1. Introduction

Leather is a natural material commonly used to produce a wide range of footwear. Depending on the type of footwear and its intended use, a different type of leather with specific features is required. For such purpose during post-tanning operations, numerous finishing additives and treatments are used to improve certain leather properties, such as water resistance, oleophobicity, perspirability, flame retardancy, antimicrobial properties and abrasion resistance or antistatic properties [

1].

Specifically, leather is a hydrophilic material due to the polar groups of the collagen fibers’ amino acid residues that promote their interaction with water molecules. However, this property is not desirable in certain applications where water-resistant leather is required. This repellence can be achieved by a combination of the material’s structure and finish with specific chemicals such as fluorocarbons, wax emulsions, metallic soaps and surface-active agents [

2,

3,

4].

More durable waterproofing treatments are mainly based on halocarbons compounds, including chlorofluorocarbons (CFCs), perfluorocarbons (PFCs), hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which are considered as greenhouse gases (GHGs), since they absorb infrared radiation emitted by the Earth in a spectral range where the energy is not removed by CO

2 or water vapour [

5].

For instance, HCFCs have been used to replace CFCs in several applications because they have a shorter atmospheric lifetime, and consequently, cause less ozone depletion. HFCs and PFCs have also been identified as potential replacements for ozone depleting substances (ODS) in the long term since they do not contain bromine or chlorine and do not cause significant ozone depletion. However, all these substances are also GHGs, and contribute thus to varying degrees to climate change [

5]. For this reason, there is a high concern about the continued release of these persistent organic pollutants (POPs) into the environment [

6], being also bioacumulative chemicals. That is why most companies are looking for alternatives to replace not only the compounds used for waterproofing but also the chemical process used to do so [

7,

8,

9,

10,

11], to reduce not only the input of materials into the process but also the production of waste, contributing thus to reduce environmental footprint of the process [

12].

Some alternative processes to traditional ones are currently based on plasma technologies as they are more resource-efficient and sustainable processes. These technologies might imply a significant reduction in the environmental impacts of traditional coating processes in terms of greenhouse gas emissions, reduction of hazardous chemicals and waste, and water and energy consumption [

13].

Specifically, the plasma polymerisation technology can infuse monomers into plasma and coat surfaces with ultra-thin layers, such as polymer coatings, by formation of gas-phase free radicals and their recombination at radical sites during film growth resulting in stable and durable structures [

14] able to impart functional properties to a great variety of materials. Many monomers can be used for the deposition of ultra-thin films by plasma polymerisation, among which the most widely used is hexamethyldisiloxane (HMDSO) [

9,

10,

11,

15,

16].

Different studies focused on plasma polymerisation of HMDSO to obtain super hydrophobic and water repellency properties to different materials. They reported that the achieved film properties depend on the plasma composition [

6,

7] and the polymerisation process conditions, such as plasma power and monomer flux [

8,

9,

10,

11,

12,

13,

14,

15,

16,

17]. Nevertheless, little work has been carried out on plasma deposition on natural leathers.

In addition, Thomas Gengenbach and Hans Griesser conducted extensive studies on the generation of hydrophobic coatings by low-pressure plasma for various polymer, glass and silicon substrates, and also in the electronics sector. The aforementioned studies have been summarised by Siow et al., which includes the works from the 1980s as well as those from electronic sectors [

18]. The role of surface restructuring in the ageing behaviour of siloxane plasma polymer was discussed by Gengenbach and Griesser in their study of HMDSO and hexamethyldisilazane (HMDSN) plasma polymers [

19]. In another study, they concluded that the perfluoro-1,3-dimethylcyclohexane (PFDMCH) plasma polymers were therefore well deposited and suited for applications that require long-term stability and predictable, stable interfacial properties [

20].

In this sense, a previous work carried out by the authors was based on the use of Multiple Laser Surface Enhancement (MLSE) technology in the framework of the European Life Textileather project [

13], to provide leathers and textiles with functional properties such as water, fire and stain resistances, as well as antimicrobial properties. MLSE technology combines atmospheric plasma and laser treatments in the presence of non-toxic gases, such as nitrogen (N

2) and oxygen (O

2), allowing the surface modification of materials [

21]. This treatment produces nanometric scale modifications, which enables the functionalisation of the material without noticeably affecting its appearance. In addition, Kayaoglu et al. reported surface modifications of natural leather samples through plasma polymerisation of different HMDSO/toluene compositions at low pressure that showed promising results towards improving the easy clean property of natural leather in upholstery applications [

14]. Gaidau et al. also reported the use of cold plasma generated by dielectric barrier discharge (DBD) at atmospheric pressure and room temperature as a promising technique for dry reactivation and physical modification of collagen and keratin-based materials to improve complex characteristics, such as water repellence and flame retardancy [

22]. Finally, a concise overview on plasma treatment for application on textile and leather materials was provided recently by Tudoran et al. [

23].

In the present study, a low-pressure plasma system was used for the development of hydrophobic coating by plasma polymerisation on natural leather for footwear applications. For the coating treatments, the chemical precursor 100% hexamethyldisiloxane (HMDSO) was selected because it contains silicon groups, which can be favourable for improving the hydrophobic properties of the materials. For this purpose, a plasma process involving consecutive activation and etching using oxygen as the reactive gas, and HMDSO polymerisation using argon as the inert gas, has been carried out. The properties of the thin film deposited on the leather surface were characterised by different experimental techniques, in terms of water repellence, surface modifications, thickness and colour and appearance changes. The aim of this research is to use plasma treatment as an environmentally friendly finishing method to impart hydrophobicity to the surface of natural leather, which can be used in the footwear and leather industries as well as in the textile industry [

24,

25,

26,

27,

28,

29,

30,

31,

32].

2. Experimental

2.1. Materials

In this work, hexamethyldisiloxane (HMDSO, (CH

3)

3-Si-O-Si-(CH

3)

3, 98% purity) provided by Merck Life Science S.L.U. (Madrid, Spain) was used as a hydrophobic monomeric precursor, as received. For plasma polymerisation processes, a blue chrome-tanned cow leather with aniline finishing supplied by the company Pies Cuadrados Leather S.L. (Aspe, Spain) was used as representative upper material for footwear applications.

Table 1 includes the main physical and mechanical properties of the used leather.

Argon (Ar) and oxygen (O2) were used as carrier gases, both with 99.995% purity and supplied by Carburos Metálicos S.A. (Barcelona, Spain).

2.2. Plasma Treatment

Plasma polymerised HMDSO films on leather samples were prepared in a nano low-pressure plasma equipment (Diener Electronic Vertriebs GmbH, Germany), of modular configuration, with a chamber volume of 24 L, in stainless steel and with a tray for sample support. The plasma reactor was operating at a fixed frequency of 13.56 MHz and 300 W of maximum power. All the samples in this work were treated at the plasma power of 150 W. A composition of 100% HMDSO was injected by a micro-dossing pump during plasma polymerisation on natural leather samples.

This low-pressure plasma system is equipped with two gas supply channels. Oxygen (O

2) and argon (Ar) were used as working gases with flows at 500 mL/min and 685 mL/min, respectively. A micro-dosing pump introduces the monomer into the reactor at 0.5 µL/s. The thermostatised treatment chamber allows the temperature to be raised during the plasma process, which increases the effectiveness of the deposition process [

23,

33]. (

Table 2).

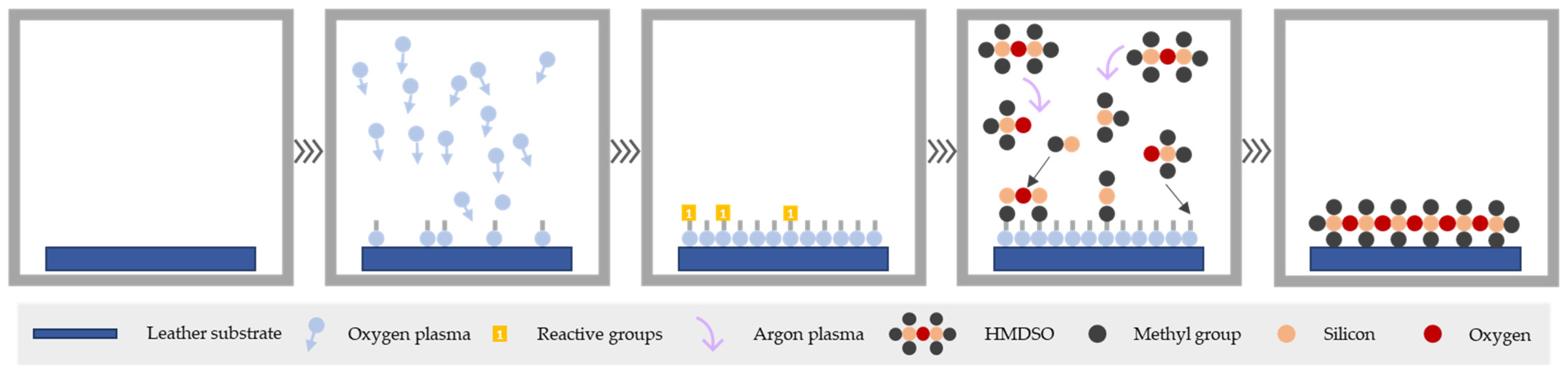

The treatment comprises different and consecutive stages: activation, polymerisation and etching.

Firstly, activation with plasma was carried out to create radical sites in which HMDSO reacts, and greatly facilitated thus the adhesion of non-reactive or non-wettable surfaces. The type of mechanisms that primarily contribute to the activation effect depend on the material to be treated and the nature of the plasma gas. As a working gas, oxygen was used to provide leather with new surface functionalities that completely reverse the polarity of leather samples increasing its surface wettability to improve the HMDSO deposition. In addition to these factors, the working pressure, the power of the plasma and the activation time of the gas used are also crucial.

Secondly, HMDSO was added to produce its polymerisation by plasma. This monomer is in a liquid state under ambient conditions, and when subjected to vacuum conditions, it becomes gaseous. This causes it to be susceptible to being excited by an energy source, which gives rise to silicon radicals and atoms of silicon, hydrogen, carbon and oxygen that interact on the surface of the treated material. Consequently, an ultra-thin coating layer is deposited onto leather surface permanently. For this stage, argon was selected as conductive gas because it is an inert gas and does not react with the monomeric precursor. It has a large mechanical effect since it continuously removes individual atoms from the surface contributing to a suitable layer anchorage. The properties provided by the newly deposited layer will depend on both the nature of the monomer used and the different conditions used during the process. The parameters that greatly influence the surface finish and therefore determine the water repellence obtained are the pump flow, the conductive gas, the selected prepolymer, the coating time and the number of coats applied, among others [

34].

After the polymerisation stage, a fast-etching process was conducted with oxygen gas to strengthen the polymerised HMDSO layer anchorage and achieve coatings with a considerable and effective thickness.

Finally, three HMDSO layers were deposited onto leather samples surface with argon gas according to the operating conditions described in

Table 2, which were previously optimised in the framework of the COATPLAS project [

35,

36]. In addition,

Figure 1 summarises the process conducted in this work.

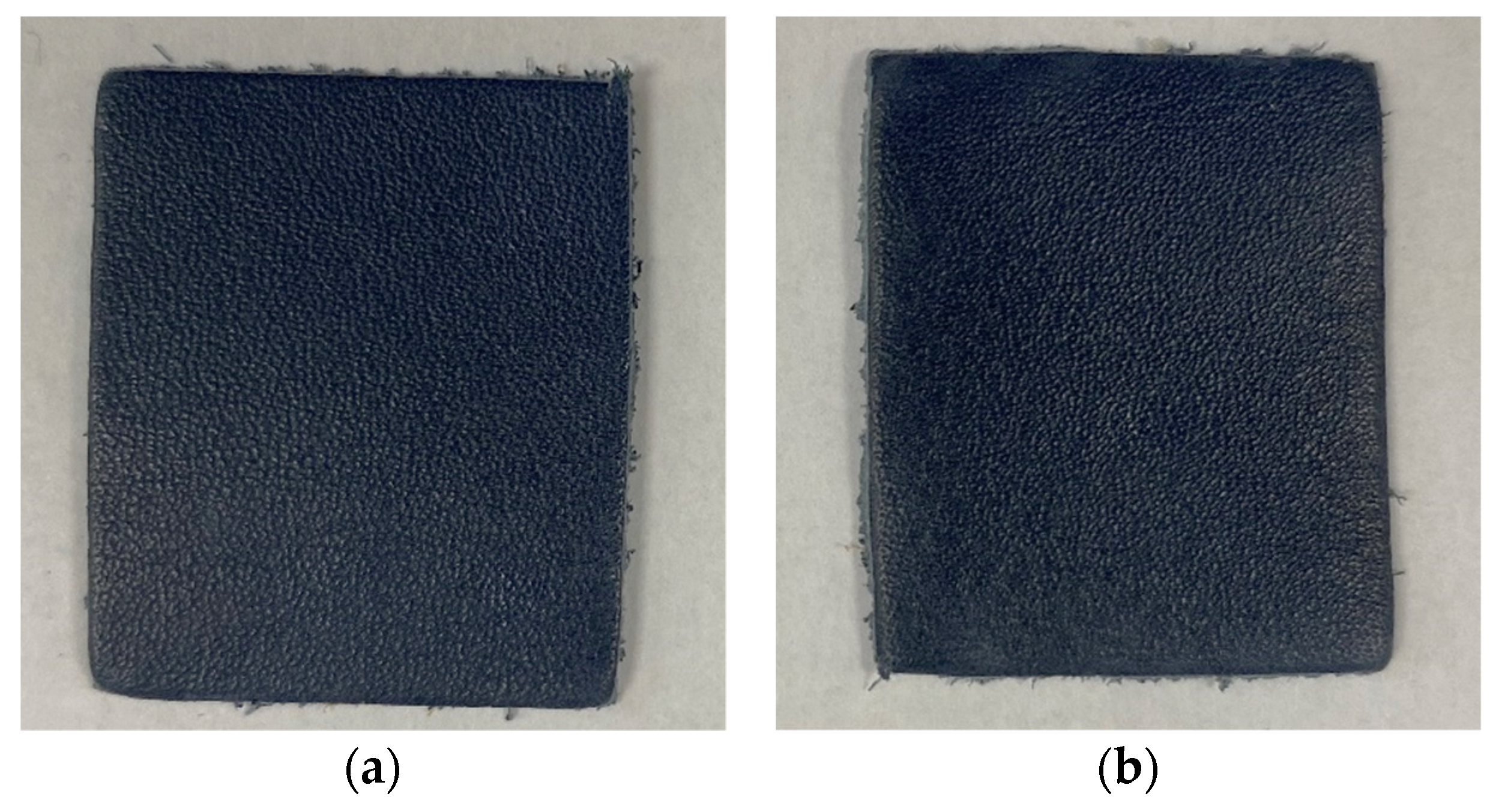

Samples with and without plasma treatment will be referenced as “plasma coated leather” and “untreated leather”, respectively.

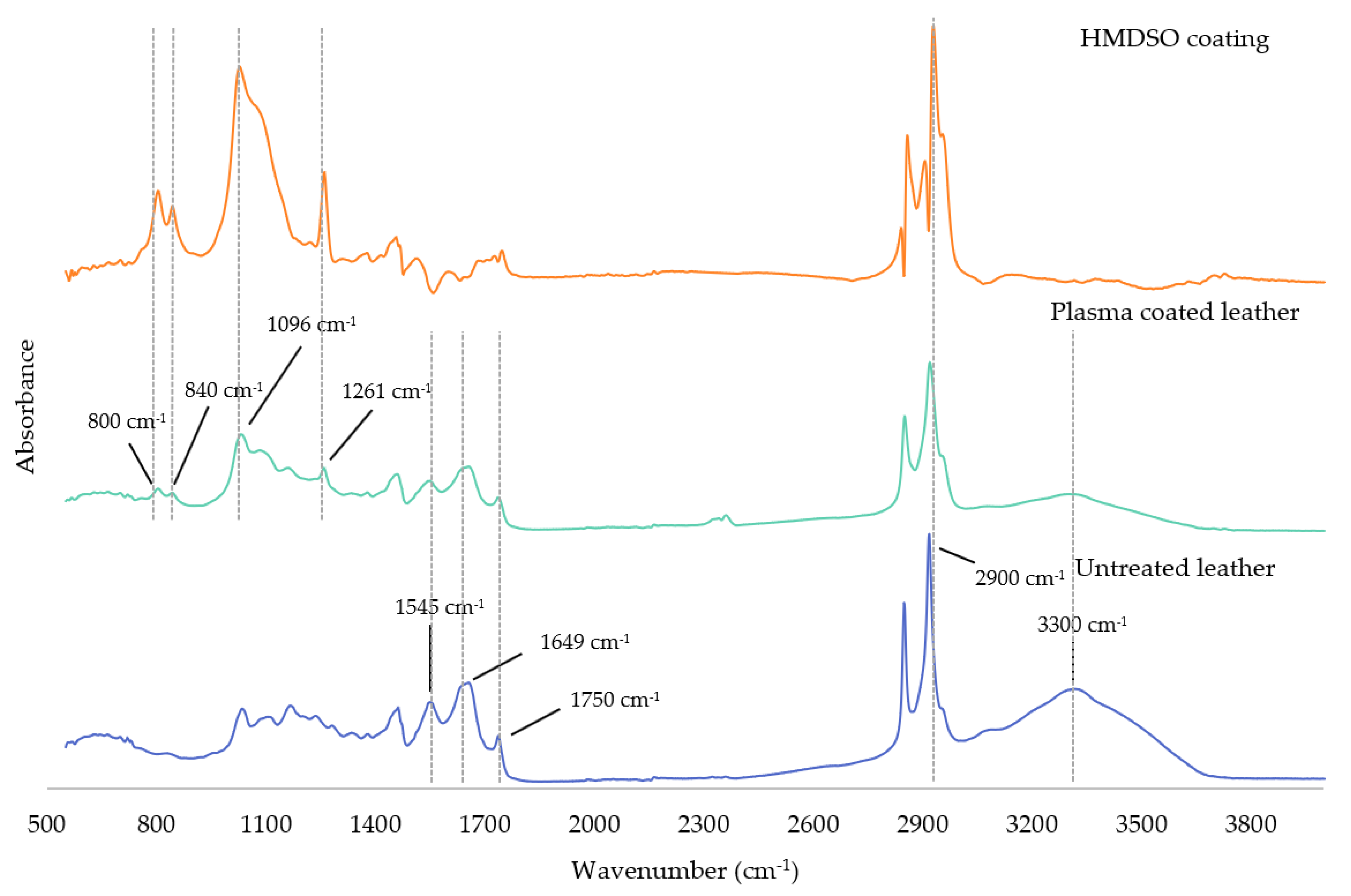

2.3. Fourier Transform Infrared Spectroscopy (FTIR)

The surface chemical modifications of the coated leather were determined using a Varian 660-IR infrared spectrophotometer (VARIAN Australia PTY LTD; Mulgrave, Australia). Attenuated total reflectance (ATR) mode with 16 scans at a resolution of 4 cm−1 was used as the FTIR sampling technique. This ATR accessory works by measuring changes in the infrared beam when the beam comes into contact with the sample.

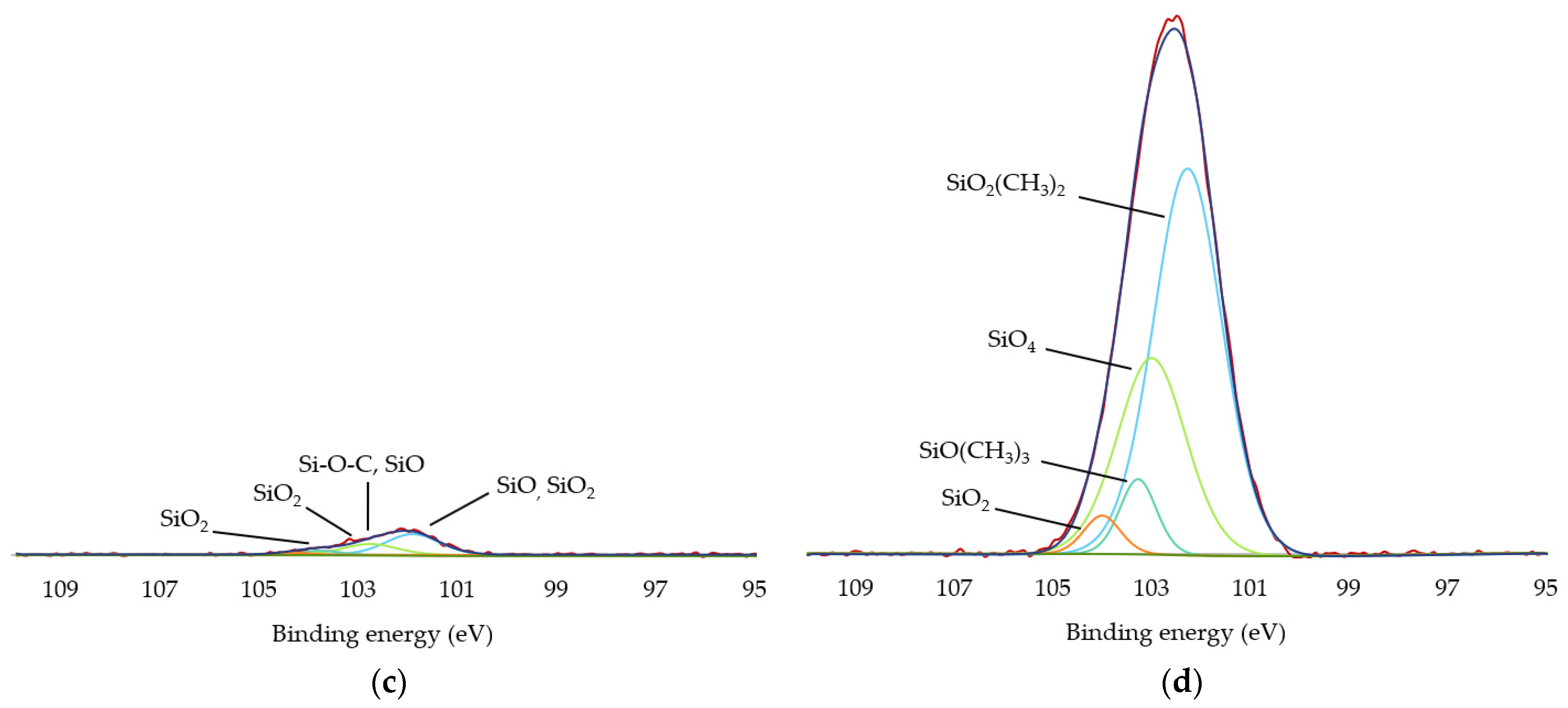

2.4. X-Ray Photoelectron Spectroscopy (XPS)

An X-ray Photoelectron Spectroscopy (XPS, K-ALPHA, Thermo Scientific) was used to analyse the chemical compositions of the surface of the siloxane polymer film obtained by plasma. Due to these films being extremely thin, XPS is the most suitable technique to determine their chemical properties. This analysis was conducted by the Technical Research Services (SSTTI) of the University of Alicante (UA). XPS measurements were collected with K-ALPHA (Al-K) radiation (1486.6 eV), monochromatised by a double crystal monochromator and yielding a focused X-ray spot (elliptical in shape with a major axis length of 400 µm) were generated at 3 mA × 12 kV. The alpha hemispherical analyser operated in constant energy mode, scanning through the 200 eV energy to measure the entire energy band, and used 50 eV in a narrow scan to selectively measure specific elements. Avantage software was used to analyse the XPS data, and the smart background function was used to approximate the experimental background and calculate the elemental composition of the surface based on the peak area subtracted from the background. Charge compensation was achieved using the systems flood gun, which provides low-energy electrons and low-energy argon ions from a single source.

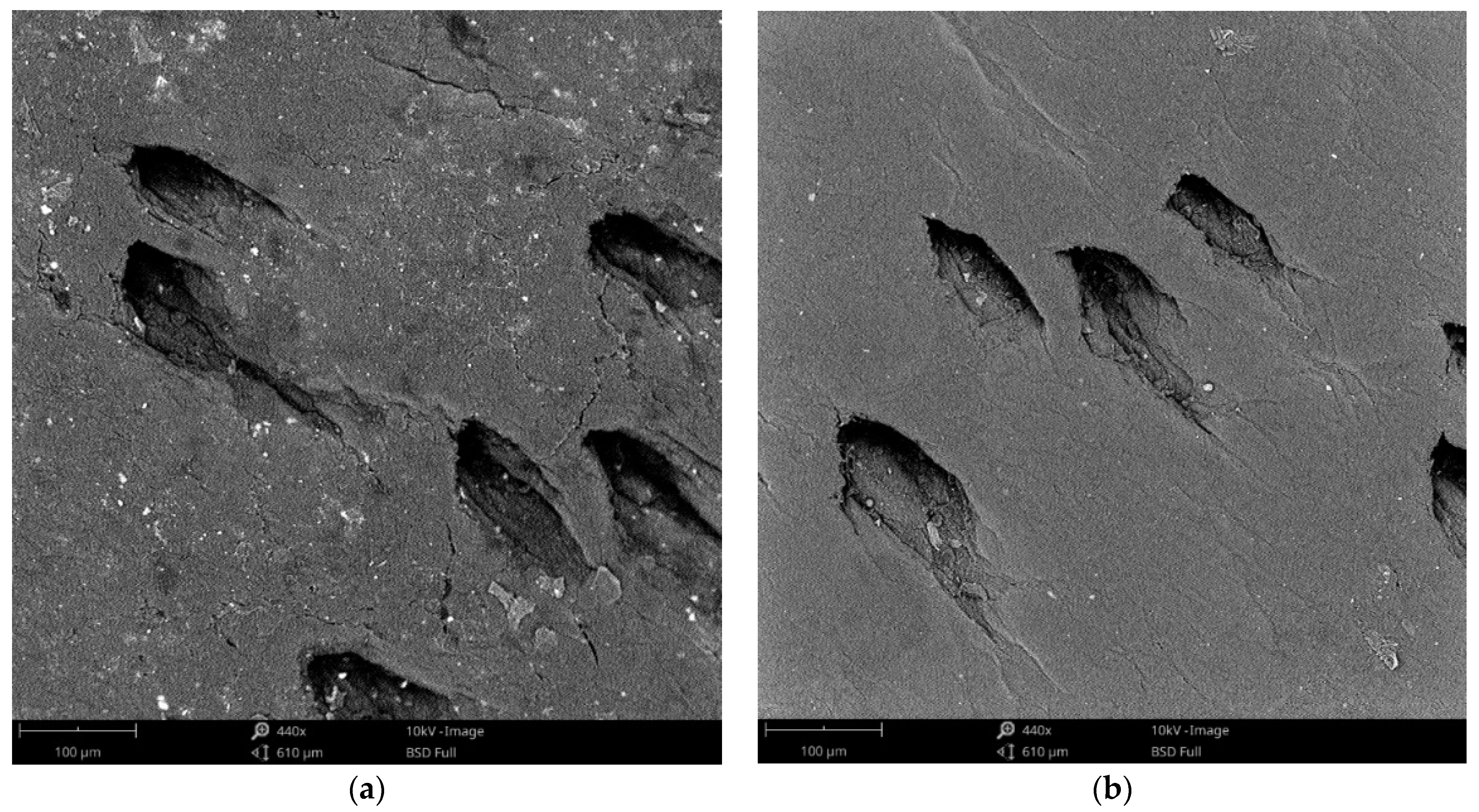

2.5. Scanning Electron Microscopy (SEM)

The surface modifications and morphological analysis were conducted with a Phenom ProX scanning electron microscope (Phenom World, Eindhoven, Netherlands). Samples were cut into square specimens of 2 mm x 2 mm. The microscope operates under high vacuum, using an electron beam at a potential of 5–15 keV, so that there is greater resolution of the image, going from micrometric to nanometric scale.

2.6. Sample Colour Measurements

The measurement of the colour difference of plasma treated leathers was carried out with the spectrophotometer CM-600d according to the standard EN ISO 22700:2020 [

37]. This portable spectrophotometer is designed to assess the colour and appearance of samples of different sizes, including the surfaces of flat, shaped or curved objects. It has a fixed aperture of 8 mm and two measurement modes to suit the surface conditions of each sample: Specular Reflectance Included (SPINC) and Specular Reflectance Excluded (SPEX), the latter being used for measurement as it considers the surface finish of the sample. Measurements were made at three spots in the central part of the sample.

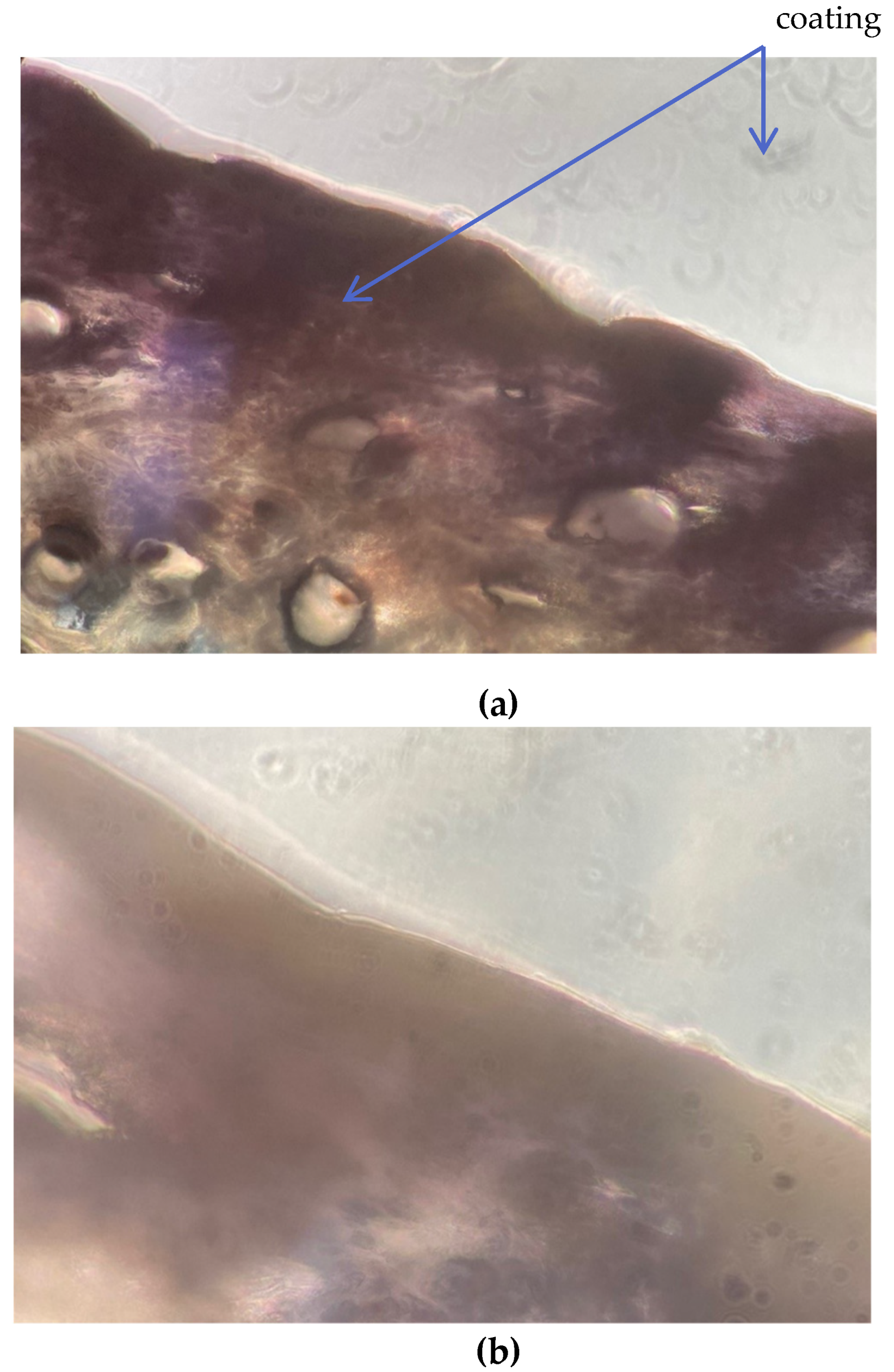

2.7. Surface Coating Thickness

The thickness of layer deposited onto the leather surface was determined according to the standard EN ISO 17186-method A [

38]. A macm 1 rotary microtome (model 2030, Leica Reichert-Jung Biocut, Germany) was used with an optical microscope (model STD-18, Zeiss, Germany) equipped with a x 10 ocular with a graduated scale including a range of 2.6–261.9 µm and a x 16 magnification lens.

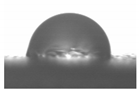

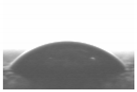

2.8. Water Contact Angles (WCA) Measurements

The hydrophobicity of the plasma coating was evaluated by determining the water contact angles. An optical contact angle measurement goniometer (Muver, Petrel, Spain) was used. This equipment has a thermostatised chamber that allows working in a saturated atmosphere, with an exhaustive control of the temperature at 25 °C. The equipment is provided with a vision system on a camera with a telecentric lens, which is backlit by a matrix of LEDs, and was used for droplet images captures. Deionised water was used as test liquid with a controlled volume of 4 µL by a syringe. Three drops were placed and measured at different points of the samples. Measurement procedure was performed as described in the standard EN 828-2013 [

39]. The measurements were carried out at various times: 0 min, 5 min, 15 min, 25 min, 60 min and 90 min after plasma treatment to follow the wettability of the leather samples as a function of the time.

4. Conclusions

In this study, the surface modifications of natural leather samples, a material commonly used for footwear applications, by plasma polymerisation with a 100% HMDSO composition have been evaluated by means of different experimental techniques. According to the results, the combination of optimised plasma activation and etching pre-treatment, both with O2 and coating treatment with HMDSO/Ar, improved the hydrophobicity of the surface due to the introduction and deposition of silane groups on the leather surface. More specifically, the formation of an ultra-thin hydrophobic layer of polysiloxane nature and completely deposited by low-pressure plasma led to high water contact angles and absorption times compared to the natural and untreated leather. Most importantly, the HMDSO plasma coating deposited on the leather samples does not affect the original pigment of the leather, neither the colour nor the surface appearance and feel.

It can be concluded that plasma deposition of HMDSO at low pressure showed promising results to provide natural leather with water repellence for footwear applications. Plasma hydrophobic coatings may be used as a more sustainable alternative to replace conventional treatments currently used based on halocarbons and organic solvents.

Finally, it should be noted that this study contributes greatly to the three pillars of the Sustainable Development Goals (SDGs): the economic, social and environmental objectives set by the European Green Deal and its Circular Economy Plan, enabling thus the footwear sector to move increasingly towards a production model based on sustainability and automation, and contributing to the flexibility of processes and the modernisation of the industry by increasing its resilience [

60].