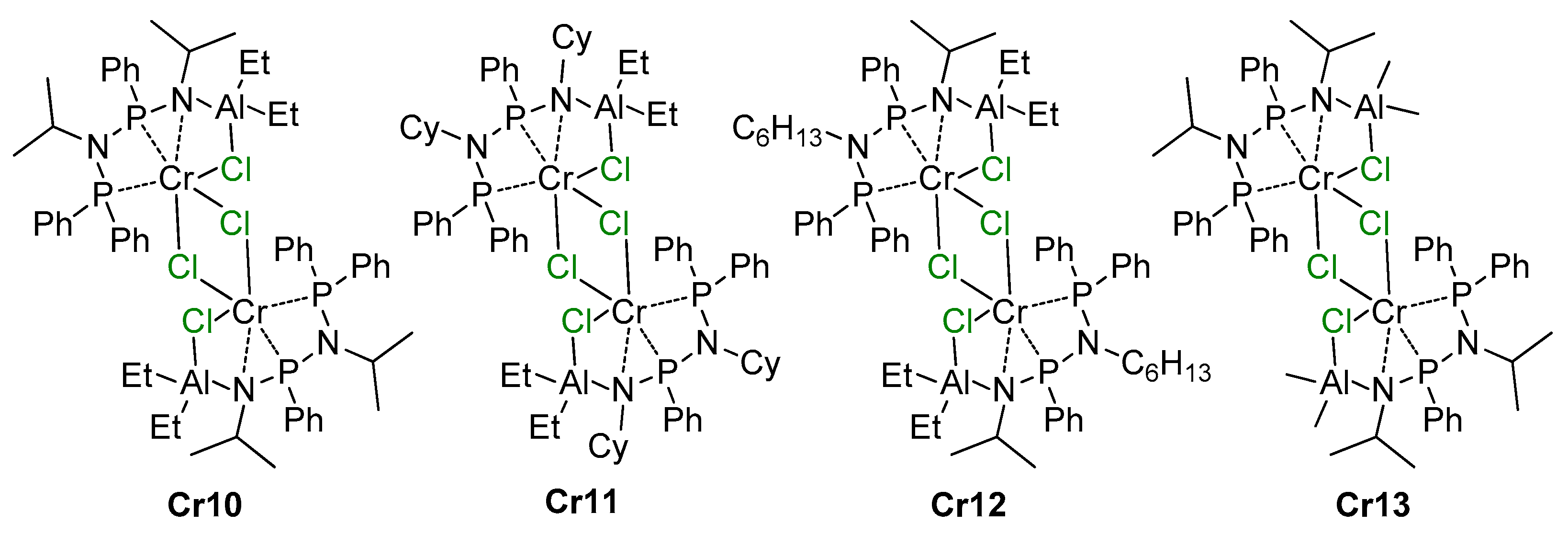

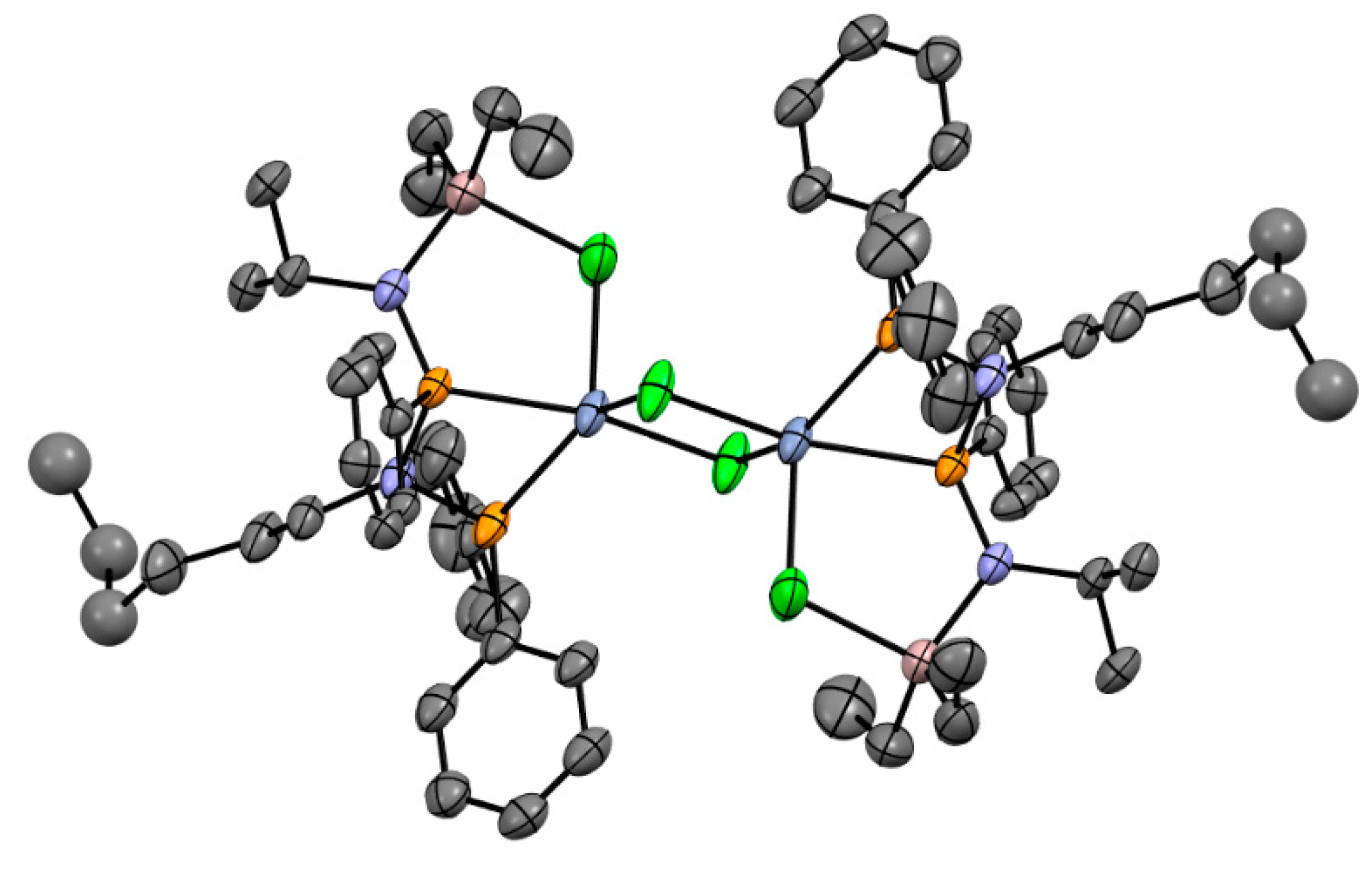

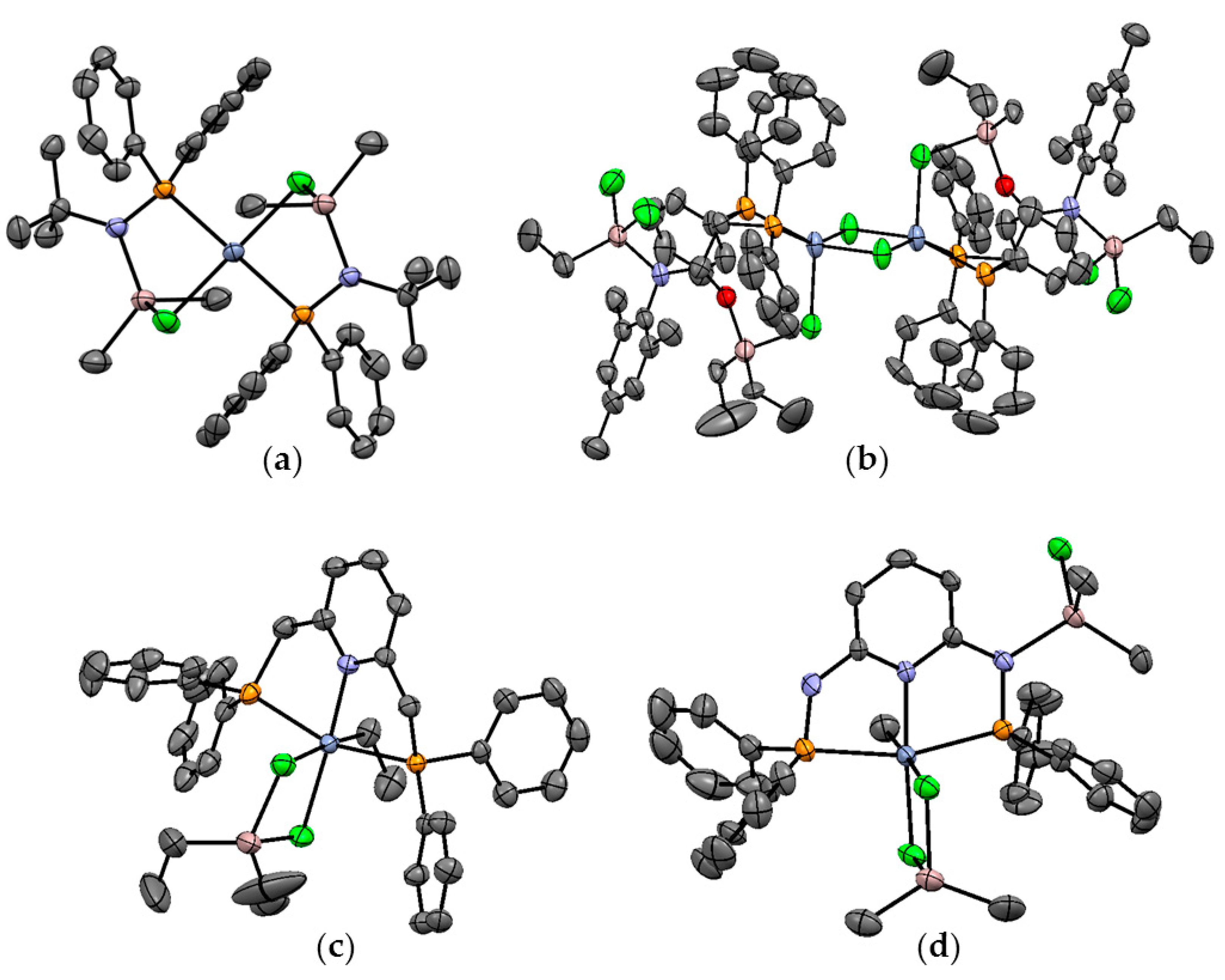

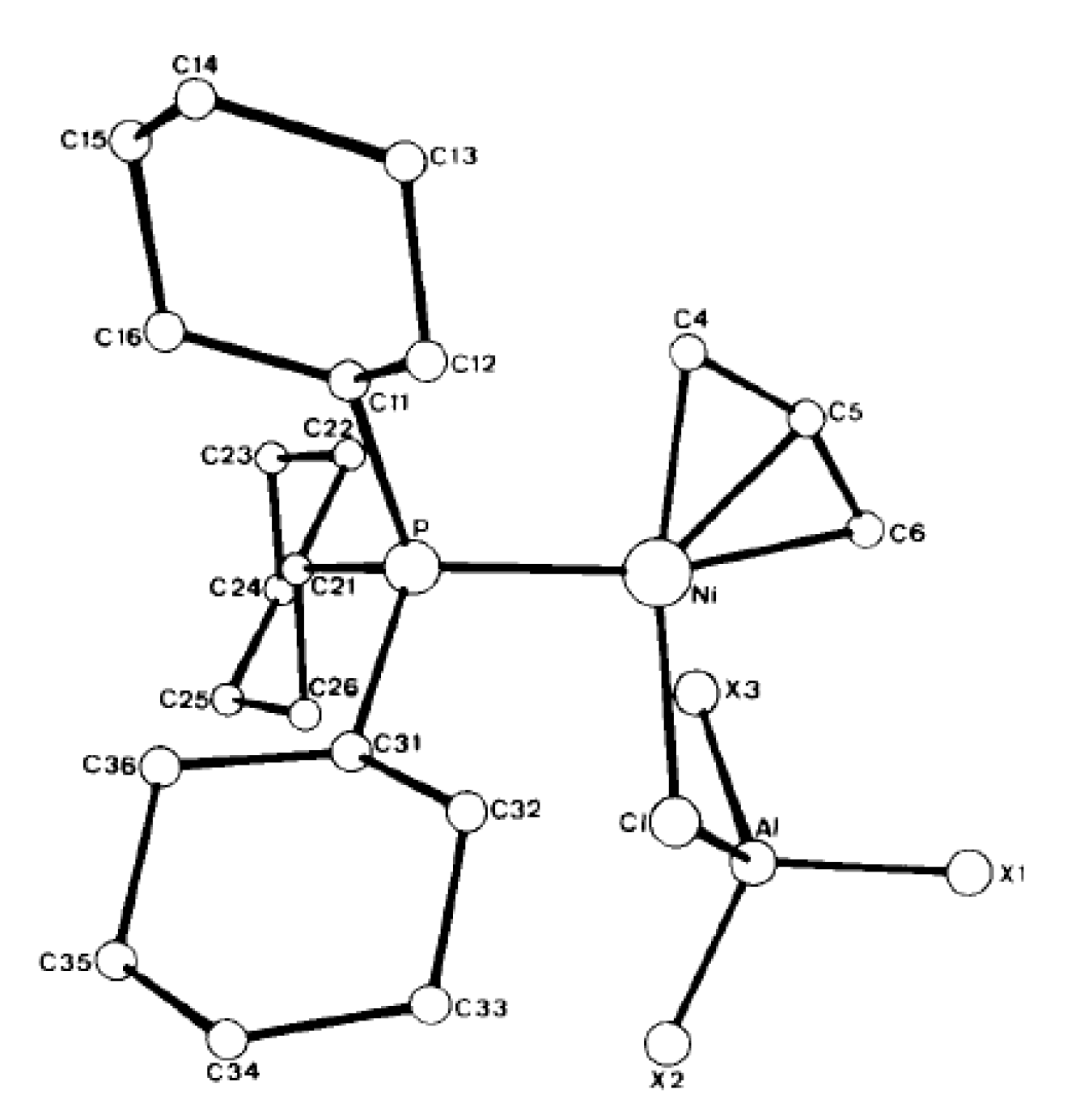

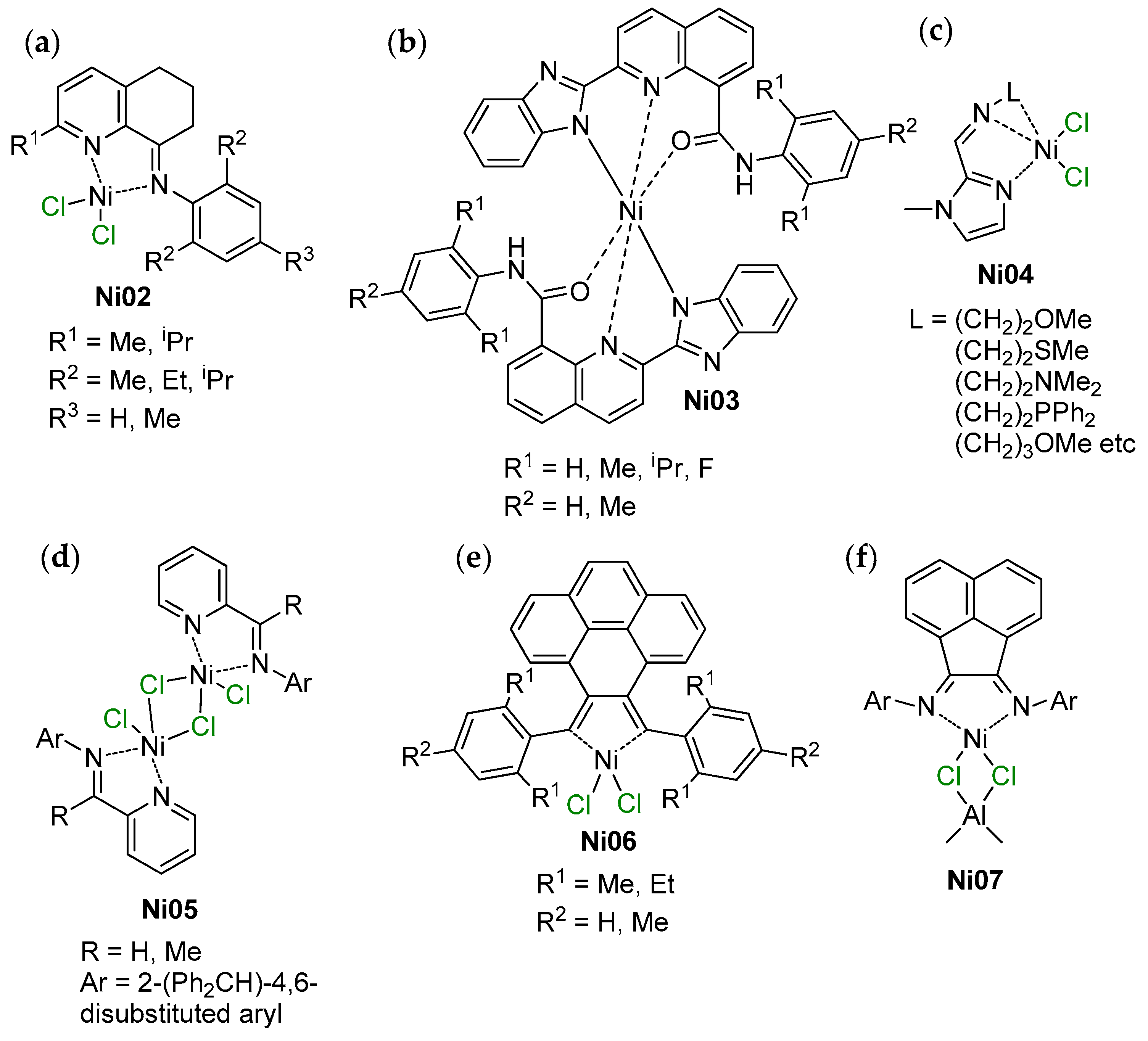

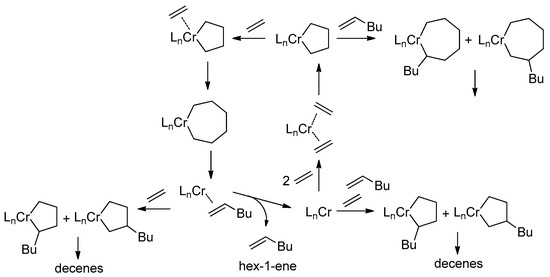

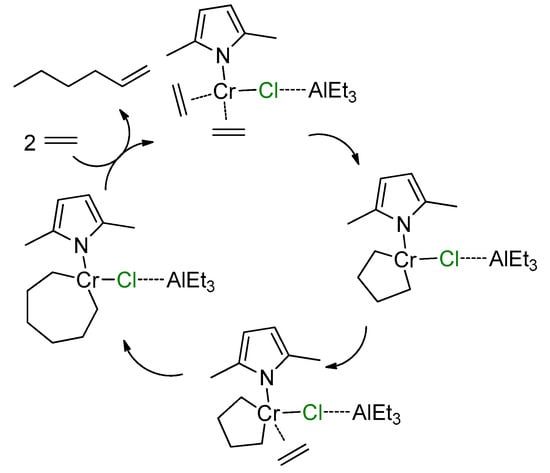

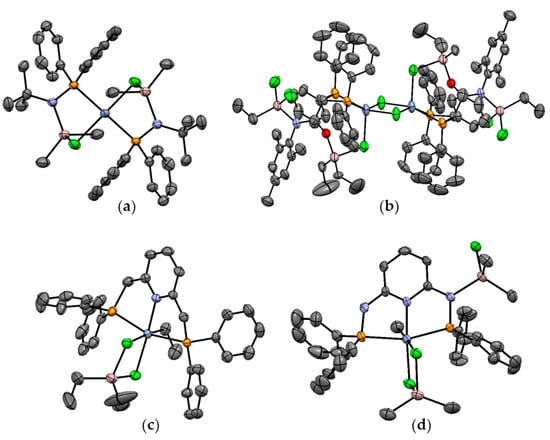

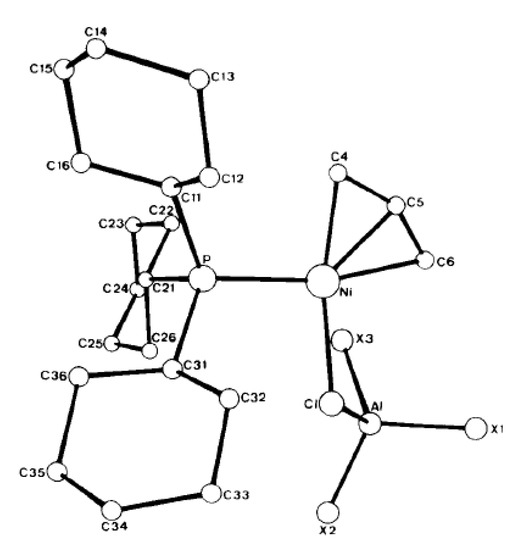

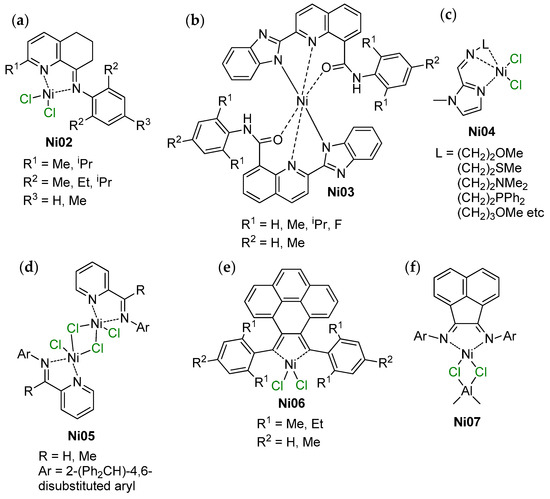

5. Complexes of Cr

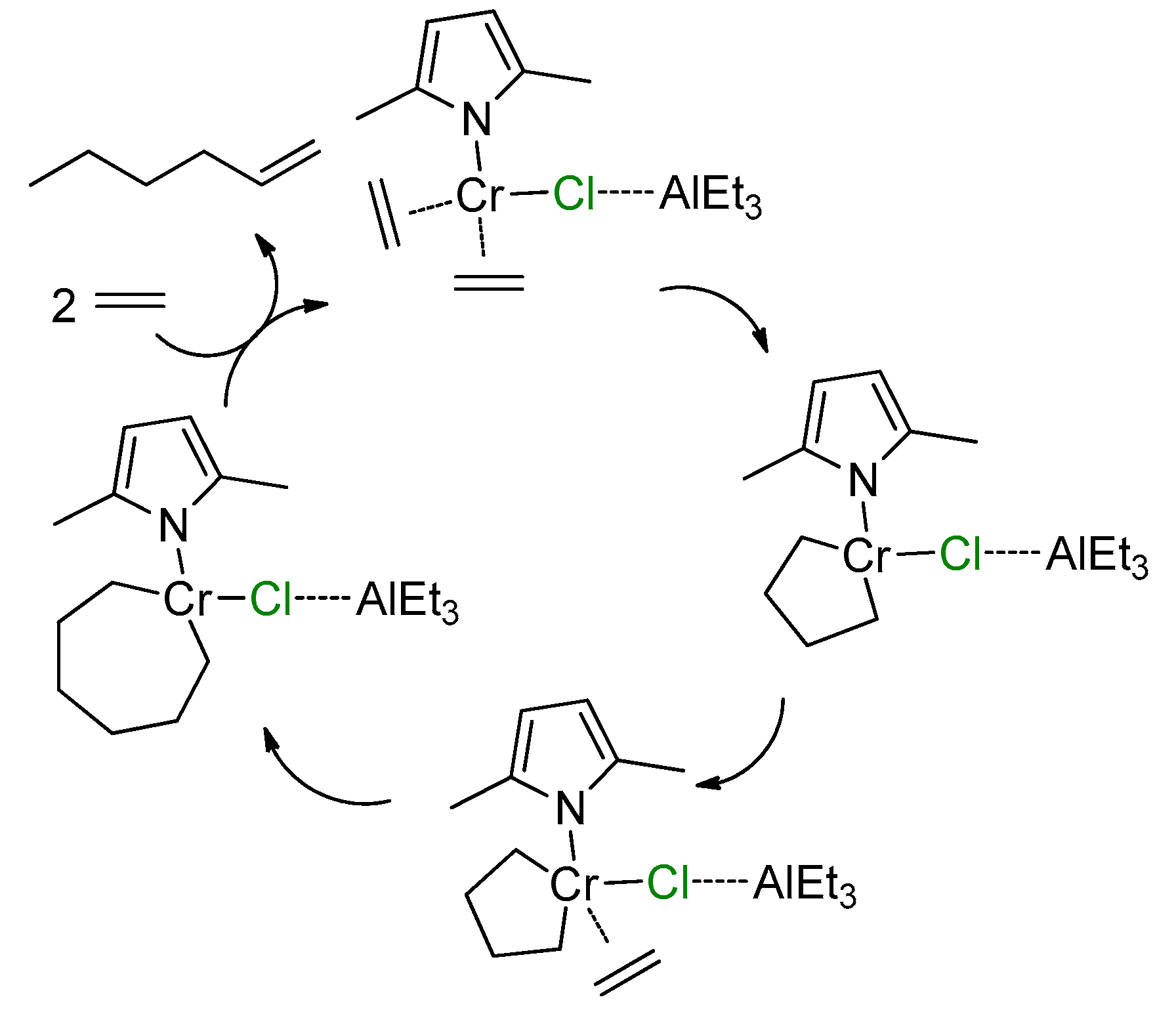

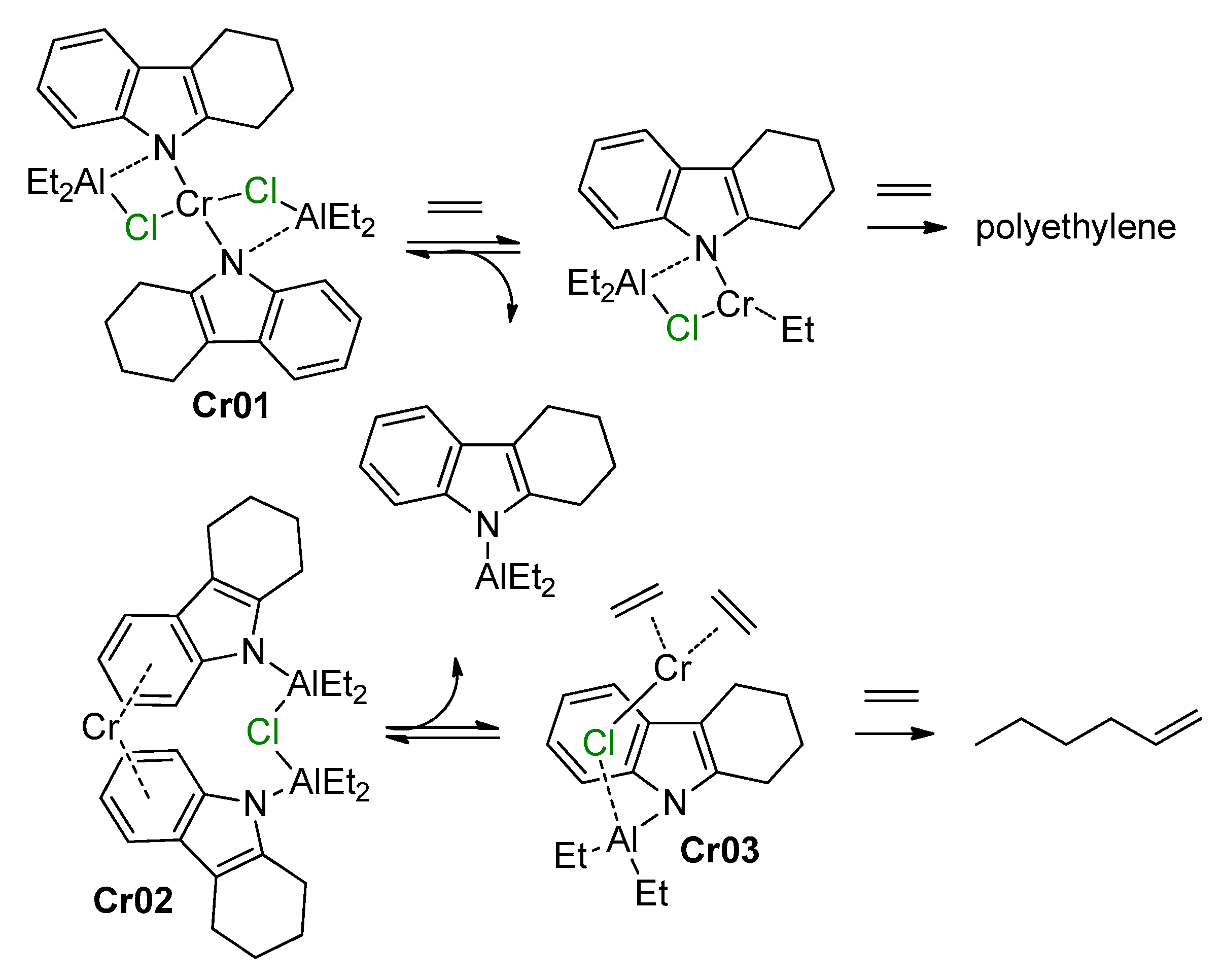

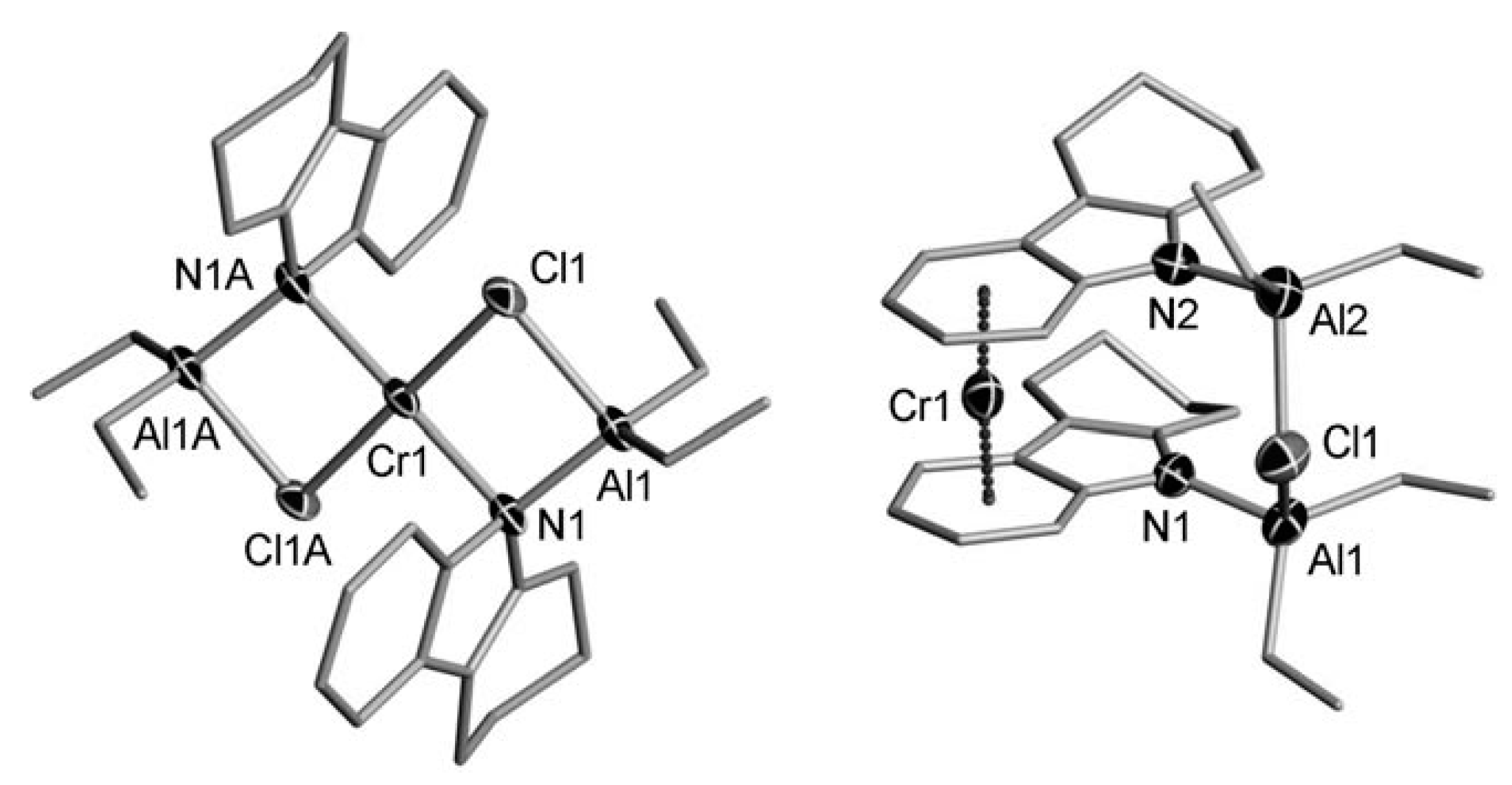

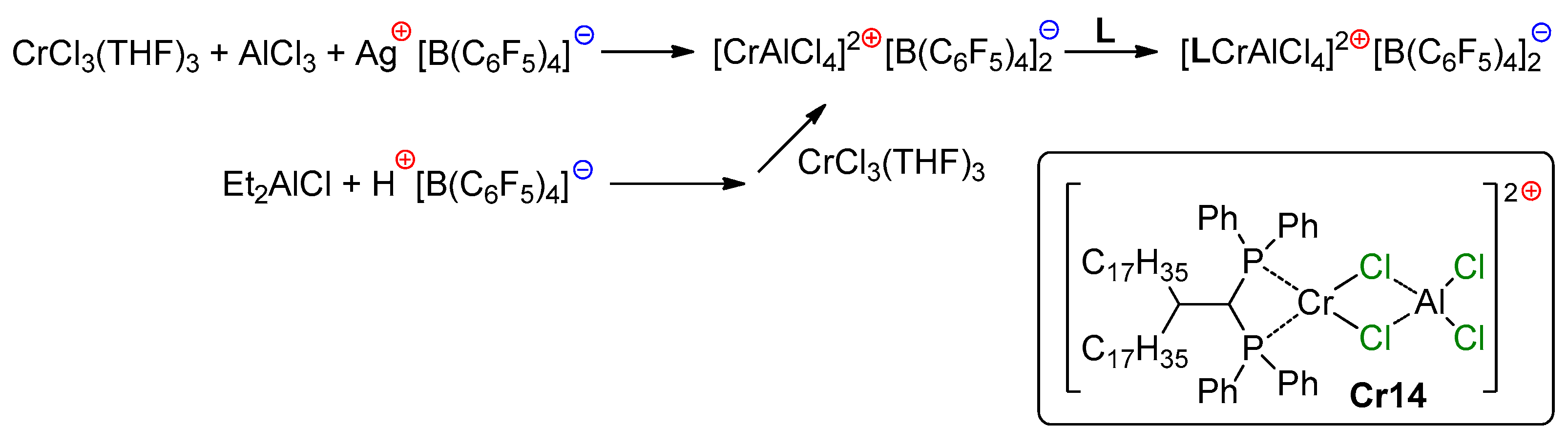

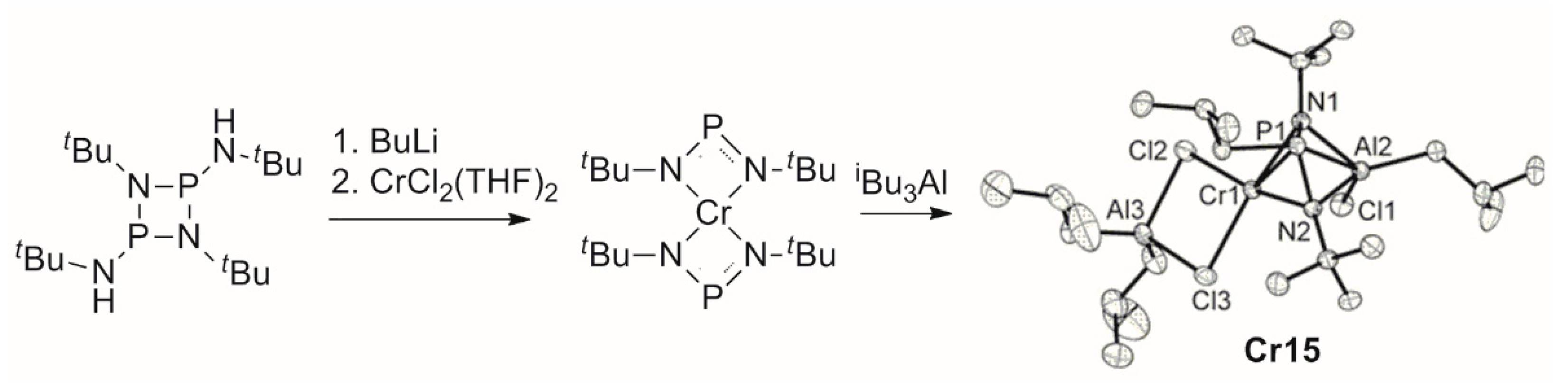

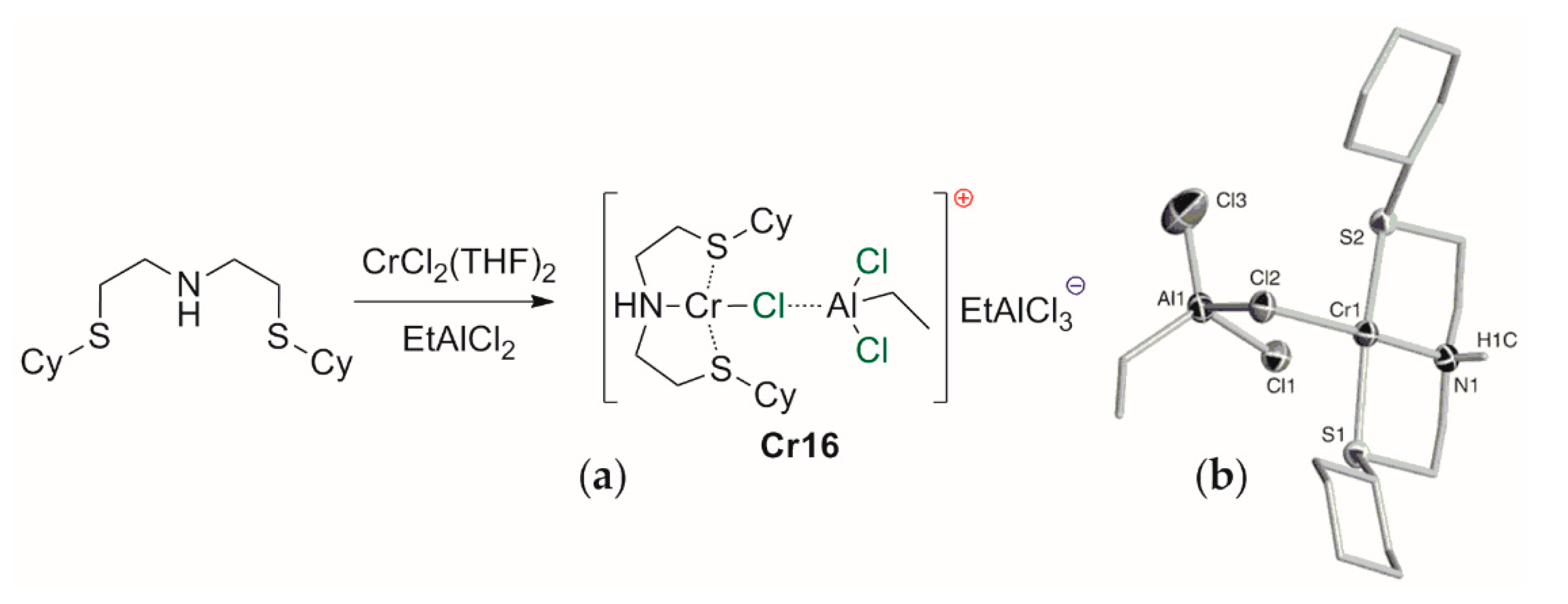

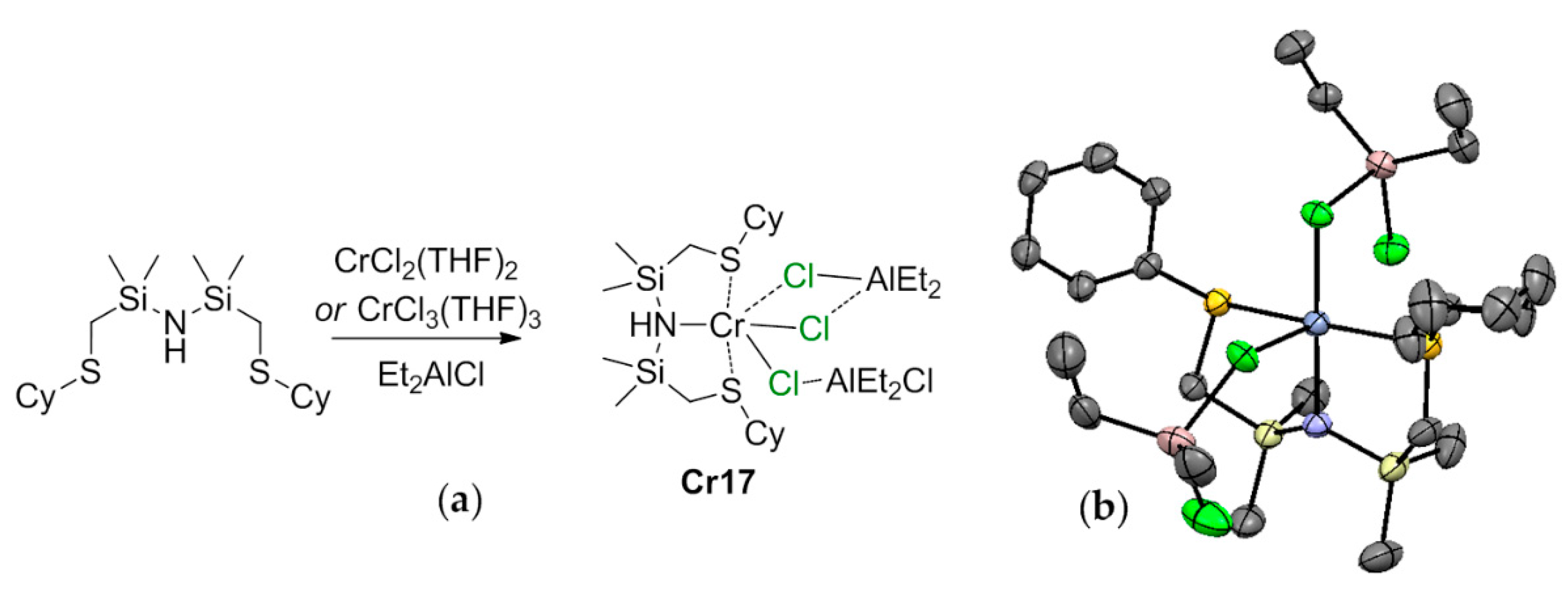

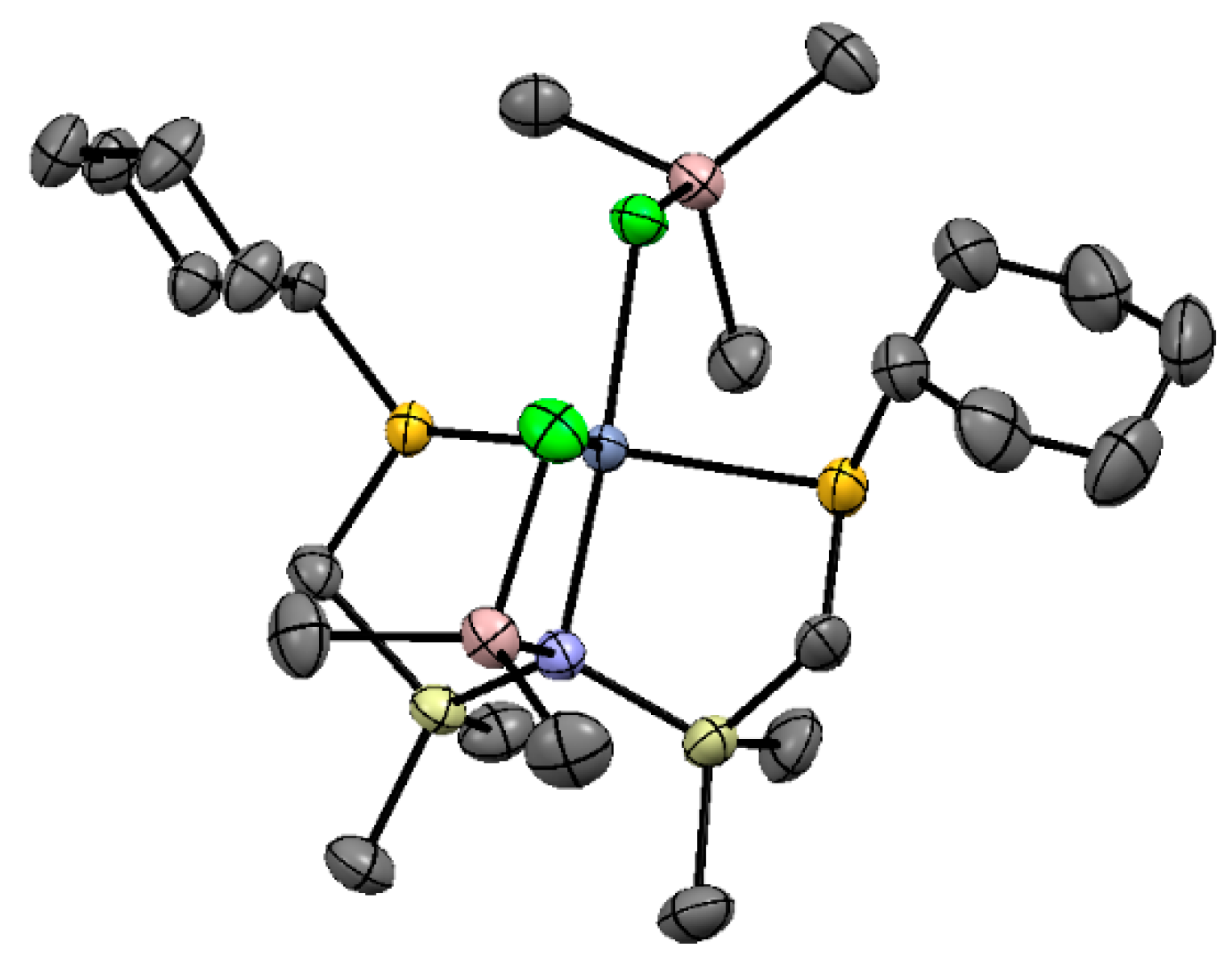

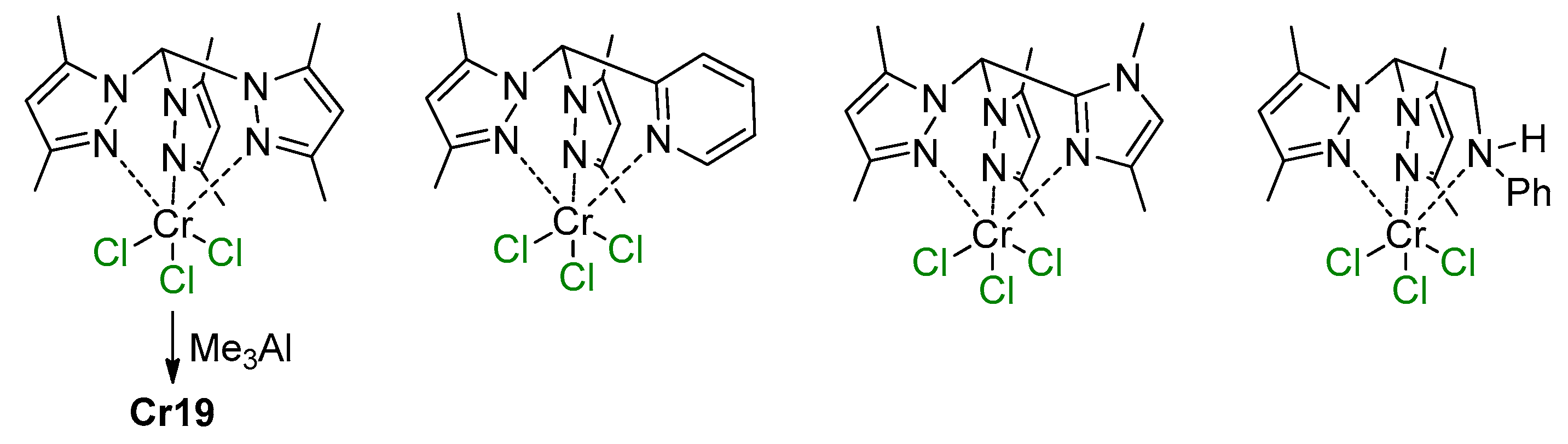

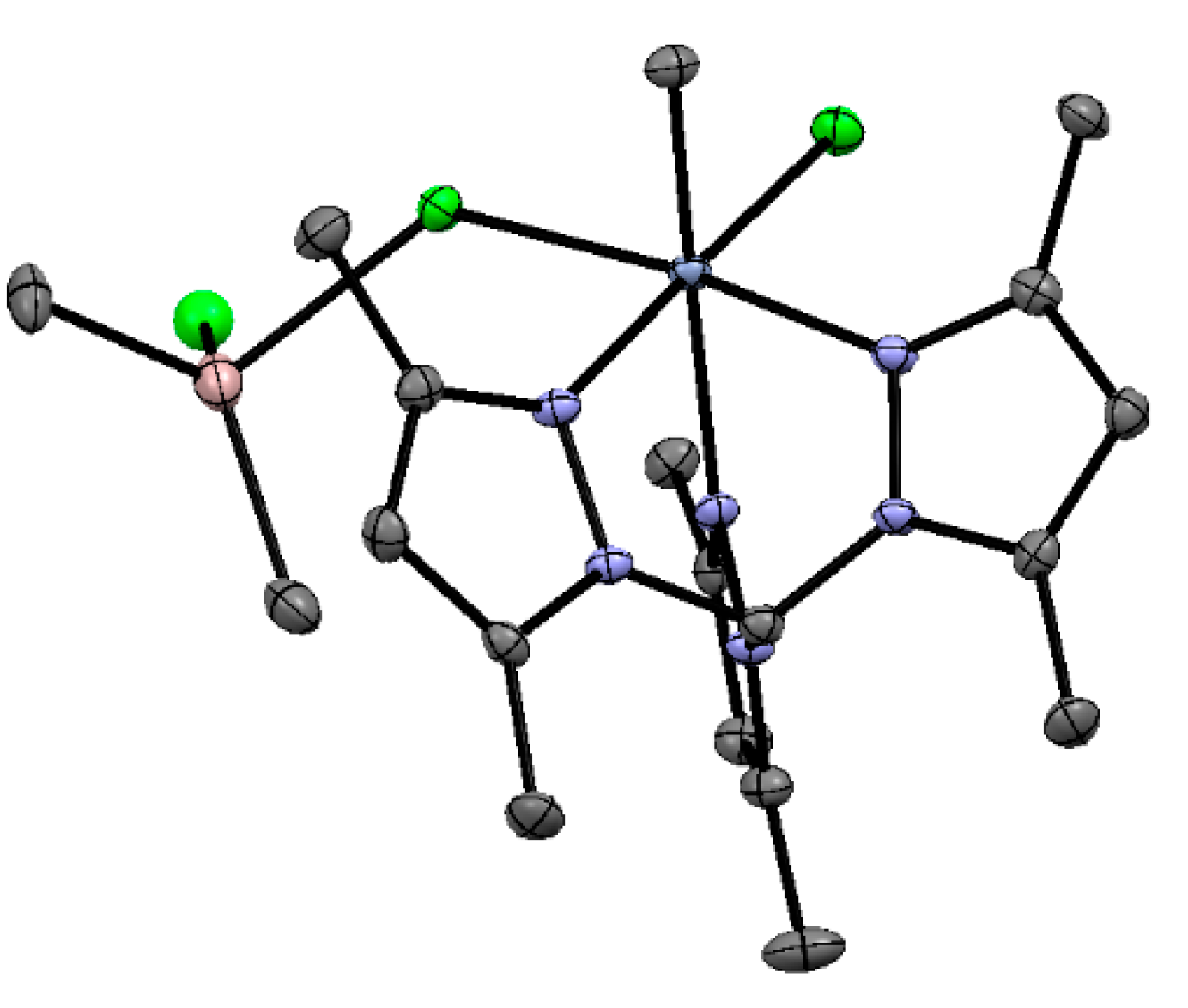

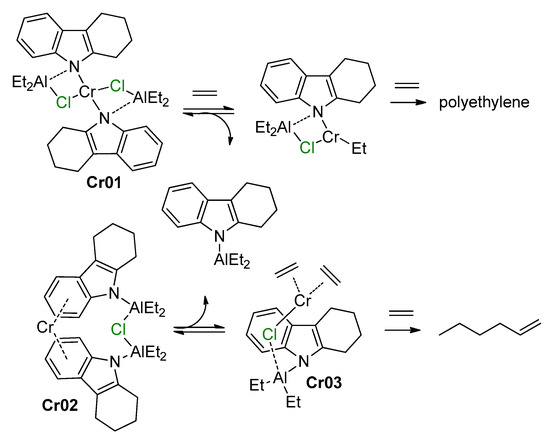

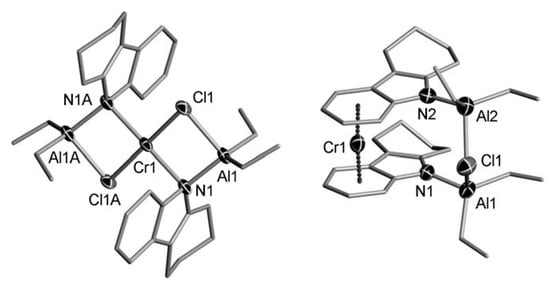

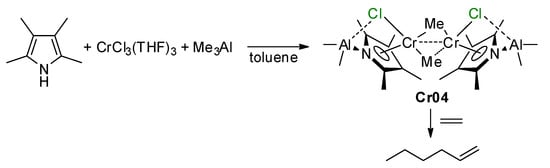

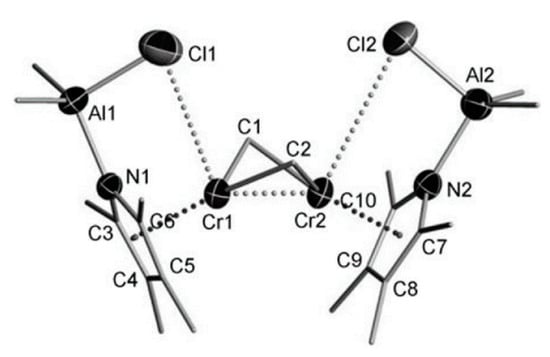

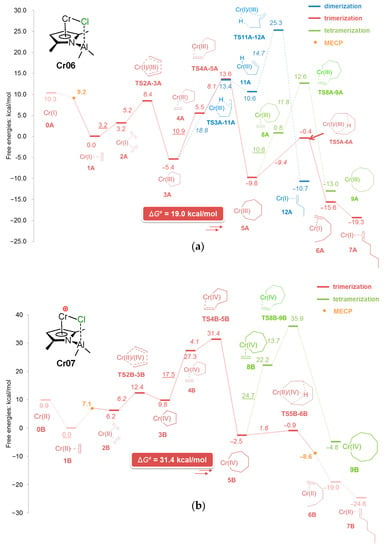

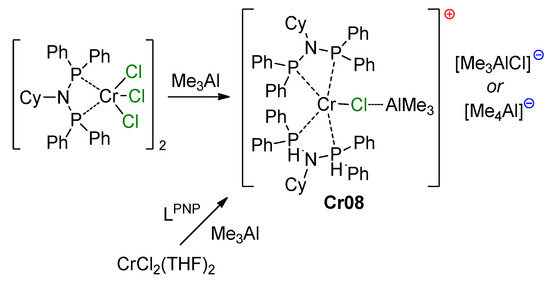

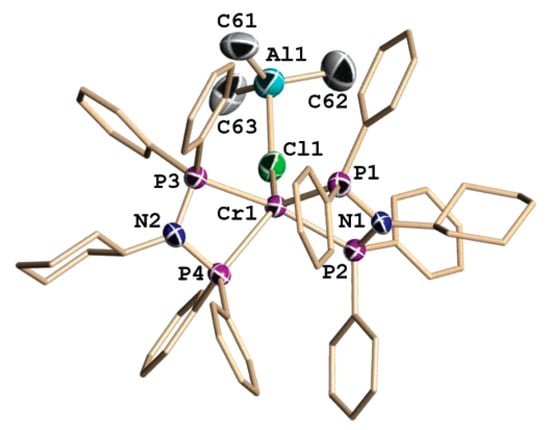

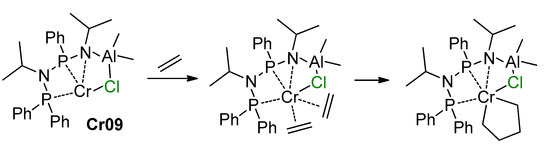

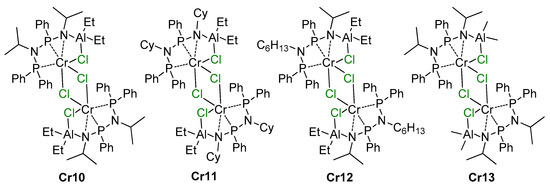

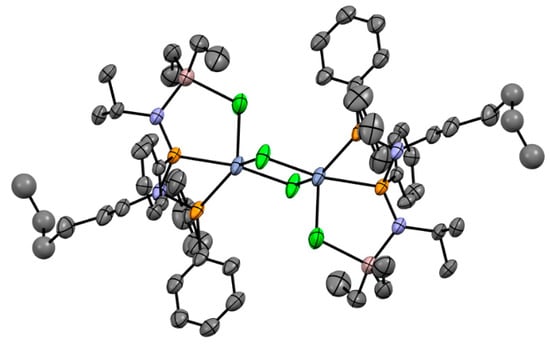

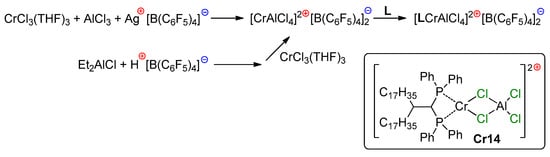

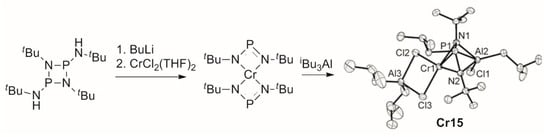

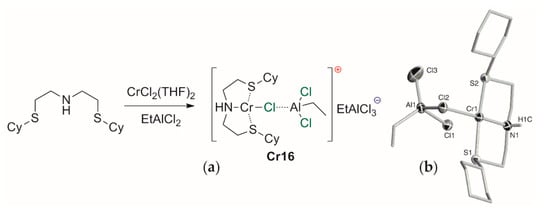

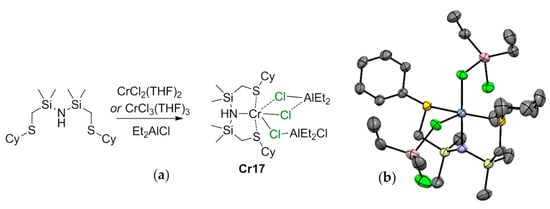

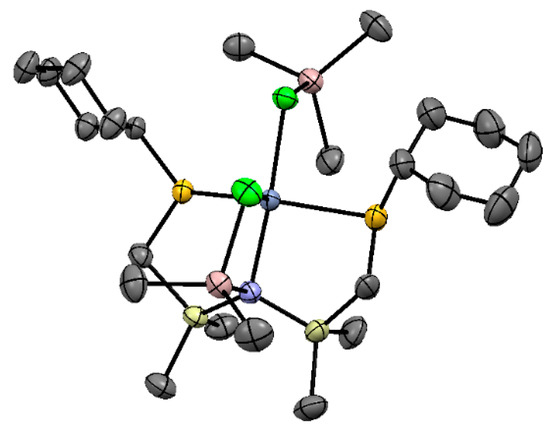

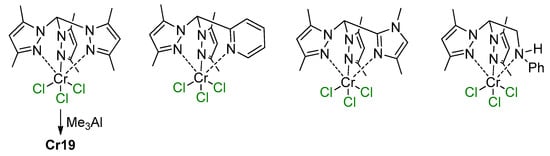

5.1. Selective Oligomerization of Ethylene Catalyzed by Cr Complexes