Determining the Parameters of the Stinging Nettle (Urtica dioica L.) Hydrolate Distillation Process

Abstract

:1. Introduction

2. Results and Discussion

3. Materials and Methods

3.1. Plant Material

3.2. Hydrolate Production

3.3. pH Value

3.4. Isolation of Volatile Compounds from Hydrolate

3.5. Analysis of Volatile Compounds

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Taylor, K. Biological Flora of the British Isles: Urtica dioica L. J. Ecol. 2009, 97, 1436–1458. [Google Scholar] [CrossRef]

- Joshi, B.C.; Mukhija, M.; Kalia, A.N. Pharmacognostical review of Urtica dioica L. Int. J. Green Pharm. 2014, 8, 201–209. [Google Scholar] [CrossRef]

- Chrubasik, J.E.; Roufogalis, B.D.; Wagner, H.; Chrubasik, S.A. A comprehensive review on nettle effect and efficacy profiles, Part I: Herba urticae. Phytomedicine 2007, 14, 423–435. [Google Scholar] [CrossRef] [PubMed]

- Asgarpanah, J.; Mohajerani, R. Phytochemistry and pharmacologic properties of Urtica dioica L. J. Med. Plants Res. 2012, 6, 5714–5719. [Google Scholar] [CrossRef]

- EDQM—Council of Europe. European Pharmacopoeia; EDQM: Strasbourg, France, 2020; ISBN 9789287189127. [Google Scholar]

- Ilies, D.-C.; Tudor, I.; Radulescu, V. Chemical composition of the essential oil of Urtica dioica. Chem. Nat. Compd. 2012, 48, 506–507. [Google Scholar] [CrossRef]

- Gül, S.; Demirci, B.; Can Başer, K.H.; Akpulat, H.A.; Akşu, P. Chemical Composition and In Vitro Cytotoxic, Genotoxic Effects of Essential Oil from Urtica dioica L. Bull. Environ. Contam. Toxicol. 2012, 88, 666–671. [Google Scholar] [CrossRef] [PubMed]

- Catty, S. Hydrosols the Next Aromatherapy, 1st ed.; Healing Arts Press: Rochester, Vermont, 2001; ISBN 0892819464. [Google Scholar]

- Maciąg, A.; Kalemba, D. Composition of rugosa rose (Rosa rugosa Thunb.) hydrolate according to the time of distillation. Phytochem. Lett. 2015, 11, 373–377. [Google Scholar] [CrossRef]

- Price, L.; Price, S. Understanding Hydrolats: The Specific Hydrosol from Aromatherapy; Churchill Livingstone: London, UK, 2004; ISBN 9780443073168. [Google Scholar]

- Wajs-Bonikowska, A.; Sienkiewicz, M.; Stobiecka, A.; Maciąg, A. Chemical Composition and Biological Activity of Abies alba and A. koreana Seed and Cone Essential Oils and Characterization of Their Seed Hydrolates. Chem. Biodivers. 2015, 12, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Wawrzyńczak, K.; Więckowska, M.; Sadowska, B.; Kalemba, D. Composition and Antimicrobial Activity of Myrica gale L. Leaf and Flower Essential Oils and Hydrolates. Rec. Nat. Prod. 2021, 15, 35–45. [Google Scholar] [CrossRef]

- McRae, J.F.; Mainland, J.D.; Jaeger, S.R.; Adipietro, K.A.; Matsunami, H.; Newcomb, R.D. Genetic Variation in the Odorant Receptor OR2J3 Is Associated with the Ability to Detect the ’’Grassy’’ Smelling Odor, cis-3-hexen-1-ol. Chem. Senses 2012, 37, 585–593. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kalemba, D.; Kunicka, A. Antibacterial and Antifungal Properties of Essential Oils. Curr. Med. Chem. 2003, 10, 813–829. [Google Scholar] [CrossRef] [PubMed]

- Georgian, D.; Ramadoss, N.; Dona, C.; Basu, C. Therapeutic and Medicinal Uses of Terpenes. In Medicinal Plants; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 9783030312695. [Google Scholar]

- Adams, R.P. Identification of Essential Oil Components by Gas Chromatography/Mass Spectroscopy, 4th ed.; Allured Publishing Corp: Carol Stream, IL, USA, 2007; ISBN 1932633219. [Google Scholar]

| No | Compound | RIlit | RIexp | Total Hydrolate | Hydrolate Fraction | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | VII | |||||

| [%] | |||||||||||

| 1. | (E)-Hex-3-en-1-ol | 836 | 833 | 5.7 | 0.5 | 7.1 | - | - | - | 0.2 | - |

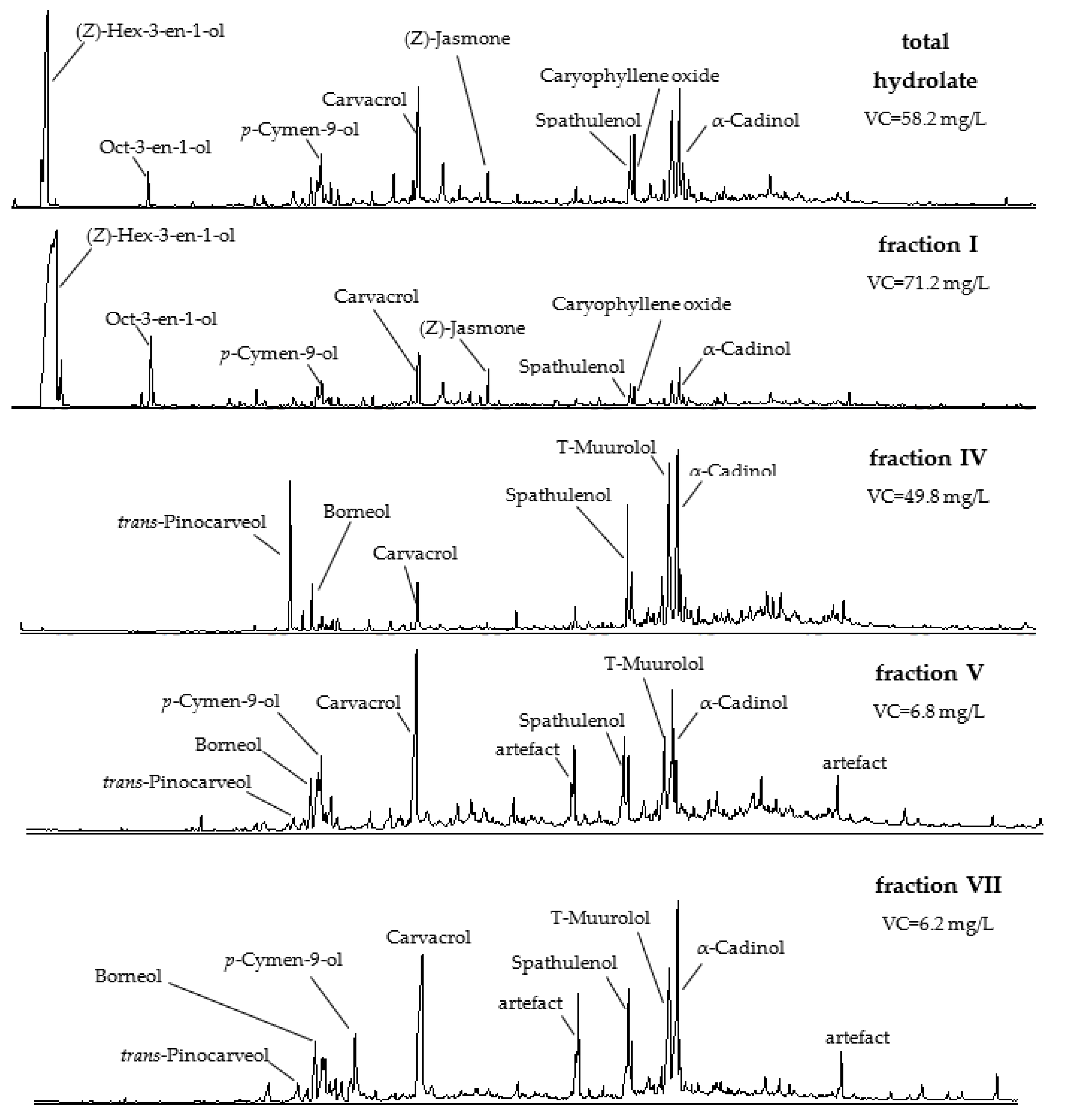

| 2. | (Z)-Hex-3-en-1-ol | 841 | 841 | 27.9 | 73.7 | 14.3 | - | - | - | - | - |

| 3. | Hexan-1-ol | 854 | 851 | 0.5 | 1.8 | 0.1 | - | - | - | - | - |

| 4. | (Z)-Hex-2-en-1-ol | 951 | 857 | t | 0.4 | t | - | - | - | - | t |

| 5. | α-Thujene | 926 | 920 | - | - | - | - | t | t | - | 0.1 |

| 6. | α-Pinene | 934 | 928 | - | - | - | - | t | t | - | t |

| 7. | Camphene | 950 | 944 | - | - | - | - | t | t | - | - |

| 8. | 6-Methyl-2-heptanol | 950 | 952 | 0.1 | 0.1 | 0.4 | - | - | - | - | - |

| 9. | Heptan-1-ol | 957 | 954 | - | 0.5 | - | - | - | - | - | - |

| 10. | Oct-1-en-3-ol | 962 | 962 | 1.6 | 3.4 | 0.5 | - | - | - | - | - |

| 11. | Allyl isovalerate | 920 a | 966 | 0.2 | 0.7 | - | - | - | - | - | - |

| 12. | Octan-4-ol | 975 | 974 | t | 0.1 | - | - | - | - | - | - |

| 13. | Dehydro-1,8-cineol | 979 | 974 | - | - | - | - | - | - | 0.4 | - |

| 14. | 2,6-Dimethylhept-6-en-2-ol * | - b | 1009 | 0.1 | t | - | - | - | - | - | - |

| 15. | p-Cymene | 1014 | 1010 | t | t | 0.1 | - | t | t | - | t |

| 16. | Limonene | 1025 | 1017 | t | 0.1 | t | - | t | 0.8 | - | t |

| 17. | (Z)-Oct-5-en-1-ol | 1048 | 1052 | t | 0.1 | - | - | - | - | - | - |

| 18. | Octan-1-ol | 1057 | 1053 | t | 0.3 | 0.1 | - | - | - | - | - |

| 19. | trans-Linalool oxide (f) | 1058 | 1056 | t | 0.1 | t | t | t | t | 0.2 | t |

| 20. | Heptanoic acid | 1068 | 1068 | t | 0.1 | - | - | - | - | - | - |

| 21. | cis-Linalool oxide (f) | 1072 | 1071 | t | 0.2 | t | - | t | t | - | - |

| 22. | Linalool | 1086 | 1085 | 0.2 | 0.2 | 0.1 | 0.1 | 0.4 | 0.4 | 1.0 | 0.2 |

| 23. | β-Phenyloethanol | 1088 | 1085 | 0.2 | 0.2 | 0.4 | - | t | - | t | - |

| 24. | Benzeneacetonitrile | 1089 | 1092 | 0.1 | 0.1 | - | - | - | 0.3 | - | - |

| 25. | cis-Rose oxide | 1096 | 1096 | 0.1 | 0.1 | - | - | - | - | 0.8 | - |

| 26. | trans-Rose oxide | 1116 | 1121 | t | t | 0.1 | - | t | 0.2 | - | - |

| 27. | trans-Pinocarveol | 1126 | 1123 | 0.1 | t | 0.1 | - | 0.1 | 0.2 | - | - |

| 28. | trans-Verbenol | 1134 | 1129 | 0.7 | 0.3 | 0.6 | - | t | 0.7 | t | 1.6 |

| 29. | Isopulegol | 1135 | 1130 | 0.6 | 0.1 | 0.6 | - | - | - | 3.2 | - |

| 30. | Citronellal | 1135 | 1130 | t | t | t | - | - | t | - | - |

| 31. | Camphene hydrate | 1137 | 1131 | - | - | - | - | 0.2 | - | t | t |

| 32. | Pinocarvone | 1144 | 1138 | t | 0.2 | - | - | 1.6 | t | - | - |

| 33. | p-Mentha-1,5-dien-8-ol | 1148 | 1140 | 0.4 | t | t | - | - | 0.8 | - | 1.0 |

| 34. | Isomenthone | 1146 | 1141 | - | - | - | - | t | 0.2 | - | - |

| 35. | Isoborneol | 1148 | 1142 | - | - | - | - | t | 2.0 | - | - |

| 36. | Isoisopulegol | 1150 | 1143 | t | t | 0.1 | - | t | - | - | |

| 37. | Borneol | 1155 | 1149 | 1.1 | 0.1 | 0.4 | 0.5 | 3.0 | 2.0 | 0.7 | 4.5 |

| 38. | Nonan-1-ol | 1163 | 1157 | t | 0.6 | - | - | - | - | - | |

| 39. | p-Cymen-8-ol | 1158 | 1158 | 1.6 | 0.2 | 2.0 | 1.6 | 0.5 | 5.4 | 3.3 | 3.4 |

| 40. | trans-Car-2-en-4-ol | - b | 1159 | t | 0.2 | 0.9 | 1.5 | 0.1 | - | - | 1.7 |

| 41. | p-Cymen-9-ol | 1168 | 1162 | 3.2 | 0.7 | 3.4 | 3.2 | 1.4 | 6.5 | 3.2 | 1.7 |

| 42. | 2-Methylisoborneol | 1164 | 1167 | 0.3 | 0.1 | 0.7 | 1.0 | 0.3 | 0.3 | t | 0.5 |

| 43. | α-Terpineol | 1176 | 1173 | 0.9 | 0.2 | 0.9 | 1.4 | 0.6 | 2.4 | 1.7 | 1.3 |

| 44. | Myrtenal | 1174 | 1174 | t | t | t | t | 0.2 | t | t | t |

| 45. | Verbenone | 1183 | 1181 | 0.7 | 0.2 | 1.3 | 1.4 | t | 0.8 | 0.3 | 1.5 |

| 46. | Myrtenol | 1184 | 1184 | t | t | t | t | 1.4 | t | t | t |

| 47. | Coumaran | 1191 | 1198 | 0.4 | 0.5 | t | 0.2 | t | 0.1 | 2.3 | 8.2 |

| 48. | Citronellol | 1210 | 1211 | 0.2 | 0.3 | 0.2 | 1.7 | - | t | - | - |

| 49. | Neral | 1218 | 1214 | - | - | - | 1.2 | - | - | - | - |

| 50. | Carvone | 1218 | 1215 | t | - | - | - | t | 0.2 | - | 0.1 |

| 51. | 2,2-Dimethyloct-4-enal * | - b | 1216 | - | - | - | - | 0.7 | - | - | - |

| 52. | Car-3-en-2-one | 1245 | 1222 | 0.7 | - | 1.0 | 1.1 | t | 1.3 | - | 0.6 |

| 53. | Piperitone | 1232 | 1227 | t | t | - | - | - | - | 0.3 | - |

| 54. | Geraniol | 1238 | 1237 | t | 0.1 | - | - | - | - | - | - |

| 55. | Geranial | 1247 | 1242 | 0.2 | t | - | 2.5 | t | - | - | 0.3 |

| 56. | trans-Ascaridol glycol | 1266 a | 1244 | 0.1 | 0.1 | 0.7 | - | 0.6 | 1.6 | - | 0.1 |

| 57. | p-Cymen-7-ol | 1269 | 1264 | - | - | 0.5 | - | t | t | - | t |

| 58. | Nonanoic acid | 1262 | 1264 | 0.1 | 0.1 | - | - | - | - | - | - |

| 59. | Bornyl acetate | 1273 | 1269 | 0.2 | 0.2 | 0.6 | 0.5 | 0.3 | 0.1 | t | t |

| 60. | Carvacrol | 1282 | 1280 | 10.5 | 2.5 | 16.9 | 22.0 | 4.5 | 22.0 | 10.4 | 23.4 |

| 61. | Citronellic acid | 1300 | 1302 | 0.1 | t | 0.3 | - | t | - | - | - |

| 62. | 8-Hydroxyneomentol | 1310 | 1310 | 2.7 | 0.2 | 1.2 | 0.4 | 0.4 | 0.2 | 0.4 | 0.2 |

| 63. | 8-Hydroxymenthol (isomer) * | - b | 1325 | 0.1 | 0.3 | 0.1 | - | 0.1 | t | 0.4 | t |

| 64. | 8-Hydroxymenthol (izomer) * | - b | 1331 | 0.7 | - | - | - | 0.1 | - | 2.1 | t |

| 65. | α-Terpinyl acetate | 1334 | 1332 | 0.5 | 0.1 | 0.4 | 0.4 | 0.1 | 0.8 | t | t |

| 66. | Ethyl nerolate | 1335 | 1338 | 0.3 | 0.1 | - | - | t | - | 0.3 | - |

| 67. | 5,9-Dimethyldeca-4,8-dienal * | - b | 1339 | - | 0.2 | - | - | - | - | - | - |

| 68. | (E)-Jasmone | 1359 | 1358 | 0.3 | 0.2 | 1.6 | t | 0.1 | t | t | - |

| 69. | (Z)-Jasmone | 1369 | 1367 | 1.3 | 1.0 | 1.2 | 0.3 | 0.3 | 0.9 | 0.2 | 0.3 |

| 70. | Methyleugenol | 1375 | 1370 | 0.1 | t | t | t | t | 0.3 | 0.1 | 0.1 |

| 71. | p-Menth-2-ene-1,7-diol monoacetate | - b | 1407 | 0.4 | t | 0.6 | 0.8 | 1.0 | 1.1 | 0.2 | 1.0 |

| 72. | β-Ionone epoxide | 1460 | 1461 | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | t | 0.1 | - |

| 73. | Dihydroactinidiolide | 1495 | 1489 | 0.8 | 0.2 | 1.4 | 1.6 | 1.6 | 2.0 | 2.3 | 2.4 |

| 74. | γ-Cadinene | 1512 | 1508 | 0.4 | 0.1 | 0.4 | 0.2 | 0.7 | t | t | 0.4 |

| 75. | α-Calacorene | 1534 | 1528 | 0.2 | t | 0.2 | 0.2 | 0.3 | 0.4 | 0.2 | 0.3 |

| 76. | β-Caryophyllene oxide | 1546 | 1541 | 0.1 | t | 0.1 | t | 0.2 | 0.1 | 0.5 | t |

| 77. | γ-Calacorene | 1551 | 1547 | t | t | t | t | t | t | t | t |

| 78. | Spathulenol | 1569 | 1566 | 2.8 | 0.5 | 3.8 | 7.6 | 8.2 | 4.8 | 7.2 | 5.9 |

| 79. | Caryophylene oxide | 1578 | 1572 | 3.1 | 0.4 | 2.8 | 3.6 | 3.9 | 3.6 | 8.2 | 2.6 |

| 80. | Aromadendrene epoxide | 1590 | 1592 | 0.1 | - | - | - | - | - | - | - |

| 81. | 6-epi-Cubenol | 1602 | 1603 | 0.2 | t | 0.2 | 1.0 | t | 0.1 | t | 0.2 |

| 82. | 1,10-diepi-Cubenol | 1615 | 1616 | 0.7 | 0.1 | 0.8 | 2.0 | 2.4 | 0.6 | 0.3 | 0.8 |

| 83. | T-Muurolol | 1628 | 1626 | 2.4 | 0.4 | 2.6 | 6.4 | 7.1 | 3.4 | 4.0 | 4.5 |

| 84. | α-Muurolol | 1628 | 1628 | 1.2 | 0.2 | 1.4 | 3.5 | 3.6 | 0.9 | 2.1 | 4.2 |

| 85. | T-Cadinol | 1633 | 1629 | 1.1 | 0.2 | 1.3 | 3.2 | 3.6 | 1.1 | 1.3 | t |

| 86. | α-Cadinol | 1643 | 1640 | 4.7 | 0.7 | 5.6 | 12.7 | 13.0 | 6.8 | 3.9 | 3.5 |

| 87. | trans-Calamen-10-ol | 1669 a | 1645 | 1.1 | 0.2 | 1.2 | 1.4 | 2.9 | 1.8 | 0.6 | 8.7 |

| 88. | Eudesma-4(15),7-dien-1β-ol | 1688 a | 1661 | t | 0.1 | 0.2 | t | 0.9 | 0.2 | 0.3 | t |

| 89. | cis-14-nor-Muurol-5-en-4-one | 1684 a | 1664 | 0.2 | t | 0.3 | 0.3 | 0.7 | 0.1 | 0.1 | 0.2 |

| 90. | 10-nor-Calamen-10-one | 1684 | 1673 | 0.3 | t | 0.4 | 0.5 | 1.1 | 0.4 | 0.1 | 0.3 |

| 91. | Oplopanone | 1715 | 1710 | 0.6 | 0.3 | 0.7 | 0.7 | 0.7 | 0.6 | 0.3 | 0.3 |

| 92. | Oplopanonyl acetate | 1791 | 1791 | 0.1 | - | - | - | 1.2 | - | 0.2 | - |

| 93. | Isopropyl tetradecanoate | 1827 a | 1808 | 0.2 | t | 0.6 | 0.6 | 1.3 | 0.4 | 0.2 | 0.4 |

| 94. | Platambin | 1867 a | 1833 | 0.4 | 0.1 | 0.3 | t | 0.6 | 0.3 | 0.1 | 0.2 |

| Total content of oxygenated compounds | 85.5 | 94.9 | 83.2 | 87.2 | 71.2 | 78.1 | 65.9 | 86.4 | |||

| Alcohols: | 73.9 | 89.6 | 69.3 | 71.2 | 55.9 | 64.5 | 48.7 | 67.6 | |||

| Aliphatic alcohols | 35.9 | 81.5 | 22.5 | 0.0 | 0.0 | 0.0 | 2.5 | 0.0 | |||

| Monoterpene alcohols | 23.4 | 5.6 | 29.4 | 33.4 | 13.6 | 44.5 | 26.4 | 39.6 | |||

| Sesquiterpene alcohols | 14.6 | 2.5 | 17.4 | 37.8 | 42.3 | 20.0 | 19.8 | 28.0 | |||

| Hydrocarbons | 0.7 | 0.3 | 0.7 | 0.4 | 1.0 | 1.5 | 0.2 | 0.8 | |||

| Total indentified [%] | 86.2 | 95.2 | 83.9 | 87.6 | 72.2 | 79.6 | 66.1 | 87.2 | |||

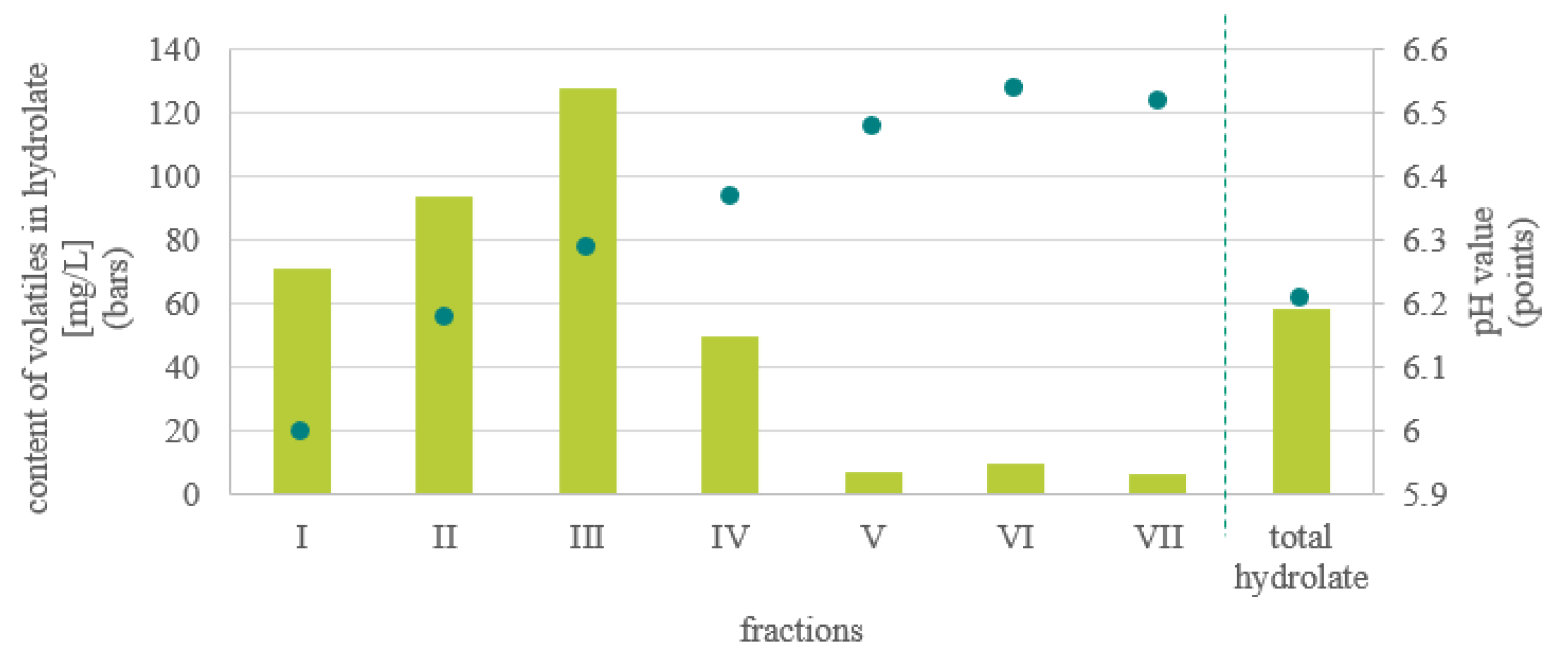

| Content of volatiles in hydrolate (VC) [mg/L] | 58.2 | 71.2 | 94.0 | 128.0 | 49.8 | 6.8 | 10.0 | 6.2 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krajewska, A.; Mietlińska, K. Determining the Parameters of the Stinging Nettle (Urtica dioica L.) Hydrolate Distillation Process. Molecules 2022, 27, 3912. https://doi.org/10.3390/molecules27123912

Krajewska A, Mietlińska K. Determining the Parameters of the Stinging Nettle (Urtica dioica L.) Hydrolate Distillation Process. Molecules. 2022; 27(12):3912. https://doi.org/10.3390/molecules27123912

Chicago/Turabian StyleKrajewska, Agnieszka, and Katarzyna Mietlińska. 2022. "Determining the Parameters of the Stinging Nettle (Urtica dioica L.) Hydrolate Distillation Process" Molecules 27, no. 12: 3912. https://doi.org/10.3390/molecules27123912

APA StyleKrajewska, A., & Mietlińska, K. (2022). Determining the Parameters of the Stinging Nettle (Urtica dioica L.) Hydrolate Distillation Process. Molecules, 27(12), 3912. https://doi.org/10.3390/molecules27123912