Photothermal-Driven Liquid Crystal Elastomers: Materials, Alignment and Applications

Abstract

:1. Introduction

2. LCE and LCE-Based Composite Material

2.1. LCE

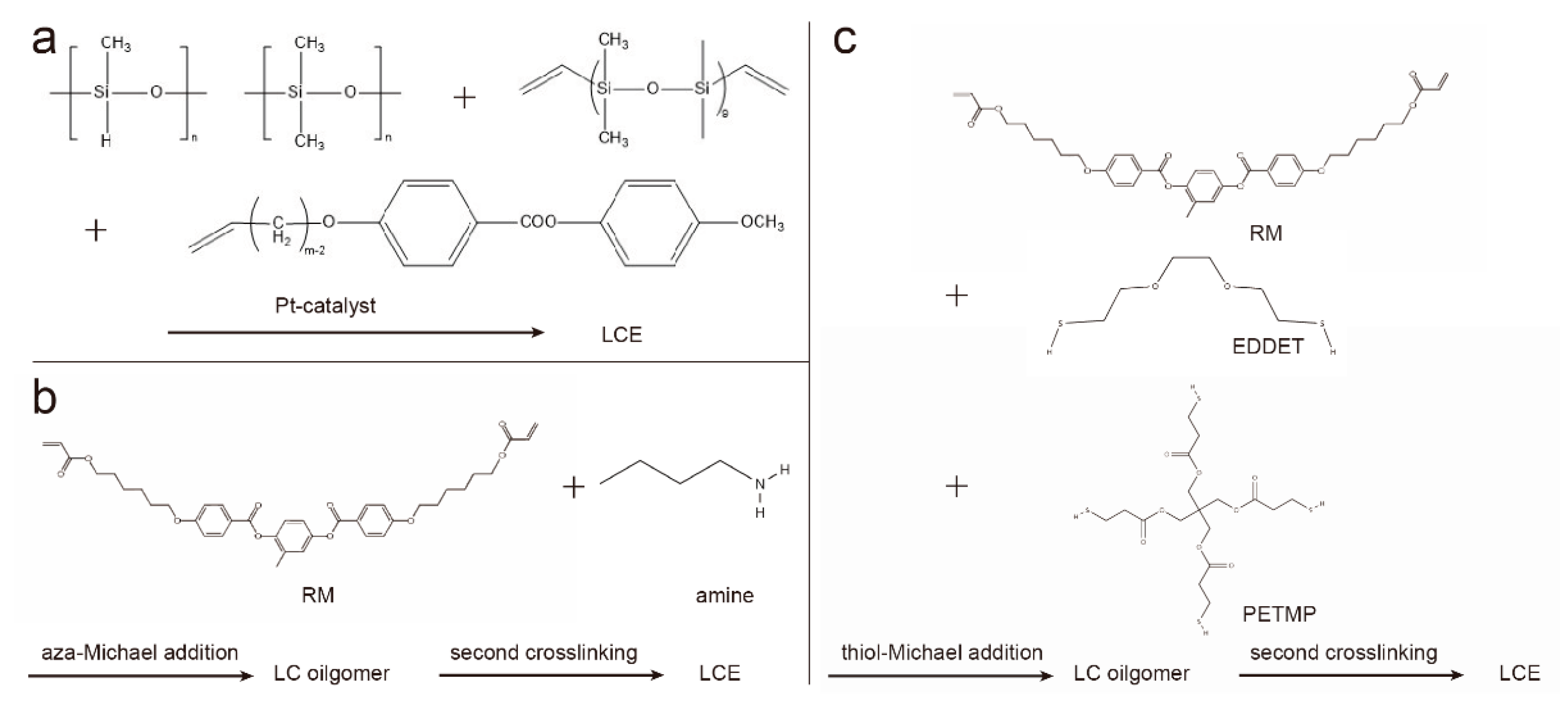

2.1.1. Two-Step Cross-Linking

2.1.2. One-Step Cross-Linking

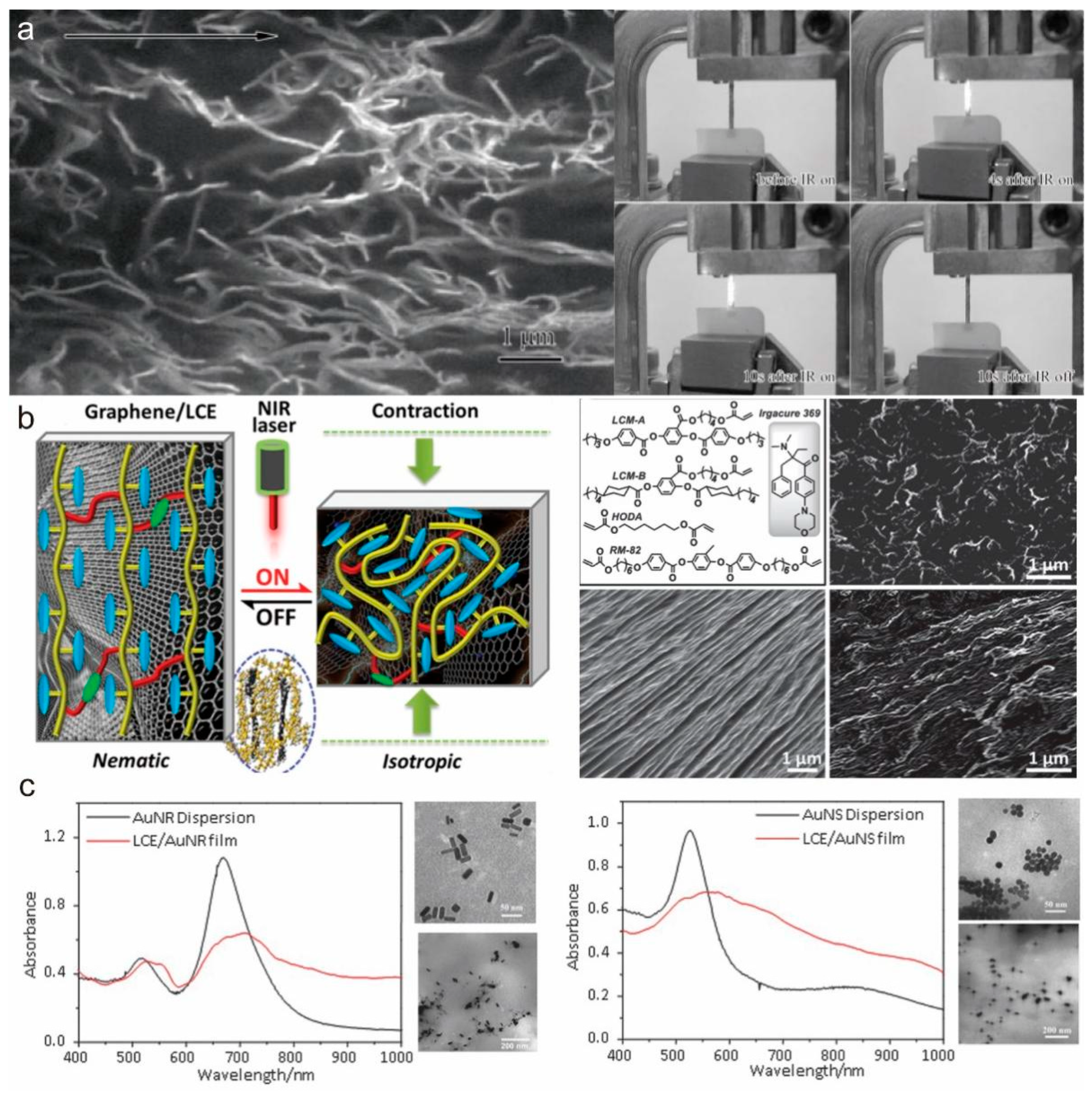

2.2. LCE-Based Composite Material

2.2.1. Carbon Based Material (CNT, Graphene, GO)

2.2.2. Metal Nanomaterial (AuNP, AuNR)

2.2.3. Organic Material (Organic Dye, PDA)

3. Alignment

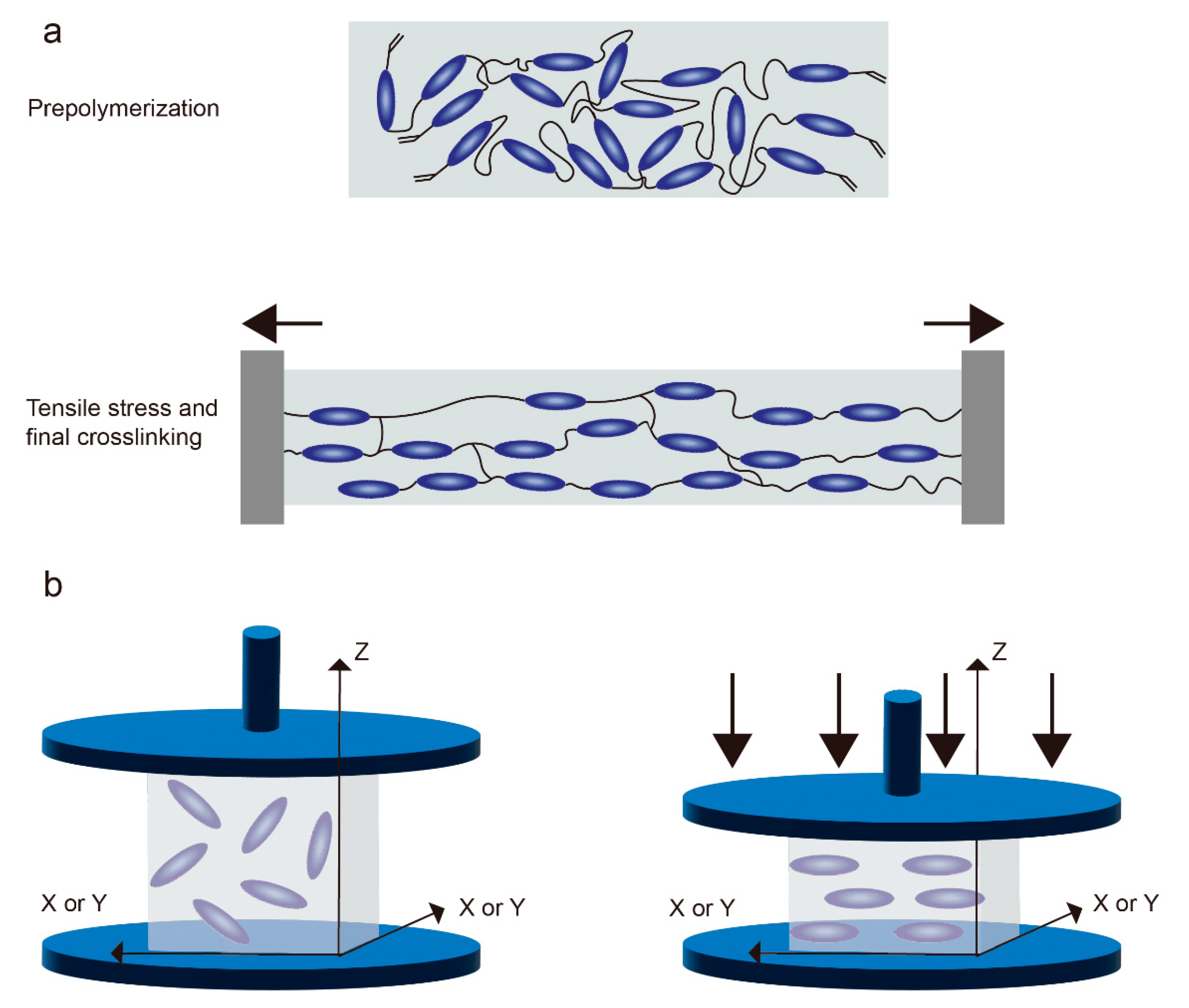

3.1. Mechanical Alignment

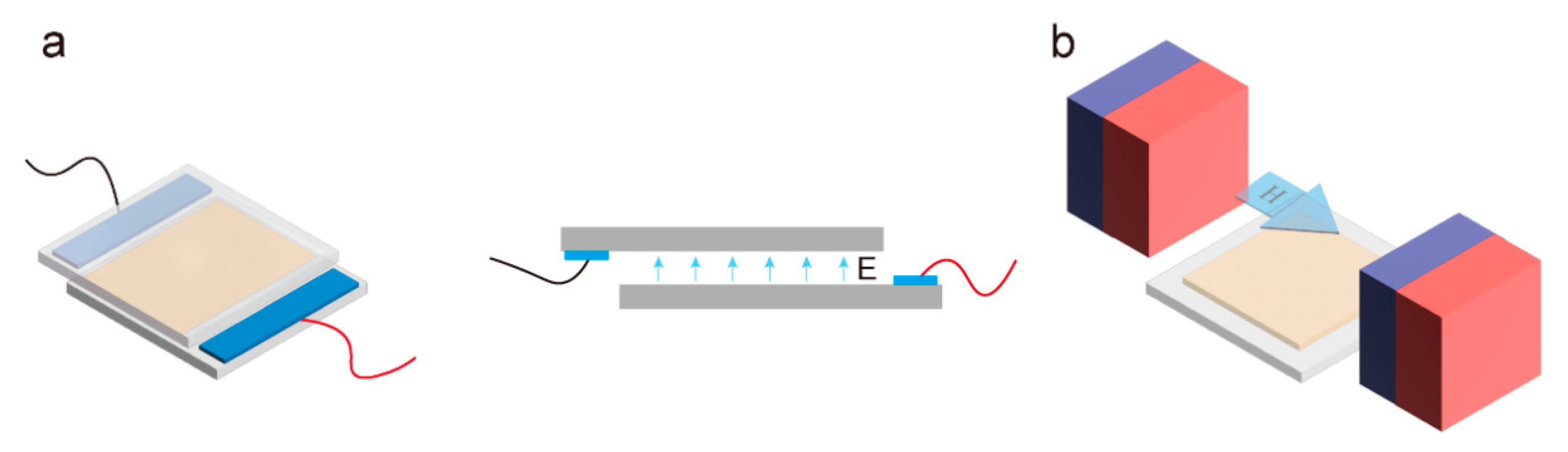

3.2. External Field-Induced Alignment

3.2.1. Electric Field

3.2.2. Magnetic Field

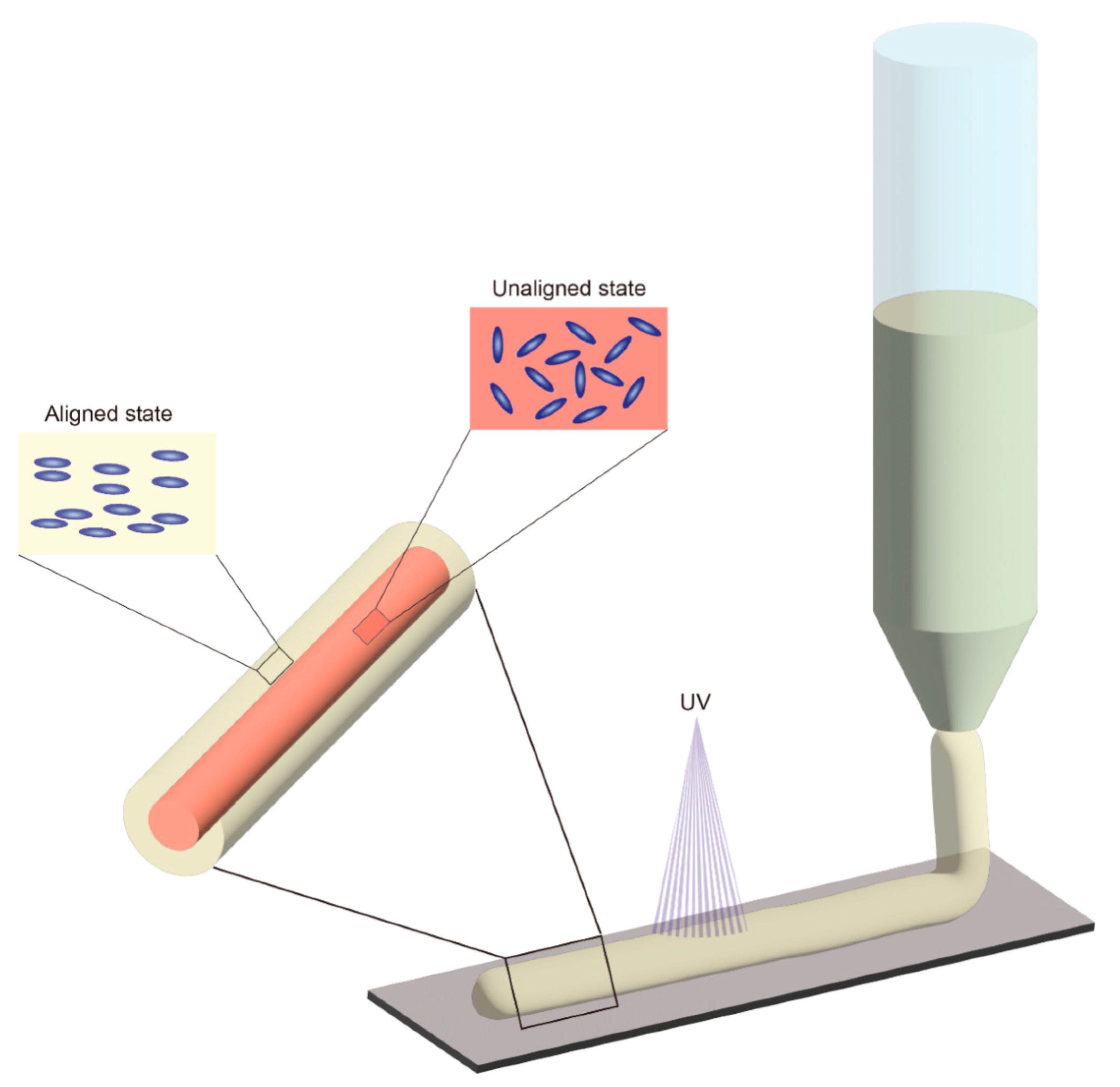

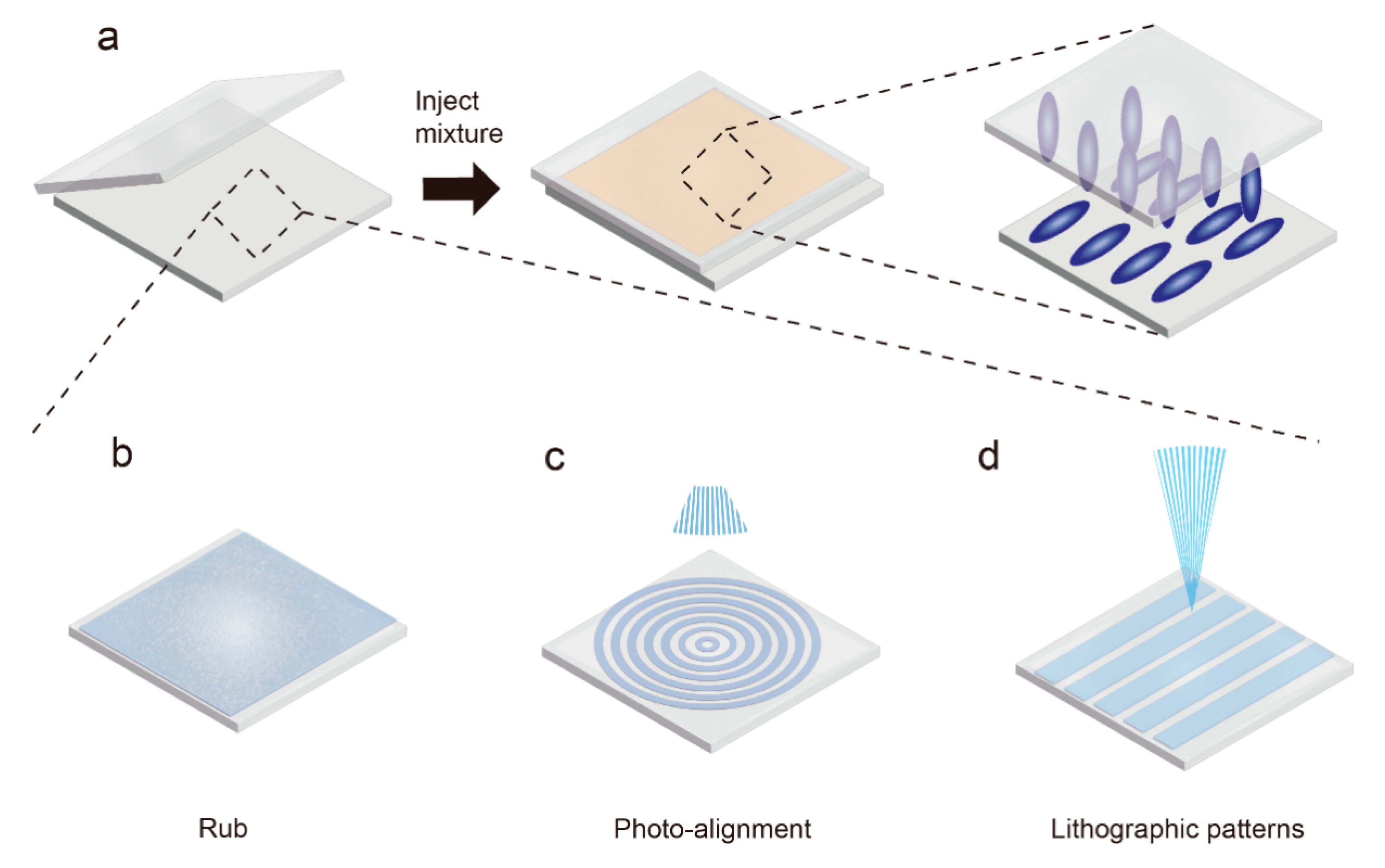

3.3. Surface-Induced Alignment

3.3.1. Alignment Layer

3.3.2. Lithographic Patterns

4. Application

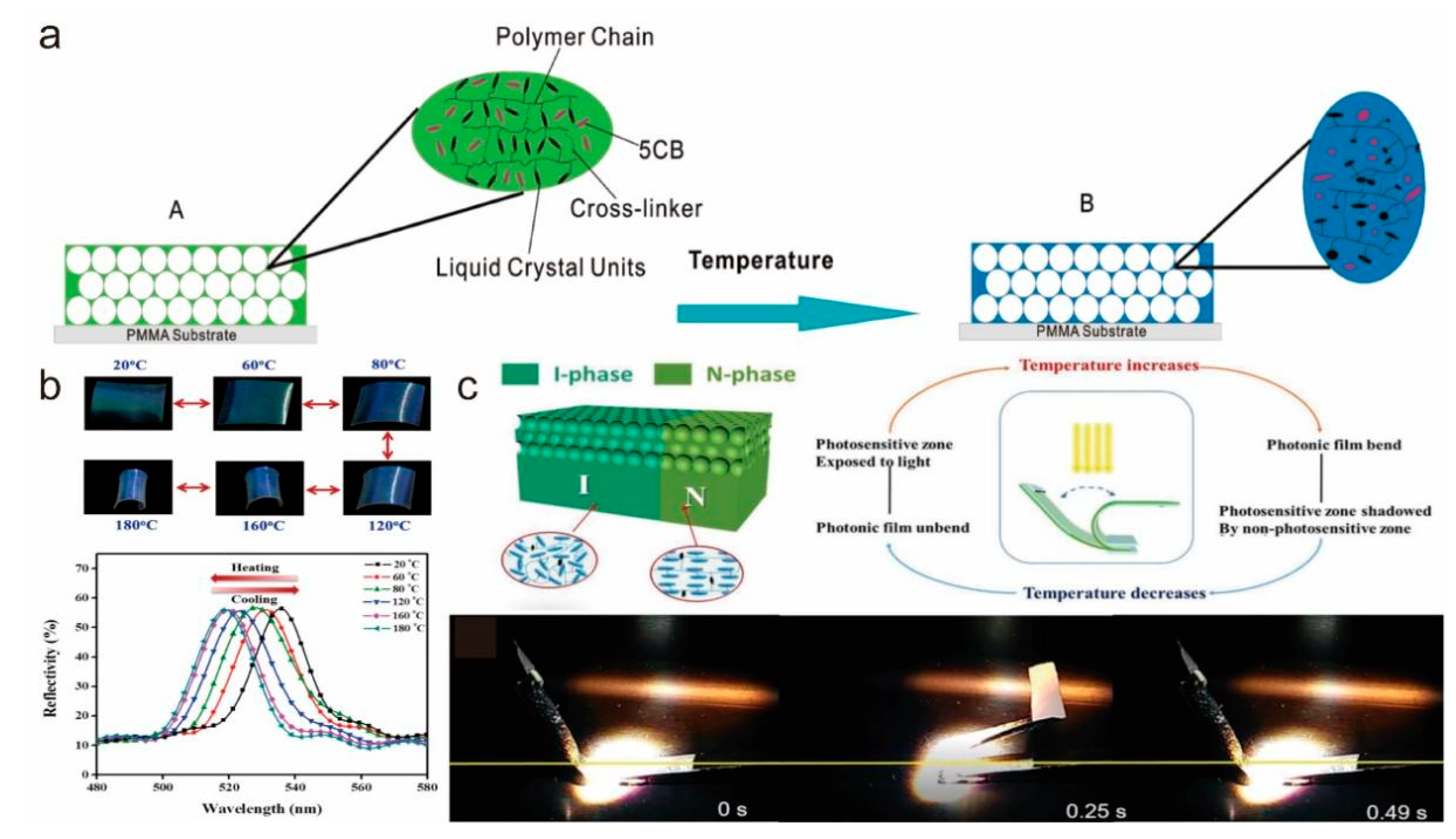

4.1. Optical Devices

4.2. Soft Robotics

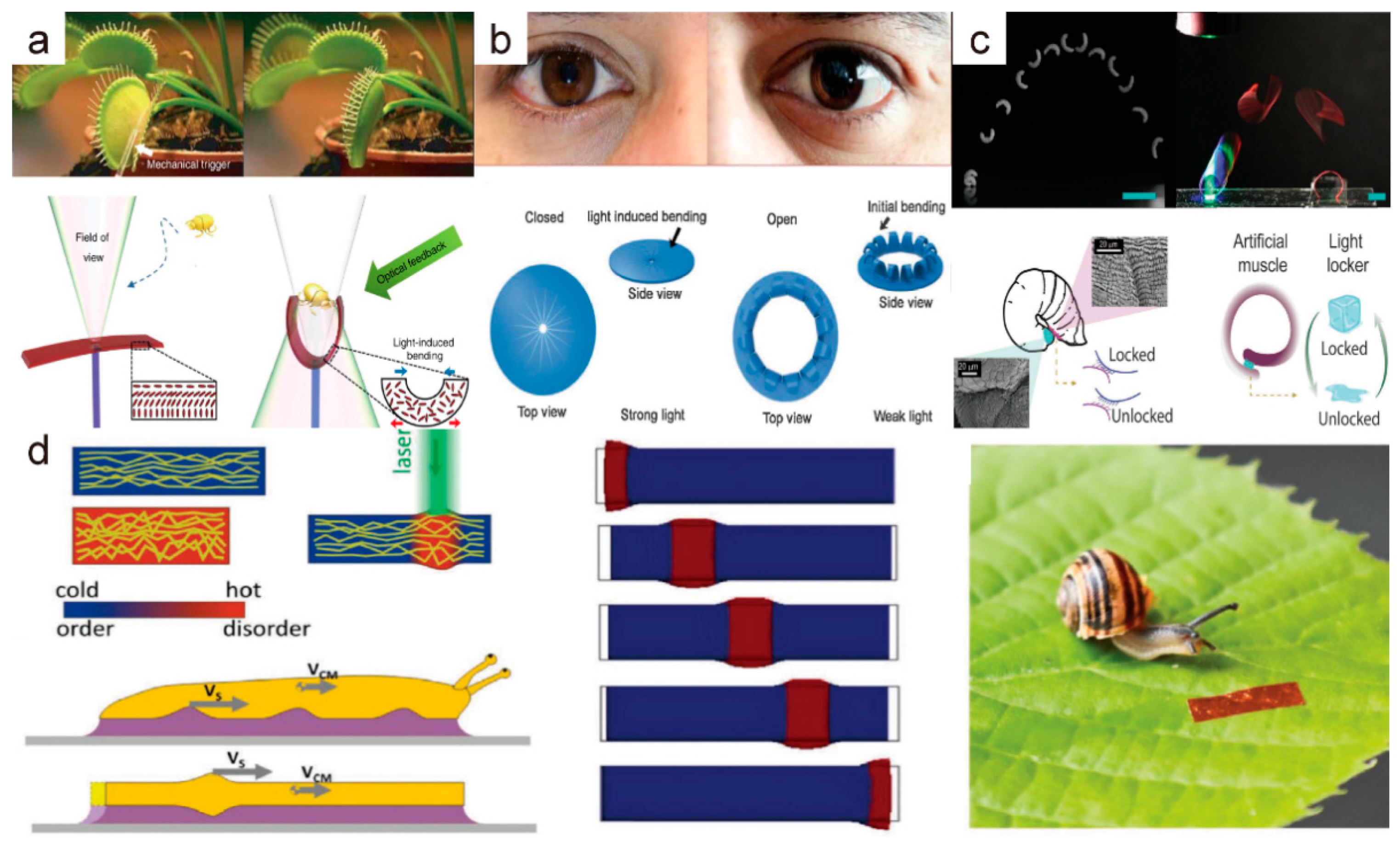

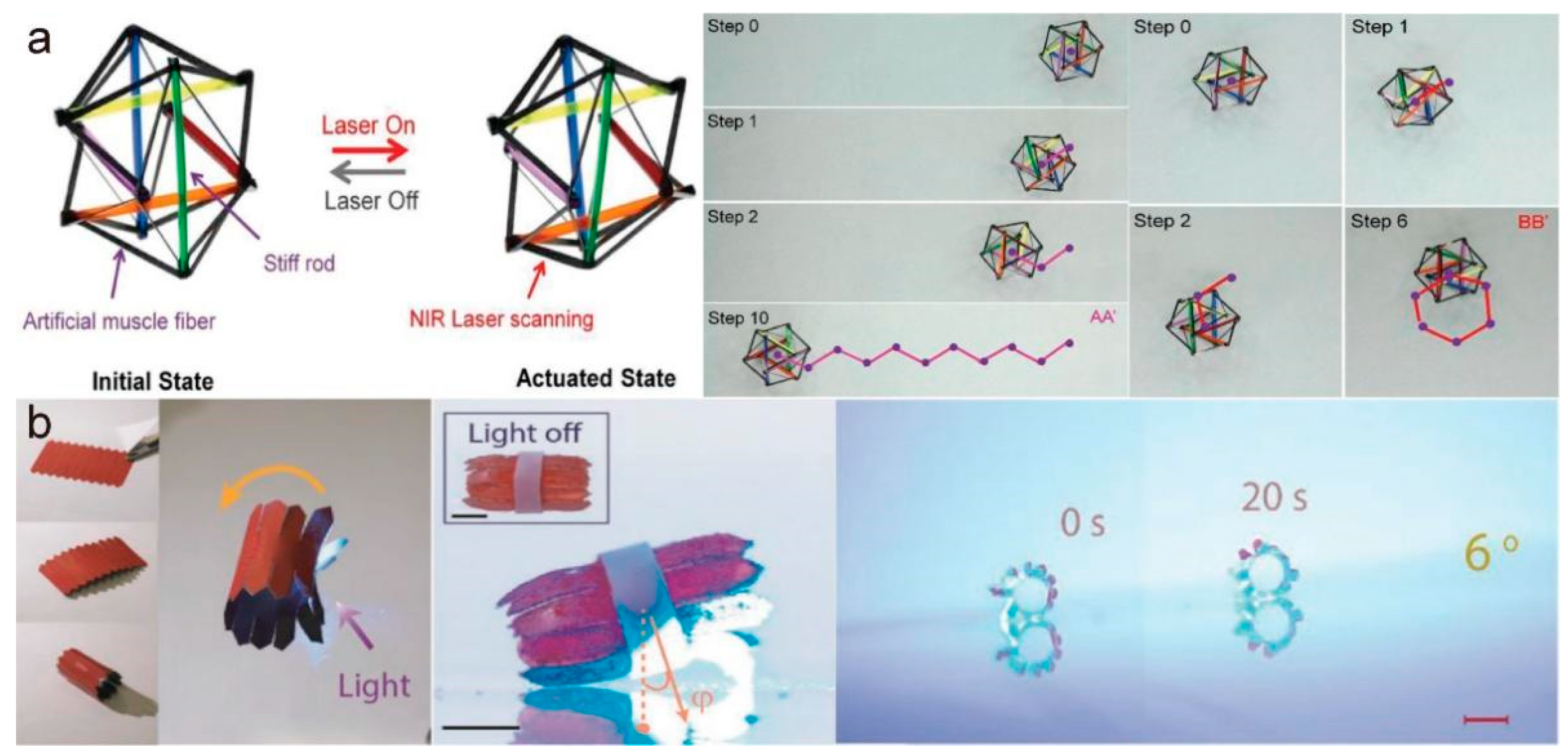

4.2.1. Bionic Robots

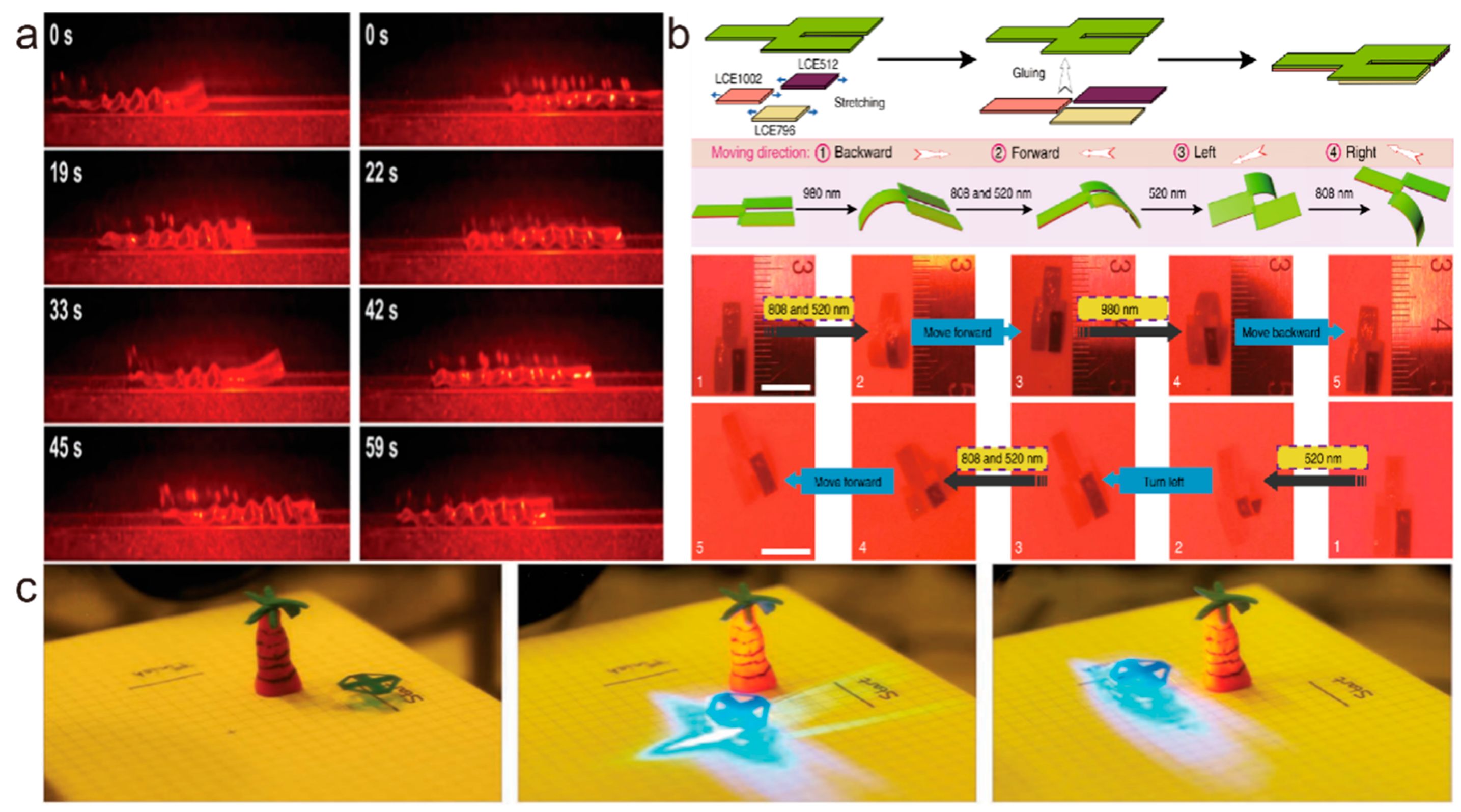

4.2.2. Crawling Soft Robots

4.2.3. Rolling Soft Robots

4.2.4. Swimming Soft Robots

4.3. Actuator

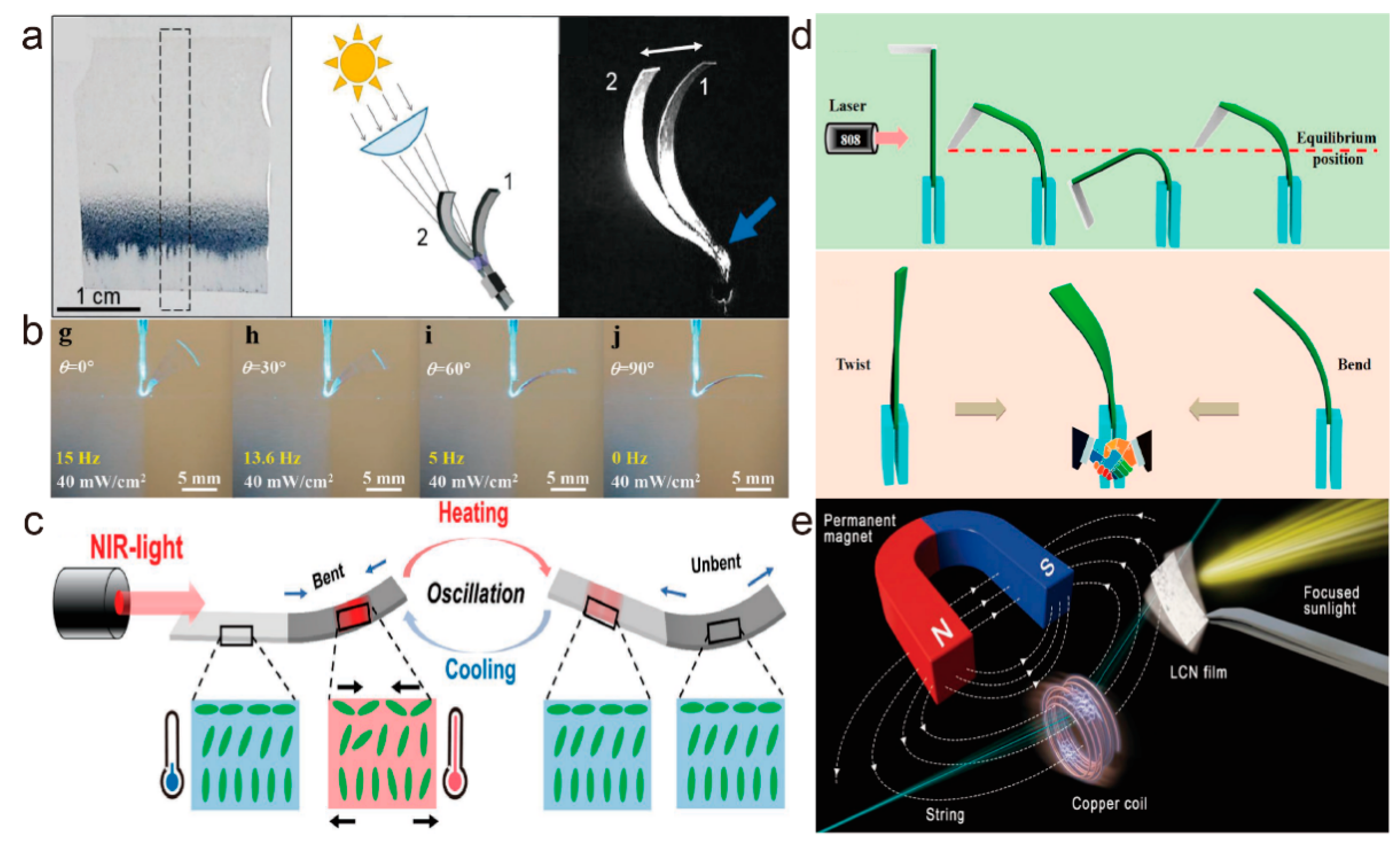

4.3.1. Oscillator

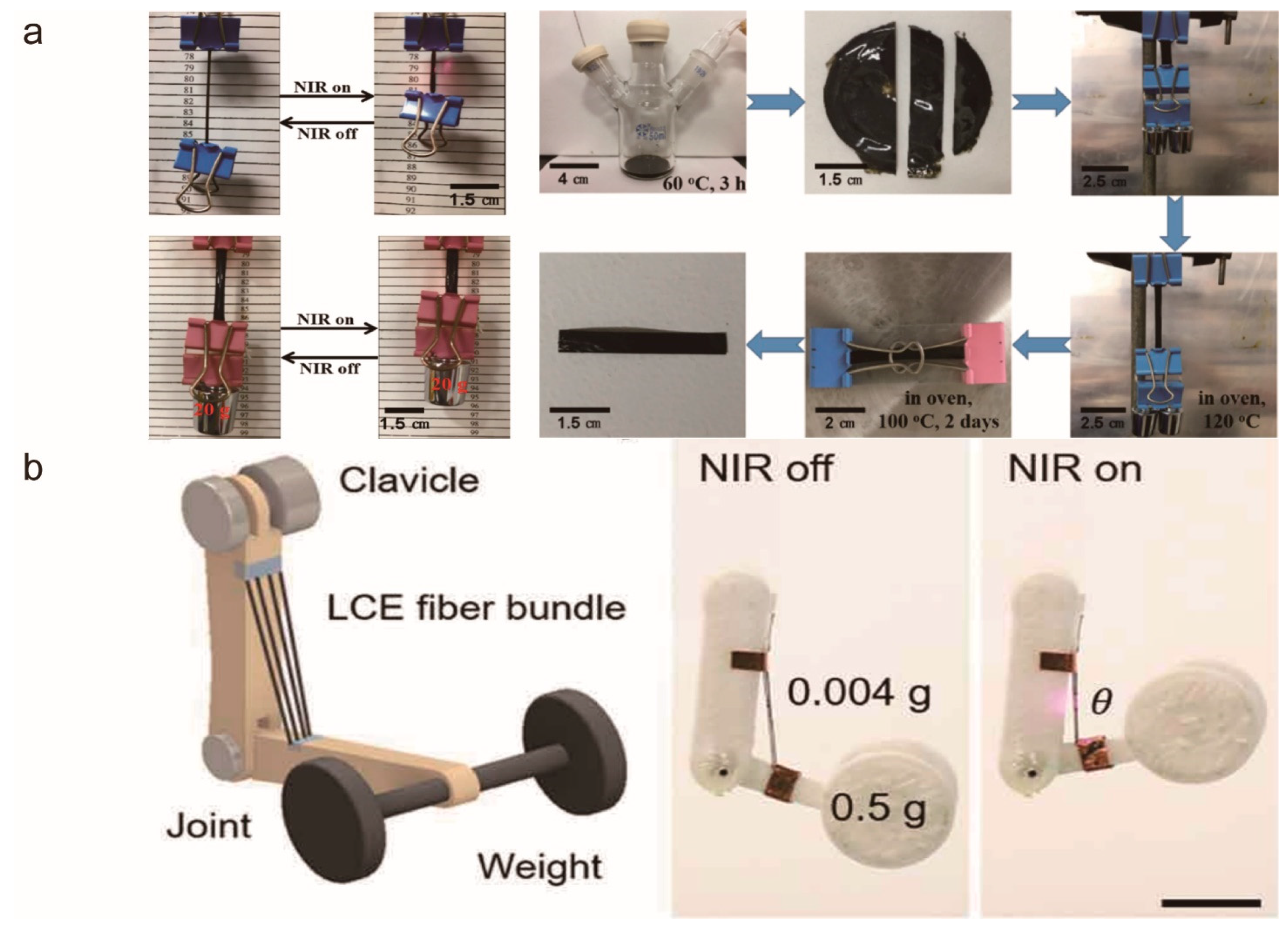

4.3.2. Artificial Muscles

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Gennes, P.G. Possibilites Offertes par la Reticulation de Polymeres en Presence D’un Cristal Liquide. Phys. Lett. A 1969, 28, 725–726. [Google Scholar] [CrossRef]

- Thomsen, D.L.; Keller, P.; Naciri, J.; Pink, R.; Jeon, H.; Shenoy, D.; Ratna, B.R. Liquid Crystal Elastomers with Mechanical Properties of a Muscle. Macromolecules 2001, 34, 5868–5875. [Google Scholar] [CrossRef]

- Ware, T.H.; McConney, M.E.; Wie, J.J.; Tondiglia, V.P.; White, T.J. Voxelated Liquid Crystal Elastomers. Science 2015, 347, 982–984. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- White, T.J.; Broer, D.J. Programmable and Adaptive Mechanics with Liquid Crystal Polymer Networks and Elastomers. Nat. Mater. 2015, 14, 1087–1098. [Google Scholar] [CrossRef]

- Wani, O.M.; Zeng, H.; Priimagi, A. A Light-driven Artificial Flytrap. Nat. Commun. 2017, 8, 15546. [Google Scholar] [CrossRef]

- Wang, M.; Cheng, Z.; Zuo, B.; Chen, X.; Huang, S.; Yang, H. Liquid Crystal Elastomer Electric Locomotives. ACS Macro Lett. 2020, 9, 860–865. [Google Scholar] [CrossRef]

- Zuo, B.; Wang, M.; Lin, B.P.; Yang, H. Visible and Infrared Three-wavelength Modulated Multi-directional Actuators. Nat. Commun. 2019, 10, 4539. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Luo, D. Polarization Dependent Light-Driven Liquid Crystal Elastomer Actuators Based on Photothermal Effect. Adv. Opt. Mater. 2020, 9, 2001861. [Google Scholar] [CrossRef]

- Deng, W.; Li, M.-H.; Wang, X.; Keller, P. Light-responsive Wires From Side-on Liquid Crystalline Azo Polymers. Liq. Cryst. 2009, 36, 1023–1029. [Google Scholar] [CrossRef]

- Yoshino, T.; Kondo, M.; Mamiya, J.; Kinoshita, M.; Yu, Y.; Ikeda, T. Three-dimensional Photomobility of Crosslinked Azobenzene Liquid-crystalline Polymer Fibers. Adv. Mater. 2010, 22, 1361–1363. [Google Scholar] [CrossRef]

- Finkelmann, H.; Kock, H.-J.; Rehage, G. Liquid Crystalline Elastomers—A New Type of Liquid Crystalline Materia. Makromol. Chem. 1981, 2, 317–322. [Google Scholar] [CrossRef]

- Ware, T.H.; White, T.J. Programmed Liquid Crystal Elastomers with Tunable Actuation Strain. Polym. Chem. 2015, 6, 4835–4844. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, X.; Yang, S. Instant Locking of Molecular Ordering in Liquid Crystal Elastomers by Oxygen-Mediated Thiol-Acrylate Click Reactions. Angew. Chem. Int. Ed. Engl. 2018, 57, 5665–5668. [Google Scholar] [CrossRef]

- Ahn, S.K.; Ware, T.H.; Lee, K.M.; Tondiglia, V.P.; White, T.J. Photoinduced Topographical Feature Development in Blueprinted Azobenzene-Functionalized Liquid Crystalline Elastomers. Adv. Funct. Mater. 2016, 26, 5819–5826. [Google Scholar] [CrossRef]

- Guo, H.; Zeng, H.; Priimagi, A. Optically Controlled Grasping-slipping Robot Moving on Tubular Surfaces. Multifunct. Mater. 2022, 5, 024001. [Google Scholar] [CrossRef]

- Yu, L.; Shahsavan, H.; Rivers, G.; Zhang, C.; Si, P.; Zhao, B. Programmable 3D Shape Changes in Liquid Crystal Polymer Networks of Uniaxial Orientation. Adv. Funct. Mater. 2018, 28, 1802809. [Google Scholar] [CrossRef]

- Barnes, M.; Sajadi, S.M.; Parekh, S.; Rahman, M.M.; Ajayan, P.M.; Verduzco, R. Reactive 3D Printing of Shape-Programmable Liquid Crystal Elastomer Actuators. ACS Appl. Mater. Interfaces 2020, 12, 28692–28699. [Google Scholar] [CrossRef]

- Ichimura, K. Photoalignment of Liquid-crystal Systems. Chem. Rev. 2000, 100, 1847–1874. [Google Scholar] [CrossRef]

- Yaroshchuk, O.; Reznikov, Y. Photoalignment of Liquid Crystals: Basics and Current Trends. J. Mater. Chem. 2012, 22, 286–300. [Google Scholar] [CrossRef]

- Ajayan, P.M.; Tour, J.M. Materials Science: Nanotube Composites. Nature 2007, 447, 1066–1068. [Google Scholar] [CrossRef]

- Ji, Y.; Huang, Y.Y.; Rungsawang, R.; Terentjev, E.M. Dispersion and Alignment of Carbon Nanotubes in Liquid Crystalline Polymers and Elastomers. Adv. Mater. 2010, 22, 3436–3440. [Google Scholar] [CrossRef]

- Torras, N.; Zinoviev, K.E.; Marshall, J.E.; Terentjev, E.M.; Esteve, J. Bending Kinetics of a Photo-actuating Nematic Elastomer cantilever. Appl. Phys. Lett. 2011, 99, 254102. [Google Scholar] [CrossRef] [Green Version]

- Courty, S.; Mine, J.; Tajbakhsh, A.R.; Terentjev, E.M. Nematic Elastomers with Aligned Carbon Nanotubes: New Electromechanical Actuators. EPL 2003, 64, 654–660. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Setyowati, K.; Li, A.; Gong, S.; Chen, J. Reversible Infrared Actuation of Carbon Nanotube-Liquid Crystalline Elastomer Nanocomposites. Adv. Mater. 2008, 20, 2271–2275. [Google Scholar] [CrossRef]

- Camargo, C.J.; Campanella, H.; Marshall, J.E.; Torras, N.; Zinoviev, K.; Terentjev, E.M.; Esteve, J. Batch Fabrication of Optical Actuators Using Nanotube–elastomer Composites Towards Refreshable Braille Displays. J. Micromech. Microeng. 2012, 22, 075009. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Huang, X.; Jiang, H. Direct Sun-Driven Artificial Heliotropism for Solar Energy Harvesting Based on a Photo-Thermomechanical Liquid-Crystal Elastomer Nanocomposite. Adv. Funct. Mater. 2012, 22, 5166–5174. [Google Scholar] [CrossRef]

- Ahn, C.; Liang, X.; Cai, S. Bioinspired Design of Light-Powered Crawling, Squeezing, and Jumping Untethered Soft Robot. Adv. Mater. Technol. 2019, 4, 1900185. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, W.; Peng, R.; He, C.; Pang, X.; Shi, D.; Jiang, T.; Lin, Z. Graphene-Enabled Superior and Tunable Photomechanical Actuation in Liquid Crystalline Elastomer Nanocomposites. Adv. Mater. 2015, 27, 6376–6381. [Google Scholar] [CrossRef]

- Li, C.; Liu, Y.; Huang, X.; Li, C.; Jiang, H. Light Actuation of Graphene-Oxide Incorporated Liquid Crystalline Elastomer Nanocomposites. Mol. Cryst. Liq. Cryst. 2015, 616, 83–92. [Google Scholar] [CrossRef]

- Liu, X.; Wei, R.; Hoang, P.T.; Wang, X.; Liu, T.; Keller, P. Reversible and Rapid Laser Actuation of Liquid Crystalline Elastomer Micropillars with Inclusion of Gold Nanoparticles. Adv. Funct. Mater. 2015, 25, 3022–3032. [Google Scholar] [CrossRef]

- Montazami, R.; Spillmann, C.M.; Naciri, J.; Ratna, B.R. Enhanced Thermomechanical Properties of a Nematic Liquid Crystal Elastomer Doped with Gold Nanoparticles. Sens. Actuator A Phys. 2012, 178, 175–178. [Google Scholar] [CrossRef]

- Ambulo, C.P.; Tasmim, S.; Wang, S.; Abdelrahman, M.K.; Zimmern, P.E.; Ware, T.H. Processing Advances in Liquid Crystal Elastomers Provide a Path to Biomedical Applications. J. Appl. Phys. 2020, 128, 140901. [Google Scholar] [CrossRef]

- Xu, J.; Chen, S.; Yang, W.; Qin, B.; Wang, X.; Wang, Y.; Cao, M.; Gao, Y.; Li, C.; Dong, Y. Photo Actuation of Liquid Crystalline Elastomer Nanocomposites Incorporated with Gold Nanoparticles Based on Surface Plasmon Resonance. Soft Matter 2019, 15, 6116–6126. [Google Scholar] [CrossRef]

- Wojcik, M.M.; Wrobel, J.; Janczuk, Z.Z.; Mieczkowski, J.; Gorecka, E.; Choi, J.; Cho, M.; Pociecha, D. Liquid-Crystalline Elastomers with Gold Nanoparticle Cross-Linkers. Chemistry 2017, 23, 8912–8920. [Google Scholar] [CrossRef]

- Tian, H.; Wang, Z.; Chen, Y.; Shao, J.; Gao, T.; Cai, S. Polydopamine-Coated Main-Chain Liquid Crystal Elastomer as Optically Driven Artificial Muscle. ACS Appl. Mater. Interfaces 2018, 10, 8307–8316. [Google Scholar] [CrossRef]

- Lan, R.; Sun, J.; Shen, C.; Huang, R.; Zhang, Z.; Zhang, L.; Wang, L.; Yang, H. Near-Infrared Photodriven Self-Sustained Oscillation of Liquid-Crystalline Network Film with Predesignated Polydopamine Coating. Adv. Mater. 2020, 32, e1906319. [Google Scholar] [CrossRef]

- Zeng, H.; Wani, O.M.; Wasylczyk, P.; Kaczmarek, R.; Priimagi, A. Self-Regulating Iris Based on Light-Actuated Liquid Crystal Elastomer. Adv. Mater. 2017, 29, 1701814. [Google Scholar] [CrossRef]

- Ge, F.; Yang, R.; Tong, X.; Camerel, F.; Zhao, Y. A Multifunctional Dye-doped Liquid Crystal Polymer Actuator: Light-Guided Transportation, Turning in Locomotion, and Autonomous Motion. Angew. Chem. Int. Ed. Engl. 2018, 57, 11758–11763. [Google Scholar] [CrossRef]

- Küpfer, J.; Finkelmann, H. Nematic Liquid Single Crystal Elastomers. Makromol. Chem. 1991, 12, 717–726. [Google Scholar] [CrossRef]

- Küupfer, J.; Finkelmann, H. Liquid crystal elastomers: Influence of the Orientational Distribution of the Crosslinks on the Phase Behaviour and Reorientation Processes. Macromol. Chem. Phys. 1994, 195, 1353–1367. [Google Scholar] [CrossRef]

- Jin, B.; Liu, J.; Shi, Y.; Chen, G.; Zhao, Q.; Yang, S. Solvent-Assisted 4D Programming and Reprogramming of Liquid Crystalline Organogels. Adv. Mater. 2022, 34, e2107855. [Google Scholar] [CrossRef]

- Agrawal, A.; Chipara, A.C.; Shamoo, Y.; Patra, P.K.; Carey, B.J.; Ajayan, P.M.; Chapman, W.G.; Verduzco, R. Dynamic Self-stiffening in Liquid Crystal Elastomers. Nat. Commun. 2013, 4, 1739. [Google Scholar] [CrossRef] [Green Version]

- Schätzle, J.; Kaufhold, W.; Finkelmann, H. Nematic Elastomers: The Influence of External Mechanical Stress on the Liquid-crystalline Phase Behavior. Makromol. Chem. 1989, 190, 3269–3284. [Google Scholar] [CrossRef]

- Mistry, D.; Traugutt, N.A.; Sanborn, B.; Volpe, R.H.; Chatham, L.S.; Zhou, R.; Song, B.; Yu, K.; Long, K.N.; Yakacki, C.M. Soft Elasticity Optimises Dissipation in 3D-printed Liquid Crystal Elastomers. Nat. Commun. 2021, 12, 6677. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Z.; Zheng, Y.; He, Q.; Wang, Y.; Cai, S. Three-dimensional Printing of Functionally Graded Liquid Crystal Elastomer. Sci. Adv. 2020, 6, eabc0034. [Google Scholar] [CrossRef]

- Stephen, M.J.; Straley, J.P. Physics of Liquid Crystals. Rev. Mod. Phys. 1974, 46, 617–704. [Google Scholar] [CrossRef]

- Kelly, S.M. Anisotropic networks. J. Mater. Chem. 1995, 5, 2047–2061. [Google Scholar] [CrossRef]

- Heilmeier, G.H.; Zanoni, L.A.; Barton, L.A. Dynamic Scattering in Nematic Liquid Crystals. Appl. Phys. Lett. 1968, 13, 46–47. [Google Scholar] [CrossRef]

- Ishihara, S.; Mizusaki, M. Alignment Control Technology of Liquid Crystal Molecules. J. Soc. Inf. Disp. 2019, 28, 44–74. [Google Scholar] [CrossRef]

- Schadt, M. Dielectric Properties of Some Nematic Liquid Crystals with Strong Positive Dielectric Anisotropy. J. Chem. Phys. 1972, 56, 1494–1497. [Google Scholar] [CrossRef]

- Fukunaga, A.; Urayama, K.; Takigawa, T.; DeSimone, A.; Teresi, L. Dynamics of Electro-Opto-Mechanical Effects in Swollen Nematic Elastomers. Macromolecules 2008, 41, 9389–9396. [Google Scholar] [CrossRef]

- Kirsch, P.; Reiffenrath, V.; Bremer, M. Nematic Liquid Crystals with Negative Dielectric Anisotropy: Molecular Design and Synthesis. Synlett 1999, 1999, 389–396. [Google Scholar] [CrossRef]

- Kossyrev, P.A.; Qi, J.; Priezjev, N.V.; Pelcovits, R.A.; Crawford, G.P. Virtual Surfaces, Director Domains, and the Fréedericksz Transition in Polymer-stabilized Nematic Liquid Crystals. Appl. Phys. Lett. 2002, 81, 2986–2988. [Google Scholar] [CrossRef] [Green Version]

- Fréedericksz, V.; Zolina, V. Forces Causing the Orientation of an Anisotropic Liquid. Trans. Faraday Soc. 1933, 29, 919–930. [Google Scholar] [CrossRef]

- Herbert, K.M.; Fowler, H.E.; McCracken, J.M.; Schlafmann, K.R.; Koch, J.A.; White, T.J. Synthesis and Alignment of Liquid Crystalline Elastomers. Nat. Rev. Mater. 2021, 7, 23–38. [Google Scholar] [CrossRef]

- You, R.; Kang, S.; Lee, C.; Jeon, J.; Wie, J.J.; Kim, T.S.; Yoon, D.K. Programmable Liquid Crystal Defect Arrays via Electric Field Modulation for Mechanically Functional Liquid Crystal Networks. ACS Appl. Mater. Interfaces 2021, 13, 36253–36261. [Google Scholar] [CrossRef]

- Trevisan, T.V.; Monteiro, G.M.; Caldeira, A.O. Enhancement of Diamagnetism by Momentum-momentum Interaction: Application to Benzene. Phys. Rev. B 2021, 103, L180402. [Google Scholar] [CrossRef]

- Li, S.; Librandi, G.; Yao, Y.; Richard, A.J.; Schneider-Yamamura, A.; Aizenberg, J.; Bertoldi, K. Controlling Liquid Crystal Orientations for Programmable Anisotropic Transformations in Cellular Microstructures. Adv. Mater. 2021, 33, e2105024. [Google Scholar] [CrossRef]

- Schuhladen, S.; Preller, F.; Rix, R.; Petsch, S.; Zentel, R.; Zappe, H. Iris-like Tunable Aperture Employing Liquid-crystal Elastomers. Adv. Mater. 2014, 26, 7247–7251. [Google Scholar] [CrossRef]

- Buguin, A.; Li, M.H.; Silberzan, P.; Ladoux, B.; Keller, P. Micro-actuators: When Artificial Muscles Made of Nematic Liquid Crystal Elastomers Meet Soft Lithography. J. Am. Chem. Soc. 2006, 128, 1088–1089. [Google Scholar] [CrossRef]

- Tabrizi, M.; Ware, T.H.; Shankar, M.R. Voxelated Molecular Patterning in Three-Dimensional Freeforms. ACS Appl. Mater. Interfaces 2019, 11, 28236–28245. [Google Scholar] [CrossRef]

- Murray, B.S.; Pelcovits, R.A.; Rosenblatt, C. Creating Arbitrary Arrays of Two-dimensional Topological Defects. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2014, 90, 052501. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Cedillo-Servin, G.; Kamien, R.D.; Yang, S. Guided Folding of Nematic Liquid Crystal Elastomer Sheets into 3D via Patterned 1D Microchannels. Adv. Mater. 2016, 28, 9637–9643. [Google Scholar] [CrossRef]

- Schadt, M. Liquid Crystal Materials and Liquid Crystal Displays. Annu. Rev. Mater. Sci. 1997, 27, 305–379. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Akomolafe, O.I.; Jiang, J.; Peng, C. Light-Actuated Liquid Crystal Elastomer Prepared by Projection Display. Materials 2021, 14, 7245. [Google Scholar] [CrossRef]

- Yang, R.; Zhao, Y. Non-Uniform Optical Inscription of Actuation Domains in a Liquid Crystal Polymer of Uniaxial Orientation: An Approach to Complex and Programmable Shape Changes. Angew. Chem. Int. Ed. Engl. 2017, 56, 14202–14206. [Google Scholar] [CrossRef]

- Kim, C.; Trajkovska, A.; Wallace, J.U.; Chen, S.H. New Insight into Photoalignment of Liquid Crystals on Coumarin-Containing Polymer Films. Macromolecules 2006, 39, 3817–3823. [Google Scholar] [CrossRef]

- Concellón, A.; Schenning, A.P.H.J.; Romero, P.; Marcos, M.; Serrano, J.L. Size-selective Adsorption in Nanoporous Polymers from Coumarin Photo-Cross-Linked Columnar Liquid Crystals. Macromolecules 2018, 51, 2349–2358. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Johnson, A.S.; Weber, J.; Akomolafe, O.I.; Jiang, J.; Peng, C. Programmable Light-driven Liquid Crystal Elastomer Kirigami with Controlled Molecular Orientations. Adv. Int. Syst. 2022, 2100233. [Google Scholar] [CrossRef]

- Aharoni, H.; Xia, Y.; Zhang, X.; Kamien, R.D.; Yang, S. Universal Inverse Design of Surfaces with Thin Nematic Elastomer Sheets. Proc. Natl. Acad. Sci. USA 2018, 115, 7206–7211. [Google Scholar] [CrossRef] [Green Version]

- Ni, B.; Liu, G.; Zhang, M.; Tatoulian, M.; Keller, P.; Li, M.H. Customizable Sophisticated Three-dimensional Shape Changes of Large-Size Liquid Crystal Elastomer Actuators. ACS Appl. Mater. Interfaces 2021, 13, 54439–54446. [Google Scholar] [CrossRef]

- Gurboga, B.; Tuncgovde, E.B.; Kemiklioglu, E. Liquid crystal-based elastomers in tissue engineering. Biotechnol. Bioeng. 2022, 119, 1047–1052. [Google Scholar] [CrossRef]

- Liang, X.; Li, D. A Programmable Liquid Crystal Elastomer Metamaterials with Soft Elasticity. Front. Robot. AI 2022, 9, 849516. [Google Scholar] [CrossRef]

- Xing, H.; Li, J.; Guo, J.; Wei, J. Bio-Inspired Thermal-responsive Inverse Opal films with Dual Structural Colors Based on Liquid Crystal Elastomer. J. Mater. Chem. C 2015, 3, 4424–4430. [Google Scholar] [CrossRef]

- Kim, S.U.; Lee, Y.J.; Liu, J.; Kim, D.S.; Wang, H.; Yang, S. Broadband and Pixelated Camouflage in Inflating Chiral Nematic Liquid Crystalline Elastomers. Nat. Mater. 2022, 21, 41–46. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Zhu, C.; Li, J.; Wei, J.; Guo, J. A Color-Changing Plasmonic Actuator Based on Silver Nanoparticle Array/Liquid Crystalline Elastomer Nanocomposites. New J. Chem. 2016, 40, 7311–7319. [Google Scholar] [CrossRef]

- Brannum, M.T.; Steele, A.M.; Venetos, M.C.; Korley, L.T.J.; Wnek, G.E.; White, T.J. Light Control with Liquid Crystalline Elastomers. Adv. Opt. Mater. 2019, 7, 1801683. [Google Scholar] [CrossRef]

- Guo, Y.; Shahsavan, H.; Sitti, M. Microscale Polarization Color Pixels from Liquid Crystal Elastomers. Adv. Opt. Mater. 2020, 8, 1902098. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Jiang, S.A.; Lin, J.D.; Yang, P.C.; Lee, C.R. Stretchable Freestanding Films of 3D Nanocrystalline Blue Phase Elastomer and Their Tunable Applications. Adv. Opt. Mater. 2020, 9, 2001427. [Google Scholar] [CrossRef]

- Xing, H.; Li, J.; Shi, Y.; Guo, J.; Wei, J. Thermally Driven Photonic Actuator Based on Silica Opal Photonic Crystal with Liquid Crystal Elastomer. ACS Appl. Mater. Interfaces 2016, 8, 9440–9445. [Google Scholar] [CrossRef]

- Akamatsu, N.; Hisano, K.; Tatsumi, R.; Aizawa, M.; Barrett, C.J.; Shishido, A. Thermo-, Photo-, and Mechano-Responsive Liquid Crystal Networks Enable Tunable Photonic Crystals. Soft Matter 2017, 13, 7486–7491. [Google Scholar] [CrossRef]

- Wu, G.; Jiang, Y.; Xu, D.; Tang, H.; Liang, X.; Li, G. Thermoresponsive Inverse Opal Films Fabricated with Liquid-crystal Elastomers and Nematic Liquid Crystals. Langmuir 2011, 27, 1505–1509. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, Z.; Wei, J.; Li, X.; Guo, J. Phototriggered Selective Actuation and Self-Oscillating in Dual-Phase Liquid Crystal Photonic Actuators. Adv. Opt. Mater. 2018, 6, 1800131. [Google Scholar] [CrossRef]

- Rogoz, M.; Dradrach, K.; Xuan, C.; Wasylczyk, P. A Millimeter-Scale Snail Robot Based on a Light-powered Liquid Crystal Elastomer Continuous Actuator. Macromol. Rapid Commun. 2019, 40, e1900279. [Google Scholar] [CrossRef]

- Guo, H.; Priimagi, A.; Zeng, H. Optically Controlled Latching and Launching in Soft Actuators. Adv. Funct. Mater. 2021, 32, 2108919. [Google Scholar] [CrossRef]

- Rogóż, M.; Zeng, H.; Xuan, C.; Wiersma, D.S.; Wasylczyk, P. Light-Driven Soft Robot Mimics Caterpillar Locomotion in Natural Scale. Adv. Opt. Mater. 2016, 4, 1689–1694. [Google Scholar] [CrossRef]

- Zeng, H.; Wani, O.M.; Wasylczyk, P.; Priimagi, A. Light-Driven, Caterpillar-Inspired Miniature Inching Robot. Macromol. Rapid Commun. 2018, 39, 1700224. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Parmeggiani, C.; Martella, D.; Burresi, M.; Wiersma, D.S. Light-fueled Microscopic Walkers. Adv. Mater. 2015, 27, 3883–3887. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.; Zeng, H.; Li, Y.; Liu, J.; Luo, D.; Priimagi, A.; Liu, Y.J. Light-Fueled Polymer Film Capable of Directional Crawling, Friction-controlled Climbing, and Self-Sustained Motion on a Human Hair. Adv. Sci. 2022, 9, e2103090. [Google Scholar] [CrossRef]

- Wang, M.; Hu, X.B.; Zuo, B.; Huang, S.; Chen, X.M.; Yang, H. Liquid Crystal Elastomer Actuator with Serpentine Locomotion. Chem. Commun. 2020, 56, 7597–7600. [Google Scholar] [CrossRef]

- da Cunha, M.P.; Ambergen, S.; Debije, M.G.; Homburg, E.; den Toonder, J.M.J.; Schenning, A. A Soft Transporter Robot Fueled by Light. Adv. Sci. 2020, 7, 1902842. [Google Scholar] [CrossRef] [Green Version]

- Kohlmeyer, R.R.; Chen, J. Wavelength-selective, IR Light-driven Hinges Based on Liquid Crystalline Elastomer Composites. Angew. Chem. Int. Ed. Engl. 2013, 52, 9234–9237. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Y.; Zheng, J.; Sun, S.; Fu, Y.; Chen, D.; Cai, W.; Wang, D.; Zhou, H.; Li, D. Fast-Response Bioinspired Near-Infrared Light-Driven Soft Robot Based on Two-Stage Deformation. ACS Appl. Mater. Interfaces 2022, 14, 16649–16657. [Google Scholar] [CrossRef]

- Zhao, T.; Zhang, Y.; Fan, Y.; Wang, J.; Jiang, H.; Lv, J.-A. Light-Modulated Liquid Crystal Elastomer Actuator with Multimodal Shape Morphing and Multifunction. J. Mater. Chem. C 2022, 10, 3796–3803. [Google Scholar] [CrossRef]

- Lin, B.-Y.; Liao, Y.-P.; Yang, Y.-J. A Miniaturized Light-Driven Soft Crawler Based on Liquid Crystal Elastomer with High-Efficient Photothermal Thin-Film. In Proceedings of the 2022 IEEE 35th International Conference on Micro Electro Mechanical Systems Conference (MEMS), Tokyo, Japan, 9–13 January 2022; pp. 628–631. [Google Scholar]

- Wang, Z.; Li, K.; He, Q.; Cai, S. A Light-Powered Ultralight Tensegrity Robot with High Deformability and Load Capacity. Adv. Mater. 2019, 31, e1806849. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.C.; Lu, H.C.; Lee, X.; Zeng, H.; Priimagi, A. Kirigami-based Light-induced Shape-morphing and Locomotion. Adv. Mater. 2020, 32, e1906233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palagi, S.; Mark, A.G.; Reigh, S.Y.; Melde, K.; Qiu, T.; Zeng, H.; Parmeggiani, C.; Martella, D.; Sanchez-Castillo, A.; Kapernaum, N.; et al. Structured Light Enables Biomimetic Swimming and Versatile Locomotion of Photoresponsive Soft Microrobots. Nat. Mater. 2016, 15, 647–653. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shahsavan, H.; Aghakhani, A.; Zeng, H.; Guo, Y.; Davidson, Z.S.; Priimagi, A.; Sitti, M. Bioinspired Underwater Locomotion of Light-driven Liquid Crystal Gels. Proc. Natl. Acad. Sci. USA 2020, 117, 5125–5133. [Google Scholar] [CrossRef] [Green Version]

- Gelebart, A.H.; Vantomme, G.; Meijer, E.W.; Broer, D.J. Mastering the Photothermal Effect in Liquid Crystal Networks: A General Approach for Self-sustained Mechanical Oscillators. Adv. Mater. 2017, 29, 1606712. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Yang, B.; Yu, M.; Yu, H. Light-Powered Self-Sustained Oscillators of Graphene Oxide/Liquid Crystalline Network Composites Showing Amplitude and Frequency Superposition. ACS Appl. Mater. Interfaces 2022, 14, 15632–15640. [Google Scholar] [CrossRef]

- Degennes, P.G. One type of nematic polymers. C. R. Hebd. Seances Acad. Sci. Ser. B 1975, 281, 101–103. [Google Scholar]

- Lu, H.-F.; Wang, M.; Chen, X.-M.; Lin, B.-P.; Yang, H. Interpenetrating Liquid-crystal Polyurethane/Polyacrylate Elastomer with Ultrastrong Mechanical Property. J. Am. Chem. Soc. 2019, 141, 14364–14369. [Google Scholar] [CrossRef]

- Guin, T.; Settle, M.J.; Kowalski, B.A.; Auguste, A.D.; Beblo, R.V.; Reich, G.W.; White, T.J. Layered Liquid Crystal Elastomer Actuators. Nat. Commun. 2018, 9, 2531. [Google Scholar] [CrossRef]

- Minori, A.F.; He, Q.; Glick, P.E.; Adibnazari, I.; Stopol, A.; Cai, S.; Tolley, M.T. Reversible Actuation for Self-folding Modular Machines Using Liquid Crystal Elastomer. Smart Mater. Struct. 2020, 29, 105003. [Google Scholar] [CrossRef]

- Lee, J.H.; Bae, J.; Hwang, J.H.; Choi, M.Y.; Kim, Y.S.; Park, S.; Na, J.H.; Kim, D.G.; Ahn, S.K. Robust and Reprocessable Artificial Muscles Based on Liquid Crystal Elastomers with Dynamic Thiourea Bonds. Adv. Funct. Mater. 2021, 32, 2110360. [Google Scholar] [CrossRef]

- Liu, L.; Liu, M.H.; Deng, L.L.; Lin, B.P.; Yang, H. Near-Infrared Chromophore Functionalized Soft Actuator with Ultrafast Photoresponsive Speed and Superior Mechanical Property. J. Am. Chem. Soc. 2017, 139, 11333–11336. [Google Scholar] [CrossRef]

- Ferrantini, C.; Pioner, J.M.; Martella, D.; Coppini, R.; Piroddi, N.; Paoli, P.; Calamai, M.; Pavone, F.S.; Wiersma, D.S.; Tesi, C.; et al. Development of Light-responsive Liquid Crystalline Elastomers to Assist Cardiac Contraction. Circ. Res. 2019, 124, e44–e54. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, D.; Zhang, B.; Sun, Q.; Zhang, Y.; Liu, S.; Wang, Y.; Liu, C.; Chen, J.; Chen, J.; et al. Intrinsic Carbon Nanotube Liquid Crystalline Elastomer Photoactuators for High-definition Biomechanics. Mater. Horiz. 2022, 9, 1045–1056. [Google Scholar] [CrossRef]

- He, Q.; Wang, Z.; Wang, Y.; Wang, Z.; Li, C.; Annapooranan, R.; Zeng, J.; Chen, R.; Cai, S. Electrospun Liquid Crystal Elastomer Microfiber Actuator. Sci. Robot. 2021, 6, eabi9704. [Google Scholar] [CrossRef]

- Kotikian, A.; Morales, J.M.; Lu, A.; Mueller, J.; Davidson, Z.S.; Boley, J.W.; Lewis, J.A. Innervated, Self-sensing Liquid Crystal Elastomer Actuators with Closed Loop Control. Adv. Mater. 2021, 33, e2101814. [Google Scholar] [CrossRef]

- Lippenberger, M.; Dengler, P.; Wandinger, A.; Schmidt, M. Photoresponsive Liquid Crystal Elastomers as Feedback Controlled Light-driven Actuators—Theory, Real-time Behaviour, Limitations. Phys. Procedia 2016, 83, 1299–1307. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Wang, Y.; Ye, W.; Su, C. Positioning Control of Liquid Crystal Elastomer Actuator Based on Double Closed-loop System Structure. Control Eng. Pract. 2022, 123, 105136. [Google Scholar] [CrossRef]

- Petsch, S.; Rix, R.; Khatri, B.; Schuhladen, S.; Müller, P.; Zentel, R.; Zappe, H. Smart Artificial Muscle Actuators: Liquid Crystal Elastomers with Integrated Temperature Feedback. Sens. Actuator A Phys. 2015, 231, 44–51. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Nan, Y.; Wu, Z.; Shen, Y.; Luo, D. Photothermal-Driven Liquid Crystal Elastomers: Materials, Alignment and Applications. Molecules 2022, 27, 4330. https://doi.org/10.3390/molecules27144330

Zhang W, Nan Y, Wu Z, Shen Y, Luo D. Photothermal-Driven Liquid Crystal Elastomers: Materials, Alignment and Applications. Molecules. 2022; 27(14):4330. https://doi.org/10.3390/molecules27144330

Chicago/Turabian StyleZhang, Wei, Yifei Nan, Zongxuan Wu, Yajing Shen, and Dan Luo. 2022. "Photothermal-Driven Liquid Crystal Elastomers: Materials, Alignment and Applications" Molecules 27, no. 14: 4330. https://doi.org/10.3390/molecules27144330

APA StyleZhang, W., Nan, Y., Wu, Z., Shen, Y., & Luo, D. (2022). Photothermal-Driven Liquid Crystal Elastomers: Materials, Alignment and Applications. Molecules, 27(14), 4330. https://doi.org/10.3390/molecules27144330