Thermodynamic Rarity Assessment of Mobile Phone PCBs: A Physical Criticality Indicator in Times of Shortage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Thermodynamic Rarity Indicator

- Crust: there are no concentrated mineral deposits (the upper continental crust can be approximated to the average mineralogical composition of the current earth’s crust), fossil fuels have been depleted, and fertile soils are entirely degraded.

- Hydrosphere: its composition can be approximated to seawater since freshwater constitutes about 2.5% of global water, of which the most important part is composed of glaciers and ice sheets (68.7%) and groundwater (30.1%).

- Atmosphere: CO2 concentration is comparable to the complete burning of all remaining fossil fuels.

2.2. Mobile Phone PCB Data: Composition, Thermodynamic Rarity Calculation and Resources Embedded Worldwide

3. Results

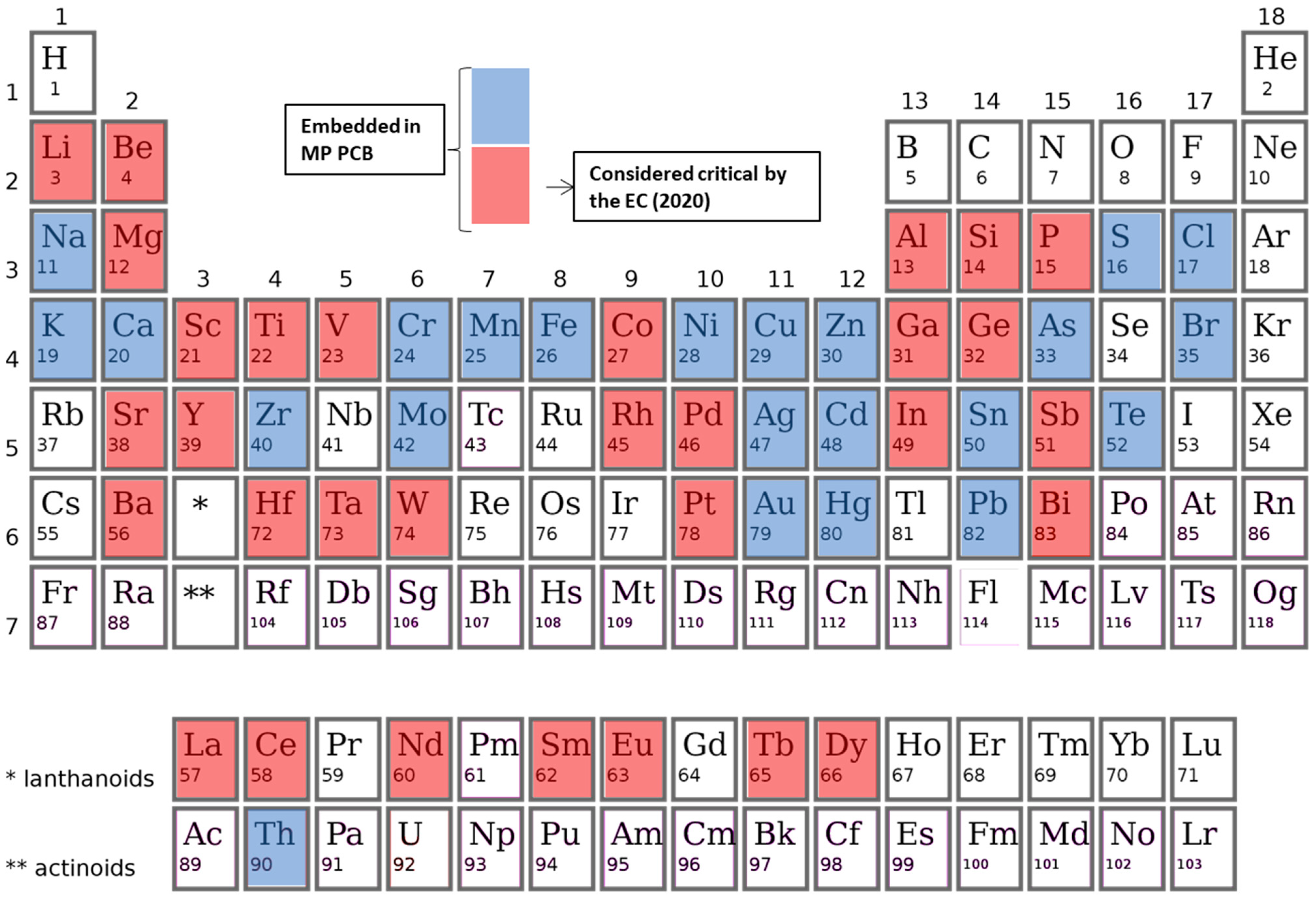

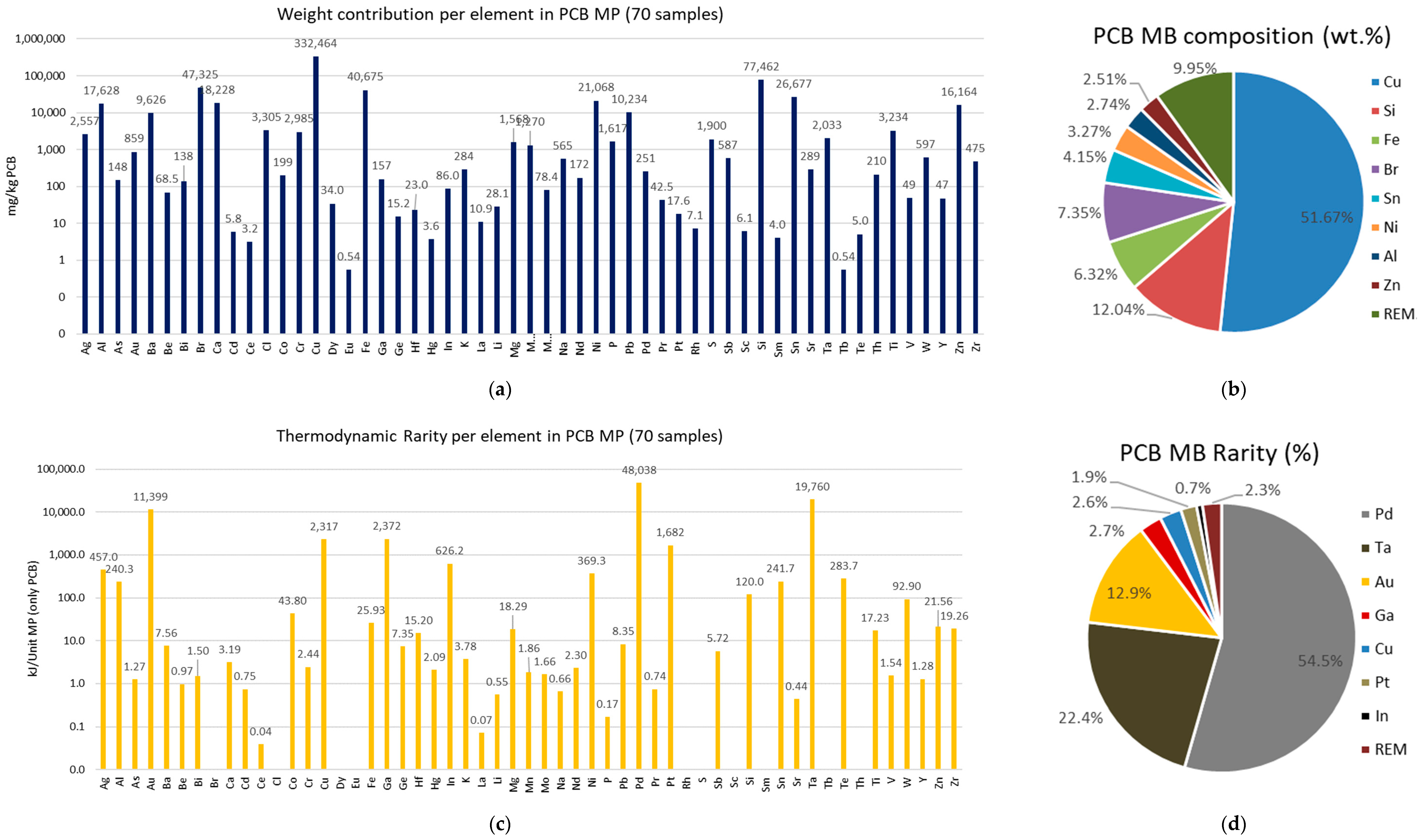

3.1. Composition and Thermodynamic Rarity of Mobile Phone PCBs

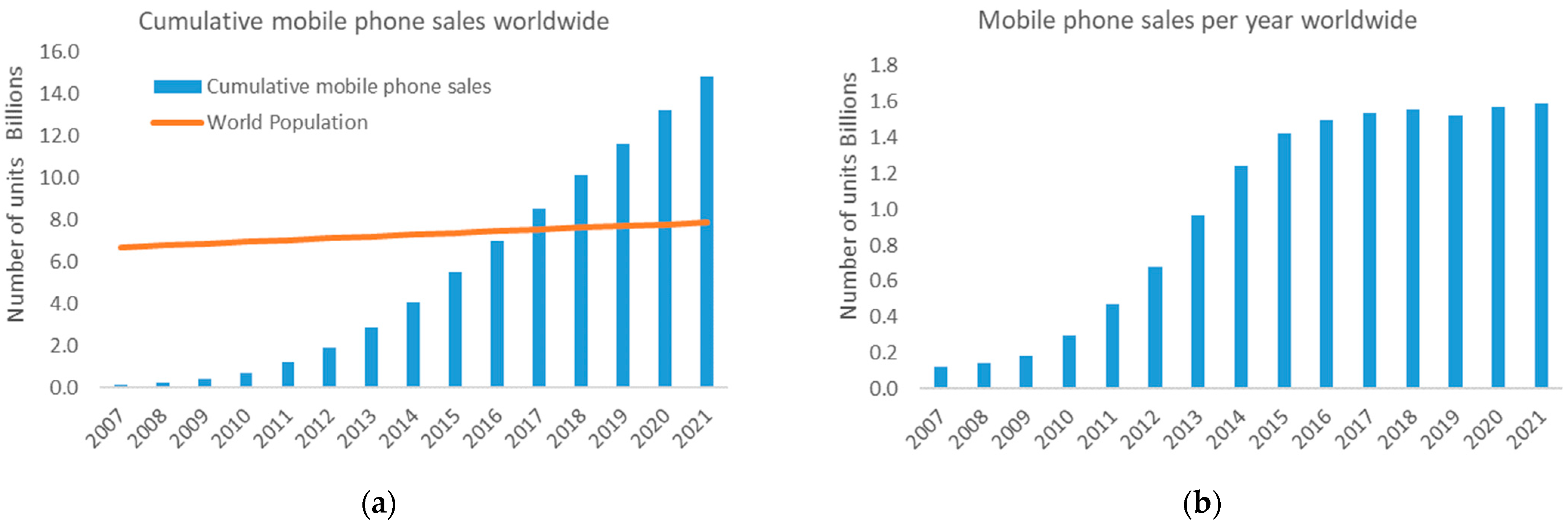

3.2. Resources Embedded in Mobile Phone PCB Worldwide

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| References (mg/kg PCB) | Ag | Al | As | Au | Ba | Be | Bi | Br | Ca | Cd | Ce | Cl | Co | Cr | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chancerel et al., 2009 | 2244 | 50 | |||||||||||||

| Chancerel et al., 2009 | 3573 | 368 | |||||||||||||

| Chancerel et al., 2009 | 5540 | 980 | |||||||||||||

| Kasper et al., 2011 | 600 | 3100 | 600 | 395,600 | |||||||||||

| Kasper et al., 2011 | 600 | 9900 | 1000 | 383,300 | |||||||||||

| Kasper et al., 2011 | 500 | 6100 | 900 | 378,100 | |||||||||||

| Oguchi et al., 2011 | 2400 | 67,000 | 4700 | 400 | 100 | 96,000 | |||||||||

| Oguchi et al., 2011 | 3800 | 15,000 | 1500 | 19,000 | 440 | 280 | 330,000 | ||||||||

| Yamane et al., 2011 | 2100 | 2600 | 344,900 | ||||||||||||

| Silvas et al., 2015 | 2100 | 2600 | 1600 | 900 | 355,000 | ||||||||||

| Ueberschaar et al., 2017 (a) | |||||||||||||||

| Ueberschaar et al., 2017 (b) | 1580 | 19,741 | 0.0438 | 529 | 14,778 | 6 | 0.044 | 38,851 | 0.044 | 0.071 | 0.044 | 255,100 | |||

| Ueberschaar et al., 2017 (b) | 1597 | 42,979 | 21 | 1038 | 19,466 | 66 | 66 | 27,837 | 2 | 7 | 253 | 464,000 | |||

| Arshadi et al., 2018 | 1470 | 57,930 | 480 | 3990 | 37,950 | 32,760 | 5310 | 1590 | 210,000 | ||||||

| Holgersson et al., 2018 | 2640 | 22,736 | 93.3 | 1051 | 2152 | 98.8 | 39.6 | 1556 | 2.1 | 952.9 | 342,667 | ||||

| Holgersson et al., 2018 | 2773 | 23,003 | 141 | 1083 | 2662 | 138 | 60.6 | 762 | 1306.7 | 395,000 | |||||

| Holgersson et al., 2018 | 2500 | 1200 | 1 | 2000 | 250,000 | ||||||||||

| Holgersson et al., 2018 | 4000 | 400 | 1 | 3000 | 200,000 | ||||||||||

| Holgersson et al., 2018 | 4000 | 800 | 1 | 700 | 200,000 | ||||||||||

| Holgersson et al., 2018 | 5000 | 1100 | 45 | 4000 | 120,000 | ||||||||||

| Holgersson et al., 2018 | 5081 | 19 | 5 | 801 | 272,402 | ||||||||||

| Holgersson et al., 2018 | 2100 | 10 | 344,900 | ||||||||||||

| Holgersson et al., 2018 | 6091 | 1591 | 590,909 | ||||||||||||

| Holgersson et al., 2018 | 3301 | 570 | 234,700 | ||||||||||||

| Li et al., 2018 | 1380 | 10,000 | 350 | 130,000 | |||||||||||

| Gu et al., 2019 | 5200 | 600 | 273,700 | ||||||||||||

| Gu et al., 2019 | 600 | 800 | 385,700 | ||||||||||||

| Gu et al., 2019 | 1000 | 200 | 566,800 | ||||||||||||

| Gu et al., 2019 | 500 | 100 | 398,600 | ||||||||||||

| Gu et al., 2019 | 2300 | 1400 | 428,000 | ||||||||||||

| Gu et al., 2019 | 300 | 900 | 417,900 | ||||||||||||

| Gu et al., 2019 | 300 | 100 | 360,000 | ||||||||||||

| Gu et al., 2019 | 1100 | 100 | 408,000 | ||||||||||||

| Gu et al., 2019 | 3400 | 319,500 | |||||||||||||

| Gu et al., 2019 | 300 | 200 | 657,400 | ||||||||||||

| Gu et al., 2019 | 80,500 | ||||||||||||||

| Gu et al., 2019 | 1300 | 1000 | 479,000 | ||||||||||||

| Korf et al., 2019 | 8118 | 14,949 | 18 | 10,739 | 5.6 | 33,901 | 5.6 | 64 | 1792 | 333,228 | |||||

| Korf et al., 2019 | 4125 | 18,333 | 28 | 6768 | 5.6 | 40,984 | 5.6 | 39 | 139 | 232,163 | |||||

| Korf et al., 2019 | 2100 | 2600 | 344,900 | ||||||||||||

| Korf et al., 2019 | 600 | 3100 | 600 | 395,600 | |||||||||||

| Korf et al., 2019 | 600 | 9900 | 1000 | 383,300 | |||||||||||

| Korf et al., 2019 | 500 | 6100 | 900 | 378,100 | |||||||||||

| Korf et al., 2019 | 2400 | 67,000 | 4700 | 400 | 100 | 96,000 | |||||||||

| Korf et al., 2019 | 3800 | 15,000 | 1500 | 19,000 | 440 | 280 | 330,000 | ||||||||

| Korf et al., 2019 | 1000 | 32,700 | 600 | 1600 | 56,700 | 45,200 | 1300 | 200 | 241,900 | ||||||

| Korf et al., 2019 | 430 | 25,200 | 145 | 1280 | 18,000 | 1.8 | 53.8 | 9480 | 1.7 | 1.7 | 500 | 123 | 371,000 | ||

| Korf et al., 2019 | 310 | 10,600 | 258 | 1410 | 19,000 | 0.8 | 39 | 12,300 | 0.6 | 4.9 | 540 | 42,000 | 306,000 | ||

| Korf et al., 2019 | 370 | 17,300 | 111 | 552 | 20,300 | 15.5 | 8340 | 0.9 | 2.1 | 270 | 650 | 494,000 | |||

| Korf et al., 2019 | 2640 | 22,736 | 93.3 | 1051 | 2152 | 98.8 | 39.6 | 1556 | 2.1 | 952.9 | 342,667 | ||||

| Korf et al., 2019 | 2773 | 23,003 | 141 | 1083 | 2662 | 138 | 60.6 | 762 | 1306.7 | 395,000 | |||||

| Sahan et al., 2019 | 2500 | 8900 | 2400 | 140 | 190 | 324,700 | |||||||||

| Sahan et al., 2019 | 1700 | 13,200 | 650 | 50 | 110 | 370,400 | |||||||||

| Sahan et al., 2019 | 2000 | 10,400 | 2900 | 270 | 3900 | 227,500 | |||||||||

| Sahan et al., 2019 | 2000 | 11,500 | 1400 | 110 | 330 | 378,000 | |||||||||

| Sahan et al., 2019 | 4700 | 12,900 | 1300 | 190 | 510 | 404,000 | |||||||||

| Sahan et al., 2019 | 8300 | 10,700 | 1800 | 110 | 130 | 206,000 | |||||||||

| Sahan et al., 2019 | 5100 | 11,800 | 1600 | 120 | 290 | 287,500 | |||||||||

| Sahan et al., 2019 | 3700 | 14,900 | 1500 | 370 | 460 | 305,200 | |||||||||

| Sahan et al., 2019 | 3200 | 16,600 | 820 | 230 | 170 | 451,400 | |||||||||

| Sahan et al., 2019 | 3900 | 16,300 | 1100 | 700 | 440 | 313,100 | |||||||||

| Sahan et al., 2019 | 2600 | 20,100 | 530 | 50 | 440 | 397,700 | |||||||||

| Sahan et al., 2019 | 5900 | 15,900 | 1600 | 300 | 140 | 282,400 | |||||||||

| Sahan et al., 2019 | 1700 | 19,700 | 170 | 100 | 15,000 | 409,800 | |||||||||

| Sahan et al., 2019 | 6100 | 378,000 | |||||||||||||

| Sahan et al., 2019 | 2100 | 2600 | 344,900 | ||||||||||||

| Sahan et al., 2019 | 8500 | 17,700 | |||||||||||||

| Sahan et al., 2019 | 1060 | 65 | 408,000 | ||||||||||||

| Sahan et al., 2019 | 540 | 43 | 398,600 | ||||||||||||

| Sahan et al., 2019 | 4700 | 15,200 | 1400 | 200 | 400 | 326,200 | |||||||||

| Average | 2557 | 17,628 | 148 | 859 | 9626 | 69 | 138 | 47,325 | 18,228 | 6 | 3 | 3305 | 199 | 2985 | 332,464 |

| St deviation | 1886 | 15,301 | 137 | 616 | 7663 | 59 | 178 | 13,258 | 17,311 | 13 | 3 | 2835 | 174 | 7838 | 116,836 |

| Minimum | 300 | 2600 | 0.044 | 10 | 1600 | 0.8 | 0.044 | 37,950 | 762 | 0.044 | 0.071 | 1300 | 0.044 | 110 | 17,700 |

| Maximum | 8300 | 67,000 | 480 | 2900 | 20,300 | 138 | 440 | 56,700 | 45,200 | 45 | 7 | 5310 | 700 | 42,000 | 657,400 |

| Number of samples | 66 | 43 | 10 | 58 | 18 | 8 | 15 | 2 | 14 | 12 | 5 | 2 | 27 | 31 | 66 |

| References (mg/kg PCB) | Dy | Eu | Fe | Ga | Ge | Hf | Hg | In | K | La | Li | Mg | Mn | Mo | Na |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chancerel et al., 2009 | |||||||||||||||

| Chancerel et al., 2009 | |||||||||||||||

| Chancerel et al., 2009 | |||||||||||||||

| Kasper et al., 2011 | 14,200 | ||||||||||||||

| Kasper et al., 2011 | 65,300 | ||||||||||||||

| Kasper et al., 2011 | 48,500 | ||||||||||||||

| Oguchi et al., 2011 | 150,000 | ||||||||||||||

| Oguchi et al., 2011 | 18,000 | 140 | |||||||||||||

| Yamane et al., 2011 | 105,700 | ||||||||||||||

| Silvas et al., 2015 | 124,900 | ||||||||||||||

| Ueberschaar et al., 2017 (a) | 140 | ||||||||||||||

| Ueberschaar et al., 2017 (b) | 0.088 | 0.09 | 13,640 | 0.02 | 0.5 | 0.5 | 0.088 | 0.088 | |||||||

| Ueberschaar et al., 2017 (b) | 68 | 1 | 166,360 | 207 | 39 | 40 | 3093 | 997 | |||||||

| Arshadi et al., 2018 | 47,090 | 510 | 5900 | 5150 | 10 | ||||||||||

| Holgersson et al., 2018 | 8608 | 0.6 | 205 | 602 | 16.2 | 7.7 | 139 | ||||||||

| Holgersson et al., 2018 | 11,481 | 0.3 | 234 | 1164 | 23.4 | 8.8 | 753 | ||||||||

| Holgersson et al., 2018 | 10,000 | ||||||||||||||

| Holgersson et al., 2018 | 15,000 | ||||||||||||||

| Holgersson et al., 2018 | 20,000 | ||||||||||||||

| Holgersson et al., 2018 | 30,000 | ||||||||||||||

| Holgersson et al., 2018 | 8434 | 8 | |||||||||||||

| Holgersson et al., 2018 | 26,300 | ||||||||||||||

| Holgersson et al., 2018 | 35,000 | ||||||||||||||

| Holgersson et al., 2018 | 23,500 | ||||||||||||||

| Li et al., 2018 | 50,000 | ||||||||||||||

| Gu et al., 2019 | |||||||||||||||

| Gu et al., 2019 | 42,700 | ||||||||||||||

| Gu et al., 2019 | 2400 | ||||||||||||||

| Gu et al., 2019 | |||||||||||||||

| Gu et al., 2019 | 46,000 | ||||||||||||||

| Gu et al., 2019 | |||||||||||||||

| Gu et al., 2019 | 10,500 | ||||||||||||||

| Gu et al., 2019 | 2800 | ||||||||||||||

| Gu et al., 2019 | 19,400 | ||||||||||||||

| Gu et al., 2019 | 15,100 | ||||||||||||||

| Gu et al., 2019 | 500 | ||||||||||||||

| Gu et al., 2019 | 5000 | ||||||||||||||

| Korf et al., 2019 | 15,089 | 210 | 12 | 5.6 | 236 | 13 | 635 | 654 | 897 | ||||||

| Korf et al., 2019 | 5366 | 184 | 7 | 5.6 | 347 | 15 | 947 | 569 | 1197 | ||||||

| Korf et al., 2019 | 105,700 | ||||||||||||||

| Korf et al., 2019 | 14,200 | ||||||||||||||

| Korf et al., 2019 | 65,300 | ||||||||||||||

| Korf et al., 2019 | 48,500 | ||||||||||||||

| Korf et al., 2019 | 150,000 | ||||||||||||||

| Korf et al., 2019 | 18,000 | 140 | |||||||||||||

| Korf et al., 2019 | 1600 | 300 | 1900 | ||||||||||||

| Korf et al., 2019 | 157,200 | 180 | 12.4 | 17.9 | 141 | 4.6 | 35 | 701 | 2407 | 244 | 412 | ||||

| Korf et al., 2019 | 251,000 | 267 | 20 | 23 | 0.34 | 134 | 6.3 | 41 | 1680 | 4900 | 265 | 400 | |||

| Korf et al., 2019 | 18,900 | 103 | 3.9 | 28.2 | 144 | 2.9 | 37 | 2000 | 480 | 75 | 391 | ||||

| Korf et al., 2019 | 8608 | 0.6 | 205 | 602 | 16.2 | 7.7 | 139 | ||||||||

| Korf et al., 2019 | 11,481 | 0.3 | 234 | 1164 | 23.4 | 8.8 | 753 | ||||||||

| Sahan et al., 2019 | 23,600 | ||||||||||||||

| Sahan et al., 2019 | 20,400 | ||||||||||||||

| Sahan et al., 2019 | 37,200 | ||||||||||||||

| Sahan et al., 2019 | 33,900 | ||||||||||||||

| Sahan et al., 2019 | 48,400 | ||||||||||||||

| Sahan et al., 2019 | 10,000 | ||||||||||||||

| Sahan et al., 2019 | 5000 | ||||||||||||||

| Sahan et al., 2019 | 14,800 | ||||||||||||||

| Sahan et al., 2019 | 6400 | ||||||||||||||

| Sahan et al., 2019 | 11,900 | ||||||||||||||

| Sahan et al., 2019 | 46,300 | ||||||||||||||

| Sahan et al., 2019 | 10,100 | ||||||||||||||

| Sahan et al., 2019 | 34,200 | ||||||||||||||

| Sahan et al., 2019 | 48,500 | ||||||||||||||

| Sahan et al., 2019 | 105,700 | ||||||||||||||

| Sahan et al., 2019 | |||||||||||||||

| Sahan et al., 2019 | 2800 | ||||||||||||||

| Sahan et al., 2019 | |||||||||||||||

| Sahan et al., 2019 | 14,600 | ||||||||||||||

| Average | 34 | 1 | 40,675 | 157 | 15 | 23 | 4 | 86 | 284 | 11 | 28 | 1568 | 1270 | 78 | 565 |

| St deviation | 48 | 1 | 50,004 | 72 | 15 | 5 | 5 | 74 | 104 | 16 | 13 | 1529 | 1882 | 111 | 358 |

| Minimum | 0.088 | 0.09 | 500 | 0.02 | 0.5 | 17.9 | 0.3 | 5.6 | 205 | 0.5 | 13 | 0.088 | 0.088 | 7.7 | 139 |

| Maximum | 68 | 1 | 251,000 | 267 | 39 | 28.2 | 12 | 144 | 510 | 40 | 41 | 5900 | 5150 | 265 | 1197 |

| Number of samples | 2 | 2 | 61 | 10 | 5 | 3 | 8 | 5 | 8 | 5 | 5 | 13 | 12 | 8 | 9 |

| References (mg/kg PCB) | Nd | Ni | P | Pb | Pd | Pr | Pt | Rh | S | Sb | Sc | Si | Sm | Sn | Sr |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chancerel et al., 2009 | 241 | ||||||||||||||

| Chancerel et al., 2009 | 287 | ||||||||||||||

| Chancerel et al., 2009 | 285 | 7 | |||||||||||||

| Kasper et al., 2011 | 34,200 | 11,700 | 20,900 | ||||||||||||

| Kasper et al., 2011 | 16,700 | 12,600 | 31,100 | ||||||||||||

| Kasper et al., 2011 | 25,400 | 12,300 | 25,500 | ||||||||||||

| Oguchi et al., 2011 | 19,000 | 34,000 | 300 | ||||||||||||

| Oguchi et al., 2011 | 13,000 | 300 | 35,000 | 430 | |||||||||||

| Yamane et al., 2011 | 26,300 | 18,700 | 33,900 | ||||||||||||

| Silvas et al., 2015 | 34,100 | 18,700 | 33,900 | ||||||||||||

| Ueberschaar et al., 2017 (a) | |||||||||||||||

| Ueberschaar et al., 2017 (b) | 0.088 | 8390 | 3707 | 103 | 0.088 | 1.75 | 1858 | 108,492 | 0.088 | 17,640 | |||||

| Ueberschaar et al., 2017 (b) | 1162 | 37,628 | 132 | 56 | 85 | 1 | 10 | 112,800 | 8 | 26,948 | |||||

| Arshadi et al., 2018 | 400 | 2790 | 1000 | 11,190 | 1900 | 2660 | 94,250 | 23,540 | 400 | ||||||

| Holgersson et al., 2018 | 9.7 | 11,600 | 910 | 3747 | 119 | 4.3 | 5.7 | 543 | 0.4 | 66,150 | 19,267 | 108 | |||

| Holgersson et al., 2018 | 60.7 | 15,433 | 1441 | 260 | 55.4 | 0.8 | 8.5 | 30.4 | 0.6 | 56,971 | 32,200 | 82.5 | |||

| Holgersson et al., 2018 | 12,000 | 200 | 1000 | ||||||||||||

| Holgersson et al., 2018 | 17,000 | 1100 | 200 | ||||||||||||

| Holgersson et al., 2018 | 9000 | 300 | 500 | ||||||||||||

| Holgersson et al., 2018 | 11,000 | 3 | 2500 | ||||||||||||

| Holgersson et al., 2018 | 1618 | 5 | 22 | ||||||||||||

| Holgersson et al., 2018 | 18,700 | ||||||||||||||

| Holgersson et al., 2018 | 13,636 | 955 | |||||||||||||

| Holgersson et al., 2018 | 9900 | 294 | 30 | ||||||||||||

| Li et al., 2018 | 1000 | 3000 | 210 | 5000 | |||||||||||

| Gu et al., 2019 | 400 | ||||||||||||||

| Gu et al., 2019 | 25,400 | 12,200 | 25,800 | ||||||||||||

| Gu et al., 2019 | 100 | 14,000 | |||||||||||||

| Gu et al., 2019 | 4000 | ||||||||||||||

| Gu et al., 2019 | 6000 | 600 | 100 | 26,000 | |||||||||||

| Gu et al., 2019 | 300 | 200 | |||||||||||||

| Gu et al., 2019 | 8600 | 12,100 | 600 | ||||||||||||

| Gu et al., 2019 | 3900 | 13,600 | 100 | 16,000 | |||||||||||

| Gu et al., 2019 | 27,100 | 17,800 | |||||||||||||

| Gu et al., 2019 | 19,800 | 10,700 | 100 | ||||||||||||

| Gu et al., 2019 | 100 | 6100 | 8600 | ||||||||||||

| Gu et al., 2019 | 8000 | 100 | 20,000 | ||||||||||||

| Korf et al., 2019 | 13,454 | 1405 | 5,6 | 44 | 334 | ||||||||||

| Korf et al., 2019 | 6870 | 2495 | 5,6 | 8 | 372 | ||||||||||

| Korf et al., 2019 | 26,300 | 18,700 | 33,900 | ||||||||||||

| Korf et al., 2019 | 34,200 | 11,700 | 20,900 | ||||||||||||

| Korf et al., 2019 | 16,700 | 12,600 | 31,100 | ||||||||||||

| Korf et al., 2019 | 25,400 | 12,300 | 25,500 | ||||||||||||

| Korf et al., 2019 | 19,000 | 34,000 | 300 | ||||||||||||

| Korf et al., 2019 | 13,000 | 300 | 35,000 | 430 | |||||||||||

| Korf et al., 2019 | 100 | 2900 | 4000 | 8900 | 1900 | 104,800 | 14,200 | 500 | |||||||

| Korf et al., 2019 | 44 | 41,500 | 283 | 99 | 7.3 | 12.2 | 11 | 60,000 | 38,100 | 284 | |||||

| Korf et al., 2019 | 32 | 57,000 | 610 | 178 | 25 | 9.8 | 12 | 80,200 | 31,400 | 233 | |||||

| Korf et al., 2019 | 9.5 | 82,900 | 597 | 100 | 5.3 | 3.16 | 17 | 45,300 | 41,700 | 372 | |||||

| Korf et al., 2019 | 9.7 | 11,600 | 910 | 3747 | 119 | 4.3 | 5.7 | 543 | 0.4 | 66,150 | 19,267 | 108 | |||

| Korf et al., 2019 | 60.7 | 15,433 | 1441 | 260 | 55.4 | 0.8 | 8.5 | 30.4 | 0.6 | 56,971 | 32,200 | 82.5 | |||

| Sahan et al., 2019 | 32,300 | 1600 | 10 | 32 | 62,700 | ||||||||||

| Sahan et al., 2019 | 13,600 | 1000 | DL | 22 | 34,300 | ||||||||||

| Sahan et al., 2019 | 23,800 | 7300 | 40 | 26 | 51,800 | ||||||||||

| Sahan et al., 2019 | 21,000 | 2600 | 260 | 28 | 28,300 | ||||||||||

| Sahan et al., 2019 | 37,700 | 16,700 | 220 | 50 | 26,200 | ||||||||||

| Sahan et al., 2019 | 11,000 | 16,300 | 360 | 33 | 29,600 | ||||||||||

| Sahan et al., 2019 | 15,800 | 17,900 | 400 | 19 | 35,500 | ||||||||||

| Sahan et al., 2019 | 31,900 | 14,600 | 820 | 7 | 29,700 | ||||||||||

| Sahan et al., 2019 | 59,300 | 23,300 | 120 | 12 | 25,300 | ||||||||||

| Sahan et al., 2019 | 27,000 | 10,000 | 470 | 15 | 13,000 | ||||||||||

| Sahan et al., 2019 | 17,000 | 27,300 | DL | 26 | 33,000 | ||||||||||

| Sahan et al., 2019 | 15,000 | 15,600 | 390 | 36 | 27,100 | ||||||||||

| Sahan et al., 2019 | 20,100 | 1900 | 140 | 26 | 13,700 | ||||||||||

| Sahan et al., 2019 | 25,400 | 12,300 | 25,500 | ||||||||||||

| Sahan et al., 2019 | 26,300 | 18,700 | 33,900 | ||||||||||||

| Sahan et al., 2019 | 30,200 | 5800 | |||||||||||||

| Sahan et al., 2019 | 3900 | 13,600 | 50 | 16,000 | |||||||||||

| Sahan et al., 2019 | 3960 | ||||||||||||||

| Sahan et al., 2019 | 29,300 | 15,500 | 400 | 20 | 23,700 | ||||||||||

| Average | 172 | 21,068 | 1617 | 10,234 | 251 | 43 | 18 | 7 | 1900 | 587 | 6 | 77,462 | 4 | 26,677 | 289 |

| St deviation | 347 | 16,147 | 1193 | 6859 | 245 | 60 | 13 | 2 | 0 | 895 | 7 | 23,840 | 6 | 10,939 | 138 |

| Minimum | 0.088 | 100 | 910 | 132 | 3 | 0.088 | 0.8 | 5.7 | 1900 | 3.16 | 0.4 | 45,300 | 0.088 | 200 | 82.5 |

| Maximum | 1162 | 82,900 | 4000 | 27,300 | 1100 | 85 | 50 | 8.5 | 1900 | 2660 | 17 | 112,800 | 8 | 62,700 | 500 |

| Number of samples | 11 | 52 | 6 | 59 | 42 | 2 | 25 | 4 | 2 | 17 | 7 | 11 | 2 | 50 | 15 |

| References (mg/kg PCB) | Ta | Tb | Te | Th | Ti | V | W | Y | Zn | Zr | Measured % of total PCB mass |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Chancerel et al., 2009 | 0.25% | ||||||||||

| Chancerel et al., 2009 | 0.42% | ||||||||||

| Chancerel et al., 2009 | 0.68% | ||||||||||

| Kasper et al., 2011 | 34,300 | 51.52% | |||||||||

| Kasper et al., 2011 | 9700 | 53.02% | |||||||||

| Kasper et al., 2011 | 18,200 | 51.55% | |||||||||

| Oguchi et al., 2011 | 8600 | 38.25% | |||||||||

| Oguchi et al., 2011 | 2600 | 5000 | 44.45% | ||||||||

| Yamane et al., 2011 | 59,200 | 59.34% | |||||||||

| Silvas et al., 2015 | 59,200 | 63.30% | |||||||||

| Ueberschaar et al., 2017 (a) | 0.01% | ||||||||||

| Ueberschaar et al., 2017 (b) | 897 | 0.088 | 0.044 | 3061 | 4412 | 0.088 | 49.28% | ||||

| Ueberschaar et al., 2017 (b) | 1006 | 1 | 10 | 6648 | 16,154 | 630 | 93.14% | ||||

| Arshadi et al., 2018 | 210 | 3060 | 9310 | 370 | 56.12% | ||||||

| Holgersson et al., 2018 | 1640 | 1 | 111 | 5 | 5642 | 225 | 49.37% | ||||

| Holgersson et al., 2018 | 712 | 0.7 | 122 | 4.1 | 6743 | 298 | 55.50% | ||||

| Holgersson et al., 2018 | 27.89% | ||||||||||

| Holgersson et al., 2018 | 24.07% | ||||||||||

| Holgersson et al., 2018 | 23.53% | ||||||||||

| Holgersson et al., 2018 | 17.36% | ||||||||||

| Holgersson et al., 2018 | 28.84% | ||||||||||

| Holgersson et al., 2018 | 39.20% | ||||||||||

| Holgersson et al., 2018 | 64.82% | ||||||||||

| Holgersson et al., 2018 | 27.23% | ||||||||||

| Li et al., 2018 | 20.09% | ||||||||||

| Gu et al., 2019 | 27.99% | ||||||||||

| Gu et al., 2019 | 20,700 | 51.39% | |||||||||

| Gu et al., 2019 | 2200 | 58.67% | |||||||||

| Gu et al., 2019 | 4600 | 40.78% | |||||||||

| Gu et al., 2019 | 100 | 51.05% | |||||||||

| Gu et al., 2019 | 41.96% | ||||||||||

| Gu et al., 2019 | 8000 | 40.02% | |||||||||

| Gu et al., 2019 | 4100 | 44.97% | |||||||||

| Gu et al., 2019 | 11,900 | 39.91% | |||||||||

| Gu et al., 2019 | 2200 | 70.58% | |||||||||

| Gu et al., 2019 | 100 | 9.59% | |||||||||

| Gu et al., 2019 | 51.44% | ||||||||||

| Korf et al., 2019 | 1508 | 1011 | 43.83% | ||||||||

| Korf et al., 2019 | 708 | 960 | 32.26% | ||||||||

| Korf et al., 2019 | 59,200 | 59.34% | |||||||||

| Korf et al., 2019 | 34,300 | 51.52% | |||||||||

| Korf et al., 2019 | 9700 | 53.02% | |||||||||

| Korf et al., 2019 | 18,200 | 51.55% | |||||||||

| Korf et al., 2019 | 8600 | 38.25% | |||||||||

| Korf et al., 2019 | 2600 | 5000 | 44.45% | ||||||||

| Korf et al., 2019 | 1500 | 700 | 300 | 52.48% | |||||||

| Korf et al., 2019 | 2800 | 6450 | 140 | 1110 | 43 | 3770 | 692 | 74.29% | |||

| Korf et al., 2019 | 2000 | 7100 | 187 | 860 | 40 | 5600 | 910 | 83.76% | |||

| Korf et al., 2019 | 2330 | 7300 | 12.8 | 1740 | 230 | 69,000 | 1280 | 81.70% | |||

| Korf et al., 2019 | 1640 | 1 | 111 | 5 | 5642 | 225 | 49.37% | ||||

| Korf et al., 2019 | 712 | 0.7 | 122 | 4.1 | 6743 | 298 | 55.50% | ||||

| Sahan et al., 2019 | 28,100 | 48.72% | |||||||||

| Sahan et al., 2019 | 8200 | 46.36% | |||||||||

| Sahan et al., 2019 | 21,200 | 38.83% | |||||||||

| Sahan et al., 2019 | 2300 | 48.17% | |||||||||

| Sahan et al., 2019 | 17,800 | 57.07% | |||||||||

| Sahan et al., 2019 | 3500 | 29.78% | |||||||||

| Sahan et al., 2019 | 7200 | 38.82% | |||||||||

| Sahan et al., 2019 | 30,200 | 44.82% | |||||||||

| Sahan et al., 2019 | 67,000 | 65.39% | |||||||||

| Sahan et al., 2019 | 5100 | 40.30% | |||||||||

| Sahan et al., 2019 | 26,900 | 57.19% | |||||||||

| Sahan et al., 2019 | 13,600 | 38.81% | |||||||||

| Sahan et al., 2019 | 18,900 | 53.54% | |||||||||

| Sahan et al., 2019 | 18,200 | 51.40% | |||||||||

| Sahan et al., 2019 | 59,200 | 59.34% | |||||||||

| Sahan et al., 2019 | 1000 | 6.32% | |||||||||

| Sahan et al., 2019 | 4100 | 44.96% | |||||||||

| Sahan et al., 2019 | 4570 | 40.77% | |||||||||

| Sahan et al., 2019 | 17,000 | 44.86% | |||||||||

| Average | 2033 | 1 | 5 | 210 | 3234 | 49 | 597 | 47 | 16,164 | 475 | 64.35% |

| St deviation | 782 | 1 | 7 | - | 2641 | 79 | 654 | 82 | 18,616 | 369 | |

| Minimum | 897 | 0.088 | 0.044 | 210 | 708 | 0.7 | 111 | 4.1 | 100 | 0.088 | |

| Maximum | 2800 | 1 | 10 | 210 | 7300 | 187 | 1740 | 230 | 69,000 | 1280 | |

| Number of samples | 7 | 2 | 2 | 1 | 13 | 7 | 7 | 7 | 54 | 11 |

References

- Eurostat EU Trade in Raw Materials, 2020–2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Extra-EU_trade_in_raw_materials#:~:text=In%202020%2C%20the%20value%20of,deficit%20of%20EUR%2026.4%20billion (accessed on 25 October 2021).

- International Energy Agency. World Energy Outlook 2021; International Energy Agency: Paris, France, 2021; Available online: https://www.iea.org/reports/world-energy-outlook-2021 (accessed on 25 October 2021).

- Kemp, J. Rising Electricity Prices in Europe. Available online: https://www.reuters.com/business/energy/europes-rising-energy-prices-will-force-factory-closures-kemp-2021-10-01/ (accessed on 25 October 2021).

- Meredith, S. Rising Electricity Prices in Europe. Available online: https://www.cnbc.com/2021/09/16/europes-energy-crisis-is-making-the-market-nervous-ahead-of-winter.html (accessed on 25 October 2021).

- Tagliapietra, S.; Zachmann, G. Rising Electricity Prices in Europe. Available online: https://www.bruegel.org/2021/09/is-europes-gas-and-electricity-price-surge-a-one-off/ (accessed on 25 October 2021).

- Liboreiro, J.; de Filippis, A. Rising Electricity Prices in Europe. Available online: https://www.euronews.com/2021/09/23/why-europe-s-energy-prices-are-soaring-and-could-get-much-worse (accessed on 25 October 2021).

- Fitch Ratings Rising Natural Gas Prices in Europe. Available online: https://www.fitchratings.com/research/corporate-finance/record-high-gas-prices-affect-many-european-corporate-sectors-22-09-2021 (accessed on 25 October 2021).

- Autotraveler Rising Fuel Prices in Europe. Available online: https://autotraveler.ru/en/spravka/fuel-price-in-europe.html (accessed on 25 October 2021).

- The News 24 Rising Food Price. Available online: https://then24.com/2021/06/28/the-imf-warns-that-the-rise-in-food-prices-has-only-just-begun-for-consumers/ (accessed on 25 October 2021).

- Amaro, S. Rising Food Price. Available online: https://www.cnbc.com/2021/07/27/imf-warns-that-inflation-could-prove-to-be-persistent.html (accessed on 25 October 2021).

- Baffes, J.; Chian Koh, W. Rising Fertilizers Prices. Available online: https://blogs.worldbank.org/opendata/fertilizer-prices-expected-stay-high-over-remainder-2021 (accessed on 25 October 2021).

- Fortuna, G. Rising Livestook Food Prices. Available online: https://www.euractiv.com/section/agriculture-food/news/animal-feed-spike-worries-eu-countries/ (accessed on 25 October 2021).

- Konings, J.; Luman, R. Rising Shipping Costs. Available online: https://think.ing.com/articles/the-rise-and-rise-of-global-shipping-costs (accessed on 25 October 2021).

- Longley, A.; Bosley, C.; Hipwell, D. Rising Shipping Costs. Available online: https://time.com/6073233/shipping-costs-surge-price-hike-goods/ (accessed on 25 October 2021).

- Reuters Semiconductor Shortage in Europe. Available online: https://www.euronews.com/next/2021/08/03/global-semiconductor-shortage-more-challenging-times-ahead-for-europe-s-major-carmakers (accessed on 25 October 2021).

- Attinasi, M.G.; de Stefani, R.; Frohm, E.; Gunnella, V.; Koester, G.; Melemenidis, A.; Tóth, M. Semiconductor Shotage in Europe. Available online: https://www.ecb.europa.eu/pub/economic-bulletin/focus/2021/html/ecb.ebbox202104_06~780de2a8fb.en.html (accessed on 25 October 2021).

- Valero, A.; Valero, A.; Calvo, G.; Ortego, A. Material Bottlenecks in the Future Development of Green Technologies. Renew. Sustain. Energy Rev. 2018, 93, 178–200. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2019; International Energy Agency: Paris, France, 2019; Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 25 October 2021).

- International Energy Agency. The Role of Critical Minerals in Clean Energy Transitions; World Energy Outlook Special Report; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Henckens, T. Scarce Mineral Resources: Extraction, Consumption and Limits of Sustainability. Resour. Conserv. Recycl. 2021, 169, 5511. [Google Scholar] [CrossRef]

- International Energy Agency Global Investments in Oil and Gas Upstream in Nominal Terms and Percentage Change from Previous Year, 2010–2020. Available online: https://www.iea.org/data-and-statistics/charts/global-investments-in-oil-and-gas-upstream-in-nominal-terms-and-percentage-change-from-previous-year-2010-2020 (accessed on 25 October 2021).

- O’Dea, S. Mobile Phone Sales between 2007 and 2021. Available online: https://www.statista.com/statistics/263437/global-smartphone-sales-to-end-users-since-2007/ (accessed on 25 October 2021).

- Bakker, C.; Wang, F.; Huisman, J.; den Hollander, M. Products That Go Round: Exploring Product Life Extension through Design. J. Clean Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Li, H.; Eksteen, J.; Oraby, E. Hydrometallurgical Recovery of Metals from Waste Printed Circuit Boards (WPCBs): Current Status and Perspectives—A Review. Resour. Conserv. Recycl. 2018, 139, 122–139. [Google Scholar] [CrossRef]

- Sahan, M.; Kucuker, M.A.; Demirel, B.; Kuchta, K.; Hursthouse, A. Determination of Metal Content of Waste Mobile Phones and Estimation of Their Recovery Potential in Turkey. Int. J. Environ. Res. Public Health 2019, 16, 887. [Google Scholar] [CrossRef] [Green Version]

- Fairphone 70% of the Carbon Footprint Is in the PCB of Mobile Phones. Available online: https://www.fairphone.com/es/2020/07/31/how-sustainable-is-the-fairphone-3 (accessed on 25 October 2021).

- Gu, F.; Summers, P.A.; Hall, P. Recovering Materials from Waste Mobile Phones: Recent Technological Developments. J. Clean. Prod. 2019, 237, 117657. [Google Scholar] [CrossRef]

- Calvo, G.; Valero, A.; Valero, A. Thermodynamic Approach to Evaluate the Criticality of Raw Materials and Its Application through a Material Flow Analysis in Europe. J. Ind. Ecol. 2018, 22, 839–852. [Google Scholar] [CrossRef] [Green Version]

- European Commission Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; Brussels, Belgium. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52020DC0474&from=EN (accessed on 25 October 2021).

- Singapore (Bloomberg) Silicon Price Rises 300%. Available online: https://newsbeezer.com/singapore/the-300-percent-increase-in-silicon-causes-another-price-shock-for-the-global-economy-economy-news-top-stories/ (accessed on 25 October 2021).

- Macrotrends Historical Copper Prices. Available online: https://www.macrotrends.net/1476/copper-prices-historical-chart-data (accessed on 25 October 2021).

- Haque, N.; Hughes, A.; Lim, S.; Vernon, C. Rare Earth Elements: Overview of Mining, Mineralogy, Uses, Sustainability and Environmental Impact. Resources 2014, 3, 614–635. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Directorate-General for Internal Market, Industry, Entrepreneurship and SMEs. Study on the Review of the List of Critical Raw Materials. Executive Summary. 2017. Available online: https://data.europa.eu/doi/10.2873/876644 (accessed on 25 October 2021).

- Calvo, G.; Mudd, G.; Valero, A.; Valero, A. Decreasing Ore Grades in Global Metallic Mining: A Theoretical Issue or a Global Reality? Resources 2016, 5, 36. [Google Scholar] [CrossRef] [Green Version]

- Palacios, J.L.; Calvo, G.; Valero, A.; Valero, A. The Cost of Mineral Depletion in Latin America: An Exergoecology View. Resour. Policy 2018, 59, 117–124. [Google Scholar] [CrossRef]

- Valero Capilla, A.; Valero Delgado, A. Thanatia. The Destiny of the Earths Mineral Resources. A Thermodynamic Cradle-to-Cradle Assessment; World Scientific: Singapore, 2015; ISBN 978-9814273930. [Google Scholar]

- Valero, A.; Valero, A. Thanatia, The Destiny of the Earth’s Mineral Resources: A Cradle to Cradle Assessment; World Scientific Publishing: Singapore, 2014; ISBN 978-981-4273-93-0. [Google Scholar]

- Valero, A.; Valero, A. Thermodynamic Rarity and the Loss of Mineralwealth. Energies 2015, 8, 821–836. [Google Scholar] [CrossRef] [Green Version]

- Valero, A.; Valero, A. Thermodynamic Rarity and Recyclability of Raw Materials in the Energy Transition: The Need for an In-Spiral Economy. Entropy 2019, 21, 873. [Google Scholar] [CrossRef] [Green Version]

- Valero, A.; Valero, A.; Calvo, G. The Material Limits of Energy Transition: Thanatia; Springer Nature: Cham, Switzerland, 2021; ISBN 978-3-030798532-1. [Google Scholar]

- Valero, A.; Valero, A.; von Gries, N. “Composed Thermodynamic Rarity” of the Materials in Electric and Electronic Equipment. In Proceedings of the ECOS 2016—The 29th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Portoroz, Slovenia, 23 June 2016. [Google Scholar]

- Ortego, A.; Valero, A.; Valero, A.; Restrepo, E. Vehicles and Critical Raw Materials: A Sustainability Assessment Using Thermodynamic Rarity. J. Ind. Ecol. 2018, 22, 1005–1015. [Google Scholar] [CrossRef] [Green Version]

- Ortego, A.; Valero, A.; Valero, A.; Iglesias, M. Downcycling in Automobile Recycling Process: A Thermodynamic Assessment. Resour. Conserv. Recycl. 2018, 136, 24–32. [Google Scholar] [CrossRef]

- Horta Arduin, R.; Mathieux, F.; Huisman, J.; Blengini, G.A.; Charbuillet, C.; Wagner, M.; Baldé, C.P.; Perry, N. Novel Indicators to Better Monitor the Collection and Recovery of (Critical) Raw Materials in WEEE: Focus on Screens. Resour. Conserv. Recycl. 2020, 157, 4772. [Google Scholar] [CrossRef] [PubMed]

- Palacios Encalada, J.L.; Valero Delgado, A.; Valero Capilla, A.F. Beyond a Tonnage Perspective for the Assessment of Mineral Reources. Focus on Latin America and the Caribbean. 2020. Available online: https://zaguan.unizar.es/record/87141/files/TESIS-2020-028.pdf (accessed on 25 October 2021).

- Chancerel, P.; Meskers, C.E.M.; Hagelüken, C.; Rotter, V.S. Assessment of Precious Metal Flows during Preprocessing of Waste Electrical and Electronic Equipment. J. Ind. Ecol. 2009, 13, 791–810. [Google Scholar] [CrossRef]

- Kasper, A.C.; Berselli, G.B.T.; Freitas, B.D.; Tenório, J.A.S.; Bernardes, A.M.; Veit, H.M. Printed Wiring Boards for Mobile Phones: Characterization and Recycling of Copper. Waste Manag. 2011, 31, 2536–2545. [Google Scholar] [CrossRef]

- Oguchi, M.; Murakami, S.; Sakanakura, H.; Kida, A.; Kameya, T. A Preliminary Categorization of End-of-Life Electrical and Electronic Equipment as Secondary Metal Resources. Waste Manag. 2011, 31, 2150–2160. [Google Scholar] [CrossRef]

- Yamane, L.H.; de Moraes, V.T.; Espinosa, D.C.R.; Tenório, J.A.S. Recycling of WEEE: Characterization of Spent Printed Circuit Boards from Mobile Phones and Computers. Waste Manag. 2011, 31, 2553–2558. [Google Scholar] [CrossRef]

- Silvas, F.P.C.; Jiménez Correa, M.M.; Caldas, M.P.K.; de Moraes, V.T.; Espinosa, D.C.R.; Tenório, J.A.S. Printed Circuit Board Recycling: Physical Processing and Copper Extraction by Selective Leaching. Waste Manag. 2015, 46, 503–510. [Google Scholar] [CrossRef] [PubMed]

- Ueberschaar, M.; Otto, S.J.; Rotter, V.S. Challenges for Critical Raw Material Recovery from WEEE—The Case Study of Gallium. Waste Manag. 2017, 60, 534–545. [Google Scholar] [CrossRef] [PubMed]

- Ueberschaar, M.; Dariusch Jalalpoor, D.; Korf, N.; Rotter, V.S. Potentials and Barriers for Tantalum Recovery from Waste Electric and Electronic Equipment. J. Ind. Ecol. 2017, 21, 700–714. [Google Scholar] [CrossRef]

- Arshadi, M.; Yaghmaei, S.; Mousavi, S.M. Content Evaluation of Different Waste PCBs to Enhance Basic Metals Recycling. Resour. Conserv. Recycl. 2018, 139, 298–306. [Google Scholar] [CrossRef]

- Holgersson, S.; Steenari, B.M.; Björkman, M.; Cullbrand, K. Analysis of the Metal Content of Small-Size Waste Electric and Electronic Equipment (WEEE) Printed Circuit Boards—Part 1: Internet Routers, Mobile Phones and Smartphones. Resour. Conserv. Recycl. 2018, 133, 300–308. [Google Scholar] [CrossRef]

- Korf, N.; Løvik, A.N.; Figi, R.; Schreiner, C.; Kuntz, C.; Mählitz, P.M.; Rösslein, M.; Wäger, P.; Rotter, V.S. Multi-Element Chemical Analysis of Printed Circuit Boards—Challenges and Pitfalls. Waste Manag. 2019, 92, 124–136. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Hou, K.; Li, J.; Zhu, X. Examining the Technology Acceptance for Dismantling of Waste Printed Circuit Boards in Light of Recycling and Environmental Concerns. J. Environ. Manag. 2011, 92, 392–399. [Google Scholar] [CrossRef] [PubMed]

- Kaya, M. Recovery of Metals and Nonmetals from Electronic Waste by Physical and Chemical Recycling Processes. Waste Manag. 2016, 57, 64–90. [Google Scholar] [CrossRef] [PubMed]

- U.S. Geological Survey Mineral Commodity Summaries 2021. 2021. Available online: https://pubs.er.usgs.gov/publication/mcs2021 (accessed on 25 October 2021).

- Wikipedia and U.S. Energy Information Administration (EIA) List of Countries by Electricity Consumption. Available online: https://en.wikipedia.org/wiki/List_of_countries_by_electricity_consumption (accessed on 25 October 2021).

- Reuter, M.A.; van Schaik, A.; Ballester, M. Limits of the Circular Economy: Fairphone Modular Design Pushing the Limits. World Metal. Erzmetall 2018, 71, 68–79. [Google Scholar]

- Valero Navazo, J.M.; Villalba Méndez, G.; Talens Peiró, L. Material Flow Analysis and Energy Requirements of Mobile Phone Material Recovery Processes. Int. J. Life Cycle Assess. 2014, 19, 567–579. [Google Scholar] [CrossRef]

| Element (ore) | Embedded Exergy (GJ/ton) | Exergy Replacement Cost (GJ/ton) | Thermodynamic Rarity (GJ/ton) |

|---|---|---|---|

| Ag | 1566 | 7371 | 8938 |

| Al (Bauxite-Gibbsite) | 54 | 627 | 682 |

| As (Arsenopyrite) | 28 | 400 | 427 |

| Au | 110,057 | 553,250 | 663,308 |

| Ba | 1 | 38 | 39 |

| Be (Beryl) | 457 | 253 | 710 |

| Bi (Bismuthinite) | 56 | 489 | 545 |

| Cd (Greenockite) | 542 | 5898 | 6440 |

| Ce (Monazite) | 523 | 97 | 620 |

| Co (Linnaeite) | 138 | 10,872 | 11,010 |

| Cr (Chromite) | 36 | 5 | 41 |

| Cu (Chalcopyrite) | 57 | 292 | 349 |

| Fe (Hematite) | 14 | 18 | 32 |

| Ga (in Bauxite) | 610,000 | 144,828 | 754,828 |

| Gd (Monazite) | 3607 | 478 | 4085 |

| Ge (in Zinc) | 498 | 23,750 | 24,248 |

| Hf | 11,183 | 21,814 | 32,997 |

| Hg (Cinnabar) | 409 | 28,298 | 28,707 |

| In (in Zinc) | 3320 | 360,598 | 363,917 |

| K (Sylvite) | 2 | 665 | 667 |

| La (Monazite) | 297 | 39 | 336 |

| Li (Spodumene) | 433 | 546 | 979 |

| Mg (from Ocean) | 10 | 26 | 36 |

| Mn (Pyrolusite) | 58 | 16 | 74 |

| Mo (Molibdenite) | 148 | 908 | 1056 |

| Na (Halite) | 43 | 44 | 87 |

| Nd (Monazite) | 592 | 78 | 670 |

| Ni (Pentlandite and Garnierite) * | 265 | 465 | 729 |

| P (Apatite) | 5 | 0 | 5 |

| Pb (Galena) | 4 | 37 | 41 |

| Pd | 583,333 | 8,983,377 | 9,566,710 |

| Pr (Monazite) | 296 | 577 | 873 |

| Pt | 291,667 | 4,491,690 | 4,783,357 |

| Sb (Stibnite) | 13 | 474 | 487 |

| Si (Quartz) | 77 | 1 | 77 |

| Sn (Cassiterite) | 27 | 426 | 453 |

| Sr | 72 | 4 | 78 |

| Ta (Tantalite) | 3091 | 482,828 | 485,919 |

| Ti (Ilmenite and Rutile) * | 196 | 7 | 203 |

| W (Scheelite) | 594 | 7430 | 8024 |

| Y (Monazite) | 1198 | 159 | 1357 |

| Zn (Sphalerite) | 42 | 155 | 197 |

| Zr (Zircon) | 1372 | 654 | 2026 |

| Source | [24] | [46] | [54] | [48] | [51] | [56] | [57] |

|---|---|---|---|---|---|---|---|

| Minimum | 20% | 22% | 21% | 12.6% | 29.5% | 21% | 21.1% |

| Maximum | 30% | 30.3% |

| Elements | Pd | Ta | Au | Ga | Cu | Pt | In | |

|---|---|---|---|---|---|---|---|---|

| (A) Tons embedded | [Tons] | 74 | 602 | 254 | 46 | 98,423 | 5.2 | 25 |

| (B) Tons embedded 2020 | [Tons/yr] | 8 | 64 | 27 | 5 | 10,500 | 0.6 | 2.7 |

| (A)/(B) Annual increase | [%] | 10.8% | 10.6% | 10.6% | 10.9% | 10.7% | 11.5% | 10.8% |

| (C) Annual primary extraction 2020 | [Tons/yr] | 210 | 1700 | 3200 | 300 | 20,000,000 | 170 | 900 |

| (A)/(C) | [%] | 35% | 35% | 7.9% | 15.3% | 0.49% | 3.1% | 2.8% |

| (B)/(C) | [%] | 3.8% | 3.8% | 0.8% | 1.7% | 0.05% | 0.4% | 0.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torrubia, J.; Valero, A.; Valero, A. Thermodynamic Rarity Assessment of Mobile Phone PCBs: A Physical Criticality Indicator in Times of Shortage. Entropy 2022, 24, 100. https://doi.org/10.3390/e24010100

Torrubia J, Valero A, Valero A. Thermodynamic Rarity Assessment of Mobile Phone PCBs: A Physical Criticality Indicator in Times of Shortage. Entropy. 2022; 24(1):100. https://doi.org/10.3390/e24010100

Chicago/Turabian StyleTorrubia, Jorge, Antonio Valero, and Alicia Valero. 2022. "Thermodynamic Rarity Assessment of Mobile Phone PCBs: A Physical Criticality Indicator in Times of Shortage" Entropy 24, no. 1: 100. https://doi.org/10.3390/e24010100

APA StyleTorrubia, J., Valero, A., & Valero, A. (2022). Thermodynamic Rarity Assessment of Mobile Phone PCBs: A Physical Criticality Indicator in Times of Shortage. Entropy, 24(1), 100. https://doi.org/10.3390/e24010100