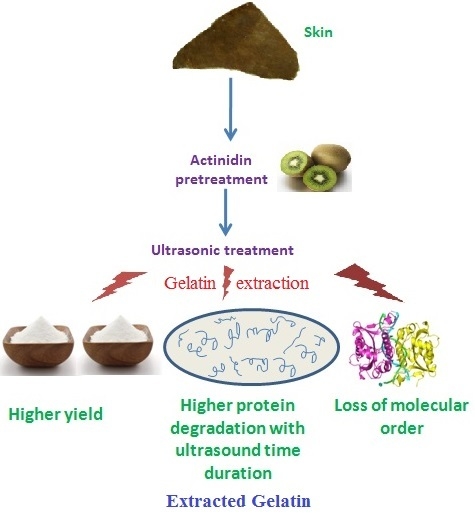

Effects of Ultrasound Assisted Extraction in Conjugation with Aid of Actinidin on the Molecular and Physicochemical Properties of Bovine Hide Gelatin

Abstract

1. Introduction

2. Results and Discussion

2.1. Gelatin Yield

2.2. Colour

2.3. pH

2.4. Amino Acid Composition of Gelatin

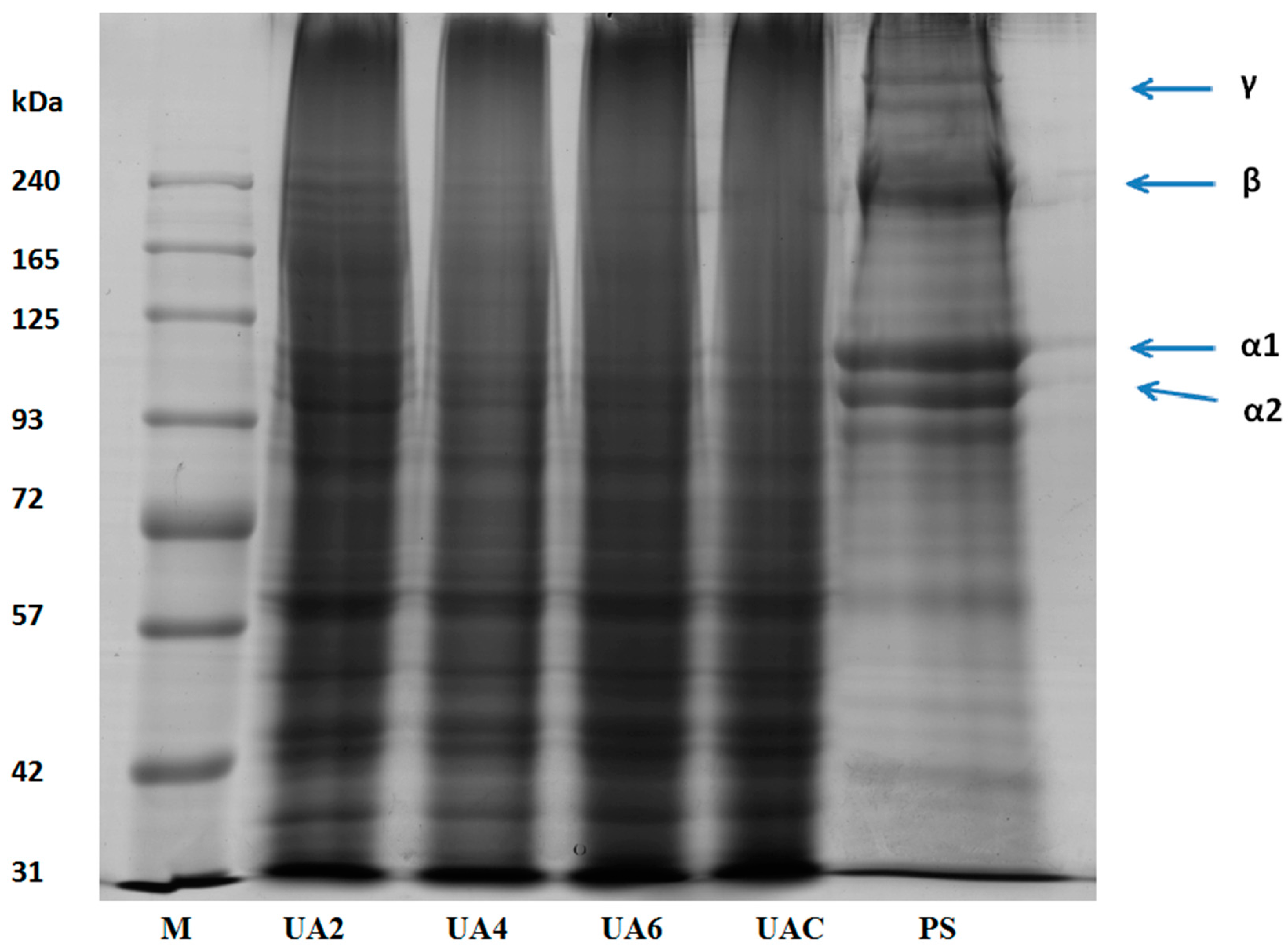

2.5. SDS-PAGE Analysis of Gelatin

2.6. Turbidity

2.7. Gel Strength

2.8. Viscosity

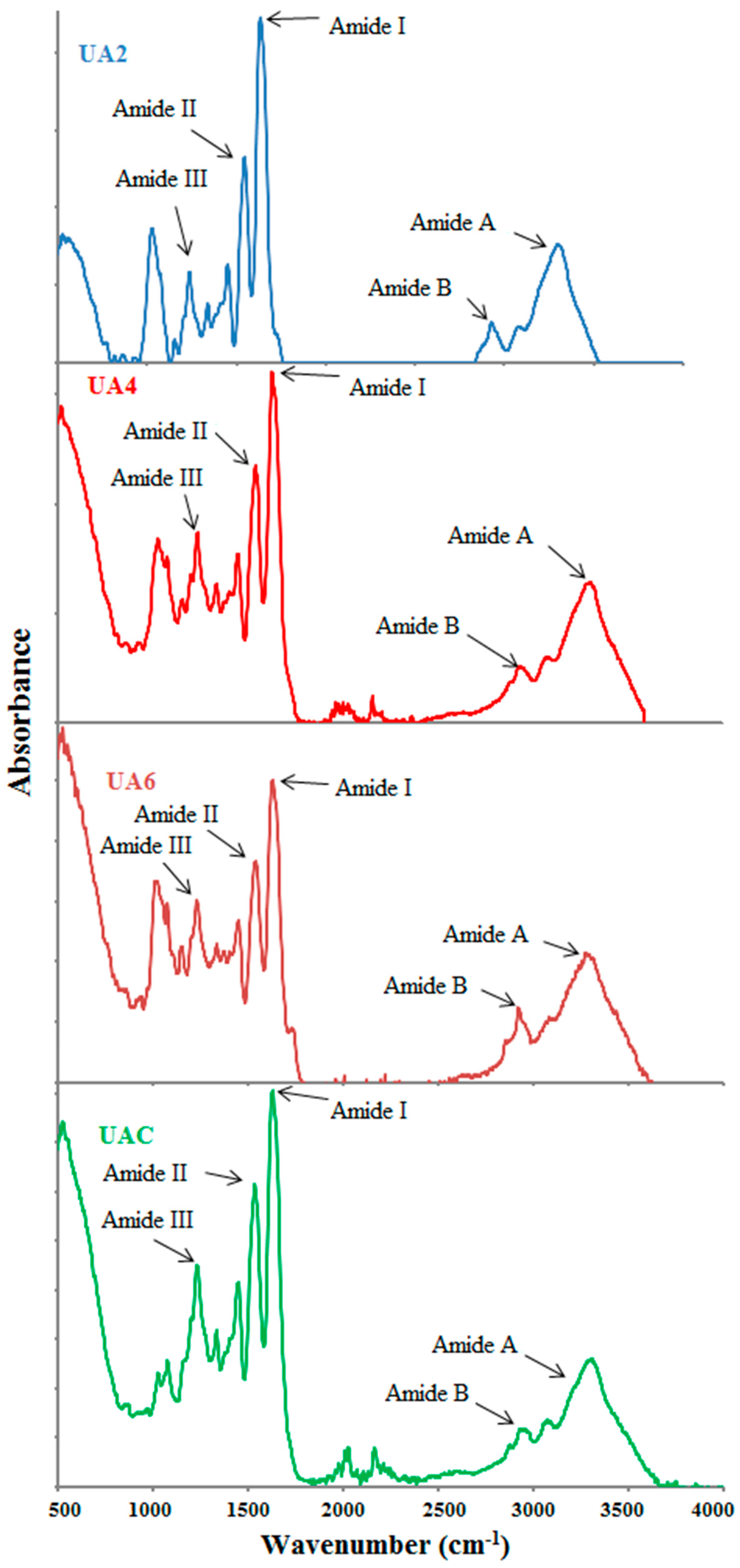

2.9. FTIR Spectra

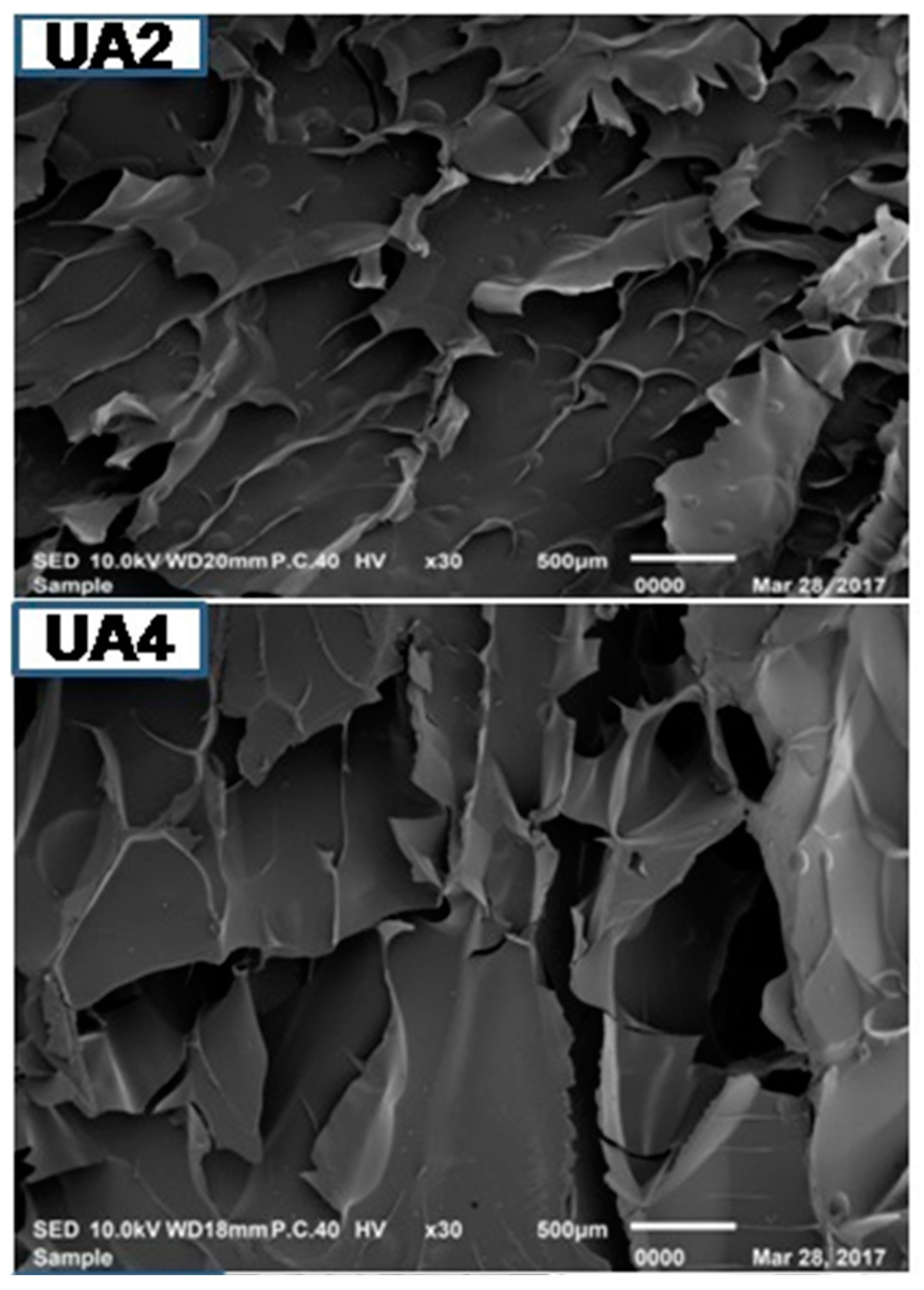

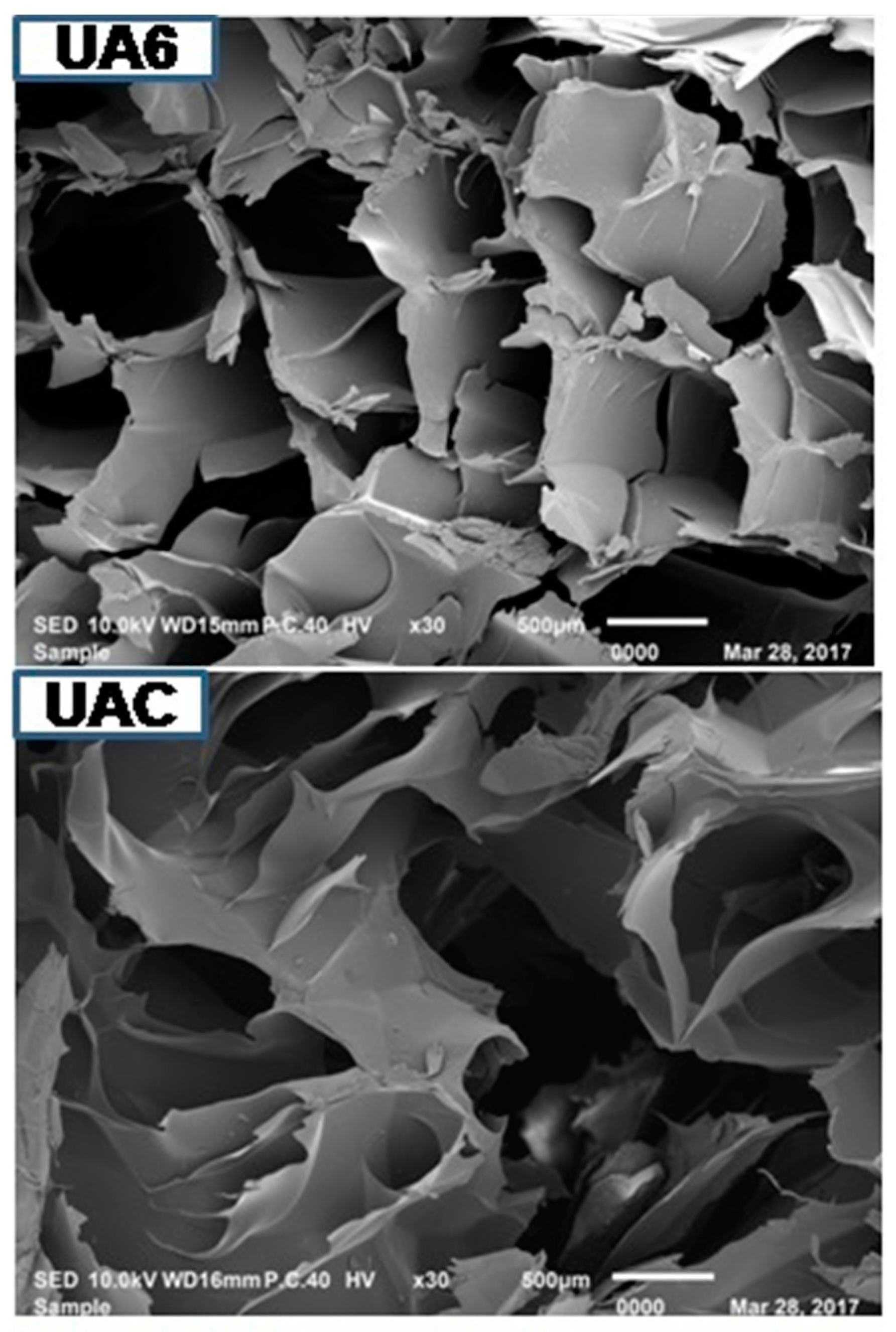

2.10. Microstructure of Gelatin

3. Materials and Methods

3.1. Chemicals

3.2. Preparation of Hide

3.3. Ultrasound Assisted Extraction of Gelatin from Bovine Hide in Conjugation with Enzyme Actinidin

3.3.1. Removal of Non-Collagenous Proteins

3.3.2. Ultrasound Assisted Gelatin Extraction in Conjugation with Enzyme Actinidin

3.4. Analyses of Gelatin

3.4.1. Yield

3.4.2. Determination of Colour

3.4.3. Determination of pH

3.4.4. Determination of Amino Acid Composition

3.4.5. Electrophoretic Analysis

3.4.6. Determination of Turbidity

3.4.7. Determination of Gel Strength

3.4.8. Determination of Viscosity

3.4.9. Fourier Transform Infrared (FTIR) Spectroscopy

3.4.10. Microstructure Analysis of Gelatin

3.5. Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Giménez, B.; Gómez-Guillén, M.; Montero, P. The role of salt washing of fish skins in chemical and rheological properties of gelatin extracted. Food Hydrocoll. 2005, 19, 951–957. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Giménez, B.; López-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef]

- Stainsby, G. Gelatin gels. In Collagen as a Food. Advances in Meat Research; Pearson, A.M., Dutson, T.R., Bailey, A.J., Eds.; Van Nostrand Reinhold Company, Inc.: New York, NY, USA, 1987; pp. 209–222. [Google Scholar]

- Djabourov, M.; Lechaire, J.-P.; Gaill, F. Structure and rheology of gelatin and collagen gels. Biorheology 1993, 30, 191–205. [Google Scholar] [CrossRef] [PubMed]

- Johnston-Banks, F.A. Gelatine. In Food Gels; Harris, P., Ed.; Elsevier Applied Sciences Publishers: New York, NY, USA, 1990; pp. 233–289. [Google Scholar]

- Bailey, A. Round table session 1–Structure of collagen. Adv. Meat Res. 1985, 4, 131–143. [Google Scholar]

- Asghar, A.; Henrickson, R.L. Chemical, biochemical, functional, and nutritional characteristics of collagen in food systems. In Advances in Food Research; Chischester, C.O., Mark, E.M., Stewart, G.F., Eds.; Academic Press: London, UK, 1982; pp. 231–372. [Google Scholar]

- Shishov, A.; Bulatov, A.; Locatelli, M.; Carradori, S.; Andruch, V. Application of deep eutectic solvents in analytical chemistry. A review. Microchem. J. 2017, 135, 33–38. [Google Scholar] [CrossRef]

- Kabir, A.; Locatelli, M.; Ulusoy, H.I. Recent Trends in Microextraction Techniques Employed in Analytical and Bioanalytical Sample Preparation. Separations 2017, 4, 36. [Google Scholar] [CrossRef]

- Diuzheva, A.; Carradori, S.; Andruch, V.; Locatelli, M.; De Luca, E.; Tiecco, M.; Tiecco, M.; Germani, R.; Menghini, L.; Nocentini, A.; et al. Use of innovative (micro) extraction techniques to characterise Harpagophytumprocumbens root and its commercial food supplements. Phytochem. Anal. 2017. [Google Scholar] [CrossRef] [PubMed]

- Vilkhu, K.; Mawson, R.; Simons, L.; Bates, D. Applications and opportunities for ultrasound assisted extraction in the food industry—A review. Innov. Food Sci. Emerg. Technol. 2008, 9, 161–169. [Google Scholar] [CrossRef]

- Jia, J.; Ma, H.; Zhao, W.; Wang, Z.; Tian, W.; Luo, L.; He, R. The use of ultrasound for enzymatic preparation of ACE-inhibitory peptides from wheat germ protein. Food Chem. 2010, 119, 336–342. [Google Scholar] [CrossRef]

- Li, D.; Mu, C.; Cai, S.; Lin, W. Ultrasonic irradiation in the enzymatic extraction of collagen. Ultrason. Sonochem. 2009, 16, 605–609. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.K.; Kim, Y.H.; Kim, Y.J.; Park, H.J.; Lee, N.H. Effects of ultrasonic treatment on collagen extraction from skins of the sea bass Lateolabrax japonicus. Fish Sci. 2012, 78, 485–490. [Google Scholar] [CrossRef]

- Tu, Z.-C.; Huang, T.; Wang, H.; Sha, X.-M.; Shi, Y.; Huang, X.-Q.; Man, Z.-Z.; Li, D.-J. Physico-chemical properties of gelatin from bighead carp (Hypophthalmichthys nobilis) scales by ultrasound-assisted extraction. J. Food Sci. Technol. 2015, 52, 2166. [Google Scholar] [CrossRef] [PubMed]

- Galea, C.A.; Dalrymple, B.P.; Kuypers, R.; Blakeley, R. Modification of the substrate specificity of porcine pepsin for the enzymatic production of bovine skin gelatin. Protein Sci. 2000, 9, 1947–1959. [Google Scholar] [CrossRef] [PubMed]

- Nalinanon, S.; Benjakul, S.; Visessanguan, W.; Kishimura, H. Improvement of gelatin extraction from bigeye snapper skin using pepsin-aided process in combination with protease inhibitor. Food Hydrocoll. 2008, 22, 615–622. [Google Scholar] [CrossRef]

- Chomarat, N.; Robert, L.; Seris, J.L.; Kern, P. Comparative efficiency of pepsin and proctase for the preparation of bovine skin gelatin. Enzym. Microb. Technol. 1994, 16, 756–760. [Google Scholar] [CrossRef]

- Pitpreecha, S.; Damrongsakkul, S. Hydrolysis of raw hide using proteolytic enzyme extracted from papaya latex. Korean J. Chem. Eng. 2006, 23, 972–976. [Google Scholar] [CrossRef]

- Damrongsakkul, S.; Ratanathammapan, K.; Komolpis, K.; Tanthapanichakoon, W. Enzymatic hydrolysis of rawhide using papain and neutrase. Ind. Eng. Chem. Res. 2008, 14, 202–206. [Google Scholar] [CrossRef]

- Badii, F.; Howell, N.K. Fish gelatin: Structure, gelling properties and interaction with egg albumen proteins. Food Hydrocoll. 2006, 20, 630–640. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Turnay, J.; Fernández-Dıaz, M.D.; Ulmo, N.; Lizarbe, M.A.; Montero, P. Structural and physical properties of gelatin extracted from different marine species: A comparative study. Food Hydrocoll. 2002, 16, 25–34. [Google Scholar] [CrossRef]

- Muyonga, J.H.; Cole, C.G.B.; Duodu, K.G. Extraction and physico-chemical characterisation of Nile perch (Lates niloticus) skin and bone gelatin. Food Hydrocoll. 2004, 18, 581–592. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, S.; Wang, Z. Pre-treatment optimization and properties of gelatin from freshwater fish scales. Food Bioprod. Process. 2011, 89, 185–193. [Google Scholar] [CrossRef]

- Ahmad, T.; Ismail, A.; Ahmad, S.A.; Khalil, K.A.; Kumar, Y.; Adeyemi, K.D.; Sazili, A.Q. Recent advances on the role of process variables affecting gelatin yield and characteristics with special reference to enzymatic extraction: A review. Food Hydrocoll. 2017, 63, 85–96. [Google Scholar] [CrossRef]

- Ha, M.; Bekhit, A.E.-D.A.; Carne, A.; Hopkins, D.L. Characterisation of commercial papain, bromelain, actinidin and zingibain protease preparations and their activities toward meat proteins. Food Chem. 2012, 134, 95–105. [Google Scholar] [CrossRef]

- Arnesen, J.A.; Gildberg, A. Extraction and characterisation of gelatine from Atlantic salmon (Salmo salar) skin. Bioresour. Technol. 2007, 98, 53–57. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, M.; Benjakul, S.; Prodpran, T.; Songtipya, P.; Kishimura, H. Characteristics and functional properties of gelatin from splendid squid (Loligo formosana) skin as affected by extraction temperatures. Food Hydrocoll. 2012, 29, 389–397. [Google Scholar] [CrossRef]

- Benjakul, S.; Oungbho, K.; Visessanguan, W.; Thiansilakul, Y.; Roytrakul, S. Characteristics of gelatin from the skins of bigeye snapper, Priacanthustayenus and Priacanthusmacracanthus. Food Chem. 2009, 116, 445–451. [Google Scholar] [CrossRef]

- Ahmad, M.; Benjakul, S. Characteristics of gelatin from the skin of unicorn leatherjacket (Aluterus monoceros) as influenced by acid pretreatment and extraction time. Food Hydrocoll. 2011, 25, 381–388. [Google Scholar] [CrossRef]

- Wang, J.; Sun, B.; Cao, Y.; Tian, Y.; Li, X. Optimisation of ultrasound-assisted extraction of phenolic compounds from wheat bran. Food Chem. 2008, 106, 804–810. [Google Scholar] [CrossRef]

- Rostagno, M.A.; Palma, M.; Barroso, C.G. Ultrasound-assisted extraction of soy isoflavones. J. Chromatogr. A 2003, 1012, 119–128. [Google Scholar] [CrossRef]

- Chemat, F.; Khan, M.K. Applications of ultrasound in food technology: Processing, preservation and extraction. Ultrason. Sonochem. 2011, 18, 813–835. [Google Scholar] [CrossRef] [PubMed]

- Balti, R.; Jridi, M.; Sila, A.; Souissi, N.; Nedjar-Arroume, N.; Guillochon, D.; Nasri, M. Extraction and functional properties of gelatin from the skin of cuttlefish (Sepia officinalis) using smooth hound crude acid protease-aided process. Food Hydrocoll. 2011, 25, 943–950. [Google Scholar] [CrossRef]

- Lassoued, I.; Jridi, M.; Nasri, R.; Dammak, A.; Hajji, M.; Nasri, M.; Barkia, A. Characteristics and functional properties of gelatin from thornback ray skin obtained by pepsin-aided process in comparison with commercial halal bovine gelatin. Food Hydrocoll. 2014, 41, 309–318. [Google Scholar] [CrossRef]

- Bougatef, A.; Balti, R.; Sila, A.; Nasri, R.; Graiaa, G.; Nasri, M. Recovery and physicochemical properties of smooth hound (Mustelus mustelus) skin gelatin. LWT-Food Sci. Technol. 2012, 48, 248–254. [Google Scholar] [CrossRef]

- Sinthusamran, S.; Benjakul, S.; Kishimura, H. Characteristics and gel properties of gelatin from skin of seabass (Lates calcarifer) as influenced by extraction conditions. Food Chem. 2014, 152, 276–284. [Google Scholar] [CrossRef] [PubMed]

- Mohtar, N.F.; Perera, C.; Quek, S.-Y. Optimisation of gelatine extraction from hoki (Macruronusnovaezelandiae) skins and measurement of gel strength and SDS–PAGE. Food Chem. 2010, 122, 307–313. [Google Scholar] [CrossRef]

- Park, J.-H.; Choe, J.-H.; Kim, H.-W.; Hwang, K.-E.; Song, D.-H.; Yeo, E.-J.; Kim, H.-Y.; Choi, Y.-S.; Lee, S.-H.; Kim, C.-J. Effects of various extraction methods on quality characteristics of duck feet gelatin. Korean J. Food Sci. Anim. Resour. 2013, 33, 162–169. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Pérez-Mateos, M.; Gómez-Estaca, J.; López-Caballero, E.; Giménez, B.; Montero, P. Fish gelatin: A renewable material for developing active biodegradable films. Trends Food Sci. Technol. 2009, 20, 3–16. [Google Scholar] [CrossRef]

- Arnesen, J.A.; Gildberg, A. Preparation and characterisation of gelatine from the skin of harp seal (Phoca groendlandica). Bioresour. Technol. 2002, 82, 191–194. [Google Scholar] [CrossRef]

- Norland, R.E. Fish gelatin. In Advances in Fisheries Technology and Biotechnology for Increased Profitability; Voight, M.N., Botta, J.K., Eds.; Technomic Publishing Co.: Lancaster, UK, 1990; pp. 325–333. [Google Scholar]

- Li, K.; Ma, H.; Li, S.; Zhang, C.; Dai, C. Effect of ultrasound on alkali extraction protein from rice dreg flour. J. Food Process Eng. 2017, 40. [Google Scholar] [CrossRef]

- Chandrapala, J.; Zisu, B.; Kentish, S.; Ashokkumar, M. The effects of high-intensity ultrasound on the structural and functional properties of α-Lactalbumin, β-Lactoglobulin and their mixtures. Food Res. Int. 2012, 48, 940–943. [Google Scholar] [CrossRef]

- Ward, A.G.; Courts, A. Science and technology of gelatin; Academic Press: London, UK, 1977. [Google Scholar]

- Zhou, P.; Regenstein, J.M. Determination of total protein content in gelatin solutions with the Lowry or Biuret assay. J. Food Sci. 2006, 71, C474–C479. [Google Scholar] [CrossRef]

- Kasankala, L.M.; Xue, Y.; Weilong, Y.; Hong, S.D.; He, Q. Optimization of gelatine extraction from grass carp (Catenopharyngodon idella) fish skin by response surface methodology. Bioresour. Technol. 2007, 98, 3338–3343. [Google Scholar] [CrossRef] [PubMed]

- Ledward, D.A. Gelation of gelatin. In Functional Properties of Food Macromolecules; Mitchell, J.R., Ledward, D.A., Eds.; Elsevier Applied Science Publishers: London, UK, 1986; pp. 171–201. [Google Scholar]

- Mizuno, K.; Hayashi, T.; Bächinger, H.P. Hydroxylation-induced Stabilization of the Collagen Triple Helix Further characterization of peptides with 4 (r)-hydroxyproline in the XAA position. J. Biol. Chem. 2003, 278, 32373–32379. [Google Scholar] [CrossRef] [PubMed]

- Krise, K.M. The Effects of Microviscosity, Bound Water and Protein Mobility on the Radiolysis and Sonolysis of Hen Egg White. Ph.D Thesis, The Pennsylvania State University, State College, PA, USA, 2011. Publication Number: 3483787. [Google Scholar]

- Hu, H.; Wu, J.; Li-Chan, E.C.Y.; Zhu, L.; Zhang, F.; Xu, X.; Fan, G.; Wang, L.; Huang, X.; Pan, S. Effects of ultrasound on structural and physical properties of soy protein isolate (SPI) dispersions. Food Hydrocoll. 2013, 30, 647–655. [Google Scholar] [CrossRef]

- Karki, B.; Lamsal, B.P.; Jung, S.; van Leeuwen, J.H.; Pometto, A.L.; Grewell, D.; Khanal, S.K. Enhancing protein and sugar release from defatted soy flakes using ultrasound technology. J. Food Eng. 2010, 96, 270–278. [Google Scholar] [CrossRef]

- Gülseren, İ.; Güzey, D.; Bruce, B.D.; Weiss, J. Structural and functional changes in ultrasonicated bovine serum albumin solutions. Ultrason. Sonochem. 2007, 14, 173–183. [Google Scholar] [CrossRef] [PubMed]

- O’Sullivan, J.; Arellano, M.; Pichot, R.; Norton, I. The effect of ultrasound treatment on the structural, physical and emulsifying properties of dairy proteins. Food Hydrocoll. 2014, 42, 386–396. [Google Scholar] [CrossRef]

- Yanjun, S.; Jianhang, C.; Shuwen, Z.; Hongjuan, L.; Jing, L.; Lu, L.; Uluko, H.; Yanling, S.; Wenming, C.; Wupeng, G. Effect of power ultrasound pre-treatment on the physical and functional properties of reconstituted milk protein concentrate. J. Food Eng. 2014, 124, 11–18. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Mason, T.J.; Lelas, V.; Paniwnyk, L.; Herceg, Z. Effect of ultrasound treatment on particle size and molecular weight of whey proteins. J. Food Eng. 2014, 121, 15–23. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Mason, T.J.; Lelas, V.; Krešić, G. Ultrasonic effect on physicochemical and functional properties of α-lactalbumin. LWT-Food Sci. Technol. 2010, 43, 254–262. [Google Scholar] [CrossRef]

- Montero, P.; Fernández-Dı́az, M.D.; Gómez-Guillén, M.C. Characterization of gelatin gels induced by high pressure. Food Hydrocoll. 2002, 16, 197–205. [Google Scholar] [CrossRef]

- Jongjareonrak, A.; Benjakul, S.; Visessanguan, W.; Tanaka, M. Skin gelatin from bigeye snapper and brownstripe red snapper: Chemical compositions and effect of microbial transglutaminase on gel properties. Food Hydrocoll. 2006, 20, 1216–1222. [Google Scholar] [CrossRef]

- Ahmad, M.; Benjakul, S.; Ovissipour, M.; Prodpran, T. Indigenous proteases in the skin of unicorn leatherjacket (Alutherus monoceros) and their influence on characteristic and functional properties of gelatin. Food Chem. 2011, 127, 508–515. [Google Scholar] [CrossRef] [PubMed]

- Jamilah, B.; Tan, K.W.; UmiHartina, M.R.; Azizah, A. Gelatins from three cultured freshwater fish skins obtained by liming process. Food Hydrocoll. 2011, 25, 1256–1260. [Google Scholar] [CrossRef]

- Gudmundsson, M.; Hafsteinsson, H. Gelatin from cod skins as affected by chemical treatments. J. Food Sci. 1997, 62, 37–39. [Google Scholar] [CrossRef]

- Muyonga, J.H.; Cole, C.G.B.; Duodu, K.G. Fourier transform infrared (FTIR) spectroscopic study of acid soluble collagen and gelatin from skins and bones of young and adult Nile perch (Lates niloticus). Food Chem. 2004, 86, 325–332. [Google Scholar] [CrossRef]

- Bandekar, J. Amide modes and protein conformation. Biochim. Biophys. Acta (BBA)-Protein Struct. Mol. Enzymol. 1992, 1120, 123–143. [Google Scholar] [CrossRef]

- Uriarte-Montoya, M.H.; Santacruz-Ortega, H.; Cinco-Moroyoqui, F.J.; Rouzaud-Sández, O.; Plascencia-Jatomea, M.; Ezquerra-Brauer, J.M. Giant squid skin gelatin: Chemical composition and biophysical characterization. Food Res. Int. 2011, 44, 3243–3249. [Google Scholar] [CrossRef]

- Yakimets, I.; Wellner, N.; Smith, A.C.; Wilson, R.H.; Farhat, I.; Mitchell, J. Mechanical properties with respect to water content of gelatin films in glassy state. Polymer 2005, 46, 12577–12585. [Google Scholar] [CrossRef]

- Barth, A. Infrared spectroscopy of proteins. Biochim. Biophys. Acta (BBA)-Bioenerg. 2007, 1767, 1073–1101. [Google Scholar] [CrossRef] [PubMed]

- Jackson, M.; Watson, P.H.; Halliday, W.C.; Mantsch, H.H. Beware of connective tissue proteins: Assignment and implications of collagen absorptions in infrared spectra of human tissues. Biochim. Biophys. Acta (BBA)-Mol. Basis Dis. 1995, 1270, 1–6. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, J.; Li, Y.; Wang, Z.; Liang, J.; Wang, R.; Chen, Y.; Ma, W.; Qi, B.; Zhang, M. Effects of ultrasound on the structure and physical properties of black bean protein isolates. Food Res. Int. 2014, 62, 595–601. [Google Scholar] [CrossRef]

- Ktari, N.; Bkhairia, I.; Jridi, M.; Hamza, I.; Riadh, B.S.; Nasri, M. Digestive acid protease from zebra blenny (Salaria basilisca): Characteristics and application in gelatin extraction. Food Res. Int. 2014, 57, 218–224. [Google Scholar] [CrossRef]

- Jamilah, B.; Harvinder, K. Properties of gelatins from skins of fish—Black tilapia (Oreochromis mossambicus) and red tilapia (Oreochromis nilotica). Food Chem. 2002, 77, 81–84. [Google Scholar] [CrossRef]

- Eastoe, J.; Leach, A. Chemical constitution of gelatin (From mammals, chicken tendon, calf skin, pig skin). In The Science and Technology of Gelatin; Academic Press Inc.: London, UK, 1977; pp. 73–105. [Google Scholar]

- Awad, E.A.; Zulkifli, I.; Farjam, A.S.; Chwen, L.T. Amino acids fortification of low-protein diet for broilers under tropical climate. 2. Nonessential amino acids and increasing essential amino acids. Ital. J. Anim. Sci. 2014, 13, 631–636. [Google Scholar] [CrossRef]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef] [PubMed]

- Cho, S.M.; Kwak, K.S.; Park, D.C.; Gu, Y.S.; Ji, C.I.; Jang, D.H.; Lee, Y.B.; Kim, S.B.I. Processing optimization and functional properties of gelatin from shark (Isurus oxyrinchus) cartilage. Food Hydrocoll. 2004, 18, 573–579. [Google Scholar] [CrossRef]

- Fernandez-Dıaz, M.D.; Montero, P.; Gomez-Guillen, M.C. Gel properties of collagens from skins of cod (Gadus morhua) and hake (Merluccius merluccius) and their modification by the coenhancers magnesium sulphate, glycerol and transglutaminase. Food Chem. 2001, 74, 161–167. [Google Scholar] [CrossRef]

Sample Availability: Extracted gelatin samples are available from the authors. |

| Sample | Yield (%) of Gelatin | pH | Turbidity (ppm) | Gel Strength (g) | Viscosity (mPa.s) |

|---|---|---|---|---|---|

| UAC | 18.72 ± 018 b | 2.91 ± 0.02 c | 53.28 ± 0.47 b | 627.5 ± 4.48 a | 16.33 ± 0.03 a |

| UA2 | 8.64 ± 0.08 d | 2.75 ± 0.01 d | 105.53 ± 0.15 a | 451.5 ± 5.29 d | 15.67 ± 0.03 c |

| UA4 | 15.17 ± 0.18 c | 2.97 ± 0.01 b | 25.98 ± 0.27 d | 520.3 ± 4.18 b | 15.87 ± 0.06 b |

| UA6 | 19.65 ± 0.19 a | 3.03 ± 0.02 a | 32.03 ± 0.15 c | 502.2 ± 4.06 c | 15.60 ± 0.04 c |

| Treatment | L* | a* | b* |

|---|---|---|---|

| UAC | 64.45 ± 0.29 b | 1.91 ± 0.02 b | 17.10 ± 0.20 a |

| UA2 | 73.15 ± 0.23 a | 0.26 ± 0.05 c | 10.27 ± 0.18 d |

| UA4 | 62.64 ± 0.09 c | 2.47 ± 0.05 a | 16.40 ± 0.21 b |

| UA6 | 63.43 ± 0.55b c | 1.84 ± 0.07 b | 14.57 ± 0.23 c |

| Amino Acids | Gelatin Samples | |||

|---|---|---|---|---|

| UAC | UA2 | UA4 | UA6 | |

| Hydroxyproline (Hyp) | 17.00 | 10.77 | 12.64 | 13.65 |

| Aspartic acid (Asp) | 2.99 | 3.02 | 3.29 | 3.28 |

| Serine (Ser) | 3.30 | 2.30 | 2.64 | 2.91 |

| Glutamic acid (Glu) | 8.28 | 6.07 | 6.61 | 6.96 |

| Glycine (Gly) | 25.54 | 16.86 | 18.95 | 20.60 |

| Histidine (His) | 0.96 | 0.63 | 0.71 | 0.74 |

| Arginine (Arg) | 8.41 | 5.43 | 6.31 | 6.89 |

| Threonine (Thr) | 1.91 | 1.29 | 1.49 | 1.58 |

| Alanine (Ala) | 7.64 | 5.43 | 6.06 | 6.31 |

| Proline (Pro) | 11.39 | 8.33 | 9.26 | 9.78 |

| Tyrosine (Tyr) | 0.66 | 0.40 | 0.46 | 0.50 |

| Valine (Val) | 2.18 | 1.60 | 1.78 | 1.87 |

| Lysine (Lys) | 3.28 | 2.37 | 2.72 | 2.79 |

| Isoleucine (Ile) | 1.34 | 0.95 | 1.07 | 1.12 |

| Leucine (Leu) | 2.81 | 2.02 | 2.26 | 2.35 |

| Phenylalanine (Phe) | 1.99 | 1.37 | 1.55 | 1.64 |

| Imino acids (Pro + Hyp) | 28.39 | 19.10 | 21.90 | 23.43 |

| Band | Peak Wavenumber (cm−1) | |||

|---|---|---|---|---|

| UA2 | UA4 | UA6 | UAC | |

| Amide I | 1632 | 1632 | 1636 | 1632 |

| Amide II | 1547 | 1543 | 1539 | 1539 |

| Amide III | 1238 | 1238 | 1242 | 1234 |

| Amide A | 3302 | 3310 | 3279 | 3291 |

| Amide B | 2928 | 2924 | 2936 | 2936 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, T.; Ismail, A.; Ahmad, S.A.; Khalil, K.A.; Leo, T.K.; Awad, E.A.; Imlan, J.C.; Sazili, A.Q. Effects of Ultrasound Assisted Extraction in Conjugation with Aid of Actinidin on the Molecular and Physicochemical Properties of Bovine Hide Gelatin. Molecules 2018, 23, 730. https://doi.org/10.3390/molecules23040730

Ahmad T, Ismail A, Ahmad SA, Khalil KA, Leo TK, Awad EA, Imlan JC, Sazili AQ. Effects of Ultrasound Assisted Extraction in Conjugation with Aid of Actinidin on the Molecular and Physicochemical Properties of Bovine Hide Gelatin. Molecules. 2018; 23(4):730. https://doi.org/10.3390/molecules23040730

Chicago/Turabian StyleAhmad, Tanbir, Amin Ismail, Siti A. Ahmad, Khalilah A. Khalil, Teik K. Leo, Elmutaz A. Awad, Jurhamid C. Imlan, and Awis Q. Sazili. 2018. "Effects of Ultrasound Assisted Extraction in Conjugation with Aid of Actinidin on the Molecular and Physicochemical Properties of Bovine Hide Gelatin" Molecules 23, no. 4: 730. https://doi.org/10.3390/molecules23040730

APA StyleAhmad, T., Ismail, A., Ahmad, S. A., Khalil, K. A., Leo, T. K., Awad, E. A., Imlan, J. C., & Sazili, A. Q. (2018). Effects of Ultrasound Assisted Extraction in Conjugation with Aid of Actinidin on the Molecular and Physicochemical Properties of Bovine Hide Gelatin. Molecules, 23(4), 730. https://doi.org/10.3390/molecules23040730