Effect of Ti on the Structure and Mechanical Properties of TixZr2.5-xTa Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Composition of TixZr2.5-xTa Alloys

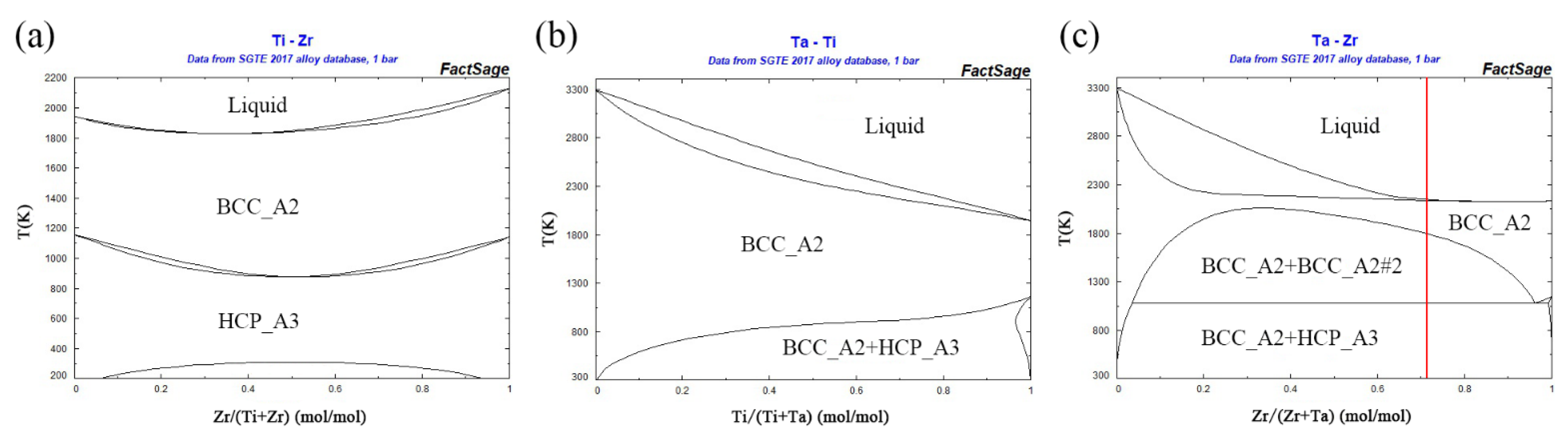

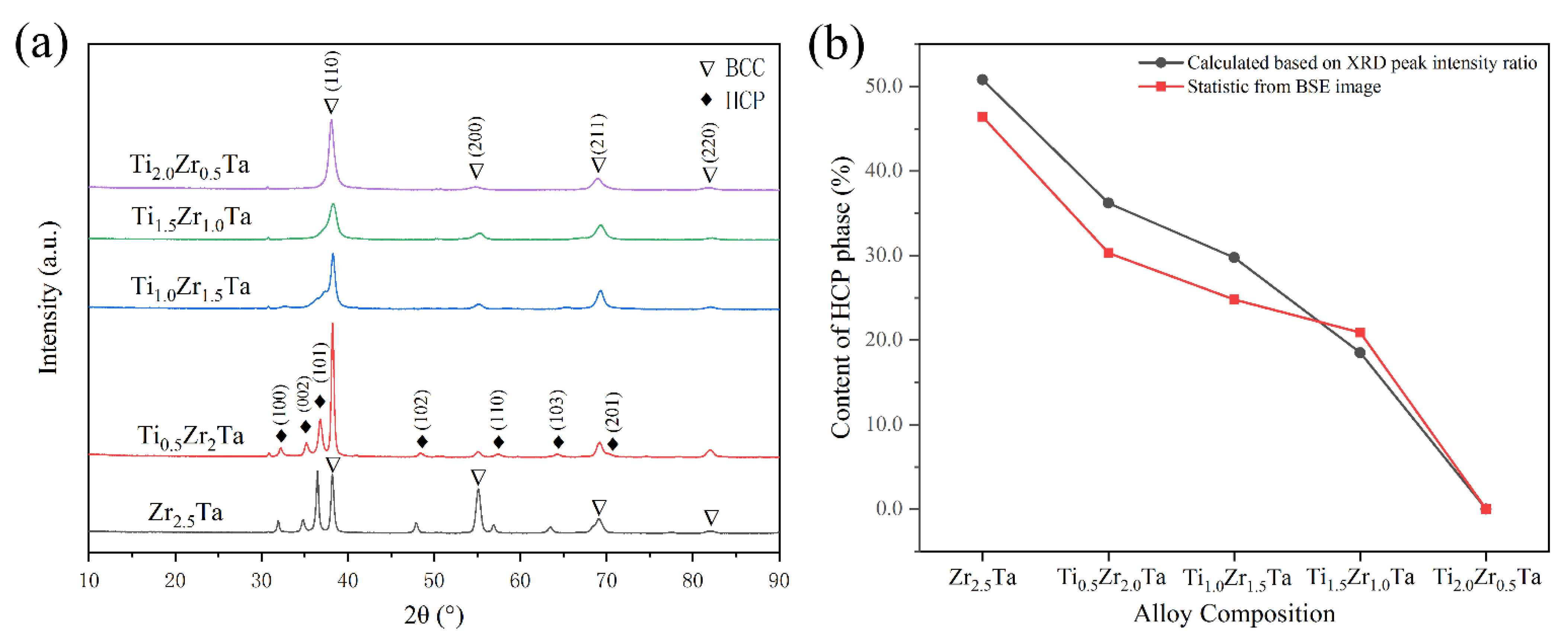

3.2. Lattice Structure of TixZr2.5-xTa Alloys

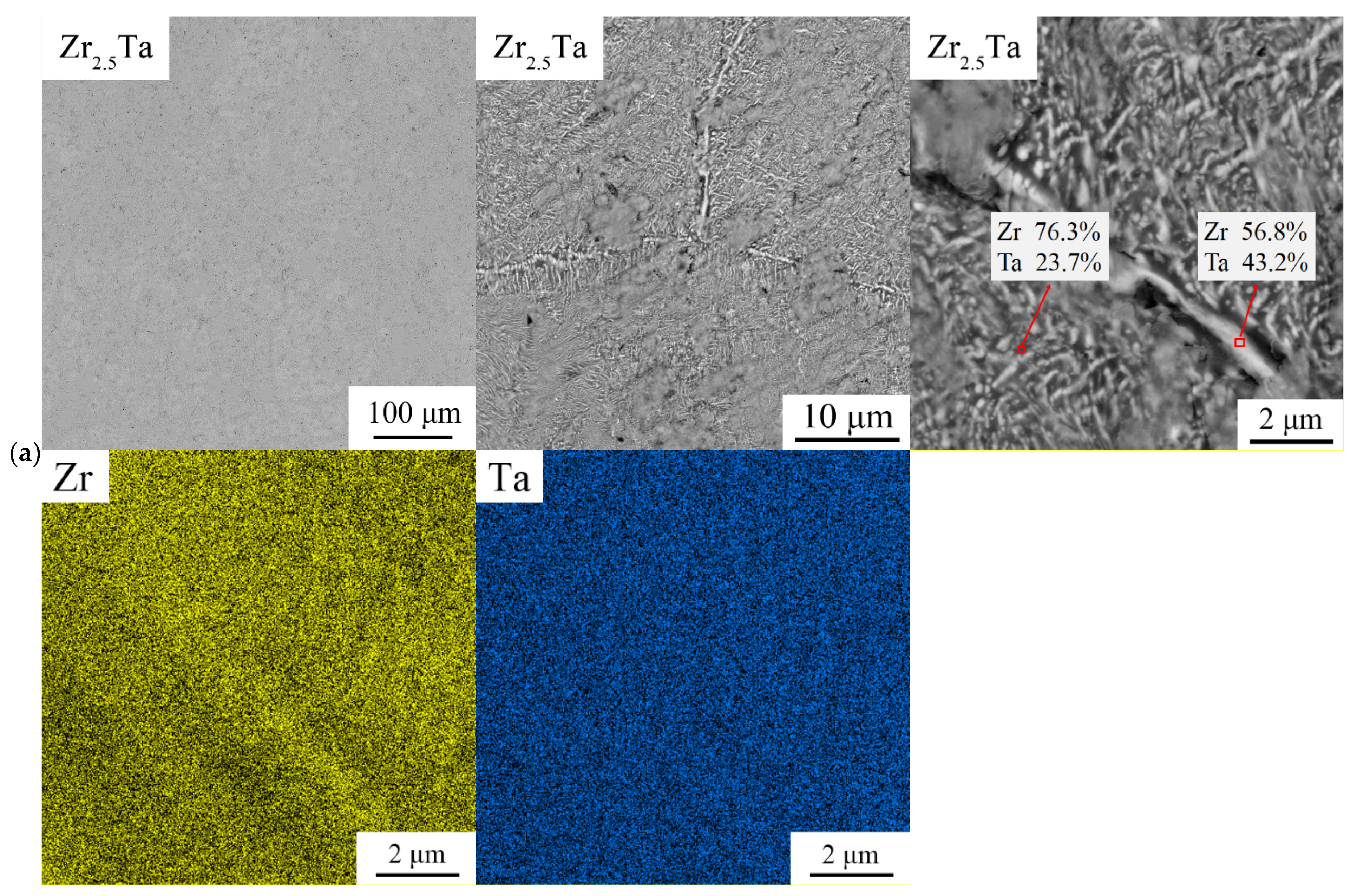

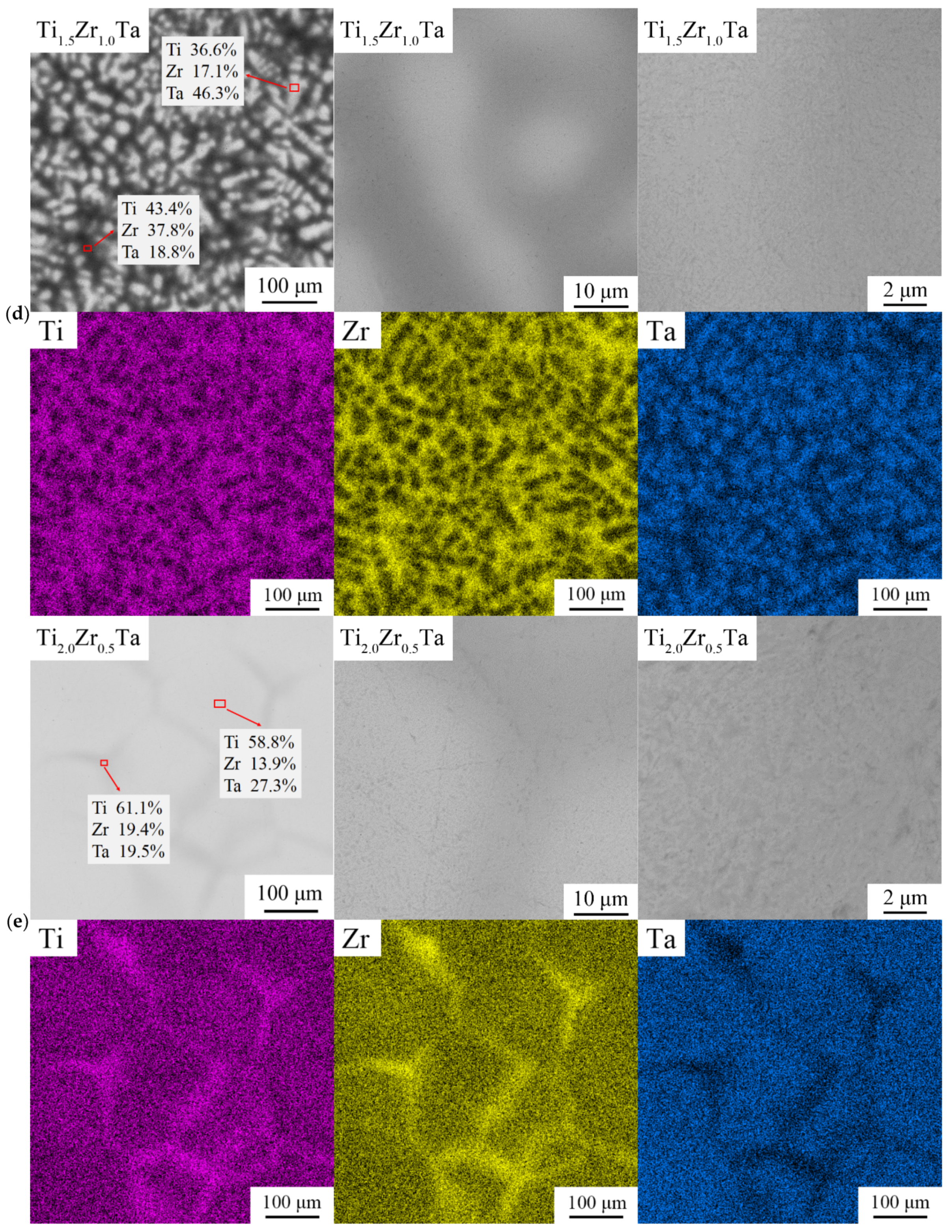

3.3. Morphology of TixZr2.5-xTa Alloys

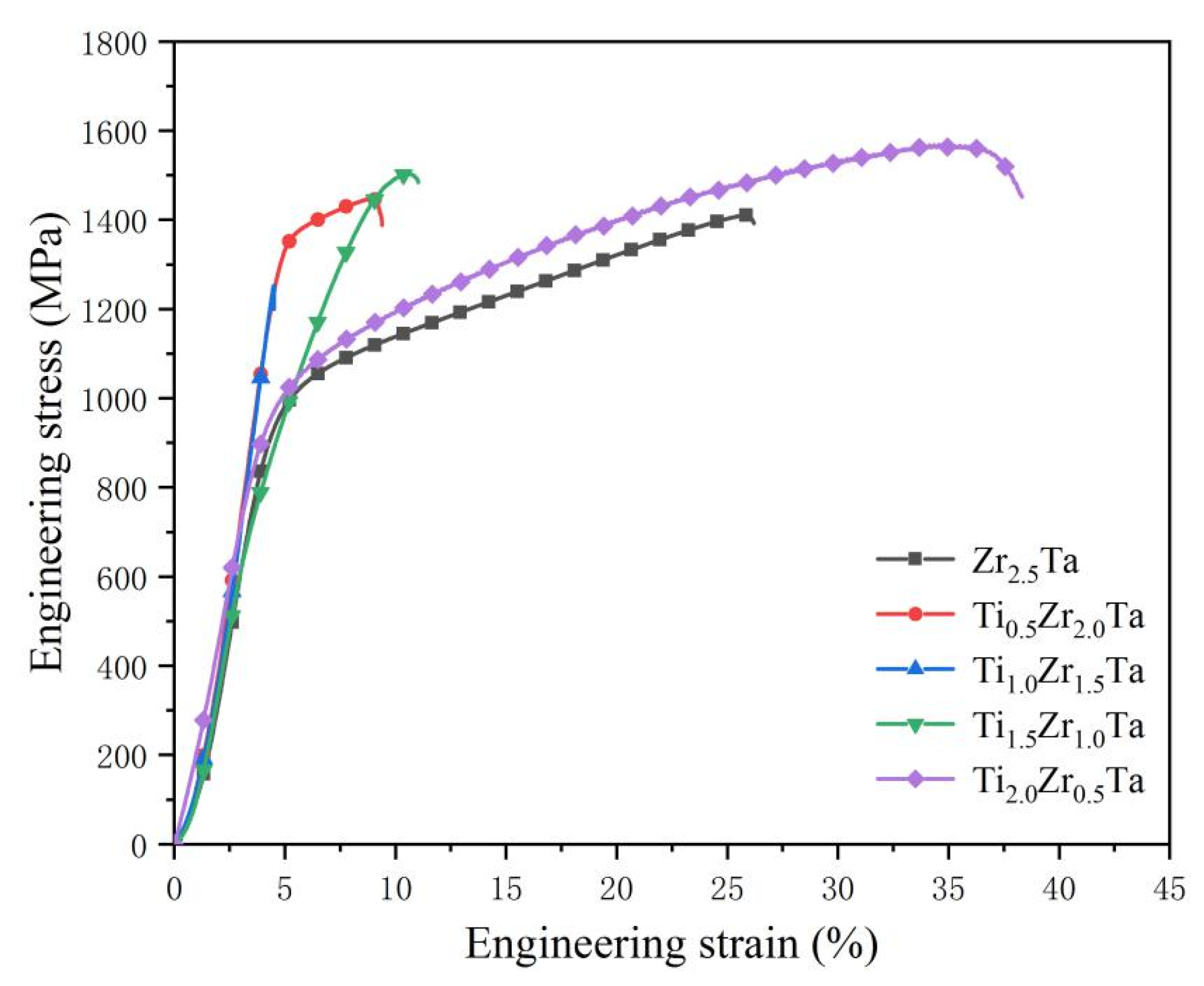

3.4. Mechanical Properties of TixZr2.5-xTa Alloys

4. Discussion

4.1. Effect of the Mixing Entropy

4.2. Effect of Ti on the Lattice Structure of TixZr2.5-xTa Alloys

4.3. Effect of Ti on the Morphology of TixZr2.5-xTa Alloys

4.4. Effect of Ti on the Mechanical Properties of TixZr2.5-xTa Alloys

5. Conclusions

- The phase transformation of TixZr2.5-xTa (x = 0, 0.5, 1.0, 1.5, 2.0) nonequal-ratio ternary alloys depends not on the value of ΔSmix, but on the amount of Ti atoms. The Zr2.5Ta alloy is characterized by a BCC + HCP dual phase structure. With the introduction of Ti, the content of the HCP phase decreases gradually.

- The degree of component segregation becomes increasingly developed as x increases from 0 to 1.5 and then gradually disappears as x further increases to 2.0, which is closely related to the relative content of Ti-Ta. As the Ti/(Ti + Ta) ratio increases from 0 to 66.6 at%, the dendrite morphology and component segregation of TixZr2.5-xTa alloys first increasingly develop and then gradually disappear.

- With the addition of Ti, the yield strength first decreases and then increases. However, the trends of compressive strength and fracture strain are completely opposite. When x increases to 2.0, the Ti2.0Zr0.5Ta alloy with a single BCC phase and equiaxed grains shows the best mechanical properties, and its yield strength, compressive strength and fracture strain reach 883 MPa, 1568 MPa and 34.58%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.F.; Shi, A.S.; Qiao, L.; Zhang, J.; Zhang, Y.G.; Guan, Z.W. Experimental study on impact-initiated characters of multifunctional energetic structural materials. J. Appl. Phys. 2013, 113, 083508. [Google Scholar] [CrossRef]

- Mason, B.A.; Groven, L.J.; Son, S.F. The role of microstructure refinement on the impact ignition and combustion behavior of mechanically activated Ni/Al reactive composites. J. Appl. Phys. 2013, 114, 113501. [Google Scholar] [CrossRef] [Green Version]

- Aydelotte, B.B.; Thadhani, N.N. Mechanistic aspects of impact initiated reactions in explosively consolidated metal plus aluminum powder mixtures. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2013, 570, 164–171. [Google Scholar] [CrossRef]

- Aydelotte, B.; Braithwaite, C.; Thadhani, N.N. Fragmentation of structural energetic materials: Implications for performance. J. Phys. Conf. Ser. 2014, 500, 132001. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Qiu, L.; Zhao, X.; Li, Y.; Rao, T.; He, S.; Qin, L.; Tao, J. Multilayered Al/Ni energetic structural materials with high energy density and mechanical properties prepared by a facile approach of electrodeposition and hot pressing. Mater. Sci. Eng. A 2019, 757, 23–31. [Google Scholar] [CrossRef]

- Kettwich, S.C.; Kappagantula, K.; Kusel, B.S.; Avjian, E.K.; Danielson, S.T.; Miller, H.A.; Pantoya, M.L.; Iacono, S.T. Thermal investigations of nanoaluminum/perfluoropolyether core–shell impregnated composites for structural energetics. Thermochim. Acta 2014, 591, 45–50. [Google Scholar] [CrossRef]

- Tu, J.; Qiao, L.; Shan, Y.; Xin, C.; Liu, J.; Stoica, M. Study on the Impact-Induced Energy Release Characteristics of Zr68.5Cu12 Ni12Al7.5 Amorphous Alloy. Materials 2021, 14, 1447. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Li, S.; Bai, S. Quasi-static and impact-initiated response of Zr55Ni5Al10Cu30 alloy. J. Non-Cryst. Solids 2018, 481, 59–64. [Google Scholar] [CrossRef]

- Ren, K.; Liu, H.; Chen, R.; Tang, Y.; Guo, B.; Li, S.; Wang, J.; Wang, R.; Lu, F. Compression properties and impact energy release characteristics of TiZrNbV high-entropy alloy. Mater. Sci. Eng. A 2021, 827, 142074. [Google Scholar] [CrossRef]

- Wei, C.T.; Vitali, E.; Jiang, F.; Du, S.W.; Benson, D.J.; Vecchio, K.S.; Thadhani, N.N.; Meyers, M.A. Quasi-static and dynamic response of explosively consolidated metal–aluminum powder mixtures. Acta Mater. 2012, 60, 1418–1432. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, H.; Tang, Y.; Zhu, L.A.; Ye, Y.; Li, S.; Bai, S. Microstructure, mechanical properties and energetic characteristics of a novel high-entropy alloy HfZrTiTa0.53. Mater. Des. 2017, 133, 435–443. [Google Scholar] [CrossRef]

- Milošev, I.; Žerjav, G.; Calderon-Moreno, J.; Popa, M. Electrochemical properties, chemical composition and thickness of passive film formed on novel Ti–20Nb–10Zr–5Ta alloy. Electrochim. Acta 2014, 99, 176–189. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, X.; Wang, H.; Wu, Y.; Jiang, S.; Lu, Z. Development of advanced materials via entropy engineering. Scr. Mater. 2019, 165, 164–169. [Google Scholar] [CrossRef]

- Xue, G.-L.; Yang, H.-L.; Xing, H.-X.; Ye, C.-R.; Liu, J.; Miao, J.-L.; Ruan, J.-M. Effect of Ti on microstructure, mechanical properties and corrosion resistance of Zr-Ta-Ti alloys processed by spark plasma sintering. J. Cent. South Univ. 2020, 27, 2185–2197. [Google Scholar] [CrossRef]

- Kim, H.-J.; Jeong, Y.-H.; Choe, H.-C.; Brantley, W.A. Hydroxyapatite formation on biomedical Ti–Ta–Zr alloys by magnetron sputtering and electrochemical deposition. Thin Solid Film. 2014, 572, 119–125. [Google Scholar] [CrossRef]

- Ţălu, Ş. Micro and Nanoscale Characterization of Three-Dimensional Surfaces; Napoca Star Publishing House: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Liu, J.; Chang, L.; Liu, H.; Li, Y.; Yang, H.; Ruan, J. Microstructure, mechanical behavior and biocompatibility of powder metallurgy Nb-Ti-Ta alloys as biomedical material. Mater. Sci. Eng. C 2017, 71, 512–519. [Google Scholar] [CrossRef]

- Zhang, W.; Liaw, P.; Zhang, Y. Science and technology in high-entropy alloys. Sci. China Mater. 2018, 61, 2–22. [Google Scholar] [CrossRef] [Green Version]

- Camargo, P.H.C.; Gaskell, D.R.; David, E. Laughlin: Introduction to the Thermodynamics of Materials. J. Mater. Sci. 2018, 53, 9363–9367. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, Y.; You, L.; Qiu, W.; Zhang, Y.; Yuan, Y.; Lu, Z.; Song, X. Nanoscale phase separation of TiZrNbTa high entropy alloy induced by hydrogen absorption. Scr. Mater. 2020, 178, 503–507. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Qian, M.; Shi, Z.; Song, T.; Huang, L.; Zou, J. A novel quaternary equiatomic Ti-Zr-Nb-Ta medium entropy alloy (MEA). Intermetallics 2018, 101, 39–43. [Google Scholar] [CrossRef]

- Akihisa, I.; Akira, T. Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar]

- Muñoz-Morris, M.A.; Garcia Oca, C.; Morris, D.G. An analysis of strengthening mechanisms in a mechanically alloyed, oxide dispersion strengthened iron aluminide intermetallic. Acta Mater. 2002, 50, 2825–2836. [Google Scholar] [CrossRef]

- Manzoni, A.M.; Haas, S.; Daoud, H.; Glatzel, U.; Forster, C.; Wanderka, N. Tensile Behavior and Evolution of the Phases in the Al10Co25Cr8Fe15Ni36Ti6 Compositionally Complex/High Entropy Alloy. Entropy 2018, 20, 646. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jian, H.; Luo, J.; Ou, L.; Tang, X.; Yan, C. Micro-morphology of Fatigue Crack Initiation and Propagation Behavior in High Strength Aluminum Alloy. Mater. Sci. Eng. A 2017, 684, 213–221. [Google Scholar] [CrossRef] [Green Version]

| Alloy | Ti (at%) | Zr (at%) | Ta (at%) | |

|---|---|---|---|---|

| Zr2.5Ta | Designed | \ | 71.4 | 28.6 |

| Actual | \ | 72.8 ± 0.2 | 27.2 ± 0.2 | |

| Ti0.5Zr2.0Ta | Designed | 14.3 | 57.1 | 28.6 |

| Actual | 13.8 ± 0.1 | 59.3 ± 0.1 | 26.9 ± 0.2 | |

| Ti1.0Zr1.5Ta | Designed | 28.6 | 42.8 | 28.6 |

| Actual | 28.0 ± 0.2 | 45.3 ± 0.6 | 26.7 ± 0.5 | |

| Ti1.5Zr1.0Ta | Designed | 42.8 | 28.6 | 28.6 |

| Actual | 41.9 ± 0.1 | 30.4 ± 0.2 | 27.7 ± 0.1 | |

| Ti2.0Zr0.5Ta | Designed | 57.1 | 14.3 | 28.6 |

| Actual | 59.9 ± 0.4 | 12.1 ± 0.4 | 28.0 ± 0.8 | |

| Alloy | σy (MPa) | σc (MPa) | ε (%) |

|---|---|---|---|

| Zr2.5Ta | 886 | 1410 | 25.77 |

| Ti0.5Zr2.0Ta | 1298 | 1447 | 8.86 |

| Ti1.0Zr1.5Ta | 1252 | 1252 | 4.50 |

| Ti1.5Zr1.0Ta | 735 | 1502 | 10.58 |

| Ti2.0Zr0.5Ta | 883 | 1568 | 34.58 |

| Alloy | Zr2.5Ta | Ti0.5Zr2Ta | Ti1.0Zr1.5Ta | Ti1.5Zr1.0Ta | Ti2Zr0.5Ta |

|---|---|---|---|---|---|

| ΔSmix | 0.598R | 0.956R | 1.079R | 1.079R | 0.956R |

| Phase structure | BCC + HCP | BCC + HCP | BCC + HCP | BCC + HCP | BCC |

| Element | Ti-Zr | Ti-Ta | Zr-Ta |

|---|---|---|---|

| ΔHmix (kJ/mol) | 0 | 1 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Tang, Y.; Li, S.; Ye, Y.; Zhu, L.; Zhang, Z.; Liu, X.; Wang, Z.; Bai, S. Effect of Ti on the Structure and Mechanical Properties of TixZr2.5-xTa Alloys. Entropy 2021, 23, 1632. https://doi.org/10.3390/e23121632

Zhang B, Tang Y, Li S, Ye Y, Zhu L, Zhang Z, Liu X, Wang Z, Bai S. Effect of Ti on the Structure and Mechanical Properties of TixZr2.5-xTa Alloys. Entropy. 2021; 23(12):1632. https://doi.org/10.3390/e23121632

Chicago/Turabian StyleZhang, Bin, Yu Tang, Shun Li, Yicong Ye, Li’an Zhu, Zhouran Zhang, Xiyue Liu, Zhen Wang, and Shuxin Bai. 2021. "Effect of Ti on the Structure and Mechanical Properties of TixZr2.5-xTa Alloys" Entropy 23, no. 12: 1632. https://doi.org/10.3390/e23121632

APA StyleZhang, B., Tang, Y., Li, S., Ye, Y., Zhu, L., Zhang, Z., Liu, X., Wang, Z., & Bai, S. (2021). Effect of Ti on the Structure and Mechanical Properties of TixZr2.5-xTa Alloys. Entropy, 23(12), 1632. https://doi.org/10.3390/e23121632