The Effect of Microwave Pretreatment on Micronutrient Contents, Oxidative Stability and Flavor Quality of Peanut Oil

Abstract

1. Introduction

2. Results and Discussion

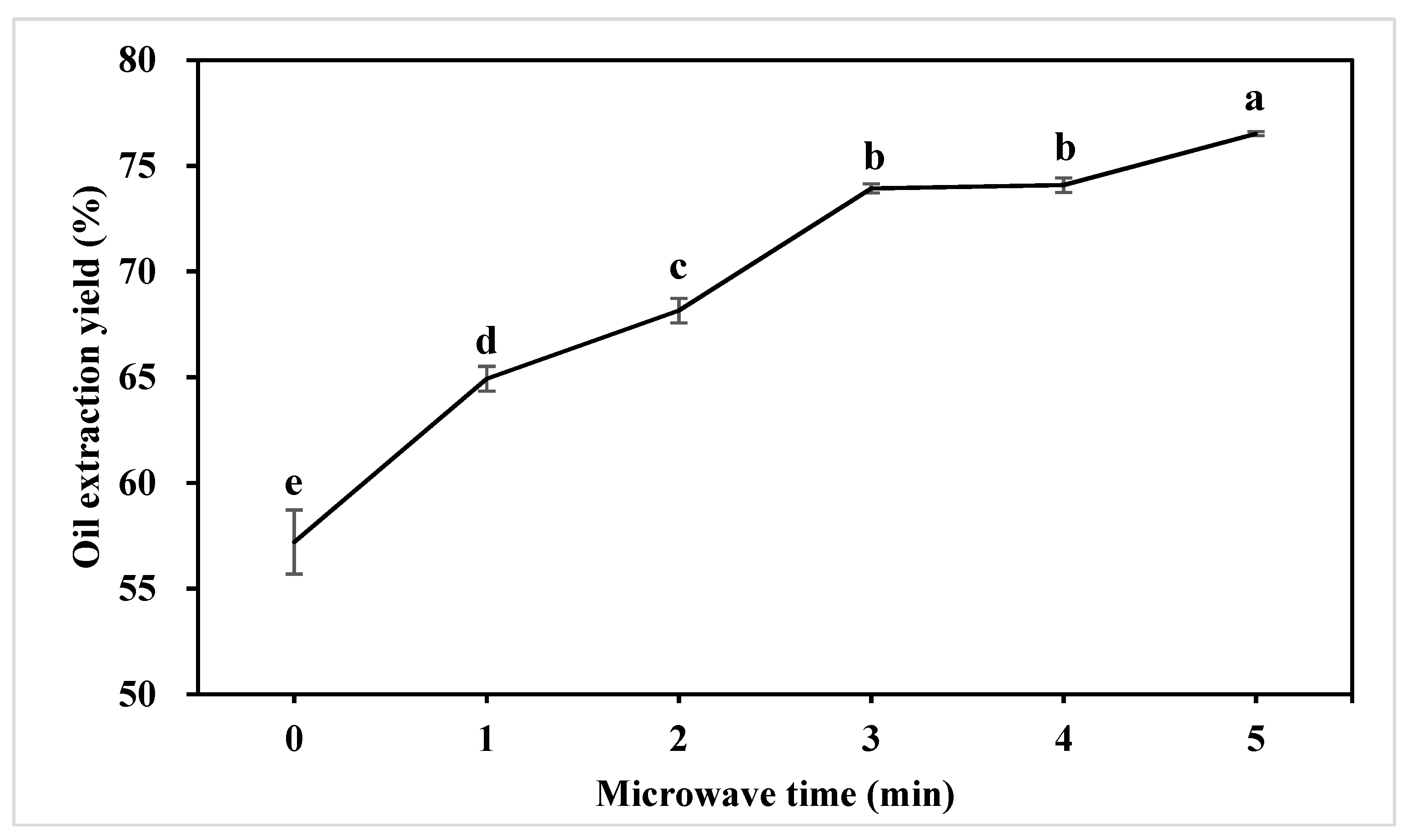

2.1. Effect of Microwave Pretreatment on Oil Extraction Yield

2.2. Effect of Microwave Pretreatment on Physicochemical Properties of Oil

2.3. Effect of Microwave Pretreatment on the Free Phytosterols and Tocopherols Content of Oil

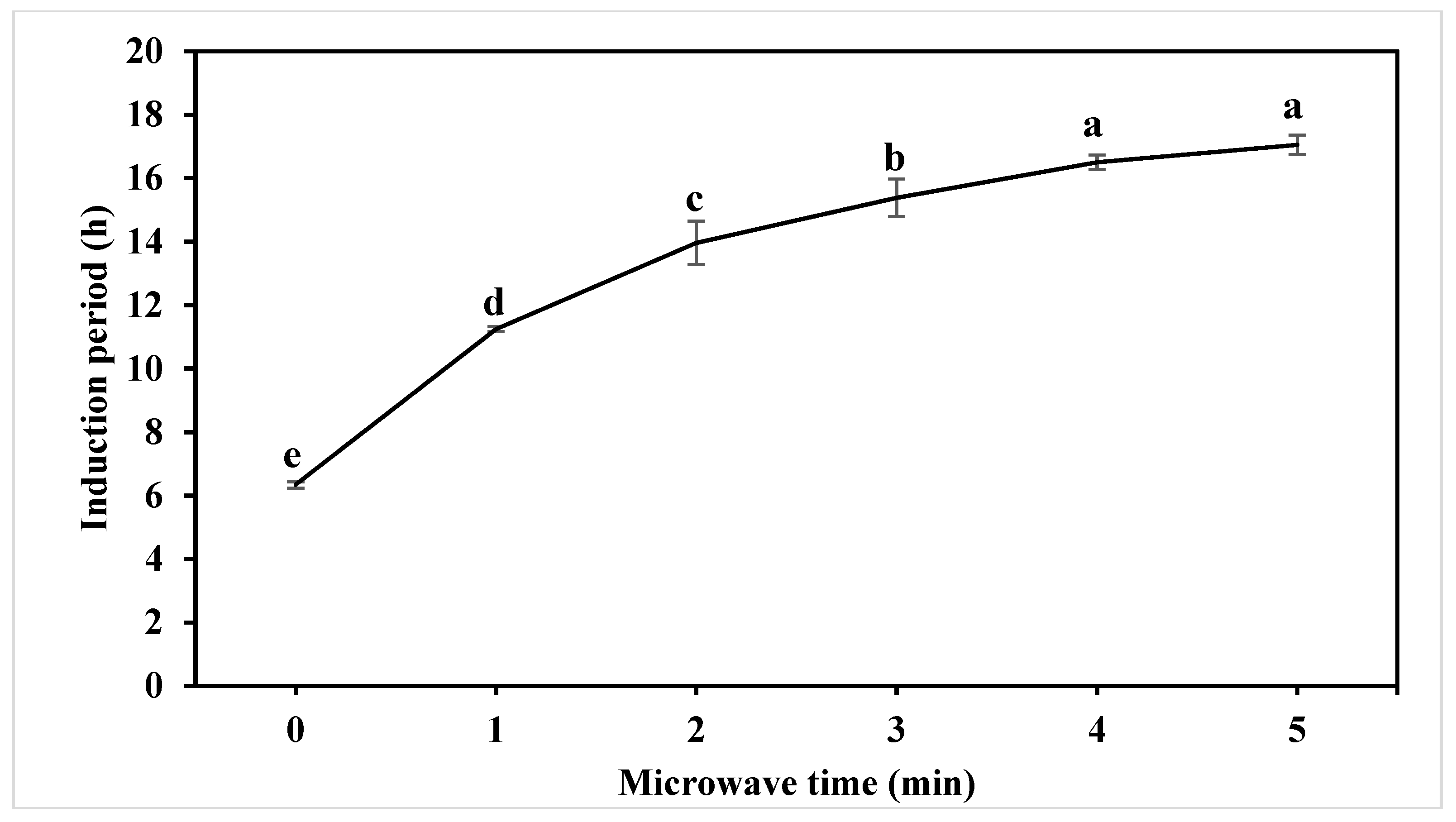

2.4. Effect Of Microwave Pretreatment on Oxidative Stability of Oil

2.5. Effect of Microwave Pretreatment on Volatile Compounds of Oil

3. Materials and Methods

3.1. Materials

3.2. Microwave Pretreatment

3.3. Cold Pressing

3.4. Physicochemical Properties and Oxidative Stability

3.5. Determination of Free Tocopherols and Phytosterols by High-Performance Liquid Chromatography (HPLC)

3.5.1. Saponification of Extracted Oil Samples

3.5.2. HPLC Analysis of Free Tocopherols and Phytosterols

3.6. Volatile Compounds Analysis

3.6.1. Headspace-Solid Phase Micro-Extraction

3.6.2. Gas Chromatography Mass Spectrometry (GC-MS) Analysis

3.6.3. Identification

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- FAOSTAT. Available online: http://www.fao.org/faostat/ (accessed on 22 November 2018).

- Wang, Q.; Liu, L.; Wang, L.; Guo, Y.; Wang, J. Introduction. In Peanuts: Processing Technology and Product Development, 1st ed.; Wang, Q., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 1–22. [Google Scholar]

- USDA. Available online: https://www.fas.usda.gov/data/oilseeds-world-markets-and-trade/ (accessed on 8 November 2018).

- Bao, Y.; Han, J.; Hu, F.B.; Giovannucci, E.L.; Stampfer, M.J.; Willett, W.C.; Fuchs, C.S. Association of nut consumption with total and cause-specific mortality. N. Engl. J. Med. 2013, 369, 2001–2011. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, S.; Khalid, N.; Ahmed, I.; Shahzad, A.; Suleria, H.A.R. Physicochemical characteristics, functional properties, and nutritional benefits of peanut oil: A review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1562–1575. [Google Scholar] [CrossRef] [PubMed]

- Wong, A. Chemical and microbiological considerations of phytosterols and their relative efficacies in functional foods for the lowering of serum cholesterol levels in humans: A review. J. Funct. Foods 2014, 6, 60–72. [Google Scholar] [CrossRef]

- Shahzad, N.; Khan, W.; MD, S.; Ali, A.; Saluja, S.S.; Sharma, S.; Al-Allaf, F.A.; Abduljaleel, Z.; Ibrahim, I.A.A.; Abdel-Wahab, A.F.; et al. Phytosterols as a natural anticancer agent: Current status and future perspective. Biomed. Pharmacother. 2017, 88, 786–794. [Google Scholar] [CrossRef] [PubMed]

- Koubaa, M.; Mhemdi, H.; Barba, F.J.; Roohinejad, S.; Greiner, R.; Vorobiev, E. Oilseed treatment by ultrasounds and microwaves to improve oil yield and quality: An overview. Food Res. Int. 2016, 85, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Uquiche, E.; Jeréz, M.; Ortíz, J. Effect of pretreatment with microwaves on mechanical extraction yield and quality of vegetable oil from Chilean hazelnuts (Gevuina avellana Mol). Innov. Food Sci. Emerg. Technol. 2008, 9, 495–500. [Google Scholar] [CrossRef]

- Azadmard-Damirchi, S.; Habibi-Nodeh, F.; Hesari, J.; Nemati, M.; Achachlouei, B.F. Effect of pretreatment with microwaves on oxidative stability and nutraceuticals content of oil from rapeseed. Food Chem. 2010, 121, 1211–1215. [Google Scholar] [CrossRef]

- Terigar, B.G.; Balasubramanian, S.; Sabliov, C.M.; Lima, M.; Boldor, D. Soybean and rice bran oil extraction in a continuous microwave system: From laboratory- to pilot-scale. J. Food Eng. 2011, 104, 208–217. [Google Scholar] [CrossRef]

- Cheng, S.F.; Nor, L.M.; Chuah, C.H. Microwave pretreatment: A clean and dry method for palm oil production. Ind. Crop. Prod. 2011, 34, 967–971. [Google Scholar] [CrossRef]

- Taghvaei, M.; Jafari, S.M.; Assadpoor, E.; Nowrouzieh, S.; Alishah, O. Optimization of microwave-assisted extraction of cottonseed oil and evaluation of its oxidative stability and physicochemical properties. Food Chem. 2014, 160, 90–97. [Google Scholar] [CrossRef]

- Zhong, J.; Wang, Y.; Yang, R.; Liu, X.; Yang, Q.; Qin, X. The application of ultrasound and microwave to increase oil extraction from Moringa oleifera seeds. Ind. Crop. Prod. 2018, 120, 1–10. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Torbati, M.; Azadmard-Damirchi, P.; Savage, G. Effect of roasting and microwave pre-treatments of Nigella sativa L. seeds on lipase activity and the quality of the oil. Food Chem. 2019, 274, 480–486. [Google Scholar] [CrossRef] [PubMed]

- Özcan, M.M.; Al-Juhaimi, F.Y.; Ahmed, I.A.M.; Osmen, M.A. Effect of different microwave power setting on quality of chia seed oil obtained in a cold press. Food Chem. 2019, 278, 190–196. [Google Scholar] [CrossRef]

- Wroniak, M.; Rekas, A.; Siger, A.; Janowicz, M. Microwave pretreatment effects on the changes in seeds microstructure, chemical composition and oxidative stability of rapeseed oil. LWT-Food Sci. Technol. 2016, 68, 634–641. [Google Scholar] [CrossRef]

- Rekas, A.; Wroniak, M.; Ścibisz, I. Microwave radiation and conventional roasting in conjunction with hulling on the oxidative state and physicochemical properties of rapeseed oil. Eur. J. Lipid Sci. Technol. 2017, 119, 1600501. [Google Scholar] [CrossRef]

- Rekas, A.; Siger, A.; Wroniak, M.; Ścibisz, I.; Derewiaka, D.; Anders, A. Dehulling and microwave pretreatment effects on the physicochemical composition and antioxidant capacity of virgin rapeseed oil. J. Food Sci. Technol. 2017, 54, 627–638. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Huang, F.; Liu, C.; Zheng, C.; Zhou, Q.; Wang, H. Influence of microwave treatment of rapeseed on minor components content and oxidative stability of oil. Food Bioprocess Technol. 2013, 6, 3206–3216. [Google Scholar] [CrossRef]

- Zhou, Q.; Yang, M.; Huang, F.; Zheng, C.; Deng, Q. Effect of pretreatment with dehulling and microwaving on the flavor characteristics of cold-pressed rapeseed oil by GC-MS-PCA and electronic nose discrimination. J. Food Sci. 2013, 78, C961–C970. [Google Scholar] [CrossRef]

- Ramos, L.B.; Sánchez, R.J.; De Figueiredo, A.K.; Nolasco, S.M.; Fernández, M.B. Optimization of microwave pretreatment variables for canola oil extraction. J. Food Process Eng. 2017, 40, e12431. [Google Scholar] [CrossRef]

- Rekas, A.; Ścibisz, I.; Siger, A.; Wroniak, M. The effect of microwave pretreatment of seeds on the stability and degradation kinetics of phenolic compounds in rapeseed oil during long-term storage. Food Chem. 2017, 222, 43–52. [Google Scholar] [CrossRef]

- Yoshida, H.; Hirakawa, Y.; Tomiyama, Y.; Mizushina, Y. Effects of microwave treatment on the oxidative stability of peanut (Arachis hypogaea) oils and the molecular species of their triacylglycerols. Eur. J. Lipid Sci. Technol. 2003, 105, 351–358. [Google Scholar] [CrossRef]

- Anjum, F.; Anwar, F.; Jamil, A.; Iqbal, M. Microwave roasting effects on the physico-chemical composition and oxidative stability of sunflower seed oil. J. Am. Oil Chem. Soc. 2006, 83, 777–784. [Google Scholar] [CrossRef]

- Cai, L.; Cao, A.; Aisikaer, G.; Ying, T. Influence of kernel roasting on bioactive components and oxidative stability of pine nut oil. Eur. J. Lipid Sci. Technol. 2013, 115, 556–563. [Google Scholar] [CrossRef]

- Shrestha, K.; De Meulenaer, B. Effect of seed roasting on canolol, tocopherol, and phospholipid contents, maillard type reactions, and oxidative stability of mustard and rapeseed oils. J. Agric. Food Chem. 2014, 62, 5412–5419. [Google Scholar] [CrossRef]

- Zheng, C.; Yang, M.; Zhou, Q.; Liu, C.S.; Huang, F.H. Changes in the content of canolol and total phenolics, oxidative stability of rapeseed oil during accelerated storage. Eur. J. Lipid Sci. Technol. 2014, 116, 1675–1684. [Google Scholar] [CrossRef]

- Zhou, Q.; Zheng, C.; Wan, C.; Guo, P.; Li, W.; Liu, C.; Huang, F. Effects of microwave pretreatment on oxidation of pressed rapeseed oil during accelerated storage. Oil Crop Sci. 2017, 2, 169–180. [Google Scholar]

- Yang, Y.; Decker, E.A.; Xiao, H.; McClements, D.J. Enhancing vitamin E bioaccessibility: Factors impacting solubilization and hydrolysis of α-tocopherol acetate encapsulated in emulsion-based delivery systems. Food Funct. 2015, 6, 83–96. [Google Scholar] [CrossRef]

- Choe, E.; Min, D.B. Mechanisms and factors for edible oil oxidation. Compr. Rev. Food Sci. Food Saf. 2006, 5, 169–186. [Google Scholar] [CrossRef]

- Przybylski, R.; Eskin, N.A.M. Minor components and the stability of vegetable oils. INFORM 2006, 17, 186–188. [Google Scholar]

- Tuberoso, C.I.G.; Kowalczyk, A.; Sarritzu, E.; Cabras, P. Determination of antioxidant compounds and antioxidant activity in commercial oilseeds for food use. Food Chem. 2007, 103, 1494–1501. [Google Scholar] [CrossRef]

- Ramesh, M.; Rao, P.H.; Ramadoss, C.S. Microwave treatment of groundnut (Arachis hypogaea): Extractability and quality of oil and its relation to lipase and lipoxygenase activity. LWT-Food Sci. Technol. 1995, 28, 96–99. [Google Scholar] [CrossRef]

- Liu, X.; Jin, Q.; Liu, Y.; Huang, J.; Wang, X.; Mao, W.; Wang, S. Changes in volatile compounds of peanut oil during the roasting process for production of aromatic roasted peanut oil. J. Food Sci. 2011, 76, C404–C412. [Google Scholar] [CrossRef] [PubMed]

- Baker, G.L.; Cornell, J.A.; Gorbet, D.W.; O’Keefe, S.F.; Sims, C.A.; Talcott, S.T. Determination of pyrazine and flavor variations in peanut genotypes during roasting. J. Food Sci. 2003, 68, 394–400. [Google Scholar] [CrossRef]

- Davis, J.P.; Dean, L.L. Peanut composition, flavor and nutrition. In Peanuts Genetics, Processing, and Utilization, 1st ed.; Stalker, H.T., Wilson, R.F., Eds.; Academic Press and AOCS Press: Cambridge, MA, USA, 2017; pp. 289–345. [Google Scholar]

- Schirack, A.V.; Sanders, T.H.; Sandeep, K.P. Effect of processing parameters on the temperature and moisture content of microwave-blanched peanuts. J. Food Process Eng. 2006, 30, 225–240. [Google Scholar] [CrossRef]

- ISO 659. Oilseeds—Determination of Oil Content (Reference Method); International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Swetman, T.; Head, S. Calculation of oil extraction efficiency. INFORM 1998, 9, 1191. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-84890554709&origin=inward (accessed on 20 November 2018).

- AOCS Official Method Cd 3d-63. Acid value of fats and oils. In Official Methods and Recommended Practices of the AOCS; AOCS Press: Urbana, IL, USA, 2017. [Google Scholar]

- AOCS Official Method Cd 8b-90. Peroxide value, acetic acid, isooctane method. In Official Methods and Recommended Practices of the AOCS; AOCS Press: Urbana, IL, USA, 2017. [Google Scholar]

- Chung, T.Y.; Eiserich, J.P.; Shibamoto, T. Volatile compounds identified in headspace samples of peanut oil heated under temperatures ranging from 50 to 200. degree C. J. Agric. Food Chem. 1993, 41, 1467–1470. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| MW Time (min) | Color (Red Units) | Color (Yellow Units) | Acid Value (mg KOH/g Oil) | Peroxide Value (meq O2/kg Oil) |

|---|---|---|---|---|

| 0 | 0.00 ± 0.00 f | 1.20 ± 0.10 c | 0.31 ± 0.02 d | 0.54 ± 0.08 e |

| 1 | 0.10 ± 0.00 e | 1.40 ± 0.00 c | 0.41 ± 0.01 c | 0.64 ± 0.00 e |

| 2 | 0.20 ± 0.00 d | 2.37 ± 0.44 b | 0.43 ± 0.03 bc | 2.58 ± 0.08 d |

| 3 | 0.23 ± 0.03 c | 2.67 ± 0.24 b | 0.45 ± 0.01 ab | 3.86 ± 0.16 c |

| 4 | 0.30 ± 0.00 b | 2.67 ± 0.24 b | 0.46 ± 0.02 ab | 5.10 ± 0.00 b |

| 5 | 0.40 ± 0.00 a | 3.47 ± 0.38 a | 0.47 ± 0.00 a | 5.30 ± 0.08 a |

| MH Time (min) | Phytosterols | Tocopherols | |||

|---|---|---|---|---|---|

| Total | α-Tocopherol | γ-Tocopherol | δ-Tocopherol | Total | |

| 0 | 273.55 ± 2.51 f | 13.87 ± 0.27 e | 3.97 ± 0.06 e | 0.58 ± 0.02 c | 18.42 ± 0.29 e |

| 1 | 298.49 ± 3.26 e | 13.93 ± 0.17 e | 4.00 ± 0.07 e | 0.60 ± 0.04 c | 18.53 ± 0.22 e |

| 2 | 310.33 ± 5.21 d | 15.82 ± 0.06 d | 4.37 ± 0.03 d | 0.60 ± 0.04 c | 20.79 ± 0.08 d |

| 3 | 325.13 ± 6.76 c | 16.79 ± 0.22 c | 4.58 ± 0.08 c | 0.66 ± 0.01 b | 22.03 ± 0.25 c |

| 4 | 339.16 ± 3.73 b | 20.38 ± 0.03 b | 5.05 ± 0.11 b | 0.69 ± 0.03 b | 26.12 ± 0.12 b |

| 5 | 363.35 ± 4.22 a | 21.36 ± 0.24 a | 5.66 ± 0.04 a | 0.86 ± 0.02 a | 27.88 ± 0.27 a |

| Compounds | Odor Description | Microwave Pretreatment Time | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 min | 1 min | 2 min | 3 min | 4 min | 5 min | ||||||

| Peak Area (×107) | Relative Content (%) | Peak Area (×107) | Relative Content (%) | Peak Area (×107) | Relative Content (%) | Peak Area (×107) | Relative Content (%) | Peak Area (×107) | Relative Content (%) | ||

| 2-methyl-pyrazine | Nutty, roasted | ND | ND | ND | 1.07 ± 0.01 | 2.27 ± 0.02 | 2.92 ± 0.03 | 3.84 ± 0.03 | 3.56 ± 0.02 | 3.47 ± 0.01 | |

| 2,5-dimethyl-pyrazine | Roasted | ND | ND | ND | 2.33 ± 0.01 | 4.97 ± 0.03 | 4.23 ± 0.10 | 5.56 ± 0.12 | 4.34 ± 0.06 | 4.23 ± 0.07 | |

| 2,6-dimethyl-pyrazine | Nutty, roasted, sweet | ND | ND | ND | 0.77 ± 0.01 | 1.64 ± 0.03 | 2.07 ± 0.09 | 2.72 ± 0.10 | 2.43 ± 0.02 | 2.36 ± 0.03 | |

| 2-ethyl-pyrazine | Peanut-butter, nutty, woody, buttery | ND | ND | ND | 0.42 ± 0.01 | 0.90 ± 0.02 | 0.95 ± 0.03 | 1.25 ± 0.04 | 1.05 ± 0.04 | 1.02 ± 0.03 | |

| 2,3-dimethyl-pyrazine | Nutty, green | ND | ND | ND | ND | ND | 1.02 ± 0.01 | 1.35 ± 0.01 | 1.05 ± 0.01 | 1.02 ± 0.01 | |

| 2-ethyl-6-methyl-pyrazine | Nutty | ND | ND | ND | ND | ND | 1.18 ± 0.02 | 1.55 ± 0.03 | 1.48 ± 0.04 | 1.44 ± 0.03 | |

| 2-ethyl-5-methyl-pyrazine | Nutty, roasted, grassy | ND | ND | ND | ND | ND | 2.30 ± 0.04 | 3.03 ± 0.05 | 2.60 ± 0.02 | 2.53 ± 0.01 | |

| trimethyl-pyrazine | Nutty, roasted, grassy | ND | ND | 0.47 ± 0.02 | 1.31 ± 0.06 | 1.44 ± 0.04 | 3.06 ± 0.07 | 2.93 ± 0.02 | 3.86 ± 0.03 | 3.34 ± 0.18 | 3.25 ± 0.11 |

| 2,5-dimethyl-3-ethyl-pyrazine | Nutty, roasted, earthy | ND | ND | ND | 1.68 ± 0.02 | 3.59 ± 0.04 | 3.51 ± 0.11 | 4.61 ± 0.13 | 3.82 ± 0.13 | 3.72 ± 0.07 | |

| 2,3-Dimethyl-5-ethyl-pyrazine | Nutty, roasted | ND | ND | ND | 0.29 ± 0.01 | 0.63 ± 0.01 | 0.81 ± 0.04 | 1.07 ± 0.05 | 1.02 ± 0.02 | 0.99 ± 0.01 | |

| 2-ethenyl-6-methyl-pyrazine | ND | ND | ND | 0.22 ± 0.01 | 0.46 ± 0.02 | 0.33 ± 0.02 | 0.43 ± 0.02 | 0.44 ± 0.01 | 0.43 ± 0.01 | ||

| 3,5-diethyl-2-methyl-pyrazine | ND | ND | ND | ND | ND | 0.81 ± 0.04 | 1.07 ± 0.06 | 1.00 ± 0.07 | 0.97 ± 0.04 | ||

| 2-methyl-6-(1-propenyl)-, (E)- pyrazine | ND | ND | ND | 0.48 ± 0.02 | 1.02 ± 0.04 | 0.79 ± 0.09 | 1.04 ± 0.10 | 1.06 ± 0.05 | 1.04 ± 0.04 | ||

| acetyl-pyrazine | ND | ND | ND | ND | ND | ND | ND | 1.88 ± 0.07 | 1.83 ± 0.08 | ||

| 2-acetyl-3-methyl-pyrazine | Nutty, vegetable | ND | ND | ND | ND | ND | 1.52 ± 0.08 | 1.99 ± 0.10 | 2.50 ± 0.12 | 2.44 ± 0.06 | |

| Total | 0.47 ± 0.02 | 1.31 ± 0.06 | 8.70 ± 0.06 | 18.54 ± 0.13 | 25.37 ±0.20 | 33.37 ± 0.24 | 31.56 ± 0.31 | 30.74 ± 0.20 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.; Liu, H.; Shi, A.; Liu, L.; Fauconnier, M.L.; Wang, Q. The Effect of Microwave Pretreatment on Micronutrient Contents, Oxidative Stability and Flavor Quality of Peanut Oil. Molecules 2019, 24, 62. https://doi.org/10.3390/molecules24010062

Hu H, Liu H, Shi A, Liu L, Fauconnier ML, Wang Q. The Effect of Microwave Pretreatment on Micronutrient Contents, Oxidative Stability and Flavor Quality of Peanut Oil. Molecules. 2019; 24(1):62. https://doi.org/10.3390/molecules24010062

Chicago/Turabian StyleHu, Hui, Hongzhi Liu, Aimin Shi, Li Liu, Marie Laure Fauconnier, and Qiang Wang. 2019. "The Effect of Microwave Pretreatment on Micronutrient Contents, Oxidative Stability and Flavor Quality of Peanut Oil" Molecules 24, no. 1: 62. https://doi.org/10.3390/molecules24010062

APA StyleHu, H., Liu, H., Shi, A., Liu, L., Fauconnier, M. L., & Wang, Q. (2019). The Effect of Microwave Pretreatment on Micronutrient Contents, Oxidative Stability and Flavor Quality of Peanut Oil. Molecules, 24(1), 62. https://doi.org/10.3390/molecules24010062