Advanced Exergy-Based Optimization of a Polygeneration System with CO2 as Working Fluid

Abstract

1. Introduction

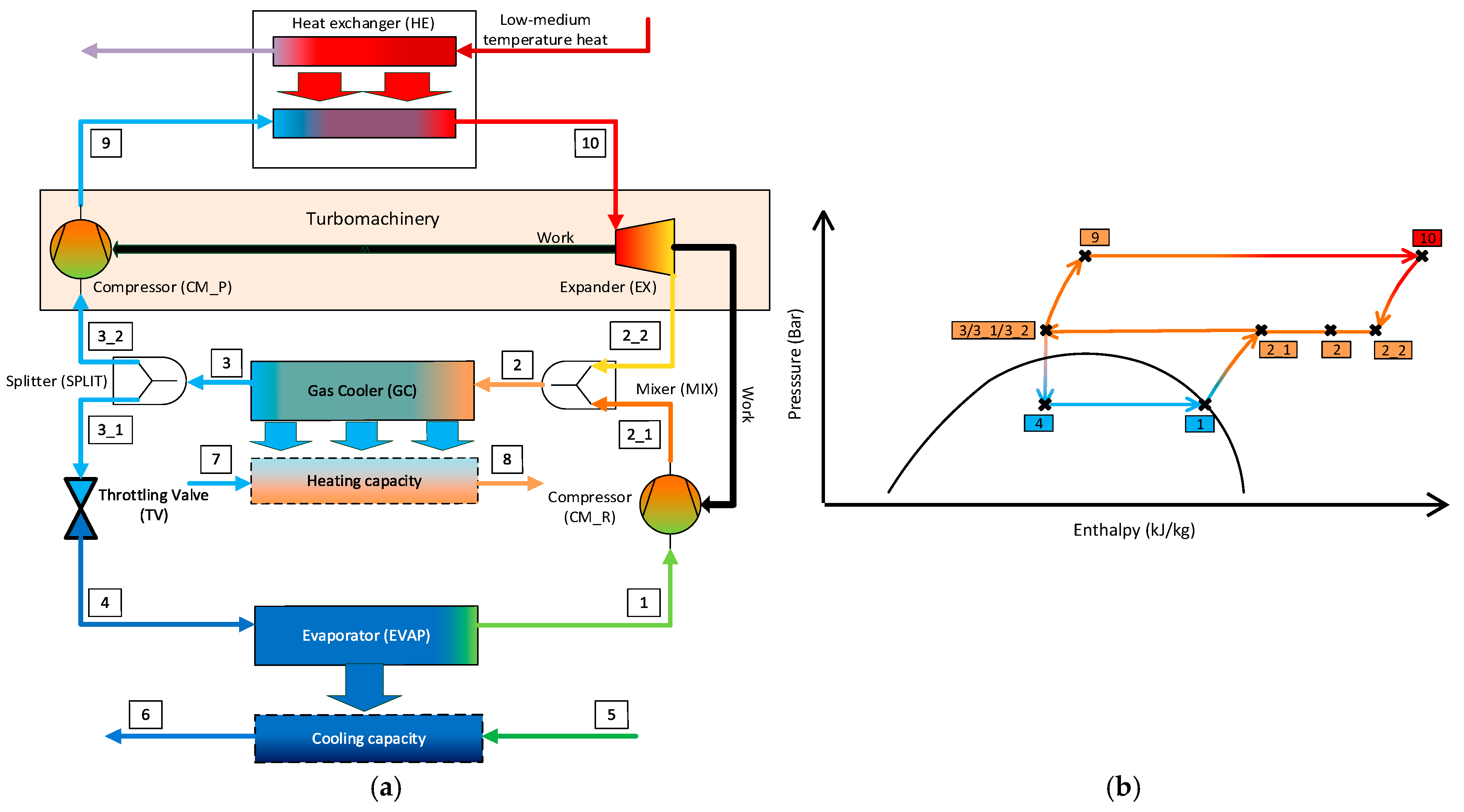

- The power cycle consists of a compressor for the power cycle (CM–P), a heat exchanger (HE), and an expander (EX). The “driving energy” is a medium-temperature heat source.

- The refrigeration cycle consists of a throttling valve (TV), an evaporator (EVAP), and a compressor for the refrigeration cycle (CM–R). The refrigeration capacity is generated within the EVAP.

2. Methodology

2.1. Advanced Exergy-Based Analysis

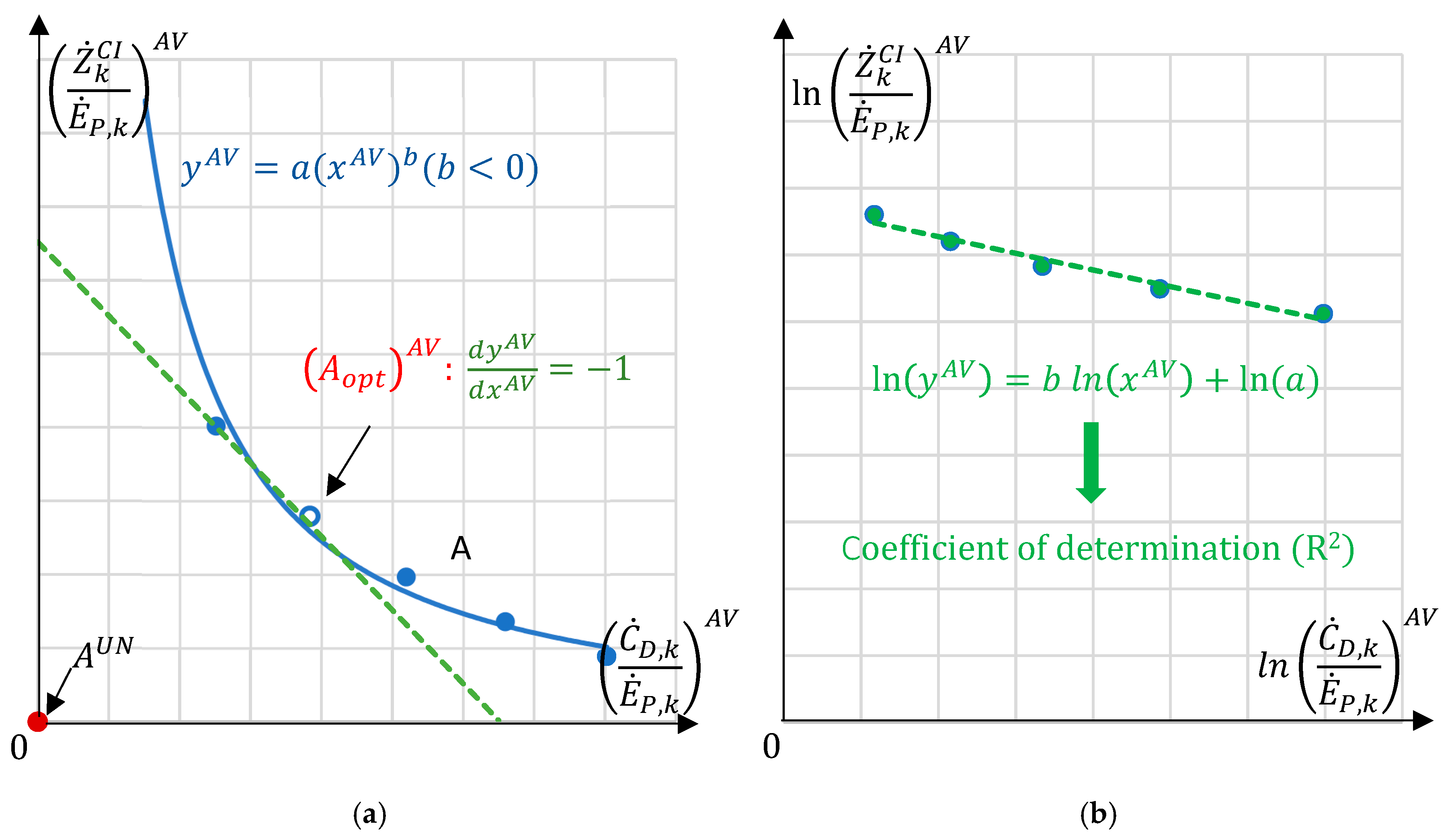

2.2. Advanced Exergy-Based Graphical Optimization

3. Results and Discussion

3.1. Results of Advanced Exergy-Based Analyses

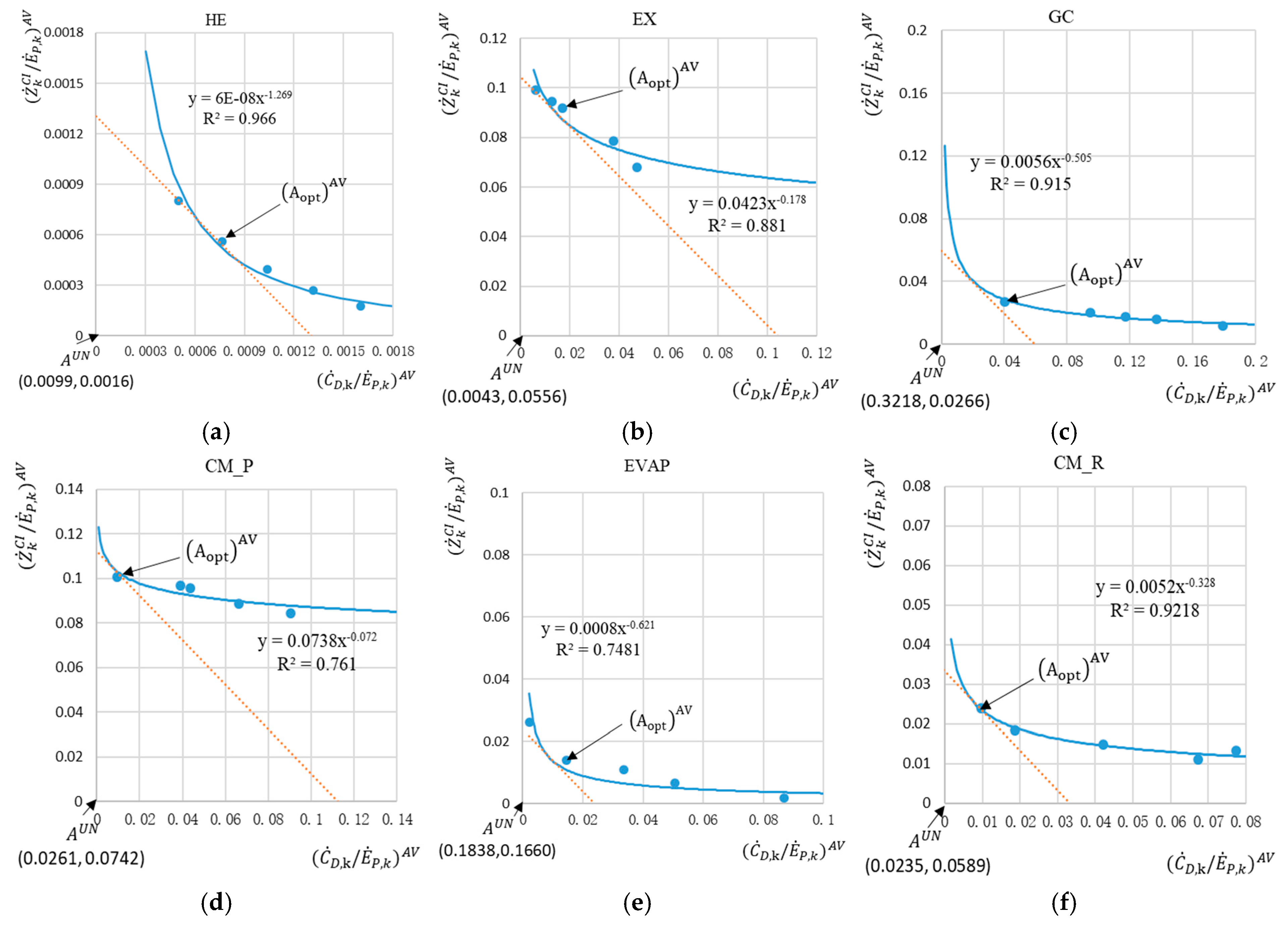

3.2. Results of Advanced Exergy-Based Graphical Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| fuel cost per unit of exergy of kth component, USD/kWh | |

| product cost per unit of exergy of kth component, USD/kWh | |

| destruction cost rate associated with kth component, USD/h | |

| mechanical exergy rate of ith stream, kW | |

| thermal exergy rate of ith stream, kW | |

| fuel exergy rate of kth component, kW | |

| product exergy rate of kth component, kW, | |

| exergy destruction rate of kth component, kW | |

| avoidable exergy destruction rate of kth component, kW | |

| unavoidable exergy destruction rate of kth component, kW | |

| material factor for the calculation of purchased equipment cost, - | |

| exergoeconomic factor of kth component, % | |

| modified exergoeconomic factor of kth component, % | |

| THS | thermodynamic average temperature of the stream of matter providing the low to medium-grade heat, K |

| capital investment cost rate of kth component, USD/h | |

| avoidable capital investment cost rate of kth component, USD/h | |

| unavoidable capital investment cost rate of kth component, USD/h | |

| pinch point temperature difference, K | |

| exergetic efficiency of kth component, % | |

| modified exergetic efficiency of kth component, % | |

| isentropic efficiency, % | |

| Abbreviations | |

| CM–P | compressor in power sub-cycle |

| CM–R | compressor in refrigeration sub-cycle |

| EVAP | evaporator |

| EX | expander |

| GC | gas cooler |

| HE | heat exchanger |

| MIX | mixer |

| SPLIT | splitter |

| TV | throttling valve |

References

- IEA. World Energy Outlook 2023. Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 5 August 2024).

- Liu, P.; Gerogiorgis, D.I.; Pistikopoulos, E.N. Modeling and optimization of polygeneration energy systems. Catal. Today 2007, 127, 347–359. [Google Scholar] [CrossRef]

- Chicco, G.; Mancarella, P. Trigeneration primary energy saving evaluation for energy planning and policy development. Energy Policy 2007, 35, 6132–6144. [Google Scholar] [CrossRef]

- Lorentzen, G. Revival of carbon dioxide as a refrigerant. Int. J. Refrig. 1994, 17, 292–300. [Google Scholar] [CrossRef]

- Luo, J.; Morosuk, T.; Tsatsaronis, G. Exergoeconomic investigation of a multi-generation system with CO2 as the working fluid using waste heat. Energy Convers. Manag. 2019, 197, 111882. [Google Scholar] [CrossRef]

- Tashtoush, B.; Luo, J.; Morosuk, T. Exergy-Based Optimization of a CO2 Polygeneration System: A Multi-Case Study. Energies 2024, 17, 291. [Google Scholar] [CrossRef]

- Morosuk, T.; Tsatsaronis, G. Advanced exergy-based methods used to understand and improve energy-conversion systems. Energy 2019, 169, 238–246. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Morosuk, T.V. Advanced Exergoeconomic Evaluation and its Application to Compression Refrigeration Machines. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, IMECE 2007, Seattle, WA, USA, 11–15 November 2007. IMECE2007-412202. [Google Scholar]

- Morosuk, T.; Tsatsaronis, G. Splitting physical exergy: Theory and application. Energy 2019, 167, 698–707. [Google Scholar] [CrossRef]

- Cain, J.W. Mathematics of fitting scientific data. In Molecular Life Sciences: An Encyclopedic Reference; Bell, E., Ed.; Springer: New York, NY, USA, 2014; pp. 1–7. [Google Scholar]

| Component | ||

|---|---|---|

| HE | ||

| EX | ||

| GC | ||

| CM_P | ||

| CM_R | ||

| EVAP | ||

| TV | ||

| MIX | Dissipative Component: | |

| SPLIT | - | - |

| Overall System | ||

| Component | Parameter [Unit] | “Best” Case | Base Case | “Worst” Case |

|---|---|---|---|---|

| HE | 5 | 20 | 40 | |

| EX | 98 | 90 | 70 | |

| GC | 1 | 5 | 10 | |

| CM_P | 95 | 85 | 70 | |

| EVAP | 1 | 5 | 10 | |

| CM_R | 95 | 85 | 70 |

| Component | |||||

|---|---|---|---|---|---|

| HE | 62.21 | 5.27 | 95.5 | 0.044 | 62.3 |

| EX | 1.02 | 4.49 | 94.4 | 6.967 | 95.0 |

| GC | 20.60 | 6.31 | 77.9 | 0.394 | 38.3 |

| CM_P | 1.12 | 2.56 | 90.5 | 2.333 | 87.7 |

| EVAP | 2.78 | 1.06 | 86.8 | 0.075 | 39.5 |

| CM_R | 1.93 | 4.45 | 90.3 | 0.851 | 60.1 |

| TV | 13.93 | 8.73 | 61.5 | 0.002 | 0.5 |

| MIX | 9.58 | 2.87 | - | 0.000 | 0.0 |

| Base Case | Optimization Results | Engineering Solution | Improvement Potential | |

|---|---|---|---|---|

| Operating parameters for each component | ||||

| HE | ΔT = 20 K | ΔT = 15 K | ΔT = 15 K | high |

| EX | η = 0.9 | η = 0.9 | η = 0.9 | relatively low |

| GC | ΔT = 5 K | ΔT = 2 K | ΔT = 2 K | highest (possible but difficult) |

| CM_P | η = 0.85 | η = 0.90 | η = 0.85 | relatively low |

| EVAP | ΔT = 5 K | ΔT = 4 K | ΔT = 4 K | lowest |

| CM_R | η = 0.85 | η = 0.92 | η = 0.85 | low |

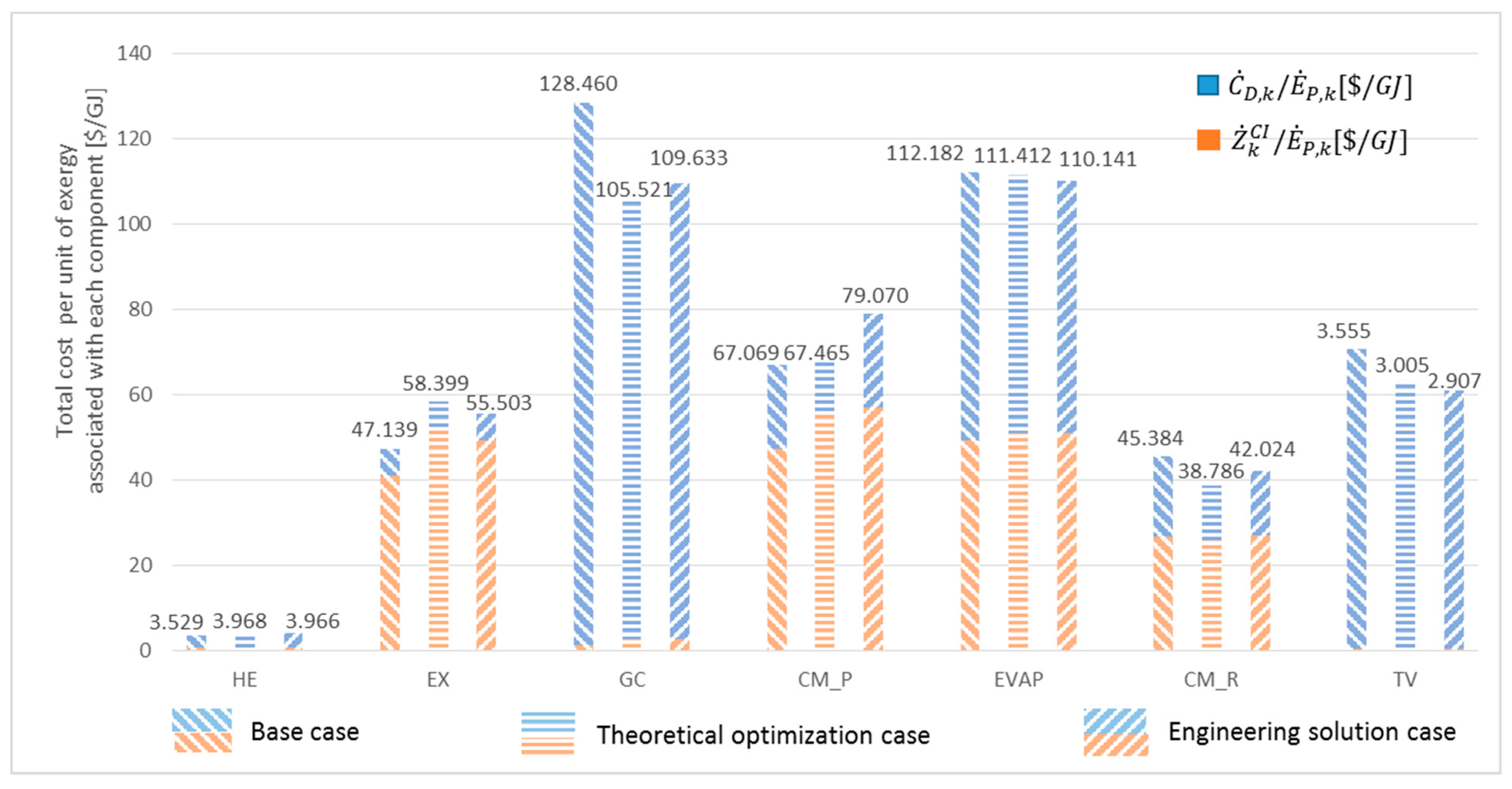

| Exergetic and exergoeconomic analysis | ||||

| 16.5 | 19.1 | 18.4 | ||

| 0.00 | 0.00 | 0.00 | ||

| 6.95 | 7.14 | 7.14 | ||

| 22.21 | 17.21 | 18.21 | ||

| 0.47 | 0.31 | 0.31 | ||

| 0.82 | 0.57 | 0.58 | ||

| 0.84 | 0.86 | 0.84 | ||

| 0.83 | 0.78 | 0.76 | ||

| Relative change to the base case | ||||

| Overall exergetic efficiency | 15.4% | 11.3% | ||

| Overall average product cost | −7.1% | −8.5% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, J.; Zhu, Q.; Morosuk, T. Advanced Exergy-Based Optimization of a Polygeneration System with CO2 as Working Fluid. Entropy 2024, 26, 886. https://doi.org/10.3390/e26100886

Luo J, Zhu Q, Morosuk T. Advanced Exergy-Based Optimization of a Polygeneration System with CO2 as Working Fluid. Entropy. 2024; 26(10):886. https://doi.org/10.3390/e26100886

Chicago/Turabian StyleLuo, Jing, Qianxin Zhu, and Tatiana Morosuk. 2024. "Advanced Exergy-Based Optimization of a Polygeneration System with CO2 as Working Fluid" Entropy 26, no. 10: 886. https://doi.org/10.3390/e26100886

APA StyleLuo, J., Zhu, Q., & Morosuk, T. (2024). Advanced Exergy-Based Optimization of a Polygeneration System with CO2 as Working Fluid. Entropy, 26(10), 886. https://doi.org/10.3390/e26100886